1. Introduction

When grains are poured from a point source onto a horizontal plane, they form a conical pile (or heap) that has a well-defined angle of repose (see figure 1). This is one of the most fundamental of granular flows, and has been used throughout the ages to store bulk solids in industrial processes, agriculture and food processing (Bates Reference Bates1997; Schulze Reference Schulze2008). When the source is not a point, a wide range of pile shapes can develop, and this has motivated the development of simple sandpile models, which assume that all the slopes are at, or close to, the angle of repose (Hadeler & Kuttler Reference Hadeler and Kuttler1999; Nuca, Giudicec & Preziosi Reference Nuca, Giudicec and Preziosi2021).

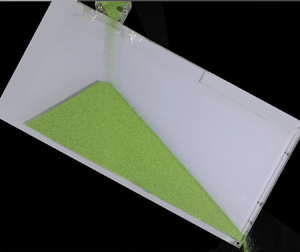

Figure 1. Conical pile formed from the ![]() $710\unicode{x2013}750\,\mathrm {\mu }{\rm m}$ green glass spheres used in the super-stable heap experiments. The angle of repose is approximately

$710\unicode{x2013}750\,\mathrm {\mu }{\rm m}$ green glass spheres used in the super-stable heap experiments. The angle of repose is approximately ![]() $22^{\circ }$.

$22^{\circ }$.

Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003) discovered that when material is continually poured from a point source onto a flat plane (or chute) that is confined laterally by frictional sidewalls, a heap can form whose faces are inclined significantly above the angle of repose. They termed such piles super-stable heaps. An example is shown in figure 2. Interestingly, the super-inclination of the pile's sides requires the continued flow of grains over their surfaces to keep them stable. When the inflow is shut off, the pile slowly collapses back to a conventional heap, or completely flows off the inclined chute, if it is inclined above the angle of repose.

Figure 2. Experimental set-up for the super-stable heap. Two 10 mm thick perspex front and back confining walls are separated by 3 mm perspex bars across the left and bottom boundaries (as well as a perspex spacer along part of the top boundary) to form a ![]() $600\,{\rm mm} \times 300\,{\rm mm}$ rectangular domain. A silo with a funnel is attached to the top, with a ‘double gate’ mechanism to control the mass-inflow rate and open and close the inlet. Material exits the domain through the right-hand side of the rectangular domain and lands on a balance. This measures the mass accumulation as a function of time. The left-hand stand adjusts the inclination angle of the system, whilst the right-hand stand has a fixed height, allowing for in-plane rotation.

$600\,{\rm mm} \times 300\,{\rm mm}$ rectangular domain. A silo with a funnel is attached to the top, with a ‘double gate’ mechanism to control the mass-inflow rate and open and close the inlet. Material exits the domain through the right-hand side of the rectangular domain and lands on a balance. This measures the mass accumulation as a function of time. The left-hand stand adjusts the inclination angle of the system, whilst the right-hand stand has a fixed height, allowing for in-plane rotation.

Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003, Reference Taberlet, Richard, Henry and Delannay2004) observed that at steady state, a super-stable slope was inclined at a constant angle ![]() $\zeta$ and had a flow of uniform depth

$\zeta$ and had a flow of uniform depth ![]() $h$ along its surface (measured perpendicular to the free surface). They used a simple force balance argument to show that for a chute of width

$h$ along its surface (measured perpendicular to the free surface). They used a simple force balance argument to show that for a chute of width ![]() $W$, the slope inclination angle satisfies

$W$, the slope inclination angle satisfies

where ![]() $\mu _i$ is a constant internal friction angle and

$\mu _i$ is a constant internal friction angle and ![]() $\mu _w$ is the wall friction. Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003) found that for dry polydisperse beach sand (0.1–0.8 mm), the best fit to the experimental data was obtained with

$\mu _w$ is the wall friction. Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003) found that for dry polydisperse beach sand (0.1–0.8 mm), the best fit to the experimental data was obtained with ![]() $\mu _i=\tan 23.3^\circ$ and

$\mu _i=\tan 23.3^\circ$ and ![]() $\mu _w=\tan {33.7^\circ }$. The experiments showed that as the mass-inflow rate was increased, the flow layer depth increased, and the pile inclination steepened in agreement with (1.1). For high mass-inflow rates in narrow channels, the slopes were in excess of

$\mu _w=\tan {33.7^\circ }$. The experiments showed that as the mass-inflow rate was increased, the flow layer depth increased, and the pile inclination steepened in agreement with (1.1). For high mass-inflow rates in narrow channels, the slopes were in excess of ![]() $60^\circ$, which is over 2.5 times the inclination angle in a wide chute.

$60^\circ$, which is over 2.5 times the inclination angle in a wide chute.

Taberlet, Richard & Delannay (Reference Taberlet, Richard and Delannay2008) used three-dimensional discrete element method/discrete particle method (DEM/DPM) simulations, with frictional sidewalls, to model the development of a super-stable heap. This was computationally very expensive, however, and there was little analysis of the growth of the heap, and no analysis of its decay. Instead, Taberlet et al. (Reference Taberlet, Richard, Henry and Delannay2004) focussed on DEM/DPM simulations in a short periodic box that was inclined at a fixed angle ![]() $\zeta$ to the horizontal, which developed a steady uniform flow that transported the same mass flux as the full simulation. These periodic simulations showed that as well as developing a velocity profile that increased strongly towards the top of the pile, the solids volume fraction decreased continuously towards the free surface, which itself was poorly defined. The fact that super-stable heaps develop steady uniform flows along their free surfaces makes them of fundamental rheological interest. This is because measurements of the velocity profiles and slope inclination angle at different mass-inflow rates can be used to constrain the granular rheology and determine parameter values and/or functional fits (GDR MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006).

$\zeta$ to the horizontal, which developed a steady uniform flow that transported the same mass flux as the full simulation. These periodic simulations showed that as well as developing a velocity profile that increased strongly towards the top of the pile, the solids volume fraction decreased continuously towards the free surface, which itself was poorly defined. The fact that super-stable heaps develop steady uniform flows along their free surfaces makes them of fundamental rheological interest. This is because measurements of the velocity profiles and slope inclination angle at different mass-inflow rates can be used to constrain the granular rheology and determine parameter values and/or functional fits (GDR MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006).

The aim of this paper is to use a continuum theory to model the growth, steady-state behaviour and drainage of a super-stable heap. This is more challenging than one might imagine at first, because the flow encompasses simultaneously existing and evolving solid-like, liquid-like and gaseous granular regions. The focus of the modelling here is on the dense solid and liquid regimes, while the dilute free-falling jet that supplies the grains from the hopper is parametrized in a simple way. Even with this reduced focus, the super-stable heap raises fundamental issues about modelling granular flows. Rate-independent Coulomb models, in which the inter-particle friction ![]() $\mu$ is constant (Drucker & Prager Reference Drucker and Prager1952), are not appropriate, because they are unable to determine the steady uniform velocity profile that develops at the surface of the flow. Besides, for time-dependent problems, Schaeffer (Reference Schaeffer1987) showed that the Drucker–Prager rheology was mathematically ill-posed, in the sense that linear instabilities grew at an unbounded rate as the wavenumber of the perturbation tended to infinity (Joseph & Saut Reference Joseph and Saut1990).

$\mu$ is constant (Drucker & Prager Reference Drucker and Prager1952), are not appropriate, because they are unable to determine the steady uniform velocity profile that develops at the surface of the flow. Besides, for time-dependent problems, Schaeffer (Reference Schaeffer1987) showed that the Drucker–Prager rheology was mathematically ill-posed, in the sense that linear instabilities grew at an unbounded rate as the wavenumber of the perturbation tended to infinity (Joseph & Saut Reference Joseph and Saut1990).

Over the past fifteen years, there has been significant development in the continuum modelling of granular materials. Many of the theories are complex; however, the incompressible ![]() $\mu (I)$-rheology (Jop et al. Reference Jop, Forterre and Pouliquen2006) has garnered considerable attention, because of its comparative simplicity, and its ability to describe steady-state liquid-like flows in a variety of configurations (GDR MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005; Jop et al. Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014). It is a rate-dependent theory, in which the friction

$\mu (I)$-rheology (Jop et al. Reference Jop, Forterre and Pouliquen2006) has garnered considerable attention, because of its comparative simplicity, and its ability to describe steady-state liquid-like flows in a variety of configurations (GDR MiDi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005; Jop et al. Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014). It is a rate-dependent theory, in which the friction ![]() $\mu$ now becomes a function of the dimensionless inertial number

$\mu$ now becomes a function of the dimensionless inertial number

where ![]() $\dot {\gamma }$ is the shear rate,

$\dot {\gamma }$ is the shear rate, ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\rho _*$ is the intrinsic density of the grains, and

$\rho _*$ is the intrinsic density of the grains, and ![]() $d$ is the particle diameter (GDR MiDi 2004). In the original form of the

$d$ is the particle diameter (GDR MiDi 2004). In the original form of the ![]() $\mu (I)$-rheology, the friction

$\mu (I)$-rheology, the friction

starts at a finite value ![]() $\mu _s>0$, when

$\mu _s>0$, when ![]() $I=0$, and asymptotes to

$I=0$, and asymptotes to ![]() $\mu _d>\mu _s$ as

$\mu _d>\mu _s$ as ![]() $I\rightarrow \infty$. It is valid in what is known as the dense inertial regime (

$I\rightarrow \infty$. It is valid in what is known as the dense inertial regime (![]() $I\in [10^{-3},10^{-1}]$), where the flow is liquid-like. However, most practical problems involve transitions to quasi-static flow (

$I\in [10^{-3},10^{-1}]$), where the flow is liquid-like. However, most practical problems involve transitions to quasi-static flow (![]() $I<10^{-3}$) and/or collisional behaviour (

$I<10^{-3}$) and/or collisional behaviour (![]() $I>10^{-1}$). This has led to problems when trying to use the

$I>10^{-1}$). This has led to problems when trying to use the ![]() $\mu (I)$-rheology to simulate column collapses and silos (Lagrée, Staron & Popinet Reference Lagrée, Staron and Popinet2011; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2012; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017), because the theory is ill-posed at high and low inertial numbers (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015).

$\mu (I)$-rheology to simulate column collapses and silos (Lagrée, Staron & Popinet Reference Lagrée, Staron and Popinet2011; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2012; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017), because the theory is ill-posed at high and low inertial numbers (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015).

Ill-posedness of mathematical models is a common, yet insidious, problem. This is because low-resolution simulations may be regularized by numerical diffusion and appear plausible. It is only when the numerical grid is refined that it becomes apparent that the results do not converge towards a well-defined solution, and blow up if the grid is sufficiently fine (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019). It is possible to formulate well-posed granular rheologies by introducing compressibility, although the original form of the compressible ![]() $\mu (I)$-rheology, with a rigid one-to-one dependence of the solids volume fraction

$\mu (I)$-rheology, with a rigid one-to-one dependence of the solids volume fraction ![]() $\varPhi$ on

$\varPhi$ on ![]() $I$, is always ill-posed (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Goddard & Lee Reference Goddard and Lee2018; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019). Other approaches to obtain a well-posed

$I$, is always ill-posed (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Goddard & Lee Reference Goddard and Lee2018; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019). Other approaches to obtain a well-posed ![]() $\mu (I)$-based theory are to include either non-local effects or higher spatial gradients (Bouzid et al. Reference Bouzid, Trulsson, Claudin, Clément and Andreotti2013; Henann & Kamrin Reference Henann and Kamrin2013; Goddard & Lee Reference Goddard and Lee2017). However, all of these theories introduce greater complexity into the modelling framework, and new numerical methods need to be developed to solve them.

$\mu (I)$-based theory are to include either non-local effects or higher spatial gradients (Bouzid et al. Reference Bouzid, Trulsson, Claudin, Clément and Andreotti2013; Henann & Kamrin Reference Henann and Kamrin2013; Goddard & Lee Reference Goddard and Lee2017). However, all of these theories introduce greater complexity into the modelling framework, and new numerical methods need to be developed to solve them.

This paper stays within the general framework of the ![]() $\mu (I)$-rheology, but uses a modified

$\mu (I)$-rheology, but uses a modified ![]() $\mu (I)$ relation, developed by Barker & Gray (Reference Barker and Gray2017). This completely regularizes the theory at low inertial numbers, and significantly extends the range of well-posedness at high inertial numbers. It is known as the partially regularized

$\mu (I)$ relation, developed by Barker & Gray (Reference Barker and Gray2017). This completely regularizes the theory at low inertial numbers, and significantly extends the range of well-posedness at high inertial numbers. It is known as the partially regularized ![]() $\mu (I)$-rheology. The major advantage of this is that it allows practical granular flow problems to be solved using numerical solvers that have been developed for fluid flows (Lagrée et al. Reference Lagrée, Staron and Popinet2011; Staron et al. Reference Staron, Lagrée and Popinet2012; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Maguire et al. Reference Maguire, Barker, Rauter, Johnson and Gray2024).

$\mu (I)$-rheology. The major advantage of this is that it allows practical granular flow problems to be solved using numerical solvers that have been developed for fluid flows (Lagrée et al. Reference Lagrée, Staron and Popinet2011; Staron et al. Reference Staron, Lagrée and Popinet2012; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021; Maguire et al. Reference Maguire, Barker, Rauter, Johnson and Gray2024).

This paper begins in § 2 by performing a series of experiments to quantify the growth, steady-state behaviour and decay of a super-stable granular heap. In § 3, the partially regularized ![]() $\mu (I)$-rheology is introduced, and the mass and momentum equations are averaged across the width of the cell, reducing a three-dimensional problem to a two-dimensional one in which the sidewall friction appears as a momentum source. In § 4, these equations are used to solve for the steady-state velocity profiles that develop through the depth of the uniform flow along the super-inclined free surface. It is shown that it is not always possible to construct solutions using the classical

$\mu (I)$-rheology is introduced, and the mass and momentum equations are averaged across the width of the cell, reducing a three-dimensional problem to a two-dimensional one in which the sidewall friction appears as a momentum source. In § 4, these equations are used to solve for the steady-state velocity profiles that develop through the depth of the uniform flow along the super-inclined free surface. It is shown that it is not always possible to construct solutions using the classical ![]() $\mu (I)$ law (1.3), whereas the partially regularized

$\mu (I)$ law (1.3), whereas the partially regularized ![]() $\mu (I)$ function always has solutions, and can capture the experimental behaviour at different mass fluxes using a single set of parameters. The numerical method to solve the equations is described in § 5, and this is then used in § 6 to quantitatively simulate the experimental growth and decay of a super-stable heap. The main results are summarized in § 7 along with limitations of the model and potential future avenues of research.

$\mu (I)$ function always has solutions, and can capture the experimental behaviour at different mass fluxes using a single set of parameters. The numerical method to solve the equations is described in § 5, and this is then used in § 6 to quantitatively simulate the experimental growth and decay of a super-stable heap. The main results are summarized in § 7 along with limitations of the model and potential future avenues of research.

2. Super-stable heap experiments

The experimental set-up consists of two ![]() $600\times 300\times 10\,{\rm mm}$ perspex sheets, which form a box that is separated by a 3 mm gap, as shown in figure 2. The gap width is slightly narrower than the smallest width selected by Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003), which makes the wall friction effects slightly stronger, and ensures that there is a blunt velocity profile across the width of the cell (Jop et al. Reference Jop, Forterre and Pouliquen2005). Observations made at the sidewall are therefore representative of the flow across the cell width. A perspex bar parallel to the base provides a boundary for the grains to flow and accumulate on. Additional perspex spacers along the left and top boundaries are used to set the gap width. The experimental domain rests on two ‘legs’. The right leg remains fixed, and the experimental domain is able to pivot about this point. The left leg is adjustable and can raise/lower the left-hand side of the domain to allow for the inclination angle of the system to be adjusted. A small silo is attached to the top of the domain to supply the grains. The inlet is controlled by two gates. One gate is fixed in position to control the mass-inflow rate, while the other gate opens and closes the inlet. Material exits the domain through the right-hand boundary, and lands on a balance that records the weight as a function of time.

$600\times 300\times 10\,{\rm mm}$ perspex sheets, which form a box that is separated by a 3 mm gap, as shown in figure 2. The gap width is slightly narrower than the smallest width selected by Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003), which makes the wall friction effects slightly stronger, and ensures that there is a blunt velocity profile across the width of the cell (Jop et al. Reference Jop, Forterre and Pouliquen2005). Observations made at the sidewall are therefore representative of the flow across the cell width. A perspex bar parallel to the base provides a boundary for the grains to flow and accumulate on. Additional perspex spacers along the left and top boundaries are used to set the gap width. The experimental domain rests on two ‘legs’. The right leg remains fixed, and the experimental domain is able to pivot about this point. The left leg is adjustable and can raise/lower the left-hand side of the domain to allow for the inclination angle of the system to be adjusted. A small silo is attached to the top of the domain to supply the grains. The inlet is controlled by two gates. One gate is fixed in position to control the mass-inflow rate, while the other gate opens and closes the inlet. Material exits the domain through the right-hand boundary, and lands on a balance that records the weight as a function of time.

All experimental results in this paper are obtained using ![]() $710\unicode{x2013}750\,\mathrm {\mu }{\rm m}$ spherical sodalime-glass deco beads manufactured by Sigmund Lindner GmbH, which are large enough that the humidity does not effect their flow properties. The beads have a

$710\unicode{x2013}750\,\mathrm {\mu }{\rm m}$ spherical sodalime-glass deco beads manufactured by Sigmund Lindner GmbH, which are large enough that the humidity does not effect their flow properties. The beads have a ![]() $2\,\mathrm {\mu }{\rm m}$ base coating of silver, and a

$2\,\mathrm {\mu }{\rm m}$ base coating of silver, and a ![]() $1\unicode{x2013}3\,\mathrm {\mu }{\rm m}$ coloured coating formed by a Sol-Gel process, which is very stable to wear and stable over time. The results also assume that the rectangular domain is inclined at a fixed angle

$1\unicode{x2013}3\,\mathrm {\mu }{\rm m}$ coloured coating formed by a Sol-Gel process, which is very stable to wear and stable over time. The results also assume that the rectangular domain is inclined at a fixed angle ![]() $\theta = 29.2^\circ$ to the horizontal, which is above the repose angle of the grains of approximately

$\theta = 29.2^\circ$ to the horizontal, which is above the repose angle of the grains of approximately ![]() $22^\circ$ (figure 1). In the absence of sidewall friction, the grains falling from the hopper would impact the base, flow down the slope, and exit the domain. Here, however, the sidewall friction provides additional resistance, which reduces the flow rate down the incline and allows a super-stable heap to develop (figure 2).

$22^\circ$ (figure 1). In the absence of sidewall friction, the grains falling from the hopper would impact the base, flow down the slope, and exit the domain. Here, however, the sidewall friction provides additional resistance, which reduces the flow rate down the incline and allows a super-stable heap to develop (figure 2).

Figure 3 shows the complete time-dependent development towards a steady super-stable heap for inflow rate ![]() $0.0046\,{\rm kg}\,{\rm s}^{-1}$, as well as the subsequent drainage once the inflow is cut off. The inflowing grains fall from the hopper, hit the bed, and flow down the incline and out of the domain. However, the sidewall friction retards the flow sufficiently that the outflow rate is less than the inflow rate. As a result, a pile of static grains begins to form, with its apex directly underneath the free-falling jet and its right-hand toe located at the outlet. Grains that fall onto the top of the pile mainly avalanche down the right-hand face in a thin layer towards the outflow. In order to account for the mismatch in inflow and outflow rates, some of the inflowing particles are deposited along the free surface of the pile, with more being deposited near its apex than near the outlet. The net effect of this is that the free surface remains approximately linear in shape, but steepens over time (Taberlet et al. Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003). This progressive steepening allows the grains to avalanche down the slope faster, and ultimately the mass-inflow and mass-outflow rates are able to balance. A steady state is then reached in which there is no deposition. To balance the growth of the right-hand pile face, there has to be a corresponding growth in the left-hand face to keep the pile stable. Some grains therefore also avalanche down the left-hand side to build the pile up. Once the pile of grains has reached steady state, the flow of grains down the left-hand face stops, as shown in movie 1 of the supplementary material (available at https://doi.org/10.1017/jfm.2024.1106), and all the inflowing grains avalanche down the right-hand face. Figure 3(a vi) shows the steady-state super-stable heap. All the free-surface profiles during its growth are superimposed on this image for comparison. From this, it is easy to see the gradual steepening of the pile (on both the left- and right-hand faces), as well as the rising of the apex with time. Note that the right-hand face is significantly steeper than the left-hand face, and the growth of the pile slows down as the steady state is approached.

$0.0046\,{\rm kg}\,{\rm s}^{-1}$, as well as the subsequent drainage once the inflow is cut off. The inflowing grains fall from the hopper, hit the bed, and flow down the incline and out of the domain. However, the sidewall friction retards the flow sufficiently that the outflow rate is less than the inflow rate. As a result, a pile of static grains begins to form, with its apex directly underneath the free-falling jet and its right-hand toe located at the outlet. Grains that fall onto the top of the pile mainly avalanche down the right-hand face in a thin layer towards the outflow. In order to account for the mismatch in inflow and outflow rates, some of the inflowing particles are deposited along the free surface of the pile, with more being deposited near its apex than near the outlet. The net effect of this is that the free surface remains approximately linear in shape, but steepens over time (Taberlet et al. Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003). This progressive steepening allows the grains to avalanche down the slope faster, and ultimately the mass-inflow and mass-outflow rates are able to balance. A steady state is then reached in which there is no deposition. To balance the growth of the right-hand pile face, there has to be a corresponding growth in the left-hand face to keep the pile stable. Some grains therefore also avalanche down the left-hand side to build the pile up. Once the pile of grains has reached steady state, the flow of grains down the left-hand face stops, as shown in movie 1 of the supplementary material (available at https://doi.org/10.1017/jfm.2024.1106), and all the inflowing grains avalanche down the right-hand face. Figure 3(a vi) shows the steady-state super-stable heap. All the free-surface profiles during its growth are superimposed on this image for comparison. From this, it is easy to see the gradual steepening of the pile (on both the left- and right-hand faces), as well as the rising of the apex with time. Note that the right-hand face is significantly steeper than the left-hand face, and the growth of the pile slows down as the steady state is approached.

Figure 3. Photographs of the (a) experimental formation and (b) draining of the super-stable heap, for slope angle ![]() $\theta = 29.2^\circ$ and mass-inflow rate

$\theta = 29.2^\circ$ and mass-inflow rate ![]() $Q = 0.0046\,{\rm kg}\,{\rm s}^{-1}$. The inlet is opened at

$Q = 0.0046\,{\rm kg}\,{\rm s}^{-1}$. The inlet is opened at ![]() $t_{exp} = 0$, and the photos of the filling are taken at

$t_{exp} = 0$, and the photos of the filling are taken at ![]() $t_{exp} = 6$, 12, 20, 43, 83 and

$t_{exp} = 6$, 12, 20, 43, 83 and ![]() $321$ s. Photo (a vi) shows the steady state, with the earlier free-surface profiles superimposed for comparison. The inlet is cut off at

$321$ s. Photo (a vi) shows the steady state, with the earlier free-surface profiles superimposed for comparison. The inlet is cut off at ![]() $t_{exp} = 340.5$ s. The draining images are at times

$t_{exp} = 340.5$ s. The draining images are at times ![]() $t_{exp} = 341$, 344, 346, 370, 398 and 424 s. For comparison, the free-surface shapes during the draining phase are superimposed on the first of these images. All of the material leaves the domain at

$t_{exp} = 341$, 344, 346, 370, 398 and 424 s. For comparison, the free-surface shapes during the draining phase are superimposed on the first of these images. All of the material leaves the domain at ![]() $t_{exp} = 429.5$ s. Movie 1 of the supplementary material shows the growth and decay of a closely similar super-stable heap for a mass-inflow rate

$t_{exp} = 429.5$ s. Movie 1 of the supplementary material shows the growth and decay of a closely similar super-stable heap for a mass-inflow rate ![]() $Q = 0.0060\,{\rm kg}\,{\rm s}^{-1}$.

$Q = 0.0060\,{\rm kg}\,{\rm s}^{-1}$.

At steady state, the super-stable heap is stabilized by the material that flows across its surface. As soon as the inflow is cut off, this delicate balance is destroyed, the pile is gradually eroded, and the particles flow out of the domain along the free surface as shown in figure 3(b). The first photo shows the heap almost immediately after the inflow is shut off, when the pile is still close to steady state. The later photos show the evolution of the heap as it drains. All the free-surface profiles are superimposed on the first image to contrast it against the growth phase of the pile. Rather than keeping a linear profile, as in the case of growth, the top of the pile initially erodes faster than the material near the outlet, which is still stabilized by the grains flowing over it. The upper part of the right-hand face therefore has a lower inclination than material further down the pile, where the steady-state inclination is maintained for a short period. Since the flow rate decreases progressively, the region close to the steady-state inclination is eventually propagated out of the system, and erosion occurs all the way along the right-hand side of the free surface. The left-hand free surface remains stationary and unaffected by the outflow, until the surface avalanche erodes downwards and mobilizes it. Since the angle of repose of the granular material is less than ![]() $\theta =29.2^\circ$, the heap is able to drain entirely. Movie 1 of the supplementary material shows the full time-dependent growth and collapse of a closely similar pile that forms at mass-inflow rate

$\theta =29.2^\circ$, the heap is able to drain entirely. Movie 1 of the supplementary material shows the full time-dependent growth and collapse of a closely similar pile that forms at mass-inflow rate ![]() $Q = 0.0060\,{\rm kg}\,{\rm s}^{-1}$.

$Q = 0.0060\,{\rm kg}\,{\rm s}^{-1}$.

Higher mass-inflow rates spontaneously develop steeper slopes in order to transport the inflowing material out of the domain, and hence produce a larger steady-state heap. This is shown in figure 4 for mass-inflow rates ![]() $Q = 0.0020$,

$Q = 0.0020$, ![]() $0.0046$ and

$0.0046$ and ![]() $0.0060\,{\rm kg}\,{\rm s}^{-1}$. The balance beneath the outlet records the total mass that has flowed out of the system as a function of time, from which the mass-outflow rate can be calculated by taking the time derivative of the data. Figure 5 shows both the total accumulated mass and the mass-outflow rate as functions of time for each of the mass-inflow rates in figure 4. All of the curves have a similar form. At time

$0.0060\,{\rm kg}\,{\rm s}^{-1}$. The balance beneath the outlet records the total mass that has flowed out of the system as a function of time, from which the mass-outflow rate can be calculated by taking the time derivative of the data. Figure 5 shows both the total accumulated mass and the mass-outflow rate as functions of time for each of the mass-inflow rates in figure 4. All of the curves have a similar form. At time ![]() $t_{exp} = 0$ s, the inlet is opened. Initially, there is no mass, and there is a short delay, from the start of the inflow to the time at which material first arrives at the balance. Since some mass is deposited between the hopper and the balance (in order to build the pile) the initial mass-outflow rate is not equal to the mass-inflow rate. As the pile gets steeper, however, the mass-outflow rate steadily rises over time until the mass-inflow and mass-outflow rates balance. This corresponds to the linearly increasing section of the curves in figure 5(a) and the horizontal plateau in figure 5(b). Larger mass-inflow rates necessarily produce higher gradient mass accumulation curves. This is similar to what Taberlet et al. (Reference Taberlet, Richard, Henry and Delannay2004, Reference Taberlet, Richard and Delannay2008) found in their DEM/DPM simulations. The length of the steady-state sections is dependent on how long the inflow is sustained. Once the inflow is shut off, there is a gradual decrease in the mass-outflow rate towards zero, and the total mass on the balance asymptotes to a constant value. In the experiments, the total mass that accumulates on the scales is different for each of the three cases. However, unsurprisingly, if one wanted to accumulate the same total mass, then the low mass-inflow rate case would have to be run for far longer than the largest inflow rate case.

$t_{exp} = 0$ s, the inlet is opened. Initially, there is no mass, and there is a short delay, from the start of the inflow to the time at which material first arrives at the balance. Since some mass is deposited between the hopper and the balance (in order to build the pile) the initial mass-outflow rate is not equal to the mass-inflow rate. As the pile gets steeper, however, the mass-outflow rate steadily rises over time until the mass-inflow and mass-outflow rates balance. This corresponds to the linearly increasing section of the curves in figure 5(a) and the horizontal plateau in figure 5(b). Larger mass-inflow rates necessarily produce higher gradient mass accumulation curves. This is similar to what Taberlet et al. (Reference Taberlet, Richard, Henry and Delannay2004, Reference Taberlet, Richard and Delannay2008) found in their DEM/DPM simulations. The length of the steady-state sections is dependent on how long the inflow is sustained. Once the inflow is shut off, there is a gradual decrease in the mass-outflow rate towards zero, and the total mass on the balance asymptotes to a constant value. In the experiments, the total mass that accumulates on the scales is different for each of the three cases. However, unsurprisingly, if one wanted to accumulate the same total mass, then the low mass-inflow rate case would have to be run for far longer than the largest inflow rate case.

Figure 4. Steady-state super-stable heaps for mass-inflow rates ![]() $Q = 0.0020$,

$Q = 0.0020$, ![]() $0.0046$ and

$0.0046$ and ![]() $0.0060\,{\rm kg}\,{\rm s}^{-1}$, and box inclination angle

$0.0060\,{\rm kg}\,{\rm s}^{-1}$, and box inclination angle ![]() $\theta = 29.2^\circ$. The pile size increases with increasing mass-inflow rate. It is useful to define three coordinate systems. The

$\theta = 29.2^\circ$. The pile size increases with increasing mass-inflow rate. It is useful to define three coordinate systems. The ![]() $(X,Z)$ coordinate system is used to represent the horizontal and gravity-aligned vertical, the

$(X,Z)$ coordinate system is used to represent the horizontal and gravity-aligned vertical, the ![]() $(\tilde {x},\tilde {z})$ system is aligned with the rectangular domain at angle

$(\tilde {x},\tilde {z})$ system is aligned with the rectangular domain at angle ![]() $\theta$ to the horizontal, and the

$\theta$ to the horizontal, and the ![]() $(x,z)$ system is aligned with the steady uniform flowing layer at angle

$(x,z)$ system is aligned with the steady uniform flowing layer at angle ![]() $\zeta$ to the horizontal. For the flow rates given, the heap inclination angles are

$\zeta$ to the horizontal. For the flow rates given, the heap inclination angles are ![]() $\zeta =41.63^\circ$, 49.35

$\zeta =41.63^\circ$, 49.35![]() $^\circ$ and 49.8

$^\circ$ and 49.8![]() $^\circ$, respectively.

$^\circ$, respectively.

Figure 5. (a) Accumulated mass and (b) the mass-outflow rate as functions of time for mass-inflow rates ![]() $Q=0.0020$,

$Q=0.0020$, ![]() $0.0046$ and

$0.0046$ and ![]() $0.0060\,{\rm kg}\,{\rm s}^{-1}$, and the box inclination angle

$0.0060\,{\rm kg}\,{\rm s}^{-1}$, and the box inclination angle ![]() $\theta =29.2^\circ$. The mass-outflow rate is calculated by taking the time derivative of the accumulated mass data. The inlet is opened at

$\theta =29.2^\circ$. The mass-outflow rate is calculated by taking the time derivative of the accumulated mass data. The inlet is opened at ![]() $t=0$ s, and the plateaus in total accumulated mass in (a) show where all of the material has drained from the system. The linear dot-dashed lines in (a) and the horizontal dot-dashed lines in (b) indicate the steady-state super-stable heap regime, when the mass-inflow rate equals the mass-outflow rate.

$t=0$ s, and the plateaus in total accumulated mass in (a) show where all of the material has drained from the system. The linear dot-dashed lines in (a) and the horizontal dot-dashed lines in (b) indicate the steady-state super-stable heap regime, when the mass-inflow rate equals the mass-outflow rate.

A JAI GO 5000C high-speed camera is oriented approximately parallel to the free surface of the super-stable heap, and used to collect 1000 images at ![]() $664$ fps of the steady-state flowing layer. Figure 6(a) shows an example

$664$ fps of the steady-state flowing layer. Figure 6(a) shows an example ![]() $1000 \times 120$ pixel image for a mass-inflow rate

$1000 \times 120$ pixel image for a mass-inflow rate ![]() $Q=0.0046\,{\rm kg}\,{\rm s}^{-1}$, with the camera inclined at

$Q=0.0046\,{\rm kg}\,{\rm s}^{-1}$, with the camera inclined at ![]() $48.9^\circ \pm 0.1^\circ$ to the horizontal. The PIVlab package (Thielicke & Stamhuis Reference Thielicke and Stamhuis2014) is used to generate velocity vectors (figure 6b), and the data are rotated by an additional

$48.9^\circ \pm 0.1^\circ$ to the horizontal. The PIVlab package (Thielicke & Stamhuis Reference Thielicke and Stamhuis2014) is used to generate velocity vectors (figure 6b), and the data are rotated by an additional ![]() $0.44^\circ$ to ensure that the down-slope direction is oriented along the

$0.44^\circ$ to ensure that the down-slope direction is oriented along the ![]() $x$ axis. The slope-aligned

$x$ axis. The slope-aligned ![]() $(x,z)$ coordinates are therefore inclined at

$(x,z)$ coordinates are therefore inclined at ![]() $\zeta = 49.34^\circ$ to the horizontal. Figure 6(c) shows the velocity magnitude

$\zeta = 49.34^\circ$ to the horizontal. Figure 6(c) shows the velocity magnitude ![]() $|{\boldsymbol {u}}|$ in the slope-aligned coordinates

$|{\boldsymbol {u}}|$ in the slope-aligned coordinates ![]() $(x,z)$. It is approximately spatially uniform in the down-slope direction, which motivates averaging the time-averaged data along the

$(x,z)$. It is approximately spatially uniform in the down-slope direction, which motivates averaging the time-averaged data along the ![]() $x$ direction to determine the velocity profile through the flow depth

$x$ direction to determine the velocity profile through the flow depth ![]() $z$.

$z$.

Figure 6. Panel (a) and movie 2 of the supplementary material show a ![]() $1000 \times 120$ pixel high-speed photo/image sequence of the grains flowing down the inclined free surface at mass-inflow rate

$1000 \times 120$ pixel high-speed photo/image sequence of the grains flowing down the inclined free surface at mass-inflow rate ![]() $Q=0.0046\,{\rm kg}\,{\rm s}^{-1}$. The camera is inclined at

$Q=0.0046\,{\rm kg}\,{\rm s}^{-1}$. The camera is inclined at ![]() $48.9^\circ \pm 0.1^\circ$ to the horizontal. One thousand of these images are used to construct the velocity field (b) using the PIVlab package (Thielicke & Stamhuis Reference Thielicke and Stamhuis2014). Green velocity vectors are obtained from particle image velocimetry (PIV) analysis, and the red ones are interpolated from the surrounding field. (c) The time-averaged velocity magnitude in

$48.9^\circ \pm 0.1^\circ$ to the horizontal. One thousand of these images are used to construct the velocity field (b) using the PIVlab package (Thielicke & Stamhuis Reference Thielicke and Stamhuis2014). Green velocity vectors are obtained from particle image velocimetry (PIV) analysis, and the red ones are interpolated from the surrounding field. (c) The time-averaged velocity magnitude in ![]() $(x,z)$ coordinates, which lie at an angle

$(x,z)$ coordinates, which lie at an angle ![]() $\zeta = 49.34^\circ$ to the horizontal. The white line is the horizontally averaged velocity magnitude

$\zeta = 49.34^\circ$ to the horizontal. The white line is the horizontally averaged velocity magnitude ![]() $|{\boldsymbol {u}}|$ through the flow depth. Note that the velocity scale is aligned with the colour bar for the contour map.

$|{\boldsymbol {u}}|$ through the flow depth. Note that the velocity scale is aligned with the colour bar for the contour map.

From the high-speed photographs (e.g. figure 6a) it is difficult to define the exact position of the free surface. Indeed, the Taberlet et al. (Reference Taberlet, Richard and Delannay2008) steady uniform DEM/DPM solutions show that the solids volume fraction decreases continuously through the flowing layer, and that there is a sparse region above it where the particles undergo ballistic motion. In order to compare the experimental velocity data with the incompressible theory (used in this paper), the free surface (![]() $z=0$) is defined by assuming a constant density throughout the material, and matching the mass-inflow rate implied by the measured velocity profiles with the rate measured by the balance. Figure 7 shows the resultant velocity profiles for the three mass-inflow rates

$z=0$) is defined by assuming a constant density throughout the material, and matching the mass-inflow rate implied by the measured velocity profiles with the rate measured by the balance. Figure 7 shows the resultant velocity profiles for the three mass-inflow rates ![]() $Q = 0.0020$,

$Q = 0.0020$, ![]() $0.0046$ and

$0.0046$ and ![]() $0.0060\,{\rm kg}\,{\rm s}^{-1}$. Higher rates lead to higher velocities and deeper flows, but these also occur on steeper slopes. Note that the sections of the velocity data that are neglected correspond to regions where the solids volume fraction is low, so the error associated with the procedure to define the free surface is not that large.

$0.0060\,{\rm kg}\,{\rm s}^{-1}$. Higher rates lead to higher velocities and deeper flows, but these also occur on steeper slopes. Note that the sections of the velocity data that are neglected correspond to regions where the solids volume fraction is low, so the error associated with the procedure to define the free surface is not that large.

Figure 7. Steady uniform velocity profiles measured using PIV for mass-inflow rates ![]() $Q = 0.0020$,

$Q = 0.0020$, ![]() $0.0046$ and

$0.0046$ and ![]() $0.0060\,{\rm kg}\,{\rm s}^{-1}$, which generate slopes at

$0.0060\,{\rm kg}\,{\rm s}^{-1}$, which generate slopes at ![]() $\zeta =41.63^\circ$, 49.35

$\zeta =41.63^\circ$, 49.35![]() $^\circ$ and 49.8

$^\circ$ and 49.8![]() $^\circ$ to the horizontal, respectively. The

$^\circ$ to the horizontal, respectively. The ![]() $z$ coordinate lies perpendicular to the inclined free surface, which is defined at

$z$ coordinate lies perpendicular to the inclined free surface, which is defined at ![]() $z = 0$. The dot-dashed lines represent velocity data that have been removed to ensure that the mass-inflow rates agree with that measured at the outlet. Since the solids volume fraction is very small in this region, this is not a large discrepancy.

$z = 0$. The dot-dashed lines represent velocity data that have been removed to ensure that the mass-inflow rates agree with that measured at the outlet. Since the solids volume fraction is very small in this region, this is not a large discrepancy.

3. Governing equations

The aim of this paper is to use the incompressible partially regularized ![]() $\mu (I)$-rheology of Barker & Gray (Reference Barker and Gray2017) to model the formation, steady-state behaviour and drainage of a super-stable heap. The granular material is therefore assumed to have constant density

$\mu (I)$-rheology of Barker & Gray (Reference Barker and Gray2017) to model the formation, steady-state behaviour and drainage of a super-stable heap. The granular material is therefore assumed to have constant density ![]() $\rho =\varPhi \rho _*$, where

$\rho =\varPhi \rho _*$, where ![]() $\varPhi$ is the solids volume fraction, and

$\varPhi$ is the solids volume fraction, and ![]() $\rho _*$ is the intrinsic density of the material that the grains are made of. This is a good leading-order approximation throughout most of the body, although this assumption fails close to the free surface of the avalanching layer, where the solids volume fraction reduces significantly (Taberlet et al. Reference Taberlet, Richard and Delannay2008).

$\rho _*$ is the intrinsic density of the material that the grains are made of. This is a good leading-order approximation throughout most of the body, although this assumption fails close to the free surface of the avalanching layer, where the solids volume fraction reduces significantly (Taberlet et al. Reference Taberlet, Richard and Delannay2008).

3.1. Integration across the experiment width

For the experiments in § 2, the frictional sidewalls are sufficiently close together that the velocity profile across the cell width is plug-like (Taberlet et al. Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003; Jop et al. Reference Jop, Forterre and Pouliquen2005). This motivates integration across the narrow gap to remove one spatial dimension from the problem. Assuming Cartesian coordinates ![]() $Ox_i$,

$Ox_i$, ![]() $i=1,2,3$, with the

$i=1,2,3$, with the ![]() $x_1$ and

$x_1$ and ![]() $x_3$ coordinates in the plane of the experiment, and the

$x_3$ coordinates in the plane of the experiment, and the ![]() $x_2$ coordinate lying across the width

$x_2$ coordinate lying across the width ![]() $W$, the incompressibility condition is

$W$, the incompressibility condition is

where ![]() $u_i$,

$u_i$, ![]() $i=1,2,3$, are the velocity components in the directions

$i=1,2,3$, are the velocity components in the directions ![]() $x_i$, respectively. Equation (3.1) can be integrated across the width of the cell by exchanging the order of integration with respect to

$x_i$, respectively. Equation (3.1) can be integrated across the width of the cell by exchanging the order of integration with respect to ![]() $x_2$ and differentiation with respect to

$x_2$ and differentiation with respect to ![]() $x_1$ and

$x_1$ and ![]() $x_3$, and assuming that

$x_3$, and assuming that ![]() $u_2=0$ at

$u_2=0$ at ![]() $x_2=0,W$. Dividing the resulting equation by the constant cell width

$x_2=0,W$. Dividing the resulting equation by the constant cell width ![]() $W$ yields a two-dimensional width-averaged incompressibility condition

$W$ yields a two-dimensional width-averaged incompressibility condition

where the width-averaged velocities in the plane of the cell are defined as

The in-plane momentum balances (for ![]() $i=1,3$) are

$i=1,3$) are

where ![]() $g_i$ is the

$g_i$ is the ![]() $i\text {th}$ component of the gravity acceleration vector

$i\text {th}$ component of the gravity acceleration vector ![]() ${\boldsymbol {g}}$, and

${\boldsymbol {g}}$, and ![]() $\sigma _{ij}$ is the

$\sigma _{ij}$ is the ![]() $i, j$ component of the Cauchy stress tensor

$i, j$ component of the Cauchy stress tensor ![]() ${\boldsymbol {\sigma }}$. The momentum balances (3.4) can also be averaged across the cell by exchanging the order of integration and differentiation. Moreover, the plug-like velocity profiles across the cell imply that the integrals of the momentum transport terms can be simplified, to give

${\boldsymbol {\sigma }}$. The momentum balances (3.4) can also be averaged across the cell by exchanging the order of integration and differentiation. Moreover, the plug-like velocity profiles across the cell imply that the integrals of the momentum transport terms can be simplified, to give

where the width-averaged stresses are

The shear stresses on the sidewalls are assumed to be given by a Coulomb law of the form

where ![]() $\mu _w$ is a constant friction coefficient,

$\mu _w$ is a constant friction coefficient, ![]() $p$ is the pressure acting on the wall, and the factor

$p$ is the pressure acting on the wall, and the factor ![]() $-\bar u_i/|\bar {{\boldsymbol {u}}}|$ ensures that the friction opposes the motion. This is consistent with the equations used by Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003, Reference Taberlet, Richard, Henry and Delannay2004, Reference Taberlet, Richard and Delannay2008) and Jop et al. (Reference Jop, Forterre and Pouliquen2005), although more complex friction laws that relate the slip velocity to the granular temperature are possible (Artoni & Richard Reference Artoni and Richard2015). Near the free surface of the heap, the velocity is predominantly down-slope, so the direction of the friction is well defined. Deeper down within the flow,

$-\bar u_i/|\bar {{\boldsymbol {u}}}|$ ensures that the friction opposes the motion. This is consistent with the equations used by Taberlet et al. (Reference Taberlet, Richard, Valance, Losert, Pasini, Jenkins and Delannay2003, Reference Taberlet, Richard, Henry and Delannay2004, Reference Taberlet, Richard and Delannay2008) and Jop et al. (Reference Jop, Forterre and Pouliquen2005), although more complex friction laws that relate the slip velocity to the granular temperature are possible (Artoni & Richard Reference Artoni and Richard2015). Near the free surface of the heap, the velocity is predominantly down-slope, so the direction of the friction is well defined. Deeper down within the flow, ![]() $\bar {{\boldsymbol {u}}}$ can be zero. For sufficiently small creep, a

$\bar {{\boldsymbol {u}}}$ can be zero. For sufficiently small creep, a ![]() $\tanh$ profile regularization is therefore used to allow the friction to smoothly transition through

$\tanh$ profile regularization is therefore used to allow the friction to smoothly transition through ![]() $\bar {{\boldsymbol {u}}}={\boldsymbol {0}}$.

$\bar {{\boldsymbol {u}}}={\boldsymbol {0}}$.

The outward-pointing normal at ![]() $x_2=0$ is

$x_2=0$ is ![]() ${\boldsymbol {n}}(0)=(0,-1,0)$, while at

${\boldsymbol {n}}(0)=(0,-1,0)$, while at ![]() $x_2=W$, we have

$x_2=W$, we have ![]() ${\boldsymbol {n}}(W)=(0,1,0)$. These definitions allow (3.7) to be used to solve for

${\boldsymbol {n}}(W)=(0,1,0)$. These definitions allow (3.7) to be used to solve for ![]() $\sigma _{i2}$ at

$\sigma _{i2}$ at ![]() $x_2=0,W$. Substituting these values into (3.5) implies that the width-averaged momentum balances in the plane of the cell are

$x_2=0,W$. Substituting these values into (3.5) implies that the width-averaged momentum balances in the plane of the cell are

where the momentum transport terms have been simplified using the width-averaged incompressibility relation (3.2). Equation (3.8) looks similar to the original momentum balance (3.4), but it is now defined in just two dimensions, with the lateral wall friction entering as a local source term. The width-averaged mass and momentum balances (3.2) and (3.8) can be written in vector notation as

where the averaging bars have now been dropped for notational simplicity (here and throughout the rest of the paper), and the gradient and dot product operators ![]() ${\boldsymbol {\nabla }}$ and

${\boldsymbol {\nabla }}$ and ![]() ${\boldsymbol {\cdot }}$ are understood to act in two dimensions. The conservation equations (3.9)–(3.10) hold in any of the coordinate systems

${\boldsymbol {\cdot }}$ are understood to act in two dimensions. The conservation equations (3.9)–(3.10) hold in any of the coordinate systems ![]() $(X,Z)$,

$(X,Z)$, ![]() $(x,z)$ and

$(x,z)$ and ![]() $(\tilde x,\tilde z)$ defined in figure 4.

$(\tilde x,\tilde z)$ defined in figure 4.

3.2. The  $\mu (I)$-rheology for granular flows

$\mu (I)$-rheology for granular flows

The Cauchy stress is decomposed into an isotropic pressure ![]() $p$ and a deviatoric stress

$p$ and a deviatoric stress ![]() ${\boldsymbol {\tau }}$,

${\boldsymbol {\tau }}$,

where ![]() ${\boldsymbol {1}}$ is the unit tensor (in two dimensions). The

${\boldsymbol {1}}$ is the unit tensor (in two dimensions). The ![]() $\mu (I)$-rheology for granular flows (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) is a nonlinear viscous law that relates the deviatoric stress

$\mu (I)$-rheology for granular flows (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) is a nonlinear viscous law that relates the deviatoric stress ![]() ${\boldsymbol {\tau }}$ to the strain-rate tensor

${\boldsymbol {\tau }}$ to the strain-rate tensor ![]() ${\boldsymbol {D}}=({\boldsymbol {\nabla }}{\boldsymbol {u}}+({\boldsymbol {\nabla }}{\boldsymbol {u}})^{\rm T})/2$ (where

${\boldsymbol {D}}=({\boldsymbol {\nabla }}{\boldsymbol {u}}+({\boldsymbol {\nabla }}{\boldsymbol {u}})^{\rm T})/2$ (where ![]() $T$ indicates transpose). The deviatoric stress and the strain rate are assumed to be aligned with one another:

$T$ indicates transpose). The deviatoric stress and the strain rate are assumed to be aligned with one another:

where

is the second invariant of the enclosed tensor. In addition, there is a yield condition of the form

where the internal friction ![]() $\mu$ is a function of the non-dimensional inertial number (1.2), which in tensorial notation becomes

$\mu$ is a function of the non-dimensional inertial number (1.2), which in tensorial notation becomes

Substituting for the Cauchy stress (3.11) and the alignment and yield conditions (3.12) and (3.14), it follows that the width-averaged momentum balance (3.10) can also be written in the form

where the granular viscosity

is pressure and strain-rate invariant dependent. The governing equations (3.9) and (3.16) are therefore of the form of the incompressible Navier–Stokes equations, making it appropriate to use computational fluid dynamics tools to solve the system numerically.

3.3. Drucker–Prager plasticity and mathematical ill-posedness

If the friction ![]() $\mu$ is constant, then the system reduces to the rate-independent Drucker–Prager model for plasticity (Drucker & Prager Reference Drucker and Prager1952). Schaeffer (Reference Schaeffer1987) showed that in this case, the equations are mathematically ill-posed over the complete range of parameter space. In this context, ill-posedness means that small perturbations to the system grow unboundedly in the high-wavenumber limit (Joseph & Saut Reference Joseph and Saut1990). This is catastrophic for numerical implementations, even though they may apparently yield plausible results at sufficiently low grid resolution. This is because numerical methods (i) are solved on grids with finite resolution, which truncates the instability, and (ii) introduce grid-dependent numerical diffusion. As a numerical grid is refined, the numerical diffusion diminishes, and progressively more unstable modes are resolved, so eventually these instabilities dominate the solution. The numerical solutions therefore become progressively more unstable on grid refinement, and do not converge towards a unique solution.

$\mu$ is constant, then the system reduces to the rate-independent Drucker–Prager model for plasticity (Drucker & Prager Reference Drucker and Prager1952). Schaeffer (Reference Schaeffer1987) showed that in this case, the equations are mathematically ill-posed over the complete range of parameter space. In this context, ill-posedness means that small perturbations to the system grow unboundedly in the high-wavenumber limit (Joseph & Saut Reference Joseph and Saut1990). This is catastrophic for numerical implementations, even though they may apparently yield plausible results at sufficiently low grid resolution. This is because numerical methods (i) are solved on grids with finite resolution, which truncates the instability, and (ii) introduce grid-dependent numerical diffusion. As a numerical grid is refined, the numerical diffusion diminishes, and progressively more unstable modes are resolved, so eventually these instabilities dominate the solution. The numerical solutions therefore become progressively more unstable on grid refinement, and do not converge towards a unique solution.

3.4. The classical  $\mu (I)$ curve and well-posedness

$\mu (I)$ curve and well-posedness

The incompressible ![]() $\mu (I)$-rheology (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) shares much of the same mathematical structure as the Drucker–Prager model, except that the friction

$\mu (I)$-rheology (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) shares much of the same mathematical structure as the Drucker–Prager model, except that the friction ![]() $\mu$ is dependent on the non-dimensional inertial number

$\mu$ is dependent on the non-dimensional inertial number ![]() $I$. In the original formulation, the

$I$. In the original formulation, the ![]() $\mu (I)$ function is given by (1.3), and starts at a value

$\mu (I)$ function is given by (1.3), and starts at a value ![]() $\mu _s$ when

$\mu _s$ when ![]() $I=0$, and asymptotes to

$I=0$, and asymptotes to ![]() $\mu _d>\mu _s$ as

$\mu _d>\mu _s$ as ![]() $I\rightarrow \infty$ (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006). A graph of the function is shown in figures 8(a,b). This inertial number dependence makes the theory rate and pressure dependent, whereas the Drucker–Prager model is rate independent. As a result, the incompressible

$I\rightarrow \infty$ (GDR MiDi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006). A graph of the function is shown in figures 8(a,b). This inertial number dependence makes the theory rate and pressure dependent, whereas the Drucker–Prager model is rate independent. As a result, the incompressible ![]() $\mu (I)$-rheology can have significantly better mathematical properties. This has allowed it to be used to calculate granular chute flows, column collapses and silo discharge (Jop et al. Reference Jop, Forterre and Pouliquen2006; Lagrée et al. Reference Lagrée, Staron and Popinet2011; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2014). However, Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) showed that the

$\mu (I)$-rheology can have significantly better mathematical properties. This has allowed it to be used to calculate granular chute flows, column collapses and silo discharge (Jop et al. Reference Jop, Forterre and Pouliquen2006; Lagrée et al. Reference Lagrée, Staron and Popinet2011; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2014). However, Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) showed that the ![]() $\mu (I)$-rheology was mathematically well-posed provided that the condition

$\mu (I)$-rheology was mathematically well-posed provided that the condition

was satisfied, where ![]() $\mu ' = \mathrm {d}\mu /\mathrm {d}I$. For the classical

$\mu ' = \mathrm {d}\mu /\mathrm {d}I$. For the classical ![]() $\mu (I)$ function (1.3), Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) showed that provided that

$\mu (I)$ function (1.3), Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) showed that provided that ![]() $\mu _d-\mu _s$ was large enough, there was a region of well-posedness for inertial numbers in the range

$\mu _d-\mu _s$ was large enough, there was a region of well-posedness for inertial numbers in the range ![]() $I\in [I_1^N, I_2^N]$. Figure 8(c) shows the condition (3.18) for the Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve (1.3). For the parameters given in table 1, the theory is well-posed for

$I\in [I_1^N, I_2^N]$. Figure 8(c) shows the condition (3.18) for the Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve (1.3). For the parameters given in table 1, the theory is well-posed for ![]() $I\in [0.004, 0.3]$, but it is ill-posed when the inertial number is either too low (

$I\in [0.004, 0.3]$, but it is ill-posed when the inertial number is either too low (![]() $0< I<0.004$) or too high (

$0< I<0.004$) or too high (![]() $I>0.3$). Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) performed numerical simulations of Bagnold flow on a 32

$I>0.3$). Barker et al. (Reference Barker, Schaeffer, Bohorquez and Gray2015) performed numerical simulations of Bagnold flow on a 32![]() $^\circ$ incline (when the theory is ill-posed) to explicitly show the rapid growth of grid-scale-dependent oblique waves, which ultimately caused the scheme to crash. Similar grid-dependent results have also been seen in the column collapse simulations of Martin et al. (Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017), and in decelerating chute flows by Barker & Gray (Reference Barker and Gray2017). The classical

$^\circ$ incline (when the theory is ill-posed) to explicitly show the rapid growth of grid-scale-dependent oblique waves, which ultimately caused the scheme to crash. Similar grid-dependent results have also been seen in the column collapse simulations of Martin et al. (Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017), and in decelerating chute flows by Barker & Gray (Reference Barker and Gray2017). The classical ![]() $\mu (I)$ curve (1.3) inherits its reciprocal dependence from measurements of

$\mu (I)$ curve (1.3) inherits its reciprocal dependence from measurements of ![]() $h_{stop}$ as a function of inclination angle, as shown in Appendix A. It is therefore questionable whether the friction really asymptotes to

$h_{stop}$ as a function of inclination angle, as shown in Appendix A. It is therefore questionable whether the friction really asymptotes to ![]() $\mu _d$ at high inertial numbers, and

$\mu _d$ at high inertial numbers, and ![]() $\mu _d$ is certainly poorly constrained by the chute flow experiments.

$\mu _d$ is certainly poorly constrained by the chute flow experiments.

Figure 8. The friction ![]() $\mu$ as a function of

$\mu$ as a function of ![]() $I$ is shown in (a,b) for the original function (1.3) of Jop et al. (Reference Jop, Forterre and Pouliquen2006) (red curve) and the partially regularized function (3.19) of Barker & Gray (Reference Barker and Gray2017) (blue curve) using the parameter values in table 1. The red and blue dots highlight the values of

$I$ is shown in (a,b) for the original function (1.3) of Jop et al. (Reference Jop, Forterre and Pouliquen2006) (red curve) and the partially regularized function (3.19) of Barker & Gray (Reference Barker and Gray2017) (blue curve) using the parameter values in table 1. The red and blue dots highlight the values of ![]() $\mu$ when

$\mu$ when ![]() $I=0$ in the two models. Different horizontal scales are needed to show the extent of the well-posed regions for (a) the original (light red shading) and (b) the partially regularized theories (light blue shading). The well posedness condition

$I=0$ in the two models. Different horizontal scales are needed to show the extent of the well-posed regions for (a) the original (light red shading) and (b) the partially regularized theories (light blue shading). The well posedness condition ![]() $C$ of

$C$ of ![]() $I$, defined in (3.18), is shown for (c) the original and (d) the partially regularized theory. The black dots indicate the points where

$I$, defined in (3.18), is shown for (c) the original and (d) the partially regularized theory. The black dots indicate the points where ![]() $C = 0$. It is these points that set the boundaries of the well-posed regions in (a,b).

$C = 0$. It is these points that set the boundaries of the well-posed regions in (a,b).

Table 1. Material parameters taken from Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021).

3.5. The Barker & Gray (Reference Barker and Gray2017) partially regularized  $\mu (I)$-rheology

$\mu (I)$-rheology

Barker & Gray (Reference Barker and Gray2017) treated the neutral stability condition for (3.18) as an ordinary differential equation (ODE) for ![]() $\mu$ as a function of

$\mu$ as a function of ![]() $I$. From this, they were able to maximize the range of well-posedness of the incompressible

$I$. From this, they were able to maximize the range of well-posedness of the incompressible ![]() $\mu (I)$-rheology. Figures 8(a,b) show the resulting function, which is given by

$\mu (I)$-rheology. Figures 8(a,b) show the resulting function, which is given by

\begin{equation} \mu(I) = \begin{cases} \sqrt{\dfrac{\alpha}{\ln(A/I)}}, & I\leq I^N_1, \\ \dfrac{\mu_s I_0 + \mu_d I + \mu_\infty I^2}{I_0 + I}, & I >I^N_1, \end{cases} \end{equation}

\begin{equation} \mu(I) = \begin{cases} \sqrt{\dfrac{\alpha}{\ln(A/I)}}, & I\leq I^N_1, \\ \dfrac{\mu_s I_0 + \mu_d I + \mu_\infty I^2}{I_0 + I}, & I >I^N_1, \end{cases} \end{equation}

where ![]() $\alpha$ and

$\alpha$ and ![]() $\mu _\infty$ are material constants, and

$\mu _\infty$ are material constants, and

ensures a continuous transition between the two branches. Also, ![]() $I_1^N=0.004$ is the lower neutral stability point of the Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve (1.3). Figure 8(a) shows that this function is very close to the original Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve, in the range where it is well-posed, i.e. for

$I_1^N=0.004$ is the lower neutral stability point of the Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve (1.3). Figure 8(a) shows that this function is very close to the original Jop et al. (Reference Jop, Forterre and Pouliquen2006) curve, in the range where it is well-posed, i.e. for ![]() $I\in [0.004, 0.3]$. Barker & Gray (Reference Barker and Gray2017) showed that it was possible to eliminate the region of the ill-posedness at low inertial numbers by introducing a creep state, in which

$I\in [0.004, 0.3]$. Barker & Gray (Reference Barker and Gray2017) showed that it was possible to eliminate the region of the ill-posedness at low inertial numbers by introducing a creep state, in which ![]() $\mu (0)=0$ and there is a logarithmic dependence in (3.19) at low inertial numbers. For large inertial numbers, the function (3.19) asymptotes to a linear dependence on

$\mu (0)=0$ and there is a logarithmic dependence in (3.19) at low inertial numbers. For large inertial numbers, the function (3.19) asymptotes to a linear dependence on ![]() $I$, as shown in figure 8(b). This significantly extends the range of inertial numbers for which the rheology is well posed to

$I$, as shown in figure 8(b). This significantly extends the range of inertial numbers for which the rheology is well posed to ![]() $[0, 16.99]$, but for large enough inertial numbers, it can still be ill-posed. For this reason, the theory is termed the partially regularized

$[0, 16.99]$, but for large enough inertial numbers, it can still be ill-posed. For this reason, the theory is termed the partially regularized ![]() $\mu (I)$-rheology. It has the advantage that it is reasonably simple and can be solved within the framework of existing computational fluid dynamics codes (Barker & Gray Reference Barker and Gray2017). In particular, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) and Maguire et al. (Reference Maguire, Barker, Rauter, Johnson and Gray2024) have coupled the theory with particle-size segregation models (Gray Reference Gray2018) to solve complex segregating flow problems in chutes and rotating drums. There are, however, new theories that always remain well-posed, but they add considerable complexity to the system (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Goddard & Lee Reference Goddard and Lee2017; Kamrin Reference Kamrin2019; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019).

$\mu (I)$-rheology. It has the advantage that it is reasonably simple and can be solved within the framework of existing computational fluid dynamics codes (Barker & Gray Reference Barker and Gray2017). In particular, Barker et al. (Reference Barker, Rauter, Maguire, Johnson and Gray2021) and Maguire et al. (Reference Maguire, Barker, Rauter, Johnson and Gray2024) have coupled the theory with particle-size segregation models (Gray Reference Gray2018) to solve complex segregating flow problems in chutes and rotating drums. There are, however, new theories that always remain well-posed, but they add considerable complexity to the system (Barker et al. Reference Barker, Schaeffer, Shearer and Gray2017; Goddard & Lee Reference Goddard and Lee2017; Kamrin Reference Kamrin2019; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019).

The linear dependence of the friction ![]() $\mu$ on

$\mu$ on ![]() $I$ at high inertial numbers, which is assumed in the Barker & Gray (Reference Barker and Gray2017) model, is supported by the high-speed flow experiments of Holyoake & McElwaine (Reference Holyoake and McElwaine2012). However, DEM/DPM simulations of dumbbells and discs suggest that a maximum friction occurs at a finite inertial number in the range 0.6–0.8, and then decreases monotonically with inertial number thereafter (Mandal & Khakhara Reference Mandal and Khakhara2016; Patro et al. Reference Patro, Prasad, Tripathi, Kumar and Tripathi2021). A classical incompressible

$I$ at high inertial numbers, which is assumed in the Barker & Gray (Reference Barker and Gray2017) model, is supported by the high-speed flow experiments of Holyoake & McElwaine (Reference Holyoake and McElwaine2012). However, DEM/DPM simulations of dumbbells and discs suggest that a maximum friction occurs at a finite inertial number in the range 0.6–0.8, and then decreases monotonically with inertial number thereafter (Mandal & Khakhara Reference Mandal and Khakhara2016; Patro et al. Reference Patro, Prasad, Tripathi, Kumar and Tripathi2021). A classical incompressible ![]() $\mu (I)$ law of this form would be mathematically ill-posed in the monotonically decreasing region, since

$\mu (I)$ law of this form would be mathematically ill-posed in the monotonically decreasing region, since ![]() $\mu '<0$, hence the well-posedness condition (3.18) implies that

$\mu '<0$, hence the well-posedness condition (3.18) implies that ![]() $C$ is strictly positive, which violates the inequality. It is, however, possible to formulate well-posed compressible

$C$ is strictly positive, which violates the inequality. It is, however, possible to formulate well-posed compressible ![]() $I$-dependent rheology models that could have non-monotonic dependence on the inertial number (Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019).

$I$-dependent rheology models that could have non-monotonic dependence on the inertial number (Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019).

4. Steady uniform flow on the pile

The experiments in § 2 show that a steady uniform-thickness flow develops on the right-hand face of the super-stable heap. Jop et al. (Reference Jop, Forterre and Pouliquen2005) constructed a one-dimensional steady-state solution for the flowing layer, with the original form (1.3) of the ![]() $\mu (I)$-rheology. Attempts to simulate this in two-dimensional time-dependent numerical simulations with the tensorial form of the

$\mu (I)$-rheology. Attempts to simulate this in two-dimensional time-dependent numerical simulations with the tensorial form of the ![]() $\mu (I)$-rheology (Jop et al. Reference Jop, Forterre and Pouliquen2006) will, however, lead to grid-dependent results (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017). This is because there is necessarily a region where the inertial number falls below

$\mu (I)$-rheology (Jop et al. Reference Jop, Forterre and Pouliquen2006) will, however, lead to grid-dependent results (Barker et al. Reference Barker, Schaeffer, Bohorquez and Gray2015; Barker & Gray Reference Barker and Gray2017). This is because there is necessarily a region where the inertial number falls below ![]() $I_1^N$, and there may be a region that exceeds

$I_1^N$, and there may be a region that exceeds ![]() $I_2^N$, both of which would be ill-posed. It is of interest to construct an equivalent one-dimensional solution for the partially regularized

$I_2^N$, both of which would be ill-posed. It is of interest to construct an equivalent one-dimensional solution for the partially regularized ![]() $\mu (I)$-rheology (Barker & Gray Reference Barker and Gray2017), which has a much wider range of applicability, and crucially does not become ill-posed at low inertial numbers.

$\mu (I)$-rheology (Barker & Gray Reference Barker and Gray2017), which has a much wider range of applicability, and crucially does not become ill-posed at low inertial numbers.

4.1. Exact solution for the shear stress and friction

The super-inclined slope coordinates ![]() $Oxz$, defined in figure 4, are used in this subsection, with the origin

$Oxz$, defined in figure 4, are used in this subsection, with the origin ![]() $O$ located at the free surface, so that

$O$ located at the free surface, so that ![]() $z=0$ corresponds to the free surface. The velocity

$z=0$ corresponds to the free surface. The velocity ![]() ${\boldsymbol {u}}$ has components

${\boldsymbol {u}}$ has components ![]() $(u,w)$ in the

$(u,w)$ in the ![]() $(x,z)$ directions, respectively. The flow is assumed to be steady and uniform in the down-slope

$(x,z)$ directions, respectively. The flow is assumed to be steady and uniform in the down-slope ![]() $x$ coordinate. This allows the mass balance equation (3.9) to be integrated, subject to the condition that

$x$ coordinate. This allows the mass balance equation (3.9) to be integrated, subject to the condition that ![]() $w=0$ at

$w=0$ at ![]() $z=0$, to show that

$z=0$, to show that

everywhere within the flow. Since ![]() ${\boldsymbol {u}}=(u(z),0)$, the strain rate and the second invariant of the strain rate (3.13) reduce to

${\boldsymbol {u}}=(u(z),0)$, the strain rate and the second invariant of the strain rate (3.13) reduce to

\begin{equation} {\boldsymbol{D}}=\left(\begin{array}{@{}cc@{}}0 & \dfrac{1}{2}\,\dfrac{\mathrm{d}u}{\mathrm{d}z}\\ \dfrac{1}{2}\,\dfrac{\mathrm{d}u}{\mathrm{d}z} & 0\end{array}\right),\quad \|{\boldsymbol{D}}\|=\dfrac{1}{2}\left|\dfrac{\mathrm{d}u}{\mathrm{d}z}\right|, \end{equation}

\begin{equation} {\boldsymbol{D}}=\left(\begin{array}{@{}cc@{}}0 & \dfrac{1}{2}\,\dfrac{\mathrm{d}u}{\mathrm{d}z}\\ \dfrac{1}{2}\,\dfrac{\mathrm{d}u}{\mathrm{d}z} & 0\end{array}\right),\quad \|{\boldsymbol{D}}\|=\dfrac{1}{2}\left|\dfrac{\mathrm{d}u}{\mathrm{d}z}\right|, \end{equation}

respectively. Assuming that ![]() $\mathrm {d}u/\mathrm {d}z >0$, the alignment and yield conditions (3.12) and (3.14) then imply that the deviatoric stress

$\mathrm {d}u/\mathrm {d}z >0$, the alignment and yield conditions (3.12) and (3.14) then imply that the deviatoric stress

and the down-slope and normal components of the momentum balance (3.10) are

respectively. Integrating (4.5) with respect to ![]() $z$, subject to the boundary condition

$z$, subject to the boundary condition ![]() $p=0$ at

$p=0$ at ![]() $z=0$, implies that the pressure is lithostatic:

$z=0$, implies that the pressure is lithostatic:

The linear dependence of the shear stress on pressure in (4.3) implies that ![]() $\tau _{xz}$ has to be zero at the free surface to be compatible. Substituting (4.6) into (4.4), and integrating with respect to

$\tau _{xz}$ has to be zero at the free surface to be compatible. Substituting (4.6) into (4.4), and integrating with respect to ![]() $z$, subject to

$z$, subject to ![]() $\tau _{xz}=0$ at

$\tau _{xz}=0$ at ![]() $z=0$, implies

$z=0$, implies

Using ![]() $\tau _{xz}=\mu (I)\,p$ and (4.6), it follows that the friction is

$\tau _{xz}=\mu (I)\,p$ and (4.6), it follows that the friction is

This implies that at the free surface (![]() $z=0$), the friction is

$z=0$), the friction is ![]() $\mu (I)=\tan \zeta$, independent of the wall friction