Article contents

In situ characterization of ion-irradiation enhanced creep of third generation Tyranno SA3 SiC fibers

Published online by Cambridge University Press: 10 February 2015

Abstract

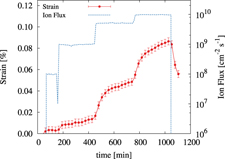

Subcritical crack growth in SiC based composites is controlled by fiber creep processes. This lifetime limiting mechanism is of special concern under irradiation as it can enhance creep related mechanisms. To evaluate the impact of irradiation on the mechanical behavior of Tyranno SA3 fibers, in situ tensile tests were conducted on single fibers. These tests were conducted under irradiation with 92 MeV Xe23+ ions at 1000 °C for different ion fluxes and stress loads using a dedicated experimental facility. It has been found that irradiation induces time-dependent deformation of the fibers under conditions where thermal creep is negligible, i.e., 300 MPa and 1000 °C. Irradiation strain rate shows linear dependence with the ion beam flux and square root dependence with the applied stress. Finally, the irradiation creep compliance is estimated to be 1.01 × 10−5 MPa−1 dpa−1.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

Footnotes

Contributing Editor: Khalid Hattar

References

REFERENCES

- 8

- Cited by