Article contents

Indentation-derived elastic modulus of multilayer thin films: Effect of unloading-induced plasticity

Published online by Cambridge University Press: 13 August 2015

Abstract

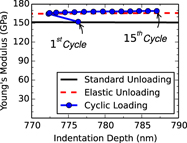

Nanoindentation is useful for evaluating the mechanical properties, such as elastic modulus, of multilayer thin film materials. A fundamental assumption in the derivation of the elastic modulus from nanoindentation is that the unloading process is purely elastic. In this work, the validity of elastic assumption as it applies to multilayer thin films is studied using the finite element method. The elastic modulus and hardness from the model system are compared to experimental results to show validity of the model. Plastic strain is shown to increase in the multilayer system during the unloading process. The indentation-derived modulus of a monolayer material shows no dependence on unloading plasticity while the modulus of the multilayer system is dependent on unloading-induced plasticity. Lastly, the cyclic behavior of the multilayer thin film is studied in relation to the influence of unloading-induced plasticity. It is found that several cycles are required to minimize unloading-induced plasticity.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 7

- Cited by