1. Introduction

Droplet impact onto solid surfaces is ubiquitous in natural phenomena and practical applications. For instance, the impact of multiple droplets is common during rain in nature, during pesticide or nutrient spraying in agriculture, during drug delivery and medical treatments (nebulisers, cryogenic tissue cooling) and in industries (spray cooling, inkjet printing, surface coating, fuel injection). In particular, the outcome of the spray impact on surfaces depends on the impact behaviour of droplets and determines the deposited liquid mass and the generation of new liquid fragments, which move away from the surface.

The study of single-droplet impact on solid surfaces dates back to the pioneering experiment of Worthington (Worthington Reference Worthington1877). Many studies followed, which also considered time-resolved observations of the impact process over the last two decades using high-speed imaging (Thoroddsen, Etoh & Takehara Reference Thoroddsen, Etoh and Takehara2008). The literature classifies droplet impact phenomena into two groups, namely single-droplet impact and multiple-droplet impact (Cossali, Marengo & Santini 2007; Cossali et al. Reference Cossali, Marengo and Santini2007; Liang & Mudawar Reference Liang and Mudawar2016; Yarin, Roisman & Tropea Reference Yarin, Roisman and Tropea2017; Breitenbach, Roisman & Tropea Reference Breitenbach, Roisman and Tropea2018; Ersoy & Eslamian Reference Ersoy and Eslamian2020; Luo et al. Reference Luo, Wu, Xiao and Chen2021), depending on the concentration of impacting droplets and their interaction characteristics on the impact surface. A good understanding of the physics of single-droplet impact on both solid and liquid surfaces is available, see e.g. Josserand & Thoroddsen (Reference Josserand and Thoroddsen2016), Marengo et al. (Reference Marengo, Antonini, Roisman and Tropea2011) and Yarin et al. (Reference Yarin2006) for comprehensive reviews. The pertinent outcomes include splashing, deposition or bouncing of droplets and liquid spreading dynamics, and are mainly scaled by two dimensionless parameters: the Weber number ![]() $We={\rho V_{0}^2 D_{0}}/{\sigma }$ and the Reynolds number

$We={\rho V_{0}^2 D_{0}}/{\sigma }$ and the Reynolds number ![]() $Re={\rho V_{0}D_{0}}/{\mu }$, where

$Re={\rho V_{0}D_{0}}/{\mu }$, where ![]() $V_{0}$ is the impact velocity,

$V_{0}$ is the impact velocity, ![]() $D_{0}$ is the initial droplet diameter, and

$D_{0}$ is the initial droplet diameter, and ![]() $\rho$,

$\rho$, ![]() $\sigma$ and

$\sigma$ and ![]() $\mu$ represent the density, surface tension, and viscosity of the droplet liquid, respectively. The temporal evolution of single droplets after the impact is usually described using a non-dimensional time, defined as

$\mu$ represent the density, surface tension, and viscosity of the droplet liquid, respectively. The temporal evolution of single droplets after the impact is usually described using a non-dimensional time, defined as ![]() $\tau ={tV_{0}}/{D_{0}}$, where

$\tau ={tV_{0}}/{D_{0}}$, where ![]() $t$ is the dimensional time. A number of empirical correlations, based on

$t$ is the dimensional time. A number of empirical correlations, based on ![]() $We$ and

$We$ and ![]() $Re$, have been proposed for the deposition/splash boundary of single-droplet impacts on solid surfaces and the size of the liquid fragments generated after the splashing (Roisman, Lembach & Tropea Reference Roisman, Lembach and Tropea2015; Yarin et al. Reference Yarin, Roisman and Tropea2017; Burzynski, Roisman & Bansmer Reference Burzynski, Roisman and Bansmer2020).

$Re$, have been proposed for the deposition/splash boundary of single-droplet impacts on solid surfaces and the size of the liquid fragments generated after the splashing (Roisman, Lembach & Tropea Reference Roisman, Lembach and Tropea2015; Yarin et al. Reference Yarin, Roisman and Tropea2017; Burzynski, Roisman & Bansmer Reference Burzynski, Roisman and Bansmer2020).

However, multiple-droplet impacts on surfaces are more common in practical spraying processes and have not been investigated sufficiently (Liang & Mudawar Reference Liang and Mudawar2016; Yarin et al. Reference Yarin, Roisman and Tropea2017; Fest-Santini et al. Reference Fest-Santini, Steigerwald, Santini, Cossali and Weigand2021). Figure 1 depicts multiple-droplet impact scenarios on a solid substrate with associated length and time scales labelled in figure 1(a). Depending on the spacing ![]() $\Delta x$ between the centre of the droplets and their time difference

$\Delta x$ between the centre of the droplets and their time difference ![]() $\Delta t_{i}$, the impacts of multiple droplets can be successive, simultaneous and non-simultaneous, as illustrated in figure 1(b). The non-simultaneous impact case is expected to be statistically much more frequent than the others. It is noted that when either

$\Delta t_{i}$, the impacts of multiple droplets can be successive, simultaneous and non-simultaneous, as illustrated in figure 1(b). The non-simultaneous impact case is expected to be statistically much more frequent than the others. It is noted that when either ![]() $\Delta x$ or

$\Delta x$ or ![]() $\Delta t_i$ crosses a finite threshold level, a drop can deposit on a surface before the impact of a second drop, leading to a different phenomenology, i.e. one drop impacting next to a sessile drop (Gilet & Bourouiba Reference Gilet and Bourouiba2015; Wang & Bourouiba Reference Wang and Bourouiba2018). Most multiple-droplet impact studies have investigated successive impacts through experiments (Barnes et al. Reference Barnes, Hardalupas, Taylor and Wilkins1999; Fujimoto, Ito & Takezaki Reference Fujimoto, Ito and Takezaki2002; Fujimoto, Tong & Takuda Reference Fujimoto, Tong and Takuda2008; Deendarlianto et al. Reference Deendarlianto, Takata, Kohno, Hidaka, Wakui, Majid, Kuntoro, Indarto and Widyaparaga2016; Zhang et al. Reference Zhang, Li, Guo and Lv2017; Chen et al. Reference Chen, Chen, Yan, Li and Lin2020; Guggilla, Narayanaswamy & Pattamatta Reference Guggilla, Narayanaswamy and Pattamatta2020; Wibowo et al. Reference Wibowo, Widyatama, Kamal, Indarto and Deendarlianto2021) and numerical simulations (Fujimoto et al. Reference Fujimoto, Ogino, Hatta and Takuda2001; Tong, Kasliwal & Fujimoto Reference Tong, Kasliwal and Fujimoto2007; Raman et al. Reference Raman, Jaiman, Lee and Low2016; Zhang et al. Reference Zhang, Li, Guo and Lv2017; Luo et al. Reference Luo, Wu, Xiao and Chen2021). These studies have considered the hydrodynamics for a range of impact conditions, including the time difference between impacts, liquid properties, surface wettability, surface roughness, surface curvature and surface inclination. It was also shown that the impact of multiple droplets on surfaces modifies the liquid fragments that are generated during splashing relative to those of single-droplet impacts (Barnes et al. Reference Barnes, Hardalupas, Taylor and Wilkins1999; Moreira, Moita & Panao Reference Moreira, Moita and Panao2010). The physical understanding of the simultaneous impact of multiple droplets onto a solid surface and how multiple-droplet interactions affect the formation of new liquid fragments is still lacking. Partly, this omission is due to the difficulty of generating two droplets impacting simultaneously on a surface, as pointed out by several researchers (Tong et al. Reference Tong, Kasliwal and Fujimoto2007; Liang et al. Reference Liang, Yu, Chen and Shen2020). Such information can provide a physical understanding of the temporal evolution of droplet-pair impacts and potentially a reference for comparison to non-simultaneous impacts.

$\Delta t_i$ crosses a finite threshold level, a drop can deposit on a surface before the impact of a second drop, leading to a different phenomenology, i.e. one drop impacting next to a sessile drop (Gilet & Bourouiba Reference Gilet and Bourouiba2015; Wang & Bourouiba Reference Wang and Bourouiba2018). Most multiple-droplet impact studies have investigated successive impacts through experiments (Barnes et al. Reference Barnes, Hardalupas, Taylor and Wilkins1999; Fujimoto, Ito & Takezaki Reference Fujimoto, Ito and Takezaki2002; Fujimoto, Tong & Takuda Reference Fujimoto, Tong and Takuda2008; Deendarlianto et al. Reference Deendarlianto, Takata, Kohno, Hidaka, Wakui, Majid, Kuntoro, Indarto and Widyaparaga2016; Zhang et al. Reference Zhang, Li, Guo and Lv2017; Chen et al. Reference Chen, Chen, Yan, Li and Lin2020; Guggilla, Narayanaswamy & Pattamatta Reference Guggilla, Narayanaswamy and Pattamatta2020; Wibowo et al. Reference Wibowo, Widyatama, Kamal, Indarto and Deendarlianto2021) and numerical simulations (Fujimoto et al. Reference Fujimoto, Ogino, Hatta and Takuda2001; Tong, Kasliwal & Fujimoto Reference Tong, Kasliwal and Fujimoto2007; Raman et al. Reference Raman, Jaiman, Lee and Low2016; Zhang et al. Reference Zhang, Li, Guo and Lv2017; Luo et al. Reference Luo, Wu, Xiao and Chen2021). These studies have considered the hydrodynamics for a range of impact conditions, including the time difference between impacts, liquid properties, surface wettability, surface roughness, surface curvature and surface inclination. It was also shown that the impact of multiple droplets on surfaces modifies the liquid fragments that are generated during splashing relative to those of single-droplet impacts (Barnes et al. Reference Barnes, Hardalupas, Taylor and Wilkins1999; Moreira, Moita & Panao Reference Moreira, Moita and Panao2010). The physical understanding of the simultaneous impact of multiple droplets onto a solid surface and how multiple-droplet interactions affect the formation of new liquid fragments is still lacking. Partly, this omission is due to the difficulty of generating two droplets impacting simultaneously on a surface, as pointed out by several researchers (Tong et al. Reference Tong, Kasliwal and Fujimoto2007; Liang et al. Reference Liang, Yu, Chen and Shen2020). Such information can provide a physical understanding of the temporal evolution of droplet-pair impacts and potentially a reference for comparison to non-simultaneous impacts.

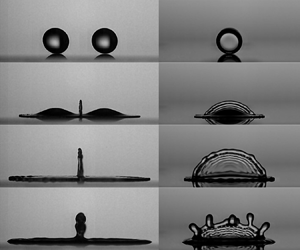

Figure 1. Multiple droplet impact on a solid surface. (a) Schematic of the associated length and time scales. (b) Schematic of successive, simultaneous and non-simultaneous impacts with respective criteria. Also, the touchdown condition (at ![]() $t=0$) and the central uprising sheet (at

$t=0$) and the central uprising sheet (at ![]() $t\gg 0$) for a case of simultaneous impacts.

$t\gg 0$) for a case of simultaneous impacts.

When two droplets simultaneously impact onto a solid surface, the spreading droplet lamellae interact and generate a central uprising sheet (figure 1). This central sheet may modify the splashing dynamics and the resulting liquid fragments. Barnes et al. (Reference Barnes, Hardalupas, Taylor and Wilkins1999) showed that the central sheet can become unstable and generate droplets that are larger than those generated during single-droplet impacts. Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) developed a theoretical model for the temporal evolution of the central sheet height for simultaneous impacts of identical droplets, which has not been verified by experimental findings. An early study used two generators of continuous monodispersed droplet streams (Barnes et al. Reference Barnes, Hardalupas, Taylor and Wilkins1999), while recent studies used microchannel syringe pumps with needle vibrators (Liang et al. Reference Liang, Yu, Chen and Shen2020; Gultekin et al. Reference Gultekin, Erkan, Ozdemir, Colak and Suzuki2021) and a multichannel micropipette (Ersoy & Eslamian Reference Ersoy and Eslamian2020) to deliver on-demand droplet pairs. However, these studies faced technical difficulties in reproducing simultaneous identical droplets. Therefore, they reported only one experimental observation of the vertical evolution of the sheet (i.e. like the bottom-right image of figure 1b) for a given ![]() $\Delta x$ and

$\Delta x$ and ![]() $We$ case, which they found as the best representative of a simultaneous impact case (Gultekin et al. Reference Gultekin, Erkan, Ozdemir, Colak and Suzuki2021). However, the central sheet grows both vertically and laterally, and a simultaneous recording from different views is required to fully characterise the sheet evolution. The study of Ersoy & Eslamian (Reference Ersoy and Eslamian2020) recorded the central sheet evolution individually from two orthogonal views (namely front and side views), where the ‘semilunar’ shape of the uprising sheet became evident in the side-view images. However, the reported results were limited, and the instability and the breakup of the central sheet into liquid fragments were not studied.

$We$ case, which they found as the best representative of a simultaneous impact case (Gultekin et al. Reference Gultekin, Erkan, Ozdemir, Colak and Suzuki2021). However, the central sheet grows both vertically and laterally, and a simultaneous recording from different views is required to fully characterise the sheet evolution. The study of Ersoy & Eslamian (Reference Ersoy and Eslamian2020) recorded the central sheet evolution individually from two orthogonal views (namely front and side views), where the ‘semilunar’ shape of the uprising sheet became evident in the side-view images. However, the reported results were limited, and the instability and the breakup of the central sheet into liquid fragments were not studied.

For simultaneous droplet impacts on liquid films, the splashing of the central sheet is reasonably understood through experiments (Cossali et al. Reference Cossali, Marengo and Santini2007) and numerical investigations (Liang et al. Reference Liang, Zhang, Yu, Chen and Shen2018; Fest-Santini et al. Reference Fest-Santini, Steigerwald, Santini, Cossali and Weigand2021). They recognised that the central sheet can disintegrate at a threshold level lower than that for equivalent single-droplet impacts in isolation (Cossali et al. Reference Cossali, Marengo and Santini2007). However, for simultaneous droplet impacts onto dry solid surfaces, no detailed study of the splashing morphology is available, and the characteristics of the central sheet and the resulting liquid fragments are largely unknown. In addition, the physical mechanism that determines the instability of the central sheet and its dependence on appropriate scaling parameters of droplet-pair impacts need to be determined.

The current study provides the first detailed morphological experimental characterisation of the temporal and spatial evolution of the central sheet and its splashing for simultaneous droplet-pair impacts on solid surfaces. It also develops a geometrical description of the underlying physics and provides a scaling model for the temporal evolution of the central sheet formed from the interacting individual lamellae. The rest of the paper is structured as follows. Section 2 describes the developed experimental approach for controlled ejection of simultaneous droplet pairs, the associated setup and the image processing approach. Section 3 reports the findings. It compares first a single-droplet impact to an equivalent droplet-pair impact with a particular focus on understanding the central sheet generation and the spreading dynamics of individual lamellae (§ 3.1). Then, the morphologies of the droplet impacts for different impact Weber numbers and inter-droplet spacings are discussed in § 3.2, followed by the geometrical description of the central sheet evolution (§ 3.3). Detailed quantitative analyses of the sheet evolution and spreading behaviour of the combined liquid mass are presented in § 3.4. The splashing characteristics of the central sheet are discussed in § 3.5. The paper ends with a summary of the main conclusions.

2. Experimental methodology

2.1. Experimental arrangement

The experiments use distilled water (![]() $\rho =996$ kg m

$\rho =996$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\sigma =0.073$ N m

$\sigma =0.073$ N m![]() $^{-1}$ and

$^{-1}$ and ![]() $\mu =0.001$ mPa s), and the impact substrate is a smooth acrylic (synthetic polymer, PMMA) plate. The mean roughness of the impact surface (

$\mu =0.001$ mPa s), and the impact substrate is a smooth acrylic (synthetic polymer, PMMA) plate. The mean roughness of the impact surface (![]() $R_a$) is 1.17 nm, measured using an optical microscope (Bruker-Nano, Contour GT-K). A drop shape analyser Kruss DSA 30 was used to measure the advancing

$R_a$) is 1.17 nm, measured using an optical microscope (Bruker-Nano, Contour GT-K). A drop shape analyser Kruss DSA 30 was used to measure the advancing ![]() $\theta _A$ and receding

$\theta _A$ and receding ![]() $\theta _R$ contact angles (

$\theta _R$ contact angles (![]() $\theta _{A}=80\pm 2^{\circ }$,

$\theta _{A}=80\pm 2^{\circ }$, ![]() $\theta _{R}=58\pm 2^{\circ }$) of the water on the acrylic surface by a sessile drop method. Figure 2 shows a schematic representation of the experimental setup. An in-house-built syringe pump was used to deliver the distilled water to the needle assembly. During each experiment, two equal-sized water droplets were simultaneously released from the blunt needle tips and allowed to impact the acrylic substrate. The impact process was recorded by a high-speed image acquisition unit, and the experimental data were extracted by post-processing the recorded images. A three-dimensional Cartesian coordinate system is defined for the impact process, as shown in figure 2. The origin of this coordinate system lies on the impact surface, in the middle of the impacting droplets. The initial droplet diameter (

$\theta _{R}=58\pm 2^{\circ }$) of the water on the acrylic surface by a sessile drop method. Figure 2 shows a schematic representation of the experimental setup. An in-house-built syringe pump was used to deliver the distilled water to the needle assembly. During each experiment, two equal-sized water droplets were simultaneously released from the blunt needle tips and allowed to impact the acrylic substrate. The impact process was recorded by a high-speed image acquisition unit, and the experimental data were extracted by post-processing the recorded images. A three-dimensional Cartesian coordinate system is defined for the impact process, as shown in figure 2. The origin of this coordinate system lies on the impact surface, in the middle of the impacting droplets. The initial droplet diameter (![]() $D_0$) was kept constant at

$D_0$) was kept constant at ![]() $3.13\pm 0.04$ mm and the impact Weber number (

$3.13\pm 0.04$ mm and the impact Weber number (![]() $We$) was varied by adjusting the droplet release height.

$We$) was varied by adjusting the droplet release height.

Figure 2. Schematic representation of the experimental arrangement (not to scale). The origin of the coordinate system is set on the substrate, in the middle of impacting droplets.

Two monochromatic high-speed cameras were synchronised to record simultaneously the front (Photron, FASTCAM APX RS) and side (Photron, FASTCAM SA1.1) perspectives of all impact processes. Both cameras were operated with a recording rate of 9000 frames/s and an exposure time of ![]() $5\,\mathrm {\mu }{\rm s}$. A standard micro-ruler, with a precision of 0.01 mm, was used to calibrate the window view of each camera. The effective spatial resolutions of the front and side cameras were 0.03 and 0.04 mm per pixel, respectively. The impact area was illuminated uniformly by two diffuser-paired LED lamps, arranged in a traditional shadowgraph imaging configuration (see figure 2).

$5\,\mathrm {\mu }{\rm s}$. A standard micro-ruler, with a precision of 0.01 mm, was used to calibrate the window view of each camera. The effective spatial resolutions of the front and side cameras were 0.03 and 0.04 mm per pixel, respectively. The impact area was illuminated uniformly by two diffuser-paired LED lamps, arranged in a traditional shadowgraph imaging configuration (see figure 2).

2.1.1. Droplet generator

A droplet generator was developed which had the ability to ensure simultaneous delivery of two same-size droplets. The droplet generator consists of two major parts: a customised needle assembly and an in-house-built 3-D printed syringe pump. The needle assembly includes two blunt tip removable needles with a mechanism to adjust the spacing between the needles, i.e. to precisely control the inter-droplet spacing (![]() $\Delta x$) during experiments. The programmable syringe pump has a microcontroller (Arduino Uno) and motor shield-based control system to actuate a fine stepper motor of the pump to precisely deliver liquid water through the needles (figure 2). The droplet generator was programmed to operate in three modes on demand: (i) droplet ejection; (ii) liquid jetting; and (iii) refilling. For the case of droplet ejection mode, the set speed and steps of the pump motor allow a certain amount of liquid to dispense out to each needle, leading to simultaneous single-droplet ejections with minimum oscillation. Any trapped air at the needle tips can lead to a non-simultaneous ejection of droplets. The liquid jetting operation mode allows draining out a volume of liquid to ensure air-free needle tips. Therefore, before ejecting the test droplets, a visible liquid meniscus was achieved at each needle tip through the liquid jetting operation. The syringe reservoir of the droplet generator can be refilled by a suction process, actuated by a reverse rotation of the pump motor.

$\Delta x$) during experiments. The programmable syringe pump has a microcontroller (Arduino Uno) and motor shield-based control system to actuate a fine stepper motor of the pump to precisely deliver liquid water through the needles (figure 2). The droplet generator was programmed to operate in three modes on demand: (i) droplet ejection; (ii) liquid jetting; and (iii) refilling. For the case of droplet ejection mode, the set speed and steps of the pump motor allow a certain amount of liquid to dispense out to each needle, leading to simultaneous single-droplet ejections with minimum oscillation. Any trapped air at the needle tips can lead to a non-simultaneous ejection of droplets. The liquid jetting operation mode allows draining out a volume of liquid to ensure air-free needle tips. Therefore, before ejecting the test droplets, a visible liquid meniscus was achieved at each needle tip through the liquid jetting operation. The syringe reservoir of the droplet generator can be refilled by a suction process, actuated by a reverse rotation of the pump motor.

2.2. Image post-processing

Several image processing routines were implemented in MATLAB to analyse the grey-scale images in batches (pre-impact or post-impact) to quantify the characteristics of the impact process. First, the quality of all images of a dataset was enhanced by applying the same filtering operations. Then, for a predefined batch of sequential images, an image processing routine binarised each image using a threshold value computed independently by applying Otsu's method (Otsu Reference Otsu1979) to each image. It is noted that changing the computed Otsu's threshold by ![]() $\pm 10\,\%$ led to negligible changes in the measured values. Finally, the binary images were processed further to obtain the measured quantities. The uncertainty in the pixel measurement was

$\pm 10\,\%$ led to negligible changes in the measured values. Finally, the binary images were processed further to obtain the measured quantities. The uncertainty in the pixel measurement was ![]() $\pm 1$ pixel, equivalent to 0.03 mm and 0.04 mm in the front-view and side-view images, respectively. The frame of the droplets’ touchdown on the surface was considered as the time reference frame with time

$\pm 1$ pixel, equivalent to 0.03 mm and 0.04 mm in the front-view and side-view images, respectively. The frame of the droplets’ touchdown on the surface was considered as the time reference frame with time ![]() $t=0$. The initial parameters, i.e.

$t=0$. The initial parameters, i.e. ![]() $D_0$,

$D_0$, ![]() $\Delta x$ and

$\Delta x$ and ![]() $V_0$, were measured from a predefined batch of consecutive images before impact. The

$V_0$, were measured from a predefined batch of consecutive images before impact. The ![]() $D_0$ was calculated from

$D_0$ was calculated from ![]() $D_{0}=\sqrt {{4A_{d}}/{{\rm \pi} }}$, where

$D_{0}=\sqrt {{4A_{d}}/{{\rm \pi} }}$, where ![]() $A_D$ represents the projected area of the droplet in an image. The

$A_D$ represents the projected area of the droplet in an image. The ![]() $V_0$ was calculated from the displacement of the droplets between two successive images. The uncertainty of the velocity estimation was within 0.025 m s

$V_0$ was calculated from the displacement of the droplets between two successive images. The uncertainty of the velocity estimation was within 0.025 m s![]() $^{-1}$. The characteristics of the central sheet evolution and the liquid spreading on the impact surface were also extracted from image processing routines and will be presented in related sections.

$^{-1}$. The characteristics of the central sheet evolution and the liquid spreading on the impact surface were also extracted from image processing routines and will be presented in related sections.

It is noted that even though the two droplets were released nominally simultaneously following the procedure of § 2.1.1, they sometimes arrived at the impact surface with one or two frame delays. This delay happened due to slight differences in each droplet distortion during release. However, in this study, we consider only droplet impacts that occur at the same frame, representing a timescale of ![]() $\approx 0.11$ ms (for the selected 9000 fps). In addition, for all these simultaneous droplet impact cases, we maintained a sample size of

$\approx 0.11$ ms (for the selected 9000 fps). In addition, for all these simultaneous droplet impact cases, we maintained a sample size of ![]() $N\geq 3$ per experimental case and the reported data represent the average value of the replicate events. It is noted that the vertical liquid sheet could not always be exactly captured from the side (i.e. front view). An angle between the

$N\geq 3$ per experimental case and the reported data represent the average value of the replicate events. It is noted that the vertical liquid sheet could not always be exactly captured from the side (i.e. front view). An angle between the ![]() $y$-axis (figure 2) and the camera axis was observed for some cases, as reflected by the sheet's projection in the front-view images (see figures 4 and 7). Apart from any inevitable misalignment in the optical arrangement, this angle could also be attributed to small differences in the diameter (or sphericity) of the two droplets, which influence the early stage of their interaction. For the dataset of the present study, the maximum angle between the central sheet axis and the camera axis is approximately

$y$-axis (figure 2) and the camera axis was observed for some cases, as reflected by the sheet's projection in the front-view images (see figures 4 and 7). Apart from any inevitable misalignment in the optical arrangement, this angle could also be attributed to small differences in the diameter (or sphericity) of the two droplets, which influence the early stage of their interaction. For the dataset of the present study, the maximum angle between the central sheet axis and the camera axis is approximately ![]() $3^{\circ }$.

$3^{\circ }$.

3. Results and discussion

In this section, starting with the central sheet formation mechanism, we will discuss the effect of the impact Weber number and inter-droplet spacing on the central sheet evolution, spreading and splashing dynamics, with a particular focus on characterising the outcomes of the impact processes.

3.1. Impact of two droplets: lamella spreading dynamics and central sheet formation

This section provides a comparison between the dynamics of two-droplet impacts (with dimensionless inter-droplet spacing ![]() $\Delta x^{*}=\Delta x/D_0=1.80$) and an equivalent single-droplet impact case (

$\Delta x^{*}=\Delta x/D_0=1.80$) and an equivalent single-droplet impact case (![]() $We\approx 80$,

$We\approx 80$, ![]() $Re\approx 3750$,

$Re\approx 3750$, ![]() $D_{0}=3.12\pm 0.02$). This allows establishing, initially qualitatively, the way that the dynamics change during the simultaneous two droplet impacts. The single-droplet impact was accomplished by masking one of the needles of the droplet-pair generator to allow the delivery of a single droplet. Figure 3(a) presents a selection of front-view images at different dimensionless times (

$D_{0}=3.12\pm 0.02$). This allows establishing, initially qualitatively, the way that the dynamics change during the simultaneous two droplet impacts. The single-droplet impact was accomplished by masking one of the needles of the droplet-pair generator to allow the delivery of a single droplet. Figure 3(a) presents a selection of front-view images at different dimensionless times (![]() $\tau \approx 0-20$) of the impact of the single droplet and the droplet pair (see also supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.249). Upon impact, the liquid lamella that emerges underneath each droplet starts to spread radially outwards on the surface, with a continuous decrease in the impacting droplet height. The spreading of the lamella on the surface is characterised by an instantaneous spread radius,

$\tau \approx 0-20$) of the impact of the single droplet and the droplet pair (see also supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.249). Upon impact, the liquid lamella that emerges underneath each droplet starts to spread radially outwards on the surface, with a continuous decrease in the impacting droplet height. The spreading of the lamella on the surface is characterised by an instantaneous spread radius, ![]() $R(t)$, which is defined in figure 3(b) for both impact processes.

$R(t)$, which is defined in figure 3(b) for both impact processes.

Figure 3. Surface impact process for a single droplet and a droplet pair on a solid surface (![]() $We =80$ for both cases, and

$We =80$ for both cases, and ![]() $\Delta x^* =1.80$ for the droplet pair). (a) Front-view images of the temporal evolution of the impact processes. Scale bars are 2 mm. (b) Schematic of the calculation of spread radius (

$\Delta x^* =1.80$ for the droplet pair). (a) Front-view images of the temporal evolution of the impact processes. Scale bars are 2 mm. (b) Schematic of the calculation of spread radius (![]() $R(t)$) from the impact centre of a droplet for both cases. (c) Dimensionless spread radius (

$R(t)$) from the impact centre of a droplet for both cases. (c) Dimensionless spread radius (![]() $R^*=R/D_0$) as a function of dimensionless time (

$R^*=R/D_0$) as a function of dimensionless time (![]() $\tau = tV_0/D_0$) for both cases, in comparison to the theory of (1) Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002), (2) Gordillo, Riboux & Quintero (Reference Gordillo, Riboux and Quintero2019) and (3) the empirical model by Lejeune, Gilet & Bourouiba (Reference Lejeune, Gilet and Bourouiba2018). See supplementary movie 1 for the corresponding video.

$\tau = tV_0/D_0$) for both cases, in comparison to the theory of (1) Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002), (2) Gordillo, Riboux & Quintero (Reference Gordillo, Riboux and Quintero2019) and (3) the empirical model by Lejeune, Gilet & Bourouiba (Reference Lejeune, Gilet and Bourouiba2018). See supplementary movie 1 for the corresponding video.

For the single-droplet impact with ![]() $We\approx 80$ (figure 3a), the rim-bounded spreading lamella reaches a maximum spread radius (

$We\approx 80$ (figure 3a), the rim-bounded spreading lamella reaches a maximum spread radius (![]() $R_{max}$) at

$R_{max}$) at ![]() $\tau \approx 2.25$. At

$\tau \approx 2.25$. At ![]() $R_{max}$, the contact line remains stationary while a receding contact angle is achieved at the lamella periphery, and subsequently, the liquid contact retracts back towards the impact centre. This receding liquid eventually deposits on the surface with an equilibrium shape at

$R_{max}$, the contact line remains stationary while a receding contact angle is achieved at the lamella periphery, and subsequently, the liquid contact retracts back towards the impact centre. This receding liquid eventually deposits on the surface with an equilibrium shape at ![]() $\tau >20$ (see supplementary movie 1). However, for the droplet-pair impact with

$\tau >20$ (see supplementary movie 1). However, for the droplet-pair impact with ![]() $\Delta x^*=1.80$ and

$\Delta x^*=1.80$ and ![]() $We\approx 80$ (figure 3a), the individual spreading lamellae start interacting with each other at the initial stage of their spreading (

$We\approx 80$ (figure 3a), the individual spreading lamellae start interacting with each other at the initial stage of their spreading (![]() $\tau \approx 0.4$). Due to the high kinetic energy of the lamellae, their interaction generates an uprising liquid sheet along the line of intersection. During this stage, stagnation points form on the surface at the intersection line, and the interacting liquid flows are redirected laterally and vertically on the impact surface (Batzdorf et al. Reference Batzdorf, Breitenbach, Schlawitschek, Roisman, Tropea, Stephan and Gambaryan-Roisman2017; Gultekin et al. Reference Gultekin, Erkan, Ozdemir, Colak and Suzuki2021). The central uprising sheet grows rapidly, reaches a summit (

$\tau \approx 0.4$). Due to the high kinetic energy of the lamellae, their interaction generates an uprising liquid sheet along the line of intersection. During this stage, stagnation points form on the surface at the intersection line, and the interacting liquid flows are redirected laterally and vertically on the impact surface (Batzdorf et al. Reference Batzdorf, Breitenbach, Schlawitschek, Roisman, Tropea, Stephan and Gambaryan-Roisman2017; Gultekin et al. Reference Gultekin, Erkan, Ozdemir, Colak and Suzuki2021). The central uprising sheet grows rapidly, reaches a summit (![]() $\tau \approx 2.25$), and falls back on the liquid mass underneath due to surface tension and gravity (

$\tau \approx 2.25$), and falls back on the liquid mass underneath due to surface tension and gravity (![]() $\tau \approx 5.5$). The surface liquid also recedes, similar to the single-droplet case, and finally attains an equilibrium shape after

$\tau \approx 5.5$). The surface liquid also recedes, similar to the single-droplet case, and finally attains an equilibrium shape after ![]() $\tau \approx 20$. For the single- and droplet-pair cases, the final equilibrium shape resembles a single sessile drop (see supplementary movie 1). The images of figure 3(a) indicate that the spreading of the non-interacting lamella segments remains unaffected on the impact surface during the formation and growth of the central uprising sheet. Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) also demonstrated similar spreading behaviour using the top-view images of droplet-pair impacts.

$\tau \approx 20$. For the single- and droplet-pair cases, the final equilibrium shape resembles a single sessile drop (see supplementary movie 1). The images of figure 3(a) indicate that the spreading of the non-interacting lamella segments remains unaffected on the impact surface during the formation and growth of the central uprising sheet. Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) also demonstrated similar spreading behaviour using the top-view images of droplet-pair impacts.

For the isolated and non-isolated impact cases of figure 3(a), we applied an image analysis algorithm that determines the impact centre of a droplet and measures the instantaneous spread radius (![]() $R(t)$), as defined in figure 3(b). The temporal evolution of the dimensionless spread radius (

$R(t)$), as defined in figure 3(b). The temporal evolution of the dimensionless spread radius (![]() $R^*(\tau )=R(t)/D_0$) for single-droplet and droplet-pair impacts up to

$R^*(\tau )=R(t)/D_0$) for single-droplet and droplet-pair impacts up to ![]() $\tau \approx 3.0$ is shown in figure 3(c). For the isolated single droplet,

$\tau \approx 3.0$ is shown in figure 3(c). For the isolated single droplet, ![]() $R^*$ of the advancing lamella reaches a maximum value, which is approximately 1.65 times the initial droplet diameter (

$R^*$ of the advancing lamella reaches a maximum value, which is approximately 1.65 times the initial droplet diameter (![]() $D_0$) at

$D_0$) at ![]() $\tau \approx 2.25$ and then

$\tau \approx 2.25$ and then ![]() $R^*$ decreases as the lamella recedes. For the non-isolated droplets of the droplet pair,

$R^*$ decreases as the lamella recedes. For the non-isolated droplets of the droplet pair, ![]() $R^*$ was measured from

$R^*$ was measured from ![]() $\tau =\tau _0\approx 0.4$, where

$\tau =\tau _0\approx 0.4$, where ![]() $\tau _0$ is the instant of the initiation of lamella interaction. The temporal evolution of

$\tau _0$ is the instant of the initiation of lamella interaction. The temporal evolution of ![]() $R^*$ of the non-isolated droplets superposes on that of the isolated single droplet, with a negligible relative difference (maximum of 1.7 %), see figure 3(c). This superposition corroborates the idea that, for the droplet-pair impact, the portion of the liquid lamella that does not contribute to the central sheet formation spreads on the dry substrate, remaining unaffected by the ascending central sheet.

$R^*$ of the non-isolated droplets superposes on that of the isolated single droplet, with a negligible relative difference (maximum of 1.7 %), see figure 3(c). This superposition corroborates the idea that, for the droplet-pair impact, the portion of the liquid lamella that does not contribute to the central sheet formation spreads on the dry substrate, remaining unaffected by the ascending central sheet.

Numerous theoretical relations exist to estimate the maximum spread radius (![]() $R_{max}$) on dry solid substrates in terms of different dimensionless parameters, which are individually a function of the impact parameters (Josserand & Thoroddsen Reference Josserand and Thoroddsen2016). However, such theoretical relations for the time-dependent spread radius,

$R_{max}$) on dry solid substrates in terms of different dimensionless parameters, which are individually a function of the impact parameters (Josserand & Thoroddsen Reference Josserand and Thoroddsen2016). However, such theoretical relations for the time-dependent spread radius, ![]() $R(t)$, are far less reported in the literature (Yarin et al. Reference Yarin2006). An earlier study of Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) considered the mass and momentum balance equations of a lamella rim to develop an analytical model, which allows estimating

$R(t)$, are far less reported in the literature (Yarin et al. Reference Yarin2006). An earlier study of Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) considered the mass and momentum balance equations of a lamella rim to develop an analytical model, which allows estimating ![]() $R(t)$ in a dimensionless form as

$R(t)$ in a dimensionless form as

where ![]() $A$,

$A$, ![]() $B$ and

$B$ and ![]() $\omega$ are three dimensionless parameters which depend on the Weber number

$\omega$ are three dimensionless parameters which depend on the Weber number ![]() $We$, the Reynolds number

$We$, the Reynolds number ![]() $Re$ and the static advancing contact angle

$Re$ and the static advancing contact angle ![]() $\theta _{A}$ (see Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) for related details). It is noted that (3.1) was developed for

$\theta _{A}$ (see Roisman et al. (Reference Roisman, Prunet-Foch, Tropea and Vignes-Adler2002) for related details). It is noted that (3.1) was developed for ![]() $1 \leq \tau \leq \tau _{max }$, where

$1 \leq \tau \leq \tau _{max }$, where ![]() $\tau _{max}$ is the dimensionless time that corresponds to the dimensionless maximum spread radius (

$\tau _{max}$ is the dimensionless time that corresponds to the dimensionless maximum spread radius (![]() $R_{max}^*$). Using the experimental parameters of the impact processes of figure 3(a), we obtain

$R_{max}^*$). Using the experimental parameters of the impact processes of figure 3(a), we obtain ![]() $A\approx 1.48$,

$A\approx 1.48$, ![]() $B\approx 0.32$ and

$B\approx 0.32$ and ![]() $\omega \approx 0.27$. The prediction of (3.1) is compared to the current measurements in figure 3(c), where the theoretical line is extended for

$\omega \approx 0.27$. The prediction of (3.1) is compared to the current measurements in figure 3(c), where the theoretical line is extended for ![]() $\tau <1$ and slightly for

$\tau <1$ and slightly for ![]() $\tau >\tau _{max}$. Although (3.1) predicts the time for

$\tau >\tau _{max}$. Although (3.1) predicts the time for ![]() $R_{max}^*$ approximately in agreement with that for the measured

$R_{max}^*$ approximately in agreement with that for the measured ![]() $R_{max}^*$ (i.e.

$R_{max}^*$ (i.e. ![]() $\tau _{max}\approx 2.25$), it overestimates

$\tau _{max}\approx 2.25$), it overestimates ![]() $R_{max}^*$ with a relative mean error of

$R_{max}^*$ with a relative mean error of ![]() $\approx 11.84\,\%$. Other authors also find similar divergence, e.g. a relative mean error of

$\approx 11.84\,\%$. Other authors also find similar divergence, e.g. a relative mean error of ![]() $11.64\pm 5.94\,\%$ (Ukiwe & Kwok Reference Ukiwe and Kwok2005) and

$11.64\pm 5.94\,\%$ (Ukiwe & Kwok Reference Ukiwe and Kwok2005) and ![]() $14.17\pm 1.88\,\%$ (Ukiwe, Mansouri & Kwok Reference Ukiwe, Mansouri and Kwok2005), while comparing their measured

$14.17\pm 1.88\,\%$ (Ukiwe, Mansouri & Kwok Reference Ukiwe, Mansouri and Kwok2005), while comparing their measured ![]() $R_{max}^*$ to the prediction of (3.1). The limitation of this theoretical model lies primarily in the fact that the authors approximated the droplet shape as a circular disc of constant thickness from

$R_{max}^*$ to the prediction of (3.1). The limitation of this theoretical model lies primarily in the fact that the authors approximated the droplet shape as a circular disc of constant thickness from ![]() $\tau =1$, which is ‘not correct’ as mentioned in a later study (Roisman, Berberović & Tropea Reference Roisman, Berberović and Tropea2009). Figure 3(a) also reveals, for both single and droplet pair cases, that the disk shape is not flat at

$\tau =1$, which is ‘not correct’ as mentioned in a later study (Roisman, Berberović & Tropea Reference Roisman, Berberović and Tropea2009). Figure 3(a) also reveals, for both single and droplet pair cases, that the disk shape is not flat at ![]() $\tau =1$, but becomes flat at

$\tau =1$, but becomes flat at ![]() $\tau \approx 2$. In addition, the contact line velocity of the spreading lamella is equated to the impact velocity (

$\tau \approx 2$. In addition, the contact line velocity of the spreading lamella is equated to the impact velocity (![]() $V_0$) in this theory, whereas the contact line velocity of a spreading lamella is several times larger than the droplet impact velocity (Ukiwe & Kwok Reference Ukiwe and Kwok2005). The temporal evolution of the velocity of the lamella contact lines and that of the central uprising sheet is detailed in Appendix A. Considering more realistic hypotheses and by applying mass and momentum balances at the lamella rim, Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) deduced a set of ordinary differential equations that govern the time-dependent spread radius

$V_0$) in this theory, whereas the contact line velocity of a spreading lamella is several times larger than the droplet impact velocity (Ukiwe & Kwok Reference Ukiwe and Kwok2005). The temporal evolution of the velocity of the lamella contact lines and that of the central uprising sheet is detailed in Appendix A. Considering more realistic hypotheses and by applying mass and momentum balances at the lamella rim, Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) deduced a set of ordinary differential equations that govern the time-dependent spread radius ![]() $R^* (\tau )$. We numerically solved their equations using MATLAB for our experimental conditions, and figure 3(c) also presents the obtained droplet spreading radius

$R^* (\tau )$. We numerically solved their equations using MATLAB for our experimental conditions, and figure 3(c) also presents the obtained droplet spreading radius ![]() $R^*(\tau )$ (for a hydrophilic surface and in our dimensionless form), which is in excellent agreement with our measurements. Recently, Gorin et al. (Reference Gorin, Di Mauro, Bonn and Kellay2022) also observed similar agreement with the theory of Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) for both Newtonian and non-Newtonian droplet impacts. Figure 3(c) also presents

$R^*(\tau )$ (for a hydrophilic surface and in our dimensionless form), which is in excellent agreement with our measurements. Recently, Gorin et al. (Reference Gorin, Di Mauro, Bonn and Kellay2022) also observed similar agreement with the theory of Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) for both Newtonian and non-Newtonian droplet impacts. Figure 3(c) also presents ![]() $R^*(\tau )$ from the empirical model of Lejeune et al. (Reference Lejeune, Gilet and Bourouiba2018) and shows a reasonably good agreement with our measurements.

$R^*(\tau )$ from the empirical model of Lejeune et al. (Reference Lejeune, Gilet and Bourouiba2018) and shows a reasonably good agreement with our measurements.

3.2. Morphology of the central sheet evolution

3.2.1. Effect of impact Weber number

Figures 4 and 5 respectively show a series of front-view and side-view images of the simultaneous impacts of two droplets at different dimensionless times for four different impact Weber numbers (![]() $We$) with a fixed inter-droplet spacing of

$We$) with a fixed inter-droplet spacing of ![]() $\Delta x^{\ast }=1.80\pm 0.03$ (see also supplementary movies 2–5). These images reveal the morphology of the central sheet evolution in vertical and lateral directions. For all cases, the kinetic energy of the droplets is high enough to generate a central sheet, with its height increasing up to a certain time and then decreasing gradually, remaining vertical on the substrate. The dimensionless time for the onset of the lamella interaction (

$\Delta x^{\ast }=1.80\pm 0.03$ (see also supplementary movies 2–5). These images reveal the morphology of the central sheet evolution in vertical and lateral directions. For all cases, the kinetic energy of the droplets is high enough to generate a central sheet, with its height increasing up to a certain time and then decreasing gradually, remaining vertical on the substrate. The dimensionless time for the onset of the lamella interaction (![]() $\tau _0$) does not vary significantly with the impact

$\tau _0$) does not vary significantly with the impact ![]() $We$, i.e.

$We$, i.e. ![]() $\tau _0$ is approximately 0.4 for all four cases. The relatively small inter-droplet spacing allows the two lamellae to interact during their initial spreading phase (

$\tau _0$ is approximately 0.4 for all four cases. The relatively small inter-droplet spacing allows the two lamellae to interact during their initial spreading phase (![]() $\tau <1$). It is evident in figure 4 that a lamella becomes thinner with an increasing

$\tau <1$). It is evident in figure 4 that a lamella becomes thinner with an increasing ![]() $We$, yielding a relatively thinner central sheet at a higher

$We$, yielding a relatively thinner central sheet at a higher ![]() $We$. The onset of central sheet formation does not appear in the images of figure 5 due to the height of the descending droplets. The ascending sheets become evident as their sizes exceed the descending droplet views at

$We$. The onset of central sheet formation does not appear in the images of figure 5 due to the height of the descending droplets. The ascending sheets become evident as their sizes exceed the descending droplet views at ![]() $\tau \approx 0.75$. In all cases, the ascending central sheet is bounded by a rim owing to surface tension effects, and the rim grows at the expense of the liquid sheet. The images at

$\tau \approx 0.75$. In all cases, the ascending central sheet is bounded by a rim owing to surface tension effects, and the rim grows at the expense of the liquid sheet. The images at ![]() $\tau =1$ (figure 5) show that the thickness of the outer rim decreases with increasing

$\tau =1$ (figure 5) show that the thickness of the outer rim decreases with increasing ![]() $We$ due to the higher liquid kinetic energy relative to surface tension. All the rim-bounded ascending central sheets grow with a ‘semilunar’ shape, resulting from the action of lamella velocity components at the base of the sheet.

$We$ due to the higher liquid kinetic energy relative to surface tension. All the rim-bounded ascending central sheets grow with a ‘semilunar’ shape, resulting from the action of lamella velocity components at the base of the sheet.

Figure 4. Central sheet evolution at different impact Weber numbers (front view: ![]() $x$–

$x$–![]() $z$ plane of figure 1). The inter-droplet spacing is kept constant at

$z$ plane of figure 1). The inter-droplet spacing is kept constant at ![]() $5.65\pm 0.15$ mm (

$5.65\pm 0.15$ mm (![]() $\Delta x^*=1.80\pm 0.03$). Here,

$\Delta x^*=1.80\pm 0.03$). Here, ![]() $\tau$ is the dimensionless time. Scale bars are 2 mm. See supplementary movies 2–5 for the corresponding videos.

$\tau$ is the dimensionless time. Scale bars are 2 mm. See supplementary movies 2–5 for the corresponding videos.

Figure 5. Central sheet evolution at different impact Weber numbers (side view: ![]() $y$–

$y$–![]() $z$ plane of figure 1). The inter-droplet spacing is kept constant at

$z$ plane of figure 1). The inter-droplet spacing is kept constant at ![]() $5.65\pm 0.15$ mm (

$5.65\pm 0.15$ mm (![]() $\Delta x^*=1.80\pm 0.03$). Here,

$\Delta x^*=1.80\pm 0.03$). Here, ![]() $\tau$ is the dimensionless time. Scale bars are 2 mm. Additionally,

$\tau$ is the dimensionless time. Scale bars are 2 mm. Additionally, ![]() $\lambda _r$ and

$\lambda _r$ and ![]() $b$ (shown at

$b$ (shown at ![]() $\tau =3$) are the instantaneous wavelength of the rim instability and the instantaneous rim thickness, respectively. See supplementary movies 2–5 for the corresponding videos.

$\tau =3$) are the instantaneous wavelength of the rim instability and the instantaneous rim thickness, respectively. See supplementary movies 2–5 for the corresponding videos.

Figure 6(a) shows simplified schematics for two identical interacting lamellae on a smooth impact substrate. The interaction of these lamellae starts with their contact line points having ![]() $\alpha = 0$ (at the origin of the coordinate system), with the time-dependent lamella velocity

$\alpha = 0$ (at the origin of the coordinate system), with the time-dependent lamella velocity ![]() $V_L$ for

$V_L$ for ![]() $\tau =\tau _0$ (figure 6a-i). Subsequently, the continued lamella spreading leads to increasing interacting contact points along the

$\tau =\tau _0$ (figure 6a-i). Subsequently, the continued lamella spreading leads to increasing interacting contact points along the ![]() $y$-axis and symmetrically about the

$y$-axis and symmetrically about the ![]() $x$-axis, forming the linear sheet base for

$x$-axis, forming the linear sheet base for ![]() $\tau >\tau _0$ (figure 6a-ii). It is noted that the lamella velocity decreases with time, and therefore, a later interaction point (having

$\tau >\tau _0$ (figure 6a-ii). It is noted that the lamella velocity decreases with time, and therefore, a later interaction point (having ![]() $\alpha >0$) initiates with a lower

$\alpha >0$) initiates with a lower ![]() $V_L$ than for

$V_L$ than for ![]() $\tau =\tau _0$, and this

$\tau =\tau _0$, and this ![]() $V_L$ has two components,

$V_L$ has two components, ![]() $V_L\cos \alpha$ and

$V_L\cos \alpha$ and ![]() $V_L\sin \alpha$, respectively, along the

$V_L\sin \alpha$, respectively, along the ![]() $x$- and

$x$- and ![]() $y$-axes. The

$y$-axes. The ![]() $x$-velocity component

$x$-velocity component ![]() $V_L\cos \alpha$ that decreases with increasing

$V_L\cos \alpha$ that decreases with increasing ![]() $\alpha$ dictates the vertical growth of the central sheet, whereas the

$\alpha$ dictates the vertical growth of the central sheet, whereas the ![]() $y$-velocity component

$y$-velocity component ![]() $V_L\sin \alpha$ that increases with

$V_L\sin \alpha$ that increases with ![]() $\alpha$ dictates the lateral extension of the sheet. Therefore, in the case of an ascending central sheet, usually, the velocity of the uprising liquid is maximum in the middle of the sheet and minimum at both ends of the sheet base, yielding the ‘semilunar’ shape of the central sheets of figure 5.

$\alpha$ dictates the lateral extension of the sheet. Therefore, in the case of an ascending central sheet, usually, the velocity of the uprising liquid is maximum in the middle of the sheet and minimum at both ends of the sheet base, yielding the ‘semilunar’ shape of the central sheets of figure 5.

Figure 6. (a) Schematic of the interaction of identical spreading lamellae: (i) at their first instant of interaction (![]() $\tau =\tau _0$); and (ii) at

$\tau =\tau _0$); and (ii) at ![]() $\tau >\tau _0$. Here,

$\tau >\tau _0$. Here, ![]() $V_L$ is the lamella velocity that decreases as the spread radius

$V_L$ is the lamella velocity that decreases as the spread radius ![]() $R$ increases with time,

$R$ increases with time, ![]() $\alpha$ is the angle for any interaction point on the linear sheet base and

$\alpha$ is the angle for any interaction point on the linear sheet base and ![]() $\alpha =0$ corresponds to the first interaction point of the sheet base. (b) Concentric waves on the central sheet surface with the wavelength shown by red arrows.

$\alpha =0$ corresponds to the first interaction point of the sheet base. (b) Concentric waves on the central sheet surface with the wavelength shown by red arrows.

Figure 5 shows that concentric waves propagate towards the ascending ‘semilunar’ central sheet rim, similar to the capillary waves that occur during droplet impact onto thin liquid films (Yarin & Weiss Reference Yarin and Weiss1995). These wavelengths (shown in figure 6b) were measured with ImageJ software and found to reduce from ![]() $0.52\pm 0.02$ mm to

$0.52\pm 0.02$ mm to ![]() $0.41\pm 0.01$ mm and

$0.41\pm 0.01$ mm and ![]() $0.26\pm 0.01$ mm for increasing

$0.26\pm 0.01$ mm for increasing ![]() $We$ of 80, 104 and 128, respectively. The mechanisms that may contribute to the instabilities across the central sheet are considered below.

$We$ of 80, 104 and 128, respectively. The mechanisms that may contribute to the instabilities across the central sheet are considered below.

The central sheet ascends vertically in ambient quiescent air due to the interaction of two expanding lamellae. If we model the first interaction of these two lamellae as an impact of one liquid lamella with a stationary object (in this case, the second lamella), the inertia at impact for the considered model would be twice the average inertia of the expanding lamellae. Accordingly, a lamella impact Weber number can be considered as ![]() $We_{L,imp}=2\rho {V_{0,imp}^2}T_{L}/{\sigma }$, where

$We_{L,imp}=2\rho {V_{0,imp}^2}T_{L}/{\sigma }$, where ![]() $V_{L,imp}$ is the average velocity of the interacting lamella edges and

$V_{L,imp}$ is the average velocity of the interacting lamella edges and ![]() $T_L$ is the average thickness of the lamella edges at

$T_L$ is the average thickness of the lamella edges at ![]() $\tau =\tau _0$. For

$\tau =\tau _0$. For ![]() $We=128$ and

$We=128$ and ![]() $\Delta x^*=1.80$ (highest

$\Delta x^*=1.80$ (highest ![]() $We$ of figure 5), we measured

$We$ of figure 5), we measured ![]() $V_{L,imp}\approx {2.8}$ m s

$V_{L,imp}\approx {2.8}$ m s![]() $^{-1}$,

$^{-1}$, ![]() $T_L\approx {0.22}$ mm from images, resulting in

$T_L\approx {0.22}$ mm from images, resulting in ![]() $We_{L,imp}\approx {47}$, which is two orders of magnitude smaller than the critical Weber number of the flapping instability for a horizontally expanding sheet in air (i.e.

$We_{L,imp}\approx {47}$, which is two orders of magnitude smaller than the critical Weber number of the flapping instability for a horizontally expanding sheet in air (i.e. ![]() $We_{cr}\simeq {10^3}$ Bremond, Clanet & Villermaux Reference Bremond, Clanet and Villermaux2007; Villermaux & Clanet Reference Villermaux and Clanet2002). Therefore, the capillary waves of the central sheets are expected to propagate towards the sheet rim without amplification, leading to no flapping instability (i.e. left and right movement) at the central sheet edge. The temporal and spatial evolution of the uprising central sheets of figure 5 supports the ‘no-flap’ condition since no sign of flapping is observed. In addition, the measured central sheet wavelengths remain sub-millimetre and much smaller than the capillary wavelength limit for a water–air interface, i.e. less than 1.725 cm as quantified from the analysis of Liu, Kijanka & Urban (Reference Liu, Kijanka and Urban2020).

$We_{cr}\simeq {10^3}$ Bremond, Clanet & Villermaux Reference Bremond, Clanet and Villermaux2007; Villermaux & Clanet Reference Villermaux and Clanet2002). Therefore, the capillary waves of the central sheets are expected to propagate towards the sheet rim without amplification, leading to no flapping instability (i.e. left and right movement) at the central sheet edge. The temporal and spatial evolution of the uprising central sheets of figure 5 supports the ‘no-flap’ condition since no sign of flapping is observed. In addition, the measured central sheet wavelengths remain sub-millimetre and much smaller than the capillary wavelength limit for a water–air interface, i.e. less than 1.725 cm as quantified from the analysis of Liu, Kijanka & Urban (Reference Liu, Kijanka and Urban2020).

The propagating waves along the central sheet eventually thicken the uprising sheet rim. At some instant, the rim becomes unstable due to contributions from gravity and surface tension and corrugated for relatively high ![]() $We$, i.e. images for

$We$, i.e. images for ![]() $We=80$, 104 and 128 at

$We=80$, 104 and 128 at ![]() $\tau \approx 2.5$ of figure 5. The destabilisation and corrugations of a rim have been attributed to Rayleigh–Taylor (RT) instability (Taylor Reference Taylor1950; Villermaux & Bossa Reference Villermaux and Bossa2011; Peters, van der Meer & Gordillo Reference Peters, van der Meer and Gordillo2013), Rayleigh–Plateau (RP) instability (Rayleigh Reference Rayleigh1878; Rozhkov, Prunet-Foch & Vignes-Adler Reference Rozhkov, Prunet-Foch and Vignes-Adler2002; Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010), and a combination of Rayleigh–Taylor and Rayleigh–Plateau (coupled RT-RP) instabilities (Agbaglah, Josserand & Zaleski Reference Agbaglah, Josserand and Zaleski2013; Agbaglah & Deegan Reference Agbaglah and Deegan2014; Krechetnikov Reference Krechetnikov2010; Roisman Reference Roisman2010; Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018; Wang & Bourouiba Reference Wang and Bourouiba2021). Therefore, uncertainties remain on the relevant underlying physics. In addition, the instability mechanism specifically for a central sheet rim has not been evaluated yet. In the present study, an uprising liquid rim (high-density fluid) decelerates in air (low-density fluid). The onset of the uprising rim destabilisation and the consequent initial corrugations (up to

$\tau \approx 2.5$ of figure 5. The destabilisation and corrugations of a rim have been attributed to Rayleigh–Taylor (RT) instability (Taylor Reference Taylor1950; Villermaux & Bossa Reference Villermaux and Bossa2011; Peters, van der Meer & Gordillo Reference Peters, van der Meer and Gordillo2013), Rayleigh–Plateau (RP) instability (Rayleigh Reference Rayleigh1878; Rozhkov, Prunet-Foch & Vignes-Adler Reference Rozhkov, Prunet-Foch and Vignes-Adler2002; Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010), and a combination of Rayleigh–Taylor and Rayleigh–Plateau (coupled RT-RP) instabilities (Agbaglah, Josserand & Zaleski Reference Agbaglah, Josserand and Zaleski2013; Agbaglah & Deegan Reference Agbaglah and Deegan2014; Krechetnikov Reference Krechetnikov2010; Roisman Reference Roisman2010; Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018; Wang & Bourouiba Reference Wang and Bourouiba2021). Therefore, uncertainties remain on the relevant underlying physics. In addition, the instability mechanism specifically for a central sheet rim has not been evaluated yet. In the present study, an uprising liquid rim (high-density fluid) decelerates in air (low-density fluid). The onset of the uprising rim destabilisation and the consequent initial corrugations (up to ![]() $\tau \approx 2.5$ in figure 5) can be attributed to the RT mechanism (Taylor Reference Taylor1950). After

$\tau \approx 2.5$ in figure 5) can be attributed to the RT mechanism (Taylor Reference Taylor1950). After ![]() $\tau \approx 2.5$, the central sheets start to retract, and the rim corrugations become more pronounced and distinguishable (see images for

$\tau \approx 2.5$, the central sheets start to retract, and the rim corrugations become more pronounced and distinguishable (see images for ![]() $We=80$,

$We=80$, ![]() $104$ and

$104$ and ![]() $128$ in figure 5). The distribution of the corrugations appears to be almost symmetric around the

$128$ in figure 5). The distribution of the corrugations appears to be almost symmetric around the ![]() $z$-axis of the coordinate system, and the number of corrugations (

$z$-axis of the coordinate system, and the number of corrugations (![]() $N_C$) increases for higher

$N_C$) increases for higher ![]() $We$ (see images at

$We$ (see images at ![]() $\tau =3.0$ of figure 5).

$\tau =3.0$ of figure 5).

Recent studies (Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013; Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018; Wang & Bourouiba Reference Wang and Bourouiba2021) considered the coupled RT-RP instability for the sheet rim instability evolution and concluded that the RP is the dominant mechanism at later times. The average distance of the rim corrugations is close to the wavelength of the fastest-growing mode of the RP instability (Rayleigh Reference Rayleigh1878), which is ![]() $\lambda _{RP} (\tau )=4.5b(\tau )$, where

$\lambda _{RP} (\tau )=4.5b(\tau )$, where ![]() $b$ (defined in figure 5 and the measured values reported in table 1) is the average rim thickness. For

$b$ (defined in figure 5 and the measured values reported in table 1) is the average rim thickness. For ![]() $\tau \approx 3.0$, table 1 shows the measured average wavelength of the rim instability

$\tau \approx 3.0$, table 1 shows the measured average wavelength of the rim instability ![]() $\lambda _{r}$ (defined in figure 5) for

$\lambda _{r}$ (defined in figure 5) for ![]() $We=80$,

$We=80$, ![]() $104$ and

$104$ and ![]() $128$, and

$128$, and ![]() $\lambda _{r}$ is close to the corresponding

$\lambda _{r}$ is close to the corresponding ![]() $\lambda _{RP}$. Therefore, the rim of the central sheet is destabilised by the combined Rayleigh–Taylor and Rayleigh–Plateau mechanisms, in agreement with the findings of Krechetnikov (Reference Krechetnikov2010), Roisman (Reference Roisman2010), Agbaglah et al. (Reference Agbaglah, Josserand and Zaleski2013), Agbaglah & Deegan (Reference Agbaglah and Deegan2014), Wang et al. (Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018) and Wang & Bourouiba (Reference Wang and Bourouiba2021) for different geometries. At later times, adjacent corrugations merge at some locations (see figure 5 for

$\lambda _{RP}$. Therefore, the rim of the central sheet is destabilised by the combined Rayleigh–Taylor and Rayleigh–Plateau mechanisms, in agreement with the findings of Krechetnikov (Reference Krechetnikov2010), Roisman (Reference Roisman2010), Agbaglah et al. (Reference Agbaglah, Josserand and Zaleski2013), Agbaglah & Deegan (Reference Agbaglah and Deegan2014), Wang et al. (Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018) and Wang & Bourouiba (Reference Wang and Bourouiba2021) for different geometries. At later times, adjacent corrugations merge at some locations (see figure 5 for ![]() $We=104$ and

$We=104$ and ![]() $128$). At

$128$). At ![]() $\tau \approx 4$, the corrugations result in protruding finger-like structures due to the increased amplitude of the rim instability for higher

$\tau \approx 4$, the corrugations result in protruding finger-like structures due to the increased amplitude of the rim instability for higher ![]() $We$ (i.e.

$We$ (i.e. ![]() $We=80$,

$We=80$, ![]() $104$ and

$104$ and ![]() $128$). For

$128$). For ![]() $We>128$, protruding fingers appear on the ascending central sheet, which can disintegrate into secondary droplets. The splashing of the central sheet will be further discussed in § 3.5.

$We>128$, protruding fingers appear on the ascending central sheet, which can disintegrate into secondary droplets. The splashing of the central sheet will be further discussed in § 3.5.

Table 1. Comparison of the measured sheet rim instability wavelength (![]() $\lambda _r$) with the wavelength of the fastest growing mode of Rayleigh–Plateau instability (

$\lambda _r$) with the wavelength of the fastest growing mode of Rayleigh–Plateau instability (![]() $\lambda _{RP}$) at

$\lambda _{RP}$) at ![]() $\tau \approx 3.0$ for different impact Weber numbers (

$\tau \approx 3.0$ for different impact Weber numbers (![]() $We$). Here,

$We$). Here, ![]() $N_C$ and

$N_C$ and ![]() $b$ are the measured number of corrugations and the average rim thickness at

$b$ are the measured number of corrugations and the average rim thickness at ![]() $\tau \approx 3.0$, respectively.

$\tau \approx 3.0$, respectively.

3.2.2. Effect of inter-droplet spacing

Figures 7 and 8 respectively show the front-view and side-view images of the simultaneous impacts of two droplets for four different inter-droplet spacings (![]() $\Delta x^*$) with a fixed impact Weber number

$\Delta x^*$) with a fixed impact Weber number ![]() $We=62\pm 1$ (see also the supplementary movies 6–9). The instant of the start of the lamella interaction (

$We=62\pm 1$ (see also the supplementary movies 6–9). The instant of the start of the lamella interaction (![]() $\tau _0$) increases with the increase of inter-droplet spacing, e.g.

$\tau _0$) increases with the increase of inter-droplet spacing, e.g. ![]() $\tau _0\approx 0.25$ for

$\tau _0\approx 0.25$ for ![]() $\Delta x^*=1.32$ and

$\Delta x^*=1.32$ and ![]() $\tau _0\approx 0.75$ for

$\tau _0\approx 0.75$ for ![]() $\Delta x^*=2.25$. For larger

$\Delta x^*=2.25$. For larger ![]() $\Delta x^*$, the spreading lamellae lose more kinetic energy through viscous dissipation due to the prolonged spreading before the interaction. Consequently, the interaction of the lamellae reduces with increasing

$\Delta x^*$, the spreading lamellae lose more kinetic energy through viscous dissipation due to the prolonged spreading before the interaction. Consequently, the interaction of the lamellae reduces with increasing ![]() $\Delta x^*$, yielding a less pronounced central uprising sheet at larger

$\Delta x^*$, yielding a less pronounced central uprising sheet at larger ![]() $\Delta x^*$ (figures 7 and 8).

$\Delta x^*$ (figures 7 and 8).

Figure 7. Central sheet evolution for different inter-droplet spacings (front view: ![]() $x$–

$x$–![]() $z$ plane of figure 1). Here,

$z$ plane of figure 1). Here, ![]() $\Delta x^* (=\Delta x/D_0)$ is the inter-droplet spacing with respect to the initial droplet diameter, and

$\Delta x^* (=\Delta x/D_0)$ is the inter-droplet spacing with respect to the initial droplet diameter, and ![]() $\tau$ is the dimensionless time. Scale bars are 2 mm. The Weber number is fixed at

$\tau$ is the dimensionless time. Scale bars are 2 mm. The Weber number is fixed at ![]() $We=62\pm 1$. See supplementary movies 6–9 for the corresponding videos.

$We=62\pm 1$. See supplementary movies 6–9 for the corresponding videos.

Figure 8. Central sheet evolution for different inter-droplet spacing (side view: ![]() $y$–

$y$–![]() $z$ plane of figure 1). Here,

$z$ plane of figure 1). Here, ![]() $\Delta x^*(=\Delta x/D_0$) is the dimensionless inter-droplet spacing, and

$\Delta x^*(=\Delta x/D_0$) is the dimensionless inter-droplet spacing, and ![]() $\tau$ is the dimensionless time. Scale bars are 2 mm. The Weber number is fixed at

$\tau$ is the dimensionless time. Scale bars are 2 mm. The Weber number is fixed at ![]() $We=62\pm 1$. See supplementary movies 6–9 for the corresponding videos.

$We=62\pm 1$. See supplementary movies 6–9 for the corresponding videos.

For ![]() $\Delta x^*=2.25$,

$\Delta x^*=2.25$, ![]() $1.96$ and

$1.96$ and ![]() $1.64$, figures 7 and 8 show that the vertical evolution and the ‘semilunar’ shape of the central sheet appear at different times, but have similar characteristics to observations in figures 4 and 5 for different Weber numbers. For

$1.64$, figures 7 and 8 show that the vertical evolution and the ‘semilunar’ shape of the central sheet appear at different times, but have similar characteristics to observations in figures 4 and 5 for different Weber numbers. For ![]() $\Delta x^*=1.32$ though, the droplet interaction and the central sheet evolution are somehow different from the other cases in two ways.

$\Delta x^*=1.32$ though, the droplet interaction and the central sheet evolution are somehow different from the other cases in two ways.

(a) The vertically descending bulk liquid portions of the two droplets come in contact and start contributing to the central sheet evolution due to the closeness of the impacting droplets for

$\Delta x^*=1.32$. For the other three cases, the sheet evolves only through the interaction of the thin lamella portions (see images at

$\Delta x^*=1.32$. For the other three cases, the sheet evolves only through the interaction of the thin lamella portions (see images at  $\tau \approx 0.5$ in figure 7). Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) theoretically defined two ‘spatio-temporal’ regions of a single spreading droplet, namely the ‘drop-region’ and the ‘lamella-region’. They divided the instantaneous dimensionless spread radius

$\tau \approx 0.5$ in figure 7). Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) theoretically defined two ‘spatio-temporal’ regions of a single spreading droplet, namely the ‘drop-region’ and the ‘lamella-region’. They divided the instantaneous dimensionless spread radius  $R^* (\tau )$ (defined in figure 3) into two parts as

$R^* (\tau )$ (defined in figure 3) into two parts as  $R^* (\tau )=r_{d-r}^* (\tau )+r_{l-r}^* (\tau )$, where

$R^* (\tau )=r_{d-r}^* (\tau )+r_{l-r}^* (\tau )$, where  $r_{d-r}^* (\tau )$ defines the instantaneous ‘drop-region’ for

$r_{d-r}^* (\tau )$ defines the instantaneous ‘drop-region’ for  $0\leq r_{d-r}^* (\tau )\leq \sqrt {3\tau /2}$, and

$0\leq r_{d-r}^* (\tau )\leq \sqrt {3\tau /2}$, and  $r_{l-r}^* (\tau )$ defines the instantaneous ‘lamella-region’ for

$r_{l-r}^* (\tau )$ defines the instantaneous ‘lamella-region’ for  $\sqrt {3\tau /2}\leq r_{l-r}^*\leq R^* (\tau )$. Therefore, for droplet-pair impacts, at any instant

$\sqrt {3\tau /2}\leq r_{l-r}^*\leq R^* (\tau )$. Therefore, for droplet-pair impacts, at any instant  $\tau$, the two drop regions interact with each other if the spatio-temporal separator

$\tau$, the two drop regions interact with each other if the spatio-temporal separator  $\sqrt {3\tau /2}$ exceeds half of the inter-droplet spacing, i.e. if

$\sqrt {3\tau /2}$ exceeds half of the inter-droplet spacing, i.e. if  $\sqrt {3\tau /2}>\Delta x^*/2$. Note that Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) used impacting droplet radius (

$\sqrt {3\tau /2}>\Delta x^*/2$. Note that Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) used impacting droplet radius ( $R_0=D_0/2$) as the length scale for their dimensionless time, whereas we use

$R_0=D_0/2$) as the length scale for their dimensionless time, whereas we use  $D_0$ for

$D_0$ for  $\tau$. For

$\tau$. For  $\Delta x^*=1.32$ and

$\Delta x^*=1.32$ and  $\tau =0.5$, we find

$\tau =0.5$, we find  $\sqrt {3\tau /2}\approx 0.87$, which considerably exceeds

$\sqrt {3\tau /2}\approx 0.87$, which considerably exceeds  $\Delta x^*/2$

$\Delta x^*/2$  $(=0.66)$, indicating that the interaction of the two drop regions occurs at

$(=0.66)$, indicating that the interaction of the two drop regions occurs at  $\tau <0.5$, i.e. at the early stage of the phenomenon (figure 7 for

$\tau <0.5$, i.e. at the early stage of the phenomenon (figure 7 for  $\Delta x^*=1.32$). The descending bulk liquid of the drop region not only has a radial velocity like a spreading lamella but also has a downwards velocity as the liquid is yet to collapse on the impact surface.

$\Delta x^*=1.32$). The descending bulk liquid of the drop region not only has a radial velocity like a spreading lamella but also has a downwards velocity as the liquid is yet to collapse on the impact surface.(b) For

$\Delta x^*=1.32$, the central sheet appears to descend suddenly at

$\Delta x^*=1.32$, the central sheet appears to descend suddenly at  $\tau \approx 1.5$, whilst all other three central sheets are still ascending (figures 7 and 8). The ‘semilunar’ central sheet becomes evident at

$\tau \approx 1.5$, whilst all other three central sheets are still ascending (figures 7 and 8). The ‘semilunar’ central sheet becomes evident at  $\tau \approx 0.5$, earlier than for all other cases. However, the growth of the ascending central sheet appears to be more dominant in the lateral direction compared to the upwards direction, as suggested by the flat-topped central sheet at

$\tau \approx 0.5$, earlier than for all other cases. However, the growth of the ascending central sheet appears to be more dominant in the lateral direction compared to the upwards direction, as suggested by the flat-topped central sheet at  $\tau \approx 1$ (figure 8 for

$\tau \approx 1$ (figure 8 for  $\Delta x^*=1.32$). This means that, at the intersection line, the redirection of the interacting liquid flows is more prominent towards the sides compared to the upwards direction. This preferential lateral growth of the sheet can be attributed to the direct interaction of vertically descending with considerable velocity bulk droplet liquid. The dominant lateral liquid flow in the sheet leads to significant stretching of the rim that causes minimum thickness on the central axis (see image at

$\Delta x^*=1.32$). This means that, at the intersection line, the redirection of the interacting liquid flows is more prominent towards the sides compared to the upwards direction. This preferential lateral growth of the sheet can be attributed to the direct interaction of vertically descending with considerable velocity bulk droplet liquid. The dominant lateral liquid flow in the sheet leads to significant stretching of the rim that causes minimum thickness on the central axis (see image at  $\tau \approx 1.5$ in figure 8). In addition, at

$\tau \approx 1.5$ in figure 8). In addition, at  $\tau \gtrsim 1.5$, the sheet starts descending symmetrically around its central axis due to gravity, forming two prominent cusps at the sides that look like ‘hornlike’ structures after the inner portion of the sheet falls back on the surface. The inclined shape of these ‘horns’ facilitates their appreciably slower descent and thus retains the existence of the central sheet for a relatively long time. This unique central sheet evolution for small inter-droplet spacings is identified for the first time and can influence the liquid fragments generated during splashing. Consequently, additional physical processes must be considered to predict the liquid sheet instabilities for small values of

$\tau \gtrsim 1.5$, the sheet starts descending symmetrically around its central axis due to gravity, forming two prominent cusps at the sides that look like ‘hornlike’ structures after the inner portion of the sheet falls back on the surface. The inclined shape of these ‘horns’ facilitates their appreciably slower descent and thus retains the existence of the central sheet for a relatively long time. This unique central sheet evolution for small inter-droplet spacings is identified for the first time and can influence the liquid fragments generated during splashing. Consequently, additional physical processes must be considered to predict the liquid sheet instabilities for small values of  $\Delta x^*$.

$\Delta x^*$.

3.3. Geometrical description of the central sheet growth

The morphology and temporal evolution of the central sheet, shown in § 3.2, demonstrate that the vertical central sheet forms and grows at the expense of the horizontal spreading lamellae. The expense of the horizontal lamellae can be reflected on the ![]() $x$–

$x$–![]() $y$ plane by two truncated circles combined at the central sheet base, as shown in figure 6(a). For all cases, the side views of the central sheet resemble a circular segment on the