Introduction

This chapter is a direct continuation of Chapter 12, so as to divide a very lengthy exposé into two parts. It has two aims: first to illustrate the argument I made in Chapter 12 with a substantive case study, and second to explore some of the consequences of this vision on invention and innovation for our understanding of societies and societal dynamics. For that illustration, I have chosen pottery-making as an example, based on my personal familiarity with that craft, both from an internal (maker’s) and from an external (scientific) perspective (van der Leeuw Reference van der Leeuw1976, Reference van der Leeuw and Picton1984, Reference van der Leeuw and Lemonnier1993).

The Niche in which the Potter Operates

One can, at least in principle, outline a generalizable external model of the global niche in which the artisan works that is valid for most, if not all, traditions of manual pottery manufacture. It has to include the natural and social context in which the potter works, the raw materials and techniques used and their affordances and constraints, the organization of the work, and finally the range of different functions for which the artifacts can be used and their implications for the products’ shapes and other characteristics. As the potter proceeds through the different stages of the manufacturing process, her actions are all focused on dealing with different kinds of challenges that are the result of the interactions between the different variables involved. We could in effect, from the potter’s point of view, consider the niche in which she operates as her possibility and problem spaces. How that niche is approached depends of course on the particular perspective of the individual potter, which in turn is (part) shaped by the society and culture in which the potter operates.

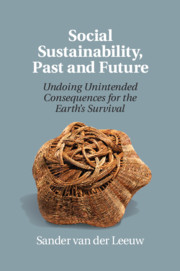

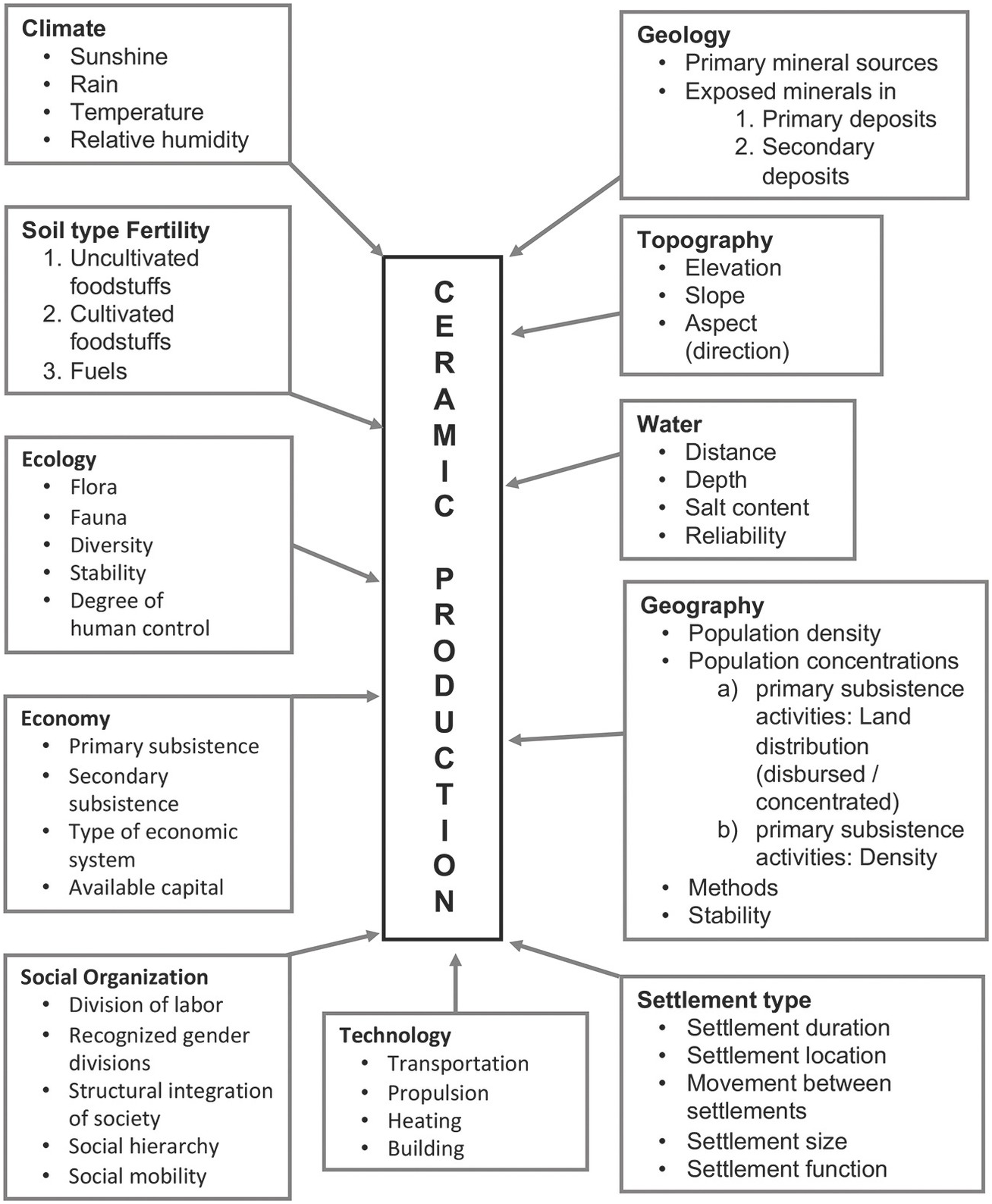

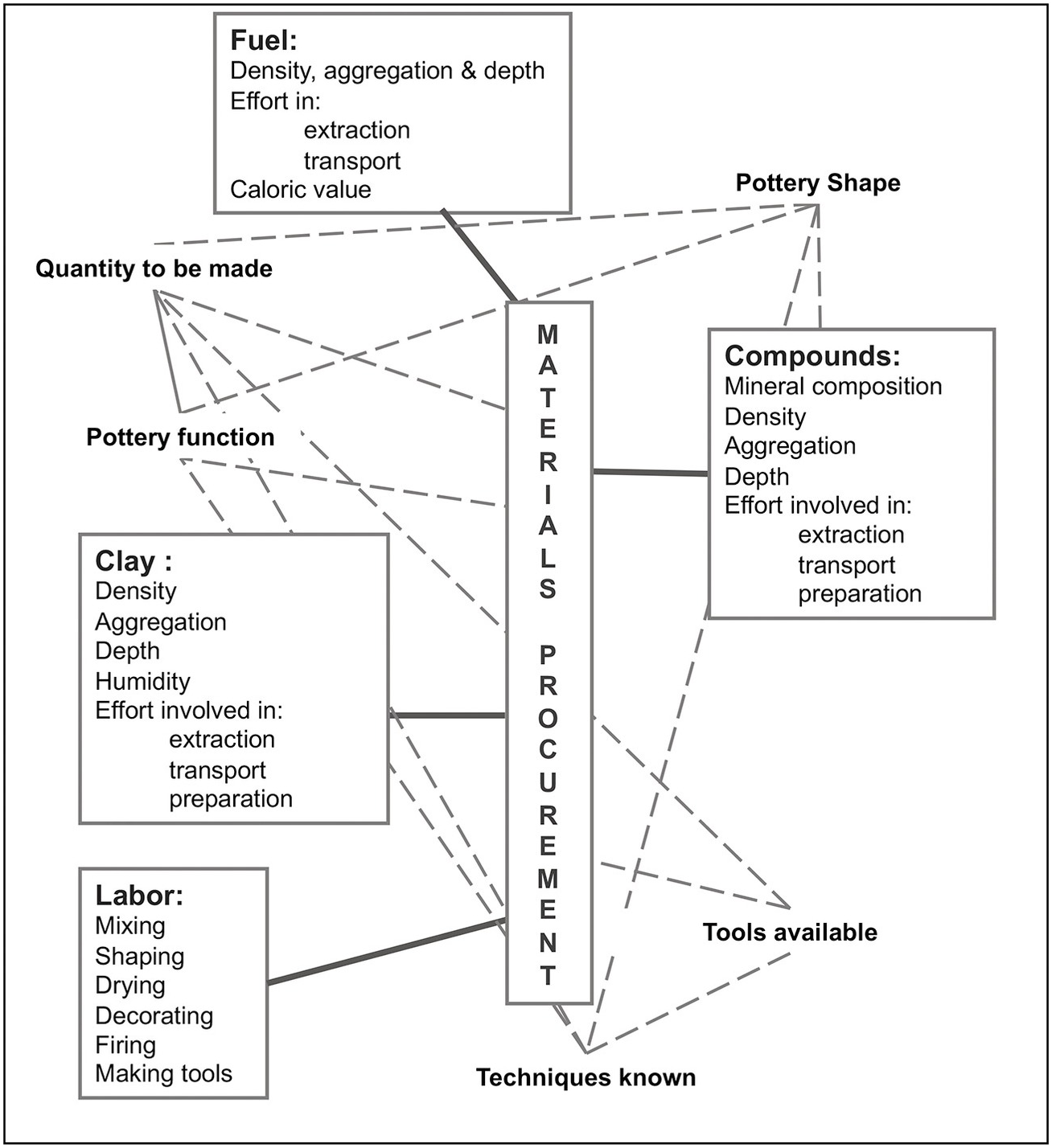

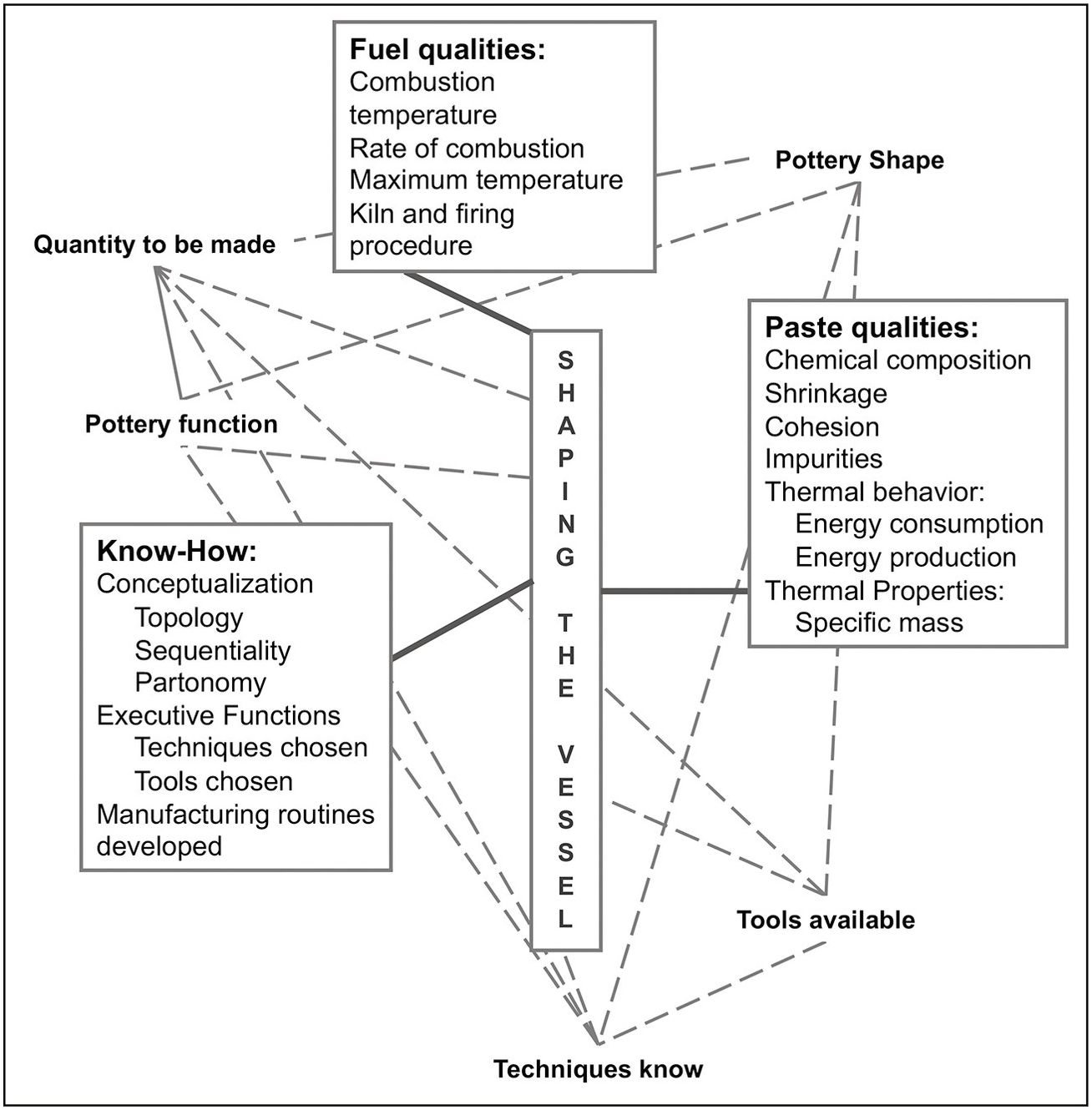

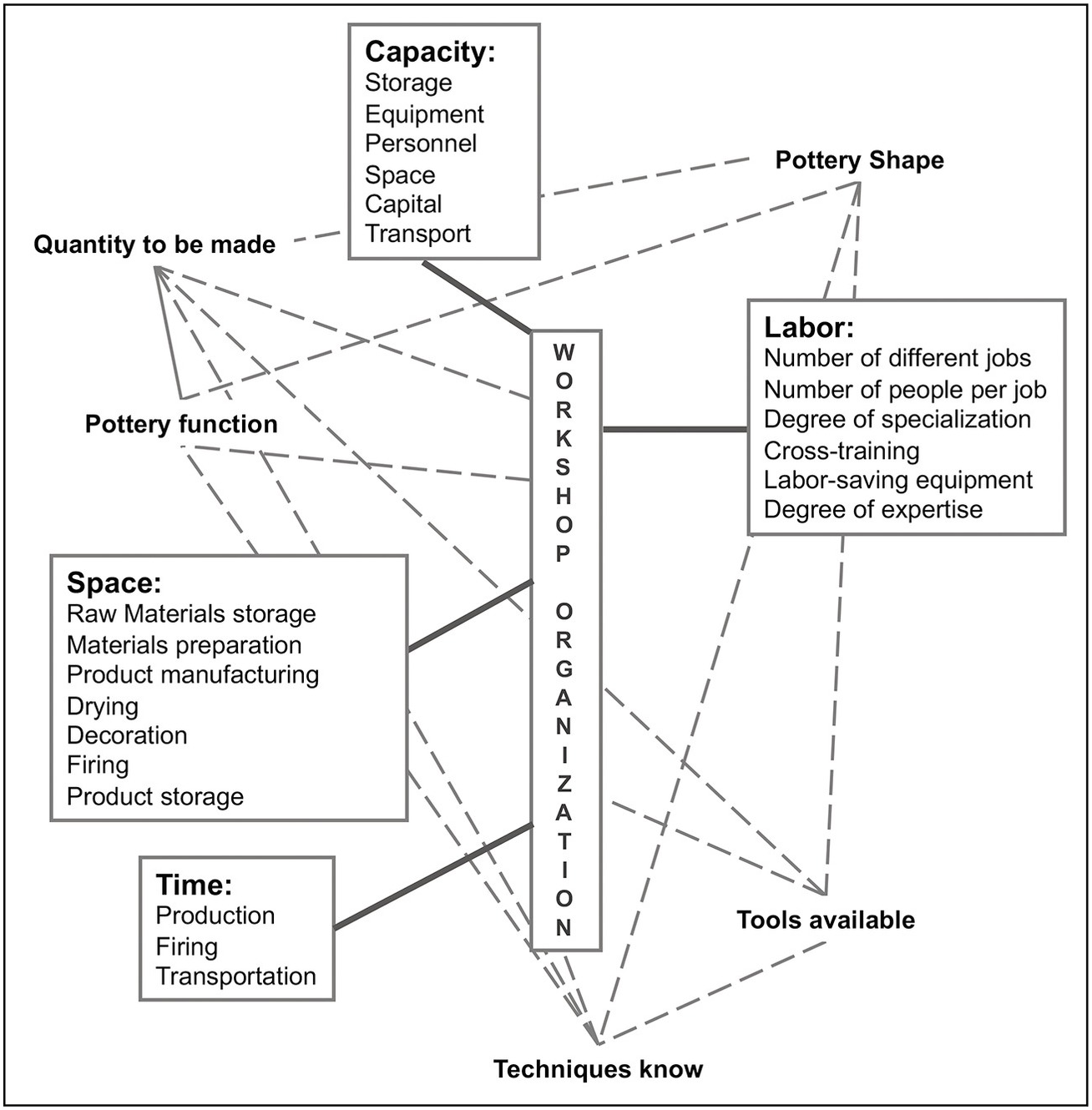

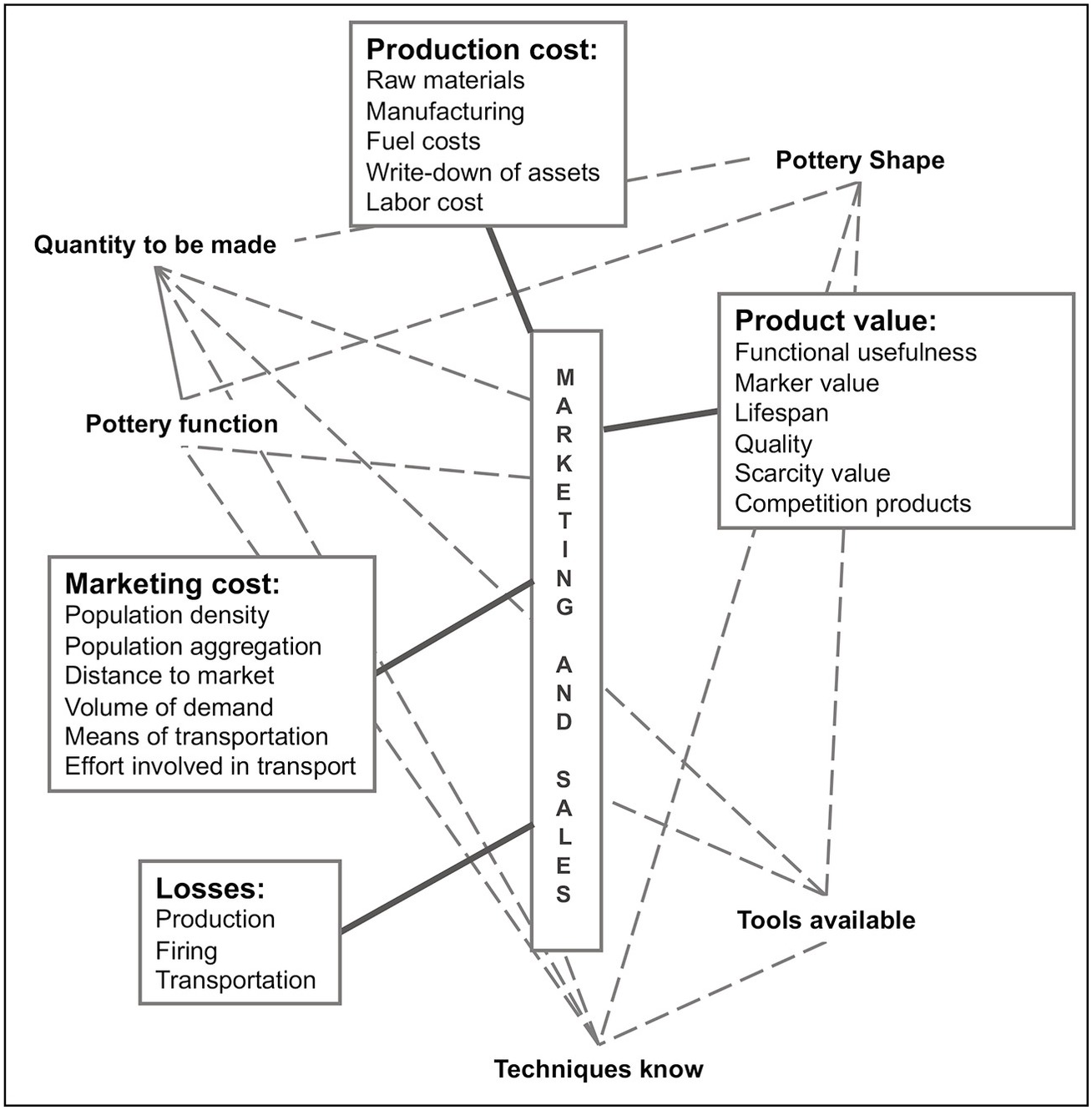

In Figures 13.1–13.7 I have tried to give a – necessarily incomplete and somewhat simplistic – idea of the niche in which the potter operates, by representing some of the variables that she has to take into account as she goes through the various stages of manufacture. It is important to emphasize here that the potter does not consciously take all these variables into account throughout the whole manufacturing process. An important aspect of manufacture is that it is staged or chunked in the sense that at each stage in the sequence (as represented by Figures 13.2–13.7), the potter is specifically preoccupied with a subset of the total set of variables that are involved in manufacture. These are considered in detail. But the variables involved in other stages do play a role in the background, as the potter also has an idea of what the end product of each stage needs to be in order to satisfy the conditions of following stages, so that the result is a product that fulfills the expectations of the community for which it is produced. Table 13.1 summarizes the technological, organizational, and economic responses of potters to different societal contexts in which they may work. It is based on a systemic perspective and the assumption that, though there is individual variability, certain generalities can be defined in this domain.

Figure 13.1 The wider context of pottery-making includes the physical, geographic, technological, social, and economic environment in which the potter works. Under each rubric only some of the actual variables are presented to give an idea of what each category stands for. These variables will differ from case to case.

Figure 13.2 Once the potter starts gathering the raw materials, she will have a number of variables from the different categories in this figure in mind. If she intends to make cooking pots, for example, the wall of the pot has to be porous because heat gets transmitted into the pot through the water that penetrates the wall. Hence the potter looks for clay with relatively large nonplastic particles in it, or if that is not available she will add such particles. But in deciding which materials to use, she will also take effort into account (depth of clay, distance, effort involved in mixing).

Figure 13.3 Paste preparation is a question of dosage and mixing of the plastic and nonplastic ingredients and water. The characteristics of each of these three are taken into account in determining the proportions of each to mix. More water makes the paste easier to shape, but if there is too much the paste will lose coherence. The exact dose of water depends to a large extent on the proportions and the nature of the clay and the nonplastic materials chosen, which in turn depend on the function of the pottery, as we see in Figure 13.2.

Figure 13.4 Conceiving the shape and other qualities of the pottery to be produced integrates the topology, partonomy, and sequentiality of her conception of pottery, her assessment of her capabilities in handling the technique chosen, the function(s) of the pottery to be produced, the nature and quality of the tools at her disposal, as well as the nature of the paste to be used (see Figure 13.3). But it also relates to the quantity to be produced, and thus to the size of the market, the capabilities of the workshop, etc. For mass production, for example, molding or throwing are more efficient than coil building.

Figure 13.5 Once the potter has conceived the vessel, the same factors will play a role in the shaping of the object. In reality, that shaping occurs in two or three phases, (1) shaping, (2) drying, and (3) firing. Much of the shaping will now be a question not of the conscious memory of the potter, but of her know-how, the musculo-skeletal memory and the memory of the nervous system, here summarized under “manufacturing routines developed.” The second phase, drying, is one in which only the atmosphere of the pot and the time allotted to drying are controlled. It may be interrupted by some minor modifications in the shape of the pottery or by decoration, but it does not require any major handling. In the third phase, firing, the paste and fuel categories play an important role, but they are integrated in the process of conceiving of the pottery. The categories “fuel qualities” and “paste qualities” have been added to this figure for reasons of space, although they should be seen as part of the last one.

Figure 13.6 The workshop organization determines the overall production capacity, but is itself composed of such elements as the degree of specialization of the functions to be fulfilled, and thus the number of people involved in the workshop. That in turn relates to the family structure and the question whether outside help is hired or not. But it also relates to the competency of the members of the workshop, its spatial organization, and the time involved in firing, for example, which is again related to the means of firing chosen and the length of firing time needed for the products made. Ultimately, of course, the workshop’s capacity greatly impacts on the quantity of pottery produced, and thus on the economics of pottery manufacture in the place of production.

Figure 13.7 Throughout the manufacturing process, in all the phases in which the potter conceives the pottery and makes her choices about how to instantiate it, the marketing of the pottery and the organization of the workshop (Figure 13.6) are domains that are systematically taken into account, as together they determine the quantity and quality of the products to be made.

Table 13.1 The economics, technology and workshop organization of pottery-making articulate as illustrated here. For simplicity’s sake I have distinguished between six different system states that combine these variables. As is clear, these states do not impose the use of specific materials or the manufacture of specific kinds of products, but they constrain the range of manufacturing and firing techniques used as well as the organization of the workshop, depending on the quantity of products to be made and marketed. In general, the larger the number of pots made, the narrower the tolerance for variation, and thus the greater the interdependency between the different variables.

| Variables | Household production | Household industry | Individual industry | Workshop industry | Village industry | Large-scale industry | |

|---|---|---|---|---|---|---|---|

| Economy | Time Number Organization Locality Hired hands Market Raw materials • Clay • Temper • Water • Fuel Investments Seasonality Labor division Time/pot Status | Occasional One None Sedent. or itinerant None Own use Local Local Local Local None Production as needed None High Amateur | Part-time Several None Sedent. or itinerant None Group use Local Local Local Local None Season w/o other work None High Semi-specialist | Full-time One None Itinerant None Regional Local Local Local Local Few All yr. except winter None Medium Specialist | Full-time Several (Guild) Sedentary Some Village/town Neighborhood Neighborhood Local Neighborhood Some All year in good weather Some-considerable Medium-low Specialist | Part/full time Several Certain Sedentary Some Region (wide) Neighborhood Neighborhood Local Neighborhood Some All year in good weather Some-considerable Medium-low Specialist | Full-time Many Certain Sedentary Labor force Regional and ex-port N’hood/distant N’hood/distant Local N’hood/distant Capital All year Detailed Low Narrow specialist |

| Technology | Manuf. technique Tools • Sed. Basin • Wheel • Drying shed • Kiln Raw materials • Clay • Temper • Water • Fuel Range of pots Functions/pot | Hand/sm. tools None None None Open fire Wide range Wide range Any Wide range Narrow Wide range | Hand/sm. tools None None; rot. supp. None Open fire Wide range Wide range Any Wide range Narrow Wide range | Hand/small tools None Turntable None Impermanent Wide range Wide range Any Wide range Wide Wide range | Mold/wheel When needed Various kinds Needed (Semi)permanent Narrower range Narrower range Any Narrower range Narrower or wide Narrower range | Mold/wheel When needed Various kinds Needed (Semi)permanent Narrower range Narrower range Any Narrower range Narrow or wide Narrower | Wheel/cast/press Needed Kickwheel Needed Permanent Narrow range Narrow range Any Narrow range Narrow or wide Narrower |

| Examples | Kabyles, N. Africa | Cameroon, Tanzania | Tibet, Turkey | Bergen-op-Zoom Farnham | Tzintzuntzan Djerba | Wedgwood Delft |

To date, few people have looked intensively at alternatives that might have been open to inventors, nor at the implications of the actual choices made among these alternatives (Pritchard & van der Leeuw Reference Pritchard, van der Leeuw, van der Leeuw and Pritchard1984, 11–12). Rather, most have taken such choices as a given, aiming as they did at describing how things were done rather than investigating why they were done in a certain way and not in others.

We have seen in Chapter 12 that we need to investigate the choices made and those not made together, rather than only those made. Choices apply to the modalities of production, but the sets of alternatives among which they figure are anchored in the much wider realm of the perceptions and conceptualizations of the potter, her mappa mundi (Renfrew Reference Renfrew1982). Within the territory on that map, she will find it easy to adapt herself to the requirements of matter and energy, but the boundaries of that territory are the real limits to her capabilities. The proposed shift in approach therefore also opens up a (potentially rich and heavily underexploited) avenue to the study of changes in cognition. We need to investigate how people choose. What determines their perceptions, their biases, their reasoning? Almost certainly, there are aspects to these questions that are highly cultural, as well as others that are more closely related to the biological mechanisms of human beings.

The sciences that could take the lead in such research are notably cultural and social anthropology. Maybe there is a gap in the market for a more sophisticated kind of ethno-archaeology? Even though a large number of descriptions are available in the ethnographic literature of how a certain potter uses a specific technique to arrive at a distinguishable form, hardly any comparative research has been done on the relationship between technique and form, and abstracted synthetic statements on the topic are virtually absent.1 The basis for research in such a direction has been laid by Krause in his book The Clay Sleeps (Reference Krause1985) and other publications (e.g., Reference Krause, van der Leeuw and Pritchard1984) that rigorously describe the formal logic of pottery making in three entirely different parts of the world.

Challenges Limit Products

If we want to study choices, alternatives, and variations in chaines opératoires, we must also study how, among the many choices that are theoretically open to a person making something, some of these are out of bounds because of specific, material, technical, or other issues.

Let us look at the role form plays in constraining construction techniques in ceramics. Each form poses certain problems of construction to each technique, which can be resolved in a number of ways. I will therefore approach technique and choice comparatively, trying to keep form as constant as possible by concentrating on the techniques involved in making globular or near-globular pots with a simple everted rim. The major constructional problems that such a shape poses are in part those posed by all pottery, in part those related to a specific shape or to a specific technique. Some of those that are relevant to my argument are the following:

1. How to control the shape of the vessel. As the making is a dynamic equilibrium between the potter and the material, control over shape is not self-evident. It is actually one of the most difficult things to achieve as a potter, especially if no tricks are to be used (van der Leeuw Reference van der Leeuw and Renaud1975, Reference van der Leeuw1976).

2. How to avoid the vessel collapsing or becoming deformed during construction (van der Leeuw Reference van der Leeuw1976). This problem is in this case particularly relevant to the base, because any pressure on a rounded base focuses on a very small area, and is thus more difficult to handle without deformation than when the base is flat.

3. How to keep the vessel in a fixed position during manufacture. This is another problem particularly relevant to round-based vessels as they cannot so easily be placed on their base.

4. How to ensure access to various parts of the vessel while it is being shaped. This aspect evidently relates to the mechanics of the human body, as well as to any cultural constraints on motion.

5. The speed with which the vessels may be made and the rhythm of work. If the work requires a number of interruptions during shaping, for example, the total day of the potter may have a very different structure than if it does not.

6. The width of the range of shapes that the technique allows the potter. Certain approaches allow the potter to make a wide range of shapes and sizes with minimal adaptations of the technique, while others do not.

These may all be seen as the nonmaterial dimensions of variability against which to assess the choices made by potters working in different contexts with different techniques.2 How potters’ know-how impacts differentially on these challenges is illustrated in this chapter by taking two examples, from different cultures, on how potters achieve essentially the same shape of (globular) pot.

Comparing Two Pottery-Making Traditions in This Light

In the following examples, I compare different ways of making essentially the same form, a simple globular pot, as found in two different pottery-making traditions. The interesting thing about this comparison is that is shows how in both traditions, and in all cases I found, the same set of challenges (as outlined) has constrained the ways in which the potters were able to produce the pots. Differences in manufacturing methods are therefore essentially differences in “work-arounds.”

Using the Paddle and Anvil on Negros Oriental, Philippines

In fieldwork in 1981 in Negros Oriental in the Philippines, I observed a number of variations on making globular pots that I have described elsewhere in their context (van der Leeuw Reference van der Leeuw1983, Reference van der Leeuw and Picton1984). Here, I will confine my descriptions to the actual shaping of the vessels.

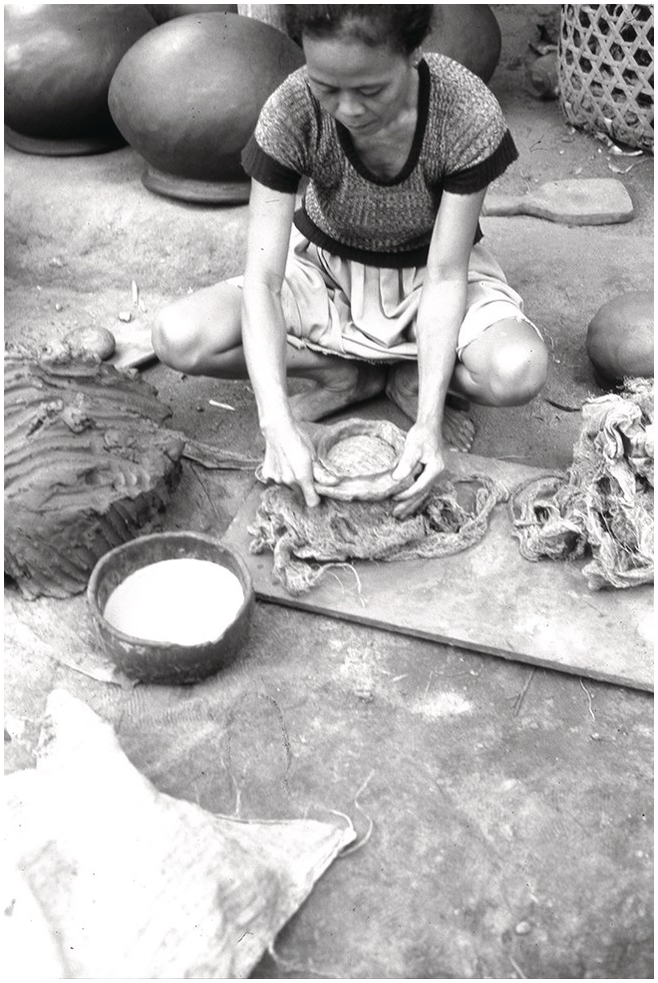

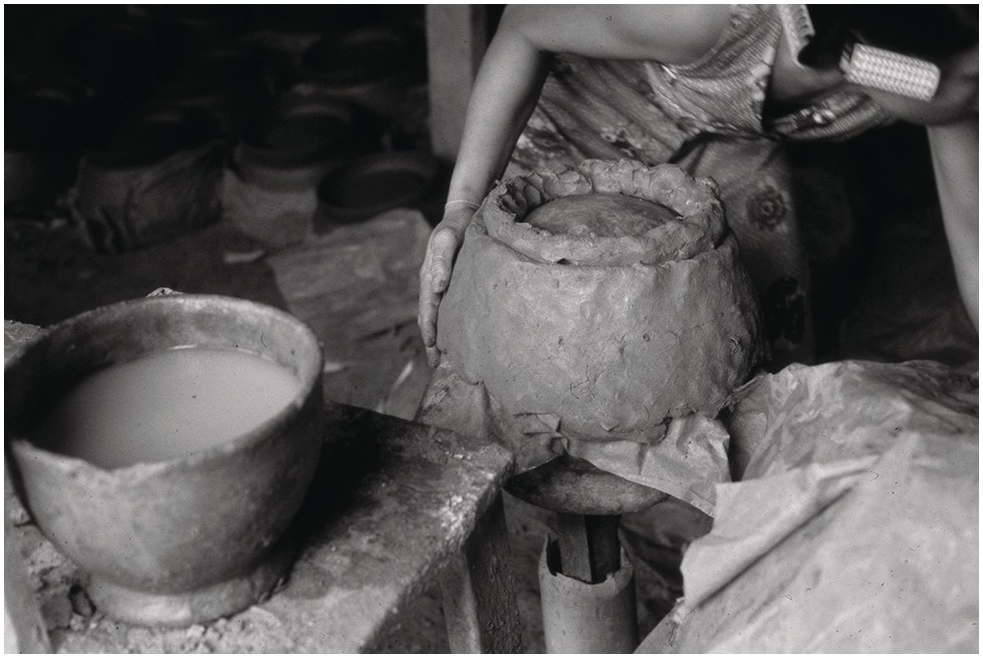

Case 1 (Tanjay, Negros Oriental, Philippines, 1981, Photo 13.8, copyright van der Leeuw). The most traditional (and at the time of fieldwork almost extinct) of these begins with the potter taking a ball of clay, placing it on a simple wooden support that can turn slowly, opening it with a thumb, while the other hand keeps the support turning, and shaping only the rim of the vessel between the thumb and first and second fingers of one hand.

Photo 13.8 A female potter in Tanjay, Negros Oriental, Philippines makes a vessel by rotating a lump of clay on a small turntable. She began by opening the ball and shaping the rim, while leaving the remainder of the pot unshaped (see the two vessels she is not working on). Next, she is thinning out the wall between one hand supporting it on the outside and the other shaping it on the inside. After some drying, she will shape the bottom of the vessels with a hammer-and-anvil technique, then let the vessel dry and fire it.

The body and bottom of the pot are shaped the next day, out of the thick, unshaped lump of clay on which the rim sits, by means of a paddle and anvil technique based around a globular anvil inside the pot. The maximum diameter is shaped first, the shoulder next, and the base last, all the while rotating the vessel around its central axis. After another drying period, the pot is polished with a pebble and left to dry until it is ready for firing.

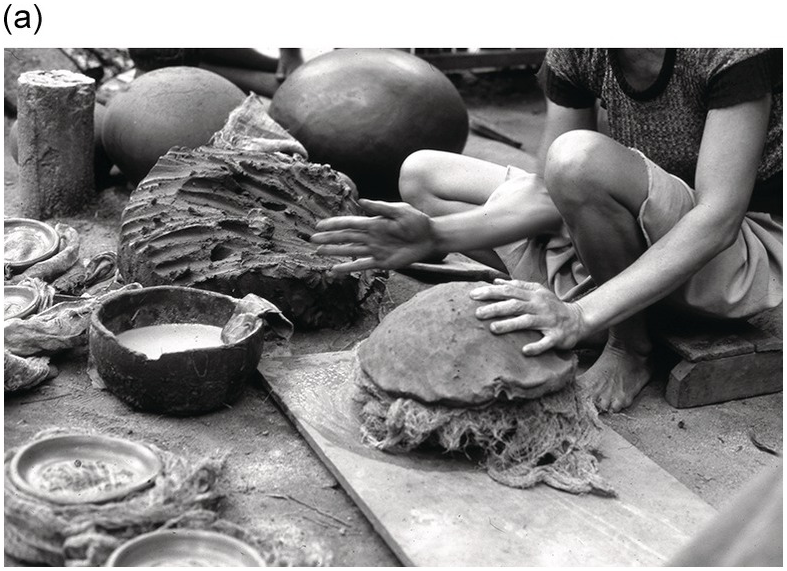

Case 2 (Zamboanguita, Negros Oriental, Philippines, 1981; Photo 13.9, copyright van der Leeuw). A variant makes the rim out of a coil of moist clay that is placed on the bottom of a fired vessel that stands upside-down (i.e., on its rim) on a flat surface, and which can turn (unpivoted). The pot is turned with one hand, the rim shaped between the thumb and the index finger of the other, which holds a piece of wet cloth. The rim is then set away to dry. Later, the potter fixes a flat “pizza” of clay to the underside of the rim and places the combination back in the sun for some more drying. The next day, the rest of the pot is shaped out of the pizza by means of the same paddle and anvil action. After some more drying, it is polished and prepared for firing.

Photo 13.9 Another female potter in Zamboanguita, Negros Oriental, Philippines is shaping a coil of clay on an inverted, fired pot covered by a piece of coarse fabric that serves as a mold. This coil will be shaped into the rim and upper shoulder of the vessel. The fabric serves to ensure that the wet clay does not stick to the inverted pot. Behind her stand some finished pots, and lies a paddle with which the vessels are given their final shape.

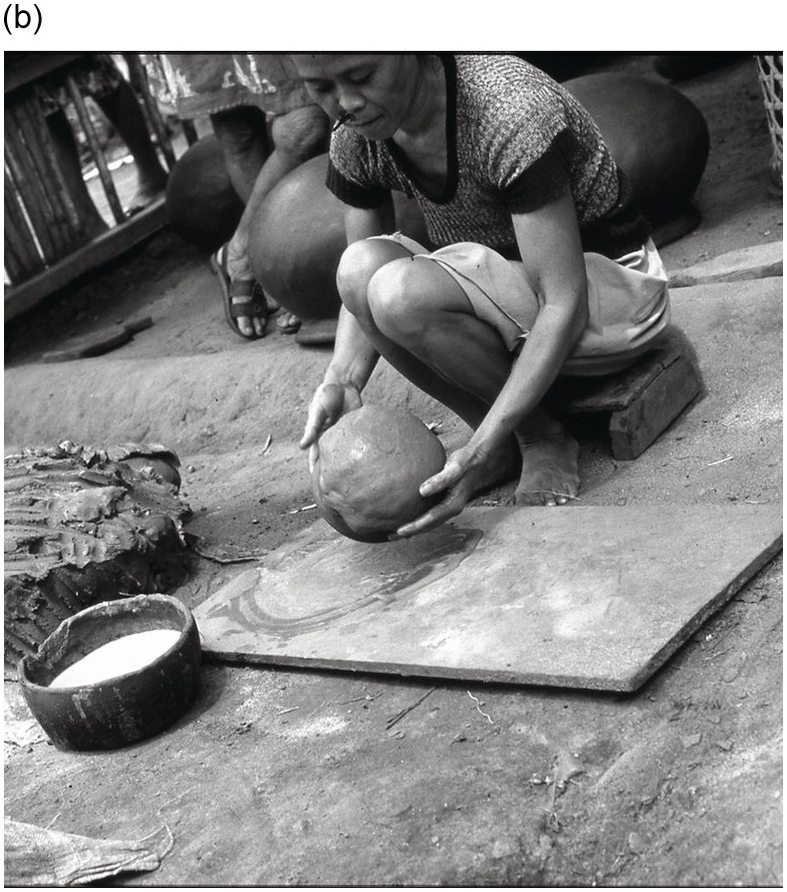

Case 3 (Zamboanguita, 1981; Photo 13.10 copyright van der Leeuw). Here, both the upper and the lower part are made separately over an upside-down fired vessel that, as in the last case, can turn unpivoted. The upper part may consist of the rim alone, but more often consists of everything above the maximum diameter. Both the upper and the lower parts are formed by placing one or more coils of paste on a sheet of plastic that covers the mold. The clay is smoothed over the mold both with the hands and with the paddle (so that, sometimes, the mold literally serves as a large anvil). Both parts are left to dry for some time and are then joined. The joint is strengthened by beating it with a paddle on a proper (small) anvil. The vessel is then set away to dry until it can be fired.

Photo 13.10a The same potter now shapes the base of a vessel over the inverted pot. After some drying, it will be united with one of the pre-shaped rims that lie in front of her, drying in the sun.

Photo 13.10b Once the two pieces have been joined, as in this photo, and have had some time to dry a little, the potter gives the vessels their final form by thinning their wall between a paddle (as seen in photo 13.9) and a rounded stone or piece of wood that serves as an anvil. Once that is done the vessel can be dried and fired.

Case 4 (San Carlos City, Negros Oriental, Philippines, 1981; Photo 13.11, copyright van der Leeuw). The sequence of steps constituting this production method is essentially the same as in case 1, but many more vessels are produced per unit time and the vessels are much larger. The support is in some cases a large potter’s wheel (made from a truck wheel) that does not differ from that used in thirteenth-century Holland for throwing. But in this case, the wheel is used as a turntable, rather than a true potter’s wheel. It was installed by the potter after he saw on a (Japanese) film of people throwing pots. But when asked he admitted that he had never been able to use it for that purpose. In the end he gave up and used the wheel simply as a turntable for the largest vessels he was making.

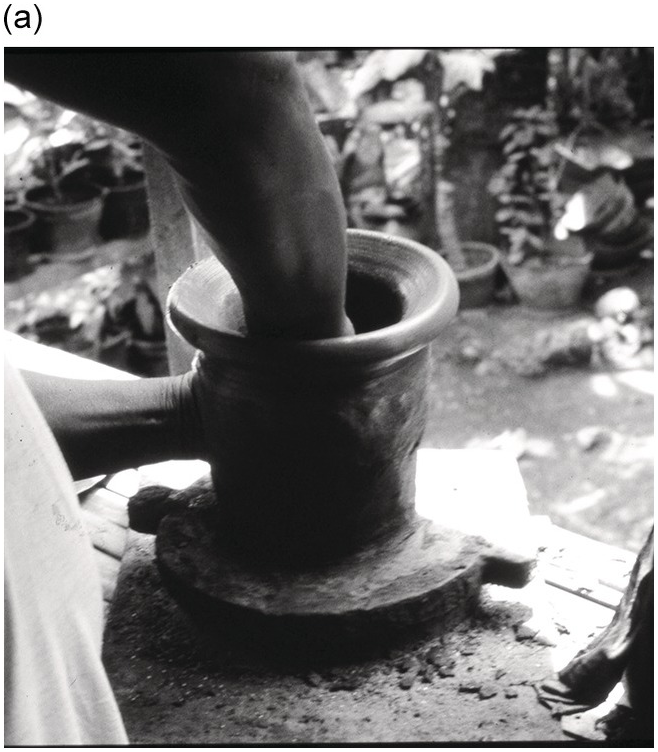

Photo 13.11a An (exceptionally male) potter in San Carlos City, Negros Oriental, Philippines shapes a vessel on a turntable by opening a lump of clay, then shaping the rim and continuing by thinning the rest of the lump somewhat between his hands.

Photo 13.11b The potter then takes the vessel off the turntable, and places it in a fabric-covered basket so that he can start working on the base of the vessel. Ultimately, the vessel wall is thinned and the vessel given its globular shape between a paddle and an anvil.

Case 5 (Dumaguete, 1981; Photo 13.12, copyright van der Leeuw). This case resembles case 3, except that the pot that serves as a mold has been mounted, again upside down, on a pivot that stands in a bamboo so that the mold can turn much more effectively. The vessels made are bigger and the production is much greater. The upper and lower halves of the vessels are made separately in small series, from several thick coils that are smoothed over the mold with the paddle. They are then joined at the maximum diameter, again between paddle and (small) anvil. They are then set apart to dry until they can be fired.

Photo 13.12 Another female potter, in Dumaguete, Negros Oriental, Philippines is shaping large vessels in two halves, by placing coils on a fired, upturned vessel that is fixed on a stick. The stick is placed in a hollow upright bamboo, so that the whole contraption can turn more freely than the turntables in the earlier photos. Three coils are shaped into the base of the vessel, and then another three coils are shaped over the same mold into its shoulder and rim (as on the photo). Finally, after some drying, the two halves are joined and left to dry until the pot can be fired.

Comparison

Comparing these cases, some interesting parallels and differences spring to mind. In all cases the basic sequence is the same: the lips (or upper parts) are made first (always in the same way), the lower parts later. In all cases, we also see the use of rotation around a fixed vertical axis, but the extent of its use varies. In cases 1, 2, and 4 it is only used to facilitate shaping the rim in a continuous motion, while the other parts of the vessel are made by means of discontinuous motions (between hammer and anvil) not strictly speaking around a vertical axis. But in cases 3 and 5 it is also used in shaping other parts of the vessel. In case 3 the pot is rotated while the paddle beats against the clay in an endless series of individual blows that shape the wall, while in case 5 the hand movement that shapes the vessel walls is continuous, against the rotating device.

In all cases, we also see tools used to determine the final (rounded) shape, be they molds (cases 2, 3, and 5) or anvils (cases 1 and 4). In two out of three (3 and 5) cases in the former group, the shaping tool also serves as a support during manufacture, while in cases 1, 2, and 4 that function is not fulfilled by anything. In cases 1 and 4, where the support is flat, the whole pot is made out of one lump, and that lump is worked in two stages: first the rim, made on the support while it is turned, and then the body, made with a paddle and anvil technique. In cases 3 and 5, where the support is a pot placed upside down, the vessel is made in two halves out of a varying number of coils. These halves are then joined. In case 2, the rim is made first, on an upside-down pot, and the body is made separately (a pizza) but is joined to the rim before the whole is shaped all at once between paddle and anvil.

Invariant elements in the manufacture therefore seem to be (a) its sequence, (b) the use of slow rotation, (c) the shaping of the rim, and (d) the shaping of the body (in all cases a paddle is used, while the mold, where used, is none other than a large anvil). Variations are possible in the (e) use which is made of rotation and its speed, (f) the nature, and (g) the timing of the support accorded the vessel during manufacture, (h) in making it out of one lump or out of several pieces of clay, (i) in the point in the procedure in which different parts of the vessel are welded together, and finally (j) in the drying periods needed. These elements seem to vary with the number of vessels produced per unit time (see van der Leeuw Reference van der Leeuw1983, Reference van der Leeuw and Picton1984).

The invariant elements are those that determine how a tradition may develop through time. In this case, for example, we see the introduction of rotation in a form that greatly resembles the potter’s wheel (case 4). But the fact that the Philippine sequence begins with the manufacture of the rim inhibits the discovery that one may indeed, very rapidly, make whole vessels on a wheel. That option is only available if the potter begins his manufacturing sequence with the bottom of the vessel, or with some intermediate part. The potter in this case had the wheel, but did not know how to use it for this purpose.

Mold-Shaping in Michoacán, Mexico

In the Mexican province of Michoacán,3 potters use a technique that, as far as we know, has never been developed in the Old World, i.e., the making of pots by molding in two halves, which each represent either a horizontal or a vertical section of the pot.4

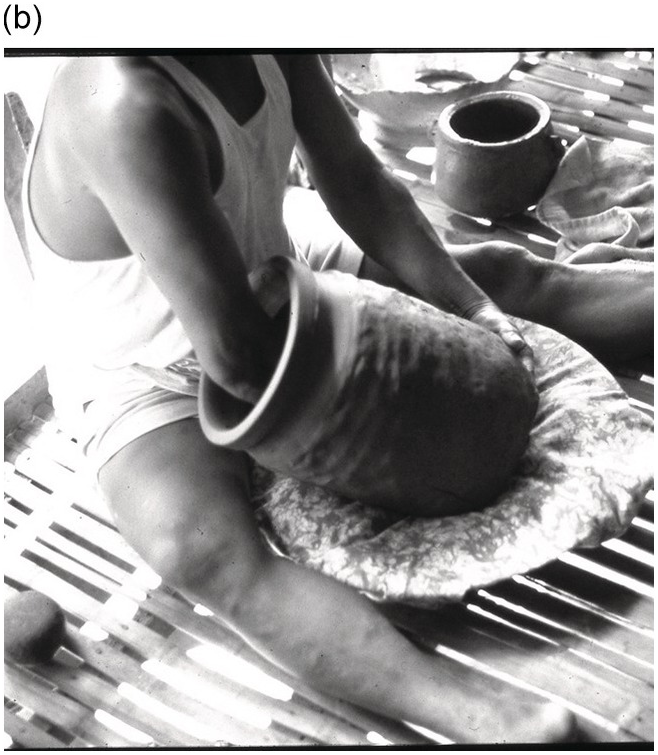

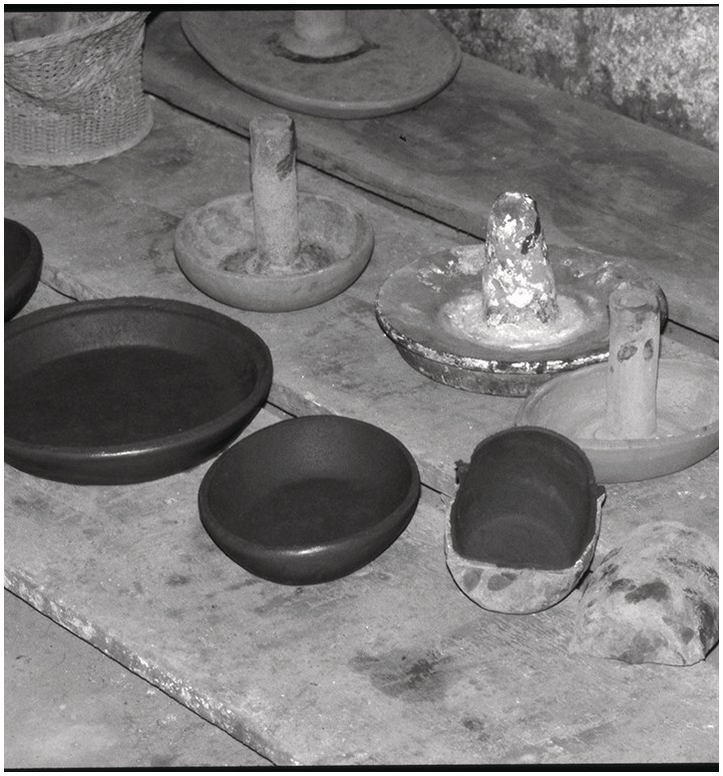

Case 6 (Patamban, Michoacán, Mexico, 1989, Photo 13.13, copyright Coudart-van der Leeuw). The paste is kneaded into balls, which are subsequently beat into flat “tortillas.” One such tortilla is placed in a fired earthenware mold. The inside of these molds represents the right or left side of a complete upstanding pot rather than the bottom or the top half. Thus, between the two of them, they dictate the shape of bottom, shoulder, and rim. After the two molds have been joined, the potter cuts excess clay from the future rim with a wire, by moving it along the outside of the joined molds. She then rubs the joint smooth on the inside and leaves it to dry in the molds for several hours. Next, the molds are taken off and the complete pot emerges. The suture will have left a ridge of clay on the outside, which is removed by scraping with a knife, and is then smoothed with a wet rag. A wide range of forms is thus made in one and the same manner.

Photo 13.13 In Michoacán, Mexico, vessels are shaped in molds. Here, a closed vessel (with its opening narrower than its belly) is shaped by placing a pancake of clay in one half mold, then doing the same in the accompanying half. Both halves are then joined from the inside of the vessel. The vessel is left to dry, and after a while one half mold can be taken off (as here in the photo). A little later the other half can be takes off, the pot placed upside down on its rim, and the outside of the joint removed with a knife. The pot is then dried until ready for firing.

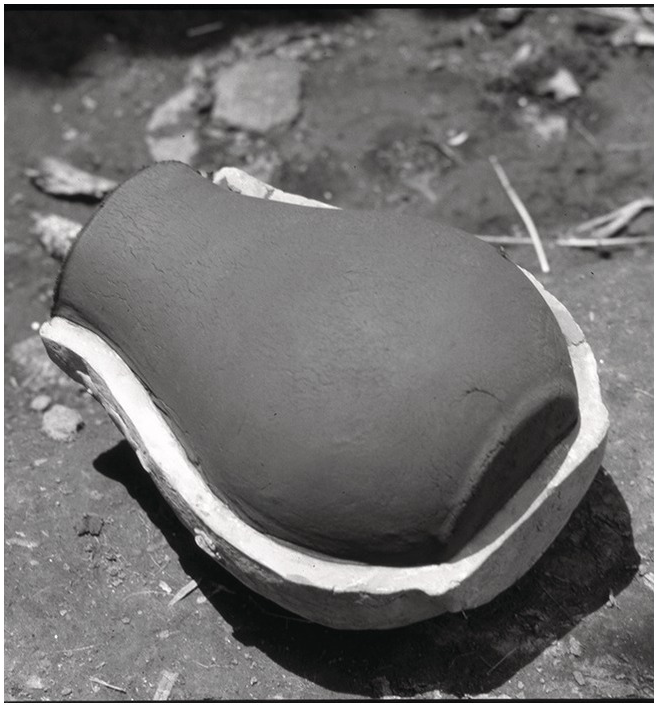

Case 7 (same location; Photo 13.14, copyright Coudart-van der Leeuw). The manufacture of open dishes, for example, follows a molding technique that is based on the horizontal (asymmetric) plane. Here, the tortilla is draped over a mold that is, like a mushroom, provided with a handle. Once it has been pressed against the mold and smoothed with a wet rag, the potter cuts off the surplus paste at the edges of the tortilla with a wire that is kept between the teeth and one hand, while the other hand rotates the mold against it. If need be, a coil is added to the base to provide a support for the vessel to stand on a flat surface. It, too, is smoothed with a wet rag. The pot is then taken off the mold and left to dry.

Photo 13.14 In Michoacán, Mexico, open vessels (bowls, plates, etc.) are shaped horizontally by placing a pancake of clay over a mushroom-shaped mold made by attaching a handle to an upside-down, fired, bowl. The potter shapes the vessel by hand against the mold, then shapes the rim by removing excess clay with a wire held between the teeth and one hand while rotating the mold. The photo shows two molds for open vessels above the resultant vessels, and one closed vessel in a vertical half-mold.

Case 8 (Huancito et al. 1991, van der Leeuw et al. Reference van der Leeuw, Papousek and Coudart1992). The procedure is the same, but the mushroom-shaped hand-held mold has, for large vessels, been replaced by a tournette that pivots in a hollow bamboo. On it, the potter places the mold over which she then drapes the pizza to be shaped, just as in the hand-held case.

Comparison

In this approach, although the shape of the mold – and thus the pot that results from the molding – may differ considerably, the manufacturing method is essentially identical.5 Invariant are (a) the sequence, making flat pizzas of clay and placing them against a mold, then drying and removing them to let the vessel stand on its own, a sequence that is independent of the shape of the vessel, as it creates no single part of the shape before any other; (b) the fact that for shaping, the usual distinction of continuous or discontinuous motion does not really apply; (c) the use of the mold both as a shaping device and as a support for the clay while it is wet; (d) the fact that the only other shaping tools are a thin nylon wire and a little rag to smooth the pot.

Variations occur in (d) whether one mold is used or more, (e) whether the pizza is placed in or over the mold, (f) whether the mold is rotated around a vertical axis or not, and (g) the shape of the mold. In the Michoacán case, the conceptualization of pottery manufacture thus does not wrestle with a sequentiality that begins with the bottom, the top, or even the shoulder or the middle as we have seen in all cases thus far: either the potter makes the body of the vessel all at once (open vessels) over a horizontal mould or makes it in two to four parts that have nothing to do with such a partonomy, joining vertically instead of horizontally, and vertically asymmetrical in themselves. Indeed, the distinction vertical–horizontal is thus rendered irrelevant within this tradition. It is replaced by the distinction between vessels that, topologically, represent half a (deformed) sphere, or a whole one (van der Leeuw et al. Reference van der Leeuw, Papousek and Coudart1992).

Some Lessons

Clearly, the approach illustrated here is much more difficult to instantiate for modern technologies. I have had to take a relatively simple example, and one I know well as a ceramicist who has observed the making of ceramics in a number of places throughout the world. But I hope it has allowed the reader to understand better how the details of information processing can contribute to creating a specific information processing structure (tradition).

In particular, in Chapter 12 and in this chapter I have tried to show how, in order to grapple productively with the ways in which inventions change our information processing apparatus by designing new ways to deal with emerging challenges. I conclude that we need to change our intellectual approach in instances like this. We need to accept that the same regulatory mechanisms are responsible for both change and its absence, and that, therefore, both need to be studied together.

In particular, we need to invert the relationship in our thinking between objects and data on the one hand, and our interpretations of these on the other. Objects and data are poly-interpretable and our interpretations are not, because they severely reduce the dimensionality of what is observed. Moreover, there are good reasons to assume that ways of seeing and doing things (traditions) outlast individual instances such as material solutions to specific challenges.

Furthermore, we need to look at the process of invention as an interaction between an external perspective on the niche where invention occurs and an internal perspective on the same. The former is constituted in the physical realm of the various factors that are potential influences on production and innovation, whereas the latter is partial and reflects the biases and choices of the person inventing. In this context, the concept of niche creation that has recently been introduced in biology is of great importance. Once a niche has been constructed, it in turn shapes perceptions and choices.

I believe that seeing the process of invention like this from the inside provides us with a much better insight into the dynamics involved, and might thus, when applied to other domains, help us steer innovation, and thereby contribute to a reflection on the unintended consequences of our inventions (by comparing the choices made with those not made) and thus, it is hoped, allow us to make wiser choices.

But an essential element in all this is how potters, and all other inventors, make their decisions. There is now a wide range of approaches from both cognitive sciences and psychology as well as from economics and other disciplines on this topic, but I will not go into these in detail, simply because there is too much to summarize. The essence of those discussions is, however, that such decisions are shaped both by biological and physical constraints and by the social networks within which the deciders function. These networks are determined by geography, social affinity, profession, and numerous other factors that together shape the value systems of the people concerned. In each case, and this is important to remember, the interaction between the dynamics within the system – whether those of an individual human being or of a social collective – and those in the context within which that system operates drives societal change and determines how a system may change. I will pursue this discussion in Chapter 16 when looking more closely at the concepts of value and value space.

The Role of Artifacts and Technology in Society

Thus far, we have looked at the role of information processing in creating novel artifacts, routines, institutions, etc. But once these have been created, they are integrated into the overall information processing toolkit of society. As we have seen, invention and innovation are essential elements in the maintenance of the flow structures that constitute human societies. But what is their precise role?

Artifacts are rarely looked upon as information processing tools, as part of the set of tools for thought and action that societies create and use in their coevolution with their environment. Yet that is an important reason for their invention because, in effect, they enable society to routinize part of its information processing. To perform a certain task that demands relatively considerable information processing if it is performed with rather simple and general-purpose tools, such as felling a tree with a stone ax, inventing a specialized tool that is more closely geared to the exact actions that are needed to perform that task, such as a saw, will reduce the information processing load of the person executing the action concerned because the tool routinizes that action. Rather than ensure that each blow of the ax hits exactly the right spot at the right angle, once the sawing has begun direction and angle are fixed and do not require any further information processing. Only the back and forth action does.

Looking at it like this, the proliferation of artifacts that has grown over time in many cultures has been due to the need to reduce the information-processing load to counterbalance its increase as a result of the growing number of people involved in the interactive groups, societies, and networks concerned. As such, it also helps to fix certain categorizations and ways of doing things materially, and thus to limit the set of options that will readily be chosen by the society.

This is another level at which the options chosen must be evaluated against those not chosen. An example from the Eastern Highlands of Papua New Guinea that my wife and I experienced in 1990 may illustrate this. In a certain village, the inhabitants invented a way to bend a sliver of bamboo upon itself, creating the kind of tweezers that can help grip objects, not unlike the tools we have in our kitchens. In their case, the tool is used to take sweet potatoes and other tubers out of the fireplace once they are cooked. But in the next village, less than half a day’s walk away, they do not have this tool, so they have to find other, more complicated, ways to remove their breakfast from the fire or burn their fingers (which therefore happens regularly). Unfortunately, we do not have enough data to decide between different possible reasons for the difference, but one way to interpret it is that the people in the two villages (who speak different languages) have a different technological worldview. There are many examples of such cultural or traditional differences between nations in the modern world. The Dutch (and South Africans), for example, cut slices of cheese with a very different cheese-knife than the French. Part of the reason is the different consistency of the cheeses, but using a French knife on a Dutch cheese would merely have changed the shape of the pieces that were cut off – not a very fundamental difference, except in the context of differences in worldview about how things should be done.

The ways things are done, including the artifacts used by a society, are part of what binds a society together. Individuals in a society develop habits that are aligned around certain kinds of knowledge. Rather than the objects people use, it is their knowledge about where to find raw materials, how to make artifacts, how to use them, etc., that defines a culture.

The complete set of artifacts that a society uses does indeed to a very substantive extent determine that society’s interaction with the material world because it structures actions in a specific way. A well-studied ethnographic example of this are the two main ways in the world in which rice or cereals are transformed into flour – by pounding with a stick in a (wooden or other) bowl as is done in many parts of East Asia, or by grinding between two stones as is done in much of Latin America. The two different physical actions have a wide range of impacts in other parts of their cultures.

Sometimes these are not immediately observable. John O’Shea once told me that the burial customs of a very small community through time – which he studied for his PhD (1987) – were remarkably stable, even though there were very few burials with long periods in between. He then asked, “How is it possible that people remember the rituals over such long times?” I think the reason is that other aspects of the culture and its activities anchored many aspects of the society’s worldview, such as spatial and ritual aspects of its culture in different ways and at different levels, so that people were guided by these choices in recollecting the burial rituals themselves.

Thus, I would argue that the technology of a particular group or society and, particularly, the ideas behind it that are only partly manifest to the people concerned, constitute the skeleton of the behavioral choices of a society, and an important element in determining its path dependent development. One way to visualize this is by looking at cities. As mentioned in the context of Padgett’s outstanding work in Florence (Reference Padgett, Casella and Rauch2000), for example, the spatial structure of the city, with its many small piazzas, led to the creation, around these piazzas, of financial transactions among neighbors, and thus gave an essential impulse to the emergence of novel inventions in the domains of accounting, banking, and trading.

In the USA, the geography of the early cities (on the coasts) enabled people to move around on foot, and for longer distances by public transportation. The streets can be, but are not necessarily, at right angles. In the mid-west and west, the (later) cities are much wider spaced and therefore depend on cars for transportation. All of us who live in such cities will be fully aware of the extent to which their plan and their amenities actually structure our lives in many, many ways. Because the life expectancy of the material infrastructure of cities exceeds that of individuals or even generations, such behavioral skeletons constrain much of their inhabitants’ behavior over a long time.

And this in turn links my argument to Arthur’s reversal of the roles of the economy and technology, which I referred to in Chapter 12, the technology of a society being in many ways the infrastructure within which both the society and the economy function. The position that he corrects (the economy as the driver of technology (and society) can be linked to the fact that, in the 1830s–1850s western society inverted the respective roles of society and the economy, from one in which the economy served the society as was the case in most premodern societies, to one in which the society served the economy, thereby opening the road for the emergence of our current market-based capitalist (and more recently financial) system (see Polanyi Reference Polanyi1944). I devote more attention to this shift and its consequences in Chapter 18.