Article contents

Hardening mechanisms in irradiated Cu–W alloys

Published online by Cambridge University Press: 18 August 2017

Abstract

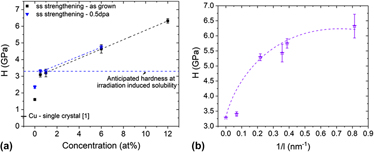

This work investigates the relative contributions to strengthening from twinning, solid-solution, precipitation, and irradiation hardening mechanisms in sputtered Cu–W thin films irradiated to different doses. A nanograin solid solution strengthening mechanism with a linear compositional dependence is observed for the as-grown alloys and for the alloy samples irradiated to 0.5 dpa. Solid solution strengthening is the major strengthening mechanism for Cu99.5W0.5 at all irradiation doses. Irradiation induces precipitation in samples with W concentrations greater than or equal to 1% at doses above ≈0.5 dpa. The growth of 1–4 nm precipitates enhances the hardness of these alloys, and the degree of strengthening is determined by the interparticle spacing. While the alloys exhibit steady-state properties after a relatively low dose (≈1 dpa), the different time scales associated with detwinning and damage accumulation in pure Cu lead transients at higher doses (>5 dpa).

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 6

- Cited by