Published online by Cambridge University Press: 21 December 2015

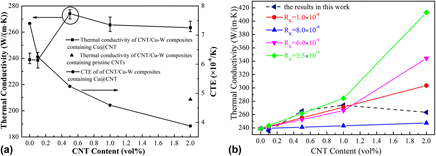

The effect of interface tailoring by Cu coating carbon nanotubes (CNTs) on the properties of CNTs enhanced copper–tungsten (CNT/Cu–W) composites is investigated. Thermal, electrical, and mechanical properties were measured, and interfacial thermal resistance between Cu and CNT was calculated according to the thermal conductivity curves. CNTs with interface tailoring showed superior dispersion state in the Cu–W composites. When the CNT contents were lower than 0.5 vol%, homogeneous dispersion CNTs and strong interfacial bond between CNTs and Cu had a positive effect on the physical properties of CNT/Cu–W composites. Such interface modification can effectively achieve thermal and electrical conduction, as well as transfer load between CNTs and Cu in the CNT/Cu–W composites. When the CNT contents were higher than 0.5 wt%, the CNT agglomerations became the dominant factor to decrease the physical properties of the composites.

Contributing Editor: Sanjay Mathur