Article contents

Fracture toughness of Cu and Ni single crystals with a nanocrack

Published online by Cambridge University Press: 21 May 2015

Abstract

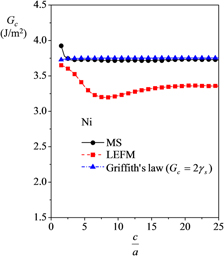

The fracture toughness values of nanosized Cu and Ni single crystals with an edge nanocrack were determined under quasi-static loading conditions. Molecular statics (MS) simulations that can essentially capture the discreteness and the nonlinearity of materials were used in the present study. Different crack lengths were used to evaluate the effects of crack size on the fracture toughness. Based on MS simulations, the energy release rate was calculated using the energies obtained from two models with neighboring crack lengths under the same loading conditions. Furthermore, continuum counterparts of the atomistic models were used to calculate the toughness by the finite element method for linear elastic fracture mechanics (LEFM). The reasons behind the discrepancies between the toughness values obtained using different methods were discussed, and the applicable ranges of the toughness and the LEFM were indicated in terms of the lattice constants.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 10

- Cited by