1. Introduction

The upscaling of emerging technologies in design and engineering science seems to be regularly examined (Boess Reference Boess2019; Wolniak et al. Reference Wolniak, Sauthoff, Lachmayer and Mozgova2019; Tozik & Reich Reference Tozik and Reich2023). This phenomenon is usually referred to as a complex phenomenon involving the development and deployment of technology in society. However, the assessment of upscaling embodies multiple facets that mobilize in practice a wide scientific literature and multiple areas of expertise. Some of these areas of expertise are not integrated into the identified traditional design framework. Societal imperatives (environment, safety, social justice) are increasingly demanded to be considered in innovation (Huntjens Reference Huntjens2021). In addition, a heterogeneous vocabulary referring to “scales” is used in the engineering literature to designate the relationship between technology and the society adopting it. The literature diversity associated with technology upscaling raises questions about the means that designers can identify to assess this phenomenon. Investigating how these resources align with societal ambitions is also crucial. This motivates the need for a literature clarification, to propose guidelines to designers that are relevant about the technology upscaling they are willing to study. This research paper therefore aims to answer the question: How can the phenomenon of “upscaling of emerging technology” be studied from the new perspectives of design communities? We split our research into two sub-questions: (1) How to characterize the concepts of emerging technology upscaling in the design communities? and (2) What are the engineering methods, practices and guidelines for assessing the “upscaling of an emerging technology” from a design integrative perspective? This review proposes a design theory based on the scientific literature from design and engineering communities to address the two research questions. This positions the contributions in integrated design defined as the intervention of actors and expertise in the design process of a system (e.g., a product or a service). This process aims to improve one or more aspects of the finished product (e.g., cost, quality, lead time; Pahl & Beitz Reference Pahl, Beitz and Wallace1996). Therefore, developing a design theory about emerging technology upscaling aims to make designers aware of the influence of their practices on the upscaling phenomenon. This theory conceptualizes different visions of the design of a technological product and is intended to be transferred to a practical audience of designers and engineers.

2. State of the art: the “upscaling of an emerging technology” as a catch-all phrase

Upscaling is a polysemic word and used in the scientific literature (Farmer Reference Farmer2002; Dijk, de Kraker & Hommels Reference Dijk, de Kraker and Hommels2018; Moreno et al. Reference Moreno, Grasman, van Engelen and Nijmeijer2018; Tsoy et al. Reference Tsoy, Steubing, van der Giesen and Guinée2020; Hjalsted et al. Reference Hjalsted, Laurent, Andersen, Olsen, Ryberg and Hauschild2021; Thiede, Wiese & Herrmann Reference Thiede, Wiese and Herrmann2021) in conjunction with number of terms related to scale: scaling up (Sanford et al. Reference Sanford, Chotani, Danielson and Zahn2016; Wolniak et al. Reference Wolniak, Sauthoff, Lachmayer and Mozgova2019; Belwal et al. Reference Belwal, Chemat, Venskutonis, Cravotto, Jaiswal, Bhatt, Devkota and Luo2020), growing (Cherp et al. Reference Cherp, Vinichenko, Tosun, Gordon and Jewell2021), deploying a technology (IRENA 2019b), scaling (Baumann & Lopatnikov Reference Baumann and Lopatnikov2017; Tanguy, Bahers & Athanassiadis Reference Tanguy, Bahers and Athanassiadis2020), reaching a level or an industrial/commercial scale (Piccinno et al. Reference Piccinno, Hischier, Seeger and Som2016; Ehrler et al. Reference Ehrler, Alarcón-Lladó, Tabernig, Veeken, Garnett and Polman2020; Verlinden Reference Verlinden2020; Bobbe et al. Reference Bobbe, Opeskin, L¨uneburg, Wanta, Pohlmann and Krzywinski2023), improving the scalability (Nordelof Reference Nordelof2019; Leccisi & Fthenakis Reference Leccisi and Fthenakis2021), using a scaling law (Baumann & Lopatnikov Reference Baumann and Lopatnikov2017), downscaling (Ryberg et al. Reference Ryberg, Andersen, Owsianiak and Hauschild2020; Hjalsted et al. Reference Hjalsted, Laurent, Andersen, Olsen, Ryberg and Hauschild2021), ecology and economy of scale (Gwehenberger et al. Reference Gwehenberger, Narodoslawsky, Liebmann and Friedl2007) and so forth. The abundance of keywords alone does not help to clearly define the upscaling and therefore turns this word into an umbrella term. As such, upscaling has a different meaning depending on the design community and the disciplinary field (e.g., chemical engineering (Balgobin & Evrard Reference Balgobin and Evrard2020), waste treatment sector (Barbero & Toso Reference Barbero and Toso2010), energy sector (Rae, Kerr & Maroto-Valer Reference Rae, Kerr and Maroto-Valer2020), food sector (Hardman, Clark & Sherriff Reference Hardman, Clark and Sherriff2022), building sector (Tanguy et al. Reference Tanguy, Bahers and Athanassiadis2020), goods production engineering (Koulin, Sewell & Shaw Reference Koulin, Sewell and Shaw2015) or nanoengineering (Moschou & Tserepi Reference Moschou and Tserepi2017)). Indeed, upscaling a technology or system can refer to technology maturity issues, industrial techno-economic optimization, technology deployment strategies or technical integration and/or social acceptance issues.

2.1. Defining an emerging technology

The same polysemy, identified for “upscaling”, goes for the concept of “emerging technology”. Three definitions of an emerging technology coexist in common designer language and are often concomitant with the terminology of an upscaling (Rotolo, Hicks & Martin Reference Rotolo, Hicks and Martin2015; Sims et al. Reference Sims, Flammini, Santos, Pereira, Carita, Bracco and Oze2017; Bergerson et al. Reference Bergerson, Brandt, Cresko, Carbajales-Dale, MacLean, Matthews, McCoy, McManus, Miller, Morrow, Posen, Seager, Skone and Sleep2020; Elshkaki Reference Elshkaki2021; Xu et al. Reference Xu, Hao, Yang, Lu and An2021): emerging technology as a promising but unmatured technology, a minor but growing technology, and emerging from a socio-technical vision.

-

• A promising technology in a laboratory or a maturing technology: In chemical and bioengineering fields, the subject of upscaling refers to an emerging technology or a process, to be understood as an early-stage technology in a laboratory. “Early-stage” and “emerging” are consistently used as synonymous by the life cycle assessment (LCA) community (Bergerson et al. Reference Bergerson, Brandt, Cresko, Carbajales-Dale, MacLean, Matthews, McCoy, McManus, Miller, Morrow, Posen, Seager, Skone and Sleep2020; Hung, Ellingsen, & Majeau-Bettez Reference Hung, Ellingsen and Majeau-Bettez2020). Additionally, institutions such as the European Commission or the International Energy Agency (IEA 2020) develop assessments and planification focused on technology maturity, relying on operational performance improvement together with lower cost (e.g., Horizon2020 2022 plan). These two types of sources are in line with defining an emerging technology as a promising and novel technology in a maturing process. Both push toward a definition mainly focused on technological maturity. An emerging technology is thus an immature technology with promising technical and/or environmental performance. This concept is not limited to the improvement of an existing technology. An emerging technology refers in that case to a non-mature technology poised to have a disruptive impact on society with regard to its supposed deployment.

-

• A minor but growing technology, deployed in a market: Also, from IEA publications, the necessary so-called “energy transitions” pull the development of technologies to satisfy a large part of the future energy needs of populations. Thus, an emerging technology in this context is not necessarily a novel or an early-stage technology but more an industrialized technology that is still marginal in the market. For instance, renewable energy systems such as wind power and photovoltaic are considered as “early adopted” technology by IEA (i.e., not early-stage technology). Both systems account together in 2020 for less than 4% of the world energy mix (IEA 2020; Ritchie, Roser & Rosado Reference Ritchie, Roser and Rosado2020). They are, however, purposed to become dominant in national energy mixes to satisfy carbon emission policies to tacking climate change. In addition, the concept of “materiality” defines the point at which a technology reaches 1% of the world’s energy mix. Thus, the requested development of renewable energies in the transition scenarios turns them into emerging technologies in terms of market or energy mix integration (Kramer & Haigh Reference Kramer and Haigh2009). This definition is consequently affiliated with the terms “technology adoption” and “materiality”. Rotolo et al. (Reference Rotolo, Hicks and Martin2015) detail five items from the scientometric domain to characterize an emerging technology: “Radical novelty, relatively fast growth, coherence, prominent impact and uncertainty and ambiguity”. “Prominent impact” is relative to expectations, imaginary and “preferred technological future” that designers promote, “relatively fast growth” associated with rapid abundance in literature and “coherence” resulting from a normative phenomenon on vocabulary structuring the state of the art of the studied emerging technology. Xu et al. (Reference Xu, Hao, Yang, Lu and An2021) reuse three of them to detect emerging technologies in literature (relatively fast growth, radical novelty and prominent impact). Remarks that these characteristics are not specific to any particular field of engineering or scientific literature.

-

• A technology emerging in a (socio-technical) system: This interpretation of emerging technology is related to integration in a so-called sociotechnical system (i.e., society) as illustrated by Geels et al. (Reference Geels, Sovacool, Schwanen and Sorrell2017). The authors present “technology niches” emerging or not in a sociotechnical system depending on its compatibility with the incumbent regime (e.g., regulations and policies, road infrastructure, industry structure, market and user practices, etc.). It is not a designer perspective but emergence-focused with a systemic vision. Integration issues are for instance addressed in the energy sector, where technologies must adapt to the power grid with geographical and techno-economic constraints. “Smart technologies” are in that context, defined as technologies helping new ones to be integrated (i.e., emerging technologies in the network; Rae et al. Reference Rae, Kerr and Maroto-Valer2020). The food sector uses a different terminology (e.g., “technological innovations” and “food system”) and emphasizes the social aspect of the emergence (Hardman et al. Reference Hardman, Clark and Sherriff2022). The emergence of technology is therefore both a technical and a social challenge, dealing with adoption by local populations, for example.

To summarize, terms relating to upscaling (or scale) and emerging technologies are used in the design and engineering literature repeatedly, without necessarily being connected to a clear definition. Our approach therefore aims to clarify the design vision by building a robust framework for analyzing the upscaling according to identified characteristics, as generic and cross-cutting as possible. This research defines such characteristics as “invariants”. Then, the objective is to empower designers with guidelines directing toward assessment methods for upscaling emerging technologies regarding a set definition.

2.2. Defining the upscaling, as a transforming function

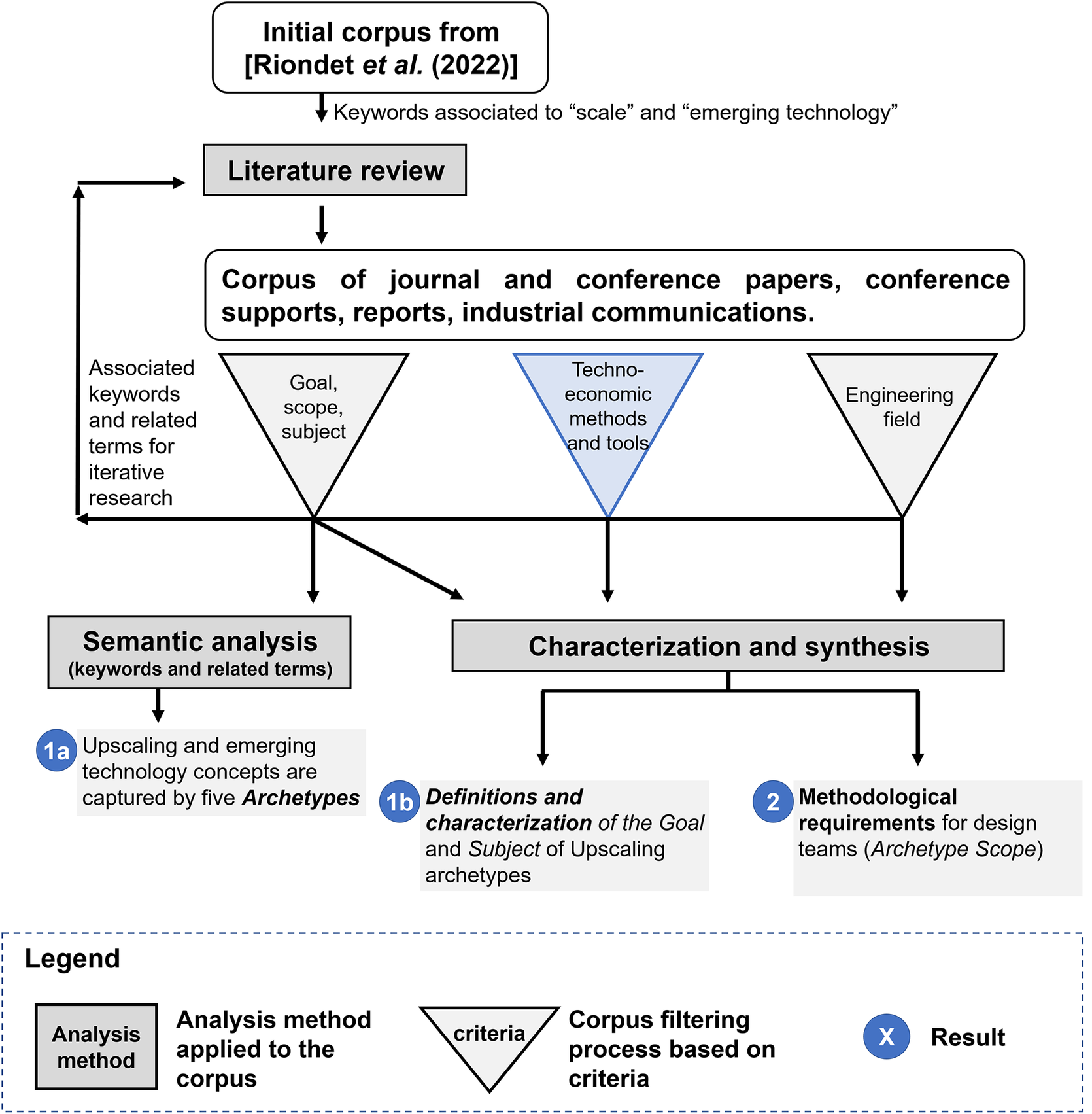

Previous research elaborated a literature reading hypothesis to characterize an upscaling process in engineering (Riondet et al. Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022). Following this hypothesis, the upscaling is assumed to be a “transforming function”. Upscaling is a phenomenon applied to a subject and bringing it from one state to another. The methods used to assess the upscaling in design and engineering, revealed in the literature analysis of this review, that they are mainly techno-economic analysis (TEA). TEA is a method used to assess a process or product system based on technical and economic performance criteria (Zimmermann et al. Reference Zimmermann, Wunderlich, Müller, Buchner, Marxen, Michailos, Armstrong, Naims, McCord, Styring, Sick and Schomäcker2020). Thus, an upscaling process is considered first as a techno-economic phenomenon. Based on the elements to be defined TEA referring to upscaling and emerging technologies, we proposed three interdependent characteristics for the upscaling of emerging technology: “subject, goal and scope” (see Figure 1).

Figure 1. Hypothesis of literature reading: upscaling as a transforming function composed of three interdependent characteristics, also called “invariants”, adapted from Riondet et al. (Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022).

The goal is based on a performance indicator. This means that the transforming function (i.e., the upscaling) can be represented on an indicator scale or domain. Moreover, the upscaling subject can be of a different nature, tangible or intangible (e.g., a product or service, an analysis boundary or a limit). Whether discipline-specific or not, methodologies to carry an upscaling rely on the scope defined linked to the goal. The subject is not necessarily the interest core of the scope. However, the scope is fully characterized by a type and the analysis boundary (or focus) pointing to the interest core.

This analysis framework enables designers to better define what they mean by upscaling a technology by characterizing “archetypes”, that is, a facet of the upscaling reflecting a specific design vision. An archetype, in our work, is therefore built on three set invariants goal, subject and scope. Building archetypes is, therefore, a simple way to embody visions of technology upscaling and subsequently, help designers and engineers identify the associated approaches and methods. However, according to the best of our knowledge, no paper explicitly characterizes the upscaling of emerging technologies in design to societal expectations, including sustainability. Additionally, no paper defines the different design and engineering approaches and methods to deal with the identified archetypes. The present article therefore uses the formalism of Riondet et al. (Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022) to deepen definitions and associated methods, to explore the links between the identified archetypes and the concept of emerging technology presented above and finally produce integrated guidelines for designers.

3. Method

3.1. Overview of the research methodology

Figure 2 illustrates the different stages of the applied methodology structuring this article, and shows the four ensuing results providing elements to address the research questions (1) (i.e., 1a and 1b) and (2).

Figure 2. Overview of article methodology and ensuing results. Results 1a and 1b are responses for research question (1) and result 2 for the research question of the same number.

As evoked in the Section 2, upscaling is considered as a techno-economic phenomenon that can be characterized via the characteristics of the analysis methods used to assess it. To do so, an “invariant” approach has been carried out, that is, the identification of elements common to several situations, enabling us to generate the missing homogeneous definition of a phenomenon.

This analysis revealed five upscaling archetypes (UAs) based on a review of a limited corpus of articles (fewer than 40 references). This review proposes to confront this conceptual framework with a larger corpus and to use it to structure our literature review process.

3.2. Literature review process

Indeed, because of the large number of articles using vocabulary referring to scale, it was not possible to use “classical” literature review methods. Thus, the methodology of literature reviewing can be described as follows: starting from the references provided by Riondet et al. (Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022), we iteratively expanded the number of reviewed references (corpus) based on two levers: specific search query strings based on keywords and search of reference affiliation in the corpus. Initially, keywords were chosen related to “upscaling”, “scale”, “scale-up”, “scale up” and “emerging technology”, and progressively driven by the selected articles (e.g., “deployment”, “massification” or “downscaling” related to “planetary boundaries (PBs)”). The search queries were conducted on Web of Science and Elsevier over the years 2022 and 2023. The affiliations were processed manually on the references of previously selected papers, following successive criteria: “Are the terms upscaling, scaling or scaling-up used in the abstract or the text?”, “Are there any words related to scale in the text?”, “Is the meaning of a keyword like upscaling in other related articles used in this article and through which other keywords?”. The reference is kept if the answer to these questions is positive. Additionally, the newly identified keywords are added to the search query strings. This process covers research works that, with a stricter keyword search, would have been ignored due to different vocabulary use. In addition, the selected literature has been restricted to the 10 following engineering fields (EFs): Chemical Engineering, Waste Treatment, Energy, Food, Building sector and Urbanism, Electronics and Information and Communications Technologies (ICT), Transport, Bioengineering, Nanoengineering and Production engineering. Were therefore excluded from the study upscaling definitions referring to numerical methods in fluids modeling science as a scientific field out of the design literature. For a review in this direction, consult Farmer (Reference Farmer2002). The literature review process was maintained until a decrease of new information related to four criteria: goal, subject, scope associated with new upscaling definitions and new identified approaches or assessment methods referring to it. It ended with a corpus of 270 references, including research papers, conference supports and scientific reports.

3.3. Semantic analysis process

During the literature review process, a clustering was carried out on the corpus to identify the co-occurrences between keywords of articles which were associated with upscaling and emerging technology (i.e., words of the research queries). This was done to characterize interactions between archetypes and balance literature searches. The first step of this process was prepared with the software “VOSviewer”. The software represents the keywords of selected articles on a map according to a proximity metric. Links are then drawn between co-occurring keywords for the same article. The co-occurrence threshold can be adjusted to represent only the most recurrent keywords. Finally, clusters are identified automatically by thresholding the number of co-occurrence links between a group of words. This makes it possible to group keywords that are used recurrently and document a common context. The second step of the semantic analysis was to complete the preliminary figure with terms identified in the papers and related to the same semantics but not presented as keywords by publishers or authors. VOSviewer is used in this literature analyses process to reveal visually the keywords and terms related to research domains the papers relate to. This brought about the state (result 1a) (see Figure 2) that UAs are consistent concepts in the literature, also covering the three “emerging technology” definitions.

3.4. Characterization and synthesis process

To complement the keyword analysis process, a systematic characterization of each archetype has been conducted on the Corpus. This led to an exhaustive definition of each of the UAs, with examples from several EFs. Moreover, a synthesis of the invariant elements, that is, goal, subject and focus as a constituent of the upscaling scope has been provided (result 1b). In parallel, design and engineering assessment methods for upscaling have been collected. Design guidelines have been extracted from them, based on methodological invariants for each UA. These generic guidelines have been produced independently from the EF (result 2). An engineering discipline filter has been added to assess the sector or activity influence on the availability of dedicated literature to upscaling.

4. Results

This section presents the results obtained from the research questions leading this research article. Sections 4.1 and 4.2 detail, respectively, the results 1b and 1a, characterizing the upscaling emerging technologies in the design communities. The Sections 4.3 and 4.4 are dedicated to support and guide the designer to assess an upscaling based on the given definition.

4.1. Definitions of archetypes

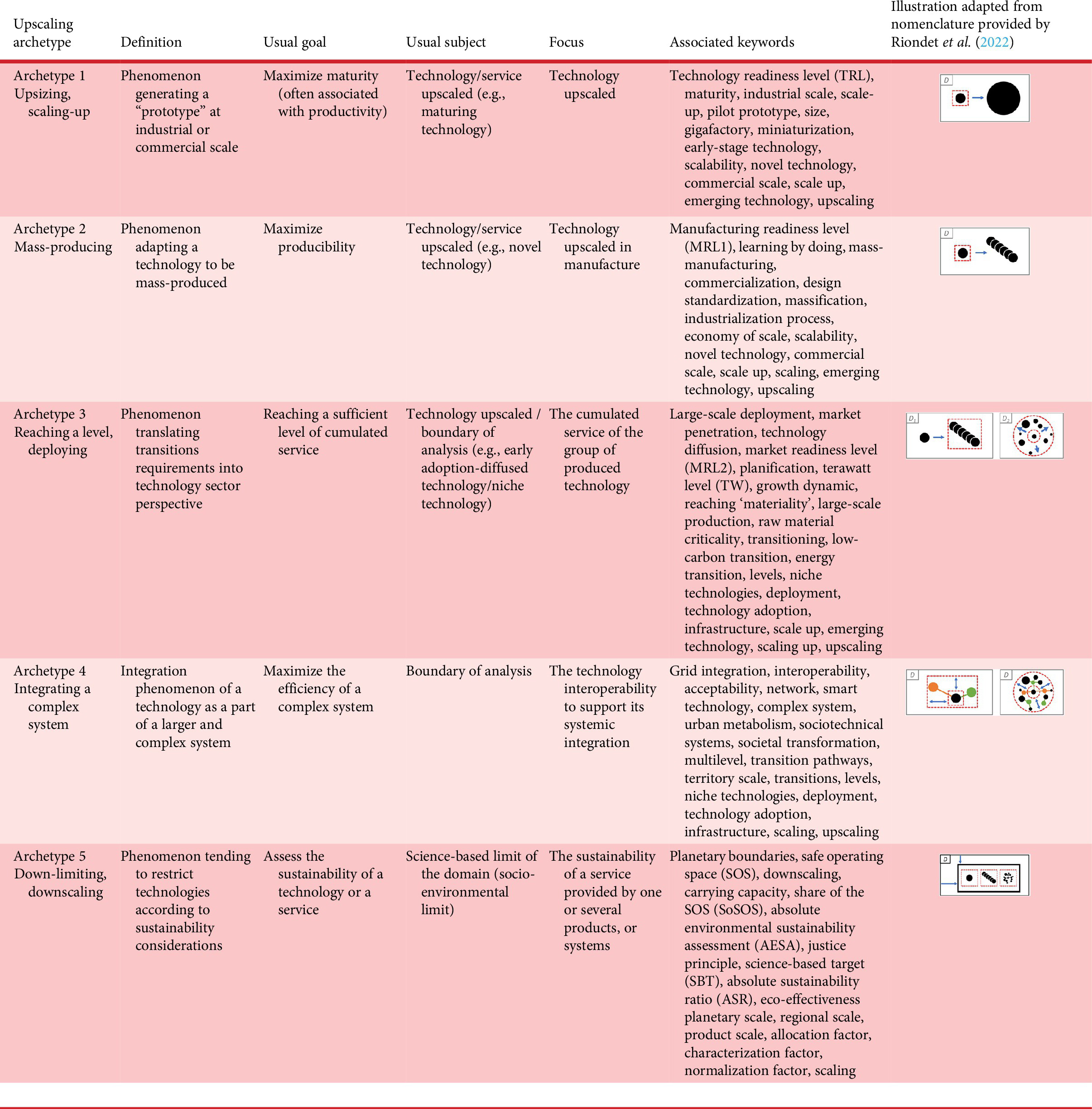

Structuring the reading of the design literature on upscaling, the following section deepens the definition of five archetypes of upscaling outlined in Riondet et al. (Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022). These updated definitions are based on a robustness test of the reading hypothesis (see Section 1) given on a larger number of references than the one originally proposed. As a result, Table 1 synthetizes the definition and characterization of these five archetypes in terms of goal, subject and upscaling focus. Each archetype is also associated with keywords, to ease further research on this topic, and is illustrated referring to the nomenclature provided by Riondet et al. (Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022). The five following subsections clarify and deepen each archetype definition by providing several engineering-based case study examples.

Table 1. Synthesis of upscaling archetypes definitions with associated keywords and symbolic illustration

4.1.1. Archetype 1 – From laboratory to industrial scale: A productivity focus

The first archetype identified is assimilated to design processes turning a “prototype”, usually developed in laboratories or research and development (R&D) departments, into a device/technology with industrial performances (Piccinno et al. Reference Piccinno, Hischier, Seeger and Som2016; Sanford et al. Reference Sanford, Chotani, Danielson and Zahn2016; Crater & Lievense Reference Crater and Lievense2018; López-Vizcaíno et al. Reference López-Vizcaíno, Yustres, Sáez, Cañizares, Asensio, Navarro and Rodrigo2019). The “scale” characterizing the evolution between the laboratory to the industry is systematically identified as a maturity scale, often equated to the technology readiness level (TRL; Hetherington et al. Reference Hetherington, Borrion, Griffiths and McManus2014; Belwal et al. Reference Belwal, Chemat, Venskutonis, Cravotto, Jaiswal, Bhatt, Devkota and Luo2020; van der Giesen et al. Reference van der Giesen, Cucurachi, Guinée, Kramer and Tukker2020). This indicator has various definitions according to institutions and purpose (Buchner et al. Reference Buchner, Stepputat, Zimmermann and Schomacker2019). However, a maturity scale usually evolves between 1 and 9, the latter corresponding to the industrialization phase. In the European Commission’s definition of TRL (Council of Europe 2019), the upscaling can therefore be described as the process enabling a technology turn from the fourth level (prototyping) to the seventh level (prototype at the industrial scale), in one step or several if necessary (Moreno et al. Reference Moreno, Grasman, van Engelen and Nijmeijer2018; López-Vizcaíno et al. Reference López-Vizcaíno, Yustres, Sáez, Cañizares, Asensio, Navarro and Rodrigo2019). Remark that the IEA also employs TRLs to categorize the technologies that will be used for the energy transition. Then, the TRL are grouped into four levels: prototype, demonstrations, early adoption and mature (IEA 2020). In other terms, to move “from laboratory scale to industrial scale” means increasing the technology maturity which can be transposed to productivity and/or size (Crater & Lievense Reference Crater and Lievense2018; Roy et al. Reference Roy, Radivojevic, Forrer, Marti, Jonnalagadda, Backman, Morrell, Plahar, Kim, Hillson and Martin2021). In the PV industry, as another example, upscaling is assimilated to “upsizing”, meaning, to increase the size of a solar cell, for a new technology (i.e., for OPV technology (Bernardo et al. Reference Bernardo, Lopes, Lidzey and Mendes2021) or perovskite technology (da Silva Filho et al. Reference da Silva Filho, Gonçalves, Marques and de Freitas2021)), implying to adjust concomitantly its structure design to optimize its performances, such as the mechanical and thermal stability. Thus, the upscaling subject consequently refers to the performance of a technology/production unit (i.e., size, productivity, stability, maturity). The objective of the upscaling is to increase the intensity of the production unit performance studied, to be considered as an “industrial” intensity.

It can be noted that, on the one hand, the “industrial scale” supposedly reached TRL 7 depends mainly on the discipline and technology, and can vary from 2 (Sanford et al. Reference Sanford, Chotani, Danielson and Zahn2016) to 10 or more orders of magnitude (Crater & Lievense Reference Crater and Lievense2018). For instance (da Silva Filho et al. Reference da Silva Filho, Gonçalves, Marques and de Freitas2021) in photovoltaic engineering, refers to cell area upscaled from 0.1 cm2 to 10 or 100 cm2, while (Crater & Lievense Reference Crater and Lievense2018) in bioengineering, increases the production capacity of a fermentation process from 0.5–10 L to 20–200 kL with a scale factor of several thousand orders of magnitude. On the other hand, some technologies are upscaled continuously (e.g., increased in size) even after their industrialization (TRL = 9). For instance, commercial wind turbines are intended to measure 230–250 m and account for 15–20 megawatt (MW) of installed capacity in 2030, compared to, respectively, 220 m and 12 MW in 2021 (IEA 2020). In that regard, the initial definition can also encompass the miniaturization process and yield maximization in photovoltaic cell engineering, for instance, as a process leading to increase the productivity per unit of device. Finally, this archetype definition can be expanded to the production unit itself. For instance, Sallerström et al. (Reference Sallerström, Sundin, Kurilova-Palisaitiene and Sundin2022) use this definition to designate the expansion of a “repair workshop”, remaining on an artisanal scale. Conversely, the term “gigafactory” refers to the idea of increasing the productivity of an industrial process unit or system. In other words, “megafactories” can be assimilated to the result of the upscaling of classic factories to improve their productivity, sometimes up to an explicit scale (i.e., the “megawatt” or “gigawatt-scale” of yearly produced battery capacity (Chordia, Nordelöf & Ellingsen Reference Chordia, Nordelöf and Ellingsen2021)).

4.1.2. Archetype 2 –Mass-producing: A producibility and manufacturability focus

The second archetype of upscaling refers to the mass production of given products and design processes. The upscaling would be carried out to facilitate and amplify this mass production. While the first archetype is rather associated with research activities, archetype 2 (mass-producing) is predominantly represented in industrial engineering. This implies more specific approaches depending on the industrial sector or the companies. Consequently, examples are numerous but transverse properties conferred by archetype 2 are “learning by doing” culture, being supported by standards, well-established methods, as well as empirical industrial knowledge.

Indeed, according to Kramer & Haigh (Reference Kramer and Haigh2009), “scale-up means learning by doing, which takes time in the energy industry”. Depending on the industrial sector, a longer temporality than the previous archetype, up to decades, is applied. Concerning the link with standards, authors call for the creation of dedicated databases (e.g., Bioengineering Platform to Industrialize Biotechnology (Culler Reference Culler2016) and/or creation or alignment with existing standards (Koulin et al. Reference Koulin, Sewell and Shaw2015; Moschou & Tserepi Reference Moschou and Tserepi2017)). Regulatory uncertainty and lack of standards are an identified barrier to upscaling, especially for certain domains such as food supply with new products (e.g., edible insect in the United Kingdom (Yang & Cooke Reference Yang and Cooke2021)).

The focus is made on “fabricability” and “producibility” in this UA, which means integrating in design additional economic and industrial constraints. For instance, the “panelization” in electronics (i.e., units connected as a single array to be manufactured simultaneously) is identified as a means to upscale a product by adapting its shape to processes for mass production (Moschou & Tserepi Reference Moschou and Tserepi2017). As a consequence, and based on the model of indicator TRL, the manufacturing readiness level indicator (MRL1) is used to reflect a manufacturing capability risks scale from 1 to 10. It notably incorporates material, costs and funding, quality, standards and facilities aspects (Manufacturing Readiness Level (MRL) Deskbook 2022). In this framework, the goal of upscaling could be expressed as reaching the 10th level titled “Full rate production demonstrated and lean production practices in place”. Other metrics such as maturity life cycle (or product life cycle stage) from 0, passing to 30 (industrialization) to 90 (obsolete technology) in microelectronics seem to transpose the MRL from the point of view of the technology developed (Baudry Reference Baudry2013). In this case, the indicator integrates the decline of the studied technology, which is not the case for MRL or TRL.

Thus, the upscaling addressed in this subsection aims at finding the optimal process configuration to massively produce something, while reducing the associated production costs (Moschou & Tserepi Reference Moschou and Tserepi2017; Yang & Cooke Reference Yang and Cooke2021). To summarize, the goal of archetype 2 is to massively duplicate a product (i.e., at “industrial scale”, under profitability implicit conditions), and the subject is the product to be massively produced.

4.1.3. Archetype 3 – Reaching a level and/or managing a deployment: A cumulative service focus

The third archetype identified is assimilated to the processes enabling and managing a technology deployment. This deployment, as a transition, is “purposive” (Geels et al. Reference Geels, Sovacool, Schwanen and Sorrell2017), which means that products manufactured are considered as a group or fleet, having to satisfy a certain level of requirements. In other terms, upscaling in this subsection could be considered as the implementation of transitioning for a sector or a technology (i.e., photovoltaic industry or electric vehicles (EV)). This level of cumulated service can be defined relatively to:

-

1. Past technology deployments observed in other industries. Historical dynamics, following an S-curve trend, give orders of magnitude of critical mass to reach. Also called “materiality”, this quantity can be used to study current or future technology deployment (Kramer & Haigh Reference Kramer and Haigh2009; Cherp et al. Reference Cherp, Vinichenko, Tosun, Gordon and Jewell2021).

-

2. A maturity or a share of the market. An example could be increasing renewable energy sharing in the energy mix. The market readiness level (MRL2) is an indicator of assessing the risks for emerging technology deployment in an emerging market (Bergerson et al. Reference Bergerson, Brandt, Cresko, Carbajales-Dale, MacLean, Matthews, McCoy, McManus, Miller, Morrow, Posen, Seager, Skone and Sleep2020) and can be used to characterize a level to reach in this example. In the line, Sims et al. (Reference Sims, Flammini, Santos, Pereira, Carita, Bracco and Oze2017) use the indicator current technology adoption rate (Sims et al. Reference Sims, Flammini, Santos, Pereira, Carita, Bracco and Oze2017).

-

3. An environmental pressure such as climate change and following scenarios to struggle climate shifts. For instance, the “terawatt (TW) level” in the renewable energy industry sector refers to the order of magnitude of 1 TW of capacity installed, and is considered as a titanic industrial and political challenge, but essential to achieve (Verlinden Reference Verlinden2020). The electrical vehicle industry, and more broadly, technology industries involved directly in energy transition face similar constraints.

In practice, these three ways to define the thresholds/goals of cumulated service are independent and not necessarily coherent with each other. For instance, Cherp et al. (Reference Cherp, Vinichenko, Tosun, Gordon and Jewell2021) confronted “materiality” for wind and solar power with 1.5°C-compatible scenarios and concluded that “some 1.5°C and 2°C pathways pose serious feasibility concerns”, which supposes a premature slowdown of the deployment dynamic or a different political and industrial context of deployment.

Thus, and more than for the others, archetype 3 (reaching a level) relies on the foresight approach and future-oriented scenarios. Archetype 3 expresses a phenomenon of form of long-term technology deployment (i.e., several decades) on a global (IEA 2020; IRENA 2019a,b) or national scale (Veyrenc et al. Reference Veyrenc, Houvenage, Assaiante, De Lauretis, Di Bono, Dubois, Le Du, Leonard and Rious2022). In other terms, and unlike the second archetype of upscaling, “the industrialization is not an aim” in itself (Riondet et al. Reference Riondet, Rio, Perrot-Bernardet and Zwolinski2022). Archetype 3 equates industrialization as a means to intensify to reach a (sufficient) cumulated service threshold for a specific technology sector. This sufficiency threshold is defined by societal requirements, including sustainability constraints.

4.1.4. Archetype 4 – Integrating a complex system: A interaction focus

The fourth archetype requires first to define a “complex system”. A complex system, according to Amaral & Ottino (Reference Amaral and Ottino2004), integrates a large number of units or subsystems, interacting strongly with each other and their environment. Subsystems need not to be “neither structureless nor identical”. They can evolve at different time scales and have different lifetimes. Cluzel (Reference Cluzel2012) and Kim et al. (Reference Kim, Cluzel, Leroy, Yannou and Bris2020) added that complex systems are large-scale systems with a very limited long-term predictability during the design phase and are “supervised by human decisions and management”. Such systems can be entirely technical (i.e., a national electricity grid) or socio-technical. Also referred as “networks”, complex systems involve interactions with human behavior and social and political phenomena (Dijk et al. Reference Dijk, de Kraker and Hommels2018).

The concept of “urban metabolism”, in the building sector and urbanism, is another designation to define a complex system with material or energy loops. The objective of the upscaling in archetype 4 is to integrate a system into a complex system or an urban metabolism, and then to improve its efficiency and/or its extent. It is the case for new public transport design in a city (Onat et al. Reference Onat, Kucukvar, Halog and Cloutier2017) or city farming implementation into the food system (Hardman et al. Reference Hardman, Clark and Sherriff2022) for instance. To implement this integration, the upscaling is applied considering the boundary of the analysis. Onat et al. (Reference Onat, Kucukvar, Halog and Cloutier2017) define this process as “broadening the scope of analysis from product-level assessment to national and global levels”. Archetype 4, in a wide framework, applies an “up-and-down zoom” focusing iteratively on the complex system and the designed technology as a subsystem. In other words, archetype 4 gives an expression of the study scope variation (i.e., its scale). This archetype highlights the technology integration issues by varying the scope of the study.

4.1.5. Archetype 5 – Down-limiting or downscaling: An absolute sustainability focus

The fifth archetype appears strongly linked to the PB framework and the concept of absolute sustainability: Rockström et al. Reference Rockström, Steffen, Noone, Persson, Chapin, Lambin, Lenton, Scheffer, Folke, Schellnhuber, Nykvist, de Wit, Hughes, van der Leeuw, Rodhe, Sörlin, Snyder, Costanza, Svedin, Falkenmark, Karlberg, Corell, Fabry, Hansen, Walker, Liverman, Richardson, Crutzen and Foley2009 proposed a theoretical framework based on environmental and systemic Earth science-based results. The so-called PBs depict limits that mankind should not cross to guarantee habitability on Earth. The PB paradigm hinges on the concept that human activities are included in a planetary system regulated by nine socio-ecological phenomena, including climate change. Humanity, including industrial development, is therefore summoned to stay in a Safe Operating Space (SOS) to ensure the stability of this biochemical system. This framework has been updated four times between 2009 and 2023 (Steffen et al. Reference Steffen, Richardson, Rockström, Cornell, Fetzer, Bennett, Biggs, Carpenter, de Vries, de Wit, Folke, Gerten, Heinke, Mace, Persson, Ramanathan, Reyers and Sörlin2015; Lade et al. Reference Lade, Steffen, de Vries, Carpenter, Donges, Gerten, Hoff, Newbold, Richardson and Rockstr¨om2020; Persson et al. Reference Persson, Carney Almroth, Collins, Cornell, de Wit, Diamond, Fantke, Hassellöv, MacLeod, Ryberg, Søgaard Jørgensen, Villarrubia-Gómez, Wang and Hauschild2022; Richardson et al. Reference Richardson, Steffen, Lucht, Bendtsen, Cornell, Donges, Dr¨uke, Fetzer, Bala, von Bloh, Feulner, Fiedler, Gerten, Gleeson, Hofmann, Huiskamp, Kummu, Mohan, Nogués-Bravo, Petri, Porkka, Rahmstorf, Schaphoff, Thonicke, Tobian, Virkki, Wang-Erlandsson, Weber and Rockström2023). As presented by Hauschild, Kara & Ropke (Reference Hauschild, Kara and Ropke2020) referring to absolute sustainability, the goal is not to design a more sustainable product but a sustainable one. Hauschild (Reference Hauschild2015) set the basic principles for targeting “eco-effectiveness”, as a trade-off between the societal value of the product and the related environmental damages. In that context, “downscaling” and “down-limiting” refer to generating local expressions of global environmental limits (such as PBs) on the technology scale to limit its unsustainability. This process is also called operating a share of the Safe Operating Space (SoSOS) or defining carrying capacities.

Those socio-environmental limits the product must not exceed are defined by designers. This challenges the relationship between technology, society and the environment by raising technical and environmental constraints with social justice expectations (Bjørn et al. Reference Bjørn, Chandrakumar, Boulay, Doka, Fang, Gondran, Hauschild, Kerkhof, King, Margni, McLaren, Mueller, Owsianiak, Peters, Roos, Sala, Sandin, Sim, Vargas-Gonzalez and Ryberg2020; Ryberg et al. Reference Ryberg, Andersen, Owsianiak and Hauschild2020; Hjalsted et al. Reference Hjalsted, Laurent, Andersen, Olsen, Ryberg and Hauschild2021). A well-known example would be the concept of “carbon budget” allocated to a country, a specific human activity or a product, to limit global warming below two degrees Celsius (i.e., the global threshold associated with the SOS). Each environmental impact indicators are addressed in this approach, not only the climate change. The downscaling is applied to an absolute environmental limit to assess the sustainability of a product, or a system. Archetype 5 (down-limiting) captures, more than the others, the imperatives associated with sustainability expectations from society. Until recently, it has been identified as a research field in development.

4.2. Interactions between upscaling and emerging technology concepts and archetypes

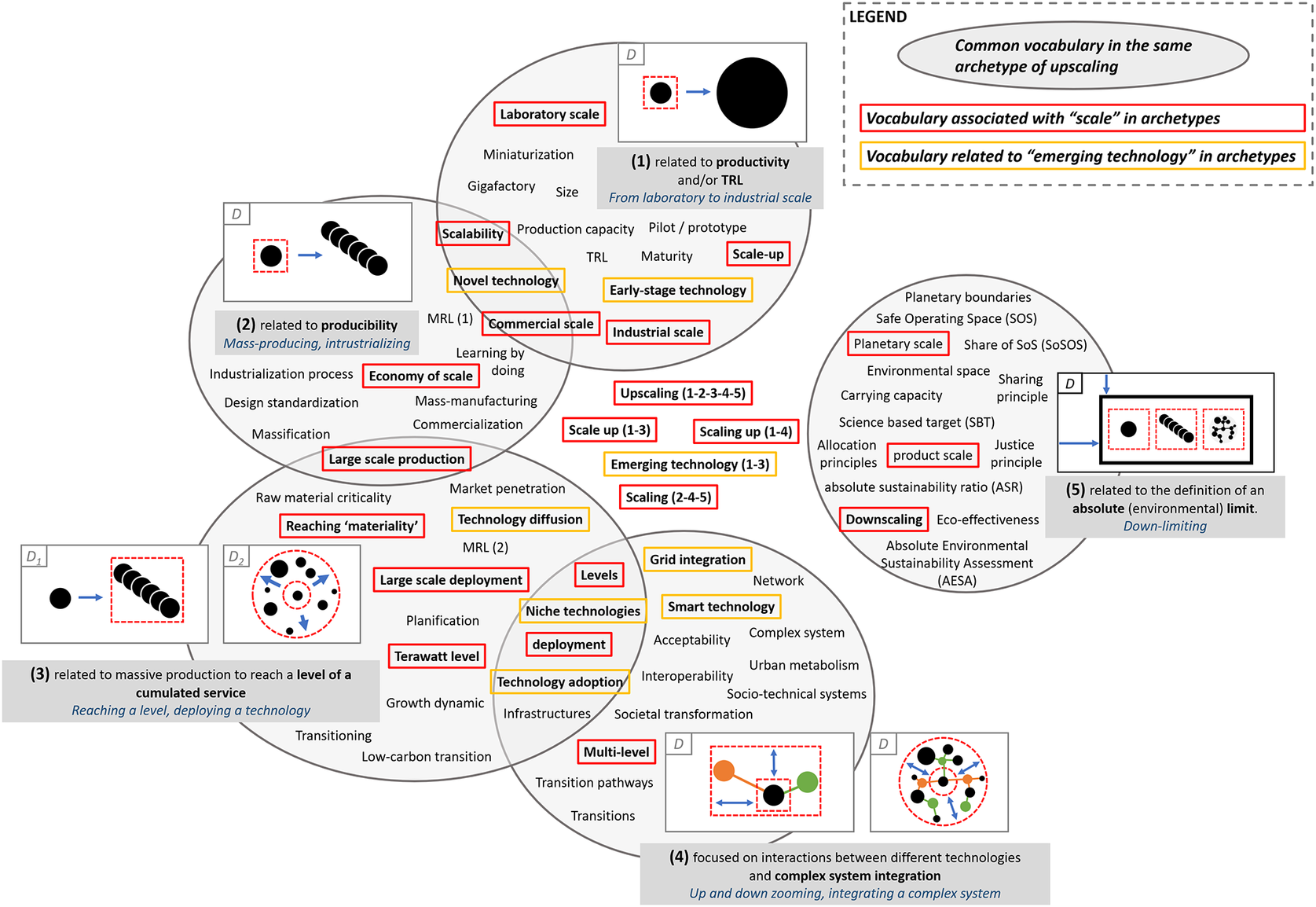

As mentioned in Section 1, archetypes represent facets of the phenomenon of upscaling. They are sometimes evoked as characteristics in a given definition. Rae et al. (Reference Rae, Kerr and Maroto-Valer2020) exemplify this aggregated vision on the case of smart local energy system (SLES). Authors provide a definition for upscaling comprising four characteristics overlapping the first four archetypes: “growing” (archetype 1), “replication” (archetype 2), “accumulation” (archetype 3) and “transforming” (archetype 4). This latest characteristic reflects the adaptation of the studied object to the surrounding context of its implementation. This fits well to the archetype 4 definition, by defining the context as the complex system to be integrated. The five archetypes could also be interpreted as visions of the upscaling from different disciplines’ points of view or different activity-skill perceptions: research and development, manufacturing engineering, planning and industrial management, systemic engineering, and finally, environmental engineering and justice. Based on such definition process the associated keywords in the related domain literature material have been collected (see Table 1 , column 6). This content is organized on Figure 3 based on each archetype identified literature co-occurrence (represented as grey circles). Keywords at the center of the figure are shared by several archetypes. For instance, “Scaling [2–4–5]” means that the word “scaling” is used in relation to UAs 2, 4, and 5. Words framed in red are explicitly related to scale or level concerns. This figure therefore aims at helping designers to identify UAs interactions and to reinterpret keywords in the light of the established archetypes’ definitions.

Figure 3. Representation of interactions between archetypes illustrated by their associated semantic fields.

4.2.1. Upscaling archetype interactions

Four main observations can be drawn from this proposed vision of the literature findings:

-

• Archetypes 1 and 2 are linked with the scalability property, as the hybridization of upsizing and massification and vocabulary associated with a “commercial scale” and economic consideration.

-

• Archetypes 2 and 3 are linked with vocabulary related to “large-scale production”.

-

• Archetypes 3 and 4 are linked with “large-scale deployments”, “levels” and “infrastructures” considerations.

-

• Archetype 5 is isolated from the others which is justified by the fact that it is a relatively new sustainability paradigm, not particularly integrated in the design process or engineering communities. The vocabulary used in the literature material consulted is therefore different despite the term “upscaling” in common with other archetypes.

Note that this representation justifies the use of “upscaling” as a generic term, because it appears in the lexical fields of all archetypes. The term “scale-up” coming from chemical engineering, seems specific to archetype 1, unlike “to scale up” which is a more widespread verb.

4.2.2. Emerging technology definitions and interaction with upscaling archetypes

Complementarily to the “scale” vocabulary analysis, the words framed in black in Figure 3 are explicitly related to emerging technology concerns. This representation reveals in the literature study the interactions between upscaling and emerging technology concepts, in line with the three main definitions provided by the literature and detailed in Section 2; an emerging technology as a promising but unmatured technology, a minor but growing technology, and emerging from a socio-technical vision. Now confronting UA to the concept of “emerging technology”, our main observations are:

-

• Emerging technology” and “upscaling” are aligned concepts with the first definition – “maturing technology”–included in archetype 1.

-

• The second definition – “growing technology” – is covered with the first three archetypes with “novel technology” and “technology diffusion”.

-

• The third definition – “emerging in a sociotechnical system” – is related to archetypes 3 and 4 with “niche technology” to be deployed, and “technology adoption” associated challenges.

-

• More broadly, the three definitions are more or less divergent and not necessarily consistent with each other as the defined object differs. It depends on the context, discipline study and authors.

Finally, the concept of UAs, in addition to characterizing the upscaling, captures the different definitions of emerging technology. From this state and to study the upscaling of emerging technology, archetype will be used as a unifying analysis tool. In other words, assessing the upscaling of an emerging technology involves studying UAs.

4.3. Upscaling assessment methods for designers, by archetype

Designers need to be familiar with the methods available to analyze or anticipate the upscaling of a technology. In other terms, the scope of an upscaling (see Section 4.1) is based on analysis methods and tools. This section therefore tends to characterize the scope of upscaling and establish generic methodological principles, depending on the archetype. The literature study was extended to identify the methods for researchers, engineers and planners (as designers), to assess or anticipate a technology/service upscaling. A synthesis of these methods and principles is available in Section 4.4 (Table 2). The findings detailed in this section show that the existing methods are mainly driven by technical-economic or socio-technical considerations, and rarely by environmental aspects rigorously. Only archetype 3 and archetype 5, present environmental considerations.

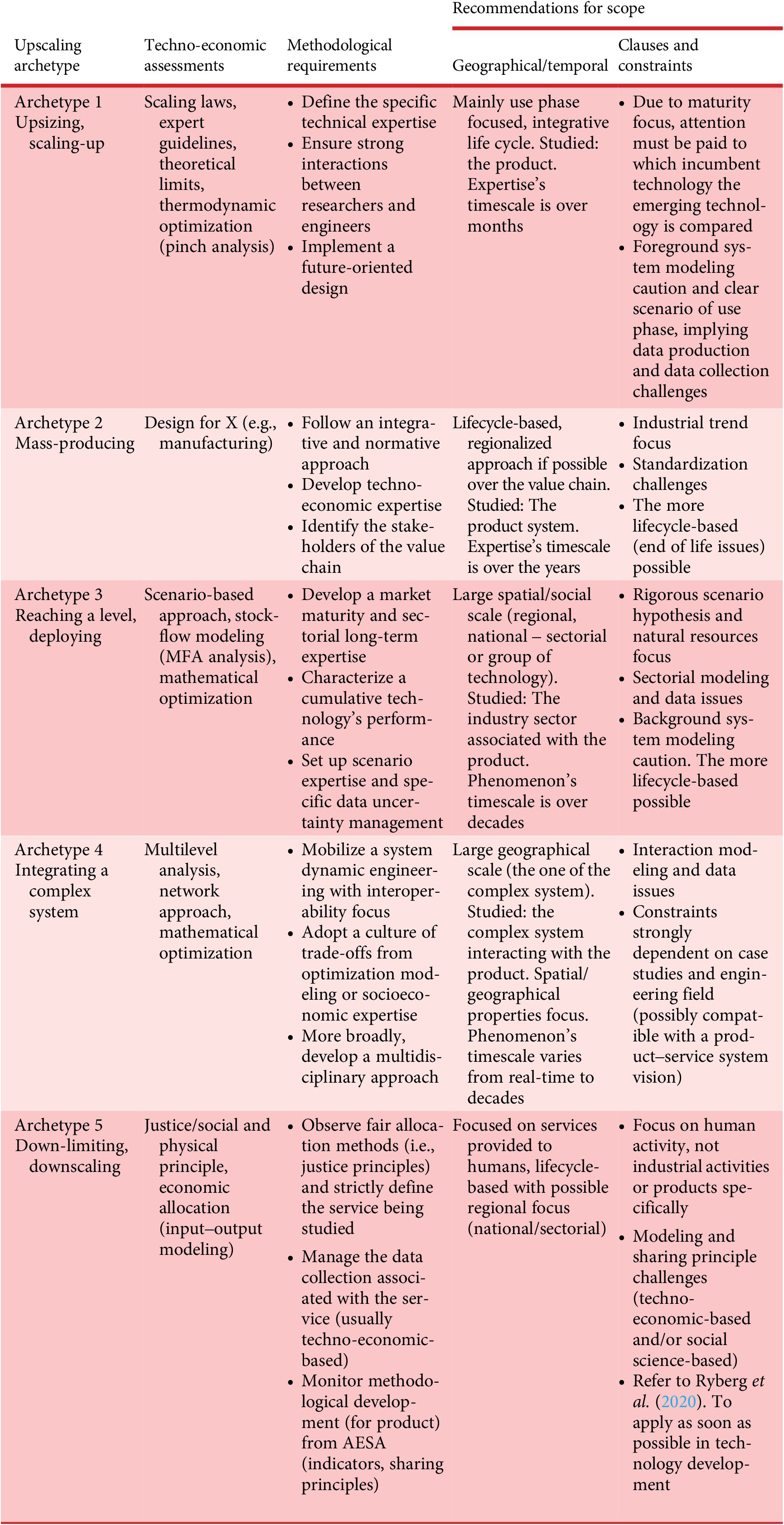

Table 2. Synthesis for designers of assessments, methodological requirements and recommendations for scope, according to upscaling archetypes.

4.3.1. Archetype 1 – From laboratory to industrial scale

Increasing productivity/size/stability and increasing maturity from laboratory scale to industrial scale, both require in the chemical industry some discussions between researchers and chemical engineers. This process leads to “empiric rules” and guidelines to deal with upscaling hazards. This discussion appears necessary because of the intrinsic risks induced by the upscaling to the production site (i.e., heat evacuation for exothermic reactions). Each context forces R&D teams to “choose the correct conditions to scale” (Laird Reference Laird2010).

On the one hand, empirical rules and guidelines both illustrate the predominance of design of experiments (DoEs) found in the methods associated with scaling-up a process or a system (Ceschin Reference Ceschin2014; Baumann & Lopatnikov Reference Baumann and Lopatnikov2017; Camburn et al. Reference Camburn, Viswanathan, Linsey, Anderson, Jensen, Crawford, Otto and Wood2017). For instance, López-Vizcaíno et al. (Reference López-Vizcaíno, Yustres, Sáez, Cañizares, Asensio, Navarro and Rodrigo2019) carried out a step-by-step upscaling on a chemical process (e.g., electrochemically-assisted soil remediation) with four experimental setups based on different capacity productions. The aim was to determine the effect of scale on techno-economic parameters, including the total annual cost of a processing unit. Their work illustrates a “scaling law” development. This model usually translates a simplified relationship between design parameters and characteristics of the designed system, often in the form of a power law. These extrapolation models are sometimes combined with techno-economic limits to qualify their validity domain (i.e., mechanical strength limit for the size of a vessel in the chemical industry or thermodynamic yield of reverse electrodialysis process) (Baumann & Lopatnikov Reference Baumann and Lopatnikov2017; Moreno et al. Reference Moreno, Grasman, van Engelen and Nijmeijer2018). The Shockey–Queisser limit is another example of a theoretical limit used in research. It represents, in photovoltaic science, the maximum yield value obtainable for a specific cell technology. Researchers, such as Ehrler et al. (Reference Ehrler, Alarcón-Lladó, Tabernig, Veeken, Garnett and Polman2020), use it to characterize the remaining room for improvement in a cell yield according to its structure/composition. Different types of PV technologies are then responses to overtake the limit associated with incumbent individual Si cells (i.e., tandem technology).

On the other hand, due to the cost engaged by such experimentations, numerical tools are also used to simulate, optimize, or study a system (Piccinno et al. Reference Piccinno, Hischier, Seeger and Som2016; Moreno et al. Reference Moreno, Grasman, van Engelen and Nijmeijer2018; Tsoy et al. Reference Tsoy, Steubing, van der Giesen and Guinée2020; Patel et al. Reference Patel, Gami, Patel and Patel2023). The main characteristic of optimization is the looping of energy and/or material fluxes. The structure of the laboratory system switches from linear but inefficient, to a more efficient, parallelized and looped structure (Shibasaki, Fischer & Barthel Reference Shibasaki, Fischer and Barthel2007). This approach is embedded in the systems-oriented design (SOD). In this speciality pinch analysis is an example of thermodynamic assessment enabling designers to minimize the energy consumption of a system by reusing residual heat (or cold) for pre-heating steps. Note that these numerical tools hinge on theoretical models and empirical know-how that have been capitalized during anterior (or parallel) experimentation phases. Consequently, a combination of experimentation and numerical simulations strengthen the upscaling management (Belwal et al. Reference Belwal, Chemat, Venskutonis, Cravotto, Jaiswal, Bhatt, Devkota and Luo2020; da Silva Filho et al. Reference da Silva Filho, Gonçalves, Marques and de Freitas2021).

Several requirements to carry a scaling-up could be summarized as follows:

-

• Control the technology maturity level and plan accordingly.

-

• Consider the specific technical expertise of the technology to be upscaled (i.e., theoretical law and/or scaling law, identification of leverages of improvement in the performance design).

-

• Integrate the design of experiments expertise, to produce lacking data and documents upscaling models.

-

• Ensure a strong interaction between researchers in laboratories and engineers in the industry (leading to guidelines and preventive lock-in identification in case of upscaling).

These specificities are mostly relevant in the chemical industry and are transmutable to other sectors.

4.3.2. Archetype 2 – Mass-producing

Mass-producing a technology relies on industrial engineering known how. It aims at developing the corresponding value chain, or adapting the structure of the technology to the existing value chains in an economic model-based perspective. In other terms, archetype 2 follows a normative process driven by industrial planning. This planning is historically based on “learning by doing” methodologies (i.e., industrial sector specific) and usually based on trend extrapolation models.

For instance, in Thiede et al. (Reference Thiede, Wiese and Herrmann2021), two groups of upscaling strategies related to additive manufacturing are compared: one optimizing the existing production system parameters (operative strategy) and the second focused on the production system change in terms of machine or technology chosen. Each of these strategies is characterized according to several performance indicators (time, cost, quality, “sustainability” and flexibility). This comparison results in a confrontation between three processes and guidelines depending on the economic model chosen (i.e., produced volume desired). In this case, the so-called sustainability indicator reflects the energy demand of the machine. This indicator in our view is inappropriate and reveals the difficulties of integrating environmental assessment methods in design, which should involve multiple environmental impact categories (e.g., the nine planetary boundaries), as well as sustainability issues that include additional sociocultural criteria.

Another example of product design adaptation to mass production constraints based on a numerical model can be taken from Koulin et al. (Reference Koulin, Sewell and Shaw2015). The shape of a product (wind power) has been adapted (optimized) to eliminate an energy-cost-effective manufacturing step (a rolling process) and then facilitates mass production by enabling its automation.

Panelization, in electronics, is also a shape optimization to facilitate the mass production of microchips. This production organization for discontinuous processes imposes nonfunctional shape standards to products to increase the number of produced units per batch. In that context, adapting an emerging technology, even from a different industrial sector (i.e., bioengineering), to this production technique would accelerate its upscaling by capitalizing on existing production means (Moschou & Tserepi Reference Moschou and Tserepi2017).

Learning curves and empirical models, such as Moore’s Law, remain the most representative methodology to support this UA (Basnet & Magee Reference Basnet and Magee2016). However, as with any extrapolated model, hypotheses sustaining the identified trends are not always explicit (i.e., validity domain). They reflect an improvement phenomenon over time, up to decades, as a consequence of production system optimization and industrial know-–how development. Such model is used in several industrial sectors for midterm planification (i.e., electronics, photovoltaics, agriculture) (Marra, Pannell & Abadi Ghadim Reference Marra, Pannell and Abadi Ghadim2003; Fischer et al. Reference Fischer, Woodhouse, Herritsch and Trube2019). In other terms, learning curves are phenomenological models used to continue a historical trend. They do not, however, provide a systemic understanding of the factors maintaining the trend. The contextual information to interpret their validity domain is rarely presented.

Complementarily, databases concerning the product’s process parameters and value chain structure are developed to enhance the skills related to massification. Such available database (if any) can be interpreted as an indicator of the maturity of the upscaling management in a specific industrial sector (Culler Reference Culler2016; Yang & Cooke Reference Yang and Cooke2021). Archetype 2 (mass-producing) is based on past centuries of industrial developments, linked to globalization. The business model associated with the mass production scheme is therefore a key parameter linked to the industrial sector(s) involved. This context has motivated the emergence of life cycle engineering, a group of methodologies based on a systemic and integrative approach in industry to support designers with “Design for X” (X stands for manufacturing for instance). It enables the implementation of the industrialization of a product while minimizing cost and externalities (M. Hauschild et al. Reference Hauschild, Kara and Ropke2020). Industrial engineering know-how, market regulation, policies, trading rules, labor standards, supply chain organization, etc. are crucial factors that push designers to explore product and process developments, as well as include value-based perceptions in the upscaling assessment they conduct (Yang & Cooke Reference Yang and Cooke2021).

To conclude on, methodological requirements associated with the mass-producing UA to designers are the following:

-

• Control of the manufacturing maturity level and conduct development planning accordingly.

-

• Design with integrative and normative approaches developed in industrial engineering.

-

• Define the product’s life cycle and its evolution over time associated with a chosen business model (cf. design for life cycle engineering methods).

-

• Choose relevant indicators of performance/value, clarify data collection on purpose, and integrate the ongoing technical/industrial/economic planning, to the upscaling model (e.g., evolution of processes, varying product design over time, correctly identifying costs and benefits).

4.3.3. Archetype 3 – Reaching a level and/or deploying a technology

Deploying a technology to reach a level of cumulated service hinges, more than other archetypes, on a foresight approach from a technology sector perspective. Foresight (or prospective) approach uses models to study potential futures and assess their plausibility (as well as their desirability). Archetype 3 (reaching a level) follows consequently a decision-support approach, mainly based on scenarios. Some typologies exist but there is no consensus on the way to produce scenarios (Gall, Vallet & Yannou Reference Gall, Vallet and Yannou2022). This situation leads to a great diversity of models and the associated indicators of feasibility or reliability.

On the one hand, sectorial consortium (e.g., IRENA 2019b) or specialized researchers (e.g., Kramer & Haigh Reference Kramer and Haigh2009; Verlinden Reference Verlinden2020; Khalifa et al. Reference Khalifa, Mastrorocco, Au, Barnes, Carpenter and Baxter2021; Vidal et al. Reference Vidal, Le Boulzec, Andrieu and Verzier2021) propose a desired deployment of technologies (i.e., renewable energy, electric vehicle) often represented as an S-curve (or exponential curve) from now to a specific time horizon (2030, 2050 or 2070). This model is phenomenological (i.e., descriptive of a past trend) and could be considered as one scenario of deployment among others.

On the other hand, more holistic models assess the co-emergence of groups of technologies. For instance, electricity storage technologies are intended to emerge in parallel with renewable energy technologies to struggle with their intermittency. However, their developers, mainly institutional (i.e., IEA, ADEME), usually set some performances or some cumulated service targets, for each separated industrial sector assessed (IEA 2020; ADEME 2021). For instance, the Réseau de Transport d’Electricité (RTE), the French electricity transmission system operator presented in 2021 that six power production pathways to reach carbon neutrality by 2050 (Veyrenc et al. Reference Veyrenc, Houvenage, Assaiante, De Lauretis, Di Bono, Dubois, Le Du, Leonard and Rious2022). Other organizations, focusing, for instance, on agriculture technologies include milestones without stating a particular pathway (Sims et al. Reference Sims, Flammini, Santos, Pereira, Carita, Bracco and Oze2017). Watari, Nansai & Nakajima (Reference Watari, Nansai and Nakajima2020) present a literature review of prospective criticality for 48 chemical elements. These elements are presented sorted by 10 technology categories, making explicit the link between material, product’s scale and technology expected deployment.

These two types of propositions are often criticized in terms of feasibility or reliability with regard to historical trends (Breyer et al. Reference Breyer, Bogdanov, Gulagi, Aghahosseini, Barbosa, Koskinen, Barasa, Caldera, Afanasyeva, Child, Farfan and Vainikka2017; Cherp et al. Reference Cherp, Vinichenko, Tosun, Gordon and Jewell2021) and to the associated raw material demands (Rietveld et al. Reference Rietveld, Boonman, Harmelen, Hauck and Bastein2019; European Commission et al. Reference Blengini, El Latunussa, Eynard, Torres De Matos, Wittmer, Georgitzikis, Pavel, Carrara, Mancini, Unguru, Blagoeva, Mathieux and Pennington2020; Elshkaki Reference Elshkaki2021).

A material demand analysis is usually carried out with a material flow analysis (MFA). Note that different methodological formats of MFA exist according to the perimeter of the study (e.g., national, industrial, enterprise or product level). A synthesis of these methods and their specificities is available in the guide of the Organisation for Economic Co-operation and Development (OECD) published in 2008 (OECD 2008). In the archetype 3 case, material system analysis (MSA) and an economy-wide MF analysis (EW-MFA) are usually conducted. Relying on the analysis provided by this method, the “criticality of raw material” appears as the main constraining feasibility indicator to elaborate plausible scenarios of technology deployment in the energy, digital or mobility (Bobba et al. Reference Bobba, Carrara, Huisman, Mathieux and Pavel2020; van Exter et al. Reference van Exter, Bouwens, Bosch, Bosch, Favrin, Zeijlmans, Sprecher, van der Vlies, Wirtz and van Oorschot2021). Again, no consensus has been found in literature to characterize the criticality of a material, leading on again to multiple methodological choices. Schrijvers et al. (Reference Schrijvers, Hool, Blengini, Chen, Dewulf, Eggert, van Ellen, Gauss, Goddin, Habib, Hagel¨uken, Hirohata, Hofmann-Amtenbrink, Kosmol, Le Gleuher, Grohol, Ku, Lee, Liu, Nansai, Nuss, Peck, Reller, Sonnemann, Tercero, Thorenz and Wäger2020) and, more recently, Hackenhaar et al. (Reference Hackenhaar, Alvarenga, Bachmann, Riva, Horn, Graf and Dewulf2022) documented some non-exhaustive lists of methodology according to the goal, the scope, the outcomes and the operability of the criticality assessment methods targeted.

Hofmann et al. (Reference Hofmann, Hofmann, Hagelüken and Hool2018) point out, however, the difficulty for materials scientists and engineers to adopt such assessment methods, deeming that the political and environmental issues these methods address do not fall within the scope of their expertise. In addition, temporal validity of indicators involve regular update of data and a fine understanding of their computation. In addition, the temporal validity of indicators involves regular updates of data and a fine understanding of their computation. It is important to note that MFA and criticality assessments hinge together on material demand data, which was not systematically documented in the European Union before 2012 prior to the Commission Decision has defined the roles and responsibilities of the organism “Eurostat” (Commission 2012).

More generally, assessments at such scales (regional, national) are data intensive and consequently studies are made possible generally by public organizations with data collection authorities. Additionally, Hofmann et al. (Reference Hofmann, Hofmann, Hagelüken and Hool2018) note that criticality assessment better corresponds to the scale of the product, than of the material. Ferro & Bonollo Reference Ferro and Bonollo2019 endorse this vision providing an example of the integration of criticality indicators in classic material selection for product design. Criticality assessment would therefore benefit from life cycle engineering, for instance, to evaluate the dissipation of resources (e.g., Charpentier Poncelet et al. Reference Charpentier Poncelet, Helbig, Loubet, Beylot, Muller, Villeneuve, Laratte, Thorenz, Tuma and Sonnemann2021).

Finally, and concerning data management issues, Maier et al. (Reference Maier, Guillaume, van Delden, Riddell, Haasnoot and Kwakkel2016) presented a framework to characterize uncertainties in a prospective approach: “Thinking about future uncertainty in terms of multiple plausible futures, rather than probability distributions, has implications in terms of the way uncertainty is quantified or described, the way system performance is measured and the way futures strategies, designs or plans are developed”. This transitioning archetype is thus associated with long-term planification methods, supposing existing models to support decision perspective by providing criteria of go/no-go or at least validity/reliability indicators. This vision is usually referred to as the prospective or foresight approach and relies on:

-

• A control of the market maturity level and/or a clear goal with a time and spatial perimeter focus on a technology or an industrial sector (e.g., carbon neutrality of China for 2060, TW photovoltaic installed capacity in Europe in 2050).

-

• A technology’s performances characterization (implying data collection difficulties).

-

• Industrial sector data and engineering models (i.e., capacity production, material and/or power flows).

-

• A scenario expertise and a specific data uncertainty management (quality, accuracy, sensitivity) and a model validity domain investigation (i.e., hypothesis review). Ideally with a distinction between fields of possible evolution of technological, and industrial including the background context. More broadly, it refers to foresight (or prospective) expertise belonging to a long tradition of thinking (Berger Reference Berger1964).

4.3.4. Archetype 4 – Integrating a complex system

Designing complex product systems or integrating technology into a complex system relies, more than other UAs, on a systemic approach focused on subsystem interactions between the designed product and its sociotechnical environment (more or less technical or social).

An intelligible example is for designing and managing a power plant or a storage site, both depending on existing grid characteristics (Fitó et al. Reference Fitó, Vallée, Ruby and Cuisinier2022). Concerning the optimization approach, many different models exist (LP, MILP, master investment algorithms) and are applied to different geographical scales, from city to global scale, with varying optimization horizons (e.g., from an hour to several years). For more detailed information about optimization models dedicated to energy system planning, refer to Cuisinier et al. (Reference Cuisinier, Bourasseau, Ruby, Lemaire and Penz2021). Tanguy et al. (Reference Tanguy, Bahers and Athanassiadis2020) present a very literal study case of up-and-down zooming on a port city, identified as an urban metabolism interacting with other regions of varying geographical scales (local, national and global). MFA and network representation (e.g., Sankey diagram) are very suitable for such assessments. Commercial software is also used to design a digital twin of a local grid composed of power sources, storage and consumer sites (e.g., industrial site, houses) and size of it, based on simulations covering several years (“Seed Energy – Odyssey” 2022).

Another example of complex system design is given by Metais et al. (Reference Metais, Jouini, Perez, Berrada and Suomalainen2022) investigating the three different modeling possibilities to consider the performance dependency between charging infrastructures and batteries for electrical vehicles (i.e., node-based, path-based, tour-based approach). The key parameters reviewed in 287 articles applied to that study case are the charging station location, its power capacity and its interoperability carried out by interface devices (AC/DC converters) that can be partly embedded in each vehicle. The optimization goal, however, varies in the literature: some studies aim at maximizing the number of EVs charged, others at minimizing the infrastructure cost for a given demand and some, fewer, intend to minimize the distance to a charging station. The design trade-offs resulting from these optimizations drastically differ, which consequently highlights the importance of stating the goal of the optimization study and the design parameters chosen to conduct this optimization.

Optimization can also deal with interdisciplinarity, for example, with an agriculture-energy system, developed by Barlow et al. (Reference Barlow, Biddanda, Mendke, Miyingo, Sicko, Papalambros, Chien and O’Neal2021). This complex system is composed of three subsystems: an irrigation network, crops and an electricity microgrid. Designing the microgrid implies consequently to quantifying the energy demand for water pumping and households, which itself depends on crops. Thus, minimizing electricity cost in this model leads to optimizing the irrigation subsystem. The authors regret economic profit to be used as the indicator, and rather argue in favor of “social benefit” optimization. One of the main drawbacks of the optimization approach is to set predefined rules/constraints that could not be effective all along the simulation which reduces its accuracy for long-term forecasting. This drawback is especially significant in models depending on climate assumptions, for renewable energy planning for instance (van Beuzekom, Hodge & Slootweg Reference van Beuzekom, Hodge and Slootweg2021). The robustness of the conclusions of such optimization can then be threatened if data assumptions concerning climate change evolve. Evaluation methods therefore exist to assess the “credibility” of a model and are applied to complex systems modeling, including so-called multiagent models (Li et al. Reference Li, Dong, Zhao, Gong and Zhang2021). System dynamic models are another type of model used at varying scale (e.g., house to global scale) to describe and define evolution pathways depending on design or planning decisions.

On the one hand, for local scale (e.g., house or city scale), complex system analysis hinge on network biophysical models and also on local system analysis (LSA) assessing the fluxes between urban area and nearby ecosystems (OECD 2008). These models are used in the system design approach, illustrated by Toso, Luthe & Kiss (Reference Toso, Luthe and Kiss2018) giving multiple examples of food waste and water treatments (Barbero & Toso Reference Barbero and Toso2010; Toso et al. Reference Toso, Luthe and Kiss2018). This approach focuses on the product’s service integrating design interactions with its environment (e.g., rainwater or heat) and stresses the valuation of coproducts to satisfy human needs.

On the other hand, on a larger scale (i.e., national or global scale) global biophysical models are completed by socioeconomic modeling (e.g., IMAGE, REMIND, MEDEAS, WORLD3) to do long-term prospective exercise concerning climate or resources management (Meadows et al. Reference Meadows, Meadows, Randers and Behrens1972; Capellán-Pérez et al. Reference Capellán-Pérez, de Blas, Nieto, de Castro, Miguel, Carpintero, Mediavilla, Lobejón, Ferreras-Alonso, Rodrigo, Frechoso and Álvarez-Antelo2020; IPCC 2022). For instance, the “shared socioeconomic pathways” (SSPs) are scenarios used by the Intergovernmental Panel on Climate Change (IPCC) to model five global socioeconomic pathways driven by climate policy assumptions distributed between mitigation and adaptation to climate change.

Note that these two developments of system dynamic models are both less, but still, affected by the long-term assumption’s uncertainties. This implies recurrent upgrading to meet upscaling assessments and designers’ road maps.

The literature study investigated in this research shows that in general terms, human behavior and social aspects, in the energy or mobility sector, are less studied with social science methodologies compared to urban, waste or food/agriculture sectors where they are more prevalent.

The example of the upscaling (i.e., integration) of urban farming in the food system given by Hardman et al. (Reference Hardman, Clark and Sherriff2022) illustrates this phenomenon. Barriers have been characterized such as the financial one, soil contamination and interactions with urban areas (i.e., vandalism or on the contrary involvement of the community). The authors call for a data-driven approach to identify “market opportunities and revenue streams” to strengthen the business model and best practices. Sims et al. (Reference Sims, Flammini, Santos, Pereira, Carita, Bracco and Oze2017) added social organization (e.g., social norms, collective actions and private–nongovernmental issues) as a key barrier to the adoption of climate technologies in the agri-food sector.

Finally, Ceschin & Gaziulusoy (Reference Ceschin and Gaziulusoy2019) review multiple examples of models used to consider a product environment, including a system design approach, in a design for sustainability goal, and elaborate a multilevel analysis framework of product design methods. It encourages designers to assess their product based on multi-scale vision, from material or component, to sociotechnical systems, and even product–service system vision. This up-and-down zooming on product requires different modeling skills, from technical expertise to social science-based analysis (e.g., consumption habits, community practices, sociotechnical system dynamics). By framing the design problem and the scope of the design intervention, this framework pushes for interdisciplinary practices of design and supports designers to integrate into their practices other expertise models. Thus, archetype 4 (integrating) is associated with network models and/or techno-social approaches hinging on:

-

• System dynamic engineering, requiring specific resource management (data and computing) due to the high complexity of models with different levels of integration (product/service).

-

• Interoperability between models linked to the product/service integrated in a complex system.

-

• Culture of trade-offs from optimization modeling or socioeconomic expertise.

-

• Multidisciplinary approach.

4.3.5. Archetype 5 – Down-limiting or downscaling

As opposed to the first four archetypes, archetype 5 (down-limiting) is intrinsically bound to an environmental sustainability paradigm as it is associated with the PB framework. Ryberg et al. (Reference Ryberg, Andersen, Owsianiak and Hauschild2020) develop the main assessment method supporting this archetype, called absolute environmental sustainability assessment (AESA). It discusses the sustainability of a product calculating an absolute sustainability ratio (ASR). This implies for the numerator the LCA application to collect the product’s environmental impacts. The denominator of the ASR is the allocated the environmental space (SoSOS or carrying capacity) associated with the product’s scale. These two quantities have to be computed in the same environmental indicators. This necessity brought about two approaches: Ryberg et al. (Reference Ryberg, Andersen, Owsianiak and Hauschild2020) developing PB indicators for LCA and Bjørn & Hauschild (Reference Bjørn and Hauschild2015) translating PB framework into classic LCA indicators. Both promote the definition of the carrying capacities at the product’s scale supported by sharing principles and the analysis of the resilience capacities of the environment.

A sharing principle is an allocation rule founded on ethics, economic and social expertise. Ryberg et al. (Reference Ryberg, Andersen, Owsianiak and Hauschild2020) identify seven distributive justice theories (utilitarianism, prioritarianism, difference principle, luck egalitarianism, egalitarianism, sufficientarianism and libertarianism) and define recommendations for assigning a SoSOS depending on the studied system and geographical and temporal constraints. Following the clause and constraints of the chosen justice theory, the SoSOS assigned to human beings on the geographical and temporal scope is then assigned to industrial units based on the value created for humans on this scope. This expertise is also referred to as defining science-based targets (Smith Reference Smith2024).

Finally, Kara, Herrmann & Hauschild (Reference Kara, Herrmann and Hauschild2023) advocate the operationalization of such an approach by proposing a six-step methodology, including a LCA. This research work synthesizes the design levers to integrate the PB framework into the design with optimization perspectives.

Thus, archetype 5 (down-limiting) is associated with an absolute sustainability framework hinging on:

-

• Justice principles to define and allocate a SoSOS aligned to the technological system being upscaled.

-

• Methodological developments for AESAs, lifecycle-based.

-

• A focus on human activity and not only on industrial activities.

The result of the chosen method is then injected into an environmental method to assess the absolute environmental sustainability of the technology-based product or service under development.

4.4. Synthesis for upscaling archetype assessment

Table 2 presents a synthesis of the techno-economic methods, as a summary for designers of methodological requirements identified in the literature study conducted in the previous sections, combined with the recommendations for scope and for each archetype.

This table is therefore intended to guide design teams in the assessment of upscaling. Designers are encouraged to question their upscaling objectives and compare them with those of the archetypes.

Further research findings could complete and revise the recommendations in the coming years by the interested communities, according to new methods, case studies, demonstrating feasibility or incompatibility.

5. Discussion

5.1. How to apply archetypes while designing technology upscaling?

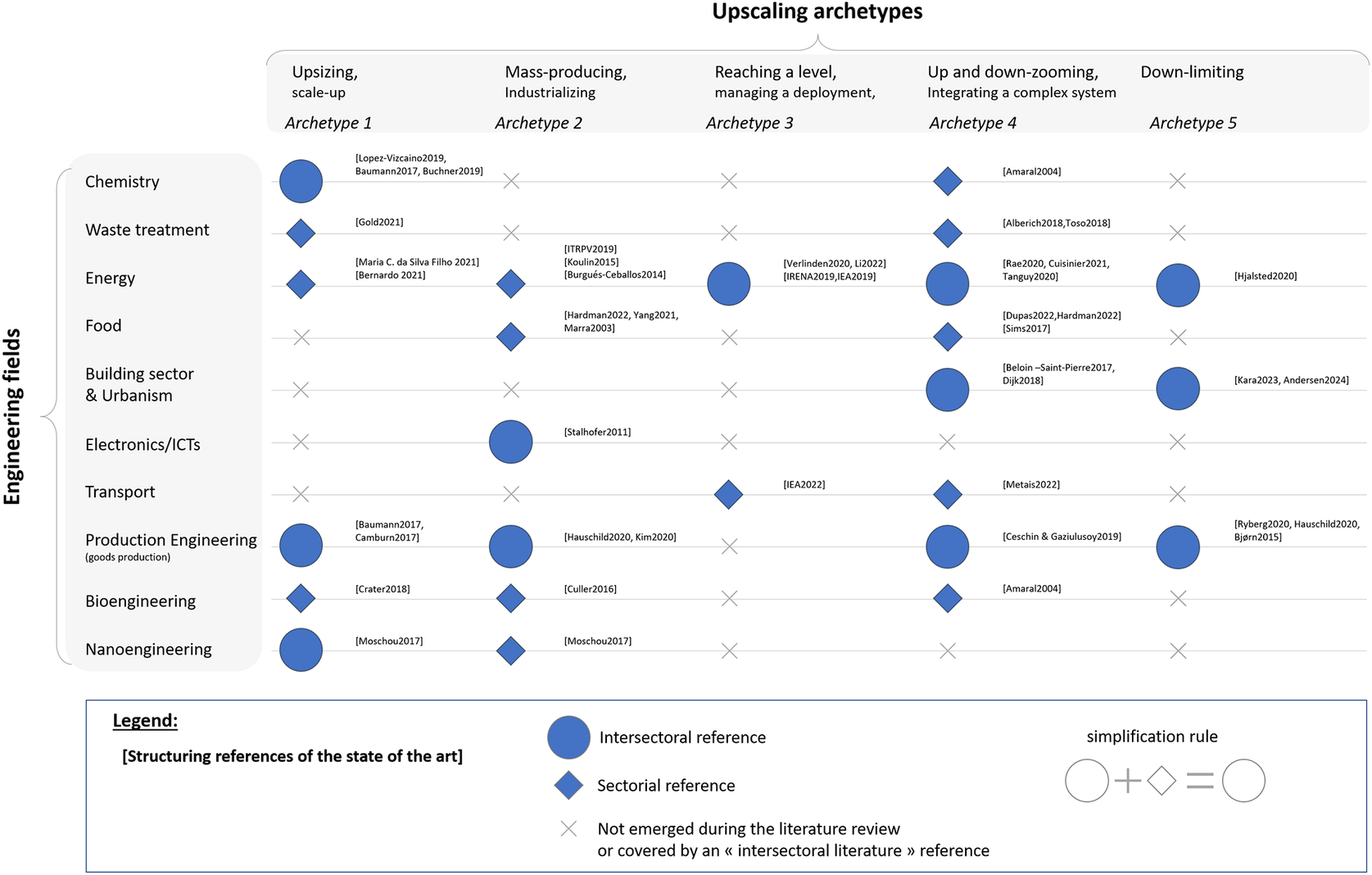

For each UA, definitions, tools, practices and methodological invariants have been detailed in the previous sections. The literature review process also revealed a disparity in the practices of designers depending on their object of study and their EF. This disparity questions the practical relevance of UAs presented above. This section therefore proposes a visual framework to detail this disparity of methods adoption regarding the archetype and the EF involved. It depicts a representation of our literature review and could help designers to deal with UAs use.

5.2. A framework for visualizing the selected literature for upscaling assessment