1. Introduction

Transport of passive and active scalars in multiphase turbulence is very important in many industrial processes and natural phenomena, from vaporization of atomized fuel jets (Gorokhovski & Herrmann Reference Gorokhovski and Herrmann2008; Ashgriz Reference Ashgriz2011; Gao et al. Reference Gao, Chen, Qiu, Ding and Xie2022; Boyd & Ling Reference Boyd and Ling2023) to rain formation and atmosphere–ocean heat/mass exchanges (Duguid & Stampfer Reference Duguid and Stampfer1971; Deike Reference Deike2022) or even to the uptake of nutrients and other biochemicals by cells in complex flows (Aksnes & Egge Reference Aksnes and Egge1991; Magar & Pedley Reference Magar and Pedley2005). While the mixing of active or passive scalars in turbulent single-phase flows has been extensively analysed using experiments and simulations (Kim & Moin Reference Kim and Moin1989; Kasagi, Tomita & Kuroda Reference Kasagi, Tomita and Kuroda1992; Antonia & Orlandi Reference Antonia and Orlandi2003; Pirozzoli, Bernardini & Orlandi Reference Pirozzoli, Bernardini and Orlandi2016; Zonta, Marchioli & Soldati Reference Zonta, Marchioli and Soldati2012a; Zonta, Onorato & Soldati Reference Zonta, Onorato and Soldati2012b; Zonta & Soldati Reference Zonta and Soldati2014), when multiphase flows are considered, the situation becomes much more challenging (Gauding et al. Reference Gauding, Thiesset, Varea and Danaila2022; Ni Reference Ni2024).

One crucial aspect of multiphase turbulence – which makes the analysis of these flows particularly difficult – is the presence of interfaces that dynamically move and deform in time and space according to the flow conditions and that clearly alter/mediate heat and species transport and mixing, as well as phase change phenomena (Deckwer Reference Deckwer1980; Gvozdić et al. Reference Gvozdić, Alméras, Mathai, Zhu, van Gils, Verzicco, Huisman, Sun and Lohse2018; Liu et al. Reference Liu, Chong, Yang, Verzicco and Lohse2022; Pelusi et al. Reference Pelusi, Ascione, Sbragaglia and Bernaschi2023; Roccon, Zonta & Soldati Reference Roccon, Zonta and Soldati2023).

In this context, previous works mostly focused on the heat/mass transfer from/to isolated drops and bubbles using analytical (Boussinesq Reference Boussinesq1905; Levich Reference Levich1962; Bird, Stewart & Lightfoot Reference Bird, Stewart and Lightfoot2002), numerical (Bothe et al. Reference Bothe, Koebe, Wielage, Prüss and Warnecke2004; Figueroa-Espinoza & Legendre Reference Figueroa-Espinoza and Legendre2010; Herlina & Wissink Reference Herlina and Wissink2016; Albernaz et al. Reference Albernaz, Do-Quang, Hermanson and Amberg2017; Farsoiya, Popinet & Deike Reference Farsoiya, Popinet and Deike2021; Farsoiya et al. Reference Farsoiya, Magdelaine, Antkowiak, Popinet and Deike2023) and experimental techniques (Ohta, Shimoyama & Ohigashi Reference Ohta, Shimoyama and Ohigashi1975; Hiromitsu & Kawaguchi Reference Hiromitsu and Kawaguchi1995; Wu et al. Reference Wu, Hsu, Kuo and Sheen2003; Birouk & Gökalp Reference Birouk and Gökalp2006; Marti et al. Reference Marti, Martinez, Mazo, Garman and Dunn-Rankin2017). When swarms of drops/bubbles are considered, the number of available investigations is more limited. For very small drops/bubbles, numerical investigations usually rely on the Lagrangian approach, in which drops/bubbles are assumed to have sub-Kolmogorov size and are treated as material points (Kuerten Reference Kuerten2016; Maxey Reference Maxey2017; Chong et al. Reference Chong, Ng, Hori, Yang, Verzicco and Lohse2021; Wang et al. Reference Wang, Alipour, Soligo, Roccon, De Paoli, Picano and Soldati2021a; Wang, Dalla Barba & Picano Reference Wang, Dalla Barba and Picano2021b). When larger drops/bubbles are considered (i.e. larger than the Kolmogorov scale), the problem becomes more complex, since the interface shape and deformation play a crucial role. Not surprisingly, remarkable works in this context have appeared only recently, both for the case of passive scalar transport and for the case of active scalars/phase change (Méès et al. Reference Méès, Grosjean, Marié and Fournier2020; Dodd et al. Reference Dodd, Mohaddes, Ferrante and Ihme2021; Scapin et al. Reference Scapin, Dalla Barba, Lupo, Rosti, Duwig and Brandt2022; Shao, Jin & Luo Reference Shao, Jin and Luo2022; Hidman et al. Reference Hidman, Ström, Sasic and Sardina2023). Relevant to the present work is the observation done by Dodd et al. (Reference Dodd, Mohaddes, Ferrante and Ihme2021) and Scapin et al. (Reference Scapin, Dalla Barba, Lupo, Rosti, Duwig and Brandt2022), and also confirmed by the experiments of Méès et al. (Reference Méès, Grosjean, Marié and Fournier2020), where the Sherwood number (i.e. dimensionless mass transfer coefficient) measured during drop evaporation in turbulence is larger compared to that obtained from widely used correlations (Frössling Reference Frössling1938; Ranz Reference Ranz1952; Birouk & Gökalp Reference Birouk and Gökalp2002).

In this work, we focus on the numerical simulation of the heat transfer process in a drop-laden turbulent channel flow, particularly on the role of the Prandtl number ![]() $Pr$, i.e. the ratio between momentum and thermal diffusivity, in the process. Compared with single-phase turbulence, where the range of scales that must be resolved to perform a direct numerical simulation (DNS) is purely dictated by the smallest scales of turbulence (Kolmogorov scale), when the mixing of scalars in multiphase turbulence is analysed, two further additional scales come into the picture. The first one is the Batchelor scale (Batchelor Reference Batchelor1959; Batchelor, Howells & Townsend Reference Batchelor, Howells and Townsend1959), which determines the smallest scale of the temperature/concentration field. The second important scale is the Kolmogorov–Hinze scale (Kolmogorov Reference Kolmogorov1941; Hinze Reference Hinze1955), and is linked to the multiphase nature of the flow. This scale can be used, perhaps with some limitations (Qi et al. Reference Qi, Tan, Corbitt, Urbanik, Salibindla and Ni2022), to determine the critical size of a drop/bubble that will not undergo breakage in turbulence. These two scales – and their corresponding ratio to the Kolmogorov scale, i.e. the smallest length scale of the turbulent flow field – control the system dynamics and define the minimal grid requirements that must be satisfied to perform a DNS of scalar mixing in multiphase turbulence (always keeping in mind that performing a simulation that resolves the interface dynamics down to the molecular scale is, at present, almost unfeasible). In this context, the major constraint is usually posed by the Batchelor scale, which becomes smaller than the Kolmogorov length scale when Prandtl numbers larger than unity are considered. Overall, the wide range of scales involved in the process makes simulations of scalar mixing in multiphase turbulence a challenging task and limits the space parameters that can be explored by means of DNS. Our simulations are initialized by injecting a swarm of large and deformable drops (initially warmer) inside a turbulent channel flow (initially colder). The system is described by coupling the DNS of turbulent heat transfer with a phase-field method, employed to describe the drop topology (Zheng et al. Reference Zheng, Babaee, Dong, Chryssostomidis and Karniadakis2015; Mirjalili, Jain & Mani Reference Mirjalili, Jain and Mani2022). We simulate realistic values of the Prandtl number up to

$Pr$, i.e. the ratio between momentum and thermal diffusivity, in the process. Compared with single-phase turbulence, where the range of scales that must be resolved to perform a direct numerical simulation (DNS) is purely dictated by the smallest scales of turbulence (Kolmogorov scale), when the mixing of scalars in multiphase turbulence is analysed, two further additional scales come into the picture. The first one is the Batchelor scale (Batchelor Reference Batchelor1959; Batchelor, Howells & Townsend Reference Batchelor, Howells and Townsend1959), which determines the smallest scale of the temperature/concentration field. The second important scale is the Kolmogorov–Hinze scale (Kolmogorov Reference Kolmogorov1941; Hinze Reference Hinze1955), and is linked to the multiphase nature of the flow. This scale can be used, perhaps with some limitations (Qi et al. Reference Qi, Tan, Corbitt, Urbanik, Salibindla and Ni2022), to determine the critical size of a drop/bubble that will not undergo breakage in turbulence. These two scales – and their corresponding ratio to the Kolmogorov scale, i.e. the smallest length scale of the turbulent flow field – control the system dynamics and define the minimal grid requirements that must be satisfied to perform a DNS of scalar mixing in multiphase turbulence (always keeping in mind that performing a simulation that resolves the interface dynamics down to the molecular scale is, at present, almost unfeasible). In this context, the major constraint is usually posed by the Batchelor scale, which becomes smaller than the Kolmogorov length scale when Prandtl numbers larger than unity are considered. Overall, the wide range of scales involved in the process makes simulations of scalar mixing in multiphase turbulence a challenging task and limits the space parameters that can be explored by means of DNS. Our simulations are initialized by injecting a swarm of large and deformable drops (initially warmer) inside a turbulent channel flow (initially colder). The system is described by coupling the DNS of turbulent heat transfer with a phase-field method, employed to describe the drop topology (Zheng et al. Reference Zheng, Babaee, Dong, Chryssostomidis and Karniadakis2015; Mirjalili, Jain & Mani Reference Mirjalili, Jain and Mani2022). We simulate realistic values of the Prandtl number up to ![]() $Pr=8$, similar to those obtained in liquid–liquid systems. We remark here that simulations of mass transfer problems in wall-bounded flow configurations, where the typical Schmidt number

$Pr=8$, similar to those obtained in liquid–liquid systems. We remark here that simulations of mass transfer problems in wall-bounded flow configurations, where the typical Schmidt number ![]() $Sc$ (i.e. the mass transfer counterpart of

$Sc$ (i.e. the mass transfer counterpart of ![]() $Pr$) is

$Pr$) is ![]() ${O}({10^2 \sim 10^3})$, e.g.

${O}({10^2 \sim 10^3})$, e.g. ![]() $Sc \simeq 600$ for

$Sc \simeq 600$ for ![]() $CO_2$ in freshwater (Wanninkhof Reference Wanninkhof1992), are currently out of reach even using the most advanced computing. Indeed, the resulting Batchelor scale would be at least one order of magnitude smaller, thus requiring grid resolutions comparable to or larger than those employed for state-of-the-art single-phase DNS (Lee & Moser Reference Lee and Moser2015; Pirozzoli et al. Reference Pirozzoli, Romero, Fatica, Verzicco and Orlandi2021) but with a much larger computational cost as the systems of equations to be solved are more complex and restrictive (also from the temporal discretization point of view).

$CO_2$ in freshwater (Wanninkhof Reference Wanninkhof1992), are currently out of reach even using the most advanced computing. Indeed, the resulting Batchelor scale would be at least one order of magnitude smaller, thus requiring grid resolutions comparable to or larger than those employed for state-of-the-art single-phase DNS (Lee & Moser Reference Lee and Moser2015; Pirozzoli et al. Reference Pirozzoli, Romero, Fatica, Verzicco and Orlandi2021) but with a much larger computational cost as the systems of equations to be solved are more complex and restrictive (also from the temporal discretization point of view).

The present study has three main objectives. First, we want to investigate the macroscopic dynamic of the drops and of the heat transfer process by analysing the drop size distribution and the mean temperature behaviour of the two phases over time. Second, we want to characterize the influence of the Prandtl number, i.e. of the microscopic flow properties, on the macroscopic flow properties (mean temperature, heat transfer coefficient) and, building on top of the numerical results, we want to develop a physical-based model to explain the observed results. Third, we want to study the influence of the Prandtl number and drop size on the temperature distribution inside the drops, so as to evaluate the corresponding flow mixing/ homogenization.

The paper is organized as follows. In § 2, the governing equations, the numerical method and the simulation setup are presented. In § 3, the simulation results, in terms of drop size distribution and mean temperature of the two phases and heat transfer coefficient, are carefully characterized and discussed. A simplified model is also developed to explain the observed results. The temperature distribution inside the drops is then evaluated at different Prandtl numbers and drop sizes. Finally, conclusions are presented in § 4.

2. Methodology

We consider a swarm of large and deformable drops injected in a turbulent channel flow. The channel has dimensions ![]() $L_x \times L_y \times L_z = 4 {\rm \pi}h \times 2 {\rm \pi}h \times 2h$ along the streamwise (

$L_x \times L_y \times L_z = 4 {\rm \pi}h \times 2 {\rm \pi}h \times 2h$ along the streamwise (![]() $x$), spanwise (

$x$), spanwise (![]() $\kern 0.06em y$) and wall-normal direction (

$\kern 0.06em y$) and wall-normal direction (![]() $z$). To describe the dynamics of the system, we couple DNS of the Navier–Stokes and energy equations, used to describe the turbulent flow, with a phase-field method (PFM), used to describe the interfacial phenomena. The employed numerical framework is described in more detail in the following.

$z$). To describe the dynamics of the system, we couple DNS of the Navier–Stokes and energy equations, used to describe the turbulent flow, with a phase-field method (PFM), used to describe the interfacial phenomena. The employed numerical framework is described in more detail in the following.

2.1. Phase-field method

To describe the dynamics of drops and the corresponding topological changes (e.g. coalescence and breakage), we employ an energy-based PFM (Jacqmin Reference Jacqmin1999; Badalassi, Ceniceros & Banerjee Reference Badalassi, Ceniceros and Banerjee2003; Roccon et al. Reference Roccon, Zonta and Soldati2023), which is based on the introduction of a scalar quantity, the phase field ![]() $\phi$, required to identify the two phases. The phase field

$\phi$, required to identify the two phases. The phase field ![]() $\phi$ has a uniform value in the bulk of each phase (

$\phi$ has a uniform value in the bulk of each phase (![]() $\phi =+1$ inside the drops;

$\phi =+1$ inside the drops; ![]() $\phi =-1$ inside the carrier fluid) and undergoes a smooth change across the thin transition layer that separates the two phases. The transport of the phase field variable is described by a Cahn–Hilliard equation, which in dimensionless form reads as

$\phi =-1$ inside the carrier fluid) and undergoes a smooth change across the thin transition layer that separates the two phases. The transport of the phase field variable is described by a Cahn–Hilliard equation, which in dimensionless form reads as

where ![]() ${\boldsymbol u}=(u,v,w)$ is the velocity vector,

${\boldsymbol u}=(u,v,w)$ is the velocity vector, ![]() $Pe$ is the Péclet number,

$Pe$ is the Péclet number, ![]() $\mu$ is the phase field chemical potential and

$\mu$ is the phase field chemical potential and ![]() $f_p$ is a penalty-flux term which will be further discussed later. The Péclet number is

$f_p$ is a penalty-flux term which will be further discussed later. The Péclet number is

where ![]() $u^*_\tau$ is the friction velocity (

$u^*_\tau$ is the friction velocity (![]() $u_\tau ^*=\sqrt {\tau _w^*/\rho ^*}$, with

$u_\tau ^*=\sqrt {\tau _w^*/\rho ^*}$, with ![]() $\tau _w^*$ the wall-shear stress and

$\tau _w^*$ the wall-shear stress and ![]() $\rho ^*=\rho _c^*=\rho _d^*$ the density of the fluids),

$\rho ^*=\rho _c^*=\rho _d^*$ the density of the fluids), ![]() $h^*$ is the channel half-height,

$h^*$ is the channel half-height, ![]() ${\mathcal {M}}^*$ is the mobility and

${\mathcal {M}}^*$ is the mobility and ![]() $\beta ^*$ is a positive constant (the superscript

$\beta ^*$ is a positive constant (the superscript ![]() $^*$ is used to denote dimensional quantities hereinafter). The chemical potential

$^*$ is used to denote dimensional quantities hereinafter). The chemical potential ![]() $\mu$ is defined as the variational derivative of a Ginzburg–Landau free-energy functional, the expression of which is chosen to represent an immiscible binary mixture of fluids (Soligo, Roccon & Soldati Reference Soligo, Roccon and Soldati2019a,Reference Soligo, Roccon and Soldatib,Reference Soligo, Roccon and Soldatic). The functional is the sum of two contributions: the first contribution,

$\mu$ is defined as the variational derivative of a Ginzburg–Landau free-energy functional, the expression of which is chosen to represent an immiscible binary mixture of fluids (Soligo, Roccon & Soldati Reference Soligo, Roccon and Soldati2019a,Reference Soligo, Roccon and Soldatib,Reference Soligo, Roccon and Soldatic). The functional is the sum of two contributions: the first contribution, ![]() $f_0$, accounts for the tendency of the system to separate into the two pure stable phases, while the second contribution,

$f_0$, accounts for the tendency of the system to separate into the two pure stable phases, while the second contribution, ![]() $f_{mix}$, is a mixing term accounting for the energy stored at the interface (i.e. surface tension). The mathematical expression of the functional in dimensionless form is

$f_{mix}$, is a mixing term accounting for the energy stored at the interface (i.e. surface tension). The mathematical expression of the functional in dimensionless form is

\begin{equation} \mathcal{F}[\phi, \boldsymbol{\nabla} \phi]= {\int_{\varOmega} \left( \underbrace{\frac{({\phi}^2-1)^2}{4}}_{f_0}+\underbrace{\frac{Ch^2}{2} | \boldsymbol{\nabla} \phi |^2}_{f_{mix}} \right)} \mathrm{d} \varOmega , \end{equation}

\begin{equation} \mathcal{F}[\phi, \boldsymbol{\nabla} \phi]= {\int_{\varOmega} \left( \underbrace{\frac{({\phi}^2-1)^2}{4}}_{f_0}+\underbrace{\frac{Ch^2}{2} | \boldsymbol{\nabla} \phi |^2}_{f_{mix}} \right)} \mathrm{d} \varOmega , \end{equation}

where ![]() $\varOmega$ is the considered domain and

$\varOmega$ is the considered domain and ![]() $Ch$ is the Cahn number, which represents the dimensionless thickness of the thin interfacial layer between the two fluids:

$Ch$ is the Cahn number, which represents the dimensionless thickness of the thin interfacial layer between the two fluids:

where ![]() $\xi ^*$ is clearly the dimensional thickness of the interfacial layer. From (2.3), the expression of the chemical potential can be derived as the functional derivative with respect to the order parameter:

$\xi ^*$ is clearly the dimensional thickness of the interfacial layer. From (2.3), the expression of the chemical potential can be derived as the functional derivative with respect to the order parameter:

At equilibrium, the chemical potential is constant throughout all the domain. The equilibrium profile for a flat interface can thus be obtained by solving ![]() $\boldsymbol {\nabla } \mu _\phi = \boldsymbol {0}$, hence,

$\boldsymbol {\nabla } \mu _\phi = \boldsymbol {0}$, hence,

where ![]() $s$ is the coordinate normal to the interface. As anticipated before, the last term in the right-hand side of the Cahn–Hilliard equation (2.1) is a penalty-flux term employed in the profile-corrected formulation of the PFM, and is used to overcome some potential drawbacks of the standard formulation of the method, e.g. mass leakages among the phases and misrepresentation of the interfacial profile (Yue, Zhou & Feng Reference Yue, Zhou and Feng2007; Li, Choi & Kim Reference Li, Choi and Kim2016). This penalty flux is defined as

$s$ is the coordinate normal to the interface. As anticipated before, the last term in the right-hand side of the Cahn–Hilliard equation (2.1) is a penalty-flux term employed in the profile-corrected formulation of the PFM, and is used to overcome some potential drawbacks of the standard formulation of the method, e.g. mass leakages among the phases and misrepresentation of the interfacial profile (Yue, Zhou & Feng Reference Yue, Zhou and Feng2007; Li, Choi & Kim Reference Li, Choi and Kim2016). This penalty flux is defined as

where ![]() $\lambda =0.0625/Ch$ (Soligo et al. Reference Soligo, Roccon and Soldati2019c).

$\lambda =0.0625/Ch$ (Soligo et al. Reference Soligo, Roccon and Soldati2019c).

2.2. Hydrodynamics

To describe the hydrodynamics of the multiphase system, the Cahn–Hilliard equation is coupled with the Navier–Stokes equations. The presence of a deformable interface (and of the corresponding surface tension forces) is accounted for by introducing an interfacial term in the Navier–Stokes equations. Recalling that in the present case, we consider two fluids with the same density (![]() $\rho ^*=\rho _c^*=\rho _d^*$) and viscosity (

$\rho ^*=\rho _c^*=\rho _d^*$) and viscosity (![]() $\mu ^*=\mu _c^* =\mu _d^*$), the continuity and Navier–Stokes equations in dimensionless form read as

$\mu ^*=\mu _c^* =\mu _d^*$), the continuity and Navier–Stokes equations in dimensionless form read as

Here ![]() $p$ is the pressure field, while

$p$ is the pressure field, while ![]() $\boldsymbol {T_c}$ is the Korteweg tensor (Korteweg Reference Korteweg1901) used to account for the surface tension forces and defined as

$\boldsymbol {T_c}$ is the Korteweg tensor (Korteweg Reference Korteweg1901) used to account for the surface tension forces and defined as

where ![]() $\boldsymbol I$ is the identity matrix and

$\boldsymbol I$ is the identity matrix and ![]() $\otimes$ represents the dyadic product. This approach is the continuum surface stress approach (Lafaurie et al. Reference Lafaurie, Nardone, Scardovelli, Zaleski and Zanetti1994; Gueyffier et al. Reference Gueyffier, Li, Nadim, Scardovelli and Zaleski1999) applied in the context of the PFM, and is analytically equivalent to the chemical potential forcing (Mirjalili, Khanwale & Mani Reference Mirjalili, Khanwale and Mani2023). The dimensionless groups appearing in the Navier–Stokes equations are the shear Reynolds number

$\otimes$ represents the dyadic product. This approach is the continuum surface stress approach (Lafaurie et al. Reference Lafaurie, Nardone, Scardovelli, Zaleski and Zanetti1994; Gueyffier et al. Reference Gueyffier, Li, Nadim, Scardovelli and Zaleski1999) applied in the context of the PFM, and is analytically equivalent to the chemical potential forcing (Mirjalili, Khanwale & Mani Reference Mirjalili, Khanwale and Mani2023). The dimensionless groups appearing in the Navier–Stokes equations are the shear Reynolds number ![]() $Re_\tau$ (ratio between inertial and viscous forces) and the Weber number

$Re_\tau$ (ratio between inertial and viscous forces) and the Weber number ![]() $We$ (ratio between inertial and surface tension forces), which are defined as

$We$ (ratio between inertial and surface tension forces), which are defined as

where ![]() $\sigma ^*$ is the surface tension. Note that, consistently with the employed adimensionalization,

$\sigma ^*$ is the surface tension. Note that, consistently with the employed adimensionalization, ![]() $We$ is defined using the half-channel height (and not the drop diameter).

$We$ is defined using the half-channel height (and not the drop diameter).

2.3. Energy equation

The time evolution of the temperature field is obtained by solving the energy equation using a one-scalar model approach (Zheng et al. Reference Zheng, Babaee, Dong, Chryssostomidis and Karniadakis2015). To avoid the introduction of further complexity in the system, we consider two fluids with the same thermophysical properties, i.e. same thermal conductivity ![]() $\lambda ^*$, same specific heat capacity

$\lambda ^*$, same specific heat capacity ![]() $c_p^*$ and therefore same thermal diffusivity

$c_p^*$ and therefore same thermal diffusivity ![]() $a^*=\lambda ^*/\rho ^* c_p^*$ (since the density of the two phases is also the same). These properties have been evaluated at a reference temperature

$a^*=\lambda ^*/\rho ^* c_p^*$ (since the density of the two phases is also the same). These properties have been evaluated at a reference temperature ![]() $\theta _{r}^*=(\theta _{d,0}^* + \theta _{c,0}^*)/2$, i.e. the average between the initial drop temperature and the carrier fluid temperature, and are assumed to be constant and uniform. Within these assumptions, the energy equation written in dimensionless form reads as

$\theta _{r}^*=(\theta _{d,0}^* + \theta _{c,0}^*)/2$, i.e. the average between the initial drop temperature and the carrier fluid temperature, and are assumed to be constant and uniform. Within these assumptions, the energy equation written in dimensionless form reads as

where ![]() $Pr$ is the Prandtl number defined as

$Pr$ is the Prandtl number defined as

with ![]() $\nu ^*=\mu ^*/\rho ^*$ the kinematic viscosity (i.e. momentum diffusivity). From a physical viewpoint,

$\nu ^*=\mu ^*/\rho ^*$ the kinematic viscosity (i.e. momentum diffusivity). From a physical viewpoint, ![]() $Pr$ represents the momentum-to-thermal diffusivity ratio.

$Pr$ represents the momentum-to-thermal diffusivity ratio.

2.4. Numerical discretization

The governing equations (2.1), (2.8), (2.9) and (2.12) are solved using a pseudo-spectral method, which uses Fourier series along the periodic directions (streamwise and spanwise) and Chebyshev polynomials along the wall-normal direction. The Navier–Stokes and continuity equations are solved using a wall-normal velocity-vorticity formulation: (2.9) is rewritten as a fourth-order equation for the wall-normal component of the velocity ![]() $w$ and a second-order equation for the wall-normal component of the vorticity

$w$ and a second-order equation for the wall-normal component of the vorticity ![]() $\omega _z$ (Kim, Moin & Moser Reference Kim, Moin and Moser1987; Speziale Reference Speziale1987). The Cahn–Hilliard equation (2.1), which in its original form is a fourth-order equation and is split into two second-order equations using the splitting scheme proposed by Badalassi et al. (Reference Badalassi, Ceniceros and Banerjee2003). Using this scheme, the governing equations are recasted as a coupled system of Helmholtz equations, which can be readily solved.

$\omega _z$ (Kim, Moin & Moser Reference Kim, Moin and Moser1987; Speziale Reference Speziale1987). The Cahn–Hilliard equation (2.1), which in its original form is a fourth-order equation and is split into two second-order equations using the splitting scheme proposed by Badalassi et al. (Reference Badalassi, Ceniceros and Banerjee2003). Using this scheme, the governing equations are recasted as a coupled system of Helmholtz equations, which can be readily solved.

The governing equations are time-advanced using an implicit-explicit scheme. For the Navier–Stokes, the linear part is integrated using a Crank–Nicolson implicit scheme, while the nonlinear part is integrated using an Adams–Bashforth explicit scheme. Similarly, for the Cahn–Hilliard and energy equations, the linear terms are integrated using an implicit Euler scheme, while the nonlinear terms are integrated in time using an Adams–Bashforth scheme. The adoption of the implicit Euler scheme for the Cahn–Hilliard equation helps to damp unphysical high-frequency oscillations that could arise from the steep gradients of the phase field.

As the characteristic length scales of the flow and temperature fields, represented by the Kolmogorov scale, ![]() $\eta _k^+$, and the Batchelor scale,

$\eta _k^+$, and the Batchelor scale, ![]() $\eta _\theta ^+$, are different when non-unitary Prandtl numbers are employed (being these two quantities linked by the following relation

$\eta _\theta ^+$, are different when non-unitary Prandtl numbers are employed (being these two quantities linked by the following relation ![]() $\eta _\theta ^+=\eta _k^+/\sqrt {Pr}$), a dual grid approach is employed to reduce the computational cost of the simulations and, at the same time, to fulfil the DNS requirements. In particular, when super-unitary Prandtl numbers are simulated, a finer grid is used to resolve the energy equation. Spectral interpolation is used to upscale/downscale the fields from the coarse to the refined grid and vice versa when required (e.g. upscaling of the velocity field to compute the advection terms in the energy equation).

$\eta _\theta ^+=\eta _k^+/\sqrt {Pr}$), a dual grid approach is employed to reduce the computational cost of the simulations and, at the same time, to fulfil the DNS requirements. In particular, when super-unitary Prandtl numbers are simulated, a finer grid is used to resolve the energy equation. Spectral interpolation is used to upscale/downscale the fields from the coarse to the refined grid and vice versa when required (e.g. upscaling of the velocity field to compute the advection terms in the energy equation).

This numerical scheme has been implemented in a parallel Fortran 2003 MPI in-house proprietary code. The parallelization strategy is based on a 2-D domain decomposition to divide the workload among all the MPI tasks. The solver execution is accelerated using openACC directives and CUDA Fortran instructions (solver execution) while the Nvidia cuFFT libraries are used to accelerate the execution of the Fourier/Chebyshev transforms. Overall, the computational method adopted allows for the accurate resolution of all the governing equations and the achievement of an excellent parallel efficiency thanks to the fine-grain parallelism offered by the numerical method used. The equivalent computational cost of the simulations is approximately 25 million CPU hours and the resulting dataset has a size of approximately 16 TB.

2.5. Boundary conditions

The system of governing equations is complemented by a set of suitable boundary conditions. For the Navier–Stokes equations, no-slip boundary conditions are enforced at the top and bottom walls (located at ![]() $z=\pm h$):

$z=\pm h$):

For the Cahn–Hilliard equation, no-flux boundary conditions are applied at the two walls, yielding to the following boundary conditions:

Likewise, for the energy equation, no-flux boundary conditions are applied at the two walls (i.e. adiabatic walls):

Along the streamwise and spanwise directions (![]() $x$ and

$x$ and ![]() $y$), periodic boundary conditions are imposed for all variables (Fourier discretization). The adoption of these boundary conditions leads to the conservation of the phase field and temperature fields over time:

$y$), periodic boundary conditions are imposed for all variables (Fourier discretization). The adoption of these boundary conditions leads to the conservation of the phase field and temperature fields over time:

where ![]() $\varOmega$ is the computational domain. Regarding the phase-field, (2.17a,b) enforces mass conservation of the entire system but does not guarantee the conservation of the mass of each phase (Yue et al. Reference Yue, Zhou and Feng2007; Soligo et al. Reference Soligo, Roccon and Soldati2019c), as some leakages between the phases may occur. This drawback is rooted in the PFM and more specifically in the curvature-driven flux produced by the chemical potential gradients (Kwakkel, Fernandino & Dorao Reference Kwakkel, Fernandino and Dorao2020; Mirjalili & Mani Reference Mirjalili and Mani2021). This issue is successfully mitigated with the adoption of the profile-corrected formulation that largely reduces this phenomenon. In the present cases, mass leakage between the phases occurs only in the initial transient when the phase field is initialized (see the section below for details on the initial condition) and is limited to 2 % of the initial mass of the drops. After this initial transient, the mass of each phase remains constant.

$\varOmega$ is the computational domain. Regarding the phase-field, (2.17a,b) enforces mass conservation of the entire system but does not guarantee the conservation of the mass of each phase (Yue et al. Reference Yue, Zhou and Feng2007; Soligo et al. Reference Soligo, Roccon and Soldati2019c), as some leakages between the phases may occur. This drawback is rooted in the PFM and more specifically in the curvature-driven flux produced by the chemical potential gradients (Kwakkel, Fernandino & Dorao Reference Kwakkel, Fernandino and Dorao2020; Mirjalili & Mani Reference Mirjalili and Mani2021). This issue is successfully mitigated with the adoption of the profile-corrected formulation that largely reduces this phenomenon. In the present cases, mass leakage between the phases occurs only in the initial transient when the phase field is initialized (see the section below for details on the initial condition) and is limited to 2 % of the initial mass of the drops. After this initial transient, the mass of each phase remains constant.

2.6. Simulation set-up

The turbulent channel flow, driven by an imposed constant pressure gradient in the streamwise direction, has a shear Reynolds number ![]() $Re_\tau =300$. The computational domain has dimensions

$Re_\tau =300$. The computational domain has dimensions ![]() $L_x \times L_y \times L_z= 4{\rm \pi} h \times 2{\rm \pi} h \times 2h$, which corresponds to

$L_x \times L_y \times L_z= 4{\rm \pi} h \times 2{\rm \pi} h \times 2h$, which corresponds to ![]() $L_x^+ \times L_y^+ \times L_z^+=3770 \times 1885 \times 600$ wall units. The value of the Weber number is kept constant and is equal to

$L_x^+ \times L_y^+ \times L_z^+=3770 \times 1885 \times 600$ wall units. The value of the Weber number is kept constant and is equal to ![]() $We=3.00$, so to be representative of liquid/liquid mixtures (Than et al. Reference Than, Preziosi, Joseph and Arney1988). To study the influence of the Prandtl number

$We=3.00$, so to be representative of liquid/liquid mixtures (Than et al. Reference Than, Preziosi, Joseph and Arney1988). To study the influence of the Prandtl number ![]() $Pr$ on the heat transfer process, we consider four different values of

$Pr$ on the heat transfer process, we consider four different values of ![]() $Pr$:

$Pr$: ![]() $Pr=1$,

$Pr=1$, ![]() $Pr=2$,

$Pr=2$, ![]() $Pr=4$ and

$Pr=4$ and ![]() $Pr=8$. These values cover a wide range of real-case scenarios: from low-Prandtl-number fluids to water–toluene mixtures.

$Pr=8$. These values cover a wide range of real-case scenarios: from low-Prandtl-number fluids to water–toluene mixtures.

The grid resolution used to resolve the continuity, Navier–Stokes and Cahn–Hilliard equations is equal to ![]() $N_x \times N_y \times N_z = 1024 \times 512 \times 513$ for all the cases considered in this work. For the energy equation, the same grid used for the flow field and phase field is employed at the lower Prandtl numbers (

$N_x \times N_y \times N_z = 1024 \times 512 \times 513$ for all the cases considered in this work. For the energy equation, the same grid used for the flow field and phase field is employed at the lower Prandtl numbers (![]() $Pr=1$ and

$Pr=1$ and ![]() $Pr=2$), while a more refined grid, with

$Pr=2$), while a more refined grid, with ![]() $N_x \times N_y \times N_z = 2048 \times 1024 \times 513$ points, is used when the larger Prandtl numbers are considered (

$N_x \times N_y \times N_z = 2048 \times 1024 \times 513$ points, is used when the larger Prandtl numbers are considered (![]() $Pr=4$ and

$Pr=4$ and ![]() $Pr=8$). The computational grid has uniform spacing in the homogeneous directions, while Chebyshev–Gauss–Lobatto points are used in the wall-normal direction. We refer the reader to table 1 for an overview of the main physical and computational parameters of the simulation. For the employed grid resolution, the Cahn number is set to

$Pr=8$). The computational grid has uniform spacing in the homogeneous directions, while Chebyshev–Gauss–Lobatto points are used in the wall-normal direction. We refer the reader to table 1 for an overview of the main physical and computational parameters of the simulation. For the employed grid resolution, the Cahn number is set to ![]() $Ch = 0.01$ while, to achieve convergence to the sharp interface limit, the corresponding phase field Péclet number is

$Ch = 0.01$ while, to achieve convergence to the sharp interface limit, the corresponding phase field Péclet number is ![]() $Pe = 1/Ch = 50$.

$Pe = 1/Ch = 50$.

Table 1. Overview of the simulation parameters. For a fixed shear Reynolds number ![]() $Re_\tau =300$ and Weber number

$Re_\tau =300$ and Weber number ![]() $We=3$, we consider a single-phase flow case and four non-isothermal drop-laden flows characterized by different Prandtl numbers: from

$We=3$, we consider a single-phase flow case and four non-isothermal drop-laden flows characterized by different Prandtl numbers: from ![]() $Pr=1$ to

$Pr=1$ to ![]() $Pr=8$. The grid resolution is modified accordingly so as to satisfy DNS requirements.

$Pr=8$. The grid resolution is modified accordingly so as to satisfy DNS requirements.

All simulations are initialized by releasing a regular array of 256 spherical drops with diameter ![]() $d = 0.4h$ (corresponding to

$d = 0.4h$ (corresponding to ![]() $d^+ = 120 w.u.$) inside a fully developed turbulent flow field (obtained from a preliminary simulation). To ensure the independence of the results from the initial flow field condition, each case is initialized with a slightly different flow field realization. Naturally, the fields are equivalent in terms of statistics as they are all obtained from a statistically steady turbulent channel flow. The volume fraction of the drops is

$d^+ = 120 w.u.$) inside a fully developed turbulent flow field (obtained from a preliminary simulation). To ensure the independence of the results from the initial flow field condition, each case is initialized with a slightly different flow field realization. Naturally, the fields are equivalent in terms of statistics as they are all obtained from a statistically steady turbulent channel flow. The volume fraction of the drops is ![]() $\varPhi = V_d/(V_c + V_d) = 5.4\,\%$, with

$\varPhi = V_d/(V_c + V_d) = 5.4\,\%$, with ![]() $V_d$ and

$V_d$ and ![]() $V_c$ the volume of the drops and carrier fluid, respectively.

$V_c$ the volume of the drops and carrier fluid, respectively.

The initial condition for the temperature field is such that all drops are initially warm (initial temperature ![]() $\theta _{d,0}=1$), while the carrier fluid is initially cold (initial temperature

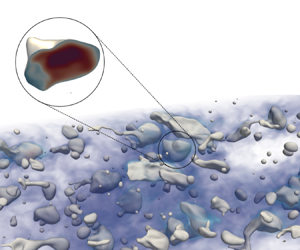

$\theta _{d,0}=1$), while the carrier fluid is initially cold (initial temperature ![]() $\theta _{c,0}=0$). To avoid numerical instabilities that might arise from a discontinuous temperature field, the transition between drops and carrier fluid is initially smoothed using a hyperbolic tangent kernel. Figure 1 (which is an instantaneous snapshot captured at

$\theta _{c,0}=0$). To avoid numerical instabilities that might arise from a discontinuous temperature field, the transition between drops and carrier fluid is initially smoothed using a hyperbolic tangent kernel. Figure 1 (which is an instantaneous snapshot captured at ![]() $t^+=1000$, for

$t^+=1000$, for ![]() $Pr=1$) shows a volume rendering of the temperature field (blue, cold; red, hot), inside which deformable drops (whose interface, iso-level

$Pr=1$) shows a volume rendering of the temperature field (blue, cold; red, hot), inside which deformable drops (whose interface, iso-level ![]() $\phi =0$, is shown in white) are transported.

$\phi =0$, is shown in white) are transported.

Figure 1. Rendering of the computational setup employed for the simulations. A swarm of large and deformable drops is released in a turbulent channel flow. The temperature field is volume-rendered (blue, low; red, high) and the drop interface is shown in white (iso-level ![]() $\phi =0$). Drops have a temperature higher than the carrier fluid (close-up view). The snapshot refers to

$\phi =0$). Drops have a temperature higher than the carrier fluid (close-up view). The snapshot refers to ![]() $Pr=1$ and

$Pr=1$ and ![]() $t^+=1000$.

$t^+=1000$.

3. Results

Results obtained from the numerical simulations will be first discussed from a qualitative viewpoint, by looking at instantaneous flow and drop visualizations, and then analysed from a more quantitative viewpoint, by looking at the drop size distribution (DSD), and at the effect of the Prandtl number ![]() $Pr$ on the average drops and fluid temperature. To explain the numerical results, and to offer a possible parametrization of the heat transfer process in drop-laden flows, we will also develop a simplified phenomenological model of the system. Finally, we will characterize the temperature distribution inside the drops, elucidating the effects of

$Pr$ on the average drops and fluid temperature. To explain the numerical results, and to offer a possible parametrization of the heat transfer process in drop-laden flows, we will also develop a simplified phenomenological model of the system. Finally, we will characterize the temperature distribution inside the drops, elucidating the effects of ![]() $Pr$ and of the drop size on it. Note that, unless differently mentioned, results are presented using the wall-unit scaling system but for the temperature field, which is made dimensionless using the initial temperature difference as a reference scale (which is a natural choice in the present case).

$Pr$ and of the drop size on it. Note that, unless differently mentioned, results are presented using the wall-unit scaling system but for the temperature field, which is made dimensionless using the initial temperature difference as a reference scale (which is a natural choice in the present case).

3.1. Qualitative discussion

The complex dynamics of drops immersed in a non-isothermal turbulent flow is visualized in figure 1, where the drops (identified by iso-contour of ![]() $\phi =0$) are shown together with a volume-rendered distribution of temperature in the carrier fluid. Also shown in figure 1 is a close-up view of the temperature distribution inside the drop. We can notice that most of the drops – because of their deformability – gather at the channel centre, as also observed in previous studies in similar configurations (Scarbolo, Bianco & Soldati Reference Scarbolo, Bianco and Soldati2016; Soligo, Roccon & Soldati Reference Soligo, Roccon and Soldati2020; Mangani et al. Reference Mangani, Soligo, Roccon and Soldati2022).

$\phi =0$) are shown together with a volume-rendered distribution of temperature in the carrier fluid. Also shown in figure 1 is a close-up view of the temperature distribution inside the drop. We can notice that most of the drops – because of their deformability – gather at the channel centre, as also observed in previous studies in similar configurations (Scarbolo, Bianco & Soldati Reference Scarbolo, Bianco and Soldati2016; Soligo, Roccon & Soldati Reference Soligo, Roccon and Soldati2020; Mangani et al. Reference Mangani, Soligo, Roccon and Soldati2022).

Once injected into the flow, each drop starts interacting with the flow and with the neighbouring drops. The result of the drop–turbulence and drop–drop interactions is the occurrence of breakage and coalescence events. A breakage event happens when the flow vigorously stretches the drop, leading to the formation of a thin ligament that breaks and generates two child drops. Upon separation, surface tension forces tend to retract the broken filaments and restore the drop spherical shape. A coalescence event is observed when two drops come close to each other. The small liquid film that separates the drops starts to drain, and a coalescence bridge is formed. Later, surface tension forces enter the picture, reshaping the drop and completing the coalescence process. The dynamic competition between breakage and coalescence events, and their interaction with the turbulent flow, determines the number of drops, their size distribution, and their shape/morphology (i.e. curvature, interfacial area, etc.).

In the present case, drops not only exchange momentum with the flow and with the other drops but also heat. Starting from an initial condition characterized by warm drops (with uniform temperature) and cold carrier fluid, and because of the imposed adiabatic boundary conditions, the system evolves towards an equilibrium isothermal state. During the transient to attain this thermal equilibrium state, heat is transported by diffusion and advection inside each of the two phases, and across the interface of the drops (see the temperature field inside and outside the drops, figure 1). The picture is then further complicated by the occurrence of breakage and coalescence events. This is represented in figure 2. When breakage occurs (figure 2a–e), a thin filament is generated (figure 2a–c), which then leads to the formation of a smaller satellite drop (figure 2d,e). The filament and the satellite drop, given the large surface-to-volume ratio, exchange heat very efficiently and rapidly become colder. In contrast, when a coalescence occurs (figure 2f–o), two drops having different temperatures merge together. This induces an efficient mixing process, during which cold parcels of one drop become warmer and vice versa, warm parcels of the other drops become colder. Overall, breakup and coalescence events induce heat transfer modifications that are, in general, hard to predict a priori, since they do depend on the relative size of the involved parents/child drops.

Figure 2. Influence of topology changes on heat transfer: time sequence (a–e) of a breakage event and (f–o) of a coalescence event. During a breakage event, heat is transferred from the drops to carrier fluid thanks to the high surface/volume ratio of the pinch-off region. In the middle and bottom rows, the mixing between parcels of fluid with different temperatures can be appreciated. The two sequences refer to the case ![]() $Pr=1$ and snapshots are separated by

$Pr=1$ and snapshots are separated by ![]() ${\rm \Delta} t^+ =15$. As a reference, the Kolmogorov–Hinze scale,

${\rm \Delta} t^+ =15$. As a reference, the Kolmogorov–Hinze scale, ![]() $d^+_H$, is also reported.

$d^+_H$, is also reported.

Naturally, the problem of heat transfer in drop-laden turbulence is strongly influenced by the Prandtl number of the flow. This can be appreciated by looking at figure 3, where we show the instantaneous temperature field, together with the shape of the drops, at a certain instant in time (![]() $t^+=1500$) and at different Prandtl numbers: (a)

$t^+=1500$) and at different Prandtl numbers: (a) ![]() $Pr=1$; (b)

$Pr=1$; (b) ![]() $Pr=2$; (c)

$Pr=2$; (c) ![]() $Pr=4$ and (d)

$Pr=4$ and (d) ![]() $Pr=8$. In each panel, the temperature field is shown on a wall-parallel

$Pr=8$. In each panel, the temperature field is shown on a wall-parallel ![]() $x^+$-

$x^+$-![]() $y^+$ plane located at the channel centre (

$y^+$ plane located at the channel centre (![]() $z^+=0$) and is visualized with a blue-red scale (blue, low; red, high). We observe that the temperature field changes significantly with

$z^+=0$) and is visualized with a blue-red scale (blue, low; red, high). We observe that the temperature field changes significantly with ![]() $Pr$. In particular, we notice an increase in the drop-to-fluid temperature difference for increasing

$Pr$. In particular, we notice an increase in the drop-to-fluid temperature difference for increasing ![]() $Pr$, going from

$Pr$, going from ![]() $Pr=1$ (figure 3a) where this difference is small, to

$Pr=1$ (figure 3a) where this difference is small, to ![]() $Pr=8$ (figure 3d) where this difference is large. The heat transfer from the drops to the carrier fluid becomes slower as

$Pr=8$ (figure 3d) where this difference is large. The heat transfer from the drops to the carrier fluid becomes slower as ![]() $Pr$ increases, consistent with a physical situation in which the

$Pr$ increases, consistent with a physical situation in which the ![]() $Pr$ number is increased by reducing the thermal diffusivity of the fluid while keeping the momentum diffusivity constant (i.e. constant kinematic viscosity, and hence shear Reynolds number). Also, the temperature structures, both inside and outside the drop, become thinner and more complicated at higher

$Pr$ number is increased by reducing the thermal diffusivity of the fluid while keeping the momentum diffusivity constant (i.e. constant kinematic viscosity, and hence shear Reynolds number). Also, the temperature structures, both inside and outside the drop, become thinner and more complicated at higher ![]() $Pr$, since their characteristic length scale, the Batchelor scale

$Pr$, since their characteristic length scale, the Batchelor scale ![]() $\eta _\theta ^+ \propto {Pr}^{-1/2}$, becomes smaller for increasing

$\eta _\theta ^+ \propto {Pr}^{-1/2}$, becomes smaller for increasing ![]() $Pr$ (Batchelor Reference Batchelor1959; Batchelor et al. Reference Batchelor, Howells and Townsend1959). In addition, smaller drops have, on average, a lower temperature compared to larger drops, regardless of the value of

$Pr$ (Batchelor Reference Batchelor1959; Batchelor et al. Reference Batchelor, Howells and Townsend1959). In addition, smaller drops have, on average, a lower temperature compared to larger drops, regardless of the value of ![]() $Pr$. All these aspects will be discussed in more detail in the next sections.

$Pr$. All these aspects will be discussed in more detail in the next sections.

Figure 3. Instantaneous visualization of the temperature field (red, hot; blue, cold) on a ![]() $x^+-y^+$ plane located at the channel centre for

$x^+-y^+$ plane located at the channel centre for ![]() $t^+=1500$. Drop interfaces (iso-level

$t^+=1500$. Drop interfaces (iso-level ![]() $\phi =0$) are reported using white lines. Each panel refers to a different Prandtl number. By increasing the Prandtl number (from top to bottom), the heat transfer becomes slower.

$\phi =0$) are reported using white lines. Each panel refers to a different Prandtl number. By increasing the Prandtl number (from top to bottom), the heat transfer becomes slower.

3.2. Drop size distribution

To characterize the collective dynamics of the drops, we compute the DSD at steady-state conditions, averaging over a time window ![]() ${\rm \Delta} t^+=3000$, from

${\rm \Delta} t^+=3000$, from ![]() $t^+=3000$ to

$t^+=3000$ to ![]() $6000$. The achievement of steady-state conditions is here evaluated by monitoring global flow properties, like flow rate and wall stress, and drop properties, like the number of drops and the overall drop surface. It is worth mentioning that a quasi-equilibrium DSD, very close to the steady one, is already achieved at

$6000$. The achievement of steady-state conditions is here evaluated by monitoring global flow properties, like flow rate and wall stress, and drop properties, like the number of drops and the overall drop surface. It is worth mentioning that a quasi-equilibrium DSD, very close to the steady one, is already achieved at ![]() $t^+ \simeq 750$, and only minor changes occur to the DSD afterwards.

$t^+ \simeq 750$, and only minor changes occur to the DSD afterwards.

Figure 4 shows the DSD obtained for the different cases considered here: ![]() $Pr=1$ (dark violet),

$Pr=1$ (dark violet), ![]() $Pr=2$ (violet),

$Pr=2$ (violet), ![]() $Pr=4$ (pink) and

$Pr=4$ (pink) and ![]() $Pr=8$ (light pink). Drop size distribution profiles are statistically the same. Small differences are due to the initial turbulence field, which is different for each simulation (see § 2.6). The DSDs have been computed considering, for each drop, the diameter of the equivalent sphere computed as

$Pr=8$ (light pink). Drop size distribution profiles are statistically the same. Small differences are due to the initial turbulence field, which is different for each simulation (see § 2.6). The DSDs have been computed considering, for each drop, the diameter of the equivalent sphere computed as

\begin{equation} d_{eq}^+ = \left( \frac{6 V^+}{\rm \pi} \right)^{1/3}, \end{equation}

\begin{equation} d_{eq}^+ = \left( \frac{6 V^+}{\rm \pi} \right)^{1/3}, \end{equation}

where ![]() $V^+$ is the volume of the drop. Also reported in figure 4 is the Kolmogorov–Hinze scale,

$V^+$ is the volume of the drop. Also reported in figure 4 is the Kolmogorov–Hinze scale, ![]() $d^+_H$, which can be computed as (Perlekar, Biferale & Sbragaglia Reference Perlekar, Biferale and Sbragaglia2012; Roccon et al. Reference Roccon, De Paoli, Zonta and Soldati2017; Soligo et al. Reference Soligo, Roccon and Soldati2019a)

$d^+_H$, which can be computed as (Perlekar, Biferale & Sbragaglia Reference Perlekar, Biferale and Sbragaglia2012; Roccon et al. Reference Roccon, De Paoli, Zonta and Soldati2017; Soligo et al. Reference Soligo, Roccon and Soldati2019a)

\begin{equation} d_H^+ = 0.725 \left(\frac{We}{Re_\tau} \right) ^{{-}3/5} | \epsilon_c|^{{-}2/5}, \end{equation}

\begin{equation} d_H^+ = 0.725 \left(\frac{We}{Re_\tau} \right) ^{{-}3/5} | \epsilon_c|^{{-}2/5}, \end{equation}

where ![]() $\epsilon _c$ is the turbulent dissipation, here evaluated at the channel centre where most of the drops collect because of their deformability (Lu & Tryggvason Reference Lu and Tryggvason2007; Soligo et al. Reference Soligo, Roccon and Soldati2020; Mangani et al. Reference Mangani, Soligo, Roccon and Soldati2022). Although recently challenged (Qi et al. Reference Qi, Tan, Corbitt, Urbanik, Salibindla and Ni2022; Vela-Martín & Avila Reference Vela-Martín and Avila2022; Ni Reference Ni2024), the Kolmogorov–Hinze scale (Kolmogorov Reference Kolmogorov1941; Hinze Reference Hinze1955) still represents a convenient estimate to evaluate the critical diameter below which drop breakage is unlikely to occur. Based on the Kolmogorov–Hinze scale, we can identify two different regimes (Garrett, Li & Farmer Reference Garrett, Li and Farmer2000; Deane & Stokes Reference Deane and Stokes2002; Deike Reference Deike2022). For drops smaller than the Kolmogorov–Hinze scale, we find the coalescence-dominated regime (left, grey area), in which drops that are smaller than the critical scale are generally not prone to break (although violent breakages can happen also for smaller drops). For drops larger than the Kolmogorov–Hinze scale, we find the breakage-dominated regime (right, white area) in which drop breakage is more likely to happen. Each regime is characterized by a specific scaling law, which describes the behaviour of the drop number density as a function of the drop size (Garrett et al. Reference Garrett, Li and Farmer2000; Deane & Stokes Reference Deane and Stokes2002; Chan, Johnson & Moin Reference Chan, Johnson and Moin2021): probability density function (PDF)

$\epsilon _c$ is the turbulent dissipation, here evaluated at the channel centre where most of the drops collect because of their deformability (Lu & Tryggvason Reference Lu and Tryggvason2007; Soligo et al. Reference Soligo, Roccon and Soldati2020; Mangani et al. Reference Mangani, Soligo, Roccon and Soldati2022). Although recently challenged (Qi et al. Reference Qi, Tan, Corbitt, Urbanik, Salibindla and Ni2022; Vela-Martín & Avila Reference Vela-Martín and Avila2022; Ni Reference Ni2024), the Kolmogorov–Hinze scale (Kolmogorov Reference Kolmogorov1941; Hinze Reference Hinze1955) still represents a convenient estimate to evaluate the critical diameter below which drop breakage is unlikely to occur. Based on the Kolmogorov–Hinze scale, we can identify two different regimes (Garrett, Li & Farmer Reference Garrett, Li and Farmer2000; Deane & Stokes Reference Deane and Stokes2002; Deike Reference Deike2022). For drops smaller than the Kolmogorov–Hinze scale, we find the coalescence-dominated regime (left, grey area), in which drops that are smaller than the critical scale are generally not prone to break (although violent breakages can happen also for smaller drops). For drops larger than the Kolmogorov–Hinze scale, we find the breakage-dominated regime (right, white area) in which drop breakage is more likely to happen. Each regime is characterized by a specific scaling law, which describes the behaviour of the drop number density as a function of the drop size (Garrett et al. Reference Garrett, Li and Farmer2000; Deane & Stokes Reference Deane and Stokes2002; Chan, Johnson & Moin Reference Chan, Johnson and Moin2021): probability density function (PDF) ![]() $\sim {d_{eq}^+}^{-3/2}$ below Kolmogorov–Hinze scale and PDF

$\sim {d_{eq}^+}^{-3/2}$ below Kolmogorov–Hinze scale and PDF ![]() $\sim {d_{eq}^+}^{-10/3}$ above it. The two scalings are represented by dot-dashed lines in figure 4.

$\sim {d_{eq}^+}^{-10/3}$ above it. The two scalings are represented by dot-dashed lines in figure 4.

Figure 4. Steady-state DSD obtained for: ![]() $Pr=1$ (dark violet, circles),

$Pr=1$ (dark violet, circles), ![]() $Pr=2$ (violet, squares),

$Pr=2$ (violet, squares), ![]() $Pr=4$ (pink, diamonds) and

$Pr=4$ (pink, diamonds) and ![]() $Pr=8$ (light pink, triangles). The Kolmogorov–Hinze (KH) scale

$Pr=8$ (light pink, triangles). The Kolmogorov–Hinze (KH) scale ![]() $d^+_H$ is reported with a vertical dashed line while the two analytical scaling laws,

$d^+_H$ is reported with a vertical dashed line while the two analytical scaling laws, ![]() ${d_{eq}^+}^{-3/2}$ for the coalescence-dominated regime (small drops, grey region) and

${d_{eq}^+}^{-3/2}$ for the coalescence-dominated regime (small drops, grey region) and ![]() ${d_{eq}^+}^{-10/3}$ for the breakage-dominated regime (larger drops, white region), are reported with dash-dotted lines.

${d_{eq}^+}^{-10/3}$ for the breakage-dominated regime (larger drops, white region), are reported with dash-dotted lines.

We note that for equivalent diameters above the Hinze scale, our results follow quite well the theoretical scaling law and match the size distributions of the drops/bubbles obtained in the literature considering similar flow instances (Deike, Melville & Popinet Reference Deike, Melville and Popinet2016; Soligo, Roccon & Soldati Reference Soligo, Roccon and Soldati2021; Deike Reference Deike2022; Di Giorgio, Pirozzoli & Iafrati Reference Di Giorgio, Pirozzoli and Iafrati2022; Crialesi-Esposito, Chibbaro & Brandt Reference Crialesi-Esposito, Chibbaro and Brandt2023). Below the Hinze scale, for equivalent diameters in the range ![]() $25<{d_{eq}^+}<{d_{H}^+}$, our results match reasonably well the theoretical scaling law. For equivalent diameters

$25<{d_{eq}^+}<{d_{H}^+}$, our results match reasonably well the theoretical scaling law. For equivalent diameters ![]() ${d_{eq}^+}<25~w.u.$, we observe an underestimation of the DSD compared with the proposed scaling. This is linked to the grid resolution, and in particular to the problem in describing very small drops (Soligo et al. Reference Soligo, Roccon and Soldati2021; Roccon et al. Reference Roccon, Zonta and Soldati2023).

${d_{eq}^+}<25~w.u.$, we observe an underestimation of the DSD compared with the proposed scaling. This is linked to the grid resolution, and in particular to the problem in describing very small drops (Soligo et al. Reference Soligo, Roccon and Soldati2021; Roccon et al. Reference Roccon, Zonta and Soldati2023).

3.3. Mean temperature of drops and carrier fluid

We now focus on the average temperature of the drops and of the carrier fluid. We consider the ensemble of all drops as one phase and the carrier fluid as the other phase (using the value of the phase field as a phase discriminator), and we compute the average temperature for each phase. The evolution in time of the drops and carrier fluid temperature, ![]() ${\bar {\theta }}_d$ and

${\bar {\theta }}_d$ and ![]() ${\bar {\theta }}_c$, respectively, is shown in figure 5 for the different values of

${\bar {\theta }}_c$, respectively, is shown in figure 5 for the different values of ![]() $Pr$. Together with the results obtained by current DNS, filled symbols in figure 5, we also show the predictions obtained by a simplified phenomenological model (solid lines), the details of which will be described and discussed later (see § 3.4). We start considering the DNS results only. As expected, we observe that the average temperature of the drops (violet to pink symbols) decreases in time, while the average temperature of the carrier fluid (blue to cyan symbols) increases in time, until the thermodynamic equilibrium, at which both phases have the same temperature, is asymptotically reached. For this reason, simulations have been run long enough for the average temperature of both phases to be sufficiently close to the equilibrium temperature. In particular, we stopped the simulations at

$Pr$. Together with the results obtained by current DNS, filled symbols in figure 5, we also show the predictions obtained by a simplified phenomenological model (solid lines), the details of which will be described and discussed later (see § 3.4). We start considering the DNS results only. As expected, we observe that the average temperature of the drops (violet to pink symbols) decreases in time, while the average temperature of the carrier fluid (blue to cyan symbols) increases in time, until the thermodynamic equilibrium, at which both phases have the same temperature, is asymptotically reached. For this reason, simulations have been run long enough for the average temperature of both phases to be sufficiently close to the equilibrium temperature. In particular, we stopped the simulations at ![]() $t^+ \simeq 6000$, when the condition

$t^+ \simeq 6000$, when the condition

with ![]() $\theta _{d,0}$ the initial temperature of the drops, is satisfied by all simulations. The equilibrium temperature,

$\theta _{d,0}$ the initial temperature of the drops, is satisfied by all simulations. The equilibrium temperature, ![]() $\theta _{eq}$, can be easily estimated a priori: since the two walls are adiabatic and the homogeneous directions are periodic, the energy of the system is conserved over time. After some algebra and recalling the definition of volume fraction,

$\theta _{eq}$, can be easily estimated a priori: since the two walls are adiabatic and the homogeneous directions are periodic, the energy of the system is conserved over time. After some algebra and recalling the definition of volume fraction, ![]() $\varPhi =V_d/(V_d+ V_c)$, we obtain the equilibrium temperature:

$\varPhi =V_d/(V_d+ V_c)$, we obtain the equilibrium temperature:

which is represented by the horizontal dashed line in figure 5.

Figure 5. Time evolution of the mean temperature of drops (violet to pink colours, different symbols) and carrier fluid (blue to cyan colours, different symbols) for the different Prandtl numbers considered. DNS results are reported with full circles while the predictions obtained from the model are reported with continuous lines. The equilibrium temperature of the system, ![]() $\theta _{eq}$, is reported with a horizontal dashed line.

$\theta _{eq}$, is reported with a horizontal dashed line.

Figure 5 also provides a clear indication that a higher Prandtl number results in a longer time required for the system to reach the equilibrium temperature, ![]() $\theta _{eq}$. The trend can be observed for both the drops and carrier fluid, as the two phases are mutually coupled (the heat released from the drops is adsorbed by the carrier fluid). This result confirms our previous qualitative observations, see figure 3 and discussion therein, where a large

$\theta _{eq}$. The trend can be observed for both the drops and carrier fluid, as the two phases are mutually coupled (the heat released from the drops is adsorbed by the carrier fluid). This result confirms our previous qualitative observations, see figure 3 and discussion therein, where a large ![]() $Pr$ (small thermal diffusivity) reduces the heat released by the drops. It is also interesting to observe that the behaviour of the mean temperature of the two phases appears self-similar at the different

$Pr$ (small thermal diffusivity) reduces the heat released by the drops. It is also interesting to observe that the behaviour of the mean temperature of the two phases appears self-similar at the different ![]() $Pr$.

$Pr$.

3.4. A phenomenological model for heat transfer rates in droplet laden flows

In an effort to provide a possible interpretation of the previous results – and in particular to explain the average temperature behaviour shown in figure 5 – we develop a simple physically sound model of the heat transfer in drop-laden turbulence. We start by considering the heat transfer mechanisms from a single drop of diameter ![]() $d^*$ to the surrounding fluid:

$d^*$ to the surrounding fluid:

where ![]() $m_d^*$,

$m_d^*$, ![]() $A_d^*$ and

$A_d^*$ and ![]() $c_p^*$ are the mass, external surface and specific heat of the drop,

$c_p^*$ are the mass, external surface and specific heat of the drop, ![]() $\mathcal {H}^*$ is the heat transfer coefficient, while

$\mathcal {H}^*$ is the heat transfer coefficient, while ![]() $\theta _d^*$ and

$\theta _d^*$ and ![]() $\theta _c^*$ are the drop and carrier fluid temperature. The heat transfer coefficient can be estimated as the ratio between the thermal conductivity of the external fluid,

$\theta _c^*$ are the drop and carrier fluid temperature. The heat transfer coefficient can be estimated as the ratio between the thermal conductivity of the external fluid, ![]() $\lambda ^*$, and a reference length scale, here represented by the thermal boundary layer thickness

$\lambda ^*$, and a reference length scale, here represented by the thermal boundary layer thickness ![]() $\delta _t^*$:

$\delta _t^*$:

With this assumption, and recalling that ![]() $\rho ^*=\rho ^*_c=\rho ^*_d$, (3.5) becomes

$\rho ^*=\rho ^*_c=\rho ^*_d$, (3.5) becomes

Reportedly (Schlichting & Gersten Reference Schlichting and Gersten2016, p. 218), the thermal boundary layer thickness, ![]() $\delta _t^*$, can be expressed as

$\delta _t^*$, can be expressed as ![]() $\delta _t^*=\delta ^* Pr^{-\alpha }$, where

$\delta _t^*=\delta ^* Pr^{-\alpha }$, where ![]() $\delta ^*$ is the momentum boundary layer thickness and

$\delta ^*$ is the momentum boundary layer thickness and ![]() $\alpha$ is an exponent that depends on the flow condition in the proximity of the boundary where the boundary layer evolves. In particular, the exponent

$\alpha$ is an exponent that depends on the flow condition in the proximity of the boundary where the boundary layer evolves. In particular, the exponent ![]() $\alpha$ ranges from

$\alpha$ ranges from ![]() $\alpha =1/3$ for no-slip conditions, usually assumed for solid particles, to

$\alpha =1/3$ for no-slip conditions, usually assumed for solid particles, to ![]() $\alpha =1/2$, usually assumed for clean gas bubbles. For an in-depth discussion on the topic, we refer the reader to Appendix A. As a consequence, the heat transfer rate observed from drops/bubbles is expected to be larger than that observed from solid particles, since the no-slip boundary condition generally weakens the flow motion near the interface (Levich Reference Levich1962; Bird et al. Reference Bird, Stewart and Lightfoot2002; Herlina & Wissink Reference Herlina and Wissink2016). We can now rewrite the equation of the model in dimensionless form, using the initial drop-to-carrier fluid temperature difference

$\alpha =1/2$, usually assumed for clean gas bubbles. For an in-depth discussion on the topic, we refer the reader to Appendix A. As a consequence, the heat transfer rate observed from drops/bubbles is expected to be larger than that observed from solid particles, since the no-slip boundary condition generally weakens the flow motion near the interface (Levich Reference Levich1962; Bird et al. Reference Bird, Stewart and Lightfoot2002; Herlina & Wissink Reference Herlina and Wissink2016). We can now rewrite the equation of the model in dimensionless form, using the initial drop-to-carrier fluid temperature difference ![]() ${\rm \Delta} \theta ^*= \theta ^*_{d,0} - \theta ^*_{c,0}$ as reference temperature, and

${\rm \Delta} \theta ^*= \theta ^*_{d,0} - \theta ^*_{c,0}$ as reference temperature, and ![]() $\nu ^*/u_{\tau }^{*2}$ as reference time:

$\nu ^*/u_{\tau }^{*2}$ as reference time:

where ![]() $d^+$ is the drop diameter in wall units, while

$d^+$ is the drop diameter in wall units, while ![]() $Re_{\delta }=u_{\tau }^* \delta ^* /\nu ^*$ is the Reynolds number based on the boundary layer thickness (which can be assumed constant among the different cases). Equation (3.8) can be rewritten as

$Re_{\delta }=u_{\tau }^* \delta ^* /\nu ^*$ is the Reynolds number based on the boundary layer thickness (which can be assumed constant among the different cases). Equation (3.8) can be rewritten as

where ![]() $\mathcal {C }$ is a constant whose value depends only on the flow structure, i.e. on

$\mathcal {C }$ is a constant whose value depends only on the flow structure, i.e. on ![]() $Re_{\delta }$. Equation (3.9) describes the heat released by a single drop of dimensionless diameter

$Re_{\delta }$. Equation (3.9) describes the heat released by a single drop of dimensionless diameter ![]() $d^+$. Assuming now that the turbulent flow is laden with drops of different diameters, the general equation describing the heat released by the

$d^+$. Assuming now that the turbulent flow is laden with drops of different diameters, the general equation describing the heat released by the ![]() $i$th drop of diameter

$i$th drop of diameter ![]() $d_i^+$ becomes

$d_i^+$ becomes

where ![]() $\mathcal {F}_i$ is the lumped-parameters representation of the right-hand side of the temperature evolution equation for the

$\mathcal {F}_i$ is the lumped-parameters representation of the right-hand side of the temperature evolution equation for the ![]() $i$th drop. As widely observed in the literature (Deane & Stokes Reference Deane and Stokes2002; Soligo et al. Reference Soligo, Roccon and Soldati2019c), and also confirmed by the present study (figure 4), we can hypothesize an equilibrium DSD by which the number density of drops scales as

$i$th drop. As widely observed in the literature (Deane & Stokes Reference Deane and Stokes2002; Soligo et al. Reference Soligo, Roccon and Soldati2019c), and also confirmed by the present study (figure 4), we can hypothesize an equilibrium DSD by which the number density of drops scales as ![]() ${d^+}^{-3/2}$ in the sub-Hinze range of diameters (

${d^+}^{-3/2}$ in the sub-Hinze range of diameters (![]() $10< d^+<110$), and as

$10< d^+<110$), and as ![]() ${d^+}^{-10/3}$ in the super-Hinze range of diameters (

${d^+}^{-10/3}$ in the super-Hinze range of diameters (![]() $110< d^+<240$). With this approximation, and considering seven classes of drop diameter for the sub-Hinze range and four classes for the super-Hinze range, we can integrate (3.10) to obtain the time evolution of the temperature of each drop in time:

$110< d^+<240$). With this approximation, and considering seven classes of drop diameter for the sub-Hinze range and four classes for the super-Hinze range, we can integrate (3.10) to obtain the time evolution of the temperature of each drop in time:

From a weighted average of the temperature (based on the number of drops in each class, as per the theoretical DSD), we obtain the average temperature of the drops, ![]() $\bar {\theta }_d$.

$\bar {\theta }_d$.

To obtain the mean temperature of the carrier fluid, we consider that (adiabatic condition at the walls) the heat released by the drops is entirely absorbed by the carrier fluid. The heat released by the drops with a certain diameter ![]() $d_i^*$ can be computed as

$d_i^*$ can be computed as

where ![]() $N^*_d(i)$ is the number of drops for that specific diameter (as per the DSD). The overall heat released by all drops can be calculated as the summation over all different classes of diameters:

$N^*_d(i)$ is the number of drops for that specific diameter (as per the DSD). The overall heat released by all drops can be calculated as the summation over all different classes of diameters:

\begin{equation} Q^*_{tot}=\sum_{i=1}^{N_{c}} Q_i^*,\end{equation}

\begin{equation} Q^*_{tot}=\sum_{i=1}^{N_{c}} Q_i^*,\end{equation}

where ![]() $N_c$ is the employed number of classes. Finally, the mean temperature of the carrier fluid is

$N_c$ is the employed number of classes. Finally, the mean temperature of the carrier fluid is

In dimensionless form (dividing by the initial drop-to-carrier fluid temperature ![]() ${\rm \Delta} \theta ^*$), (3.14) becomes

${\rm \Delta} \theta ^*$), (3.14) becomes

The results of the model are shown in figure 5. Interestingly, under the simplified hypothesis of the model (chiefly, the spherical shape of the drops, constant DSD evaluated at the equilibrium), we observe that the behaviour of the mean temperature is very well captured by the model (represented by the solid lines in figure 5):

i.e. when ![]() $\alpha =1/3$ – typical of boundary layers around solid objects (i.e. solid particles). Reasons for this behaviour might be traced back to the weakening of convective phenomena induced by the interface of the drops (Scarbolo & Soldati Reference Scarbolo and Soldati2013). This effect is more pronounced at the beginning of the simulation when large drops are not yet present. In addition, it must be also noticed that drops are strongly advected by the mean flow, and the flow condition at the drop surface can be different from the slip one and is, in general, not of simple evaluation. Given the relationship

$\alpha =1/3$ – typical of boundary layers around solid objects (i.e. solid particles). Reasons for this behaviour might be traced back to the weakening of convective phenomena induced by the interface of the drops (Scarbolo & Soldati Reference Scarbolo and Soldati2013). This effect is more pronounced at the beginning of the simulation when large drops are not yet present. In addition, it must be also noticed that drops are strongly advected by the mean flow, and the flow condition at the drop surface can be different from the slip one and is, in general, not of simple evaluation. Given the relationship ![]() $\partial \theta _d/\partial t \sim Pr^{-2/3}$ postulated by the model in (3.16), which provides results in very good agreement with the numerical ones, it seems reasonable to rescale the time variable as

$\partial \theta _d/\partial t \sim Pr^{-2/3}$ postulated by the model in (3.16), which provides results in very good agreement with the numerical ones, it seems reasonable to rescale the time variable as

A representation of the DNS results in terms of the rescaled time, (3.17), is shown in figure 6. We observe a nice collapse of the two sets of curves – drops and carrier fluid (red and blue) – for the different values of ![]() $Pr$, which clearly demonstrates the self-similar behaviour of

$Pr$, which clearly demonstrates the self-similar behaviour of ![]() $\bar {\theta }$. For this reason, the rescaling of time

$\bar {\theta }$. For this reason, the rescaling of time ![]() $\tilde t^+={t^+}/Pr^{2/3}$ will be also used in the following.

$\tilde t^+={t^+}/Pr^{2/3}$ will be also used in the following.

Figure 6. Time evolution of the mean temperature of drops (violet to pink colours) and carrier fluid (blue to cyan colours) for the different Prandtl numbers considered obtained from DNS and reported against the dimensionless time ![]() $\tilde {t}^+= t^+/Pr^{2/3}$. The equilibrium temperature of the system,

$\tilde {t}^+= t^+/Pr^{2/3}$. The equilibrium temperature of the system, ![]() $\theta _{eq}$, is reported with a horizontal dashed line. The DNS results reported over the new dimensionless time nicely collapse on top of each other, highlighting the self-similarity of the

$\theta _{eq}$, is reported with a horizontal dashed line. The DNS results reported over the new dimensionless time nicely collapse on top of each other, highlighting the self-similarity of the ![]() $\bar {\theta }_{c,d}$ profiles.

$\bar {\theta }_{c,d}$ profiles.

3.5. Heat transfer from particles and drops/bubbles

It is now important to discuss the behaviour of the heat transfer coefficient (and its dimensionless counterpart, the Nusselt number ![]() $Nu$) also in the context of available literature results. Naturally, similar considerations can be made to evaluate the mass transfer coefficient, in particular at liquid/gas interfaces (Levich Reference Levich1962; Bird et al. Reference Bird, Stewart and Lightfoot2002).

$Nu$) also in the context of available literature results. Naturally, similar considerations can be made to evaluate the mass transfer coefficient, in particular at liquid/gas interfaces (Levich Reference Levich1962; Bird et al. Reference Bird, Stewart and Lightfoot2002).

For solid particles, a balance between the convective time scale near the surface and the diffusion time scale gives a heat transfer coefficient (Krishnamurthy & Subramanian Reference Krishnamurthy and Subramanian2018),

and the corresponding Nusselt number,

where ![]() $\beta$ is an exponent that depends on the flow conditions and links the boundary layer thickness to the particle Reynolds number. Usually,

$\beta$ is an exponent that depends on the flow conditions and links the boundary layer thickness to the particle Reynolds number. Usually, ![]() $\beta =1/3$ for small Reynolds numbers (Krishnamurthy & Subramanian Reference Krishnamurthy and Subramanian2018), while

$\beta =1/3$ for small Reynolds numbers (Krishnamurthy & Subramanian Reference Krishnamurthy and Subramanian2018), while ![]() $\beta =1/2$ for large Reynolds numbers (Ranz Reference Ranz1952; Whitaker Reference Whitaker1972; Michaelides Reference Michaelides2003).