1. Introduction

Liquid films, sheets and shells have piqued the interest of fluid dynamicists for nearly two centuries (Savart Reference Savart1833a,Reference Savartb,Reference Savartc; Taylor Reference Taylor1959a,Reference Taylorb; Clanet Reference Clanet2007; Villermaux Reference Villermaux2020). A freely suspended liquid film warrants further attention among these configurations as it is inherently metastable owing to its high surface area. Indeed, if a large enough (Taylor & Michael Reference Taylor and Michael1973; Villermaux Reference Villermaux2020) hole nucleates on the film, the sheet will spontaneously retract to reduce its surface area. Such interfacial destabilization leading to film rupture and bursting can also result in waterborne disease transmission (Bourouiba Reference Bourouiba2021). The bursting of liquid films at an oil–air interface is important for various industrial applications in the chemical and petrochemical engineering sectors as well. One area of particular interest is underwater oil spills in oceans, such as the Deepwater Horizon spill in 2010 in the Gulf of Mexico (Summerhayes Reference Summerhayes2011). For these spills, droplets (or slugs) of oil may rise to the free surface of water via buoyancy, and then rupture the free surface of water directly above it. The water film will retract upon rupture, and the oil will spread on the water surface, thus perpetuating an environmental hazard. Perhaps the most widely studied example of sheet destabilization and retraction is during the bursting of liquid (e.g. soap) films in air – an area of active research since the pioneering works (Dupré Reference Dupré1867, Reference Dupré1869; Rayleigh Reference Rayleigh1891; Taylor Reference Taylor1959b; Culick Reference Culick1960; McEntee & Mysels Reference McEntee and Mysels1969) in the late nineteenth and mid-twentieth century, to the more recent investigations (Bremond & Villermaux Reference Bremond and Villermaux2005; Müller, Kornek & Stannarius Reference Müller, Kornek and Stannarius2007; Lhuissier & Villermaux Reference Lhuissier and Villermaux2012; Munro et al. Reference Munro, Anthony, Basaran and Lister2015; Deka & Pierson Reference Deka and Pierson2020). In these studies, the outer medium is assumed passive (inviscid and zero-inertia). The origin of the nucleation of the initial hole in the film can be manifold (Lohse & Villermaux Reference Lohse and Villermaux2020). After film rupture, the internal viscous stresses in the film do not contribute to the momentum balance, but dictate the distribution of momentum within the film (Savva & Bush Reference Savva and Bush2009), as long as the Ohnesorge number of the film (ratio of its viscocapillary to inertiocapillary time scales, see § 4) is less than its aspect ratio (see Deka & Pierson Reference Deka and Pierson2020). Nonetheless, half of the surface energy released goes into internal viscous dissipation (see Appendix A and Culick Reference Culick1960; de Gennes Reference de Gennes1996; Sünderhauf, Raszillier & Durst Reference Sünderhauf, Raszillier and Durst2002; Villermaux Reference Villermaux2020).

A representative schematic of the situation mentioned above is shown in figure 1(a) (henceforth referred to as the classical Taylor–Culick configuration), where the water film ( f) of thickness ![]() $h_0$ is retracting in air (a) under the action of surface tension. The retraction velocity,

$h_0$ is retracting in air (a) under the action of surface tension. The retraction velocity, ![]() $v_f$, in such a scenario is constant (after a period of initial transience) and approaches the Taylor–Culick velocity given by

$v_f$, in such a scenario is constant (after a period of initial transience) and approaches the Taylor–Culick velocity given by

\begin{equation} v_{{TC}} = \sqrt{\frac{2\gamma_{af}}{\rho_f h_0}} , \end{equation}

\begin{equation} v_{{TC}} = \sqrt{\frac{2\gamma_{af}}{\rho_f h_0}} , \end{equation}

where ![]() $2\gamma _{af}$ is the net surface tension driving the retraction (

$2\gamma _{af}$ is the net surface tension driving the retraction (![]() $\gamma _{af}$ being the interfacial tension coefficient between the film and air) and

$\gamma _{af}$ being the interfacial tension coefficient between the film and air) and ![]() $\rho _f$ is the density of the liquid film (figure 1a). Furthermore, it was observed that during the retraction, the liquid collects in a thicker rim at the retracting edge of the film, particularly for low viscosity liquids (Rayleigh (Reference Rayleigh1891), Ranz (Reference Ranz1959), Pandit & Davidson (Reference Pandit and Davidson1990); not depicted in figure 1b). The seminal work of Keller (Reference Keller1983) further explores the retraction of these films of non-uniform thickness.

$\rho _f$ is the density of the liquid film (figure 1a). Furthermore, it was observed that during the retraction, the liquid collects in a thicker rim at the retracting edge of the film, particularly for low viscosity liquids (Rayleigh (Reference Rayleigh1891), Ranz (Reference Ranz1959), Pandit & Davidson (Reference Pandit and Davidson1990); not depicted in figure 1b). The seminal work of Keller (Reference Keller1983) further explores the retraction of these films of non-uniform thickness.

Figure 1. Schematics depicting the configurations studied in the present work: (a) retraction of a water film ( f) of thickness ![]() $h_0$ in an air (a) environment (classical configuration); (b) retraction of water film ( f) in an oil (s) environment (two-phase configuration); (c) retraction of a water film sandwiched between air and oil (three-phase configuration). The dot–dashed line represents the axis of rotational symmetry, and

$h_0$ in an air (a) environment (classical configuration); (b) retraction of water film ( f) in an oil (s) environment (two-phase configuration); (c) retraction of a water film sandwiched between air and oil (three-phase configuration). The dot–dashed line represents the axis of rotational symmetry, and ![]() $R(t)$ is the radius of the growing hole centred at this axis. In all the schematics, the water film is retracting from left to right with velocity

$R(t)$ is the radius of the growing hole centred at this axis. In all the schematics, the water film is retracting from left to right with velocity ![]() $v_f$, as indicated by the arrow, and

$v_f$, as indicated by the arrow, and ![]() $\gamma _{ij}$ denotes the surface tension coefficient between fluids

$\gamma _{ij}$ denotes the surface tension coefficient between fluids ![]() $i$ and

$i$ and ![]() $j$.

$j$.

The effect of viscosity of the film (![]() $\eta _f$) during its retraction process has also been studied (Debrégeas, Martin & Brochard-Wyart Reference Debrégeas, Martin and Brochard-Wyart1995; Debrégeas, de Gennes & Brochard-Wyart Reference Debrégeas, de Gennes and Brochard-Wyart1998). Brenner & Gueyffier (Reference Brenner and Gueyffier1999) showed that although viscosity does not have any effect on the constant retraction velocity, it can have a significant effect on the shape of the retracting edge of a planar film. They report that if the radial extent of the film is greater than its Stokes length (

$\eta _f$) during its retraction process has also been studied (Debrégeas, Martin & Brochard-Wyart Reference Debrégeas, Martin and Brochard-Wyart1995; Debrégeas, de Gennes & Brochard-Wyart Reference Debrégeas, de Gennes and Brochard-Wyart1998). Brenner & Gueyffier (Reference Brenner and Gueyffier1999) showed that although viscosity does not have any effect on the constant retraction velocity, it can have a significant effect on the shape of the retracting edge of a planar film. They report that if the radial extent of the film is greater than its Stokes length (![]() $= \eta _f/(\rho _f v_{{TC}})$), a growing rim is formed, whereas the rim is absent for the converse situation. Savva & Bush (Reference Savva and Bush2009) extended the work by Brenner & Gueyffier (Reference Brenner and Gueyffier1999) for highly viscous films, and also developed a lubrication model for the retraction dynamics of a circular hole. They concluded that although viscosity does not determine the magnitude of the constant retraction velocity, it does dictate the time required (post rupture) to attain that constant velocity, which increases with increasing viscosity. Recently, Pierson et al. (Reference Pierson, Magnaudet, Soares and Popinet2020) and Deka & Pierson (Reference Deka and Pierson2020) revisited the viscous retraction dynamics by exploring self-similar solutions for slender filaments and sheets of finite length.

$= \eta _f/(\rho _f v_{{TC}})$), a growing rim is formed, whereas the rim is absent for the converse situation. Savva & Bush (Reference Savva and Bush2009) extended the work by Brenner & Gueyffier (Reference Brenner and Gueyffier1999) for highly viscous films, and also developed a lubrication model for the retraction dynamics of a circular hole. They concluded that although viscosity does not determine the magnitude of the constant retraction velocity, it does dictate the time required (post rupture) to attain that constant velocity, which increases with increasing viscosity. Recently, Pierson et al. (Reference Pierson, Magnaudet, Soares and Popinet2020) and Deka & Pierson (Reference Deka and Pierson2020) revisited the viscous retraction dynamics by exploring self-similar solutions for slender filaments and sheets of finite length.

The rheological properties of the film also influence the retraction dynamics (Dalnoki-Veress et al. Reference Dalnoki-Veress, Nickel, Roth and Dutcher1999; Tammaro et al. Reference Tammaro, Pasquino, Villone, D’ Avino, Ferraro, Di Maio, Langella, Grizzuti and Maffettone2018; Villone, Hulsen & Maffettone Reference Villone, Hulsen and Maffettone2019; Kamat, Anthony & Basaran Reference Kamat, Anthony and Basaran2020). For instance, Sen et al. (Reference Sen, Datt, Segers, Wijshoff, Snoeijer, Versluis and Lohse2021) showed that viscoelastic filaments can retract at velocities higher than the Newtonian Taylor–Culick limit due to elastic tension. Moreover, the retraction dynamics of liquids have also been studied in the context of dewetting for a wide range of scenarios (Redon, Brochard-Wyart & Rondelez Reference Redon, Brochard-Wyart and Rondelez1991; Brochard-Wyart, Martin & Redon Reference Brochard-Wyart, Martin and Redon1993; Shull & Karis Reference Shull and Karis1994; Andrieu, Sykes & Brochard Reference Andrieu, Sykes and Brochard1996; Lambooy et al. Reference Lambooy, Phelan, Haugg and Krausch1996; Haidara, Vonna & Schultz Reference Haidara, Vonna and Schultz1998; Buguin, Vovelle & Brochard-Wyart Reference Buguin, Vovelle and Brochard-Wyart1999; Péron, Brochard-Wyart & Duval Reference Péron, Brochard-Wyart and Duval2012; Peschka et al. Reference Peschka, Bommer, Jachalski, Seemann and Wagner2018; Kim et al. Reference Kim, Wu, Esmaili, Dombroskie and Jung2020). Lastly, there has also been a recent surge in the study of liquid retraction in other configurations, such as liquid strips (Lv, Clanet & Quéré Reference Lv, Clanet and Quéré2015), smectic films (Trittel et al. Reference Trittel, John, Tsuji and Stannarius2013), foam films (Petit, Le Merrer & Biance Reference Petit, Le Merrer and Biance2015) and emulsion films (Vernay, Ramos & Ligoure Reference Vernay, Ramos and Ligoure2015).

In all the aforementioned studies, the surrounding medium is assumed to play no role in the rupture dynamics. A question naturally arises: What happens when the outer medium also interacts with the retracting film? In particular, how do the viscosity and the inertia of the outer medium influence the rupture dynamics (Mysels & Vijayendran Reference Mysels and Vijayendran1973; Joanny & de Gennes Reference Joanny and de Gennes1987; Reyssat & Quéré Reference Reyssat and Quéré2006; Jian, Deng & Thoraval Reference Jian, Deng and Thoraval2020b)? A representative schematic for such a scenario is shown in figure 1(b), where a water film is retracting in a viscous oil ambient. This geometry will henceforth be referred to as the two-phase configuration where the net surface tension force responsible for retraction is ![]() $2\gamma _{sf}$ (

$2\gamma _{sf}$ (![]() $\gamma _{sf}$ being the interfacial tension coefficient between the film and the surrounding medium, see figure 1b). In such a situation, viscous dissipation is not limited only to the retracting film, but is also present in the ambient. If the ambient happens to be significantly more viscous than the film, then the dissipation in the ambient dominates. In such a situation, the retraction velocity is still a constant. However, unlike the classical case, the velocity depends on the viscosity

$\gamma _{sf}$ being the interfacial tension coefficient between the film and the surrounding medium, see figure 1b). In such a situation, viscous dissipation is not limited only to the retracting film, but is also present in the ambient. If the ambient happens to be significantly more viscous than the film, then the dissipation in the ambient dominates. In such a situation, the retraction velocity is still a constant. However, unlike the classical case, the velocity depends on the viscosity ![]() $\eta _{s}$ of the ambient medium (Martin, Buguin & Brochard-Wyart Reference Martin, Buguin and Brochard-Wyart1994; Reyssat & Quéré Reference Reyssat and Quéré2006). Common realizations of this configuration include relaxation of filaments and droplets in a viscous medium (Stone & Leal Reference Stone and Leal1989), or that of air-films during drop impact (Jian et al. Reference Jian, Channa, Kherbeche, Chizari, Thoroddsen and Thoraval2020a,Reference Jian, Deng and Thoravalb). Additionally, in this context, Anthony, Harris & Basaran (Reference Anthony, Harris and Basaran2020) showed that the so-called ‘inertially limited viscous regime’ in the early-times of drop coalescence (Paulsen et al. Reference Paulsen, Burton, Nagel, Appathurai, Harris and Basaran2012; Paulsen Reference Paulsen2013) stems from a Taylor–Culick-type retraction of the air film between the deformable drops.

$\eta _{s}$ of the ambient medium (Martin, Buguin & Brochard-Wyart Reference Martin, Buguin and Brochard-Wyart1994; Reyssat & Quéré Reference Reyssat and Quéré2006). Common realizations of this configuration include relaxation of filaments and droplets in a viscous medium (Stone & Leal Reference Stone and Leal1989), or that of air-films during drop impact (Jian et al. Reference Jian, Channa, Kherbeche, Chizari, Thoroddsen and Thoraval2020a,Reference Jian, Deng and Thoravalb). Additionally, in this context, Anthony, Harris & Basaran (Reference Anthony, Harris and Basaran2020) showed that the so-called ‘inertially limited viscous regime’ in the early-times of drop coalescence (Paulsen et al. Reference Paulsen, Burton, Nagel, Appathurai, Harris and Basaran2012; Paulsen Reference Paulsen2013) stems from a Taylor–Culick-type retraction of the air film between the deformable drops.

In the present work, we study the influence of the surrounding medium on the retraction velocity of a ruptured liquid film using both force balance and energy conservation arguments. To accomplish this goal, along with the two canonical configurations shown in figures 1(a) and 1(b), we also study the retraction dynamics of a liquid film sandwiched between air and a viscous oil bath. A representative schematic is shown in figure 1(c). This geometry will henceforth be referred to as the three-phase configuration. This paper elucidates this case experimentally by inflating an oil droplet at the water–air interface and letting the water film rupture. Such a configuration can also be found in the early stages of water film retraction when an air bubble approaches a water–oil interface if the oil layer is thick enough (Feng et al. Reference Feng, Roché, Vigolo, Arnaudov, Stoyanov, Gurkov, Tsutsumanova and Stone2014, Reference Feng, Muradoglu, Kim, Ault and Stone2016). Furthermore, we also use direct numerical simulations to demystify the retraction dynamics by using a precursor film-based three-fluid volume of fluid (VoF) method. We show that the film in this three-phase configuration still retracts with a constant velocity, and similar to the two-phase case, the retraction velocity depends on the viscosity ![]() $\eta _{s}$ of the oil bath. However, this dependence is weaker in the three-phase configuration. Furthermore, we reveal an unprecedented scaling relationship for the retraction velocity of the film, which arises from the localization of the viscous dissipation near the three-phase contact line.

$\eta _{s}$ of the oil bath. However, this dependence is weaker in the three-phase configuration. Furthermore, we reveal an unprecedented scaling relationship for the retraction velocity of the film, which arises from the localization of the viscous dissipation near the three-phase contact line.

The paper is organized as follows. Section 2 describes the problem statement for the three-phase Taylor–Culick retractions along with the experimental method employed to probe this configuration. The results from these experiments are discussed in § 3. Section 4 presents the numerical framework, and § 5 describes the simulation results for both the two-phase and three-phase configurations. Section 6 demonstrates the balance of forces in Taylor–Culick retractions, followed by the corresponding scaling relationships in § 7. Further, § 8 analyses the overall energy balance, highlighting the differences in the viscous dissipation mechanisms between the two-phase and three-phase configurations. The work culminates with conclusions in § 9. Throughout the manuscript, we refer to Appendix A for discussions on the classical Taylor–Culick retractions, and use the experimental datapoints from Reyssat & Quéré (Reference Reyssat and Quéré2006) for the two-phase configuration.

2. Film bursting at an air–liquid interface: experimental method

We study the three-phase configuration experimentally by inflating an oil drop (‘s’ for ‘surroundings’ in figure 1c) at a water–air free interface and capturing the retraction of the water film ( f in figure 1c). The schematic of the experimental set-up is shown in figure 2(a). A plastic box (from the Dutch store ‘Bodemschat’) of dimensions ![]() $25\ {\rm mm} \times 25\ {\rm mm} \times 15\ {\rm mm}$ (length

$25\ {\rm mm} \times 25\ {\rm mm} \times 15\ {\rm mm}$ (length ![]() $\times$ width

$\times$ width ![]() $\times$ height) filled with purified water (Milli-Q) was used as the liquid bath for most of the experiments. To study the effect of the viscosity of the retracting film, the water in the bath was replaced by glycerol–water (glycerol from Sigma-Aldrich) mixtures (concentrations in the range 50 %–70 % by weight) for some experiments. A dispensing needle (

$\times$ height) filled with purified water (Milli-Q) was used as the liquid bath for most of the experiments. To study the effect of the viscosity of the retracting film, the water in the bath was replaced by glycerol–water (glycerol from Sigma-Aldrich) mixtures (concentrations in the range 50 %–70 % by weight) for some experiments. A dispensing needle (![]() ${\rm inner\ diameter} = 0.41\ {\rm mm}$, HSW Fine-Ject) was submerged within the bath such that its dispensing end was at a depth of

${\rm inner\ diameter} = 0.41\ {\rm mm}$, HSW Fine-Ject) was submerged within the bath such that its dispensing end was at a depth of ![]() $2.4\ {\rm mm}$ from the free surface (depth kept constant during all experiments). A silicone oil (Wacker) droplet was created at the tip of the needle by connecting it to an oil-filled plastic syringe (

$2.4\ {\rm mm}$ from the free surface (depth kept constant during all experiments). A silicone oil (Wacker) droplet was created at the tip of the needle by connecting it to an oil-filled plastic syringe (![]() $5\,\,{\rm ml}$, Braun Injekt) via a flexible plastic polyetheretherketone (PEEK) tubing (Upchurch Scientific). The oil flow rate was maintained at

$5\,\,{\rm ml}$, Braun Injekt) via a flexible plastic polyetheretherketone (PEEK) tubing (Upchurch Scientific). The oil flow rate was maintained at ![]() $0.05\,\,{\rm ml}\,{\rm min}^{-1}$ with the help of a syringe infusion pump (Harvard Apparatus). In the present experiments, silicone oils of different viscosities were used, and their densities (

$0.05\,\,{\rm ml}\,{\rm min}^{-1}$ with the help of a syringe infusion pump (Harvard Apparatus). In the present experiments, silicone oils of different viscosities were used, and their densities (![]() $\rho _{s}$), kinematic (

$\rho _{s}$), kinematic (![]() $\nu _{s}$) and dynamic viscosities (

$\nu _{s}$) and dynamic viscosities (![]() $\eta _{s}$) are listed in table 1. It is to be noted that for only the AK 0.65 oil (

$\eta _{s}$) are listed in table 1. It is to be noted that for only the AK 0.65 oil (![]() $\eta _{s} = 4.94 \times 10^{-4}\,{\rm Pa}\,{\rm s}$), the drop is less viscous than the water film (

$\eta _{s} = 4.94 \times 10^{-4}\,{\rm Pa}\,{\rm s}$), the drop is less viscous than the water film (![]() $\eta _{f} = 8.9 \times 10^{-4}\,{\rm Pa}\,{\rm s}$), while for all the other oils, the film is less viscous. The oil–water interfacial tension (

$\eta _{f} = 8.9 \times 10^{-4}\,{\rm Pa}\,{\rm s}$), while for all the other oils, the film is less viscous. The oil–water interfacial tension (![]() $\gamma _{sf}$) was considered to be

$\gamma _{sf}$) was considered to be ![]() $0.040\,{\rm N}\,{\rm m}^{-1}$ (Peters & Arabali Reference Peters and Arabali2013).

$0.040\,{\rm N}\,{\rm m}^{-1}$ (Peters & Arabali Reference Peters and Arabali2013).

Figure 2. (a) Schematic of the experimental set-up. (b) Typical time-lapsed experimental snapshots of the film rupture and the subsequent retraction process (![]() $\nu _{s} = 10\,{\rm cSt}$). The time instant

$\nu _{s} = 10\,{\rm cSt}$). The time instant ![]() $t$ =

$t$ = ![]() $t_{0}$ denotes the first frame where rupture (indicated by the white arrow) is discernible.

$t_{0}$ denotes the first frame where rupture (indicated by the white arrow) is discernible.

Table 1. Salient properties of the silicone oils used in the present work.

The drop volume was increased by a slow infusion using the syringe pump. The needle depth below the free surface was chosen such that the drop remained anchored to the needle during inflation. As a result, the water film right above the oil droplet progressively thins with increasing volume of the drop. Below a certain thickness, the film ruptures due to van der Waals forces (Vaynblat, Lister & Witelski Reference Vaynblat, Lister and Witelski2001), and subsequently retracts into the bath. This situation is analogous to the rupture and retraction of a water film sandwiched between air and a viscous oil droplet. This is also a configuration that is flipped vertically as compared with the early-time scenario studied by Feng et al. (Reference Feng, Muradoglu, Kim, Ault and Stone2016). Another key difference is that we ensure negligible vertical velocity at the point of rupture of the water film, making this scenario ideal for studying three-phase Taylor–Culick retractions.

High-speed imaging of this rupture and retraction phenomena was performed at 50 000 f.p.s. (frames per second) for the lower viscosity oils and at 10 000 f.p.s. for the higher viscosity ones, with a ![]() $2.5\,\mathrm {\mu }{\rm s}^{-1}$ exposure time, by a high-speed camera (Fastcam Nova S12, Photron) connected to a macro lens (DG Macro

$2.5\,\mathrm {\mu }{\rm s}^{-1}$ exposure time, by a high-speed camera (Fastcam Nova S12, Photron) connected to a macro lens (DG Macro ![]() $105\ {\rm mm}$, Sigma) with

$105\ {\rm mm}$, Sigma) with ![]() $64\ {\rm mm}$ of lens extender (Kenko). The camera was pointed at a plane mirror (Thorlabs) inclined at

$64\ {\rm mm}$ of lens extender (Kenko). The camera was pointed at a plane mirror (Thorlabs) inclined at ![]() $45^{\circ }$ to the horizontal to capture the top view of the retraction phenomenon (figure 2a), while the experiments were illuminated from the top by a light-emitting diode light source (KL 2500 LED, Schott). A typical bursting event is shown in figure 2(b), where time

$45^{\circ }$ to the horizontal to capture the top view of the retraction phenomenon (figure 2a), while the experiments were illuminated from the top by a light-emitting diode light source (KL 2500 LED, Schott). A typical bursting event is shown in figure 2(b), where time ![]() $t=t_{0}$ indicates the instant when rupture is optically discernible. With increasing time, the size of the hole formed due to rupture increases as the film retracts. The phenomenological observations shown in figure 2(b) will be discussed in detail in § 3. The captured images were then further analysed using the open-source software FIJI (Schindelin, Aganda-Carreras & Frise Reference Schindelin, Aganda-Carreras and Frise2012) and an in-house OpenCV-based Python script to obtain quantitative information presented in the following sections.

$t=t_{0}$ indicates the instant when rupture is optically discernible. With increasing time, the size of the hole formed due to rupture increases as the film retracts. The phenomenological observations shown in figure 2(b) will be discussed in detail in § 3. The captured images were then further analysed using the open-source software FIJI (Schindelin, Aganda-Carreras & Frise Reference Schindelin, Aganda-Carreras and Frise2012) and an in-house OpenCV-based Python script to obtain quantitative information presented in the following sections.

3. Film bursting at an air–liquid interface: experimental results

The rupture and retraction of a water film on the surface of an oil drop of ![]() $\eta _{s}=4.94\times ~10^{-4}\,{\rm Pa}\,{\rm s}$ is shown in figure 3(a) (and supplementary movie 1 available at https://doi.org/10.1017/jfm.2022.671). The timestamps indicate (

$\eta _{s}=4.94\times ~10^{-4}\,{\rm Pa}\,{\rm s}$ is shown in figure 3(a) (and supplementary movie 1 available at https://doi.org/10.1017/jfm.2022.671). The timestamps indicate (![]() $t - t_{0}$), where

$t - t_{0}$), where ![]() $t_{0}$ is the time instant when rupture is optically discernible, and

$t_{0}$ is the time instant when rupture is optically discernible, and ![]() $t$ is the current time. As mentioned earlier, in this particular case, the water film is more viscous than the oil. It is to be noted that in the present experiments, we could not precisely control the location of rupture as it was sensitive to experimental noise (see § 4.2 of Villermaux (Reference Villermaux2020)). Hence, the rupture in the present experiments did not always occur at the apex of the thinning film. Such behaviour was also observed in other similar experiments of film rupture (Oldenziel, Delfos & Westerweel Reference Oldenziel, Delfos and Westerweel2012; de Maleprade, Clanet & Quéré Reference de Maleprade, Clanet and Quéré2016). The rupture location may also be determined by a ‘prehole’ formation, also observed by Vernay et al. (Reference Vernay, Ramos and Ligoure2015) for the bursting of emulsion-based liquid sheets. In their work, Vernay et al. (Reference Vernay, Ramos and Ligoure2015) show that the presence of emulsion oil droplets at the air–water interface results in lowering of the local interfacial tension, leading to Marangoni flows away from that location. This flow leads to a local thinning of the film, which ultimately ruptures at that location. They also report that the prehole formation always precedes rupture in their experiments. In the present experiments, the water surface is never pristine and always contains small impurities (which are practically unavoidable). It is possible that these impurities might have reduced the local surface tension, resulting in a similar Marangoni flow leading to a prehole. For the discussion on the origin of the hole nucleation, we also refer to Lohse & Villermaux (Reference Lohse and Villermaux2020). In any case, upon rupture, a circular hole is formed in the film, which grows radially in time. Therefore, the oil bounded by the periphery of the hole gets into contact with air and not with the water film. It is also noticeable that the edge of the retracting film forms a thick rim – an observation also made for the retraction of liquid films in air (Pandit & Davidson Reference Pandit and Davidson1990; Brenner & Gueyffier Reference Brenner and Gueyffier1999; Sünderhauf et al. Reference Sünderhauf, Raszillier and Durst2002). The presence of the rim can be qualitatively surmised from the experimental snapshots (figures 2b and 3a,b), where the change in the curvature of the film downstream of the rim introduces a difference in the colour intensity. As the hole increases in size (or as the film retracts further), this rim also becomes thicker. Finally, since silicone oil prefers to spread on water (Li et al. Reference Li, Diddens, Segers, Wijshoff, Versluis and Lohse2020), the retraction process ceases when the oil droplet has completely spread on water, thus creating a macroscopic film whose thickness is controlled by volume conservation and thermodynamics (de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2004).

$t$ is the current time. As mentioned earlier, in this particular case, the water film is more viscous than the oil. It is to be noted that in the present experiments, we could not precisely control the location of rupture as it was sensitive to experimental noise (see § 4.2 of Villermaux (Reference Villermaux2020)). Hence, the rupture in the present experiments did not always occur at the apex of the thinning film. Such behaviour was also observed in other similar experiments of film rupture (Oldenziel, Delfos & Westerweel Reference Oldenziel, Delfos and Westerweel2012; de Maleprade, Clanet & Quéré Reference de Maleprade, Clanet and Quéré2016). The rupture location may also be determined by a ‘prehole’ formation, also observed by Vernay et al. (Reference Vernay, Ramos and Ligoure2015) for the bursting of emulsion-based liquid sheets. In their work, Vernay et al. (Reference Vernay, Ramos and Ligoure2015) show that the presence of emulsion oil droplets at the air–water interface results in lowering of the local interfacial tension, leading to Marangoni flows away from that location. This flow leads to a local thinning of the film, which ultimately ruptures at that location. They also report that the prehole formation always precedes rupture in their experiments. In the present experiments, the water surface is never pristine and always contains small impurities (which are practically unavoidable). It is possible that these impurities might have reduced the local surface tension, resulting in a similar Marangoni flow leading to a prehole. For the discussion on the origin of the hole nucleation, we also refer to Lohse & Villermaux (Reference Lohse and Villermaux2020). In any case, upon rupture, a circular hole is formed in the film, which grows radially in time. Therefore, the oil bounded by the periphery of the hole gets into contact with air and not with the water film. It is also noticeable that the edge of the retracting film forms a thick rim – an observation also made for the retraction of liquid films in air (Pandit & Davidson Reference Pandit and Davidson1990; Brenner & Gueyffier Reference Brenner and Gueyffier1999; Sünderhauf et al. Reference Sünderhauf, Raszillier and Durst2002). The presence of the rim can be qualitatively surmised from the experimental snapshots (figures 2b and 3a,b), where the change in the curvature of the film downstream of the rim introduces a difference in the colour intensity. As the hole increases in size (or as the film retracts further), this rim also becomes thicker. Finally, since silicone oil prefers to spread on water (Li et al. Reference Li, Diddens, Segers, Wijshoff, Versluis and Lohse2020), the retraction process ceases when the oil droplet has completely spread on water, thus creating a macroscopic film whose thickness is controlled by volume conservation and thermodynamics (de Gennes, Brochard-Wyart & Quéré Reference de Gennes, Brochard-Wyart and Quéré2004).

Figure 3. Time-lapsed snapshots of the postrupture retraction of water films for different oil viscosities: (a) ![]() $\nu _{s}$ = 0.65 cSt; (b)

$\nu _{s}$ = 0.65 cSt; (b) ![]() $\nu _{s}$ = 10 cSt; and (c)

$\nu _{s}$ = 10 cSt; and (c) ![]() $\nu _{s}$ = 100 cSt. The rupture location is denoted by the white arrows, while the time stamps indicate the time since rupture is first observed (i.e.

$\nu _{s}$ = 100 cSt. The rupture location is denoted by the white arrows, while the time stamps indicate the time since rupture is first observed (i.e. ![]() $t - t_{0}$). Also see supplementary movie 1.

$t - t_{0}$). Also see supplementary movie 1.

When the viscosity of the oil phase is increased to ![]() $\eta _{s} = 9.30 \times 10^{-3}\,{\rm Pa}\,{\rm s}$, the hole opening (or film retraction) dynamics (as seen in figure 3b and supplementary movie 1) are qualitatively similar to that for the lower viscosity described before (figure 3a). Here also, the film forms a thick rim at its retracting edge. Nonetheless, an increase in the oil's viscosity decreases the retraction speed, as indicated by the timestamps (corresponding to

$\eta _{s} = 9.30 \times 10^{-3}\,{\rm Pa}\,{\rm s}$, the hole opening (or film retraction) dynamics (as seen in figure 3b and supplementary movie 1) are qualitatively similar to that for the lower viscosity described before (figure 3a). Here also, the film forms a thick rim at its retracting edge. Nonetheless, an increase in the oil's viscosity decreases the retraction speed, as indicated by the timestamps (corresponding to ![]() $t - t_{0}$). This behaviour is expected since the physical situation is analogous to a retracting water film shearing the free surface of viscous oil: increasing

$t - t_{0}$). This behaviour is expected since the physical situation is analogous to a retracting water film shearing the free surface of viscous oil: increasing ![]() $\eta _{s}$ increases the resistance to shearing, which in turn makes the retraction process slower.

$\eta _{s}$ increases the resistance to shearing, which in turn makes the retraction process slower.

Furthermore, the experimental snapshots show that the oil–air–water contact line exhibits corrugations during the retraction process, and fine streams of droplets are released from these corrugations. Similar observations were also made for film retraction in the two-phase configuration (Reyssat & Quéré Reference Reyssat and Quéré2006; Oldenziel et al. Reference Oldenziel, Delfos and Westerweel2012) and during the rupture of the intermediate film when a drop coalesces with a pool of the same liquid in the presence of an external medium (Aryafar & Kavehpour Reference Aryafar and Kavehpour2008; Kavehpour Reference Kavehpour2015). The nature of the corrugations is reminiscent of the sharp tips observed during selective withdrawal (Cohen & Nagel Reference Cohen and Nagel2002; Courrech du Pont & Eggers Reference Courrech du Pont and Eggers2006, Reference Courrech du Pont and Eggers2020) or tip streaming (Montanero & Gañán Calvo Reference Montanero and Gañán Calvo2020). In a frame of reference comoving with the rim, the film sees highly viscous oil being aspirated away from it, resulting in the formation of the sharp tips. Indeed, such a mechanism was also hinted at by Reyssat & Quéré (Reference Reyssat and Quéré2006) for the instabilities observed in their experiments for film retraction in the two-phase configuration. Tseng & Prosperetti (Reference Tseng and Prosperetti2015) showed that such instabilities are formed due to the local convergence of streamlines in the neighbourhood of a zero-vorticity point or line on the interface. However, a detailed and quantitative investigation of the formation and subsequent breakup of these liquid tips is beyond the scope of the present work.

For an even higher viscosity of the oil phase (![]() $\eta _{s} = 9.60 \times 10^{-2}\,{\rm Pa}\,{\rm s}$; see figure 3c and supplementary movie 1), the retraction of the ruptured water film is further slowed down (as evident from the timestamps in figure 3c). Furthermore, the retracting edge also does not possess a thick rim. This observation is similar to the case of Brenner & Gueyffier (Reference Brenner and Gueyffier1999) for the retraction of viscous films in air, where films of higher viscosity do not form a rim. Moreover, although the expanding holes for the lower

$\eta _{s} = 9.60 \times 10^{-2}\,{\rm Pa}\,{\rm s}$; see figure 3c and supplementary movie 1), the retraction of the ruptured water film is further slowed down (as evident from the timestamps in figure 3c). Furthermore, the retracting edge also does not possess a thick rim. This observation is similar to the case of Brenner & Gueyffier (Reference Brenner and Gueyffier1999) for the retraction of viscous films in air, where films of higher viscosity do not form a rim. Moreover, although the expanding holes for the lower ![]() $\eta _{s}$ cases (as shown in figure 3a,b) are almost circular, the one for the high viscosity case shown in figure 3(c) is highly asymmetric. This asymmetry can be attributed to the location of the rupture not being at the film's apex. Since the rupture is happening at an off-apex location, the film thickness at the location of rupture is not spatially uniform due to the curvature of the oil droplet. Hence, the retraction velocity is faster on the part of the film which has a lower thickness. Presumably, this effect is more pronounced when the overall film retraction dynamics are slower, as is the case for the experiments shown in figure 3(c). To confirm this hypothesis, one requires high-resolution measurements of the spatial variation of the film thickness, which is challenging in the present experiments (further discussed in § 7). The corrugations at the oil–air–water contact line are also observed in this case. However, since the retraction velocity itself is considerably smaller than for the case shown in figure 3(b) (see figure 4b for specific values), the tips are not as sharp, and no droplet streams are observed. To quantify the retraction dynamics, we measure the hole opening radius from each snapshot captured using the high-speed camera. For each experimental snapshot, the area of the hole

$\eta _{s}$ cases (as shown in figure 3a,b) are almost circular, the one for the high viscosity case shown in figure 3(c) is highly asymmetric. This asymmetry can be attributed to the location of the rupture not being at the film's apex. Since the rupture is happening at an off-apex location, the film thickness at the location of rupture is not spatially uniform due to the curvature of the oil droplet. Hence, the retraction velocity is faster on the part of the film which has a lower thickness. Presumably, this effect is more pronounced when the overall film retraction dynamics are slower, as is the case for the experiments shown in figure 3(c). To confirm this hypothesis, one requires high-resolution measurements of the spatial variation of the film thickness, which is challenging in the present experiments (further discussed in § 7). The corrugations at the oil–air–water contact line are also observed in this case. However, since the retraction velocity itself is considerably smaller than for the case shown in figure 3(b) (see figure 4b for specific values), the tips are not as sharp, and no droplet streams are observed. To quantify the retraction dynamics, we measure the hole opening radius from each snapshot captured using the high-speed camera. For each experimental snapshot, the area of the hole ![]() $A(t)$ is measured, and subsequently an equivalent hole opening radius

$A(t)$ is measured, and subsequently an equivalent hole opening radius ![]() $R(t)$ is calculated as

$R(t)$ is calculated as ![]() $A(t) = {\rm \pi}(R(t))^{2}$. A typical measurement from the optical images is depicted in the inset of figure 4(a). The temporal variation of the measured hole radius,

$A(t) = {\rm \pi}(R(t))^{2}$. A typical measurement from the optical images is depicted in the inset of figure 4(a). The temporal variation of the measured hole radius, ![]() $R$, is shown in figure 4(a). The time instant corresponding to the first frame in which rupture is optically discernible is denoted by

$R$, is shown in figure 4(a). The time instant corresponding to the first frame in which rupture is optically discernible is denoted by ![]() $t_{0}$. Each datapoint in figure 4(a) denotes the mean of measurements from five independent experiments, and the error bars correspond to

$t_{0}$. Each datapoint in figure 4(a) denotes the mean of measurements from five independent experiments, and the error bars correspond to ![]() $\pm$ one standard deviation. In the present work, we focus on the early moments following rupture, as indicated by the red rectangle in figure 4(a). Zooming into this early-time regime, as shown in figure 4(b), it is observed that

$\pm$ one standard deviation. In the present work, we focus on the early moments following rupture, as indicated by the red rectangle in figure 4(a). Zooming into this early-time regime, as shown in figure 4(b), it is observed that ![]() $R(t)$ varies linearly with time (as evident from the lines denoting linear fits in figure 4b). This variation indicates that the retraction velocity

$R(t)$ varies linearly with time (as evident from the lines denoting linear fits in figure 4b). This variation indicates that the retraction velocity ![]() $v_f$ (=

$v_f$ (= ![]() ${\rm d}R/{\rm d}t$), given by the slopes of the linear fits, is constant for each viscosity. This is reminiscent of the constant rupture velocity also observed for the classical (figure 1a) and two-phase (figure 1b) Taylor–Culick configurations. Furthermore, it is also observed that with increasing

${\rm d}R/{\rm d}t$), given by the slopes of the linear fits, is constant for each viscosity. This is reminiscent of the constant rupture velocity also observed for the classical (figure 1a) and two-phase (figure 1b) Taylor–Culick configurations. Furthermore, it is also observed that with increasing ![]() $\eta _{s}$ (or

$\eta _{s}$ (or ![]() $\nu _{s}$), the slope of the linear fits (hence

$\nu _{s}$), the slope of the linear fits (hence ![]() $v_f$) decreases, as expected from the qualitative observations reported in figure 3.

$v_f$) decreases, as expected from the qualitative observations reported in figure 3.

Figure 4. (a) Temporal evolution of the retraction radius (![]() $R$) for oils of different kinematic viscosity (

$R$) for oils of different kinematic viscosity (![]() $\nu _{s}$); a typical measurement is shown in the snapshot in the inset. (b) At early times, red rectangle in panel (a),

$\nu _{s}$); a typical measurement is shown in the snapshot in the inset. (b) At early times, red rectangle in panel (a), ![]() $R$ varies linearly with time; the discrete datapoints are experimental measurements and the lines are linear fits. (c) Variation of dewetting velocity (

$R$ varies linearly with time; the discrete datapoints are experimental measurements and the lines are linear fits. (c) Variation of dewetting velocity (![]() $v_f$) with the dynamic viscosity of the oil phase (

$v_f$) with the dynamic viscosity of the oil phase (![]() $\eta _{s}$); the discrete datapoints are experimental measurements and the line represents

$\eta _{s}$); the discrete datapoints are experimental measurements and the line represents ![]() $v_f \sim \eta _{s}^{-1/2}$.

$v_f \sim \eta _{s}^{-1/2}$.

The variation of ![]() $v_f$ with

$v_f$ with ![]() $\eta _{s}$ is shown in figure 4(c). The typical retraction velocities are

$\eta _{s}$ is shown in figure 4(c). The typical retraction velocities are ![]() $O(1\,{\rm m}\,{\rm s}^{-1})$. A decreasing

$O(1\,{\rm m}\,{\rm s}^{-1})$. A decreasing ![]() $v_f$ with increasing

$v_f$ with increasing ![]() $\eta _{s}$ is observed. Furthermore, for the cases where the oil is more viscous than water (

$\eta _{s}$ is observed. Furthermore, for the cases where the oil is more viscous than water (![]() $\eta _{f} = 8.9 \times 10^{-4}\,{\rm Pa}\,{\rm s}$), the retraction velocity varies as

$\eta _{f} = 8.9 \times 10^{-4}\,{\rm Pa}\,{\rm s}$), the retraction velocity varies as

as evident from the line in figure 4(c). This is a weaker dependence as compared with the expected ![]() $1/\eta _{s}$ variation observed for retraction in the two-phase configuration (Martin et al. Reference Martin, Buguin and Brochard-Wyart1994; Eri & Okumura Reference Eri and Okumura2010). We will attempt to explain the scalings for the two-phase and three-phase configurations in § 7. Furthermore, the reason for not fitting the datapoint for the case where the oil is less viscous than the water film in figure 4(c) will also be addressed therein.

$1/\eta _{s}$ variation observed for retraction in the two-phase configuration (Martin et al. Reference Martin, Buguin and Brochard-Wyart1994; Eri & Okumura Reference Eri and Okumura2010). We will attempt to explain the scalings for the two-phase and three-phase configurations in § 7. Furthermore, the reason for not fitting the datapoint for the case where the oil is less viscous than the water film in figure 4(c) will also be addressed therein.

4. Numerical framework

4.1. Governing equations

In this section, we discuss the governing equations that describe the retraction of a ruptured liquid film in the three configurations we study in this paper, namely, the classical, two-phase and three-phase Taylor–Culick retractions. We perform axisymmetric direct numerical simulations using the free-software VoF program, Basilisk C (Popinet & Collaborators Reference Popinet2013–2022; Sanjay Reference Sanjay2021b), which uses the one-fluid approximation (Tryggvason, Scardovelli & Zaleski Reference Tryggvason, Scardovelli and Zaleski2011) to solve the continuity and Navier–Stokes equations,

where, ![]() $\boldsymbol {v}$ and

$\boldsymbol {v}$ and ![]() $p$ are the velocity vector and pressure fields, respectively,

$p$ are the velocity vector and pressure fields, respectively, ![]() $\eta$ the viscosity of the fluid and

$\eta$ the viscosity of the fluid and ![]() $t$ denotes time. Furthermore,

$t$ denotes time. Furthermore, ![]() $\boldsymbol {\mathcal {D}}$ is the symmetric part of the velocity gradient tensor

$\boldsymbol {\mathcal {D}}$ is the symmetric part of the velocity gradient tensor ![]() $(\boldsymbol {\mathcal {D}} = (\boldsymbol {\nabla } \boldsymbol {v} + (\boldsymbol {\nabla } \boldsymbol {v})^{\text {T}})/2)$, and

$(\boldsymbol {\mathcal {D}} = (\boldsymbol {\nabla } \boldsymbol {v} + (\boldsymbol {\nabla } \boldsymbol {v})^{\text {T}})/2)$, and ![]() $\boldsymbol {f}_\gamma$ the singular surface tension force needed in the one-fluid approximation to comply with the dynamic boundary condition at the interfaces (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992).

$\boldsymbol {f}_\gamma$ the singular surface tension force needed in the one-fluid approximation to comply with the dynamic boundary condition at the interfaces (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992).

4.2. Non-dimensionalization of the governing equations

We non-dimensionalize the governing equations by using the inertiocapillary velocity scale ![]() $v_\gamma$, the thickness of the film

$v_\gamma$, the thickness of the film ![]() $h_0$ and the capillary pressure

$h_0$ and the capillary pressure ![]() $p_\gamma$. These scales also define the characteristic inertiocapillary time,

$p_\gamma$. These scales also define the characteristic inertiocapillary time, ![]() $\tau _\gamma$, as

$\tau _\gamma$, as

\begin{equation} \tau_\gamma = \frac{h_0}{v_\gamma} = \sqrt{\frac{\rho_fh_0^3}{2\gamma_{sf}}}, \quad v_\gamma = \sqrt{\frac{2\gamma_{sf}}{\rho_f h_{0}}}, \quad p_\gamma = \frac{2\gamma_{sf}}{h_0}. \end{equation}

\begin{equation} \tau_\gamma = \frac{h_0}{v_\gamma} = \sqrt{\frac{\rho_fh_0^3}{2\gamma_{sf}}}, \quad v_\gamma = \sqrt{\frac{2\gamma_{sf}}{\rho_f h_{0}}}, \quad p_\gamma = \frac{2\gamma_{sf}}{h_0}. \end{equation}

Here, ![]() $\gamma _{sf}$ is the surface tension coefficient between the film ( f) and the surrounding (s) medium,

$\gamma _{sf}$ is the surface tension coefficient between the film ( f) and the surrounding (s) medium, ![]() $\rho _f$ the film density and

$\rho _f$ the film density and ![]() $h_0$ its thickness. The dimensionless form of the Navier–Stokes equation (4.2) is

$h_0$ its thickness. The dimensionless form of the Navier–Stokes equation (4.2) is

where the expressions for the Ohnesorge number (![]() $Oh$; the ratio of viscocapillary to inertiocapillary time scales), the dimensionless density (

$Oh$; the ratio of viscocapillary to inertiocapillary time scales), the dimensionless density (![]() $\tilde {\rho }$) and the singular surface tension force (

$\tilde {\rho }$) and the singular surface tension force (![]() $\tilde {\boldsymbol {f}}$) depend on the specific configurations that we discuss below.

$\tilde {\boldsymbol {f}}$) depend on the specific configurations that we discuss below.

4.2.1. Two-phase Taylor–Culick configuration

In this configuration, a liquid film ( f) retracts in a viscous surrounding (s) medium (figure 5a). We use the VoF tracer ![]() $\varPsi$ to differentiate between the film (

$\varPsi$ to differentiate between the film (![]() $\varPsi =1$) and the surroundings (

$\varPsi =1$) and the surroundings (![]() $\varPsi = 0$), which follows the VoF scalar advection equation,

$\varPsi = 0$), which follows the VoF scalar advection equation,

Furthermore, the singular surface tension force is given by (Brackbill et al. Reference Brackbill, Kothe and Zemach1992)

where the curvature ![]() $\kappa$ is calculated using the height-function approach (Popinet Reference Popinet2009). We follow the same sign convention as Tryggvason et al. (Reference Tryggvason, Scardovelli and Zaleski2011, page 33): the curvature is positive if the interface folds towards its normal

$\kappa$ is calculated using the height-function approach (Popinet Reference Popinet2009). We follow the same sign convention as Tryggvason et al. (Reference Tryggvason, Scardovelli and Zaleski2011, page 33): the curvature is positive if the interface folds towards its normal ![]() $\boldsymbol {\hat {n}}$, i.e.

$\boldsymbol {\hat {n}}$, i.e. ![]() $\kappa = - \boldsymbol {\nabla } \boldsymbol{\cdot } \boldsymbol {n}$. Note that the surface tension scheme in Basilisk C is explicit in time. So, we restrict the maximum time step as the characteristic inertiocapillary time based on the wavelength of the smallest capillary wave. Additionally, the density of the film is the same as that of the surroundings, giving

$\kappa = - \boldsymbol {\nabla } \boldsymbol{\cdot } \boldsymbol {n}$. Note that the surface tension scheme in Basilisk C is explicit in time. So, we restrict the maximum time step as the characteristic inertiocapillary time based on the wavelength of the smallest capillary wave. Additionally, the density of the film is the same as that of the surroundings, giving ![]() $\tilde {\rho } = 1$. Lastly, the Ohnesorge number (

$\tilde {\rho } = 1$. Lastly, the Ohnesorge number (![]() $Oh$) is given by

$Oh$) is given by

where

are the Ohnesorge numbers based on the film and surroundings viscosities, respectively. For this configuration, we keep ![]() ${Oh}_{f}$ constant at

${Oh}_{f}$ constant at ![]() $0.05$ (based on the experiments of Reyssat & Quéré (Reference Reyssat and Quéré2006)), and vary the control parameter

$0.05$ (based on the experiments of Reyssat & Quéré (Reference Reyssat and Quéré2006)), and vary the control parameter ![]() ${Oh}_{s}$ in § 5.

${Oh}_{s}$ in § 5.

Figure 5. Computational domain for (a) two-phase and (b) three-phase Taylor–Culick retractions. For the classical case, panel (a) is used by replacing the surroundings (s) with air (a). The size of the domain is much larger than the hole radius ![]() $(\mathcal {L}_{max} \gg R(t))$. Furthermore,

$(\mathcal {L}_{max} \gg R(t))$. Furthermore, ![]() $\mathcal {L}_{max}/h_0 \gg \max ({Oh}_{f}, {Oh}_{s})$.

$\mathcal {L}_{max}/h_0 \gg \max ({Oh}_{f}, {Oh}_{s})$.

Note that the computational domain in figure 5(a) along with (4.5)–(4.8a,b) can be used to simulate classical Taylor–Culick retractions as well by replacing the surroundings (s) with air (a). We discuss the details of the classical configuration in Appendix A.

4.2.2. Three-phase Taylor–Culick configuration

In this configuration, we model the bursting of a water film at an oil drop-air interface by simulating the retraction of a fluid film ( f) on an initially flat oil bath (s), while ignoring the effects of the oil drop's curvature (as the retraction length in the early-time regime of figure 4b is much smaller than the oil drop radius, see figure 5b). We extend the traditional VoF method described in § 4.2.1 to tackle three fluids by using two VoF tracers: ![]() $\varPsi _1$, which is tagged as

$\varPsi _1$, which is tagged as ![]() $1$ for the liquids (water film, f, and oil surroundings,

$1$ for the liquids (water film, f, and oil surroundings, ![]() $s$) and

$s$) and ![]() $0$ for air (a); and

$0$ for air (a); and ![]() $\varPsi _2$ which is

$\varPsi _2$ which is ![]() $1$ for the water film ( f) and

$1$ for the water film ( f) and ![]() $0$ everywhere else (figure 5b). Note that this implementation requires an implicit declaration of the surrounding phase (s), given by

$0$ everywhere else (figure 5b). Note that this implementation requires an implicit declaration of the surrounding phase (s), given by ![]() $\varPsi _2(1-\varPsi _1)$ (Sanjay et al. Reference Sanjay, Jain, Jalaal, van der Meer and Lohse2019; Sanjay Reference Sanjay2021a,Reference Sanjayb; Mou et al. Reference Mou, Zheng, Jian, Antonini, Josserand and Thoraval2021). Additionally, both

$\varPsi _2(1-\varPsi _1)$ (Sanjay et al. Reference Sanjay, Jain, Jalaal, van der Meer and Lohse2019; Sanjay Reference Sanjay2021a,Reference Sanjayb; Mou et al. Reference Mou, Zheng, Jian, Antonini, Josserand and Thoraval2021). Additionally, both ![]() $\varPsi _1$ and

$\varPsi _1$ and ![]() $\varPsi _2$ follow the VoF tracer advection equation,

$\varPsi _2$ follow the VoF tracer advection equation,

and the dimensionless density ratio is (with ![]() $\rho _f = \rho _s$)

$\rho _f = \rho _s$)

The Ohnesorge number (![]() $Oh$) is now given by

$Oh$) is now given by

where ![]() ${Oh}_{f}$ and

${Oh}_{f}$ and ![]() ${Oh}_{s}$ follow (4.8a,b), and

${Oh}_{s}$ follow (4.8a,b), and ![]() ${Oh}_{a} = \eta _a/\sqrt {\rho _f(2\gamma _{sf})h_0}$ is the Ohnesorge number based on the viscosity of air. Both

${Oh}_{a} = \eta _a/\sqrt {\rho _f(2\gamma _{sf})h_0}$ is the Ohnesorge number based on the viscosity of air. Both ![]() ${Oh}_{f}$ and

${Oh}_{f}$ and ![]() ${Oh}_{a}$ are fixed at

${Oh}_{a}$ are fixed at ![]() $10^{-1}$ and

$10^{-1}$ and ![]() $10^{-3}$, respectively, for all the three-phase simulation data presented in this paper (see § 7), and we vary the control parameter

$10^{-3}$, respectively, for all the three-phase simulation data presented in this paper (see § 7), and we vary the control parameter ![]() ${Oh}_{s}$ in § 5. Lastly, the surface tension body force takes the form

${Oh}_{s}$ in § 5. Lastly, the surface tension body force takes the form

with ![]() $\gamma _{sa}$ and

$\gamma _{sa}$ and ![]() $\gamma _{sf}$ being the surface tension coefficients for the surroundings–air and surroundings–film interfaces, respectively.

$\gamma _{sf}$ being the surface tension coefficients for the surroundings–air and surroundings–film interfaces, respectively.

Physically, such a configuration (figure 5b and (4.9)–(4.11)) ideally implies the presence of a zero thickness precursor film of the surrounding liquid (s, represented by ![]() $(1-\varPsi _2)\varPsi _1 = 1$, (4.11)) over the liquid film ( f,

$(1-\varPsi _2)\varPsi _1 = 1$, (4.11)) over the liquid film ( f, ![]() $\varPsi _1\varPsi _2 = 1$, (4.11)). Note that this numerical assumption is applicable only when it is thermodynamically favourable for one of the fluids (here s) to spread over all the other fluids, i.e. it has a positive spreading coefficient (de Gennes et al. Reference de Gennes, Brochard-Wyart and Quéré2004; Berthier & Brakke Reference Berthier and Brakke2012),

$\varPsi _1\varPsi _2 = 1$, (4.11)). Note that this numerical assumption is applicable only when it is thermodynamically favourable for one of the fluids (here s) to spread over all the other fluids, i.e. it has a positive spreading coefficient (de Gennes et al. Reference de Gennes, Brochard-Wyart and Quéré2004; Berthier & Brakke Reference Berthier and Brakke2012), ![]() $S \equiv \gamma _{af} - \gamma _{sf} - \gamma _{sa} > 0$, and the Neumann triangle collapses at the three-phase contact line. In reality, this precursor film will have a finite thickness controlled by microscopic forces (such as van der Waals forces; Vaynblat et al. (Reference Vaynblat, Lister and Witelski2001)), and is much smaller than the length scales that we can resolve numerically in the continuum framework. Indeed, for our numerical simulations, this precursor film has an effective thickness of

$S \equiv \gamma _{af} - \gamma _{sf} - \gamma _{sa} > 0$, and the Neumann triangle collapses at the three-phase contact line. In reality, this precursor film will have a finite thickness controlled by microscopic forces (such as van der Waals forces; Vaynblat et al. (Reference Vaynblat, Lister and Witelski2001)), and is much smaller than the length scales that we can resolve numerically in the continuum framework. Indeed, for our numerical simulations, this precursor film has an effective thickness of ![]() $\varDelta /2$, where

$\varDelta /2$, where ![]() $\varDelta$ is the size of the finest grid employed in this work. We further assume that, on the time scale of film retraction, the effective spreading coefficient of the surrounding liquid (s) is

$\varDelta$ is the size of the finest grid employed in this work. We further assume that, on the time scale of film retraction, the effective spreading coefficient of the surrounding liquid (s) is ![]() $0$ (Bonn et al. Reference Bonn, Eggers, Indekeu, Meunier and Rolley2009). Consequently, the effective surface tension coefficient between the film and air is

$0$ (Bonn et al. Reference Bonn, Eggers, Indekeu, Meunier and Rolley2009). Consequently, the effective surface tension coefficient between the film and air is ![]() $\gamma _{af} = \gamma _{sf}+\gamma _{sa}$. This precursor film (Thoraval & Thoroddsen Reference Thoraval and Thoroddsen2013) is analogous to the mathematical model for spreading of a perfectly wetting liquid on a solid substrate (de Gennes et al. Reference de Gennes, Brochard-Wyart and Quéré2004; Bonn et al. Reference Bonn, Eggers, Indekeu, Meunier and Rolley2009), which regularizes the contact line singularity due to the numerical slip (with an effective slip length of

$\gamma _{af} = \gamma _{sf}+\gamma _{sa}$. This precursor film (Thoraval & Thoroddsen Reference Thoraval and Thoroddsen2013) is analogous to the mathematical model for spreading of a perfectly wetting liquid on a solid substrate (de Gennes et al. Reference de Gennes, Brochard-Wyart and Quéré2004; Bonn et al. Reference Bonn, Eggers, Indekeu, Meunier and Rolley2009), which regularizes the contact line singularity due to the numerical slip (with an effective slip length of ![]() $\Delta$/2; Afkhami et al. (Reference Afkhami, Buongiorno, Guion, Popinet, Saade, Scardovelli and Zaleski2018)) due to the discretization of the interface.

$\Delta$/2; Afkhami et al. (Reference Afkhami, Buongiorno, Guion, Popinet, Saade, Scardovelli and Zaleski2018)) due to the discretization of the interface.

4.3. Note on non-dimensionalization in the viscous regime

For highly viscous surroundings (![]() ${Oh}_{s} > 1$), it is convenient to scale the velocities with the viscocapillary velocity scale

${Oh}_{s} > 1$), it is convenient to scale the velocities with the viscocapillary velocity scale ![]() $v_\eta$, owing to the dominant interplay between viscous and capillary stresses (Stone & Leal Reference Stone and Leal1989). Further, we can use the viscocapillary time

$v_\eta$, owing to the dominant interplay between viscous and capillary stresses (Stone & Leal Reference Stone and Leal1989). Further, we can use the viscocapillary time ![]() $\tau _\eta$, film thickness

$\tau _\eta$, film thickness ![]() $h_0$, and capillary pressure

$h_0$, and capillary pressure ![]() $p_\gamma$ to normalize the time, length and pressure dimensions, respectively,

$p_\gamma$ to normalize the time, length and pressure dimensions, respectively,

where ![]() $\gamma _{sf}$ is the surface tension coefficient between the film ( f) and the surroundings (s),

$\gamma _{sf}$ is the surface tension coefficient between the film ( f) and the surroundings (s), ![]() $h_0$ the film thickness, and

$h_0$ the film thickness, and ![]() $\eta _s$ the viscosity of the surrounding medium. These viscocapillary scales modify the momentum equation as

$\eta _s$ the viscosity of the surrounding medium. These viscocapillary scales modify the momentum equation as

Here, ![]() ${Oh}_{s}$ is the surroundings Ohnesorge number (4.8a,b),

${Oh}_{s}$ is the surroundings Ohnesorge number (4.8a,b), ![]() $\tilde {\rho }$ follows

$\tilde {\rho }$ follows ![]() $\tilde {\rho } = 1$ and (4.10) for the two-phase and the three-phase configurations, respectively, and

$\tilde {\rho } = 1$ and (4.10) for the two-phase and the three-phase configurations, respectively, and ![]() $\tilde {\boldsymbol {f}}_\gamma$ equals the corresponding expressions for the two configurations. Additionally, the dimensionless viscosities are given by

$\tilde {\boldsymbol {f}}_\gamma$ equals the corresponding expressions for the two configurations. Additionally, the dimensionless viscosities are given by

\begin{equation} \tilde{\eta} = \begin{cases} \varPsi \left(\eta_f/\eta_s\right) + \left(1-\varPsi\right), & \text{two-phase case},\\ \varPsi_1\varPsi_2\left(\eta_f/\eta_s\right) + \left(1-\varPsi_2\right)\varPsi_1 + \left(1-\varPsi_1\right)\left(\eta_a/\eta_s\right), & \text{three-phase case}. \end{cases} \end{equation}

\begin{equation} \tilde{\eta} = \begin{cases} \varPsi \left(\eta_f/\eta_s\right) + \left(1-\varPsi\right), & \text{two-phase case},\\ \varPsi_1\varPsi_2\left(\eta_f/\eta_s\right) + \left(1-\varPsi_2\right)\varPsi_1 + \left(1-\varPsi_1\right)\left(\eta_a/\eta_s\right), & \text{three-phase case}. \end{cases} \end{equation}4.4. Domain size and boundary conditions

Figure 5 depicts the computational domains. The left-hand boundary represents the axis of symmetry with origin marked at ![]() $(0, 0)$. We set no-penetration and free-slip boundary conditions to all other domain boundaries along with zero gradient conditions for pressure. These boundaries are far away from the expanding hole and do not affect its growth. Furthermore, the size of the domain is chosen such that

$(0, 0)$. We set no-penetration and free-slip boundary conditions to all other domain boundaries along with zero gradient conditions for pressure. These boundaries are far away from the expanding hole and do not affect its growth. Furthermore, the size of the domain is chosen such that ![]() $\mathcal {L}_{{max}} \gg \text {max}({Oh}_{f}, {Oh}_{s})$, with a minimum

$\mathcal {L}_{{max}} \gg \text {max}({Oh}_{f}, {Oh}_{s})$, with a minimum ![]() $\mathcal {L}_{{max}}$ of

$\mathcal {L}_{{max}}$ of ![]() $200$ for

$200$ for ![]() ${Oh}_{s} \ll 1$. We have varied this domain size to ensure that the simulations are independent of its value. Note that, if this condition is not met, the assumption of infinite film, which is essential for the theoretical scaling relations developed in this work, will fail (Deka & Pierson Reference Deka and Pierson2020).

${Oh}_{s} \ll 1$. We have varied this domain size to ensure that the simulations are independent of its value. Note that, if this condition is not met, the assumption of infinite film, which is essential for the theoretical scaling relations developed in this work, will fail (Deka & Pierson Reference Deka and Pierson2020).

We employ adaptive mesh refinement to correctly resolve the different interfaces as well as regions of high velocity gradients (and hence, high viscous dissipation, see Appendix B). To ensure that the velocity field is captured accurately, these refinement criteria (see Sanjay Reference Sanjay2021b) effectively maintain a minimum of ![]() $40$ cells across the thickness of the film (i.e.

$40$ cells across the thickness of the film (i.e. ![]() $h_0/\Delta \ge 40$). As the apparent three-phase contact line and the viscous boundary layer are critical in the present work, the refinement criteria maintain a minimum of

$h_0/\Delta \ge 40$). As the apparent three-phase contact line and the viscous boundary layer are critical in the present work, the refinement criteria maintain a minimum of ![]() $40$ cells in the wedge region near the apparent three-phase contact line. Furthermore, the viscous boundary layer is almost

$40$ cells in the wedge region near the apparent three-phase contact line. Furthermore, the viscous boundary layer is almost ![]() $10$ times larger than the film thickness (see § 8.2). Consequently, a minimum of

$10$ times larger than the film thickness (see § 8.2). Consequently, a minimum of ![]() $400$ cells in the viscous boundary layer in the surrounding medium is needed to properly resolve the velocity gradients. We have conducted extensive grid independence studies so that the final results (energy transfers and the retraction velocity) are independent of the number of grid cells.

$400$ cells in the viscous boundary layer in the surrounding medium is needed to properly resolve the velocity gradients. We have conducted extensive grid independence studies so that the final results (energy transfers and the retraction velocity) are independent of the number of grid cells.

5. Taylor–Culick retractions: numerics

Figures 6 and 7 elucidate the two-phase and three-phase Taylor–Culick retractions. For low viscous surroundings (![]() ${Oh}_{s} \le 1$), figures 6(a) and 7(a) show the growth of the dimensionless hole radius (

${Oh}_{s} \le 1$), figures 6(a) and 7(a) show the growth of the dimensionless hole radius (![]() $\tilde {R}(t) = R(t)/h_0$) in time (normalized with the inertiocapillary time scale,

$\tilde {R}(t) = R(t)/h_0$) in time (normalized with the inertiocapillary time scale, ![]() $\tau _\gamma$), and the insets contain the growth rate of this hole:

$\tau _\gamma$), and the insets contain the growth rate of this hole: ![]() $\dot {\tilde {R}}_\gamma (t) = \tau _\gamma \,{\rm d}\tilde {R}(t)/{\rm d}t$. After the initial transients, the hole grows (i.e. the film retracts) linearly in time with a constant velocity (

$\dot {\tilde {R}}_\gamma (t) = \tau _\gamma \,{\rm d}\tilde {R}(t)/{\rm d}t$. After the initial transients, the hole grows (i.e. the film retracts) linearly in time with a constant velocity (![]() $v_f$). We can use this retraction velocity to calculate the film Weber number,

$v_f$). We can use this retraction velocity to calculate the film Weber number,

which is represented by the black dashed lines in figures 6(a) and 7(a). Here ![]() ${We}_{f}$ is an output parameter of the retraction process. Note that, for very low

${We}_{f}$ is an output parameter of the retraction process. Note that, for very low ![]() ${Oh}_{s}$, as the rim grows with time, the inertial drag on the moving rim due to the surrounding medium overcomes the driving capillary forces, resulting in a decrease of the tip velocity (see insets of figure 6a and Jian et al. (Reference Jian, Deng and Thoraval2020b)). However, we can still calculate a velocity scale (and hence

${Oh}_{s}$, as the rim grows with time, the inertial drag on the moving rim due to the surrounding medium overcomes the driving capillary forces, resulting in a decrease of the tip velocity (see insets of figure 6a and Jian et al. (Reference Jian, Deng and Thoraval2020b)). However, we can still calculate a velocity scale (and hence ![]() ${We}_{f}$) associated with the Taylor–Culick-like retraction immediately after the initial transients (as marked by the black dashed lines in the insets of figure 6a for the lowest

${We}_{f}$) associated with the Taylor–Culick-like retraction immediately after the initial transients (as marked by the black dashed lines in the insets of figure 6a for the lowest ![]() ${Oh}_{s}$).

${Oh}_{s}$).

Figure 6. Two-phase Taylor–Culick retractions: temporal evolution of the dimensionless hole radius (![]() $\tilde {R}(t)$) for (a)

$\tilde {R}(t)$) for (a) ![]() ${Oh}_{s} \le 1$ and (b)

${Oh}_{s} \le 1$ and (b) ![]() ${Oh}_{s} \ge 1$. Time is normalized using the inertiocapillary time scale,

${Oh}_{s} \ge 1$. Time is normalized using the inertiocapillary time scale, ![]() $\tau _\gamma = \sqrt {\rho _f h_0^3/\gamma _{sf}}$ in panel (a) and the viscocapillary time scale,

$\tau _\gamma = \sqrt {\rho _f h_0^3/\gamma _{sf}}$ in panel (a) and the viscocapillary time scale, ![]() $\tau _\eta = \eta _s h_0/\gamma _{sf}$ in panel (b). Insets of these panels show the variation of the dimensionless growth rate of the hole radius at different

$\tau _\eta = \eta _s h_0/\gamma _{sf}$ in panel (b). Insets of these panels show the variation of the dimensionless growth rate of the hole radius at different ![]() ${Oh}_{s}$, and mark the definitions of

${Oh}_{s}$, and mark the definitions of ![]() ${We}_{f}$ and

${We}_{f}$ and ![]() ${Ca}_{s}$. Lastly, panel (c) illustrates the morphology of the flow at different

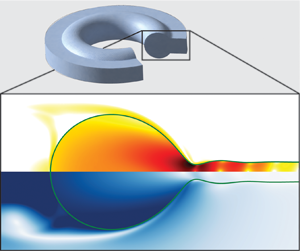

${Ca}_{s}$. Lastly, panel (c) illustrates the morphology of the flow at different ![]() ${Oh}_{s}$ at

${Oh}_{s}$ at ![]() $\tilde {R} = 30$. In each snapshot, the left-hand side contour shows the velocity magnitude normalized with the (terminal) film velocity

$\tilde {R} = 30$. In each snapshot, the left-hand side contour shows the velocity magnitude normalized with the (terminal) film velocity ![]() $v_f$ and the right-hand side shows the dimensionless rate of viscous dissipation per unit volume normalized using the inertiocapillary scales, represented on a

$v_f$ and the right-hand side shows the dimensionless rate of viscous dissipation per unit volume normalized using the inertiocapillary scales, represented on a ![]() $\log _{{10}}$ scale to differentiate the regions of maximum dissipation. Here, the film Ohnesorge number is

$\log _{{10}}$ scale to differentiate the regions of maximum dissipation. Here, the film Ohnesorge number is ![]() ${Oh}_{f} = 0.05$. Also see supplementary movie 2.

${Oh}_{f} = 0.05$. Also see supplementary movie 2.

Figure 7. Three-phase Taylor–Culick retractions: temporal evolution of the dimensionless hole radius (![]() $\tilde {R}(t)$) for (a)

$\tilde {R}(t)$) for (a) ![]() ${Oh}_{s} \le 1$ and (b)

${Oh}_{s} \le 1$ and (b) ![]() ${Oh}_{s} \ge 1$. Time is normalized using the inertiocapillary time scale,

${Oh}_{s} \ge 1$. Time is normalized using the inertiocapillary time scale, ![]() $\tau _\gamma = \sqrt {\rho _f h_0^3/\gamma _{sf}}$ in panel (a) and the viscocapillary time scale,

$\tau _\gamma = \sqrt {\rho _f h_0^3/\gamma _{sf}}$ in panel (a) and the viscocapillary time scale, ![]() $\tau _\eta = \eta _s h_0/\gamma _{sf}$ in panel (b). Insets of these panels show the variation of the dimensionless growth rate of the hole radius at different

$\tau _\eta = \eta _s h_0/\gamma _{sf}$ in panel (b). Insets of these panels show the variation of the dimensionless growth rate of the hole radius at different ![]() ${Oh}_{s}$, and mark the definitions of

${Oh}_{s}$, and mark the definitions of ![]() ${We}_{f}$ and

${We}_{f}$ and ![]() ${Ca}_{s}$. Lastly, panel (c) illustrates the morphology of the flow at different

${Ca}_{s}$. Lastly, panel (c) illustrates the morphology of the flow at different ![]() ${Oh}_{s}$ at

${Oh}_{s}$ at ![]() $\tilde {R} = 30$. In each snapshot, the left-hand side contour shows the velocity magnitude normalized with the (terminal) film velocity

$\tilde {R} = 30$. In each snapshot, the left-hand side contour shows the velocity magnitude normalized with the (terminal) film velocity ![]() $v_f$ and the right-hand side shows the dimensionless rate of viscous dissipation per unit volume normalized using the inertiocapillary scales, represented on a

$v_f$ and the right-hand side shows the dimensionless rate of viscous dissipation per unit volume normalized using the inertiocapillary scales, represented on a ![]() $\log _{{10}}$ scale to differentiate the regions of maximum dissipation. Here, the film Ohnesorge number is

$\log _{{10}}$ scale to differentiate the regions of maximum dissipation. Here, the film Ohnesorge number is ![]() ${Oh}_{f} = 0.10$ and that of air is

${Oh}_{f} = 0.10$ and that of air is ![]() ${Oh}_{a} = 10^{-3}$. Also see supplementary movie 3.

${Oh}_{a} = 10^{-3}$. Also see supplementary movie 3.

Furthermore, when the surroundings is highly viscous (![]() ${Oh}_{s} \ge 1$), we plot the growing hole radius

${Oh}_{s} \ge 1$), we plot the growing hole radius ![]() $\tilde {R}(t)$ as a function of time, which is normalized by the viscocapillary time scale

$\tilde {R}(t)$ as a function of time, which is normalized by the viscocapillary time scale ![]() $\tau _\eta$, see figures 6(b), 7(b) and § 4.3. The insets of these panels contain the growth rate of the hole, calculated as

$\tau _\eta$, see figures 6(b), 7(b) and § 4.3. The insets of these panels contain the growth rate of the hole, calculated as ![]() $\dot {\tilde {R}}_\eta = \tau _\eta \,{\rm d}\tilde {R}/{\rm d}t$. Once again, we observe that the growth of the hole (and the film retraction) depends linearly on time with a constant velocity, which can be used to calculate the surroundings capillary number,

$\dot {\tilde {R}}_\eta = \tau _\eta \,{\rm d}\tilde {R}/{\rm d}t$. Once again, we observe that the growth of the hole (and the film retraction) depends linearly on time with a constant velocity, which can be used to calculate the surroundings capillary number,

marked with the black dashed lines in figures 6(b), 7(b) and the corresponding insets. Here ![]() ${Ca}_{s}$ is another output parameter of the retraction process. Note that the velocity of the retracting film (

${Ca}_{s}$ is another output parameter of the retraction process. Note that the velocity of the retracting film (![]() $v_f$) is the same as the velocity scale in the surrounding medium (

$v_f$) is the same as the velocity scale in the surrounding medium (![]() $v_s$), following the kinematic boundary condition at the circumference of the growing hole. Consequently, the two output parameters,

$v_s$), following the kinematic boundary condition at the circumference of the growing hole. Consequently, the two output parameters, ![]() ${We}_{f}$ (5.1) and

${We}_{f}$ (5.1) and ![]() ${Ca}_{s}$ (5.2), are related as

${Ca}_{s}$ (5.2), are related as ![]() ${Ca}_{s} = {Oh}_{s}\sqrt {{We}_{f}}$ (see § 7).

${Ca}_{s} = {Oh}_{s}\sqrt {{We}_{f}}$ (see § 7).

Lastly, figures 6(c) and 7(c) illustrate the flow morphologies for the two-phase and three-phase configurations, respectively, when the hole has grown to ![]() $\tilde {R} = 30$. Readers can refer to supplementary movies 2 and 3 for the temporal dynamics of the two-phase and three-phase configurations, respectively. Similar to the classical Taylor–Culick retraction case (Appendix A and supplementary movie 4), both the film and the surroundings move. However, unlike the classical case, even for low

$\tilde {R} = 30$. Readers can refer to supplementary movies 2 and 3 for the temporal dynamics of the two-phase and three-phase configurations, respectively. Similar to the classical Taylor–Culick retraction case (Appendix A and supplementary movie 4), both the film and the surroundings move. However, unlike the classical case, even for low ![]() ${Oh}_{s}$, the surrounding medium takes away momentum from the film owing to inertia (added mass-like effect), thus reducing the retraction velocity (see insets of figures 6a and 7a). Furthermore, contrary to the classical case where the dissipation is highest at the neck connecting the rim to the rest of the film (see Appendix A), the dissipation in the other two configurations is spread out, and also occurs in the surrounding medium.

${Oh}_{s}$, the surrounding medium takes away momentum from the film owing to inertia (added mass-like effect), thus reducing the retraction velocity (see insets of figures 6a and 7a). Furthermore, contrary to the classical case where the dissipation is highest at the neck connecting the rim to the rest of the film (see Appendix A), the dissipation in the other two configurations is spread out, and also occurs in the surrounding medium.