Article contents

Magnetic field–dependent microstructure evolution and magnetic property of Fe–6.5 Si–0.05 B alloy during solidification

Published online by Cambridge University Press: 09 December 2019

Abstract

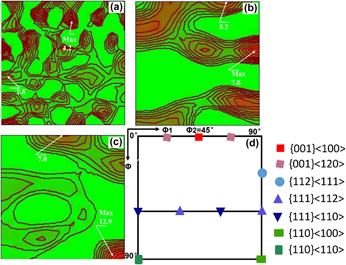

Fe–6.5 Si–0.05 B alloy was used in the study to investigate the texture evolution and magnetic property of the ferromagnetic crystal under an axial high magnetic field during bulk solidification. Optical microscopy (OM) and X-ray diffraction (XRD) were applied to analyze the microstructures and texture evolution of the alloy solidified under different magnetic field intensities. The result shows that with an increase in the magnetic field intensity from 0 to 2 T, the texture gradually changes from random orientation to {100} 〈120〉, eventually becoming a mixture of cube and Goss texture. The alloys treated at 1 and 2 T showed magnetic anisotropic behavior, while the alloy treated at 0 T showed magnetic isotropic behavior. The change in magnetic property comes from the evolution of α-Fe crystal orientation. Furthermore, a method for controlling the crystallization process and crystallographic orientation by adjusting the magnetic field intensity was proposed.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 5

- Cited by