Article contents

Experiments on Marangoni spreading – evidence of a new type of interfacial instability

Published online by Cambridge University Press: 07 March 2023

Abstract

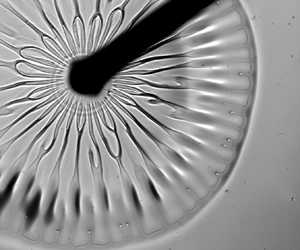

Marangoni spreading on thin films is widely observed in nature and applied in industry. It has serious implications for airway drug delivery, especially in surfactant displacement therapy. This paper reports the results of experimental investigations of a surfactant-laden droplet spreading on films made of more viscous Newtonian fluids as well as on films made of viscoelastic fluids. The experiments used particle seeding, the transmission-speckle method and particle tracking velocimetry (PTV) to determine the deformation of the film–droplet interface and to measure velocity fields. Radially aligned patterns were observed on Newtonian films. Similar patterns, but with much smaller wavenumber, were observed on viscoelastic films in combination with rapid azimuthal variations of the film thickness. The Saffman–Taylor instability at the film–droplet interface explains the formation of patterns on a more viscous Newtonian film, and their onset requires exceeding the critical capillary number. The pattern formation on viscoelastic films is correlated with an instability at the film–droplet–air contact line when the liquid is expelled radially by the spreading droplet. PTV revealed azimuthal variations of the velocity field in the vicinity of the contact line. The observed contact line instability is different from previously reported fingering instabilities of Newtonian thin films. A simple scaling law accounting for the Marangoni-stress-induced elastic shear deformation is proposed to describe the flow field in the patterns formed in the viscoelastic films.

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2023. Published by Cambridge University Press

References

Ma et al. Supplementary Movie 1

Spreading of a surfactant-laden aqueous droplet on a more viscous viscoelastic (left) and Newtonian (right) thin liquid film. Both films have similar viscosities (22.7 mPa.s for the viscoelastic Boger 2 fluid, 21.5 mPa.s for the Newtonian PEG solution, fluid properties are given in Table 1). Rib-like structures characterized by low wavenumbers are formed at the Boger film - droplet interface (left), whereas radially aligned structures characterized by large wavenumbers are formed at the Newtonian film-droplet interface (right). Many very small fingers form at the end of spreading on Boger film (left) after deposition of a second surfactant-laden droplet.

- 8

- Cited by