Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Ruiz, Esperanza

Cillero, Domingo

Martínez, Pedro J.

Morales, Ángel

Vicente, Gema San

de Diego, Gonzalo

and

Sánchez, José María

2014.

Bench-scale study of electrochemically assisted catalytic CO2 hydrogenation to hydrocarbon fuels on Pt, Ni and Pd films deposited on YSZ.

Journal of CO2 Utilization,

Vol. 8,

Issue. ,

p.

1.

Warwick, Michael E. A.

Kaunisto, Kimmo

Carraro, Giorgio

Gasparotto, Alberto

Maccato, Chiara

and

Barreca, Davide

2015.

A study of Pt/α-Fe2O3 Nanocomposites by XPS.

Surface Science Spectra,

Vol. 22,

Issue. 1,

p.

47.

Warwick, M. E. A.

Barreca, D.

Bontempi, E.

Carraro, G.

Gasparotto, A.

Maccato, C.

Kaunisto, K.

Ruoko, T.-P.

Lemmetyinen, H.

Sada, C.

Gönüllü, Y.

and

Mathur, S.

2015.

Pt-functionalized Fe2O3photoanodes for solar water splitting: the role of hematite nano-organization and the platinum redox state.

Physical Chemistry Chemical Physics,

Vol. 17,

Issue. 19,

p.

12899.

Sarker, Subrata

Seo, Hyun Woo

Bakare, Fatai Olawale

Aziz, Md. Abdul

and

Kim, Dong Min

2016.

Facile and rapid preparation of platinum counter electrodes for dye-sensitized solar cells.

Journal of Photochemistry and Photobiology A: Chemistry,

Vol. 321,

Issue. ,

p.

122.

Ruiz, Esperanza

Martínez, Pedro J.

Morales, Ángel

Vicente, Gema San

Diego, Gonzalo de

and

Sánchez, José M.

2016.

Effect of combustion gas components on electrochemically promoted CO 2 capture performance of Pt/K-βAl 2 O 3 at bench scale.

Electrochimica Acta,

Vol. 188,

Issue. ,

p.

184.

Kang, Wenbo

Zhu, Dongmei

Huang, Zhibin

and

Luo, Fa

2018.

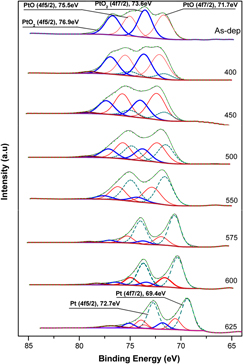

Effects of O2 Partial Pressure on Composition and Infrared Emissivity of PtO

x

Films Prepared by Reactive Magnetron Sputtering.

Journal of Electronic Materials,

Vol. 47,

Issue. 5,

p.

2746.

Sasaki, Hideaki

Matsushita, Haruka

Sakamoto, Keisuke

Sakamoto, Tatsuaki

and

Maeda, Masafumi

2019.

Formation of Pt3O4 particles on PtO2–CeO2 solid solution.

Journal of Physics and Chemistry of Solids,

Vol. 135,

Issue. ,

p.

109097.

Wollny, Patrick

Angel, Steven

Wiggers, Hartmut

Kempf, Andreas M.

and

Wlokas, Irenaeus

2020.

Multiscale Simulation of the Formation of Platinum-Particles on Alumina Nanoparticles in a Spray Flame Experiment.

Fluids,

Vol. 5,

Issue. 4,

p.

201.

Ihnatiuk, Daryna

Tossi, Camilla

Tittonen, Ilkka

and

Linnik, Oksana

2020.

Effect of Synthesis Conditions of Nitrogen and Platinum Co-Doped Titania Films on the Photocatalytic Performance under Simulated Solar Light.

Catalysts,

Vol. 10,

Issue. 9,

p.

1074.

Lyu, Xianglong

Chen, Jingyuan

Liu, Jiayu

Peng, Yixin

Duan, Shifang

Ma, Xing

and

Wang, Wei

2022.

Reversing a Platinum Micromotor by Introducing Platinum Oxide.

Angewandte Chemie International Edition,

Vol. 61,

Issue. 24,

Yi, Feng

Arlington, Shane Q.

Gorham, Justin

Osborn, William

Crumlin, Ethan J.

Nemsak, Slavomir

and

LaVan, David A.

2022.

Growth and Decomposition of Pt Surface Oxides.

The Journal of Physical Chemistry Letters,

Vol. 13,

Issue. 26,

p.

6171.

Lyu, Xianglong

Chen, Jingyuan

Liu, Jiayu

Peng, Yixin

Duan, Shifang

Ma, Xing

and

Wang, Wei

2022.

Reversing a Platinum Micromotor by Introducing Platinum Oxide.

Angewandte Chemie,

Vol. 134,

Issue. 24,