Front Cover (OFC, IFC) and matter

JMR volume 32 issue 18 Cover and Front matter

-

- Published online by Cambridge University Press:

- 26 September 2017, pp. f1-f5

-

- Article

-

- You have access

- Export citation

Articles

Application of high-energy oscillating electric current pulse to relieve pulsed-laser surface irradiation induced residual stress in AISI 1045 steel

-

- Published online by Cambridge University Press:

- 03 November 2016, pp. 473-481

-

- Article

- Export citation

Back Cover (OBC, IBC) and matter

JMR volume 32 issue 23 Cover and Back matter

-

- Published online by Cambridge University Press:

- 12 December 2017, pp. b1-b5

-

- Article

-

- You have access

- Export citation

Articles

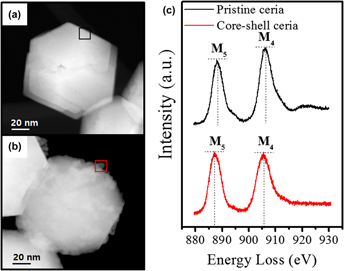

Ce3+-enriched core–shell ceria nanoparticles for silicate adsorption

-

- Published online by Cambridge University Press:

- 27 June 2017, pp. 2829-2836

-

- Article

- Export citation

Front Cover (OFC, IFC) and matter

JMR volume 32 issue 6 Cover and Front matter

-

- Published online by Cambridge University Press:

- 28 March 2017, pp. f1-f5

-

- Article

-

- You have access

- Export citation

Invited Articles

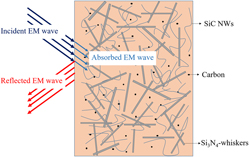

Electromagnetic interference shielding and mechanical properties of Si3N4–SiOC composites fabricated by 3D-printing combined with polymer infiltration and pyrolysis

-

- Published online by Cambridge University Press:

- 02 May 2017, pp. 3394-3401

-

- Article

- Export citation

Articles

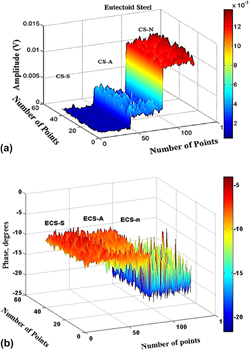

Thermal, structural, and microstructural characterization of eutectoid steel at different heat treatments

-

- Published online by Cambridge University Press:

- 08 March 2017, pp. 2202-2209

-

- Article

- Export citation

Invited Articles

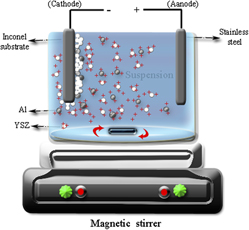

Fabrication and characterization of YSZ/Al2O3 nano-composite coatings on Inconel by electrophoretic deposition

-

- Published online by Cambridge University Press:

- 10 July 2017, pp. 3402-3408

-

- Article

- Export citation

Back Cover (OBC, IBC) and matter

JMR volume 32 issue 9 Cover and Back matter

-

- Published online by Cambridge University Press:

- 16 May 2017, pp. b1-b5

-

- Article

-

- You have access

- Export citation

JMR volume 32 issue 6 Cover and Back matter

-

- Published online by Cambridge University Press:

- 28 March 2017, pp. b1-b3

-

- Article

-

- You have access

- Export citation

JMR volume 32 issue 16 Cover and Back matter

-

- Published online by Cambridge University Press:

- 29 August 2017, pp. b1-b3

-

- Article

-

- You have access

- Export citation

Front Cover (OFC, IFC) and matter

JMR volume 32 issue 4 Cover and Front matter

-

- Published online by Cambridge University Press:

- 28 February 2017, pp. f1-f5

-

- Article

-

- You have access

- Export citation

Back Cover (OBC, IBC) and matter

JMR volume 32 issue 7 Cover and Back matter

-

- Published online by Cambridge University Press:

- 13 April 2017, pp. b1-b4

-

- Article

-

- You have access

- Export citation

JMR volume 32 issue 18 Cover and Back matter

-

- Published online by Cambridge University Press:

- 26 September 2017, pp. b1-b4

-

- Article

-

- You have access

- Export citation

JMR volume 32 issue 1 Cover and Back matter

-

- Published online by Cambridge University Press:

- 12 January 2017, pp. b1-b3

-

- Article

-

- You have access

- Export citation

Front Cover (OFC, IFC) and matter

JMR volume 32 issue 3 Cover and Front matter

-

- Published online by Cambridge University Press:

- 14 February 2017, pp. f1-f5

-

- Article

-

- You have access

- Export citation

Back Cover (OBC, IBC) and matter

JMR volume 32 issue 8 Cover and Back matter

-

- Published online by Cambridge University Press:

- 28 April 2017, pp. b1-b2

-

- Article

-

- You have access

- Export citation

Articles

Dispersion of antimony doped tin oxide nanopowders for preparing transparent thermal insulation water-based coatings

-

- Published online by Cambridge University Press:

- 13 June 2017, pp. 2414-2422

-

- Article

- Export citation

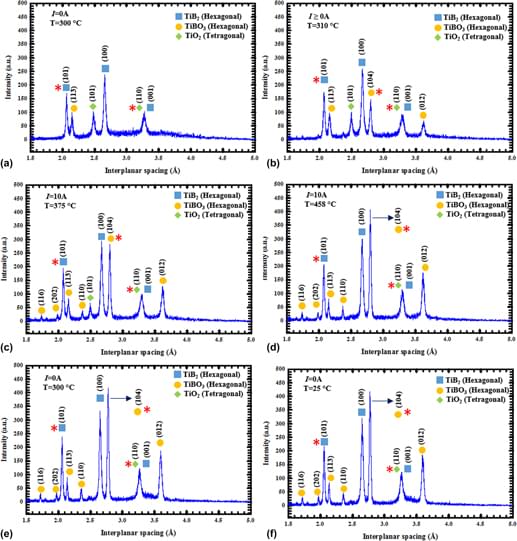

Electric field effect on chemical and phase equilibria in nano-TiB2–TiO2–TiBO3 system at <650 °C: an in situ time-resolved energy dispersive x-ray diffraction study with an ultrahigh energy synchrotron probe

-

- Published online by Cambridge University Press:

- 19 December 2016, pp. 482-494

-

- Article

- Export citation

Front Cover (OFC, IFC) and matter

JMR volume 32 issue 14 Cover and Front matter

-

- Published online by Cambridge University Press:

- 27 July 2017, pp. f1-f5

-

- Article

-

- You have access

- Export citation