1. Introduction

Rigid splitter plates in the wake of a circular cylinder have been shown to cause significant changes in the wake characteristics, and in the forces acting on the body. In his pioneering study, Roshko (Reference Roshko1954) reported suppression of the vortex shedding for splitter plate lengths greater than five times the diameter of the cylinder. Since this study, many subsequent investigations, such as Bearman (Reference Bearman1965), Apelt, West & Szewczyk (Reference Apelt, West and Szewczyk1973, Reference Apelt, West and Szewczyk1975) and Kwon & Choi (Reference Kwon and Choi1996) among others, have studied this problem extensively, and have shown interesting changes in the vortex shedding instability as the length of the splitter plate is varied. For example, in the case of short splitter plates whose length to cylinder diameter ratio, ![]() $L/D \leq 3$, Apelt et al. (Reference Apelt, West and Szewczyk1973, Reference Apelt, West and Szewczyk1975) highlight interesting changes in the shedding frequency and in the cylinder base suction pressure in the near-wake region compared with longer plates with

$L/D \leq 3$, Apelt et al. (Reference Apelt, West and Szewczyk1973, Reference Apelt, West and Szewczyk1975) highlight interesting changes in the shedding frequency and in the cylinder base suction pressure in the near-wake region compared with longer plates with ![]() $L/D = 5.0$, where the near-wake interaction of the shear layers vortices are completely inhibited.

$L/D = 5.0$, where the near-wake interaction of the shear layers vortices are completely inhibited.

Recently, there have been many studies that have explored the addition of different forms of flexibilities to the cylinder–splitter plate system, where the dynamics can be richer. For example, Assi, Bearman & Kitney (Reference Assi, Bearman and Kitney2009) and Shukla, Govardhan & Arakeri (Reference Shukla, Govardhan and Arakeri2009) have studied rigid splitter plates that are not fixed, but are hinged to the cylinder. These investigations show that depending on the damping associated with the hinge, the plates can oscillate or reach an equilibrium position that is at an angle to the free-stream. For relatively large hinge damping, Assi et al. (Reference Assi, Bearman and Kitney2009) showed that the splitter plates do not oscillate, but assume a stable position at an angle to the flow direction. With this configuration, they showed that vortex-induced vibrations (VIVs) of the cylinder were effectively suppressed with significant drag reduction as well. On the other hand, at very low hinge damping levels, Shukla et al. (Reference Shukla, Govardhan and Arakeri2009) have reported that by varying the length of the splitter plate, the response of the hinged–rigid splitter plates exhibit two different regimes of flap oscillations. For ![]() $L/D < 3.5$ the response of the plates show a strong periodic oscillation whereas for

$L/D < 3.5$ the response of the plates show a strong periodic oscillation whereas for ![]() $L/D > 3.5$ response of the plates exhibit a weak periodic oscillation whose spectra show a broad band peak similar to the that seen in the velocity spectra of the long fixed–rigid splitter plate. In the case of flexible splitter plates, interactions between the shear layers on the two sides are possible at every given streamwise point along the splitter plate, which can lead to richer dynamics of the plate as seen in the studies of Sahu, Mohd & Mittal (Reference Sahu, Mohd and Mittal2019), Mohd & Mittal (Reference Mohd and Mittal2021), Mao, Liu & Sung (Reference Mao, Liu and Sung2022) and Pfister & Marquet (Reference Pfister and Marquet2020) at low Reynolds numbers for a circular cylinder, and at intermediate Reynolds numbers and high mass ratios (in air) for a square cylinder by Sharma & Dutta (Reference Sharma and Dutta2020). There have, however, been no reported detailed studies on the flow past a cylinder with a flexible splitter plate at large Reynolds numbers, and this is the focus of the present work. It may be noted that some preliminary results of the flap dynamics in this configuration have been reported in Shukla, Govardhan & Arakeri (Reference Shukla, Govardhan and Arakeri2013), where a limited set of flap dynamics results for a few flap cases were presented. In the present paper, we present a more comprehensive investigation including results from large variations in the splitter plate flexural rigidity (

$L/D > 3.5$ response of the plates exhibit a weak periodic oscillation whose spectra show a broad band peak similar to the that seen in the velocity spectra of the long fixed–rigid splitter plate. In the case of flexible splitter plates, interactions between the shear layers on the two sides are possible at every given streamwise point along the splitter plate, which can lead to richer dynamics of the plate as seen in the studies of Sahu, Mohd & Mittal (Reference Sahu, Mohd and Mittal2019), Mohd & Mittal (Reference Mohd and Mittal2021), Mao, Liu & Sung (Reference Mao, Liu and Sung2022) and Pfister & Marquet (Reference Pfister and Marquet2020) at low Reynolds numbers for a circular cylinder, and at intermediate Reynolds numbers and high mass ratios (in air) for a square cylinder by Sharma & Dutta (Reference Sharma and Dutta2020). There have, however, been no reported detailed studies on the flow past a cylinder with a flexible splitter plate at large Reynolds numbers, and this is the focus of the present work. It may be noted that some preliminary results of the flap dynamics in this configuration have been reported in Shukla, Govardhan & Arakeri (Reference Shukla, Govardhan and Arakeri2013), where a limited set of flap dynamics results for a few flap cases were presented. In the present paper, we present a more comprehensive investigation including results from large variations in the splitter plate flexural rigidity (![]() $EI$) on the flap dynamics, force measurements and wake velocity measurements.

$EI$) on the flap dynamics, force measurements and wake velocity measurements.

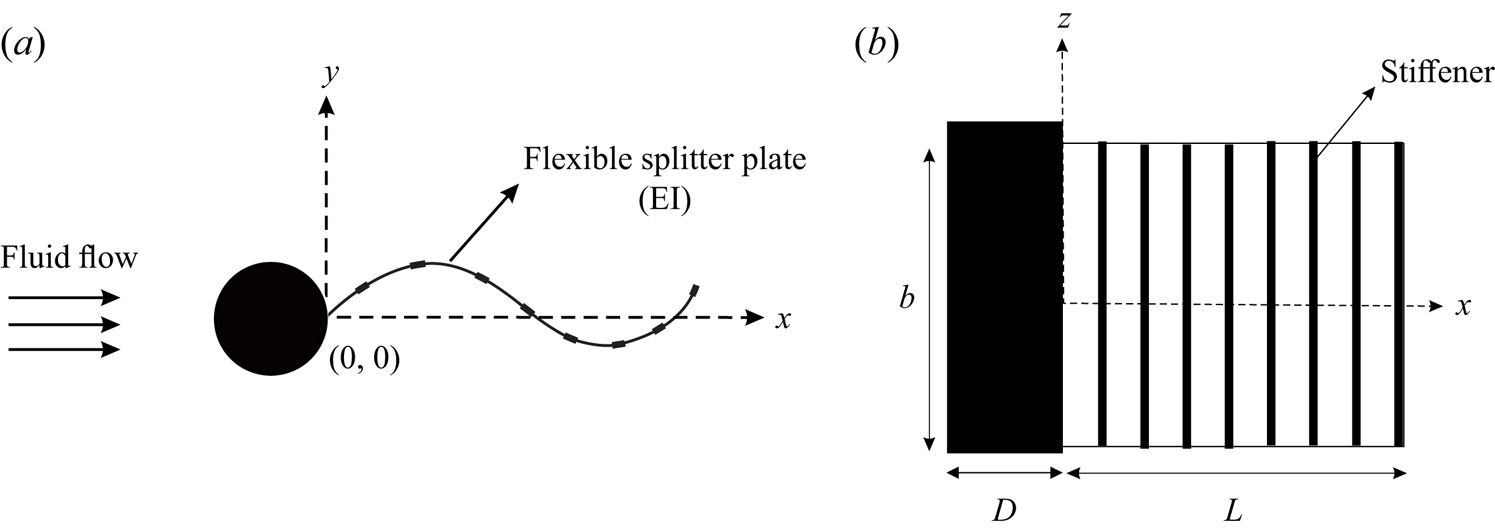

In the present work, we study the problem of a fully flexible splitter plate/flap in the wake of a cylinder at Reynolds numbers in the range of 2000–22 000. The flap is attached to the base of the cylinder and is free to deform continuously along the length of the flap, as shown in the schematic in figure 1. Compared with the hinged–rigid splitter plate case, where an integrated effect of the pressure differences across the length of the plate results in angular motions of the plate, here local pressure differences across the plate can lead to local deformations. Hence, one can expect that the dynamics of the flap can be relatively more complex than in the hinged–rigid splitter plate case. For this fully flexible splitter plate case, the flexural rigidity (![]() $EI$) of the plate or sheet becomes an important parameter in addition to the splitter plate length to cylinder diameter ratio (

$EI$) of the plate or sheet becomes an important parameter in addition to the splitter plate length to cylinder diameter ratio (![]() $L/D$) and the Reynolds number (

$L/D$) and the Reynolds number (![]() $Re$) based on the cylinder diameter. There can also be other parameters related to the plate, such as the mass per unit length of the plate and its internal structural damping. The mass in these problems has typically been characterised by a mass ratio defined as

$Re$) based on the cylinder diameter. There can also be other parameters related to the plate, such as the mass per unit length of the plate and its internal structural damping. The mass in these problems has typically been characterised by a mass ratio defined as ![]() $m^{\ast } = \rho _{s} / \rho _{f}\times t/D$, where

$m^{\ast } = \rho _{s} / \rho _{f}\times t/D$, where ![]() $\rho _{s} / \rho _{f}$ is the ratio of the solid (flap) material density to that of the fluid, and

$\rho _{s} / \rho _{f}$ is the ratio of the solid (flap) material density to that of the fluid, and ![]() $t/D$ is the ratio of the flap thickness to the cylinder diameter (Mohd & Mittal Reference Mohd and Mittal2021). In the present experiments done in a water tunnel with thin plates/flaps with

$t/D$ is the ratio of the flap thickness to the cylinder diameter (Mohd & Mittal Reference Mohd and Mittal2021). In the present experiments done in a water tunnel with thin plates/flaps with ![]() $\rho _{s}/\rho _{f}$ of about 1, the mass ratio (

$\rho _{s}/\rho _{f}$ of about 1, the mass ratio (![]() $m^{\ast }$) is very small (

$m^{\ast }$) is very small (![]() $1\times 10^{-2}$) for all flap cases studied unlike in studies such as (Mohd & Mittal Reference Mohd and Mittal2021), where (

$1\times 10^{-2}$) for all flap cases studied unlike in studies such as (Mohd & Mittal Reference Mohd and Mittal2021), where (![]() $m^{\ast }$) is greater than 1. Therefore, the plate inertia may be neglected in the present work, and it is purely the added mass that is important, resulting in a strong coupling of the structure and the fluid. Hence, the main parameters influencing the motions in the present study are the flap length to cylinder diameter ratio (

$m^{\ast }$) is greater than 1. Therefore, the plate inertia may be neglected in the present work, and it is purely the added mass that is important, resulting in a strong coupling of the structure and the fluid. Hence, the main parameters influencing the motions in the present study are the flap length to cylinder diameter ratio (![]() $L/D$), the Reynolds number (

$L/D$), the Reynolds number (![]() $Re$) and the flexural rigidity (

$Re$) and the flexural rigidity (![]() $EI$). The present system may be considered to be an idealisation of flexible ribbon faring (Zdravkovich Reference Zdravkovich1981, Reference Zdravkovich1982; Blevins Reference Blevins1990; Kwon et al. Reference Kwon, Cho, Park and Choi2002) that are used to suppress VIVs. In this paper, we present a comprehensive study of the cylinder–splitter plate/flap system including results from large variations in the splitter plate flexural rigidity (

$EI$). The present system may be considered to be an idealisation of flexible ribbon faring (Zdravkovich Reference Zdravkovich1981, Reference Zdravkovich1982; Blevins Reference Blevins1990; Kwon et al. Reference Kwon, Cho, Park and Choi2002) that are used to suppress VIVs. In this paper, we present a comprehensive study of the cylinder–splitter plate/flap system including results from large variations in the splitter plate flexural rigidity (![]() $EI$) on the flap dynamics, forces, and wake velocity field. In addition to the interest from drag reduction and suppression of VIVs, the system also presents possibilities for energy extraction using piezo-electric membranes (Allen & Smits Reference Allen and Smits2001; Akaydin, Elvin & Andreopoulos Reference Akaydin, Elvin and Andreopoulos2010; Abdi, Rezazadeh & Abdi Reference Abdi, Rezazadeh and Abdi2019), and is also related to the flag flutter problem, which has been studied extensively in the absence of the flag pole (bluff body); see e.g. Argentina & Mahadevan Reference Argentina and Mahadevan2005; Connell & Yue Reference Connell and Yue2007; Eloy, Kofman & Schouveiler Reference Eloy, Kofman and Schouveiler2012.

$EI$) on the flap dynamics, forces, and wake velocity field. In addition to the interest from drag reduction and suppression of VIVs, the system also presents possibilities for energy extraction using piezo-electric membranes (Allen & Smits Reference Allen and Smits2001; Akaydin, Elvin & Andreopoulos Reference Akaydin, Elvin and Andreopoulos2010; Abdi, Rezazadeh & Abdi Reference Abdi, Rezazadeh and Abdi2019), and is also related to the flag flutter problem, which has been studied extensively in the absence of the flag pole (bluff body); see e.g. Argentina & Mahadevan Reference Argentina and Mahadevan2005; Connell & Yue Reference Connell and Yue2007; Eloy, Kofman & Schouveiler Reference Eloy, Kofman and Schouveiler2012.

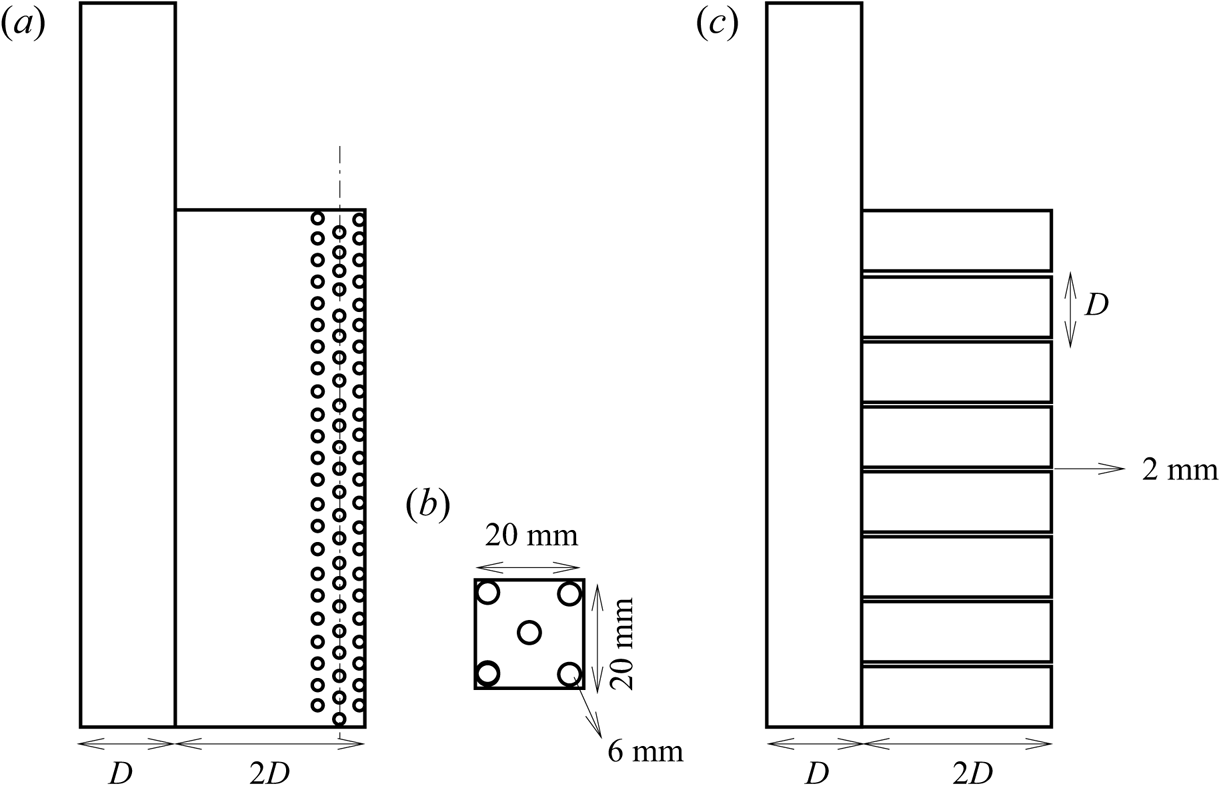

Figure 1. Schematic of a flexible splitter plate/flap in the wake of a circular cylinder: (a) top view; (b) side view. In the figure, the flexible splitter plate/flap of length ![]() $L$, and flexural rigidity

$L$, and flexural rigidity ![]() $EI$ is placed downstream of the cylinder of diameter

$EI$ is placed downstream of the cylinder of diameter ![]() $D$.

$D$.

In the present case, we extensively investigate two specific flap lengths (![]() $L$), one corresponding to

$L$), one corresponding to ![]() $L/D=5$ and the other with

$L/D=5$ and the other with ![]() $L/D=2$. In the

$L/D=2$. In the ![]() $L/D=5$ flap case, the flap length is sufficiently long that for large

$L/D=5$ flap case, the flap length is sufficiently long that for large ![]() $EI$ values it approaches a long rigid plate case, which is known to suppress vortex shedding. On the other hand, for the

$EI$ values it approaches a long rigid plate case, which is known to suppress vortex shedding. On the other hand, for the ![]() $L/D=2$ flap case, even the rigid plate is not expected to suppress shedding. We show that the observed flap dynamics for the two length cases can be dramatically different. In both length cases, at large values of

$L/D=2$ flap case, even the rigid plate is not expected to suppress shedding. We show that the observed flap dynamics for the two length cases can be dramatically different. In both length cases, at large values of ![]() $EI$, the configuration approaches that of a rigid splitter plate, while at very low values of

$EI$, the configuration approaches that of a rigid splitter plate, while at very low values of ![]() $EI$, the effects of the flexible splitter plate would be expected to be small. On the other hand, one might expect that at intermediate values of the flexural rigidity, there would be significant interactions between the elastic deformations of the flap, the fluid forces acting on the flap and the wake dynamics. We have experimentally studied this in the present work through measurements of the flap deformations, forces and the wake dynamics.

$EI$, the effects of the flexible splitter plate would be expected to be small. On the other hand, one might expect that at intermediate values of the flexural rigidity, there would be significant interactions between the elastic deformations of the flap, the fluid forces acting on the flap and the wake dynamics. We have experimentally studied this in the present work through measurements of the flap deformations, forces and the wake dynamics.

In § 3, we discuss results for the ![]() $L/D=5$ cases. This includes the effect of the flap's flexural rigidity (

$L/D=5$ cases. This includes the effect of the flap's flexural rigidity (![]() $EI$) on its dynamics, the fluctuating lift and mean drag forces acting on the body and the wake dynamics obtained from particle image velocimetry (PIV) measurements. This is followed in § 4 by a similar discussion about

$EI$) on its dynamics, the fluctuating lift and mean drag forces acting on the body and the wake dynamics obtained from particle image velocimetry (PIV) measurements. This is followed in § 4 by a similar discussion about ![]() $L/D=2$ cases, where the length of the flap is less than or equal to the recirculation zone. The main conclusions from the study are presented in § 5.

$L/D=2$ cases, where the length of the flap is less than or equal to the recirculation zone. The main conclusions from the study are presented in § 5.

2. Experimental details

The main part of the work presented in this paper was performed in a free surface water tunnel in the fluid mechanics laboratory of the mechanical engineering department at the Indian Institute of Science (IISc). The test section of the tunnel is ![]() $1\ {\rm m}\times 1\ {\rm m}$ in cross section and 3 m long. The tunnel is a closed circuit type with contraction ratio of 7.50. The maximum speed of the tunnel is 1 m s

$1\ {\rm m}\times 1\ {\rm m}$ in cross section and 3 m long. The tunnel is a closed circuit type with contraction ratio of 7.50. The maximum speed of the tunnel is 1 m s![]() $^{-1}$. The test section frame is made of mild steel with six glass panels on the side walls and three Perspex panels on the floor, and the maximum height of the water level in the test section is 1 m from the base of the test section.

$^{-1}$. The test section frame is made of mild steel with six glass panels on the side walls and three Perspex panels on the floor, and the maximum height of the water level in the test section is 1 m from the base of the test section.

A Pitot static probe in conjunction with a two-liquid manometer was used for measuring the flow speed in the test section. The two liquid manometer contained two liquids with a density ratio of ![]() ${ \rho _{l} }/{ \rho _{w} } = 1.12$, which provided a magnification factor of approximately 8 in the manometer reading compared with a single liquid water manometer reading (

${ \rho _{l} }/{ \rho _{w} } = 1.12$, which provided a magnification factor of approximately 8 in the manometer reading compared with a single liquid water manometer reading (![]() $\Delta H$) as given by the equation

$\Delta H$) as given by the equation

\begin{equation} \frac{\Delta h}{\Delta H}= \frac{1}{ \dfrac{\rho_{l}}{\rho_{w}}-1}, \end{equation}

\begin{equation} \frac{\Delta h}{\Delta H}= \frac{1}{ \dfrac{\rho_{l}}{\rho_{w}}-1}, \end{equation}

where ![]() $\rho _l$ is the density of the manometer liquid,

$\rho _l$ is the density of the manometer liquid, ![]() $\rho _w$ is the density of water in the tunnel,

$\rho _w$ is the density of water in the tunnel, ![]() $\Delta h$ is the two-liquid manometer reading and

$\Delta h$ is the two-liquid manometer reading and ![]() $\Delta H$ is the dynamic head in the test section in terms of the equivalent water column. With this amplification factor, the two-liquid manometer provided good sensitivity to measure the mean flow. Wake velocity field measurements using PIV were done in another smaller water tunnel in the department, because of the prohibitive cost of seeding the large volume of water in the larger water tunnel. The smaller water tunnel has a test section with cross-sectional dimensions of 0.45 m (height)

$\Delta H$ is the dynamic head in the test section in terms of the equivalent water column. With this amplification factor, the two-liquid manometer provided good sensitivity to measure the mean flow. Wake velocity field measurements using PIV were done in another smaller water tunnel in the department, because of the prohibitive cost of seeding the large volume of water in the larger water tunnel. The smaller water tunnel has a test section with cross-sectional dimensions of 0.45 m (height) ![]() $\times$ 0.28 m (width) and is 1.2 m long. The tunnel is also a closed circuit type with a contraction ratio of 6. The maximum speed of this tunnel is 0.30 m s

$\times$ 0.28 m (width) and is 1.2 m long. The tunnel is also a closed circuit type with a contraction ratio of 6. The maximum speed of this tunnel is 0.30 m s![]() $^{-1}$. The upstream end of the contraction contains the flow straightener consisting of 250 mm long and 5 mm diameter plastic straws to improve the flow quality in the test section.

$^{-1}$. The upstream end of the contraction contains the flow straightener consisting of 250 mm long and 5 mm diameter plastic straws to improve the flow quality in the test section.

The test circular cylinder was constructed of brass. The cylinder model was carefully machined such that it could be dismantled into two semicircular halves by removing the holding screws along the span of the model. Once the two halves were assembled, the screws holes were carefully filled in with sealant material such that the surface of the cylinder was smooth. This arrangement was necessary to place the flexible splitter plates in between the two halves of the model. The diameter of the cylinder was 0.035 m and its length was 0.43 m, giving a cylinder aspect ratio (length/diameter) of 8.5. The blockage of the model in the larger tunnel was 3.5 % and in the smaller tunnel was 11.7 %. To encourage two-dimensional vortex shedding, end plates were used for all the measurements presented in this thesis. The end plates were made of Perspex sheet of thickness 1 mm. The length of the end plate along the streamwise direction was ![]() $10D$ and the width of the plate across the flow direction was

$10D$ and the width of the plate across the flow direction was ![]() $6D$ (

$6D$ (![]() $D$ is the cylinder diameter), which was sufficient to cover the full length and oscillatory motion of the flexible plate.

$D$ is the cylinder diameter), which was sufficient to cover the full length and oscillatory motion of the flexible plate.

2.1. Flexible splitter plate

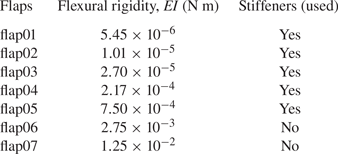

The flexible splitter plates or flaps were made from sheets of different elastic materials and thicknesses procured from stationery shops. This enabled us to get a very large range of flexural rigidities (![]() $EI$) for the flaps, which were measured from simple static deflection tests of the flap under its own self weight. With knowledge of the geometry, careful weighing of the flap to obtain mass per unit length and the tip deflection, the flexural rigidity per unit span of these flaps were calculated as tabulated in table 1 for each of the 7 flaps used. As seen in the table, the

$EI$) for the flaps, which were measured from simple static deflection tests of the flap under its own self weight. With knowledge of the geometry, careful weighing of the flap to obtain mass per unit length and the tip deflection, the flexural rigidity per unit span of these flaps were calculated as tabulated in table 1 for each of the 7 flaps used. As seen in the table, the ![]() $EI$ values of the flaps spanned about 4 orders in magnitude. The flap aspect ratio, defined as the flap streamwise length (

$EI$ values of the flaps spanned about 4 orders in magnitude. The flap aspect ratio, defined as the flap streamwise length (![]() $L$) to the flap width (

$L$) to the flap width (![]() $b$), was 1.7 and 4.25 for the

$b$), was 1.7 and 4.25 for the ![]() $L/D=5$ and

$L/D=5$ and ![]() $L/D=2$ flap cases, respectively. Initial tests showed that the motion of the flap had spanwise variations for low flexural rigidity (

$L/D=2$ flap cases, respectively. Initial tests showed that the motion of the flap had spanwise variations for low flexural rigidity (![]() $EI$) flaps. In order to achieve two-dimensional motions of the flap, we used spanwise stiffeners to locally enhance the spanwise stiffness of the flaps (Shelley, Vandenberghe & Zhang Reference Shelley, Vandenberghe and Zhang2005), as shown in figure 1. The stiffeners were made from relatively rigid elastic material with thickness of approximately 450

$EI$) flaps. In order to achieve two-dimensional motions of the flap, we used spanwise stiffeners to locally enhance the spanwise stiffness of the flaps (Shelley, Vandenberghe & Zhang Reference Shelley, Vandenberghe and Zhang2005), as shown in figure 1. The stiffeners were made from relatively rigid elastic material with thickness of approximately 450 ![]() $\mathrm {\mu }$m. These stiffeners were carefully cut out with the help of a sharp knife and glued on both sides of the flaps at regular streamwise intervals. The stiffener streamwise size (width) and number were chosen in such a manner as to keep the width of the stiffeners to be small compared with the streamwise wavelength of the plate deformations, and the separation between two successive stiffeners to be large enough compared with the stiffener width, to not affect the flexural rigidity (

$\mathrm {\mu }$m. These stiffeners were carefully cut out with the help of a sharp knife and glued on both sides of the flaps at regular streamwise intervals. The stiffener streamwise size (width) and number were chosen in such a manner as to keep the width of the stiffeners to be small compared with the streamwise wavelength of the plate deformations, and the separation between two successive stiffeners to be large enough compared with the stiffener width, to not affect the flexural rigidity (![]() $EI$) of the base flap in the streamwise direction. This resulted in 10 stiffeners being used for the

$EI$) of the base flap in the streamwise direction. This resulted in 10 stiffeners being used for the ![]() $L/D=5$ case and 4 stiffeners for the

$L/D=5$ case and 4 stiffeners for the ![]() $L/D=2$ case. It was also ensured that the stiffener streamwise width was kept small compared with the streamwise wavelength of the plate deformations to again ensure that there was no effect on

$L/D=2$ case. It was also ensured that the stiffener streamwise width was kept small compared with the streamwise wavelength of the plate deformations to again ensure that there was no effect on ![]() $EI$ of the base flap. It may be noted that stiffeners were used only for flaps whose flexural rigidity was low (flap01 to flap05) to keep the deformations two-dimensional, while no stiffeners were used in the higher

$EI$ of the base flap. It may be noted that stiffeners were used only for flaps whose flexural rigidity was low (flap01 to flap05) to keep the deformations two-dimensional, while no stiffeners were used in the higher ![]() $EI$ flap cases, as indicated in table 1. The flap deformations in all flap cases presented were ensured to be two-dimensional. Flap tip amplitudes and deformation profiles in both with and without stiffener cases were seen to be close as indicated by the collapse of the tip amplitude values for flap05 (with stiffener) and flap07 (without stiffener) when plotted with non-dimensional stiffness parameter,

$EI$ flap cases, as indicated in table 1. The flap deformations in all flap cases presented were ensured to be two-dimensional. Flap tip amplitudes and deformation profiles in both with and without stiffener cases were seen to be close as indicated by the collapse of the tip amplitude values for flap05 (with stiffener) and flap07 (without stiffener) when plotted with non-dimensional stiffness parameter, ![]() $K^{\ast }$, as shown in figure 6.

$K^{\ast }$, as shown in figure 6.

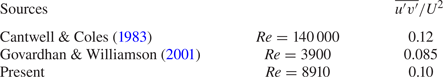

Table 1. Measured flexural rigidity ![]() $EI$ per unit span of the different flexible splitter plate/flaps that were used in the present investigation.

$EI$ per unit span of the different flexible splitter plate/flaps that were used in the present investigation.

2.2. Measurements

Flap dynamics were captured using a Fastcam PCI R2 camera in conjunction with a Roithner 1 W continuous green (532 nm) laser. The laser sheet was generated using a 7 mm cylindrical lens and illuminated a viewing area with a streamwise length of about ![]() $9D$. The camera framing rates were chosen according to the oscillation frequency of the plate, which was dependent on the flow speed. The maximum framing rate used was 250 frames/second, which was sufficient to capture at least 40 images per cycle of the plate/flap motion at the highest flow speed, with significantly higher images per cycle being captured at lower flow speeds.

$9D$. The camera framing rates were chosen according to the oscillation frequency of the plate, which was dependent on the flow speed. The maximum framing rate used was 250 frames/second, which was sufficient to capture at least 40 images per cycle of the plate/flap motion at the highest flow speed, with significantly higher images per cycle being captured at lower flow speeds.

In all cases, recorded images of the flap motions were processed in MATLAB to determine tip deflection at each time instant. From the resulting time traces of tip deflection, the amplitude and frequency of flap motions were deduced. Throughout the paper, the normalised amplitude of the tip oscillations is defined as ![]() $A^{\ast } = \sqrt {2} {Y'_{rms}/D}$, where

$A^{\ast } = \sqrt {2} {Y'_{rms}/D}$, where ![]() $Y'_{rms}$ is the root-mean-square (r.m.s.) of the fluctuating part of the transverse tip deflection. The normalised frequency of tip oscillations is defined as

$Y'_{rms}$ is the root-mean-square (r.m.s.) of the fluctuating part of the transverse tip deflection. The normalised frequency of tip oscillations is defined as ![]() $f_{A}D/U$, where

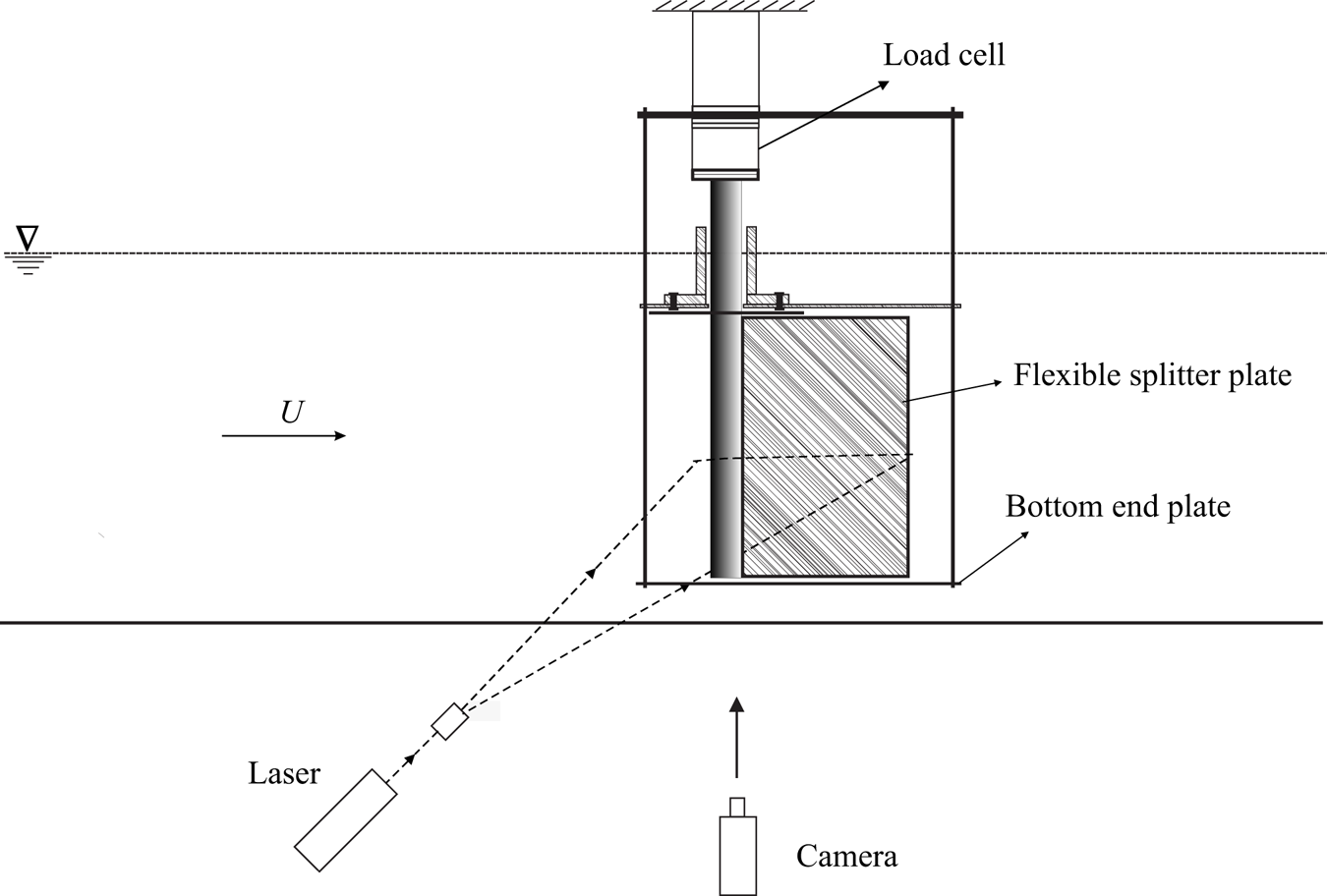

$f_{A}D/U$, where ![]() $f_{A}$ is the flapping frequency of the flap that is obtained from the spectra of the time traces of tip deflection. Force measurements were carried out using a load cell attached to the top end of the cylinder and can be seen in figure 2. The load cell used had a strain-gauge-based sensing element connected to a Wheatstone bridge. The load cell directly measured the hydrodynamic forces acting on the cylinder–splitter plate configuration when it was exposed to the flow. The output voltage from the Wheatstone bridge was amplified and conditioned before acquisition. Prior to measurements, the load cell was calibrated with standard weights, and had a calibration constant of 50.2 mV/gram-force (gm-f) with an uncertainty of

$f_{A}$ is the flapping frequency of the flap that is obtained from the spectra of the time traces of tip deflection. Force measurements were carried out using a load cell attached to the top end of the cylinder and can be seen in figure 2. The load cell used had a strain-gauge-based sensing element connected to a Wheatstone bridge. The load cell directly measured the hydrodynamic forces acting on the cylinder–splitter plate configuration when it was exposed to the flow. The output voltage from the Wheatstone bridge was amplified and conditioned before acquisition. Prior to measurements, the load cell was calibrated with standard weights, and had a calibration constant of 50.2 mV/gram-force (gm-f) with an uncertainty of ![]() $\pm 0.16$ mV (gm-f)

$\pm 0.16$ mV (gm-f)![]() $^{-1}$ based on the calibration data. This represents an error of approximately 0.3 % in the reported values of force due to calibration issues. The data acquisition of the load cell signal after signal conditioning was done using a NI Compact Data Acquisition-Model 1974 (

$^{-1}$ based on the calibration data. This represents an error of approximately 0.3 % in the reported values of force due to calibration issues. The data acquisition of the load cell signal after signal conditioning was done using a NI Compact Data Acquisition-Model 1974 (![]() $NIcDAQ-1974$).

$NIcDAQ-1974$).

Figure 2. Schematic of the visualisation system used for PIV measurements and for recording of the flap dynamics along with experimental set-up showing the major components of the system.

Particle image velocimetry was used to measure the wake velocity field. For this technique, the flow was seeded with silver-coated spherical hollow glass particles (SH400S33) of 14 ![]() $\mathrm {\mu }$ mean diameter from Potters Industries, USA, whose density was 1.7 g cm

$\mathrm {\mu }$ mean diameter from Potters Industries, USA, whose density was 1.7 g cm![]() $^{-1}$. The images of these particle were recorded using a two-dimensional PIV system after illumination by laser sheet from a New Wave Solo Nd:YAG PIV laser; a schematic of the visualisation system is given in figure 2. Pairs of such images recorded with small time intervals of the order of a few milliseconds were processed using DynamicStudio software from Dantec Inc., and a revised version of the MATLAB-based PIV code whose details are given in Govardhan & Williamson (Reference Govardhan and Williamson2000). The processing resulted in a velocity field over the entire region of imaging. The field of view used had a width of

$^{-1}$. The images of these particle were recorded using a two-dimensional PIV system after illumination by laser sheet from a New Wave Solo Nd:YAG PIV laser; a schematic of the visualisation system is given in figure 2. Pairs of such images recorded with small time intervals of the order of a few milliseconds were processed using DynamicStudio software from Dantec Inc., and a revised version of the MATLAB-based PIV code whose details are given in Govardhan & Williamson (Reference Govardhan and Williamson2000). The processing resulted in a velocity field over the entire region of imaging. The field of view used had a width of ![]() $6D$ to

$6D$ to ![]() $8D$ for the PIV measurements reported here. This was found to give sufficient resolution of the vortical structures in the wake, while also giving a reasonable overview of the wake dynamics. A Dantec PIV camera with a resolution of

$8D$ for the PIV measurements reported here. This was found to give sufficient resolution of the vortical structures in the wake, while also giving a reasonable overview of the wake dynamics. A Dantec PIV camera with a resolution of ![]() $1360\ {\rm pixel}\times 1036\ {\rm pixel}$ was used to acquire particle images. The camera and laser were synchronised by providing appropriate delay time between the laser pulses (L1 and L2) and the camera using a Stanford Delay Generator (DG 645). The separation times (

$1360\ {\rm pixel}\times 1036\ {\rm pixel}$ was used to acquire particle images. The camera and laser were synchronised by providing appropriate delay time between the laser pulses (L1 and L2) and the camera using a Stanford Delay Generator (DG 645). The separation times (![]() $\Delta t$) between the two laser pulses (L1 and L2) was in the range of 2–15 ms, which were selected according to the flow speed in such a way that it would give about 6 pixel displacement at each speed (for the uniform flow).

$\Delta t$) between the two laser pulses (L1 and L2) was in the range of 2–15 ms, which were selected according to the flow speed in such a way that it would give about 6 pixel displacement at each speed (for the uniform flow).

Phase-averaged PIV measurements were done for all the periodic modes found in the present work to elucidate the repeatable large-scale coherent vortical structures in the flow. The PIV images for the phase averaging at a particular phase were chosen by ensuring that the variations in flap tip deflections and flap deflection profile were within 5 % of the chosen value at a given phase of flap deformation. The phase was determined based on the flap tip position with reference to the extreme location of the flap tip during the oscillation cycle. These chosen PIV images were then processed, with at least 10 such conditional velocity fields being averaged to obtain each of the phase-averaged velocity fields presented in this paper. The resultant phase-averaged fields for the ![]() $L/D=5$ and

$L/D=5$ and ![]() $L/D=2$ cases are shown in §§ 3 and 4, respectively.

$L/D=2$ cases are shown in §§ 3 and 4, respectively.

3. Flexible splitter plate with  $L/D=5$

$L/D=5$

In this section, we report results for a flexible splitter plate/flap with a flap length to cylinder diameter ratio ![]() $L/D$ of 5.0. As discussed in the introduction, a rigid flap of this length would completely suppress vortex shedding from the body. In our case, the flexible plate or flap is attached to the base of the cylinder and is free to deform continuously along the length of the flap. The hinged–rigid splitter plate case with this length (Shukla et al. Reference Shukla, Govardhan and Arakeri2009), discussed in the introduction, showed only weak aperiodic oscillations as only weak interaction was possible between the shear layer on either side of the cylinder in that configuration. In contrast, in the present work with a flexible flap, local pressure communication is possible at every streamwise location along the flap length/surface, which can lead to local deformations of the plate/flap. Hence, one can expect relatively more complex deformations than in the hinged–rigid splitter plate case.

$L/D$ of 5.0. As discussed in the introduction, a rigid flap of this length would completely suppress vortex shedding from the body. In our case, the flexible plate or flap is attached to the base of the cylinder and is free to deform continuously along the length of the flap. The hinged–rigid splitter plate case with this length (Shukla et al. Reference Shukla, Govardhan and Arakeri2009), discussed in the introduction, showed only weak aperiodic oscillations as only weak interaction was possible between the shear layer on either side of the cylinder in that configuration. In contrast, in the present work with a flexible flap, local pressure communication is possible at every streamwise location along the flap length/surface, which can lead to local deformations of the plate/flap. Hence, one can expect relatively more complex deformations than in the hinged–rigid splitter plate case.

We present results for a flexible flap in the wake of a circular cylinder in three subsections. In the first subsection, we discuss the flap kinematics including the effect of the flow speed and the flap's flexural rigidity ![]() $EI$ on it, and the combination of the flow speed and

$EI$ on it, and the combination of the flow speed and ![]() $EI$ effect into a single normalised stiffness parameter,

$EI$ effect into a single normalised stiffness parameter, ![]() $K^{\ast }$, of the cylinder–flap combination. The force measurements are subsequently presented in the second subsection, with the corresponding wake velocity fields from PIV measurements being presented in the final subsection.

$K^{\ast }$, of the cylinder–flap combination. The force measurements are subsequently presented in the second subsection, with the corresponding wake velocity fields from PIV measurements being presented in the final subsection.

3.1. Flap kinematics

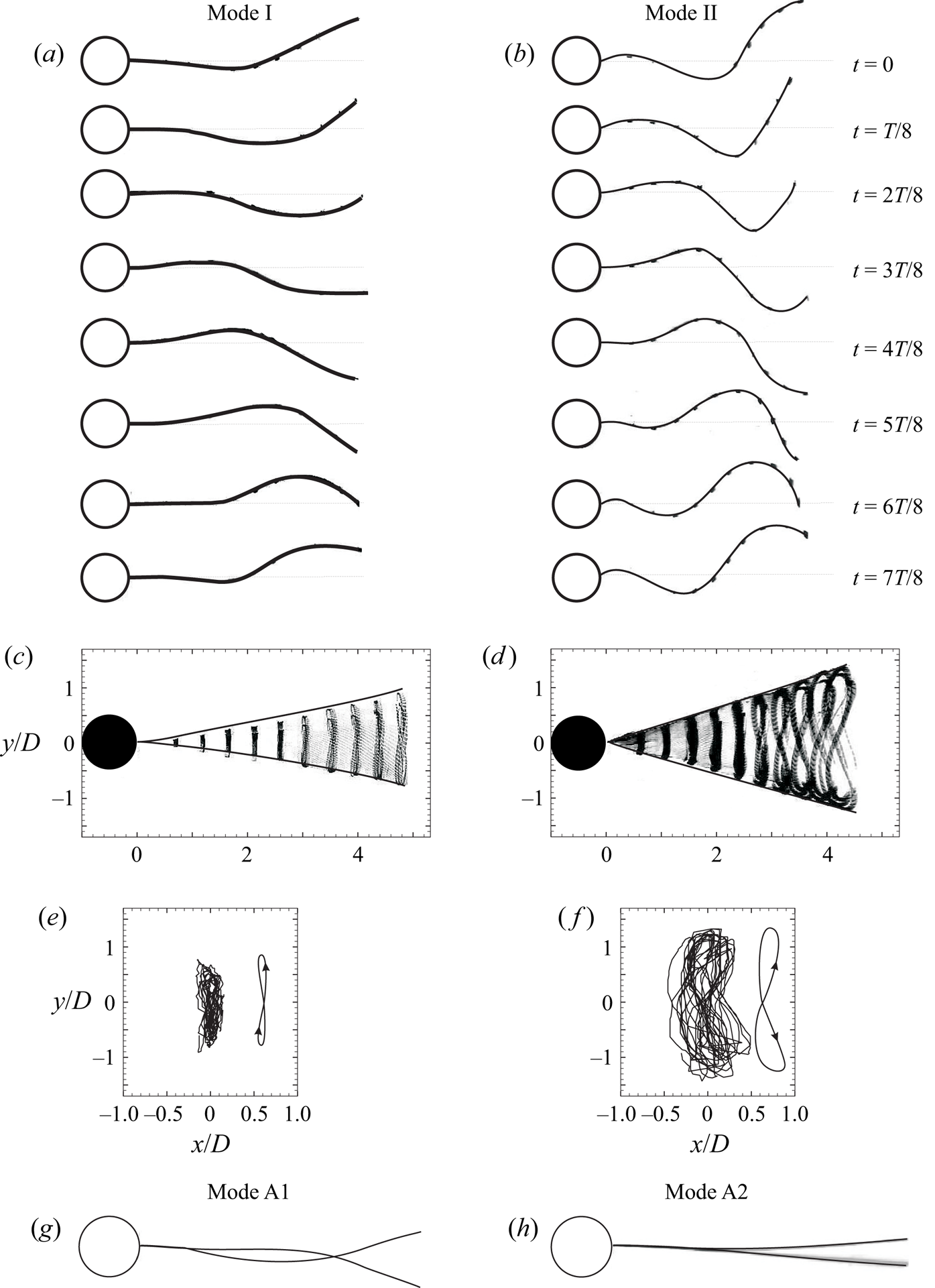

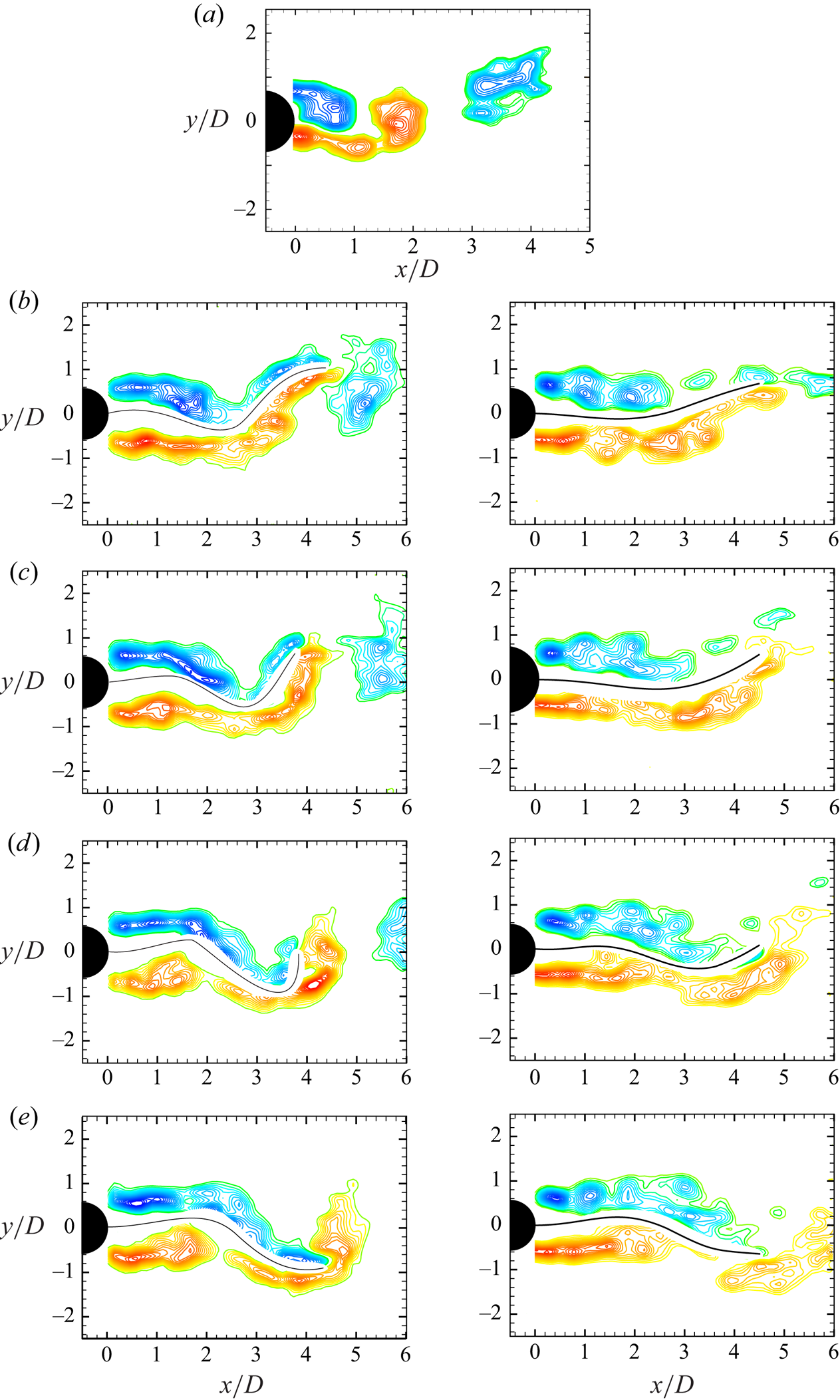

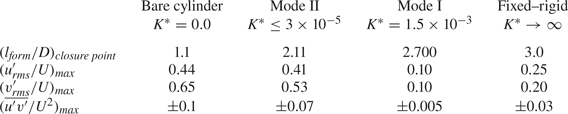

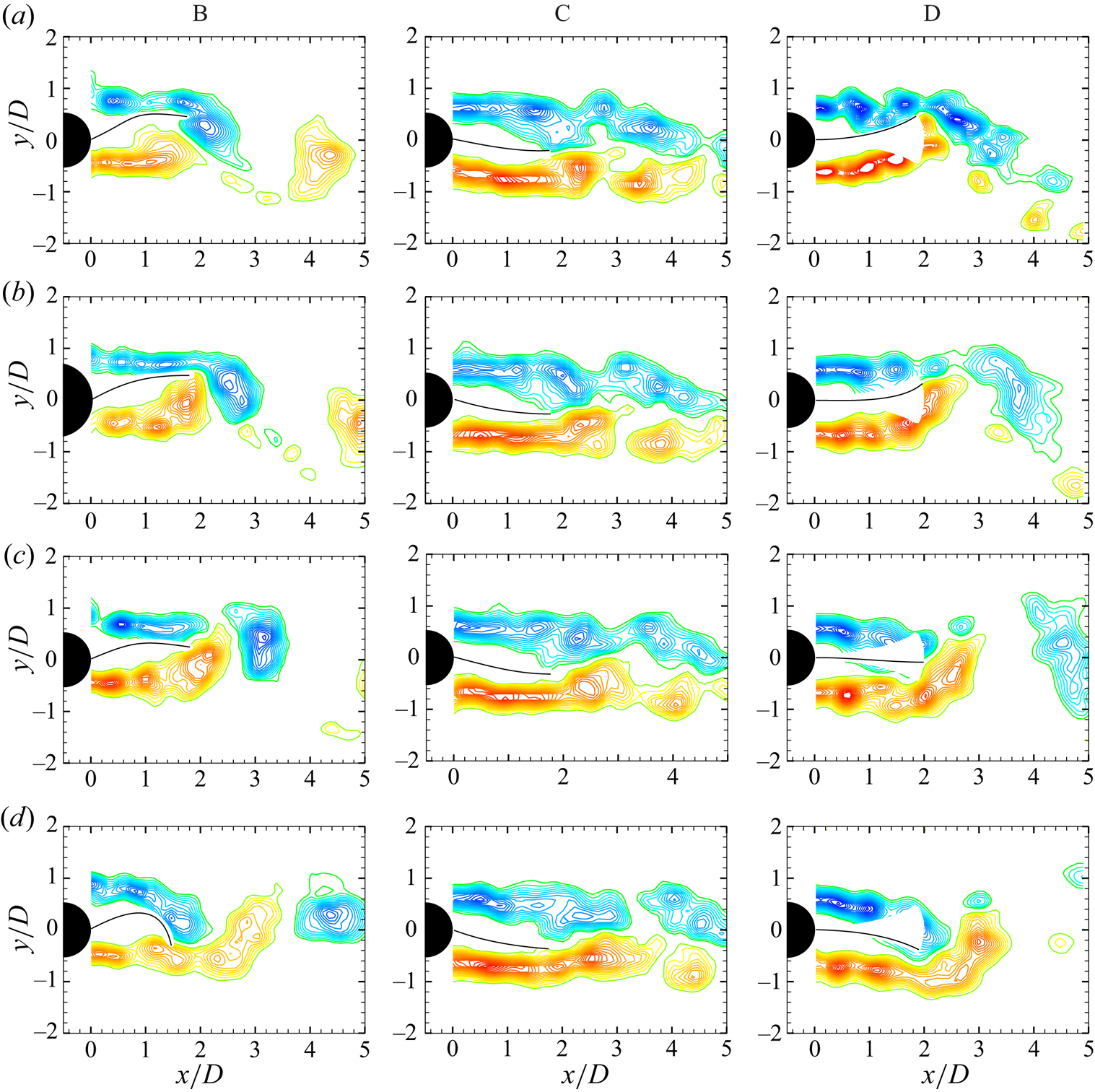

The flap visualisations in figure 3 show a time sequence of eight images in a cycle for two sample cases with ![]() $EI$ and

$EI$ and ![]() $Re$ values as given in the caption. The eight images in the figure are separated by one-eighth of the oscillation period (

$Re$ values as given in the caption. The eight images in the figure are separated by one-eighth of the oscillation period (![]() $T$). It may be noted that the two cases shown in figures 3(a) and 3(b) correspond to mode I and mode II response, respectively, as discussed later with reference to the amplitude response plot of the type shown in figure 4. The time sequence in figure 3(b) shows large-amplitude periodic oscillations of the flap with tip amplitudes of the order of one cylinder diameter. In the first image of this sequence (

$T$). It may be noted that the two cases shown in figures 3(a) and 3(b) correspond to mode I and mode II response, respectively, as discussed later with reference to the amplitude response plot of the type shown in figure 4. The time sequence in figure 3(b) shows large-amplitude periodic oscillations of the flap with tip amplitudes of the order of one cylinder diameter. In the first image of this sequence (![]() $t=0$) corresponding to mode II, a local maximum deflection can be seen just downstream of the cylinder. As time progresses, this local maximum is seen to move to the right and one can follow the peak as it travels along the flap, and reaches close to the tip of the flap at

$t=0$) corresponding to mode II, a local maximum deflection can be seen just downstream of the cylinder. As time progresses, this local maximum is seen to move to the right and one can follow the peak as it travels along the flap, and reaches close to the tip of the flap at ![]() $t=7T/8$. At this time, one can see the formation of a new local maximum again close to the cylinder, which travels downstream, and the cycle repeats. One can equivalently also see a peak on the lower side travel along the flap, with the cycle repeating. This clearly suggests that the deformations of the flap in mode II are in the form of a travelling wave, and a simple model for this is discussed later in this subsection. In the case of mode I shown in figure 3(a), a similar travelling-wave pattern of flap deformation may be seen, although the amplitudes are smaller than in mode II in figure 3(b). Superposed images of the flap deformations in the two cases are shown in figures 3(c) and 3(d), respectively, with these images showing that the amplitude of the travelling wave grows almost linearly with streamwise distance in both the cases. Further, the trajectory of the flap tip in both cases is shown in figures 3(e) and 3(f), respectively, and one can clearly see the figure-of-eight shapes traced out by the flap tips in both cases, with the same of rotation being the same in both cases. A closer look at the figure of eight in the two cases shows some differences in its streamwise orientation, which we show to be related to the phase of the streamwise flap tip oscillations relative to the transverse motions that will be shown to drastically change the vortex formation in the two cases. Also shown in figures 3(g) and 3(h) are two non-periodic asymmetric modes that we refer to as modes A1 and A2, which are seen with higher flap flexural rigidities and at lower flow speeds. In the case of mode A1, the flap deformation continues to be in the form of a travelling wave and the asymmetry about the mean line is clear about 1

$t=7T/8$. At this time, one can see the formation of a new local maximum again close to the cylinder, which travels downstream, and the cycle repeats. One can equivalently also see a peak on the lower side travel along the flap, with the cycle repeating. This clearly suggests that the deformations of the flap in mode II are in the form of a travelling wave, and a simple model for this is discussed later in this subsection. In the case of mode I shown in figure 3(a), a similar travelling-wave pattern of flap deformation may be seen, although the amplitudes are smaller than in mode II in figure 3(b). Superposed images of the flap deformations in the two cases are shown in figures 3(c) and 3(d), respectively, with these images showing that the amplitude of the travelling wave grows almost linearly with streamwise distance in both the cases. Further, the trajectory of the flap tip in both cases is shown in figures 3(e) and 3(f), respectively, and one can clearly see the figure-of-eight shapes traced out by the flap tips in both cases, with the same of rotation being the same in both cases. A closer look at the figure of eight in the two cases shows some differences in its streamwise orientation, which we show to be related to the phase of the streamwise flap tip oscillations relative to the transverse motions that will be shown to drastically change the vortex formation in the two cases. Also shown in figures 3(g) and 3(h) are two non-periodic asymmetric modes that we refer to as modes A1 and A2, which are seen with higher flap flexural rigidities and at lower flow speeds. In the case of mode A1, the flap deformation continues to be in the form of a travelling wave and the asymmetry about the mean line is clear about 1![]() $D$ downstream of the cylinder base. On the other hand, in the case of mode A2, the flap deformation is in the shape of the first bending mode of the flap, and the asymmetry about the mean line is clear at the flap tip location.

$D$ downstream of the cylinder base. On the other hand, in the case of mode A2, the flap deformation is in the shape of the first bending mode of the flap, and the asymmetry about the mean line is clear at the flap tip location.

Figure 3. Time sequence of pictures showing the deformation shapes of flap over one oscillation cycle for mode I (a) and mode II (b). Each of the pictures shown in (a) and (b) are separated by one-eighth of the oscillation period, ![]() $T$. The superimposed images and tip trajectories of these modes are shown in (c) and (e) for mode I and in (d) and (f) for mode II, respectively. The non-periodic and asymmetric modes A1 and A2 are shown in (g) and (h), respectively. Parameters: (a,c,e)

$T$. The superimposed images and tip trajectories of these modes are shown in (c) and (e) for mode I and in (d) and (f) for mode II, respectively. The non-periodic and asymmetric modes A1 and A2 are shown in (g) and (h), respectively. Parameters: (a,c,e) ![]() $EI = 7.50\times 10^{-4}$ N m,

$EI = 7.50\times 10^{-4}$ N m, ![]() $Re\approx 1.43\times 10^{4}$,

$Re\approx 1.43\times 10^{4}$, ![]() $K^{\ast } = 1.40\times 10^{-3}$; (b,d,f)

$K^{\ast } = 1.40\times 10^{-3}$; (b,d,f) ![]() $EI = 5.45\times 10^{-6}$ N m,

$EI = 5.45\times 10^{-6}$ N m, ![]() $Re\approx 1.35\times 10^{4}$,

$Re\approx 1.35\times 10^{4}$, ![]() $K^{\ast } = 1.1\times 10^{-5}$; (g)

$K^{\ast } = 1.1\times 10^{-5}$; (g) ![]() $Re = 9552$,

$Re = 9552$, ![]() $EI = 7.50\times 10^{-4}$ N m,

$EI = 7.50\times 10^{-4}$ N m, ![]() $K^{\ast } = 2.9\times 10^{-3}$; (h)

$K^{\ast } = 2.9\times 10^{-3}$; (h) ![]() $Re = 9090$,

$Re = 9090$, ![]() $EI = 1.25\times 10^{-2}$ N m,

$EI = 1.25\times 10^{-2}$ N m, ![]() $K^{\ast } = 5.0\times 10^{-2}$. Supplementary movies 1 and 2 (available at https://doi.org/10.1017/jfm.2023.755) show the temporal behaviour of flap deformations corresponding to mode II and mode I oscillations, respectively.

$K^{\ast } = 5.0\times 10^{-2}$. Supplementary movies 1 and 2 (available at https://doi.org/10.1017/jfm.2023.755) show the temporal behaviour of flap deformations corresponding to mode II and mode I oscillations, respectively.

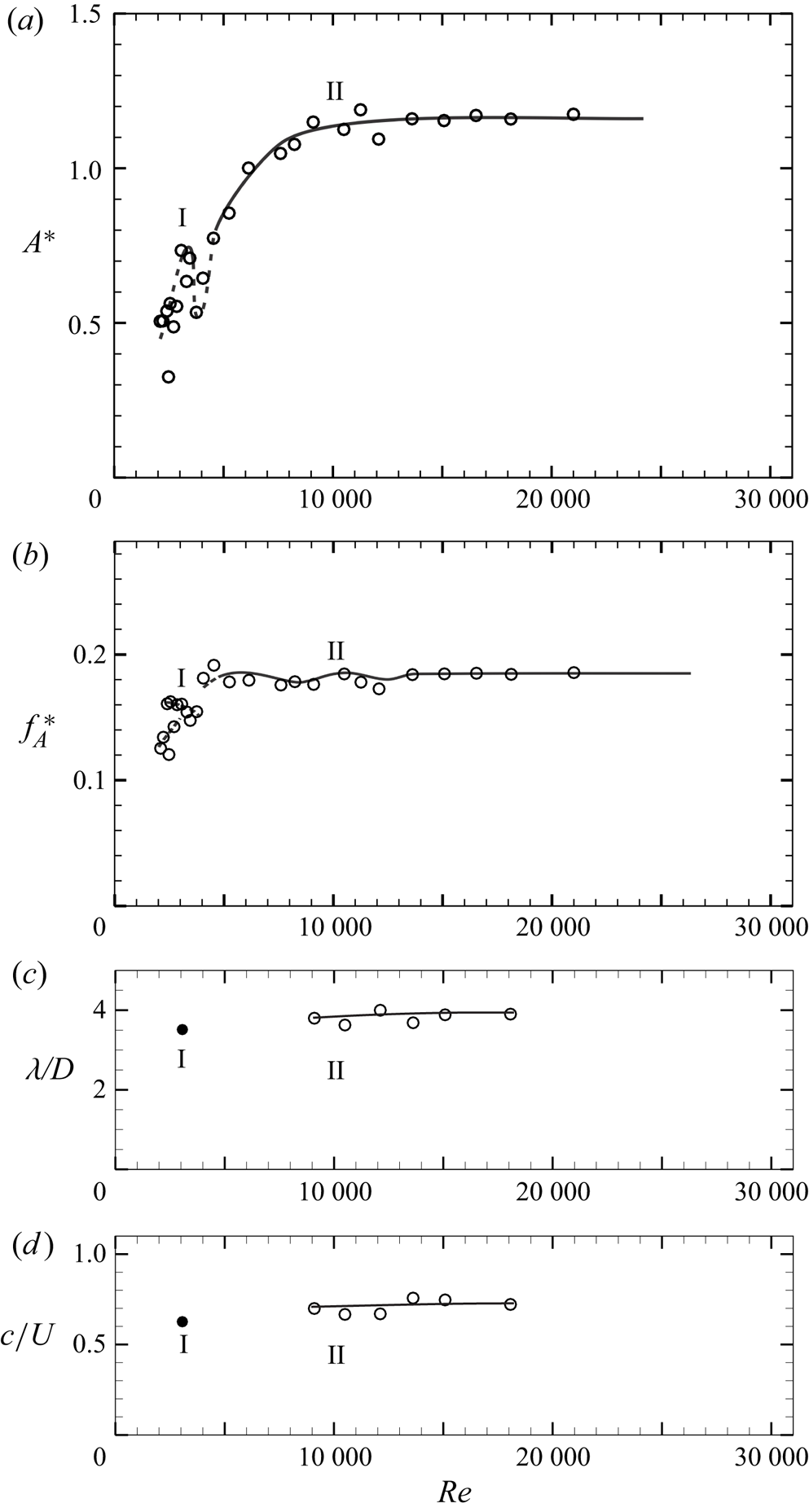

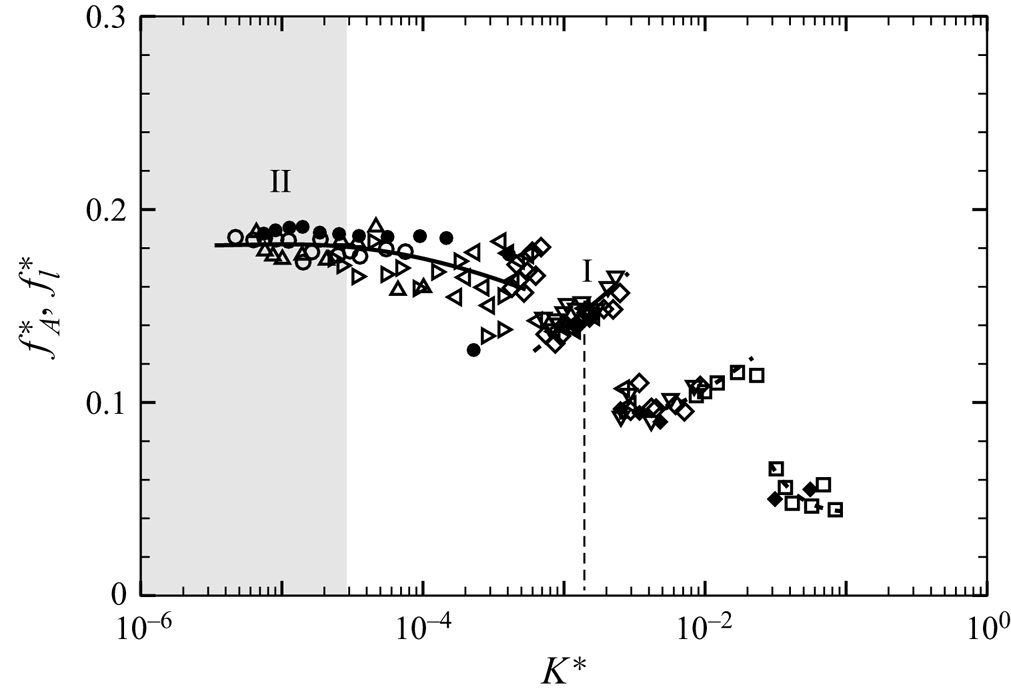

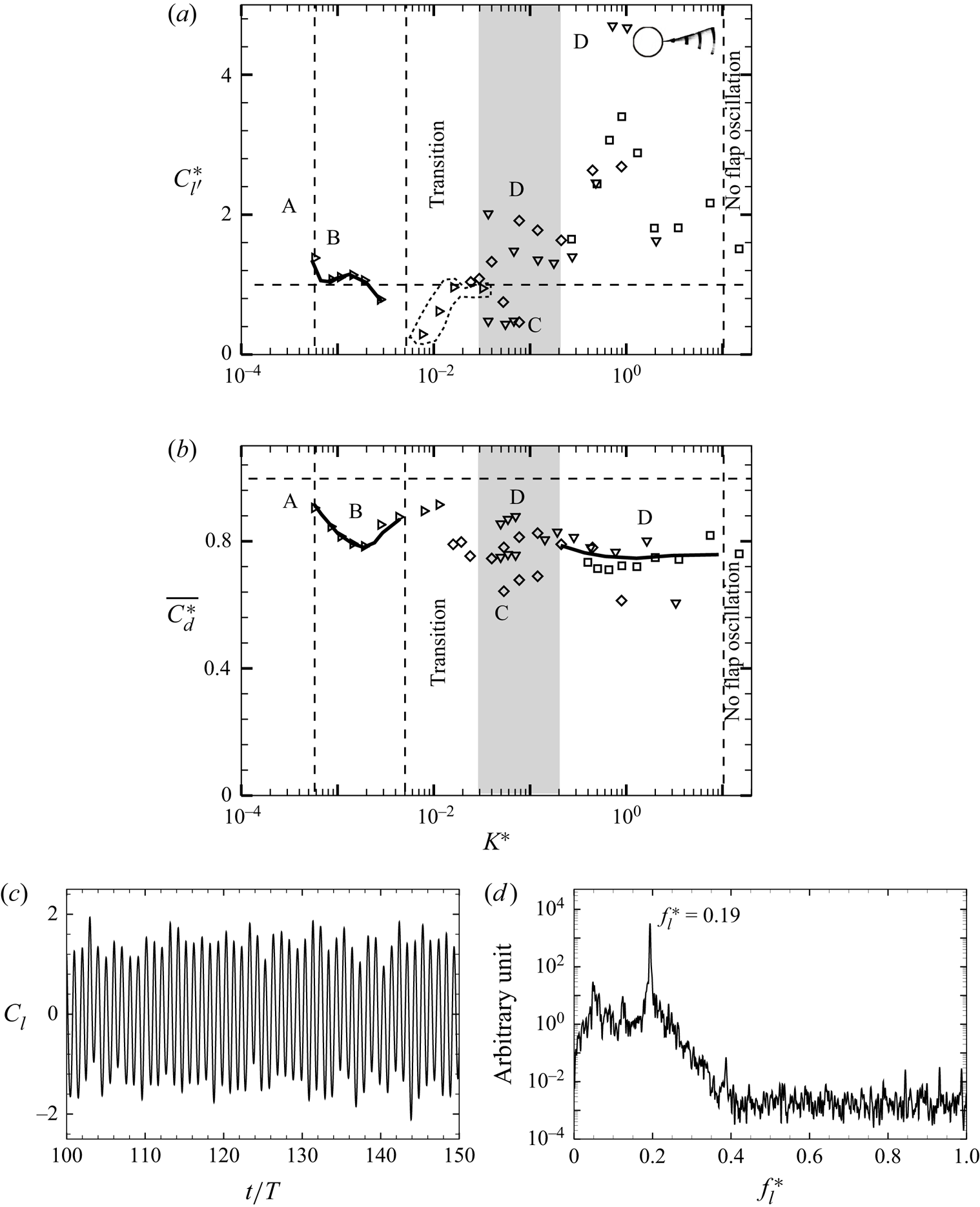

Figure 4. (a) Amplitude, (b) frequency, (c) wavelength and (d) phase speed of the thin ![]() $L/D = 5$ flexible splitter plate/flap motion with

$L/D = 5$ flexible splitter plate/flap motion with ![]() $Re$. The two periodic flap deformation modes on the plot are marked as mode I and mode II. In (a) and (b), regions with aperiodic flap motions are indicated by dashed lines, whereas periodic flap motions are indicated by solid lines. Wavelength and phase-speed data in (c) and (d) are shown only for the periodic flap motions. Here

$Re$. The two periodic flap deformation modes on the plot are marked as mode I and mode II. In (a) and (b), regions with aperiodic flap motions are indicated by dashed lines, whereas periodic flap motions are indicated by solid lines. Wavelength and phase-speed data in (c) and (d) are shown only for the periodic flap motions. Here ![]() $EI = 5.45\times 10^{-6}$ N m.

$EI = 5.45\times 10^{-6}$ N m.

The observed shapes of the flap are indicative of the unsteady pressure field on the flap surface due to the shed vortices from the cylinder. As these shed vortices convect downstream along the flap, the flaps deform depending on the streamwise location of the shed vortex, with the travelling wave speed likely being decided by the convection speed of the shed vortices. We shall later present the corresponding vorticity fields to highlight this point. On a more general note, the observed deformation shapes of the flap seen here are reminiscent of the undulating shapes of a fluttering flag that have been studied by Connell & Yue (Reference Connell and Yue2007) and Eloy et al. (Reference Eloy, Kofman and Schouveiler2012) with the deformation shapes in both cases being in the form of a travelling wave.

Although there are variations in the deformation shapes with flow speed and flexural rigidity (![]() $EI$), as shown in figures 3(a) and 3(b), the deformations are in general in the form of a travelling wave except for the non-periodic mode A2. The simplest model of a travelling wave with a single frequency is one whose frequency/wavelength does not change as the wave propagates. In this case, the deflection (

$EI$), as shown in figures 3(a) and 3(b), the deformations are in general in the form of a travelling wave except for the non-periodic mode A2. The simplest model of a travelling wave with a single frequency is one whose frequency/wavelength does not change as the wave propagates. In this case, the deflection (![]() $Y_{x}$) at any streamwise location (

$Y_{x}$) at any streamwise location (![]() $x$) can be written as

$x$) can be written as

where ![]() $f(x)$ is the amplitude variation with

$f(x)$ is the amplitude variation with ![]() $x$,

$x$, ![]() $\omega$ is the angular oscillation frequency and

$\omega$ is the angular oscillation frequency and ![]() $k =2\pi /\lambda$ is the wave number associated with the disturbance of wavelength

$k =2\pi /\lambda$ is the wave number associated with the disturbance of wavelength ![]() $\lambda$.

$\lambda$.

The amplitude variation (![]() $\,f(x)$) with streamwise distance (

$\,f(x)$) with streamwise distance (![]() $x$) may be obtained from visualised images of the flaps as shown in figure 3(c), which suggests that amplitude increases almost linearly with

$x$) may be obtained from visualised images of the flaps as shown in figure 3(c), which suggests that amplitude increases almost linearly with ![]() $x$. Hence, a simple linear amplitude model is used with zero amplitude at the base of the cylinder and increasing linearly to a maximum value of

$x$. Hence, a simple linear amplitude model is used with zero amplitude at the base of the cylinder and increasing linearly to a maximum value of ![]() $A$ at the tip:

$A$ at the tip: ![]() $f(x) = (A/L) x$, where

$f(x) = (A/L) x$, where ![]() $A$ is the transverse measured flap tip amplitude from the flap visualisations. The phase speed (

$A$ is the transverse measured flap tip amplitude from the flap visualisations. The phase speed (![]() $c = \omega / k$) and wavelength associated with the travelling wave model can also be estimated directly by using the recorded images. The phase speed was obtained from the streamwise location of the node of the flap at successive times, and was found to be about

$c = \omega / k$) and wavelength associated with the travelling wave model can also be estimated directly by using the recorded images. The phase speed was obtained from the streamwise location of the node of the flap at successive times, and was found to be about ![]() $0.8U$ (where

$0.8U$ (where ![]() $U$ is the free-stream velocity) with some variation with flow speed. The wavelength (

$U$ is the free-stream velocity) with some variation with flow speed. The wavelength (![]() $\lambda$) was measured directly as the distance between the streamwise location of successive wave amplitude peaks and was found to be about

$\lambda$) was measured directly as the distance between the streamwise location of successive wave amplitude peaks and was found to be about ![]() $4D$. The measured

$4D$. The measured ![]() $c$ and

$c$ and ![]() $\lambda$ values are broadly consistent with the speed and spacing of shed vortices from a bare cylinder, which may be expected for a very thin flap with very small values of flexural rigidity

$\lambda$ values are broadly consistent with the speed and spacing of shed vortices from a bare cylinder, which may be expected for a very thin flap with very small values of flexural rigidity ![]() $EI$, as in this case. The variation of the normalised wave length (

$EI$, as in this case. The variation of the normalised wave length (![]() $\lambda /D$) and phase speed (

$\lambda /D$) and phase speed (![]() $c/U$) at different

$c/U$) at different ![]() $Re$ is shown in figures 4(c) and 4(d), respectively.

$Re$ is shown in figures 4(c) and 4(d), respectively.

The variation of the normalised tip amplitude and frequency of the flap with ![]() $Re$ is shown in figure 4(a,b), for the case of the flap shown in figure 3(b). In the figure, the normalised flapping amplitude (

$Re$ is shown in figure 4(a,b), for the case of the flap shown in figure 3(b). In the figure, the normalised flapping amplitude (![]() $A^{\ast } = (\sqrt {2}Y'_{rms}/D)$) and frequency (

$A^{\ast } = (\sqrt {2}Y'_{rms}/D)$) and frequency (![]() $\,f^{\ast }_{A} = f_{A}D/U$) of the flap have been defined using the r.m.s. flap tip deflection, and the dominant frequency of the flap tip oscillation, as discussed in § 2. The amplitude response of the flap resembles that of a tethered sphere (Govardhan & Williamson Reference Govardhan and Williamson2005), with the presence of a local peak in amplitude response at

$\,f^{\ast }_{A} = f_{A}D/U$) of the flap have been defined using the r.m.s. flap tip deflection, and the dominant frequency of the flap tip oscillation, as discussed in § 2. The amplitude response of the flap resembles that of a tethered sphere (Govardhan & Williamson Reference Govardhan and Williamson2005), with the presence of a local peak in amplitude response at ![]() $Re \approx 2500$ followed by a decrease and an eventual rise of the amplitudes (

$Re \approx 2500$ followed by a decrease and an eventual rise of the amplitudes (![]() $A^{\ast }$) to a saturated level of about 1.1. As in the tethered sphere case, we refer to the local peak in amplitude response as mode I and the higher saturated amplitude as mode II, and we shall see the differences between these two modes, apart from the amplitude, in the oscillation frequency, the forces and in the wake velocity fields.

$A^{\ast }$) to a saturated level of about 1.1. As in the tethered sphere case, we refer to the local peak in amplitude response as mode I and the higher saturated amplitude as mode II, and we shall see the differences between these two modes, apart from the amplitude, in the oscillation frequency, the forces and in the wake velocity fields.

The mode I oscillations occur at the local peak in the amplitude response where the motion of the flap is very regular. On either side of it, at higher and lower flow speed or ![]() $Re$, the motions of the flap are aperiodic, and the corresponding long time averaged flap tip amplitudes, defined here in terms of the r.m.s. flap tip deflection are smaller, and the spectra are also broad band. In the figure the aperiodic oscillations are shown in dashed line, whereas the periodic oscillations are indicated by a solid line. At lowest

$Re$, the motions of the flap are aperiodic, and the corresponding long time averaged flap tip amplitudes, defined here in terms of the r.m.s. flap tip deflection are smaller, and the spectra are also broad band. In the figure the aperiodic oscillations are shown in dashed line, whereas the periodic oscillations are indicated by a solid line. At lowest ![]() $EI$ values, as in this case, the periodic mode I occurs only in a narrow regime of the local peak in amplitude marked as mode I. The periodic mode II of the flap oscillation occurs in this case for

$EI$ values, as in this case, the periodic mode I occurs only in a narrow regime of the local peak in amplitude marked as mode I. The periodic mode II of the flap oscillation occurs in this case for ![]() $Re > 9000$, and exhibits a saturated maximum amplitude (

$Re > 9000$, and exhibits a saturated maximum amplitude (![]() $A^{\ast } \approx 1.1$) and frequency (

$A^{\ast } \approx 1.1$) and frequency (![]() $\,f^{\ast } \approx 0.19$). The normalised wavelength (

$\,f^{\ast } \approx 0.19$). The normalised wavelength (![]() $\lambda /D$) and phase speed (

$\lambda /D$) and phase speed (![]() $c/U$) of the propagating wave along the length of the flap for mode I are both a little lower in magnitude compared with that for periodic mode II, where these quantities of wave propagation become almost saturated and appear to be unaffected by flow speed or

$c/U$) of the propagating wave along the length of the flap for mode I are both a little lower in magnitude compared with that for periodic mode II, where these quantities of wave propagation become almost saturated and appear to be unaffected by flow speed or ![]() $Re$. It should be noted that the normalised phase speed (

$Re$. It should be noted that the normalised phase speed (![]() $c/U \approx 0.8$) in mode II is very close to the convection speed of shed vortices in the cylinder wake without flap. The non-periodic modes A1 and A2 occur at lower flow speeds and are not clear in this flap case. They will be seen clearly in the other (stiffer) flap cases shown in figures 5 and 6.

$c/U \approx 0.8$) in mode II is very close to the convection speed of shed vortices in the cylinder wake without flap. The non-periodic modes A1 and A2 occur at lower flow speeds and are not clear in this flap case. They will be seen clearly in the other (stiffer) flap cases shown in figures 5 and 6.

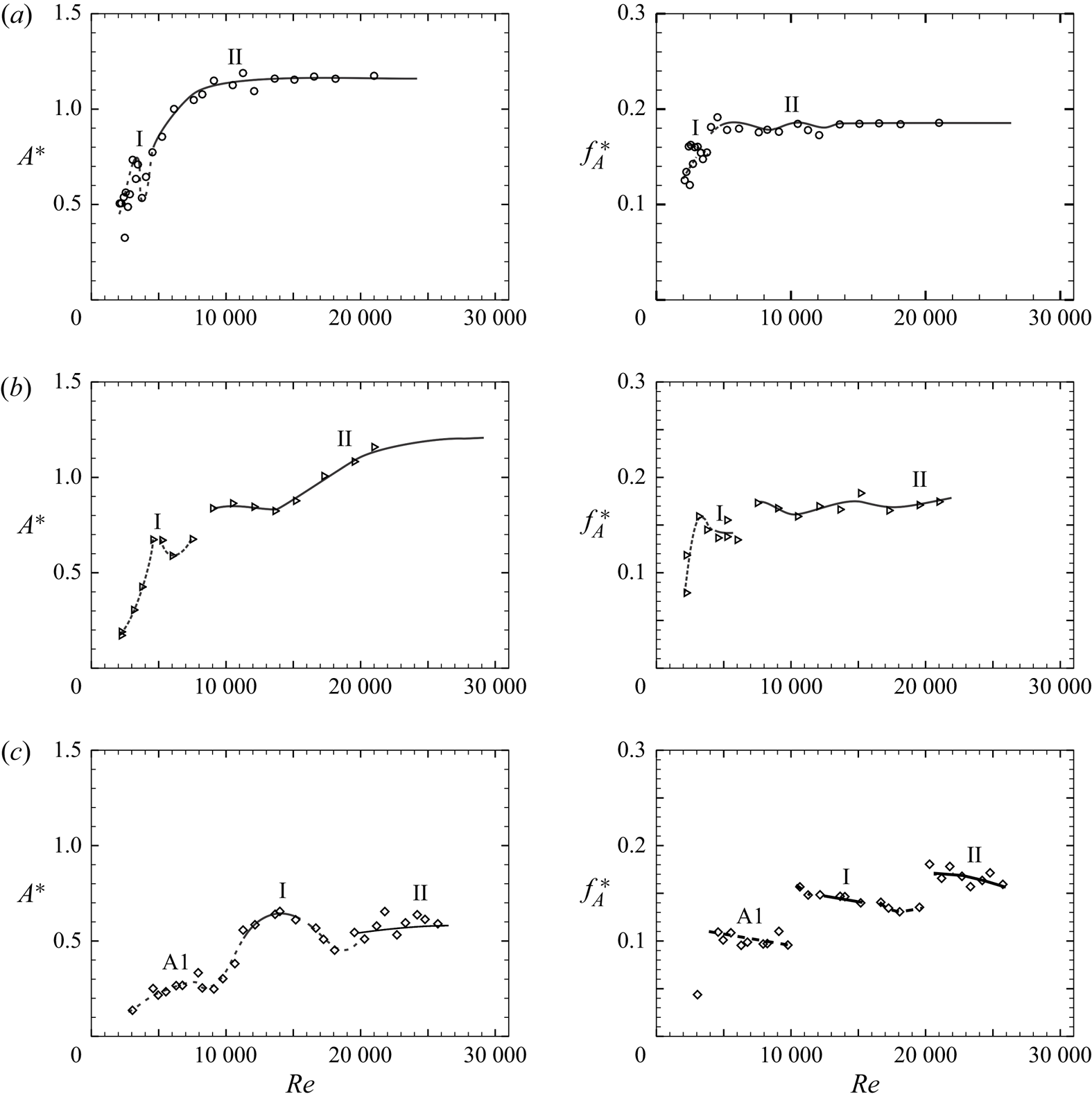

Figure 5. Amplitude (left column) and frequency (right column) response of the flap tip oscillation with ![]() $Re$ for different flexural rigidity (

$Re$ for different flexural rigidity (![]() $EI$) flaps: (a)

$EI$) flaps: (a) ![]() $EI = 5.45\times 10^{-6}$ N m (

$EI = 5.45\times 10^{-6}$ N m (![]() $\circ$); (b)

$\circ$); (b) ![]() $EI = 2.70\times 10^{-5}$ N m (

$EI = 2.70\times 10^{-5}$ N m (![]() $\triangleright$); (c)

$\triangleright$); (c) ![]() $EI = 7.50\times 10^{-4}$ N m (

$EI = 7.50\times 10^{-4}$ N m (![]() $\diamondsuit$). Each of the plots shows the response at a particular

$\diamondsuit$). Each of the plots shows the response at a particular ![]() $EI$, with the

$EI$, with the ![]() $EI$ value increasing from (a) to (c). The periodic modes I and II of the response plots appear to occur at higher

$EI$ value increasing from (a) to (c). The periodic modes I and II of the response plots appear to occur at higher ![]() $Re$ as

$Re$ as ![]() $EI$ of the flap increases. The non-periodic mode A1 is seen for the stiffer flap in (c) at lower

$EI$ of the flap increases. The non-periodic mode A1 is seen for the stiffer flap in (c) at lower ![]() $Re$.

$Re$.

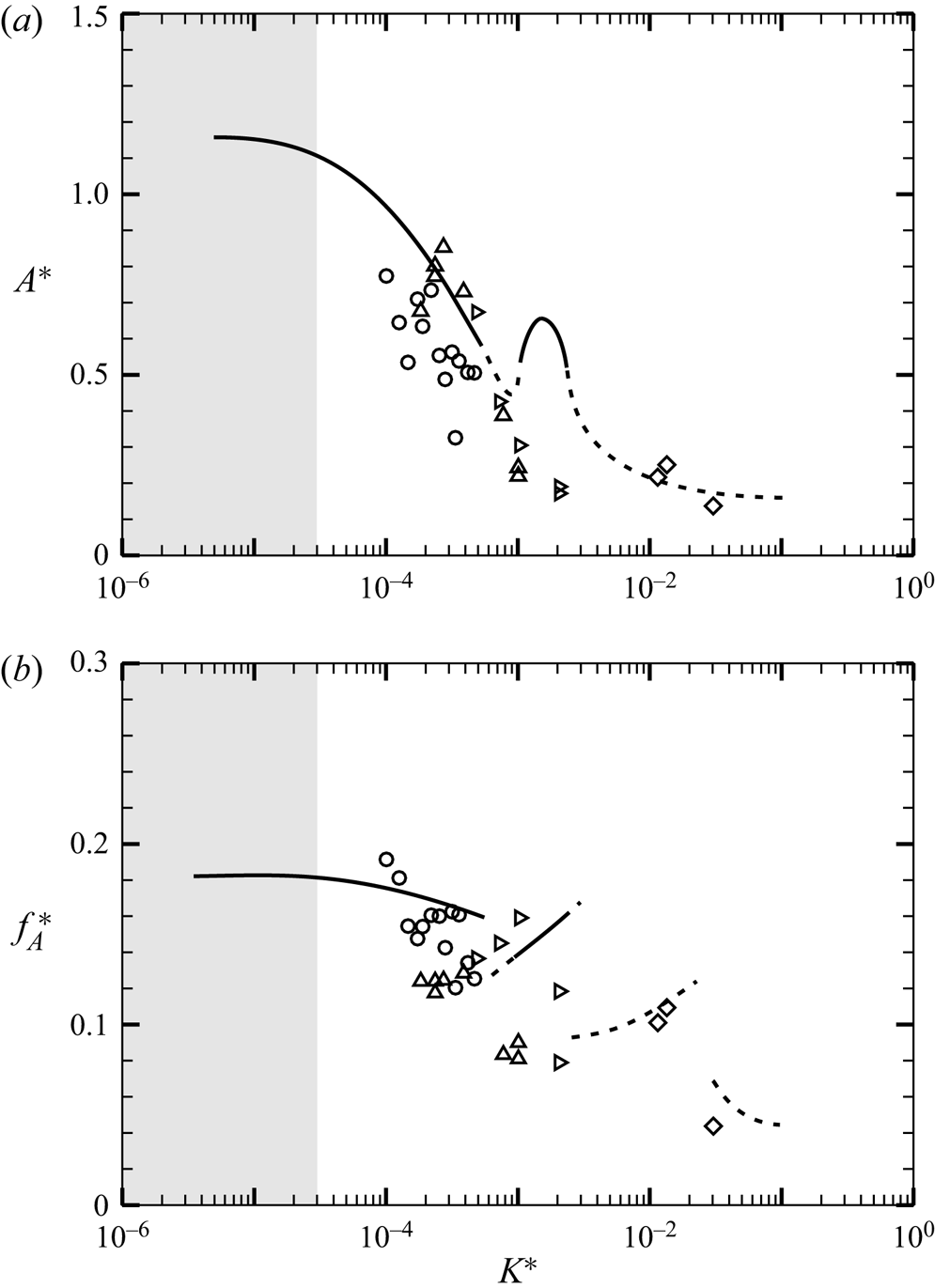

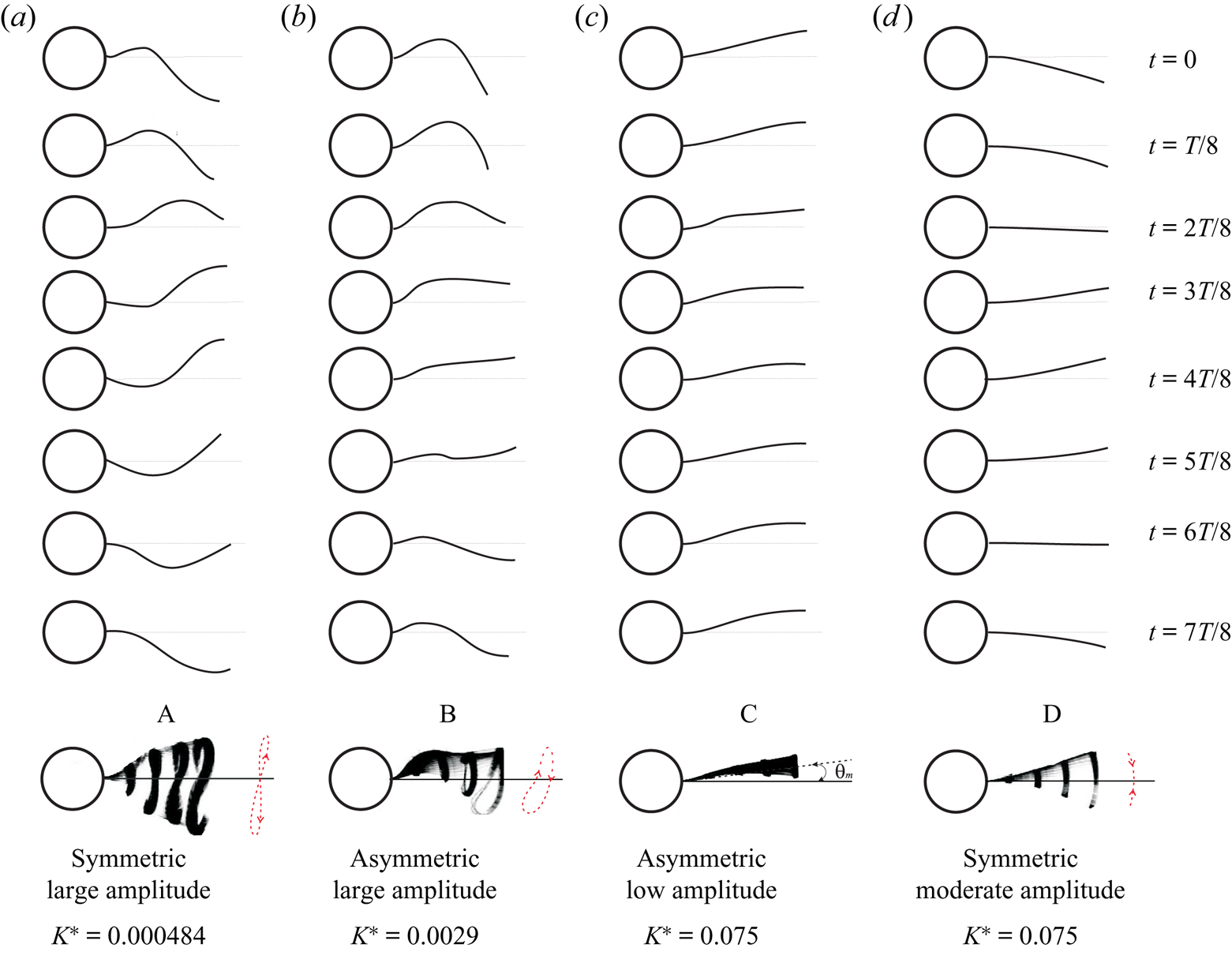

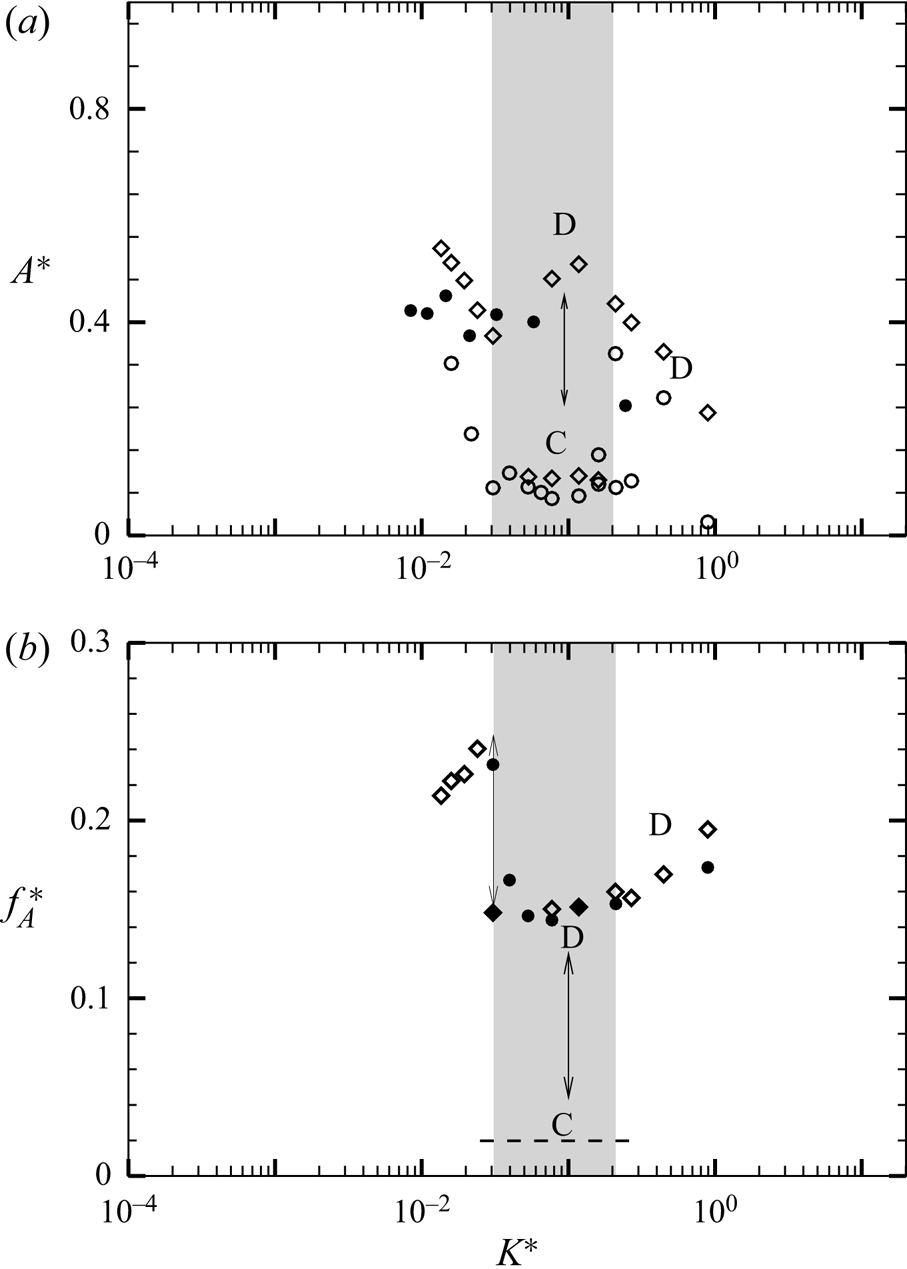

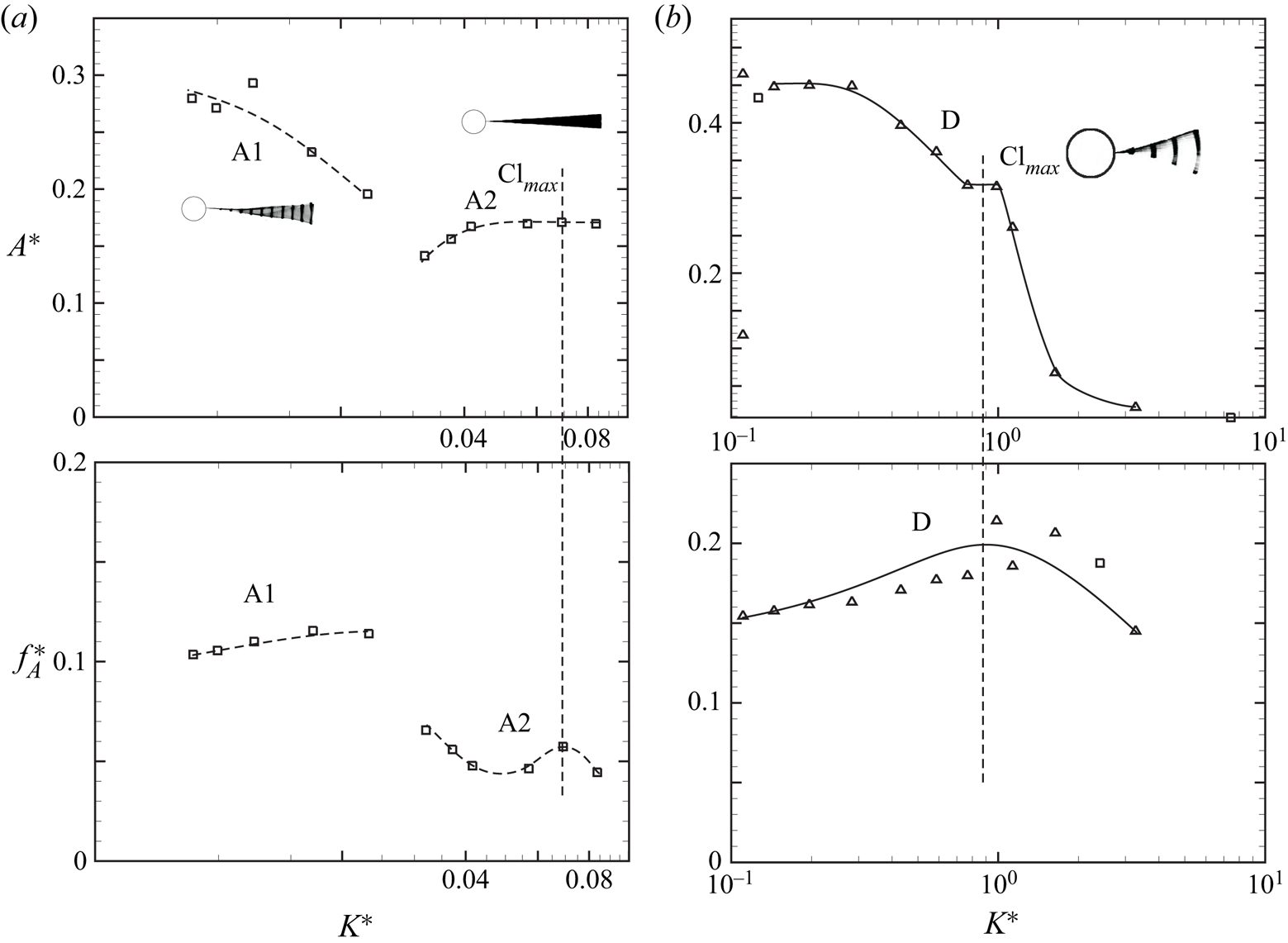

Figure 6. (a) Amplitude, (b) frequency response of the flap tip deflection with the non-dimensional stiffness, ![]() $K^{\ast }$ for

$K^{\ast }$ for ![]() $Re > 5000$. The corresponding wavelength and phase speed of the flap deformations is shown in (c) and (d), respectively. Solid and dashed lines in the plots have the same meaning as in figure 4. In (a), all the open data symbols shown are from the bigger tunnel, whereas the solid red symbols correspond to the data from the smaller tunnel used for PIV measurements:

$Re > 5000$. The corresponding wavelength and phase speed of the flap deformations is shown in (c) and (d), respectively. Solid and dashed lines in the plots have the same meaning as in figure 4. In (a), all the open data symbols shown are from the bigger tunnel, whereas the solid red symbols correspond to the data from the smaller tunnel used for PIV measurements: ![]() $\circ$,

$\circ$, ![]() $EI = 5.45\times 10^{-6}$ N m;

$EI = 5.45\times 10^{-6}$ N m; ![]() $\triangle$,

$\triangle$, ![]() $EI = 1.01\times 10^{-5}$ N m;

$EI = 1.01\times 10^{-5}$ N m; ![]() $\triangleright$,

$\triangleright$, ![]() $EI = 2.70\times 10^{-5}$ N m;

$EI = 2.70\times 10^{-5}$ N m; ![]() $\triangleleft$,

$\triangleleft$, ![]() $EI = 2.17\times 10^{-4}$ N m;

$EI = 2.17\times 10^{-4}$ N m; ![]() $\diamondsuit$,

$\diamondsuit$, ![]() $EI = 7.50\times 10^{-4}$ N m;

$EI = 7.50\times 10^{-4}$ N m; ![]() $\square$,

$\square$, ![]() $EI = 1.25\times 10^{-2}$ N m.

$EI = 1.25\times 10^{-2}$ N m.

In figure 5, we present the tip amplitude (left column) and frequency (right column) data as a function of ![]() $Re$ for different values of flexural rigidity (

$Re$ for different values of flexural rigidity (![]() $EI$), with

$EI$), with ![]() $EI$ increasing from (a) to (c). In each case, the local peak in amplitude at lower

$EI$ increasing from (a) to (c). In each case, the local peak in amplitude at lower ![]() $Re$ is marked as (mode) I and the periodic regime at higher

$Re$ is marked as (mode) I and the periodic regime at higher ![]() $Re$ as (mode) II, with the similar notation also shown in the frequency response. In the stiff flap in figure 5(c), one can also see the emergence of the non-periodic mode A1 at lower

$Re$ as (mode) II, with the similar notation also shown in the frequency response. In the stiff flap in figure 5(c), one can also see the emergence of the non-periodic mode A1 at lower ![]() $Re$. It is clear from these response plots that as the flexural rigidity or

$Re$. It is clear from these response plots that as the flexural rigidity or ![]() $EI$ of the flaps is increased, the two periodic modes, one corresponding to local peak in

$EI$ of the flaps is increased, the two periodic modes, one corresponding to local peak in ![]() $A^{\ast }$ or mode I, and the other corresponding to the saturated amplitude and frequency, or mode II, shift to higher

$A^{\ast }$ or mode I, and the other corresponding to the saturated amplitude and frequency, or mode II, shift to higher ![]() $Re$, indicating that larger flow speeds are required to get the same mode of response. This suggests that there is a better non-dimensional parameter to characterise the effect of flexural rigidity (

$Re$, indicating that larger flow speeds are required to get the same mode of response. This suggests that there is a better non-dimensional parameter to characterise the effect of flexural rigidity (![]() $EI$) of the flap, as discussed in the following. In VIV studies of elastically mounted bodies, a non-dimensional velocity,

$EI$) of the flap, as discussed in the following. In VIV studies of elastically mounted bodies, a non-dimensional velocity, ![]() $U^{\ast }=U/(f_{n}D)$ is used, where

$U^{\ast }=U/(f_{n}D)$ is used, where ![]() $f_{n}$ is the natural frequency based on the stiffness (

$f_{n}$ is the natural frequency based on the stiffness (![]() $k$) of the spring and the inertia (

$k$) of the spring and the inertia (![]() $m$) of the moving mass. In the present case of a thin elastic flap, its natural frequency is the same as the natural frequency of an elastic cantilevered beam and is given as

$m$) of the moving mass. In the present case of a thin elastic flap, its natural frequency is the same as the natural frequency of an elastic cantilevered beam and is given as ![]() $f_{n} = (a_{n}/(2\pi L^{2}))\sqrt {{EI}/{m_{L}}}$, where

$f_{n} = (a_{n}/(2\pi L^{2}))\sqrt {{EI}/{m_{L}}}$, where ![]() $EI$ is the flexural rigidity (N m) of the flap per unit span length,

$EI$ is the flexural rigidity (N m) of the flap per unit span length, ![]() $a_{n}$ is a constant that is dependent on the mode shape and

$a_{n}$ is a constant that is dependent on the mode shape and ![]() $m_{L}$ is the mass of the vibrating flap per unit streamwise length (and per unit span length), which should also include the fluid added mass. Since in the present work the mass of the flap is very low compared with the added mass or inertia, as mentioned in the introduction, the mass of the flap is not considered as a parameter for the investigation. Thus, the natural frequency of the flap in the present problem depends upon the mode of oscillation and added inertia of the fluid flow. Hence, this type of natural-frequency-based parameter is not convenient, as although the flexural rigidity of the flap is clear, the relevant inertia is not a priori well defined. Thus, a better parameter here would be a non-dimensional bending stiffness of the flap (

$m_{L}$ is the mass of the vibrating flap per unit streamwise length (and per unit span length), which should also include the fluid added mass. Since in the present work the mass of the flap is very low compared with the added mass or inertia, as mentioned in the introduction, the mass of the flap is not considered as a parameter for the investigation. Thus, the natural frequency of the flap in the present problem depends upon the mode of oscillation and added inertia of the fluid flow. Hence, this type of natural-frequency-based parameter is not convenient, as although the flexural rigidity of the flap is clear, the relevant inertia is not a priori well defined. Thus, a better parameter here would be a non-dimensional bending stiffness of the flap (![]() $K^{\ast }$), which may be defined as in Shukla et al. (Reference Shukla, Govardhan and Arakeri2013) as

$K^{\ast }$), which may be defined as in Shukla et al. (Reference Shukla, Govardhan and Arakeri2013) as

where ![]() $EI/L^{3}$ is the stiffness (per unit span) and

$EI/L^{3}$ is the stiffness (per unit span) and ![]() $(1/2)\rho U^{2}$ is the dynamic pressure (

$(1/2)\rho U^{2}$ is the dynamic pressure (![]() $\rho$ is the density of the fluid,

$\rho$ is the density of the fluid, ![]() $U$ is the free-stream velocity). This non-dimensional stiffness is similar to the relative bending rigidity of the flap as defined in the flag flutter problem (Argentina & Mahadevan Reference Argentina and Mahadevan2005; Connell & Yue Reference Connell and Yue2007).

$U$ is the free-stream velocity). This non-dimensional stiffness is similar to the relative bending rigidity of the flap as defined in the flag flutter problem (Argentina & Mahadevan Reference Argentina and Mahadevan2005; Connell & Yue Reference Connell and Yue2007).

Figure 6 shows amplitude (a) and frequency (b) response of the flap with non-dimensional stiffness ![]() $K^{\ast }$ for

$K^{\ast }$ for ![]() $Re > 5000$, respectively. All amplitude and frequency data of the response plots in figure 6 (

$Re > 5000$, respectively. All amplitude and frequency data of the response plots in figure 6 (![]() $Re > 5000$) appear to collapse well and demonstrate a trend shown by the combination of solid and dashed line, with the solid line indicating periodic motions and the dashed line representing aperiodic motions, as shown in figure 7. On the other hand, response data for

$Re > 5000$) appear to collapse well and demonstrate a trend shown by the combination of solid and dashed line, with the solid line indicating periodic motions and the dashed line representing aperiodic motions, as shown in figure 7. On the other hand, response data for ![]() $Re <5000$ are scattered from the higher

$Re <5000$ are scattered from the higher ![]() $Re$ trend, and do not collapse when plotted with

$Re$ trend, and do not collapse when plotted with ![]() $K^{\ast }$ as shown in figure 8. In this case, we choose to show the trend line for the

$K^{\ast }$ as shown in figure 8. In this case, we choose to show the trend line for the ![]() $Re > 5000$ data along with the

$Re > 5000$ data along with the ![]() $Re < 5000$ data to highlight the differences in the

$Re < 5000$ data to highlight the differences in the ![]() $Re < 5000$ data from the other set.

$Re < 5000$ data from the other set.

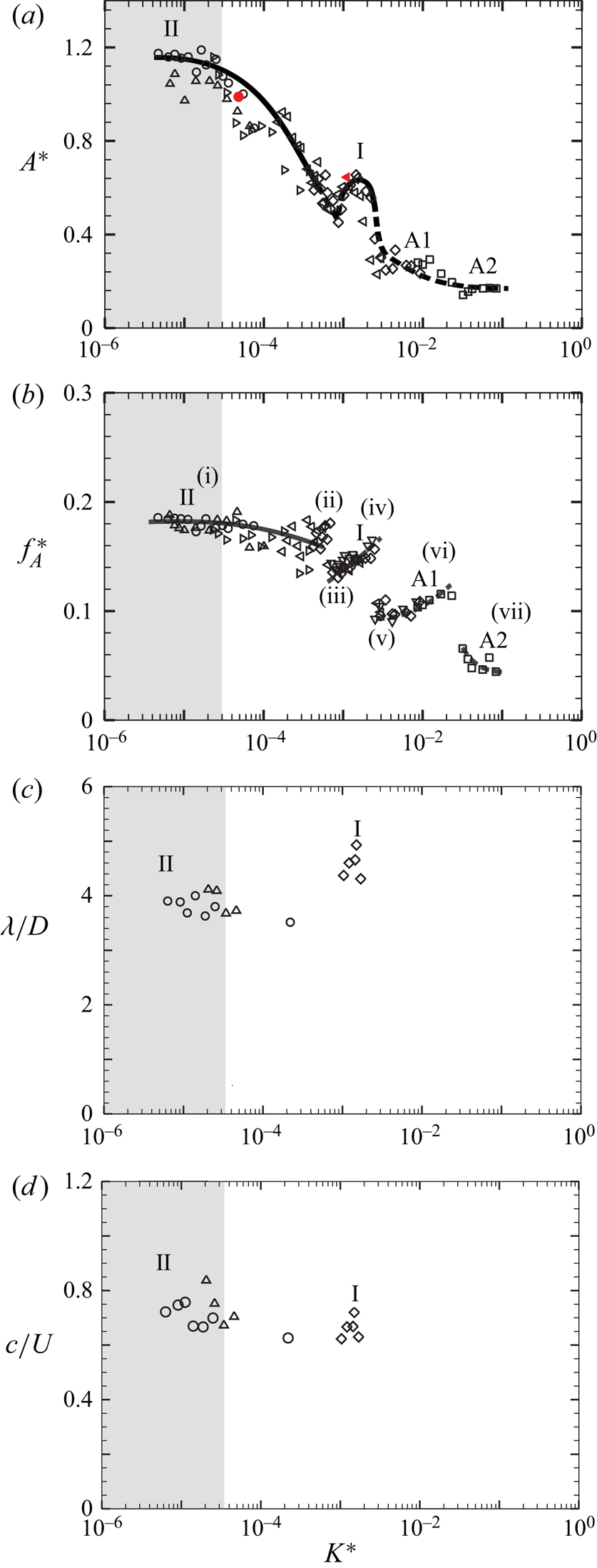

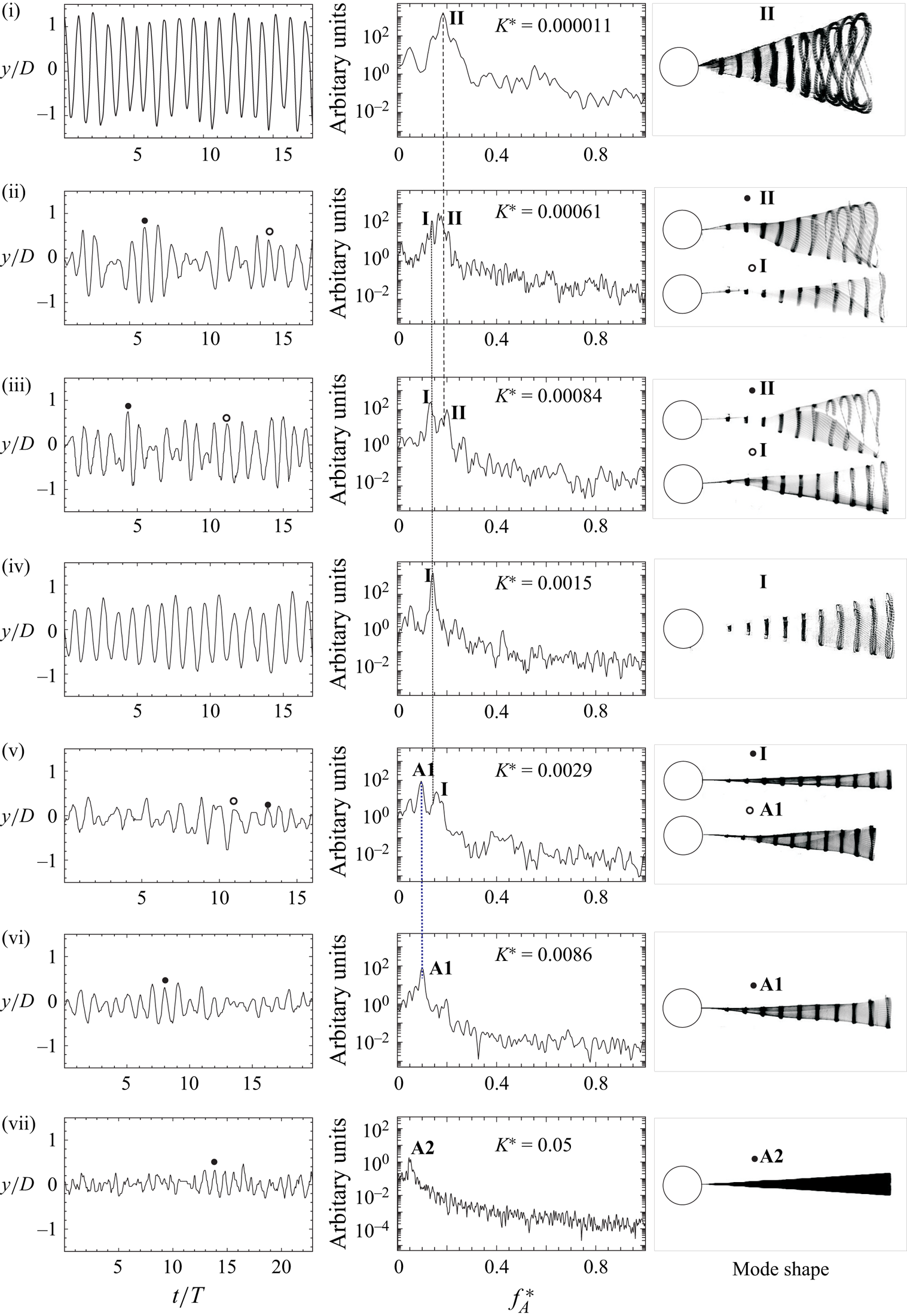

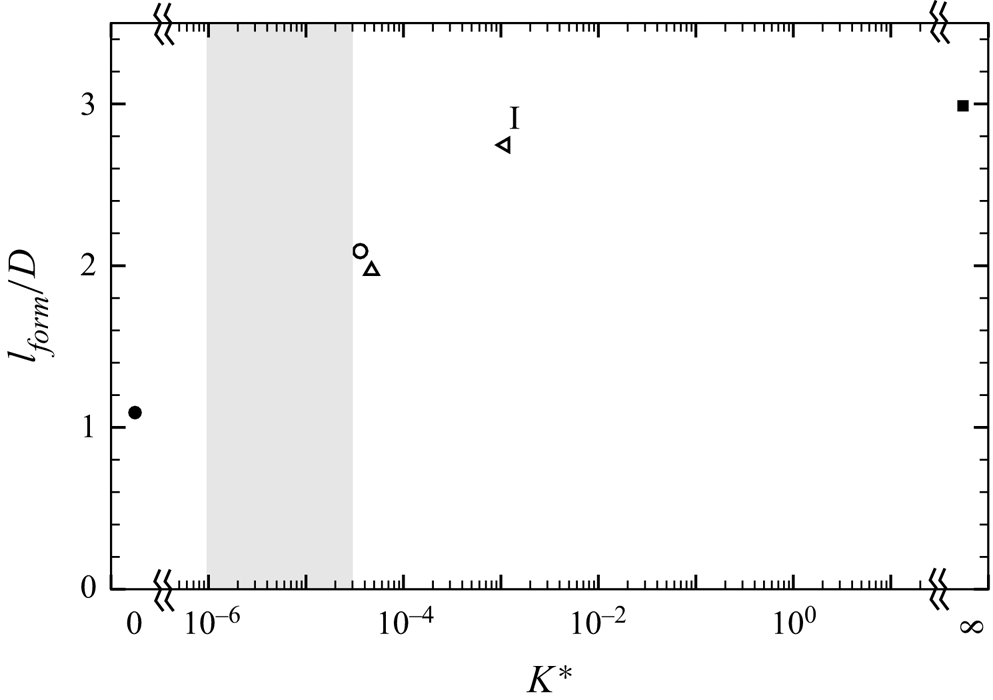

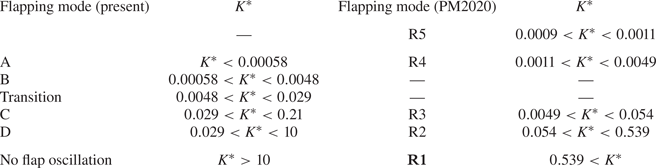

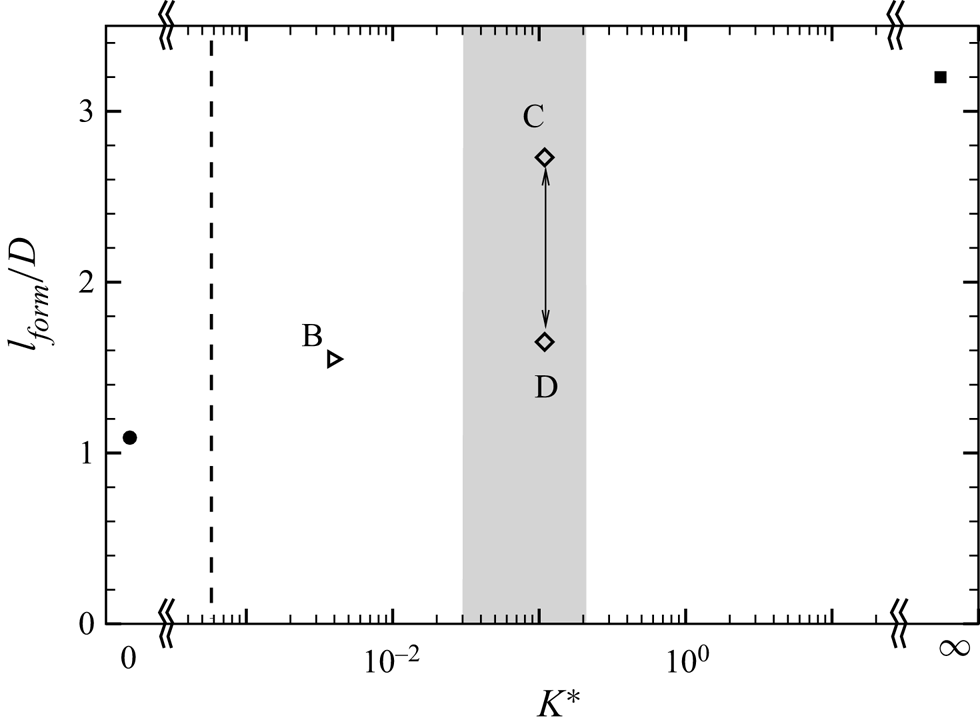

Figure 7. Transition between modes as ![]() $K^{\ast }$ is increased for

$K^{\ast }$ is increased for ![]() $Re>5000$. At each

$Re>5000$. At each ![]() $K^{\ast }$, the figure shows flap tip time traces, spectra and mode shape corresponding to the dominant (one or two) frequencies. The corresponding points in the response are marked in figure 6 as (i) to (vii): (i)

$K^{\ast }$, the figure shows flap tip time traces, spectra and mode shape corresponding to the dominant (one or two) frequencies. The corresponding points in the response are marked in figure 6 as (i) to (vii): (i) ![]() $K^{\ast } = 1.1\times 10^{-5}$; (ii)

$K^{\ast } = 1.1\times 10^{-5}$; (ii) ![]() $K^{\ast } = 6.1\times 10^{-4}$; (iii)

$K^{\ast } = 6.1\times 10^{-4}$; (iii) ![]() $K^{\ast } = 8.4\times 10^{-4}$; (iv)

$K^{\ast } = 8.4\times 10^{-4}$; (iv) ![]() $K^{\ast } = 1.5\times 10^{-3}$; (v)

$K^{\ast } = 1.5\times 10^{-3}$; (v) ![]() $K^{\ast } = 2.9\times 10^{-3}$; (vi)

$K^{\ast } = 2.9\times 10^{-3}$; (vi) ![]() $K^{\ast } = 8.6\times 10^{-3}$; (vii)

$K^{\ast } = 8.6\times 10^{-3}$; (vii) ![]() $K^{\ast } = 5\times 10^{-2}$.

$K^{\ast } = 5\times 10^{-2}$.

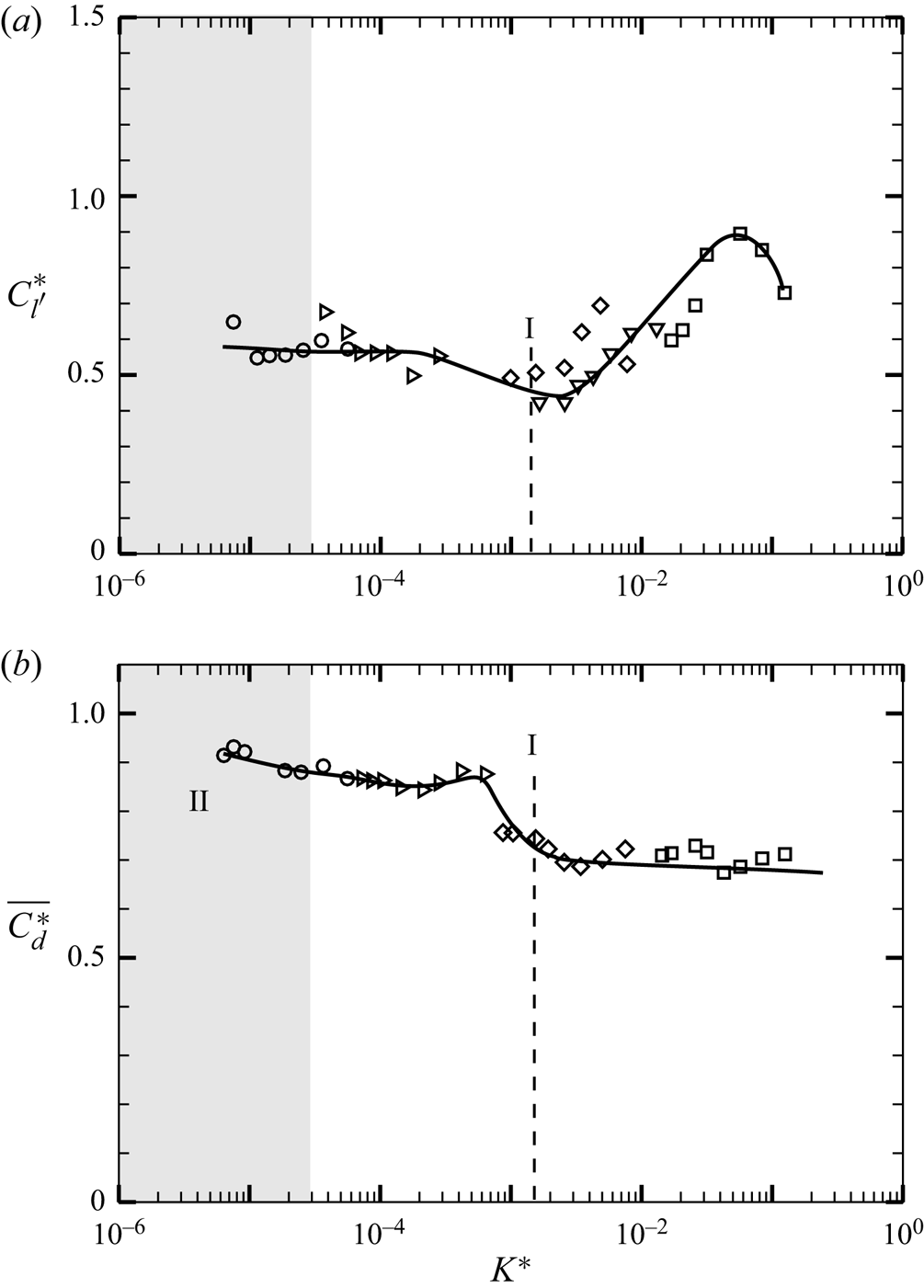

Figure 8. (a) Amplitude and (b) frequency response plots of the flaps with the non-dimensional bending stiffness, ![]() $K^{\ast }$, for

$K^{\ast }$, for ![]() $Re < 5000$. Lines shown in plots are trend lines of the response for

$Re < 5000$. Lines shown in plots are trend lines of the response for ![]() $Re > 5000$:

$Re > 5000$: ![]() $\circ$,

$\circ$, ![]() $EI = 5.45\times 10^{-6}$ N m;

$EI = 5.45\times 10^{-6}$ N m; ![]() $\triangle$,

$\triangle$, ![]() $EI = 1.01\times 10^{-5}$ N m;

$EI = 1.01\times 10^{-5}$ N m; ![]() $\triangleright$,

$\triangleright$, ![]() $EI = 2.70\times 10^{-5}$ N m;

$EI = 2.70\times 10^{-5}$ N m; ![]() $\triangleleft$,

$\triangleleft$, ![]() $EI = 2.17\times 10^{-4}$ N m;

$EI = 2.17\times 10^{-4}$ N m; ![]() $\diamondsuit$,

$\diamondsuit$, ![]() $EI = 7.50\times 10^{-4}$ N m;

$EI = 7.50\times 10^{-4}$ N m; ![]() $\square$,

$\square$, ![]() $EI = 1.25\times 10^{-2}$ N m.

$EI = 1.25\times 10^{-2}$ N m.

It is therefore clear that there is a distinct difference between the two data sets. The difference appears to be related to the large reduction in fluctuating lift for a bare cylinder in the ![]() $Re$ range between about 1600 and 5000 discussed by Norberg (Reference Norberg2003). This drop is likely related to changes in the three-dimensional shedding mode at these

$Re$ range between about 1600 and 5000 discussed by Norberg (Reference Norberg2003). This drop is likely related to changes in the three-dimensional shedding mode at these ![]() $Re$ as discussed in Prasad & Williamson (Reference Prasad and Williamson1997). We shall henceforth, for sake of clarity, concentrate mainly on

$Re$ as discussed in Prasad & Williamson (Reference Prasad and Williamson1997). We shall henceforth, for sake of clarity, concentrate mainly on ![]() $Re > 5000$ data, where all the amplitude response data is well collapsed by the non-dimensional stiffness

$Re > 5000$ data, where all the amplitude response data is well collapsed by the non-dimensional stiffness ![]() $K^{\ast }$ independent of

$K^{\ast }$ independent of ![]() $Re$. From the collapsed data in figure 6 for

$Re$. From the collapsed data in figure 6 for ![]() $Re > 5000$, one can see that the periodic mode I oscillations occur at

$Re > 5000$, one can see that the periodic mode I oscillations occur at ![]() $K^{\ast } \approx 1.5\times 10^{-3}$, while the periodic mode II response occur at very low

$K^{\ast } \approx 1.5\times 10^{-3}$, while the periodic mode II response occur at very low ![]() $K^{\ast }$ (

$K^{\ast }$ (![]() $\approx \leq 3.0\times 10^{-5}$). Although the low

$\approx \leq 3.0\times 10^{-5}$). Although the low ![]() $K^{\ast }$ data corresponding to the saturated mode II are seen to collapse well, a closer look shows that the amplitude data shows some variations, from about 1 to 1.2 depending on the flap's stiffness. This is likely related to a weak

$K^{\ast }$ data corresponding to the saturated mode II are seen to collapse well, a closer look shows that the amplitude data shows some variations, from about 1 to 1.2 depending on the flap's stiffness. This is likely related to a weak ![]() $Re$ effect as seen for example in the case of VIVs of a cylinder in Govardhan & Williamson (Reference Govardhan and Williamson2006), where the amplitude varied logarithmically with

$Re$ effect as seen for example in the case of VIVs of a cylinder in Govardhan & Williamson (Reference Govardhan and Williamson2006), where the amplitude varied logarithmically with ![]() $Re$. It should be emphasised here that while there is a band of amplitudes at a given

$Re$. It should be emphasised here that while there is a band of amplitudes at a given ![]() $K^*$ value related to a possible weak

$K^*$ value related to a possible weak ![]() $Re$ effect, the overall collapse, in terms of

$Re$ effect, the overall collapse, in terms of ![]() $K^*$, for example, in the range of

$K^*$, for example, in the range of ![]() $K^*$ values where mode II or mode I is seen, does seem to collapse well independent of

$K^*$ values where mode II or mode I is seen, does seem to collapse well independent of ![]() $Re$, as long as

$Re$, as long as ![]() $Re>5000$, as shown in figure 6. At high

$Re>5000$, as shown in figure 6. At high ![]() $K^{\ast }\approx 1\times 10^{-2}$, the non-periodic and asymmetric mode A1 can be seen, while the other non-periodic mode A2, is seen at even higher

$K^{\ast }\approx 1\times 10^{-2}$, the non-periodic and asymmetric mode A1 can be seen, while the other non-periodic mode A2, is seen at even higher ![]() $K^{\ast } \approx 5\times 10^{-2}$, the latter having deformations in the form of the first bending mode. The corresponding variations of the wavelength and phase speed of the plate deformations with

$K^{\ast } \approx 5\times 10^{-2}$, the latter having deformations in the form of the first bending mode. The corresponding variations of the wavelength and phase speed of the plate deformations with ![]() $K^{\ast }$ are shown in figures 4(c) and 4(d), respectively. Figure 6(d) shows that there is a reduction in the phase speed from values of approximately

$K^{\ast }$ are shown in figures 4(c) and 4(d), respectively. Figure 6(d) shows that there is a reduction in the phase speed from values of approximately ![]() $0.8U$ to

$0.8U$ to ![]() $0.7U$ as

$0.7U$ as ![]() $K^*$ (and flexural rigidity) is increased from values corresponding to mode II to higher

$K^*$ (and flexural rigidity) is increased from values corresponding to mode II to higher ![]() $K^*$ values corresponding to mode I. The variations of both phase speed and wavelength while significant (about 15 to 20 %) within this range are not too large. This may be attributed to the very low plate mass ratios (

$K^*$ values corresponding to mode I. The variations of both phase speed and wavelength while significant (about 15 to 20 %) within this range are not too large. This may be attributed to the very low plate mass ratios (![]() $m^*$) used in the present experiments, which implies that the fluid added mass dominates over structural mass, resulting in a strong coupling of the fluid and the structure. At

$m^*$) used in the present experiments, which implies that the fluid added mass dominates over structural mass, resulting in a strong coupling of the fluid and the structure. At ![]() $K^*$ values higher than at mode I, periodic oscillations are not seen, and hence phase speed and wavelength data are not shown in these cases.

$K^*$ values higher than at mode I, periodic oscillations are not seen, and hence phase speed and wavelength data are not shown in these cases.

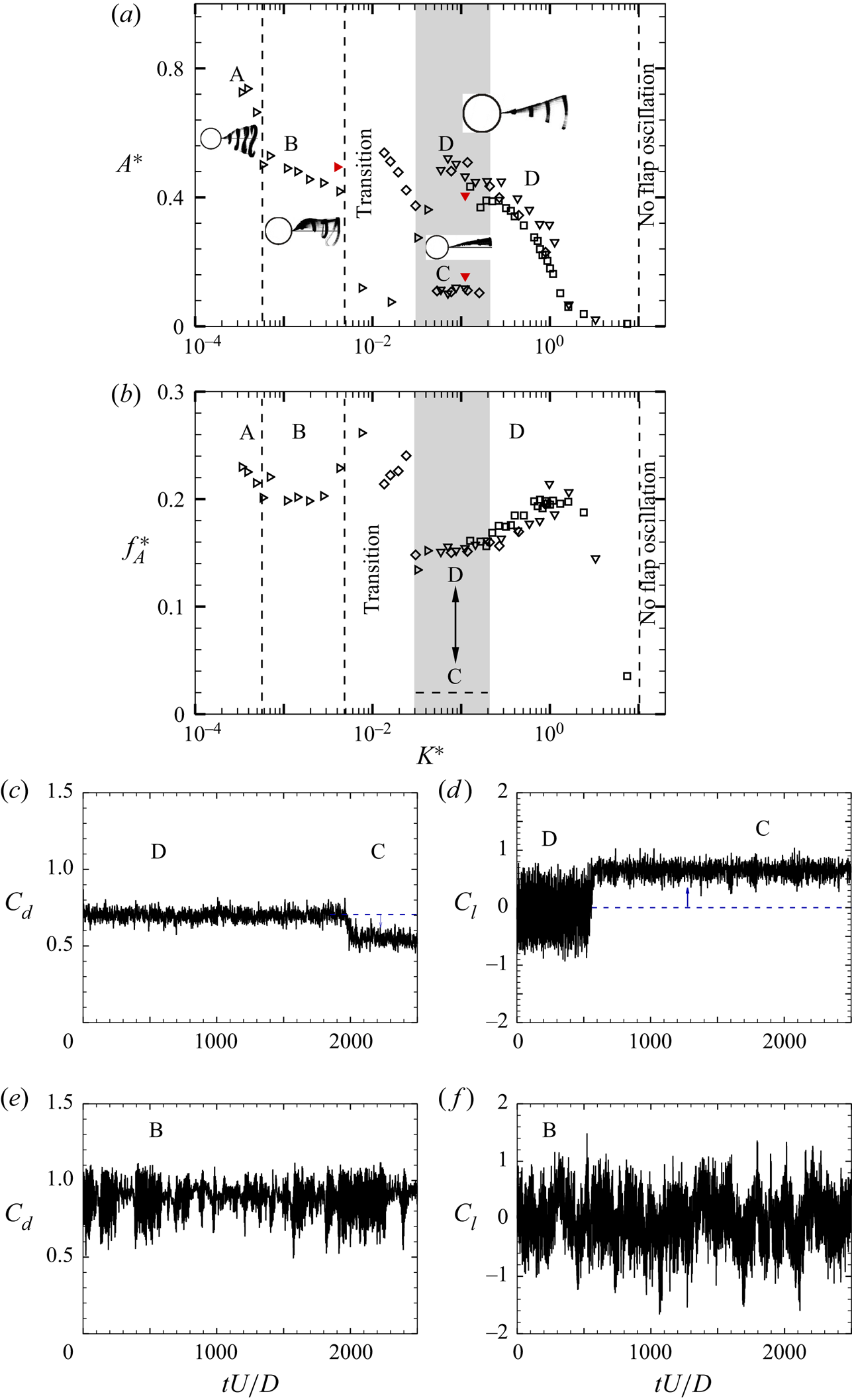

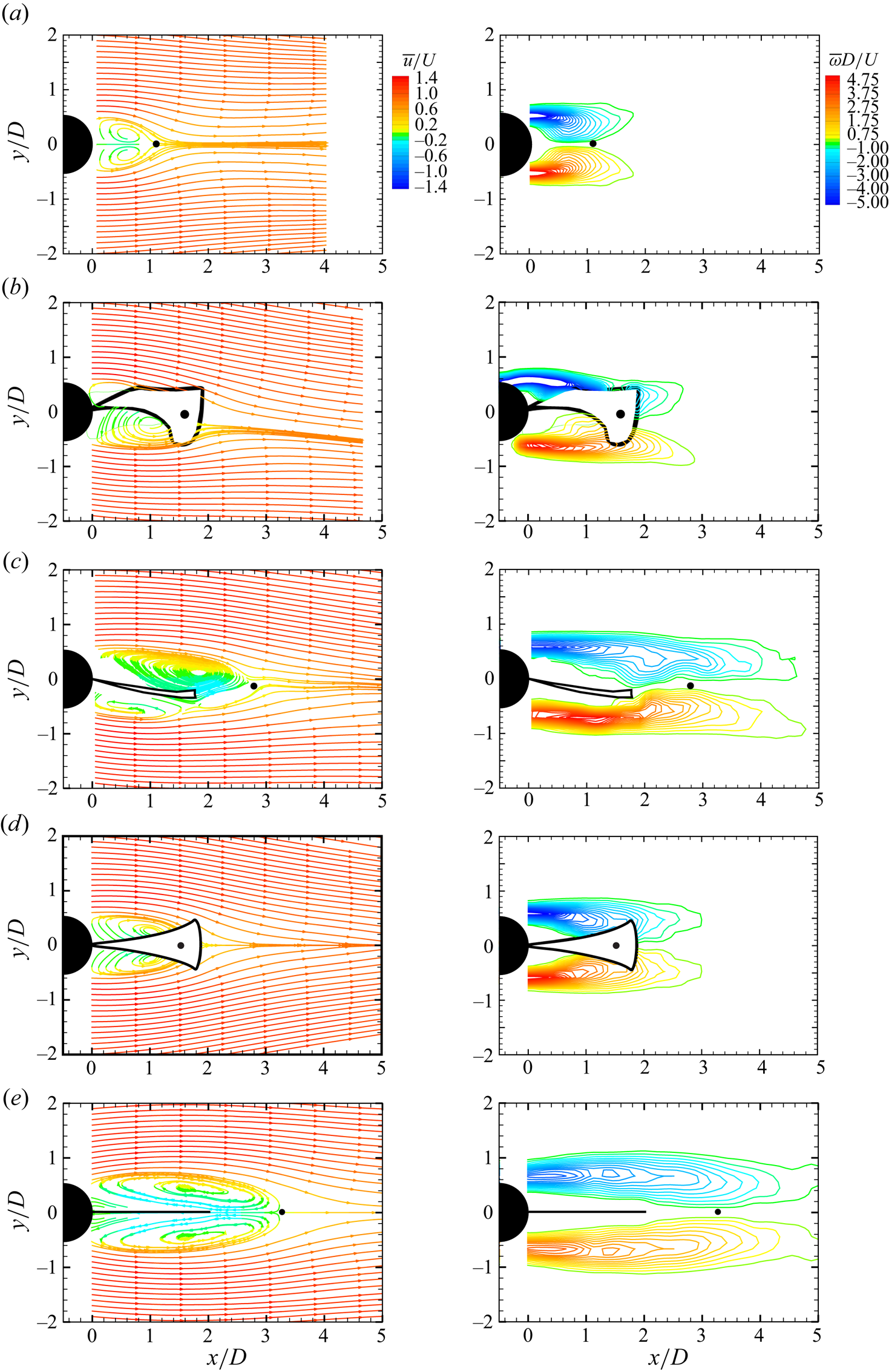

As ![]() $K^*$ is increased from very low values, the flap dynamics transitions from one mode to the other. These transitions and the resulting competition between modes is illustrated in figure 7, which shows, at a few different

$K^*$ is increased from very low values, the flap dynamics transitions from one mode to the other. These transitions and the resulting competition between modes is illustrated in figure 7, which shows, at a few different ![]() $K^*$ values (marked in figure 6 as (i) to (vii)), the plate tip time traces, its long-time averaged spectra and mode shapes corresponding to the dominant (one or two) frequencies. In (i), at low

$K^*$ values (marked in figure 6 as (i) to (vii)), the plate tip time traces, its long-time averaged spectra and mode shapes corresponding to the dominant (one or two) frequencies. In (i), at low ![]() $K^*$ values, periodic plate tip deformations can be seen with a single dominant frequency corresponding to mode II oscillations as shown by the superposed plate deformation profile. At higher

$K^*$ values, periodic plate tip deformations can be seen with a single dominant frequency corresponding to mode II oscillations as shown by the superposed plate deformation profile. At higher ![]() $K^*$ values (in (ii)), one can see the existence of two frequencies, the higher one corresponding to mode II type oscillations, while the lower one corresponds to mode I type oscillations, with mode II type having larger relative streamwise oscillations as seen earlier. The flapping mode shape in cases with two frequencies as in (ii) are superposed only over a single cycle that is identified on the time trace by

$K^*$ values (in (ii)), one can see the existence of two frequencies, the higher one corresponding to mode II type oscillations, while the lower one corresponds to mode I type oscillations, with mode II type having larger relative streamwise oscillations as seen earlier. The flapping mode shape in cases with two frequencies as in (ii) are superposed only over a single cycle that is identified on the time trace by ![]() $\circ$ and

$\circ$ and ![]() $\bullet$, and the corresponding symbol is also shown with the mode shape. In (iii), at larger

$\bullet$, and the corresponding symbol is also shown with the mode shape. In (iii), at larger ![]() $K^*$ values, the two peaks in frequency continues, with mode I now becoming dominant compared to in (ii). It may be noted here that in both (ii) and (iii), the flap deflection profiles are not very periodic and show asymmetry about the mean line that is evident at about 1

$K^*$ values, the two peaks in frequency continues, with mode I now becoming dominant compared to in (ii). It may be noted here that in both (ii) and (iii), the flap deflection profiles are not very periodic and show asymmetry about the mean line that is evident at about 1![]() $D$ downstream of the cylinder base. Subsequently, with increasing

$D$ downstream of the cylinder base. Subsequently, with increasing ![]() $K^*$, we see the emergence of periodic mode I oscillations in (iv). This is followed by non-periodic oscillations with mode I and A1 in (v), mainly mode A1 in (vi) and finally at higher

$K^*$, we see the emergence of periodic mode I oscillations in (iv). This is followed by non-periodic oscillations with mode I and A1 in (v), mainly mode A1 in (vi) and finally at higher ![]() $K^*$ values, mode A2, whose deflection profile is like the first bending mode of a cantilever. It may be noted that the large lift fluctuations discussed later occurs in this mode. These figures thus illustrate the transition and competition between modes that occur as

$K^*$ values, mode A2, whose deflection profile is like the first bending mode of a cantilever. It may be noted that the large lift fluctuations discussed later occurs in this mode. These figures thus illustrate the transition and competition between modes that occur as ![]() $K^*$ is continually increased from low values.

$K^*$ is continually increased from low values.

Superposed images of the flap tip deflection corresponding to the two periodic modes are shown in figures 3(![]() $c$) and 3(

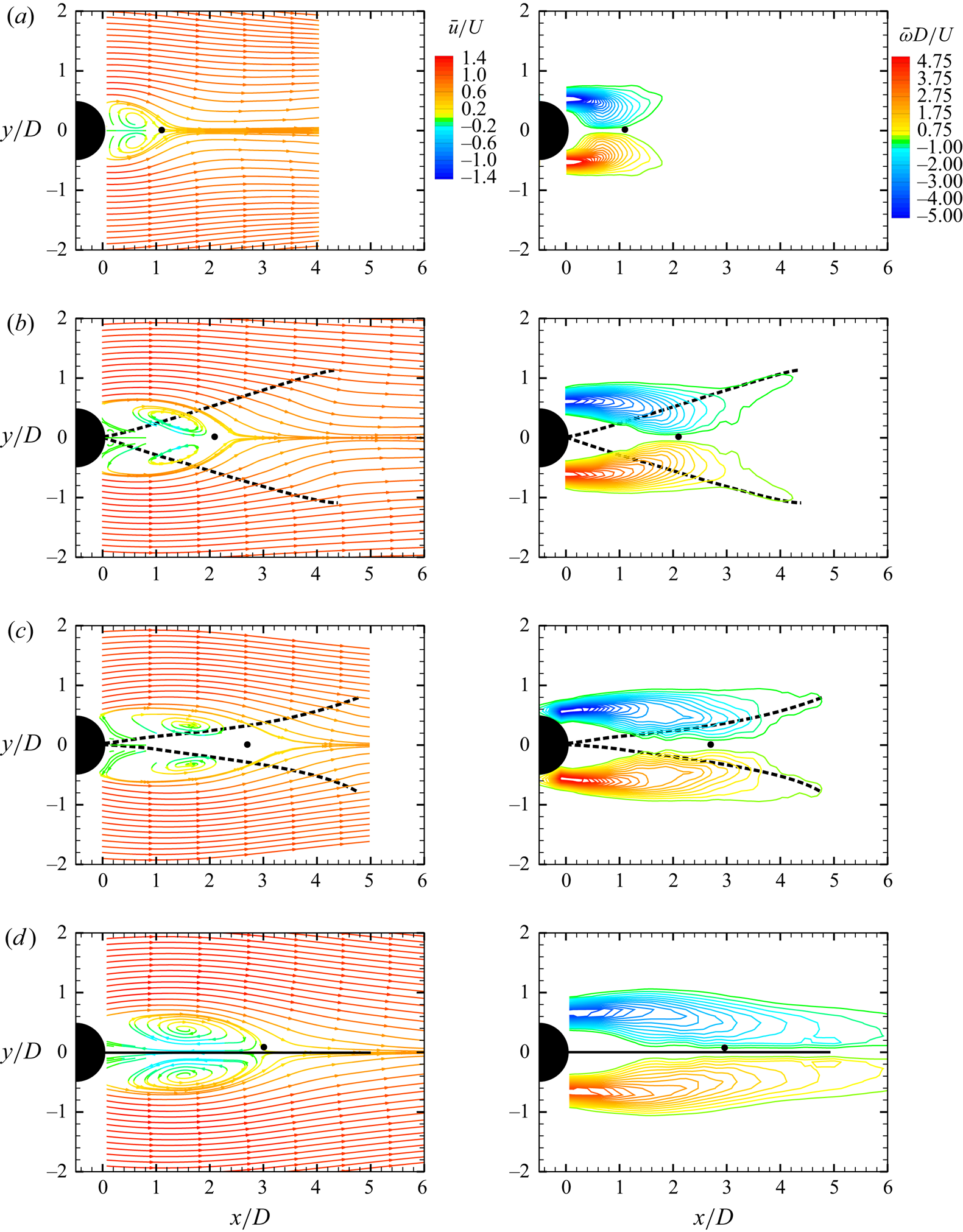

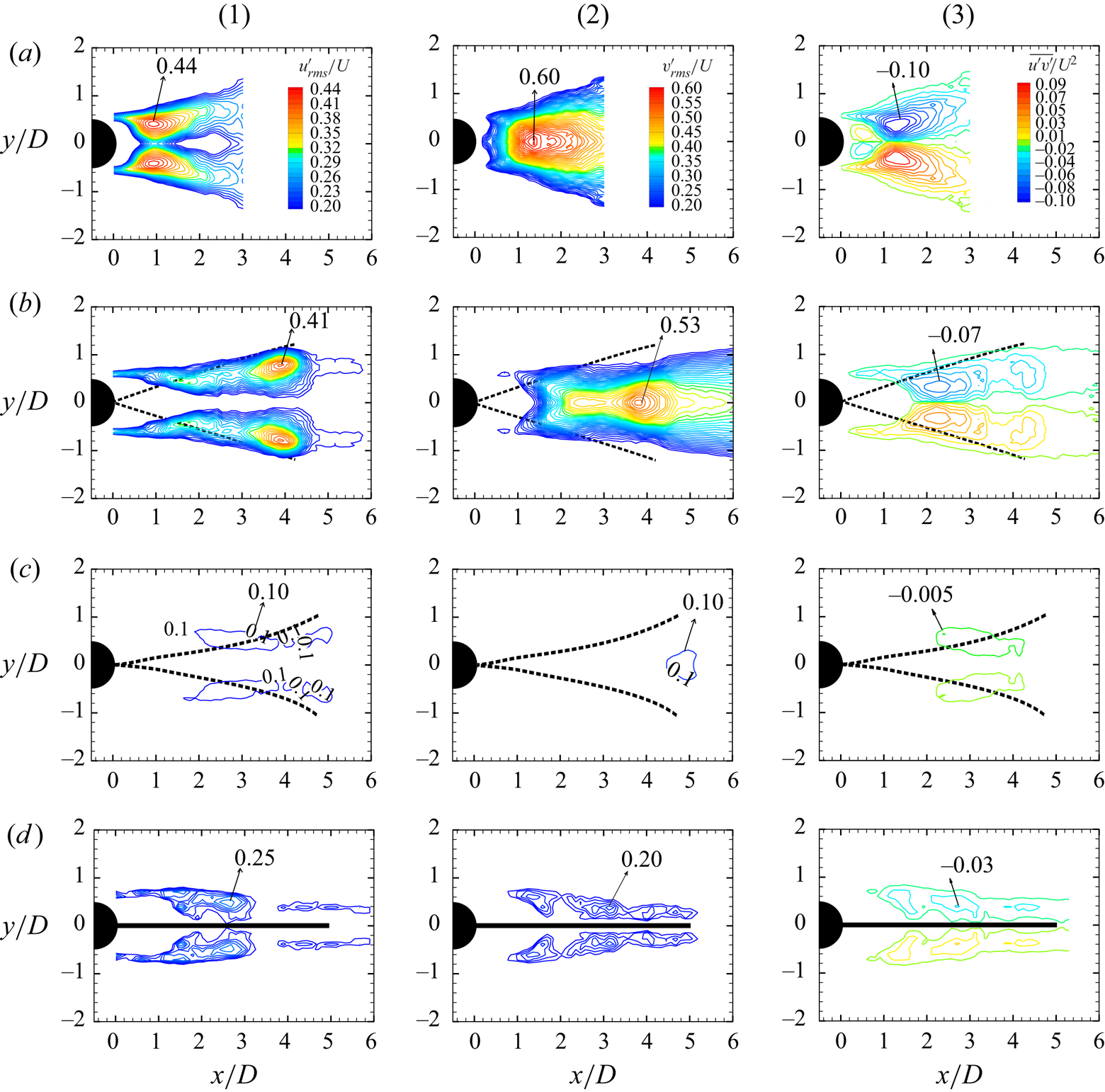

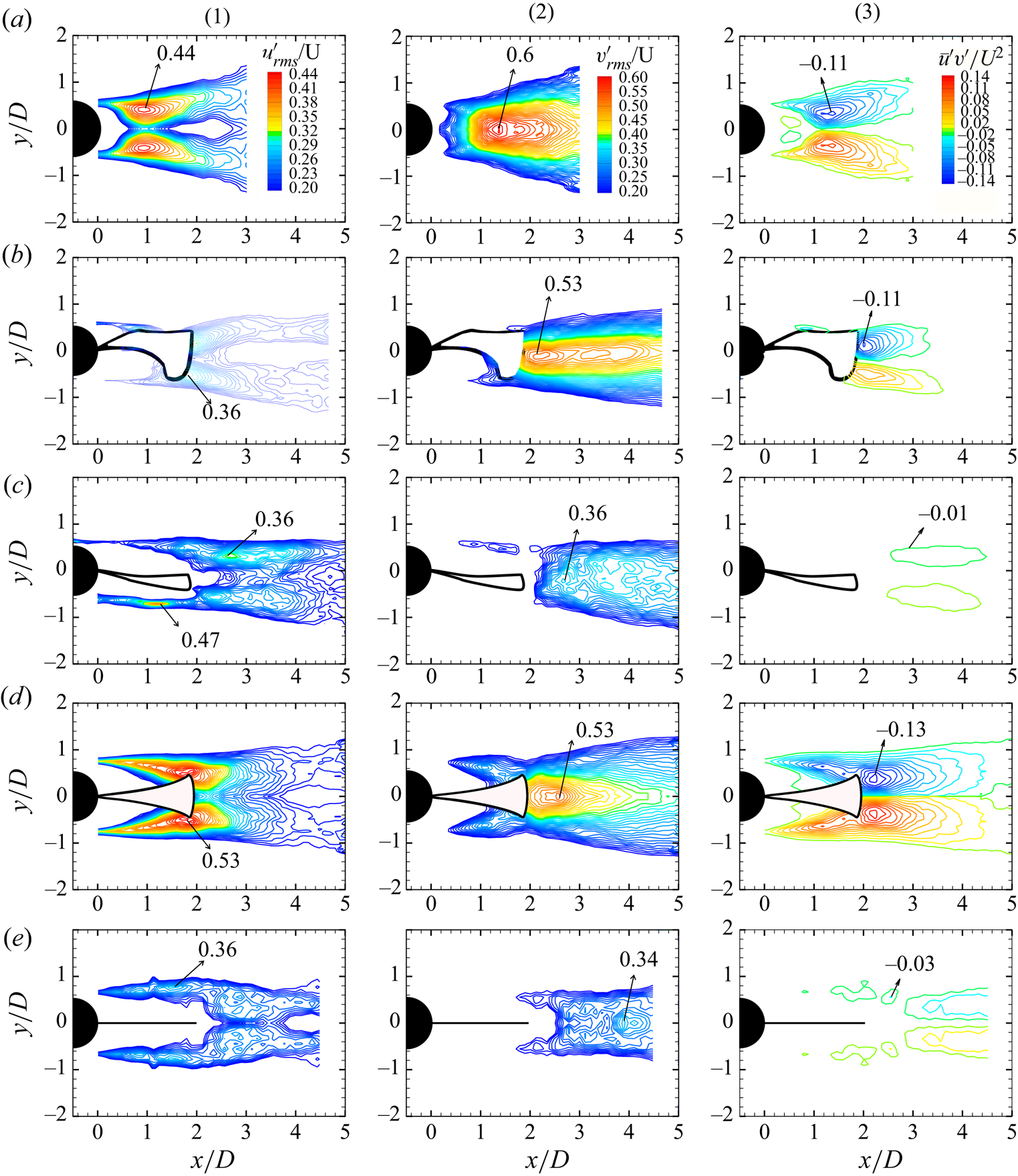

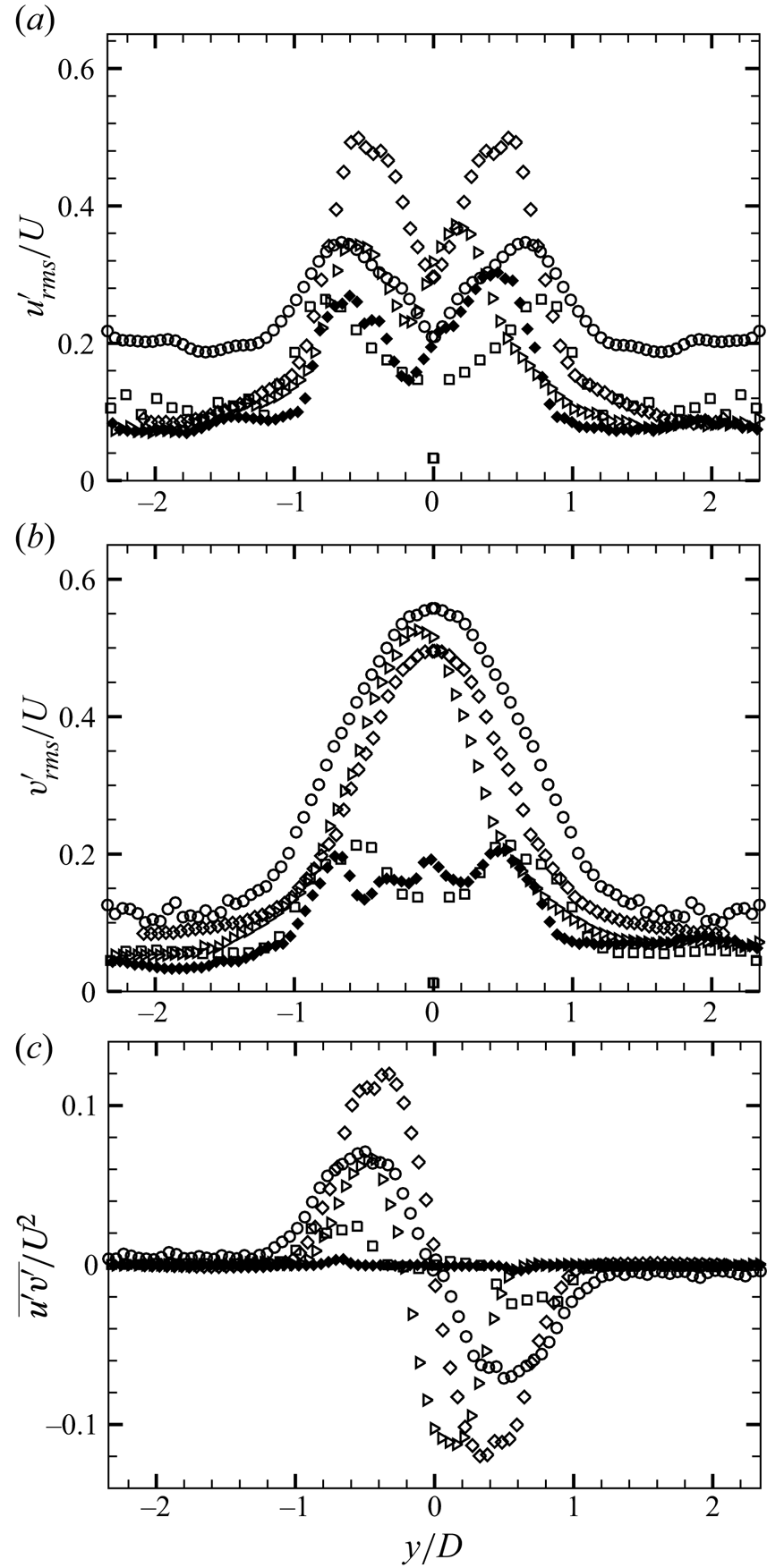

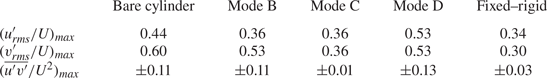

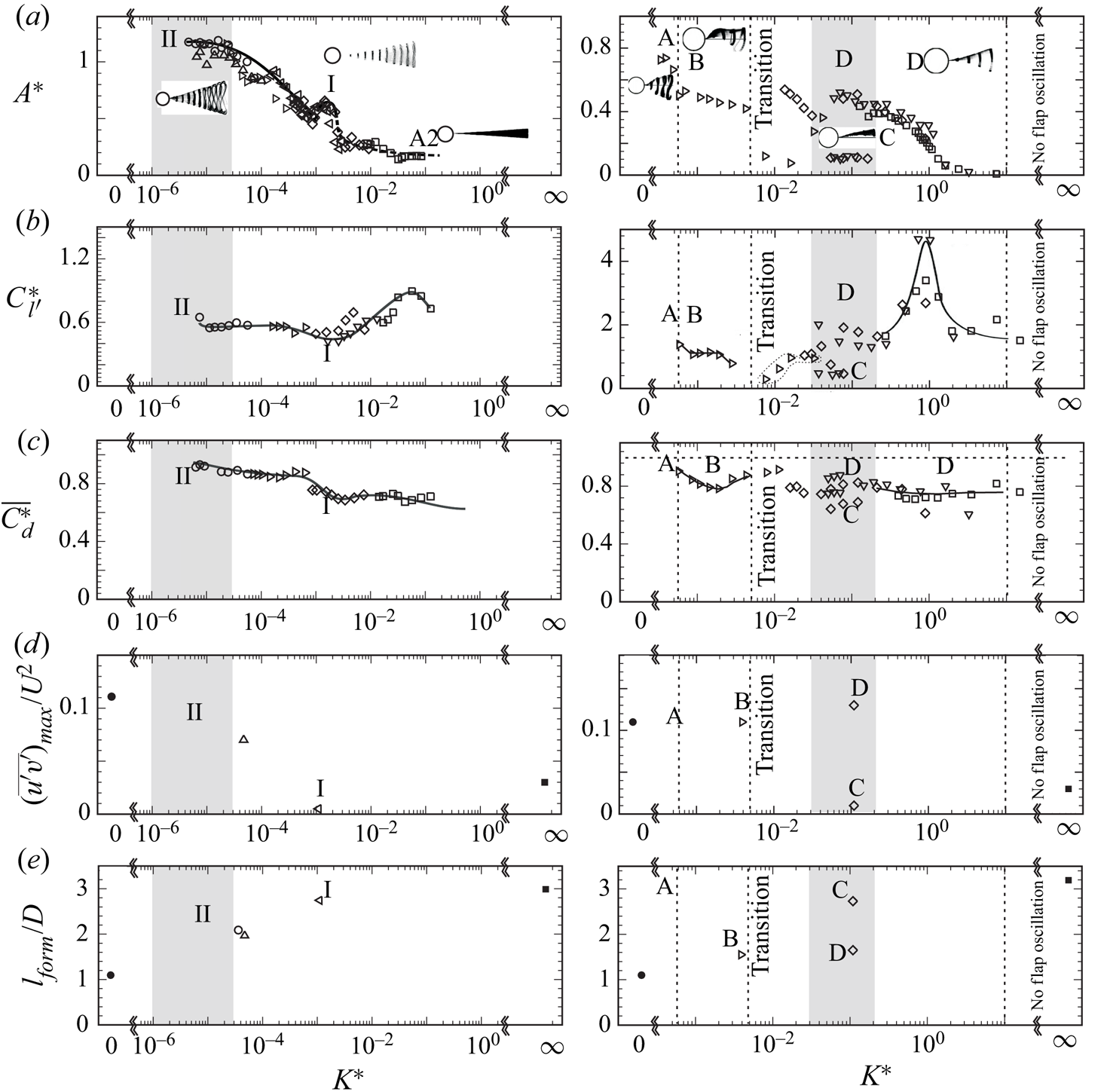

$c$) and 3(![]() $d$) to highlight differences between the modes, as discussed briefly earlier, both cases corresponding to