Published online by Cambridge University Press: 08 June 2020

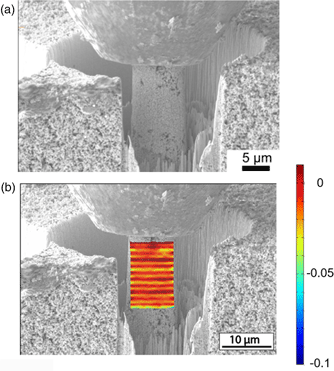

Porous metals represent a class of materials where the interplay of ligament length, width, node structure, and local geometry/curvature offers a rich parameter space for the study of critical length scales on mechanical behavior. Colloidal crystal templating of three-dimensionally ordered macroporous (3DOM, i.e., inverse opal) tungsten provides a unique structure to investigate the mechanical behavior at small length scales across the brittle–ductile transition. Micropillar compression tests show failure at 50 MPa contact pressure at 30 °C, implying a ligament yield strength of approximately 6.1 GPa for a structure with 5% relative density. In situ SEM frustum indentation tests with in-plane strain maps perpendicular to loading indicate local compressive strains of approximately 2% at failure at 30 °C. Increased sustained contact pressure is observed at 225 °C, although large (20%) nonlocal strains appear at 125 °C. The elevated-temperature mechanical performance is limited by cracks that initiate on planes of greatest shear under the indenter.

These authors contributed equally to this work.