1. Introduction

Natural flyers and swimmers employ the complex interaction between the foils and the surrounding fluid to generate sufficient thrust to locomotion, where the deformation of the flexible foil adds new challenges to the flow–structure interaction. Thus, a vast number of investigations from various aspects have been deployed to reveal the mechanism of the interaction between the flexible foil and the fluid, such as from active and passive foil deformation (Tytell et al. Reference Tytell, Hsu, Williams, Cohen and Fauci2010; Flammang & Lauder Reference Flammang and Lauder2013; Ulrich & Peters Reference Ulrich and Peters2014; Joshi & Bhattacharya Reference Joshi and Bhattacharya2022), from localized and distributed flexibility (Shahzad et al. Reference Shahzad, Tian, Young and Lai2018; Shi, Xiao & Zhu Reference Shi, Xiao and Zhu2020; Wang, Huang & Lu Reference Wang, Huang and Lu2020; Kurt, Mivehchi & Moored Reference Kurt, Mivehchi and Moored2021; Wang et al. Reference Wang, Ren, Hu, Li and Sitti2021; Demirer et al. Reference Demirer, Oshinowo, Erturk and Alexeev2022), from tethered and unconstrained motion (Arora et al. Reference Arora, Kang, Shyy and Gupta2018; Lin, Wu & Zhang Reference Lin, Wu and Zhang2020; Fernandez-Feria, Sanmiguel-Rojas & Lopez-Tello Reference Fernandez-Feria, Sanmiguel-Rojas and Lopez-Tello2022; Wu et al. Reference Wu, Shu, Wan, Wang and Chen2022) and from vortical structures and their interactions (Eldredge & Jones Reference Eldredge and Jones2019; Linehan & Mohseni Reference Linehan and Mohseni2020; Jia et al. Reference Jia, Scofield, Wei and Bhattacharya2021; Zhang et al. Reference Zhang, Huang, Pan, Yang and Huang2021; Verma & Hemmati Reference Verma and Hemmati2022). Among these investigations, elucidating the propulsive performance of the flexible foil earns much attention as this will not only help to unveil the flight or swimming mechanism (Wu Reference Wu2011; Gazzola, Argentina & Mahadevan Reference Gazzola, Argentina and Mahadevan2014; Sun Reference Sun2014; Lauder Reference Lauder2015; Chin & Lentink Reference Chin and Lentink2016; Saadat et al. Reference Saadat, Fish, Domel, Di Santo, Lauder and Haj-Hariri2017; Dabiri Reference Dabiri2019; Wang et al. Reference Wang, He, He, Wang, Chen and Liu2022), it will also help to optimize the manmade flying vehicles and swimming robotics through flapping propulsion (Karasek et al. Reference Karasek, Muijres, De Wagter, Remes and de Croon2018; Zhu et al. Reference Zhu, White, Wainwright, Di Santo, Lauder and Bart-Smith2019; Chin et al. Reference Chin, Kok, Zhu, Chan, Chahl, Khoo and Lau2020; Haider et al. Reference Haider, Shahzad, Mumtaz Qadri and Ali Shah2021; Lee, Kim & Chu Reference Lee, Kim and Chu2021; Zhong et al. Reference Zhong, Zhu, Fish, Kerr, Downs, Bart-smith and Quinn2021). For flexible foils flapping in fluid, even the intrinsically three-dimensional problem can be simplified to the two-dimensional counterpart, unveiling the coupling mechanism between the motion of the foil and the surrounding fluid is still difficult, which is mainly contributed by the two-way coupling between the non-steady flow and the complex deformation of the foil (Zhu, He & Zhang Reference Zhu, He and Zhang2014; Akkala, Eslam Panah & Buchholz Reference Akkala, Eslam Panah and Buchholz2015). While experiments and simulations have been the widely adopted procedures to elucidate this flow–structure interaction in general, theoretical modelling also holds much potential in revealing the coupling mechanism between them, as it can not only provide valuable insights into the understanding of this fluid–structure interaction, but also reveals the effect of those physical parameters over large ranges with high efficiency (Chen et al. Reference Chen, Li, Guo, Tong and Ji2018; Riso, Riccardi & Mastroddi Reference Riso, Riccardi and Mastroddi2018).

Among the early research that focuses on the theoretical modelling for the flapping foil in fluid, the pioneer works from Theodorsen (Reference Theodorsen1935), Garrick (Reference Garrick1936) and von Kármán and Sears (Reference von Kármán and Sears1938) have revealed the performance of the rigid thin plate flapping in fluid, where the fluid was treated as inviscid and incompressible while the flapping amplitude was sufficiently small, all of which guaranteed the suitability of the linear potential flow theory. When treating the foil as a flexible body, the theoretical work of Wu, who aimed to fish propulsion, has solved the flow disturbed by a waving plate through the one-way coupling method, where the progressing wave of the flexibility foil was set by the given wavelength and phase velocity along the chord (Wu Reference Wu1961). These early investigations provide basic ingredients to the flow dynamics, which inspired the recently formulated analytical solutions for the response of the flexible foil flapping in fluid. Based on the linear potential theory, Alben built a theoretical framework to determine the vortex sheet on the flexible foil and in the wake, together with the deformation of the foil, which aimed to unveil the optimal flexibility of the foil when flapping in fluid (Alben Reference Alben2008). While the Chebyshev series method was employed in his work, the complex interaction between the foil deformation and the fluid–structure interaction was less clear. Later on, besides the widely prescribed motions of pitching and heaving, the shifting motion of the foil was included in his theory (Alben Reference Alben2011). Floryan and Rowley focused on the relationship between propulsive efficiency and resonance for a flexible foil with vanishing mass, and their theorical model revealed that the propulsive efficiency did not show resonant behaviour unless the viscosity drag was included in the thrust or the stiffness of the foil is sufficient low (Floryan & Rowley Reference Floryan and Rowley2018). For compliant membrane wings, Tzezana and Breuer used the Chebyshev series method to elucidate the thrust, drag and wake structure when flapping in fluid (Alon Tzezana & Breuer Reference Alon Tzezana and Breuer2019). While these studies focused on uniformly distributed flexibility along the foil, Moore treated the foil with torsional flexibility and formulated exact solutions to describe the emergent pitching motion, along with expressions for thrust generation and power consumption (Moore Reference Moore2014). Based on the Chebyshev numerical method, Moore investigated the role of stiffness distribution of the foil in the thrust production and clarified that the torsional spring was the optimal flexibility arrangement for thrust (Moore Reference Moore2015). For distributed flexibility with a low mass ratio, Floryan and Rowley used the Chebyshev numerical method to elucidate the propulsive performance and the optimal distribution of flexibility of the passively flexible foil and revealed that thrust increment will accompany power consumption when the stiffness is large (Floryan & Rowley Reference Floryan and Rowley2020). While the Chebyshev series method seems the standard method to determine the deformation of the foil and the fluid flow through the collocation procedure (Walker & Patil Reference Walker and Patil2014; Moore Reference Moore2017), it has obviously simplified the direct two-dimensional fluid solver, which makes rapid searching of all possible material distributions possible. However, the numerical solution from the Chebyshev series method makes the correlation between the performance of the foil and the physical parameters still less clear, which calls for the development of closed-form theory to this flow–structure interaction.

Following the vortical impulse theory while in the limit of linearized inviscid flows, Fernandez-Feria updated the thrust force and the propulsive efficiency for a pitching and heaving rigid foil (Fernandez-Feria Reference Fernandez-Feria2016), which was originally formulated by von Kármán and Sears (Reference von Kármán and Sears1938). Based on the vortical impulse theory, Alaminos-Quesada and Fernandez-Feria investigated the propulsion of a foil undergoing a flapping undulatory motion, where analytical expressions are given in the case when a chordwise flexure mode, which is approximated by a quadratic function, is superimposed to a pitching or heaving motion of the foil (Alaminos-Quesada & Fernandez-Feria Reference Alaminos-Quesada and Fernandez-Feria2019). Later on, they updated their work to the two-coupling problem where the passive small deflection is allowed for the foil (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021). Their analytical solution is closed form and is realized by using a quartic approximation to the deflection, which compares well with previous reports given by Floryan and Rowley through the Chebyshev series method (Floryan & Rowley Reference Floryan and Rowley2018). Subsequently, Alaminos-Quesada and Fernandez-Feria used this approximation method to determine the propulsion performance of tandem flapping foils (Alaminos-Quesada & Fernandez-Feria Reference Alaminos-Quesada and Fernandez-Feria2021), the flutter stability (Fernandez-Feria Reference Fernandez-Feria2022) and the energy harvesting through a pitching flexible foil (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2022). Compared with these previous numerical solutions from the Chebyshev series method, although their analytical solution (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021) has obviously uncovered the coupling mechanism of this flow–structure interaction to a larger extent, their lengthy forms of the analytical expressions seem less clear when employed to elucidate the effect of the stiffness and the mass of the flapping foil and the driving frequency on its performance.

In this study, we propose an analytical solution to the pitching foil with flexibility, which aims to reveal the kinematics and the performance of the flexible pitching foil with simple analytical expressions. The analytical solution is realized by transforming the deflection of the foil into the averaged deformation angle, where this deformation angle together with the driving pitching motion at the leading edge defines the pitching motion of the equivalent flat foil. With this treatment, the pitching amplitude and the phase angle, together with the propulsive performance, are given analytically in simple closed forms. With this simple closed-form solution, three critical conditions are resolved analytically for the first time, where explicit expressions are given among the dimensionless stiffness, the mass ratio and the reduced pitching frequency. These three critical conditions include the resonance condition for a broad range of physical parameters, the equal pitching amplitude condition between the flexible foil and the rigid counterpart, which signifies the gain from flexibility, and the phase angle transition from ![]() ${\rm \pi}/2$ to

${\rm \pi}/2$ to ![]() $- {\rm \pi}/2$. Through introducing a bluff type drag to the thrust, the net thrust and the propulsive efficiency are clarified, which recovers these previous reports nicely.

$- {\rm \pi}/2$. Through introducing a bluff type drag to the thrust, the net thrust and the propulsive efficiency are clarified, which recovers these previous reports nicely.

2. Theoretical modelling

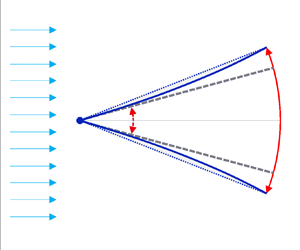

As shown in figure 1, a two-dimensional thin foil with a cord length of c is immersed in an inviscid flow. The pitching motion of the foil is realized by driving its motion at the leading pivot point with a small pitching motion of ![]() ${\theta _0}$. The flow has a constant free-stream speed

${\theta _0}$. The flow has a constant free-stream speed ![]() ${U_\infty }$ along the x axis. As a common practice, the origin point is set to the middle point of the foil. As the thin foil pitches along its leading pivot point, the pitching motion will introduce an inertial force caused by the foil and aerodynamical load caused by the surrounding flow to the foil, both of which cause the deformation of the original flat foil. We focus on the small deformation scenario of the foil, where it has sufficient stiffness such that the deformation of the foil is small when compared with its chord.

${U_\infty }$ along the x axis. As a common practice, the origin point is set to the middle point of the foil. As the thin foil pitches along its leading pivot point, the pitching motion will introduce an inertial force caused by the foil and aerodynamical load caused by the surrounding flow to the foil, both of which cause the deformation of the original flat foil. We focus on the small deformation scenario of the foil, where it has sufficient stiffness such that the deformation of the foil is small when compared with its chord.

Figure 1. Schematic of the pitching motion of a thin foil with passive bending deformation. The length scale has been scaled by ![]() $c/2$. The pitching angle

$c/2$. The pitching angle ![]() $\theta $ is the result from the driving pitching angle

$\theta $ is the result from the driving pitching angle ![]() ${\theta _0}$ and the averaged deformation angle

${\theta _0}$ and the averaged deformation angle ![]() ${\theta _d}$ determined by the deflection of the foil.

${\theta _d}$ determined by the deflection of the foil.

To clarify the response of the flexible foil as a result of the driving pitch motion, we use the elastokinetics method to determine the deformation of the foil under the dynamical loading of the inertial force and the aerodynamic fluid force, as has been done in our recent work (Du & Wu Reference Du and Wu2023). With the deflection of the foil, the averaged deformation angle ![]() ${\theta _d}$ of the foil will be introduced. Together with the driving pitch angle at the leading edge and the deformation angle of the foil, the finalized pitching angle of the foil can be determined, as shown in figure 1. As the averaged deformation angle

${\theta _d}$ of the foil will be introduced. Together with the driving pitch angle at the leading edge and the deformation angle of the foil, the finalized pitching angle of the foil can be determined, as shown in figure 1. As the averaged deformation angle ![]() ${\theta _d}$ is sufficiently small, we use a flat foil with the pitching angle

${\theta _d}$ is sufficiently small, we use a flat foil with the pitching angle ![]() $\theta $ to determine the fluid flow, where the camber effect of the foil is ignored in the current study. In the following of this section, we will first introduce the solution to the fluid flow, which gives the pressure loading on the foil analytically. Then, based on the pressure loading and the inertial force on the foil, its deformation will be formulated, from which the averaged deformation angle of the foil can be determined. Together with the deformation angle and the driving pitch motion at the leading point, the pitching motion of the foil will be derived analytically.

$\theta $ to determine the fluid flow, where the camber effect of the foil is ignored in the current study. In the following of this section, we will first introduce the solution to the fluid flow, which gives the pressure loading on the foil analytically. Then, based on the pressure loading and the inertial force on the foil, its deformation will be formulated, from which the averaged deformation angle of the foil can be determined. Together with the deformation angle and the driving pitch motion at the leading point, the pitching motion of the foil will be derived analytically.

2.1. Fluid pressure on the foil

In the pure pitching configuration with small amplitude, as shown in figure 1, the time-harmonic vertical displacement ![]() $\mathcal{ H}$ is given by

$\mathcal{ H}$ is given by

where the length x and ![]() $\mathcal{ H}$ have been scaled by half-chord of the foil

$\mathcal{ H}$ have been scaled by half-chord of the foil ![]() $c/2$ and the time t has been scaled by the driving flapping period T. The finalized pitching amplitude

$c/2$ and the time t has been scaled by the driving flapping period T. The finalized pitching amplitude ![]() $\varPhi $ in (2.1) includes the contribution of the driving pitch amplitude and the deformation of the foil, which is the key parameter needed to be determined in this study. Here,

$\varPhi $ in (2.1) includes the contribution of the driving pitch amplitude and the deformation of the foil, which is the key parameter needed to be determined in this study. Here, ![]() $\textrm{i}$ is the imaginary unit and the real part in

$\textrm{i}$ is the imaginary unit and the real part in ![]() $\textrm{i}$ should be taken.

$\textrm{i}$ should be taken.

In order to determine the pressure distribution on the foil, we resort to the classic solution by Wu (Reference Wu1961). For small amplitude oscillation of the foil in an incompressible inviscid flow, the linear inviscid theory applies and the seminar work of Wu has provided the analytical solution to the flow in detail (Wu Reference Wu1961). Based on this solution, Moore derived the fluid flow for a flat foil with time-harmonic heaving and pitching kinematics and provided the solution for the pressure distribution on the foil (Moore Reference Moore2014). We use their solution to obtain the pressure distribution on the pitching foil. Based on the vertical displacement ![]() $\mathcal{ H}$ given in (2.1), the fluid flow can be determined by setting

$\mathcal{ H}$ given in (2.1), the fluid flow can be determined by setting ![]() ${\beta _0} = 2\varPhi$ and

${\beta _0} = 2\varPhi$ and ![]() ${\beta _1} = \varPhi $ in (2.5) in Moore's solution (Moore Reference Moore2014). With the knowledge of the fluid flow, the pressure on the foil, as given in (A7) in Moore's solution (Moore Reference Moore2014), can be given analytically as

${\beta _1} = \varPhi $ in (2.5) in Moore's solution (Moore Reference Moore2014). With the knowledge of the fluid flow, the pressure on the foil, as given in (A7) in Moore's solution (Moore Reference Moore2014), can be given analytically as

where ![]() $\rho $ is the density of fluid,

$\rho $ is the density of fluid, ![]() $f = 1/T$ is the pitching frequency,

$f = 1/T$ is the pitching frequency, ![]() $U = 2{U_\infty }/cf$ is the dimensionless free-stream velocity,

$U = 2{U_\infty }/cf$ is the dimensionless free-stream velocity, ![]() ${U_\infty }$ is the free-stream velocity in the far field and

${U_\infty }$ is the free-stream velocity in the far field and ![]() ${C_k}$ is the well-known Theodorsen function (Theodorsen Reference Theodorsen1935) given by

${C_k}$ is the well-known Theodorsen function (Theodorsen Reference Theodorsen1935) given by

\begin{equation}{C_k} = \frac{{H_1^{(2)}(k)}}{{\textrm{i}H_0^{(2)}(k) + H_1^{(2)}(k)}} = {F_k} + \textrm{i}{G_k},\end{equation}

\begin{equation}{C_k} = \frac{{H_1^{(2)}(k)}}{{\textrm{i}H_0^{(2)}(k) + H_1^{(2)}(k)}} = {F_k} + \textrm{i}{G_k},\end{equation}

where ![]() $k = {\rm \pi}fc/{U_\infty } = 2{\rm \pi} /U$ is the reduced frequency,

$k = {\rm \pi}fc/{U_\infty } = 2{\rm \pi} /U$ is the reduced frequency, ![]() $H_0^{(2)}$ and

$H_0^{(2)}$ and ![]() $H_1^{(2)}$ are the Hankel function of the second kind with orders 0 and 1, respectively. The reduced frequency k can be correlated to the widely used Strouhal number through

$H_1^{(2)}$ are the Hankel function of the second kind with orders 0 and 1, respectively. The reduced frequency k can be correlated to the widely used Strouhal number through

Thus, although we assume the system has a small Strouhal number, the reduced frequency k can be any positive number presuming that the pitching amplitude is small enough. As the pressure distribution given in (2.2) is derived from the incompressible linear inviscid theory, it applies when the Reynolds number is sufficient large such that the viscosity force can be ignored, the oscillation amplitude ![]() $\varPhi$ is small such that the disturbance to the flow lies in the linear range and the Strouhal number

$\varPhi$ is small such that the disturbance to the flow lies in the linear range and the Strouhal number ![]() $St$ of the system is small and the free-stream velocity is much lower than the local sound speed.

$St$ of the system is small and the free-stream velocity is much lower than the local sound speed.

2.2. Foil deformation

To determine the foil deformation, the inertial force of the foil will be needed. Thus, the effective displacement of the foil referring to the inertial force will be determined first. As shown in figure 1, the dotted line indicates the chord position of the foil, as has been used to determine the pressure on the foil given in (2.2), which is a straight line ![]() $(\kern0.7pt {y_c} = c(1 + x){\theta _d}/2)$ with a rotating angle

$(\kern0.7pt {y_c} = c(1 + x){\theta _d}/2)$ with a rotating angle ![]() ${\theta _d}$ compared with the driving pitching position. The finalized foil indicated by the solid line is a curved line, which can be represented by a parabola curve

${\theta _d}$ compared with the driving pitching position. The finalized foil indicated by the solid line is a curved line, which can be represented by a parabola curve ![]() $(\kern0.7pt {y_f} = c{(1 + x)^2}{\theta _d}/4)$ compared with its flat state, if the deformation of the foil is small. Based on the chord line and the parabola curve, the effective displacement of the foil when modelling the inertial force can be approximated by

$(\kern0.7pt {y_f} = c{(1 + x)^2}{\theta _d}/4)$ compared with its flat state, if the deformation of the foil is small. Based on the chord line and the parabola curve, the effective displacement of the foil when modelling the inertial force can be approximated by ![]() ${y_e} = (\kern0.7pt {y_c} + {y_f})/2 + {y_p}$, where

${y_e} = (\kern0.7pt {y_c} + {y_f})/2 + {y_p}$, where ![]() ${y_p} = c(1 + x){\theta _0}/2$ is the displacement introduced by the driving pitching motion

${y_p} = c(1 + x){\theta _0}/2$ is the displacement introduced by the driving pitching motion ![]() ${\theta _0}$ set at the leading edge. As will be shown in this work, without a fluid force, this effective displacement will bring the natural frequency of the foil with the precision of 99.4 % when compared with its exact value. Details of the analytical formulation of the vibration of a cantilever beam can be found in Appendix A. With the effective displacement

${\theta _0}$ set at the leading edge. As will be shown in this work, without a fluid force, this effective displacement will bring the natural frequency of the foil with the precision of 99.4 % when compared with its exact value. Details of the analytical formulation of the vibration of a cantilever beam can be found in Appendix A. With the effective displacement ![]() ${y_e}$, the inertial force on the foil can be given as

${y_e}$, the inertial force on the foil can be given as

\begin{equation}{f_i}(x,t) ={-} {m_l}\frac{{{\partial ^2}{y_e}}}{{\partial {t^2}}} ={-} \frac{{{m_l}c}}{2}\left( {\frac{{1 + x}}{2} + \frac{{{{(1 + x)}^2}}}{4}} \right)\frac{{{\partial ^2}{\theta _d}}}{{\partial {t^2}}} - \frac{{{m_l}c(1 + x)}}{2}\frac{{{\partial ^2}{\theta _0}}}{{\partial {t^2}}},\end{equation}

\begin{equation}{f_i}(x,t) ={-} {m_l}\frac{{{\partial ^2}{y_e}}}{{\partial {t^2}}} ={-} \frac{{{m_l}c}}{2}\left( {\frac{{1 + x}}{2} + \frac{{{{(1 + x)}^2}}}{4}} \right)\frac{{{\partial ^2}{\theta _d}}}{{\partial {t^2}}} - \frac{{{m_l}c(1 + x)}}{2}\frac{{{\partial ^2}{\theta _0}}}{{\partial {t^2}}},\end{equation}

where ![]() ${m_l}$ is the line density of the foil.

${m_l}$ is the line density of the foil.

Based on the pressure load on the foil and the inertial force, the deflection of the foil can be determined by the Euler–Bernoulli beam equation through

where B is the bending stiffness of the foil. The factor ![]() $8/{c^3}$ is introduced as the length scale has been scaled by

$8/{c^3}$ is introduced as the length scale has been scaled by ![]() $c/2$. Inserting (2.2) and (2.5) into (2.6), the deflection of the foil w can be solved analytically by including the free boundary condition at the trailing end and the fixed boundary condition at the leading edge. Details of the analytical solution to the deflection are given in Appendix B. From the deflection of the foil, the averaged deformation angle can be given as

$c/2$. Inserting (2.2) and (2.5) into (2.6), the deflection of the foil w can be solved analytically by including the free boundary condition at the trailing end and the fixed boundary condition at the leading edge. Details of the analytical solution to the deflection are given in Appendix B. From the deflection of the foil, the averaged deformation angle can be given as

Thus, with the deflection of the foil at the trailing edge ![]() $w(1)$, the averaged deformation angle of the foil can be derived as

$w(1)$, the averaged deformation angle of the foil can be derived as

\begin{equation}\begin{aligned}

{\theta _d} & ={-} \dfrac{{59{m_l}{c^4}}}{{720B}}\left(

{{{\ddot{\theta }}_d} + \dfrac{{66}}{{59}}{{\ddot{\theta

}}_0}} \right)\\ & \quad + \dfrac{{{{\rm \pi}

^2}{c^3}}}{{8B}}\left[ {\dfrac{{\rho

{f^2}{c^2}}}{4}\dfrac{{25U\left( {\textrm{i}(1 - 3{C_k}) -

\dfrac{{U{C_k}}}{{\rm \pi} }} \right)}}{{96}} + \dfrac{{\rho

{f^2}{c^2}}}{4}\dfrac{{(109{\rm \pi} - 92\textrm{i}U)}}{{48}}}

\right]\varPhi \,{\textrm{e}^{\textrm{i}2{\rm \pi} t}}.

\end{aligned}\end{equation}

\begin{equation}\begin{aligned}

{\theta _d} & ={-} \dfrac{{59{m_l}{c^4}}}{{720B}}\left(

{{{\ddot{\theta }}_d} + \dfrac{{66}}{{59}}{{\ddot{\theta

}}_0}} \right)\\ & \quad + \dfrac{{{{\rm \pi}

^2}{c^3}}}{{8B}}\left[ {\dfrac{{\rho

{f^2}{c^2}}}{4}\dfrac{{25U\left( {\textrm{i}(1 - 3{C_k}) -

\dfrac{{U{C_k}}}{{\rm \pi} }} \right)}}{{96}} + \dfrac{{\rho

{f^2}{c^2}}}{4}\dfrac{{(109{\rm \pi} - 92\textrm{i}U)}}{{48}}}

\right]\varPhi \,{\textrm{e}^{\textrm{i}2{\rm \pi} t}}.

\end{aligned}\end{equation}2.3. Flapping response with flow and foil flexibility coupling

The finalized pitching angle, as shown in figure 1, is given by

By assuming the driving pitch motion ![]() ${\theta _0}$ to be

${\theta _0}$ to be ![]() ${\varPhi _0}\,{\textrm{e}^{\textrm{i}(2{\rm \pi} t + \vartheta )}}$, with

${\varPhi _0}\,{\textrm{e}^{\textrm{i}(2{\rm \pi} t + \vartheta )}}$, with ![]() ${\varPhi _0}$ being the driving pitching amplitude and

${\varPhi _0}$ being the driving pitching amplitude and ![]() $\vartheta $ is the phase angle between the driving pitching motion and the finalized pitching motion, (2.9) can be reduced to

$\vartheta $ is the phase angle between the driving pitching motion and the finalized pitching motion, (2.9) can be reduced to

\begin{align}\left.

{\begin{array}{*{20}{c}@{}} \begin{array}{l}

\dfrac{{{{\rm \pi}^2}{c^3}}}{{8B}}\left[

{\dfrac{{118{m_l}c{f^2}}}{{45}} + \dfrac{{\rho

{f^2}{c^2}}}{4}\dfrac{{25U(3{G_k} - U{F_k}/{\rm \pi} )}}{{96}} +

\dfrac{{\rho {f^2}{c^2}}}{4}\dfrac{{109{\rm \pi} }}{{48}}}

\right]\varPhi \\ \quad + \left( {1 +

\dfrac{{7{{\rm \pi}^2}{f^2}{m_l}{c^4}}}{{180B}}} \right){\varPhi

_0}\,\textrm{cos}\,\vartheta = \varPhi , \end{array}\\

{\dfrac{{{{\rm \pi}^2}{c^3}}}{{8B}}\left[ {\dfrac{{25(1 - 3{F_k} -

U{G_k}/{\rm \pi} )}}{{96}} - \dfrac{{23}}{{12}}}

\right]\dfrac{{\rho {f^2}{c^2}U}}{4}\varPhi + \left( {1 +

\dfrac{{7{{\rm \pi}^2}{f^2}{m_l}{c^4}}}{{180B}}} \right){\varPhi

_0}\,\textrm{sin}\,\vartheta = 0,}\!\!\!\! \end{array}}

\right\}\end{align}

\begin{align}\left.

{\begin{array}{*{20}{c}@{}} \begin{array}{l}

\dfrac{{{{\rm \pi}^2}{c^3}}}{{8B}}\left[

{\dfrac{{118{m_l}c{f^2}}}{{45}} + \dfrac{{\rho

{f^2}{c^2}}}{4}\dfrac{{25U(3{G_k} - U{F_k}/{\rm \pi} )}}{{96}} +

\dfrac{{\rho {f^2}{c^2}}}{4}\dfrac{{109{\rm \pi} }}{{48}}}

\right]\varPhi \\ \quad + \left( {1 +

\dfrac{{7{{\rm \pi}^2}{f^2}{m_l}{c^4}}}{{180B}}} \right){\varPhi

_0}\,\textrm{cos}\,\vartheta = \varPhi , \end{array}\\

{\dfrac{{{{\rm \pi}^2}{c^3}}}{{8B}}\left[ {\dfrac{{25(1 - 3{F_k} -

U{G_k}/{\rm \pi} )}}{{96}} - \dfrac{{23}}{{12}}}

\right]\dfrac{{\rho {f^2}{c^2}U}}{4}\varPhi + \left( {1 +

\dfrac{{7{{\rm \pi}^2}{f^2}{m_l}{c^4}}}{{180B}}} \right){\varPhi

_0}\,\textrm{sin}\,\vartheta = 0,}\!\!\!\! \end{array}}

\right\}\end{align}from which the finalized pitching amplitude is given by

\begin{equation}\varPhi = \frac{{{A_3}}}{{\sqrt {{{(1 - {A_1})}^2} + A_2^2} }}{\varPhi _0}, \end{equation}

\begin{equation}\varPhi = \frac{{{A_3}}}{{\sqrt {{{(1 - {A_1})}^2} + A_2^2} }}{\varPhi _0}, \end{equation}and the phase angle is given by

The dimensionless parameters of ![]() ${A_1}$ and

${A_1}$ and ![]() ${A_2}$ are given by

${A_2}$ are given by

\begin{equation}\left.

{\begin{array}{*{20}{c}} {{A_1} =

\dfrac{{3{k^2}}}{{2S}}\left[ {\dfrac{{118}}{{45}}R +

\dfrac{{25{\rm \pi} (3{G_k} - 2{F_k}/k)/k + 109{\rm \pi} }}{{192}}}

\right],}\\ {{A_2} ={-} \left( {159 + 75{F_k} +

\dfrac{{50{G_k}}}{k}} \right)\dfrac{{{\rm \pi} k}}{{128S}},}\\

{{A_3} = 1 + \dfrac{{7R{k^2}}}{{15S}},} \end{array}}

\right\}\end{equation}

\begin{equation}\left.

{\begin{array}{*{20}{c}} {{A_1} =

\dfrac{{3{k^2}}}{{2S}}\left[ {\dfrac{{118}}{{45}}R +

\dfrac{{25{\rm \pi} (3{G_k} - 2{F_k}/k)/k + 109{\rm \pi} }}{{192}}}

\right],}\\ {{A_2} ={-} \left( {159 + 75{F_k} +

\dfrac{{50{G_k}}}{k}} \right)\dfrac{{{\rm \pi} k}}{{128S}},}\\

{{A_3} = 1 + \dfrac{{7R{k^2}}}{{15S}},} \end{array}}

\right\}\end{equation}

where ![]() $R = {m_l}/\rho c$ is the mass ratio representing the inertia ratio of solid to fluid and

$R = {m_l}/\rho c$ is the mass ratio representing the inertia ratio of solid to fluid and ![]() $S = 12B/\rho U_\infty ^2{c^3}$ is the dimensionless stiffness of the foil representing the ratio of elastic restoring force to the fluid forces. A nomenclature table for all the symbols is listed in Appendix C. Based on the finalized pitching amplitude and the phase angle, the pitching motion of the foil is finalized, which can be used to determine the deflection of the foil through (B1)–(B7). With the driving pitching motion at the leading edge and the deflection of the foil along its span direction, the snapshots of the flexible foil can be determined. As can be checked, the snapshots show a comparable morphology, as determined by numerical solutions (Floryan & Rowley Reference Floryan and Rowley2018, Reference Floryan and Rowley2020). We ignore the snapshots of the foil in this study as we mainly focus on the overall performance of the pitching foil.

$S = 12B/\rho U_\infty ^2{c^3}$ is the dimensionless stiffness of the foil representing the ratio of elastic restoring force to the fluid forces. A nomenclature table for all the symbols is listed in Appendix C. Based on the finalized pitching amplitude and the phase angle, the pitching motion of the foil is finalized, which can be used to determine the deflection of the foil through (B1)–(B7). With the driving pitching motion at the leading edge and the deflection of the foil along its span direction, the snapshots of the flexible foil can be determined. As can be checked, the snapshots show a comparable morphology, as determined by numerical solutions (Floryan & Rowley Reference Floryan and Rowley2018, Reference Floryan and Rowley2020). We ignore the snapshots of the foil in this study as we mainly focus on the overall performance of the pitching foil.

From (2.11), we introduce the response parameter ![]() $\varUpsilon $ to characterize the response of the flexible foil under driving pitching motion in the fluid flow, which is defined to be

$\varUpsilon $ to characterize the response of the flexible foil under driving pitching motion in the fluid flow, which is defined to be

\begin{equation}\varUpsilon = \frac{{{{(1 - {A_1})}^2} + A_2^2}}{{A_3^2}} = \frac{{{{\left( {2S - \dfrac{{118}}{{15}}R{k^2} - {a_k}} \right)}^2} + b_k^2}}{{{{\left( {2S + \dfrac{{14}}{{15}}R{k^2}} \right)}^2}}},\end{equation}

\begin{equation}\varUpsilon = \frac{{{{(1 - {A_1})}^2} + A_2^2}}{{A_3^2}} = \frac{{{{\left( {2S - \dfrac{{118}}{{15}}R{k^2} - {a_k}} \right)}^2} + b_k^2}}{{{{\left( {2S + \dfrac{{14}}{{15}}R{k^2}} \right)}^2}}},\end{equation}

where ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$ are functions of k given by

${b_k}$ are functions of k given by

\begin{equation}\left. {\begin{array}{*{20}{c@{}}} {{a_k} = (109{k^2} + 75{G_k}k - 50{F_k})\dfrac{{\rm \pi} }{{64}},}\\ {{b_k} = (159k + 75{F_k}k + 50{G_k})\dfrac{{\rm \pi} }{{64}}.} \end{array}} \right\}\end{equation}

\begin{equation}\left. {\begin{array}{*{20}{c@{}}} {{a_k} = (109{k^2} + 75{G_k}k - 50{F_k})\dfrac{{\rm \pi} }{{64}},}\\ {{b_k} = (159k + 75{F_k}k + 50{G_k})\dfrac{{\rm \pi} }{{64}}.} \end{array}} \right\}\end{equation}

With the parameter of ![]() $\varUpsilon $, the finalized pitching amplitude can be given from (2.11) as

$\varUpsilon $, the finalized pitching amplitude can be given from (2.11) as

Therefore, the complex interaction between the flexible foil and the surrounding fluid flow will be determined by the value of ![]() $\varUpsilon $, which is a function of the mass ratio R, the dimensionless stiffness S and the reduced frequency k. While

$\varUpsilon $, which is a function of the mass ratio R, the dimensionless stiffness S and the reduced frequency k. While ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$ surely influence the response of the pitching foil, we show their value as a function of the reduced frequency k in figure 2. It shows that, when k reduces from 1 to zero,

${b_k}$ surely influence the response of the pitching foil, we show their value as a function of the reduced frequency k in figure 2. It shows that, when k reduces from 1 to zero, ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$ will decrease from their positive values to the negative ones and finally approach the fixed values determined by

${b_k}$ will decrease from their positive values to the negative ones and finally approach the fixed values determined by ![]() ${F_k}$ and

${F_k}$ and ![]() ${G_k}$, respectively. On the other side, if k is larger than 1,

${G_k}$, respectively. On the other side, if k is larger than 1, ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$ will increase with increasing k and their values will scale with

${b_k}$ will increase with increasing k and their values will scale with ![]() ${k^2}$ and k, respectively, if k is large enough, say larger than 10.

${k^2}$ and k, respectively, if k is large enough, say larger than 10.

Figure 2. Values of ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$ as a function of the reduced frequency k in the value ranges of (a) 0.001 to 1 and (b) 1 to 1000.

${b_k}$ as a function of the reduced frequency k in the value ranges of (a) 0.001 to 1 and (b) 1 to 1000.

The finalized pitching amplitude given in (2.16) shows a rather simple form compared with the reported analytical solutions. To check its accuracy, we first check the natural frequency of the system without a fluid force. Under this condition, ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$ vanish and

${b_k}$ vanish and ![]() $\varUpsilon = {(2S - 118R{k^2}/15)^2}/{(2S + 14R{k^2}/15)^2}$. Therefore, resonation happens if

$\varUpsilon = {(2S - 118R{k^2}/15)^2}/{(2S + 14R{k^2}/15)^2}$. Therefore, resonation happens if ![]() $\varUpsilon = 0$, which gives the reduced frequency

$\varUpsilon = 0$, which gives the reduced frequency ![]() ${k_0}$ as

${k_0}$ as

This gives ![]() ${k_0} \approx 0.5042\sqrt {S/R} $, which compares well with

${k_0} \approx 0.5042\sqrt {S/R} $, which compares well with ![]() ${k_0} \approx 0.5075\sqrt {S/R} $ from the exact result for the first resonant frequency of a cantilever beam (Rao Reference Rao2011) and is more precise than the value of

${k_0} \approx 0.5075\sqrt {S/R} $ from the exact result for the first resonant frequency of a cantilever beam (Rao Reference Rao2011) and is more precise than the value of ![]() ${k_0} \approx 0.497\sqrt {S/R} $ obtained from a quartic-order approximation to the beam deformation provided by Fernandez-Feria & Alaminos-Quesada (Reference Fernandez-Feria and Alaminos-Quesada2021).

${k_0} \approx 0.497\sqrt {S/R} $ obtained from a quartic-order approximation to the beam deformation provided by Fernandez-Feria & Alaminos-Quesada (Reference Fernandez-Feria and Alaminos-Quesada2021).

On the other hand, if the fluid–structure interaction is included, the resonance frequency will be determined by the minimum value of ![]() $\varUpsilon $ under given S and R. Although a numerical procedure is needed to determine the resonation frequency

$\varUpsilon $ under given S and R. Although a numerical procedure is needed to determine the resonation frequency ![]() ${k_r}$ in general, we can propose an approximation analytical relation between S, R and the resonant frequency

${k_r}$ in general, we can propose an approximation analytical relation between S, R and the resonant frequency ![]() ${k_r}$. This is realized by observing that, for given k and R, the minimum value for

${k_r}$. This is realized by observing that, for given k and R, the minimum value for ![]() $\varUpsilon $ is reached if

$\varUpsilon $ is reached if

\begin{equation}\frac{{\partial \varUpsilon }}{{\partial S}} = \frac{4}{{{{\left( {2S + \dfrac{{14}}{{15}}R{k^2}} \right)}^3}}}\left[ {\left( {2S - \frac{{118}}{{15}}R{k^2} - {a_k}} \right)\left( {\frac{{44}}{5}R{k^2} + {a_k}} \right) - b_k^2} \right] = 0,\end{equation}

\begin{equation}\frac{{\partial \varUpsilon }}{{\partial S}} = \frac{4}{{{{\left( {2S + \dfrac{{14}}{{15}}R{k^2}} \right)}^3}}}\left[ {\left( {2S - \frac{{118}}{{15}}R{k^2} - {a_k}} \right)\left( {\frac{{44}}{5}R{k^2} + {a_k}} \right) - b_k^2} \right] = 0,\end{equation}

from which the analytical relation between S, R and the resonation frequency ![]() ${k_r}$ can be given as

${k_r}$ can be given as

\begin{equation}{S_r} = \frac{1}{2}\left( {\frac{{118}}{{15}}Rk_r^2 + {a_k} + \frac{{b_k^2}}{{\dfrac{{44}}{5}Rk_r^2 + {a_k}}}} \right).\end{equation}

\begin{equation}{S_r} = \frac{1}{2}\left( {\frac{{118}}{{15}}Rk_r^2 + {a_k} + \frac{{b_k^2}}{{\dfrac{{44}}{5}Rk_r^2 + {a_k}}}} \right).\end{equation}

It can be easily checked from (2.19) that, if R is large enough, the resonation frequency ![]() ${k_r}$ will reduce to (2.17), that is the resonation is regulated by the elasticity of the foil. If R is much smaller than unity, its effect may be ignored and the resonance will be determined by

${k_r}$ will reduce to (2.17), that is the resonation is regulated by the elasticity of the foil. If R is much smaller than unity, its effect may be ignored and the resonance will be determined by

2.4. Model validation

For the dimensionless stiffness of ![]() $S = 10$, we compare the resonance frequency

$S = 10$, we compare the resonance frequency ![]() ${k_r}$ as a function of R between our theory and that from previous theories. The result shown in figure 3(a) clearly demonstrates the accuracy of our theory in capturing the resonance frequency of this flow–structure system. While the numerical result determined by Floryan & Rowley (Reference Floryan and Rowley2018) (F & R) is based on a more general theory (Floryan & Rowley Reference Floryan and Rowley2018), which can be treated as the exact solution to the problem, our numerical solution seems to match as well as that from the solution obtained by Fernandez-Feria & Alaminos-Quesada (Reference Fernandez-Feria and Alaminos-Quesada2021) (F & A) (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021) when the mass ratio R is small (

${k_r}$ as a function of R between our theory and that from previous theories. The result shown in figure 3(a) clearly demonstrates the accuracy of our theory in capturing the resonance frequency of this flow–structure system. While the numerical result determined by Floryan & Rowley (Reference Floryan and Rowley2018) (F & R) is based on a more general theory (Floryan & Rowley Reference Floryan and Rowley2018), which can be treated as the exact solution to the problem, our numerical solution seems to match as well as that from the solution obtained by Fernandez-Feria & Alaminos-Quesada (Reference Fernandez-Feria and Alaminos-Quesada2021) (F & A) (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021) when the mass ratio R is small (![]() $R < 0.1$) and matches better than F & A when R is large (

$R < 0.1$) and matches better than F & A when R is large (![]() $R > 1$). Furthermore, among all these theoretical models, the analytical relation given in (2.19) shows a comparable match to the result of F & R (Floryan & Rowley Reference Floryan and Rowley2018), thus demonstrating the applicability of our analytical solution to the flow–structure interaction problem.

$R > 1$). Furthermore, among all these theoretical models, the analytical relation given in (2.19) shows a comparable match to the result of F & R (Floryan & Rowley Reference Floryan and Rowley2018), thus demonstrating the applicability of our analytical solution to the flow–structure interaction problem.

Figure 3. The resonance frequency ![]() ${k_r}$ as a function of (a) mass ratio R for dimensionless stiffness of

${k_r}$ as a function of (a) mass ratio R for dimensionless stiffness of ![]() $S = 10$ and (b) dimensionless stiffness S for mass ratio of

$S = 10$ and (b) dimensionless stiffness S for mass ratio of ![]() $R = 0.01$. The results from F & A (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021) and F & R (Floryan & Rowley Reference Floryan and Rowley2018) are included for comparison, where the result of F & R can be treated as exact. The star in (a) corresponds to (2.20).

$R = 0.01$. The results from F & A (Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021) and F & R (Floryan & Rowley Reference Floryan and Rowley2018) are included for comparison, where the result of F & R can be treated as exact. The star in (a) corresponds to (2.20).

For a mass ratio of ![]() $R = 0.01$, we compare the resonance frequency

$R = 0.01$, we compare the resonance frequency ![]() ${k_r}$ as a function of S between our theory and that from the previous theory of F & R (Floryan & Rowley Reference Floryan and Rowley2018). The result shown in figure 3(b) shows that, when the dimensionless stiffness S is large, the numerical solution from (2.14) can always provide a comparable resonance frequency

${k_r}$ as a function of S between our theory and that from the previous theory of F & R (Floryan & Rowley Reference Floryan and Rowley2018). The result shown in figure 3(b) shows that, when the dimensionless stiffness S is large, the numerical solution from (2.14) can always provide a comparable resonance frequency ![]() ${k_r}$ to that from F & R (Floryan & Rowley Reference Floryan and Rowley2018). However, when the dimensionless stiffness S is small, the resonance frequency

${k_r}$ to that from F & R (Floryan & Rowley Reference Floryan and Rowley2018). However, when the dimensionless stiffness S is small, the resonance frequency ![]() ${k_r}$ determined from our theory is different from the results given by F & R (Floryan & Rowley Reference Floryan and Rowley2018). This is caused by the fact that our theory is based on Euler–Bernoulli beam theory, which cannot recover the flutter type resonance branch emerging when the dimensionless stiffness S is sufficient small (

${k_r}$ determined from our theory is different from the results given by F & R (Floryan & Rowley Reference Floryan and Rowley2018). This is caused by the fact that our theory is based on Euler–Bernoulli beam theory, which cannot recover the flutter type resonance branch emerging when the dimensionless stiffness S is sufficient small (![]() $S \le 0.1$). Figure 3(b) also shows that the analytical relation given in (2.19) can provide a meaningful value when the dimensionless stiffness S is larger than a typical value of 10 and the reduced frequency k is larger than 1. This is because the analytical relation given in (2.19) is derived by assuming that k and R are both fixed, which means that the minimization of

$S \le 0.1$). Figure 3(b) also shows that the analytical relation given in (2.19) can provide a meaningful value when the dimensionless stiffness S is larger than a typical value of 10 and the reduced frequency k is larger than 1. This is because the analytical relation given in (2.19) is derived by assuming that k and R are both fixed, which means that the minimization of ![]() $\varUpsilon $ over S can only bring the local ones to

$\varUpsilon $ over S can only bring the local ones to ![]() $\varUpsilon $. For given mass ratio R of the pitching foil, these local minimum values of

$\varUpsilon $. For given mass ratio R of the pitching foil, these local minimum values of ![]() $\varUpsilon $ are coincidence with the global ones only when the dimensionless stiffness S and the reduced frequency k are larger than their corresponding certain critical values.

$\varUpsilon $ are coincidence with the global ones only when the dimensionless stiffness S and the reduced frequency k are larger than their corresponding certain critical values.

To further validate our theoretical model, we make a direct comparison on the response parameter ![]() $\varUpsilon $ between our theoretical model and direct simulation with data extracted from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022). As shown in figure 4, the match is good between our theoretical model and the simulation for broad ranges of dimensionless stiffness and reduced frequency. Both model and simulation show that, when the dimensionless stiffness increases, the response parameter

$\varUpsilon $ between our theoretical model and direct simulation with data extracted from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022). As shown in figure 4, the match is good between our theoretical model and the simulation for broad ranges of dimensionless stiffness and reduced frequency. Both model and simulation show that, when the dimensionless stiffness increases, the response parameter ![]() $\varUpsilon $ will decrease firstly and reach a minimum value and then approach to the constant of 1. The minimum value for

$\varUpsilon $ will decrease firstly and reach a minimum value and then approach to the constant of 1. The minimum value for ![]() $\varUpsilon $ corresponds to the resonance condition, whereas

$\varUpsilon $ corresponds to the resonance condition, whereas ![]() $\varUpsilon = 1$ corresponds to an equal pitching amplitude between the finalized pitching motion and the driving one. For the resonance condition, our model can nicely recover the critical dimensionless stiffness for resonance, as shown by the thin vertical lines. For the equal pitching amplitude condition (

$\varUpsilon = 1$ corresponds to an equal pitching amplitude between the finalized pitching motion and the driving one. For the resonance condition, our model can nicely recover the critical dimensionless stiffness for resonance, as shown by the thin vertical lines. For the equal pitching amplitude condition (![]() $\varUpsilon = 1$), both theoretical model and simulation show that there is a critical dimensionless stiffness satisfying this condition and this critical dimensionless stiffness increases as the reduced frequency increases. Although the exact value varies a bit between the theoretical model and simulation, our theoretical model can recover the trends for the critical dimensionless stiffness as a function of the reduced frequency.

$\varUpsilon = 1$), both theoretical model and simulation show that there is a critical dimensionless stiffness satisfying this condition and this critical dimensionless stiffness increases as the reduced frequency increases. Although the exact value varies a bit between the theoretical model and simulation, our theoretical model can recover the trends for the critical dimensionless stiffness as a function of the reduced frequency.

Figure 4. The response parameter ![]() $\varUpsilon $ as a function of the dimensionless stiffness while under different reduced frequencies k from 1.257 to 3.770 shown by lines and symbols with different colours. The scatters are the results from direct simulation extracted from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022), with the driving pitching amplitude of 0.1 and mass ratio of 1. The dashed line is corresponding to

$\varUpsilon $ as a function of the dimensionless stiffness while under different reduced frequencies k from 1.257 to 3.770 shown by lines and symbols with different colours. The scatters are the results from direct simulation extracted from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022), with the driving pitching amplitude of 0.1 and mass ratio of 1. The dashed line is corresponding to ![]() $\varUpsilon = 1$ and the dotted line is corresponding to

$\varUpsilon = 1$ and the dotted line is corresponding to ![]() $\varUpsilon = 0.3$. The vertical thin lines correspond to the resonance condition determined from simulation. The inset shows the trailing amplitude normalized by the span of the foil, with the reduced frequency k of 3.142.

$\varUpsilon = 0.3$. The vertical thin lines correspond to the resonance condition determined from simulation. The inset shows the trailing amplitude normalized by the span of the foil, with the reduced frequency k of 3.142.

When driving at resonance condition, our model fails to give the accurate response parameter as that from simulation provided by Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022). This is because the driving pitching amplitude used by Peng et al. is 0.1, which makes the finalized pitching amplitude obviously larger than the ones that the linear inviscid theory holds. As shown in the inset of figure 4, for the corresponding trailing amplitude of the flexible foil, our theoretical model matches quantitatively with the simulations both for the resonance stiffness and the corresponding trailing amplitude when the dimensionless stiffness is away from the resonance value. Near the resonance condition, the finalized pitching amplitude will be as large as 0.4, which is obviously beyond the regime in which linear inviscid theory can be utilized. In fact, we have checked that, when the driving pitching amplitude is small, such that the linear inviscid theory still holds, our theory can reasonably recover the resonance pitching amplitude.

Overall, based on the comparison between our theoretical model and these previous models (Floryan & Rowley Reference Floryan and Rowley2018; Fernandez-Feria & Alaminos-Quesada Reference Fernandez-Feria and Alaminos-Quesada2021) and direct simulations (Peng et al. Reference Peng, Sun, Yang, Xiong, Wang and Wang2022), the response parameter ![]() $\varUpsilon $ coined in this work could nicely forecast the response of the flexible foil when pitching at the leading edge, demonstrating the suitability of using it to uncover the physics of the flow–structure interaction system.

$\varUpsilon $ coined in this work could nicely forecast the response of the flexible foil when pitching at the leading edge, demonstrating the suitability of using it to uncover the physics of the flow–structure interaction system.

3. Results and discussions

In § 2, we have presented the analytical formulation for the response of the flexible foil as a result of the driving pitch motion at the leading edge. Based on this formulation, this section presents the results of the kinematics and the propulsion performance of the pitching flexible foil. While the response of the pitching foil is solely determined by the mass ratio R, the dimensionless stiffness S and the reduced frequency k, in this section, a broad parameter ranges including ![]() $S \in [0.1,1000]$,

$S \in [0.1,1000]$, ![]() $k \in [0.1,100]$ and

$k \in [0.1,100]$ and ![]() $R \in [0.01,10]$ will be used to determine the response of the pitching foil. Based on these parameter ranges, the pitching amplitude and the phase angle will be determined first and then the thrust and propulsive efficiency will be presented. Here, a lower mass ratio of

$R \in [0.01,10]$ will be used to determine the response of the pitching foil. Based on these parameter ranges, the pitching amplitude and the phase angle will be determined first and then the thrust and propulsive efficiency will be presented. Here, a lower mass ratio of ![]() $R = 0.01$ corresponds to underwater swimmers and higher ones of

$R = 0.01$ corresponds to underwater swimmers and higher ones of ![]() $R \ge 1$ correspond to fliers.

$R \ge 1$ correspond to fliers.

3.1. Pitching amplitude

The responded pitching amplitude given in (2.16) shows a linear relation with the driving pitch amplitude, with the coefficient determined by ![]() $\varUpsilon $, which is given by (2.14). While the resonance condition of the foil has been clarified in § 2 as well as in these previous reports, here, we mainly focus on the critical condition that defines the situation when the flexibility of the foil enlarges the pitching amplitude. Based on (2.14), this condition can be readily given by

$\varUpsilon $, which is given by (2.14). While the resonance condition of the foil has been clarified in § 2 as well as in these previous reports, here, we mainly focus on the critical condition that defines the situation when the flexibility of the foil enlarges the pitching amplitude. Based on (2.14), this condition can be readily given by ![]() $\varUpsilon < {\varUpsilon _e} = 1$, which gives

$\varUpsilon < {\varUpsilon _e} = 1$, which gives

\begin{equation}{S_e} = \frac{1}{4}\left[ {\left( {\frac{{118}}{{15}}R{k^2} + {a_k}} \right) + \frac{{b_k^2}}{{\left( {\dfrac{{44}}{5}R{k^2} + {a_k}} \right)}}} \right].\end{equation}

\begin{equation}{S_e} = \frac{1}{4}\left[ {\left( {\frac{{118}}{{15}}R{k^2} + {a_k}} \right) + \frac{{b_k^2}}{{\left( {\dfrac{{44}}{5}R{k^2} + {a_k}} \right)}}} \right].\end{equation}Comparing (2.19) and (3.1), it shows that, for a given reduced frequency k and mass ratio R, the dimensionless stiffness S for resonance is twice as the critical one where the flexibility of the foil does not change the pitching amplitude. This relation applies when (2.19) can capture the resonance condition of the foil. From (3.1), we can determine the critical reduced frequency k in principle as there is no other unknown parameter if S and R are given.

The analytical expression of (3.1) implies there is a minimum value for ![]() ${S_e}$, indicated as

${S_e}$, indicated as ![]() ${S_{em}}$, below which there is no solution for the reduced frequency k. To check this statement, we show the map of

${S_{em}}$, below which there is no solution for the reduced frequency k. To check this statement, we show the map of ![]() ${S_e}$ as a function of R and k in figure 5. It shows that, for a given mass ratio

${S_e}$ as a function of R and k in figure 5. It shows that, for a given mass ratio ![]() $R$ in the range 0.01–10, there is a global minimum for the positive value of

$R$ in the range 0.01–10, there is a global minimum for the positive value of ![]() ${S_e}$, where the value for k is indicated as the solid line. Figure 5 also shows that, although the value for R spans four orders, the critical value for k just spans one order, indicating the value of the critical reduced frequency k is insensitive to the mass ratio R. The existence of the value

${S_e}$, where the value for k is indicated as the solid line. Figure 5 also shows that, although the value for R spans four orders, the critical value for k just spans one order, indicating the value of the critical reduced frequency k is insensitive to the mass ratio R. The existence of the value ![]() ${S_{em}}$ indicates that the foil should have sufficient bending stiffness such that its pitching amplitude can be enlarged as a result of deformation, although infinite bending stiffness will never change the pitching amplitude either.

${S_{em}}$ indicates that the foil should have sufficient bending stiffness such that its pitching amplitude can be enlarged as a result of deformation, although infinite bending stiffness will never change the pitching amplitude either.

Figure 5. The map of ![]() ${S_e}$ as a function of the mass ratio R and the reduced frequency k. The solid line is corresponding to

${S_e}$ as a function of the mass ratio R and the reduced frequency k. The solid line is corresponding to ![]() ${S_{em}}$ by numerical determining the minimum value from (3.1). The dotted line is corresponding to (3.3). The region for the value of

${S_{em}}$ by numerical determining the minimum value from (3.1). The dotted line is corresponding to (3.3). The region for the value of ![]() ${S_e}$ larger than 15 is whited out and that smaller than zero is greyed out.

${S_e}$ larger than 15 is whited out and that smaller than zero is greyed out.

As the minimum value for ![]() ${S_e}$, or

${S_e}$, or ![]() ${S_{em}}$, determines whether the flexibility of the foil can enlarge the pitching amplitude, we propose an approximated analytical solution to

${S_{em}}$, determines whether the flexibility of the foil can enlarge the pitching amplitude, we propose an approximated analytical solution to ![]() ${S_{em}}$ here. Based on (3.1), if treating

${S_{em}}$ here. Based on (3.1), if treating ![]() $44R{k^2}/5 + {a_k}$ as the unknown parameter that needs to be determined, then it has solution only when

$44R{k^2}/5 + {a_k}$ as the unknown parameter that needs to be determined, then it has solution only when

This readily gives the value of ![]() ${S_{em}}$, below which there is no solution to (3.1); that is, if

${S_{em}}$, below which there is no solution to (3.1); that is, if ![]() $S < {S_{em}}$ the pitching amplitude can never surpass its rigid counterpart. Here,

$S < {S_{em}}$ the pitching amplitude can never surpass its rigid counterpart. Here, ![]() ${S_{em}}$ can be given by

${S_{em}}$ can be given by

where ![]() ${k_m}$ is the corresponding reduced frequency. Equation (3.3) shows how to determine the lower value of

${k_m}$ is the corresponding reduced frequency. Equation (3.3) shows how to determine the lower value of ![]() ${S_{em}}$, which is realized by determining

${S_{em}}$, which is realized by determining ![]() ${k_m}$ through the second equality if the mass ratio R is specified. While (3.2) indicates the absolute treatment should be put on

${k_m}$ through the second equality if the mass ratio R is specified. While (3.2) indicates the absolute treatment should be put on ![]() ${b_k}$, implying there may be two solutions to k, we can show that, for R in the range between 0.01 and 10, only the solution that guarantees a positive

${b_k}$, implying there may be two solutions to k, we can show that, for R in the range between 0.01 and 10, only the solution that guarantees a positive ![]() ${b_k}$ is legitimate, as has been given in (3.3). To do so, we show the relation of (3.3) as the dotted line in figure 5. For a given value of R lying in the range of 0.01 and 10, figure 5 shows that the value for

${b_k}$ is legitimate, as has been given in (3.3). To do so, we show the relation of (3.3) as the dotted line in figure 5. For a given value of R lying in the range of 0.01 and 10, figure 5 shows that the value for ![]() ${k_m}$ that satisfies (3.3) lies in the range between 0.1 and 1. Based on the value range of

${k_m}$ that satisfies (3.3) lies in the range between 0.1 and 1. Based on the value range of ![]() ${k_m}$ and checking the value of

${k_m}$ and checking the value of ![]() ${b_k}$ from figure 2, it clearly shows that

${b_k}$ from figure 2, it clearly shows that ![]() ${b_k}$ is always positive. This justifies the suitability of choosing the positive value for

${b_k}$ is always positive. This justifies the suitability of choosing the positive value for ![]() ${b_k}$ in (3.3) when determining the critical dimensionless stiffness

${b_k}$ in (3.3) when determining the critical dimensionless stiffness ![]() ${S_{em}}$.

${S_{em}}$.

To check the suitability of (3.3) in determining the minimum value for ![]() ${S_{em}}$, we make a comparison between the results from (3.1) and (3.3), which have been shown by the solid line and dotted line in figure 5. The lines from figure 5 shows that the analytical relation given in (3.3) can provide a pretty good solution to

${S_{em}}$, we make a comparison between the results from (3.1) and (3.3), which have been shown by the solid line and dotted line in figure 5. The lines from figure 5 shows that the analytical relation given in (3.3) can provide a pretty good solution to ![]() ${S_{em}}$ when compared with that of the numerical results from (3.1) if the mass ratio R is large, say larger than 1. Under this condition, k approaches 0.1 and

${S_{em}}$ when compared with that of the numerical results from (3.1) if the mass ratio R is large, say larger than 1. Under this condition, k approaches 0.1 and ![]() ${b_k}$ approaches zero slowly. When R is small, there is a notable discrepancy between them, indicating the analytical relation of (3.3) failed to provide the global minimum value for

${b_k}$ approaches zero slowly. When R is small, there is a notable discrepancy between them, indicating the analytical relation of (3.3) failed to provide the global minimum value for ![]() ${S_e}$. This is because (3.3) implies the global minimum for

${S_e}$. This is because (3.3) implies the global minimum for ![]() ${S_e}$ happens when

${S_e}$ happens when ![]() ${b_k} = 44Rk_m^2/4 + {a_k}$ has been satisfied. While this is true only when

${b_k} = 44Rk_m^2/4 + {a_k}$ has been satisfied. While this is true only when ![]() ${b_k}$ is constant over k, this surely breaks down as

${b_k}$ is constant over k, this surely breaks down as ![]() ${b_k}$ is in principle a function of k. However, the weak dependence of

${b_k}$ is in principle a function of k. However, the weak dependence of ![]() ${b_k}$ as a function of k when k approaches zero guarantees that the analytical relation proposed in (3.3) can provide a reliable value for

${b_k}$ as a function of k when k approaches zero guarantees that the analytical relation proposed in (3.3) can provide a reliable value for ![]() ${S_{em}}$, which happens to be the condition when the mass ratio R is large and the corresponding value of

${S_{em}}$, which happens to be the condition when the mass ratio R is large and the corresponding value of ![]() ${k_m}$ is sufficiently small.

${k_m}$ is sufficiently small.

With the information for the minimum value of ![]() ${S_e}$, we move to determine the analytical relation among R, S and k, which defines whether the flexibility of the foil can enlarge the pitching amplitude. If (3.2) can be satisfied, the solution to

${S_e}$, we move to determine the analytical relation among R, S and k, which defines whether the flexibility of the foil can enlarge the pitching amplitude. If (3.2) can be satisfied, the solution to ![]() $44R{k^2}/5 + {a_k}$ can be given from (3.1) through

$44R{k^2}/5 + {a_k}$ can be given from (3.1) through

\begin{equation}\frac{{44}}{5}R{k^2} + {a_k} = \left( {2S + \frac{7}{{15}}R{k^2}} \right) \pm \sqrt {{{\left( {2S + \frac{7}{{15}}R{k^2}} \right)}^2} - b_k^2} .\end{equation}

\begin{equation}\frac{{44}}{5}R{k^2} + {a_k} = \left( {2S + \frac{7}{{15}}R{k^2}} \right) \pm \sqrt {{{\left( {2S + \frac{7}{{15}}R{k^2}} \right)}^2} - b_k^2} .\end{equation}

As with the intermediate functions of ![]() ${a_k}$ and

${a_k}$ and ![]() ${b_k}$, these is no simple analytical solution to k in general. Here, we can formulate asymptotic relations among R, S and k as follows. While (3.1) has been used to derive the lower boundary for the dimensionless stiffness, here we consider the condition when the dimensionless stiffness approaches a large value. Under this condition, we will demonstrate that the condition of

${b_k}$, these is no simple analytical solution to k in general. Here, we can formulate asymptotic relations among R, S and k as follows. While (3.1) has been used to derive the lower boundary for the dimensionless stiffness, here we consider the condition when the dimensionless stiffness approaches a large value. Under this condition, we will demonstrate that the condition of ![]() $4{S^2} \gg b_k^2$ can be always satisfied. Based on this relation, two asymptotic relations can be obtained from (3.4). The first one determines the lower solution for the reduced frequency

$4{S^2} \gg b_k^2$ can be always satisfied. Based on this relation, two asymptotic relations can be obtained from (3.4). The first one determines the lower solution for the reduced frequency ![]() ${k_l}$ as

${k_l}$ as

This relation is rather simple, indicating that there is a critical reduced frequency, denoted by ![]() ${k_l}$, which is solely determined by R if the value of S is large; that is,

${k_l}$, which is solely determined by R if the value of S is large; that is, ![]() ${k_l}\sim f(R)$. It can be easily checked that this critical reduced frequency

${k_l}\sim f(R)$. It can be easily checked that this critical reduced frequency ![]() ${k_l}$ is the lower boundary for the reduced frequency, below which the pitching amplitude of the flexible foil will be smaller than the rigid counterpart. The second asymptotic relation determines the upper boundary for the reduced frequency, denoted by

${k_l}$ is the lower boundary for the reduced frequency, below which the pitching amplitude of the flexible foil will be smaller than the rigid counterpart. The second asymptotic relation determines the upper boundary for the reduced frequency, denoted by ![]() ${k_u}$, as

${k_u}$, as

Based on the definition for ![]() ${a_k}$ given by (2.15), the asymptotic solution for the reduced frequency

${a_k}$ given by (2.15), the asymptotic solution for the reduced frequency ![]() ${k_u}$ can be given as

${k_u}$ can be given as

\begin{equation}{k_u} \cong \frac{2}{{\sqrt {\dfrac{{118}}{{15}}R + \dfrac{{109{\rm \pi} }}{{64}}} }}\sqrt S .\end{equation}

\begin{equation}{k_u} \cong \frac{2}{{\sqrt {\dfrac{{118}}{{15}}R + \dfrac{{109{\rm \pi} }}{{64}}} }}\sqrt S .\end{equation}

From (3.7), it shows that the solution for ![]() ${k_u}$ satisfies

${k_u}$ satisfies ![]() $S\sim k_u^2$ if S is sufficiently large. As

$S\sim k_u^2$ if S is sufficiently large. As ![]() ${k_u}$ is the upper boundary for the reduce frequency k, the condition of

${k_u}$ is the upper boundary for the reduce frequency k, the condition of ![]() $4{S^2} \gg b_k^2$ can be easily justified if we note that

$4{S^2} \gg b_k^2$ can be easily justified if we note that ![]() ${b_k}\sim k$, as the results from figure 2(b) show.

${b_k}\sim k$, as the results from figure 2(b) show.

With these analytical relations for the equal pitching amplitude condition, whether the foil with flexibility has a larger pitching amplitude can be easily checked. Firstly, we need to check that the dimensionless stiffness S is larger than the lower boundary determined by (3.3) analytically or the more accurate one of the minimum from (3.1) numerically. If this can be satisfied, we need to determine the lower and upper boundaries for the reduced frequency through (3.5) and (3.7), respectively. If the reduced frequency from the working condition lies between them, the foil will have a larger pitching amplitude than the driving one. Otherwise, the pitching amplitude of the foil will decrease as a result of deformation.

For mass ratios of 0.01 and 1, figure 6 show the pitching amplitudes as a function of dimensionless stiffness S and reduced frequency k, together with the resonance condition defined from (2.14) and the equal pitching amplitude condition of ![]() $\varUpsilon = 1$ defined from (3.1). In order to justify the accuracy of the physical model proposed in this study, we also included these previously reported results in figure 6. For a mass ratio of 0.01, we make a comparison between our theoretical model with the result from F & R (Floryan & Rowley Reference Floryan and Rowley2018). As shown in figure 6(a), the reduced frequency for resonance matches well between our theory and that from F & R when the dimensionless stiffness S is relatively large. Under this condition, the corresponding resonance frequency

$\varUpsilon = 1$ defined from (3.1). In order to justify the accuracy of the physical model proposed in this study, we also included these previously reported results in figure 6. For a mass ratio of 0.01, we make a comparison between our theoretical model with the result from F & R (Floryan & Rowley Reference Floryan and Rowley2018). As shown in figure 6(a), the reduced frequency for resonance matches well between our theory and that from F & R when the dimensionless stiffness S is relatively large. Under this condition, the corresponding resonance frequency ![]() ${k_r}$ scales with S with a power of 1/2, as (2.19) implies. The match becomes worse if the dimensionless stiffness S is small, under which

${k_r}$ scales with S with a power of 1/2, as (2.19) implies. The match becomes worse if the dimensionless stiffness S is small, under which ![]() ${k_r}$ is smaller from our theory when compared with F & R. Besides the resonance condition, the relation between the reduced frequency k and the dimensionless stiffness

${k_r}$ is smaller from our theory when compared with F & R. Besides the resonance condition, the relation between the reduced frequency k and the dimensionless stiffness ![]() ${S_e}$ for

${S_e}$ for ![]() $\varUpsilon = 1$ is consistent between our theory of (3.1) and the results from F & R. For the equal pitching amplitude condition, although our theory will shift the reduced frequency down a bit, both theories give that there is a critical stiffness

$\varUpsilon = 1$ is consistent between our theory of (3.1) and the results from F & R. For the equal pitching amplitude condition, although our theory will shift the reduced frequency down a bit, both theories give that there is a critical stiffness ![]() ${S_{em}}$ below which the pitching amplitude will decrease no matter the reduced frequency k. All these results indicate that our theory can provide a meaningful method to evaluate the flexibility effect on the pitching foil, if noting that our theory has the simple closed-form expressions.

${S_{em}}$ below which the pitching amplitude will decrease no matter the reduced frequency k. All these results indicate that our theory can provide a meaningful method to evaluate the flexibility effect on the pitching foil, if noting that our theory has the simple closed-form expressions.

Figure 6. Pitching amplitudes as a function of dimensionless stiffness S and reduced frequency k for given mass ratio of (a) ![]() $R = 0.01$ and (b)

$R = 0.01$ and (b) ![]() $R = 1$. The solid red lines correspond to the natural frequency obtained from minimization of (2.14) numerically. The solid black lines correspond to the solution given by (3.1), where the dashed black lines correspond to (3.3), (3.5) and (3.7), respectively. The dashed red line and the dotted line in (a) correspond to the result from F & R (Floryan & Rowley Reference Floryan and Rowley2018). The cycle scatters in (b) correspond to the results from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022).

$R = 1$. The solid red lines correspond to the natural frequency obtained from minimization of (2.14) numerically. The solid black lines correspond to the solution given by (3.1), where the dashed black lines correspond to (3.3), (3.5) and (3.7), respectively. The dashed red line and the dotted line in (a) correspond to the result from F & R (Floryan & Rowley Reference Floryan and Rowley2018). The cycle scatters in (b) correspond to the results from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022).

In figure 6(b), we include the simulated results from Peng et al. (Reference Peng, Sun, Yang, Xiong, Wang and Wang2022) as shown by these scattered symbols. The comparison between our theory and the simulated ones shows that the theory proposed in this study can nicely capture the effect of the flexibility of the foil on the pitching amplitude, although a certain discrepancy does exist between them if the exact pitching amplitude is concerned. The discrepancy is introduced as the pitching amplitude of the foil is well above 0.1 and even reaches up to 0.2 in their simulations (Peng et al. Reference Peng, Sun, Yang, Xiong, Wang and Wang2022). With such large pitching amplitudes, the linear potential flow theory used in this study surely breaks down. Although, with this limitation, the predictive ability of the theoretical model in forecasting the pitching amplitude for a flexible foil is still evident.

Next, we justify the analytical relations for ![]() $\varUpsilon = 1$ formulated in this study. For a low mass ratio of

$\varUpsilon = 1$ formulated in this study. For a low mass ratio of ![]() $R = 0.01$ and a relatively high mass ratio of

$R = 0.01$ and a relatively high mass ratio of ![]() $R = 1$, figure 6(a,b) shows that the flexibility of the foil may increase or decrease the pitching amplitude, which is determined by the combination of the dimensionless stiffness S and the reduced frequency k if the mass ratio R is given. When the reduced frequency is large (

$R = 1$, figure 6(a,b) shows that the flexibility of the foil may increase or decrease the pitching amplitude, which is determined by the combination of the dimensionless stiffness S and the reduced frequency k if the mass ratio R is given. When the reduced frequency is large (![]() $k > 2$), figure 6(a,b) shows that this critical stiffness

$k > 2$), figure 6(a,b) shows that this critical stiffness ![]() ${S_{em}}$ for equal pitching amplitude is half of the stiffness at which resonance happens. To obtain a larger pitching amplitude, the dimensionless stiffness S should be larger than 6.92 if the mass ratio is 0.01, under which the reduced frequency is approximately 1.14. For a mass ratio of 1, the minimum dimensionless stiffness S is 2.88 and the corresponding reduced frequency is 0.57. These critical values for S are determined from the numerical minimization of (3.1). If the analytical relation of (3.3) is used to determine the critical values, for R to be 0.01 and 1, the dimensionless stiffness turns out to be 9.26 and 3.73, with the corresponding reduced frequency being 1.93 and 0.82, respectively, as indicated by the stars in these panels. The comparison of the minimum stiffness between the numerical solution and that from the analytical relation shows that the analytical relation given by (3.3) is more suitable for the larger mass ratio condition. Although with a certain discrepancy between the analytical results compared with the numerical solutions, the analytical relation of (3.3) can provide a meaningful value for the minimum dimensionless stiffness

${S_{em}}$ for equal pitching amplitude is half of the stiffness at which resonance happens. To obtain a larger pitching amplitude, the dimensionless stiffness S should be larger than 6.92 if the mass ratio is 0.01, under which the reduced frequency is approximately 1.14. For a mass ratio of 1, the minimum dimensionless stiffness S is 2.88 and the corresponding reduced frequency is 0.57. These critical values for S are determined from the numerical minimization of (3.1). If the analytical relation of (3.3) is used to determine the critical values, for R to be 0.01 and 1, the dimensionless stiffness turns out to be 9.26 and 3.73, with the corresponding reduced frequency being 1.93 and 0.82, respectively, as indicated by the stars in these panels. The comparison of the minimum stiffness between the numerical solution and that from the analytical relation shows that the analytical relation given by (3.3) is more suitable for the larger mass ratio condition. Although with a certain discrepancy between the analytical results compared with the numerical solutions, the analytical relation of (3.3) can provide a meaningful value for the minimum dimensionless stiffness ![]() ${S_{em}}$.

${S_{em}}$.

If the dimensionless stiffness is larger than ![]() ${S_{em}}$, the pitching amplitude can be larger than the rigid counterpart only when the reduced frequency k is located between the lower boundary determined by

${S_{em}}$, the pitching amplitude can be larger than the rigid counterpart only when the reduced frequency k is located between the lower boundary determined by ![]() ${k_l}$ and the upper boundary determined by

${k_l}$ and the upper boundary determined by ![]() ${k_u}$, as figure 6 shows. Figure 6(a,b) shows that the lower boundary of

${k_u}$, as figure 6 shows. Figure 6(a,b) shows that the lower boundary of ![]() ${k_l}$ is constant over S if S is sufficiently large, which is solely determined by R, as the horizontal dashed lines in these figures show. For R to be 0.01 and 1,

${k_l}$ is constant over S if S is sufficiently large, which is solely determined by R, as the horizontal dashed lines in these figures show. For R to be 0.01 and 1, ![]() ${k_l}$ is 0.57 and 0.35, respectively, both of which can be readily determined from (3.5). As for the upper boundary of

${k_l}$ is 0.57 and 0.35, respectively, both of which can be readily determined from (3.5). As for the upper boundary of ![]() ${k_u}$, the tilted dashed lines determined from (3.7) match nicely with the upper boundary of the reduced frequency determined numerically from (3.1). Both figures show that

${k_u}$, the tilted dashed lines determined from (3.7) match nicely with the upper boundary of the reduced frequency determined numerically from (3.1). Both figures show that ![]() ${k_u}$ scales with the dimensionless stiffness S with a power of 1/2, as (3.7) gives. These consistencies between the numerical solutions and the analytical relations demonstrate the suitability of these analytical relations in forecasting the equal pitching amplitude condition as a result of foil flexibility.