Cover: SEM micrographs of failure samples in impact condition. [Z. Zhou, L. Duan, F. Wu: Investigation of Charpy impact behavior of porous twisted wire material. p. 2276].

Invited Paper

Toward high volume solution based roll-to-roll processing of OLEDs

-

- Published online by Cambridge University Press:

- 05 June 2017, pp. 2219-2229

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Articles

A new approach of the Oliver and Pharr model to fit the unloading curve from instrumented indentation testing

-

- Published online by Cambridge University Press:

- 17 April 2017, pp. 2230-2240

-

- Article

- Export citation

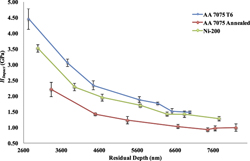

Characterization and investigation of size effect in nano-impact indentations performed using cube-corner indenter tip

-

- Published online by Cambridge University Press:

- 22 May 2017, pp. 2241-2248

-

- Article

- Export citation

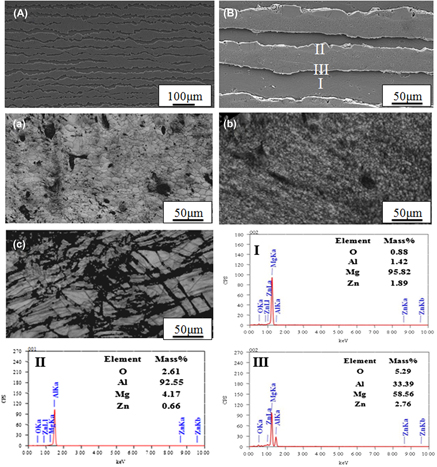

Development and properties evaluation of Mg–6% Zn/Al multilayered composites processed by accumulative roll bonding

-

- Published online by Cambridge University Press:

- 18 May 2017, pp. 2249-2257

-

- Article

- Export citation

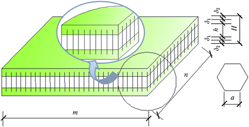

Drop-weight impact test on an integrated composite sandwich panel of aluminum honeycomb and epoxy resin

-

- Published online by Cambridge University Press:

- 22 May 2017, pp. 2258-2265

-

- Article

- Export citation

Quasi-continuum study of the buckling behavior of single-walled carbon nanocones subjected to bending under thermal loading

-

- Published online by Cambridge University Press:

- 22 May 2017, pp. 2266-2275

-

- Article

- Export citation

Investigation of Charpy impact behavior of porous twisted wire material

-

- Published online by Cambridge University Press:

- 29 May 2017, pp. 2276-2285

-

- Article

- Export citation

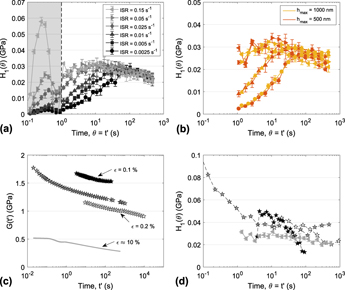

Theoretical and experimental analysis of indentation relaxation test

-

- Published online by Cambridge University Press:

- 09 June 2017, pp. 2286-2296

-

- Article

- Export citation

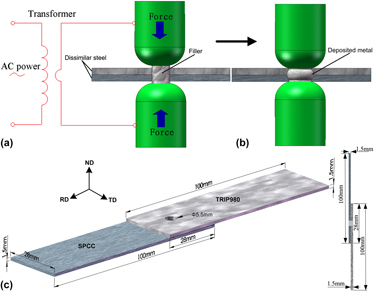

Processing optimization and comprehensive performance on resistance plug welding of dissimilar steel joints

-

- Published online by Cambridge University Press:

- 13 June 2017, pp. 2297-2306

-

- Article

- Export citation

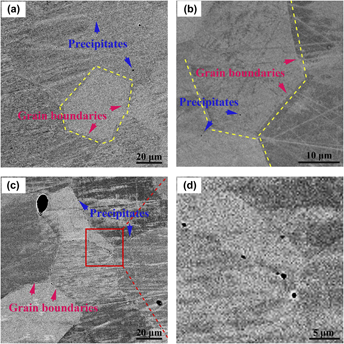

Effect of precipitates on grain growth in non-oriented silicon steel

-

- Published online by Cambridge University Press:

- 24 April 2017, pp. 2307-2314

-

- Article

- Export citation

Microstructures and mechanical properties of as-ECAPed Mg–8Sn alloys with the combined addition of Zn and Al

-

- Published online by Cambridge University Press:

- 18 April 2017, pp. 2315-2324

-

- Article

- Export citation

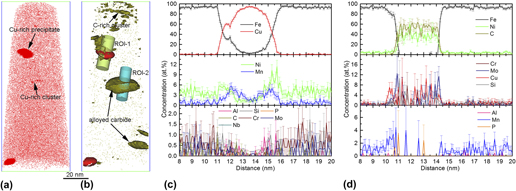

Interactive formation of Cu-rich precipitate, reverted austenite, and alloyed carbide during partial austenite reversion treatment for high-strength low-alloy steel

-

- Published online by Cambridge University Press:

- 02 May 2017, pp. 2325-2334

-

- Article

- Export citation

Inhibition effect of longitudinal alternating current during annealing on growth of interfacial layers of copper cladding aluminum composite

-

- Published online by Cambridge University Press:

- 22 May 2017, pp. 2335-2342

-

- Article

- Export citation

The inverse parameter identification of Hill’48 yield function for small-sized tube combining response surface methodology and three-point bending

-

- Published online by Cambridge University Press:

- 21 March 2017, pp. 2343-2351

-

- Article

- Export citation

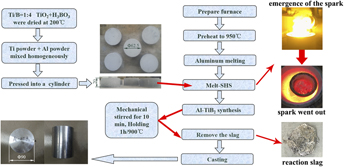

Fabrication of TiB2/Al composite by melt-SHS process with different content of titanium powder

-

- Published online by Cambridge University Press:

- 23 May 2017, pp. 2352-2360

-

- Article

- Export citation

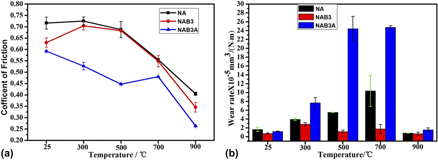

Mechanical and tribological properties of NiAl–NbC–Ag composites prepared by hot-pressing sintering

-

- Published online by Cambridge University Press:

- 22 May 2017, pp. 2361-2372

-

- Article

- Export citation

Understanding phase equilibria and segregation in Bridgman growth of Cs2LiYCl6 scintillator

-

- Published online by Cambridge University Press:

- 22 May 2017, pp. 2373-2380

-

- Article

- Export citation

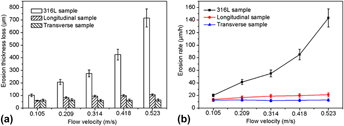

Investigation of erosion properties of directionally solidified Fe–B alloy in various velocities liquid zinc

-

- Published online by Cambridge University Press:

- 24 April 2017, pp. 2381-2388

-

- Article

- Export citation

Investigation of recrystallization behavior of large sized Nb–V microalloyed steel rod during thermomechanical controlled processing

-

- Published online by Cambridge University Press:

- 08 May 2017, pp. 2389-2396

-

- Article

- Export citation

Physical properties and lattice dynamics of bixbyite-type V2O3

-

- Published online by Cambridge University Press:

- 15 May 2017, pp. 2397-2404

-

- Article

- Export citation