Article contents

Mapping dislocation densities resulting from severe plastic deformation using large strain machining

Published online by Cambridge University Press: 08 August 2018

Abstract

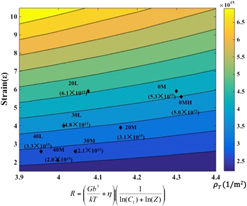

The multiplication of dislocations determines the trajectories of microstructure evolution during plastic deformation. It has been recognized that the dislocation storage and the deformation-driven subgrain formation are correlated—the principle of similitude, where the dislocation density (ρi) scales self-similarly with the subgrain size (δ):  $\delta \sqrt {{\rho _{\rm{i}}}}$ ∼ constant. Here, the robustness of this concept in Cu is probed utilizing large strain machining across a swathe of severe shear deformation conditions—strains in the range 1–10 and strain-rates 10–103/s. Deformation strain, strain-rate, and temperature characterizations are juxtaposed with electron microscopy, and dislocation densities are measured by quantification of broadening of X-ray diffraction peaks of crystallographic planes. We parameterize the variation of dislocation density as a function of strain and a rate parameter R, a function of strain-rate, temperature, and material constants. We confirm the preservation of similitude between dislocation density and the subgrain structure across orders-of-magnitude of thermomechanical conditions.

$\delta \sqrt {{\rho _{\rm{i}}}}$ ∼ constant. Here, the robustness of this concept in Cu is probed utilizing large strain machining across a swathe of severe shear deformation conditions—strains in the range 1–10 and strain-rates 10–103/s. Deformation strain, strain-rate, and temperature characterizations are juxtaposed with electron microscopy, and dislocation densities are measured by quantification of broadening of X-ray diffraction peaks of crystallographic planes. We parameterize the variation of dislocation density as a function of strain and a rate parameter R, a function of strain-rate, temperature, and material constants. We confirm the preservation of similitude between dislocation density and the subgrain structure across orders-of-magnitude of thermomechanical conditions.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 5

- Cited by