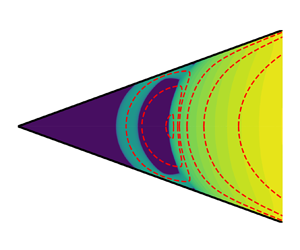

Graphical abstract from Volk, R., Bourgoin, M., Bréhier, C. & Raynal, F. 2022 Phoresis in cellular flows: from enhanced dispersion to blockage. J. Fluid Mech. 948, A42. doi:10.1017/jfm.2022.730.

JFM Rapids

Added mass and damping of structures with periodic angular shape

-

- Published online by Cambridge University Press:

- 07 September 2022, R1

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Only two Betchov homogeneity constraints exist for isotropic turbulence

-

- Published online by Cambridge University Press:

- 20 September 2022, R2

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Focus on Fluids

Clogged corners

-

- Published online by Cambridge University Press:

- 02 September 2022, F1

-

- Article

-

- You have access

- HTML

- Export citation

JFM Papers

The role of monolayer viscosity in Langmuir film hole closure dynamics

-

- Published online by Cambridge University Press:

- 02 September 2022, A1

-

- Article

- Export citation

Birefringent strands drive the flow of viscoelastic fluids past obstacles

-

- Published online by Cambridge University Press:

- 02 September 2022, A2

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Unsteady motions in the turbulent separation bubble of a two-dimensional wing

-

- Published online by Cambridge University Press:

- 02 September 2022, A3

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Detecting Lagrangian coherent structures from sparse and noisy trajectory data

-

- Published online by Cambridge University Press:

- 06 September 2022, A4

-

- Article

- Export citation

Energy transfer mechanisms in adverse pressure gradient turbulent boundary layers: production and inter-component redistribution

-

- Published online by Cambridge University Press:

- 02 September 2022, A5

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

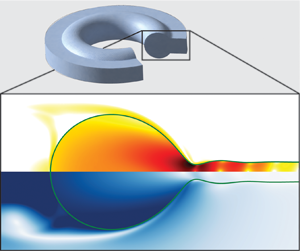

Jetting and migration of a laser-induced cavitation bubble in a rectangular channel

-

- Published online by Cambridge University Press:

- 02 September 2022, A6

-

- Article

- Export citation

Large-scale influence of numerical noises as artificial stochastic disturbances on a sustained turbulence

-

- Published online by Cambridge University Press:

- 02 September 2022, A7

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Temperature-dependent wall slip of Newtonian lubricants

-

- Published online by Cambridge University Press:

- 05 September 2022, A8

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Efficient global resolvent analysis via the one-way Navier–Stokes equations

-

- Published online by Cambridge University Press:

- 06 September 2022, A9

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Structured input–output analysis of stably stratified plane Couette flow

-

- Published online by Cambridge University Press:

- 05 September 2022, A10

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Geometrical dependence of optimal bounds in Taylor–Couette flow

-

- Published online by Cambridge University Press:

- 05 September 2022, A11

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Two-way coupled turbulent particle-laden boundary layer combustion over a flat plate

-

- Published online by Cambridge University Press:

- 06 September 2022, A12

-

- Article

- Export citation

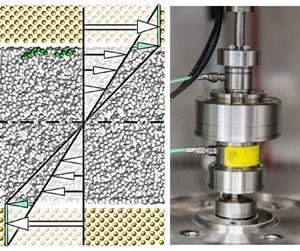

Forces governing the dynamics of liquid spreading in packed beds

-

- Published online by Cambridge University Press:

- 06 September 2022, A13

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Taylor–Culick retractions and the influence of the surroundings

-

- Published online by Cambridge University Press:

- 06 September 2022, A14

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Linear instabilities of pulsatile plane channel flow between compliant walls

-

- Published online by Cambridge University Press:

- 07 September 2022, A15

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Prandtl number effects on the hydrodynamic stability of compressible boundary layers: flow–thermodynamics interactions

-

- Published online by Cambridge University Press:

- 07 September 2022, A16

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Wave patterns of stationary gravity–capillary waves from a moving obstacle in a magnetic fluid

-

- Published online by Cambridge University Press:

- 07 September 2022, A17

-

- Article

- Export citation