Article contents

Thermodynamic study and preparation of Si–B–N ceramic coating by LPCVD from SiCl4–NH3–BCl3–H2–Ar system

Published online by Cambridge University Press: 15 August 2017

Abstract

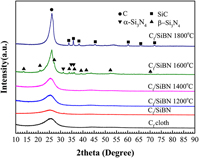

The codeposition characteristics of Si–B–N ceramics from the SiCl4–NH3–BCl3–H2–Ar system at lower temperatures and phase transformation of as-prepared Si–B–N ceramics at temperatures from 1200 to 1800 °C were investigated. Thermodynamic analysis results indicated that the BN + Si3N4 dual phase region existed from 800 to 1200 °C and that 800 °C was an optimum deposition temperature to deposit Si–B–N ceramic coating. Deposition efficiencies at equilibrium for Si3N4 and BN were high, particularly at temperatures below 1000 °C. Pressure and dilution ratio of H2 had little influence on deposition efficiencies of BN and Si3N4 at 800 °C. The amorphous Si–B–N ceramic coatings were successfully deposited at 800 °C from the same precursor system and contained N–B and N–Si bonds by XPS analysis. It kept amorphous below 1600 °C in N2 and partly transformed to α/β-Si3N4 when heat treated at 1600 °C in N2 for 2 h. These results demonstrated that the composite Si–B–N ceramics could be fabricated at 800 °C and used below 1600 °C.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Yanchun Zhou

References

REFERENCES

- 1

- Cited by