Published online by Cambridge University Press: 21 February 2017

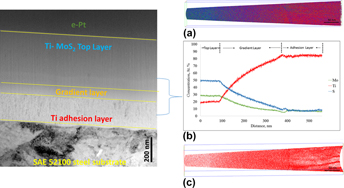

Atom probe tomography and transmission electron microscopy are used to analyze magnetron-sputtered MoS2 films containing Ti and Au/Sb2O3 as a model system for tribological coatings. Transmission electron microscopy characterization showed that the Ti–MoS2 film is dense and featureless whereas Sb2O3/Au–MoS2 film is less dense and have columnar morphology. Three-dimensional atom probe reconstructions revealed that the Ti–MoS2 films have a homogeneous composition and contain about 15 at.% Ti, which is uniformly distributed throughout the MoS2 matrix without any evidence of Ti precipitation. Sb2O3/Au–MoS2 films also showed homogeneous distribution of Sb2O3 throughout the MoS2 matrix and the presence of Au-rich precipitates. The complementary techniques of atom probe tomography and transmission electron microscopy indicate that Ti and Sb2O3 incorporation in the deposition of MoS2 produces amorphous microstructures, whereas the addition of Au forms nano-sized and well-dispersed precipitates.

Contributing Editor: Eric A. Stach