Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wang, Changshuai

Guo, YongAn

Guo, Jianting

and

Zhou, Lanzhang

2016.

Microstructural changes and their effect on tensile properties of a Ni-Fe based alloy during long-term thermal exposure.

Materials Science and Engineering: A,

Vol. 670,

Issue. ,

p.

178.

Wang, Changshuai

Guo, Yongan

Guo, Jianting

and

Zhou, Lanzhang

2016.

Microstructural characteristics and mechanical properties of a Mo modified Ni–Fe–Cr based alloy.

Materials Science and Engineering: A,

Vol. 675,

Issue. ,

p.

314.

Sun, Yanle

Fu, Liming

Fu, Zhiqiang

Shan, Aidang

and

Lavernia, Enrique J.

2017.

Enhanced thermal stability and ductility in a nanostructured Ni-based alloy.

Scripta Materialia,

Vol. 141,

Issue. ,

p.

1.

Wang, Changshuai

Wang, Tingting

Guo, Jianting

Zhou, Lanzhang

Zhao, Haiping

and

Xu, Songqian

2017.

Energy Materials 2017.

p.

143.

Wu, Dong

Li, Dianzhong

and

Lu, Shanping

2018.

Effect of Cr content on the microstructural stability and impact-toughness evolution of a Ni-Fe-based weld metal.

Journal of Alloys and Compounds,

Vol. 749,

Issue. ,

p.

465.

Wu, Dong

Li, Dianzhong

and

Lu, Shanping

2018.

Microstructural evolution and mechanical property of a Ni-Fe-based weld metal during long-term exposure at 650 °C and 700 °C.

Materials Science and Engineering: A,

Vol. 716,

Issue. ,

p.

240.

Chu, Tongjiao

Xu, Huali

Cui, Haichao

and

Lu, Fenggui

2019.

Research on the coarsening mechanism of precipitations and its effect on toughness for nickel-based weld metal during thermal aging.

Journal of Materials Research,

Vol. 34,

Issue. 15,

p.

2705.

Hou, Kunlei

Ou, Meiqiong

Wang, Min

Li, Haoze

Ma, Yingche

and

Liu, Kui

2019.

Precipitation of η phase and its effects on stress rupture properties of K4750 alloy.

Materials Science and Engineering: A,

Vol. 763,

Issue. ,

p.

138137.

Wang, Changshuai

Wu, Yunsheng

Guo, YongAn

Guo, Jianting

and

Zhou, Lanzhang

2019.

Precipitation behavior of sigma phase and its influence on mechanical properties of a Ni-Fe based alloy.

Journal of Alloys and Compounds,

Vol. 784,

Issue. ,

p.

266.

Wu, Yunsheng

Qin, Xuezhi

Wang, Changshuai

and

Zhou, Lanzhang

2021.

Microstructural evolution and its influence on the impact toughness of GH984G alloy during long-term thermal exposure.

Journal of Materials Science & Technology,

Vol. 60,

Issue. ,

p.

61.

Li, Linxu

Gong, Xiufang

Wang, Changshuai

Wu, Yunsheng

Yu, Hongyao

Su, Haijun

and

Zhou, Lanzhang

2021.

Correlation Between Phase Stability and Tensile Properties of the Ni-Based Superalloy MAR-M247.

Acta Metallurgica Sinica (English Letters),

Vol. 34,

Issue. 6,

p.

872.

Zhang, Xiangxiang

Wang, Changshuai

Wu, Yunsheng

and

Zhou, Lanzhang

2022.

Effect of phosphorus segregation on carbides and creep damage of Ni–Fe-based GH984G alloy.

Journal of Materials Research and Technology,

Vol. 19,

Issue. ,

p.

2018.

Huang, Yeshun

Zhang, Rui

Zhou, Zijian

Yan, Jingbo

Yuan, Yong

Gu, Yuefeng

Cui, Chuanyong

Zhou, Yizhou

and

Sun, Xiaofeng

2022.

Effect of long-term aging on microstructural stability and tensile deformation of a Fe–Ni-based superalloy.

Materials Science and Engineering: A,

Vol. 847,

Issue. ,

p.

143298.

Guo, QianYing

Ji, KangKang

Zhang, Teng

Qiao, ZhiXia

Li, Chong

Li, Jun

Liu, ChenXi

and

Liu, YongChang

2022.

Precipitates evolution and tensile behavior of wrought Ni-based ATI 718Plus superalloy during long-term thermal exposure.

Science China Technological Sciences,

Vol. 65,

Issue. 6,

p.

1283.

Wang, Y.C.

Mei, Q.S.

Zhang, P.

Yan, J.B.

Ma, Y.

Liao, L.Y.

Xu, T.

and

Yuan, Y.

2023.

Effect of nitrogen on the microstructure evolution and mechanical properties of Ni-Fe base superalloys during long-term thermal exposure.

Materials Characterization,

Vol. 203,

Issue. ,

p.

113058.

Guo, C.H.

Zhang, P.

Zhou, Y.L.

Li, L.M.

Yin, H.F.

Yan, J.B.

Diao, W.Z.

Li, P.

and

Yuan, Y.

2023.

Microstructural evolution and yield strength of a novel precipitate-strengthened Fe-based superalloy during thermal aging at 700 °C.

Intermetallics,

Vol. 163,

Issue. ,

p.

108077.

Cheng, Sihan

Wang, Jiaqi

Wu, Yunsheng

Qin, Xuezhi

and

Zhou, Lanzhang

2023.

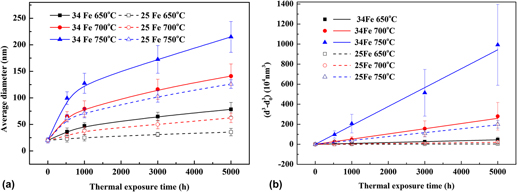

Microstructure, thermal stability and tensile properties of a Ni–Fe–Cr based superalloy with different Fe contents.

Intermetallics,

Vol. 153,

Issue. ,

p.

107785.

Prabhu, Rajalingam

Kavimani, Vijayananth

Gopal, Pudhupalayam Muthukutti

and

Sahadevan, Jhelai

2024.

Thermal barrier coating on Inconel 718: understanding cyclic oxidation kinetics.

Surface Engineering,

Vol. 40,

Issue. 4,

p.

478.

Li, Shaowei

Liu, Fang

Si, Tianxiao

and

Sun, Wenru

2024.

Incommensurate modulated structure and nano-sized γ′ phase induced by Fe during creep at 650 ℃ in Nickel-based model alloys.

Scripta Materialia,

Vol. 243,

Issue. ,

p.

115995.