Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Chen, Hongtao

Li, Jue

and

Li, Mingyu

2012.

Dependence of recrystallization on grain morphology of Sn-based solder interconnects under thermomechanical stress.

Journal of Alloys and Compounds,

Vol. 540,

Issue. ,

p.

32.

Chen, Hongtao

Yan, Bingbing

Yang, Ming

Ma, Xin

and

Li, Mingyu

2013.

Effect of grain orientation on mechanical properties and thermomechanical response of Sn-based solder interconnects.

Materials Characterization,

Vol. 85,

Issue. ,

p.

64.

Wang, Yiwei

and

Ho, Paul S.

2013.

Mode II electromigration failure mechanism in Sn-based Pb-free solder joints with Ni under-bump metallization.

Applied Physics Letters,

Vol. 103,

Issue. 12,

Kim, Youngseok

Nagao, Shijo

Sugahara, Tohru

Suganuma, Katsuaki

Ueshima, Minoru

Albrecht, Hans-Juergen

Wilke, Klaus

and

Strogies, Joerg

2014.

Enhanced reliability of Sn–Ag–Bi–In joint under electric current stress by adding Co/Ni elements.

Journal of Materials Science: Materials in Electronics,

Vol. 25,

Issue. 7,

p.

3090.

Ma, Limin

Zuo, Yong

Guo, Fu

and

Shu, Yutian

2014.

Effects of current densities on creep behaviors of Sn–3.0Ag–0.5Cu solder joint.

Journal of Materials Research,

Vol. 29,

Issue. 22,

p.

2738.

Kim, Youngseok

Nagao, Shijo

Sugahara, Tohru

Suganuma, Katsuaki

Ueshima, Minoru

Albrecht, Hans-Juergen

Wilke, Klaus

and

Strogies, Joerg

2014.

Effect of electromigration on mechanical shock behavior in solder joints of surface mounted chip components.

Japanese Journal of Applied Physics,

Vol. 53,

Issue. 4S,

p.

04EB02.

Hsu, Wei-Neng

and

Ouyang, Fan-Yi

2014.

Effects of anisotropic β-Sn alloys on Cu diffusion under a temperature gradient.

Acta Materialia,

Vol. 81,

Issue. ,

p.

141.

Parks, Gregory

Faucett, Austin

Fox, Craig

Smith, Jake

and

Cotts, Eric

2014.

The Nucleation of Sn in Undercooled Melts: The Effect of Metal Impurities.

JOM,

Vol. 66,

Issue. 11,

p.

2311.

Kim, Youngseok

Nagao, Shijo

Sugahara, Tohru

Suganuma, Katsuaki

Ueshima, Minoru

Albrecht, Hans-Juergen

Wilke, Klaus

and

Strogies, Joerg

2014.

Refinement of the Microstructure of Sn-Ag-Bi-In Solder, by Addition of SiC Nanoparticles, to Reduce Electromigration Damage Under High Electric Current.

Journal of Electronic Materials,

Vol. 43,

Issue. 12,

p.

4428.

Parks, Gregory

Lu, Minhua

Perfecto, Eric

and

Cotts, Eric

2014.

Controlling the Sn grain morphology of SnAg C4 solder bumps.

p.

690.

Albrecht, H.-J.

and

Strogies, J.

2014.

Investigations studying the electromigration phenomena in interconnects.

p.

1.

Kim, Sang-Hyuk

Hong, Seong-Ki

Yim, Hyunho

and

Lee, Hyo-Jong

2015.

Characterization of the SnAg Electrodeposits according to the Current Density and Cross-sectional Microstructure Analysis in the Cu Pillar Solder Bump.

Journal of the Korean institute of surface engineering,

Vol. 48,

Issue. 4,

p.

131.

Liu, Pilin

Overson, Alan

and

Goyal, Deepak

2015.

Key parameters for fast Ni dissolution during electromigration of Sn0.7Cu solder joint.

p.

99.

Shen, Yu-An

and

Chen, Chih

2015.

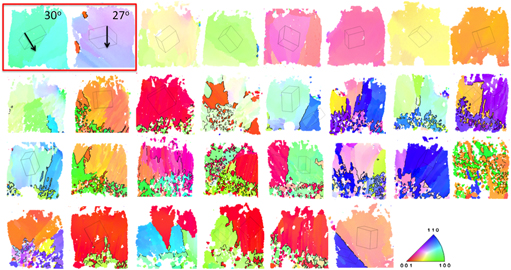

Study of grain size and orientation of 30 µm solder microbumps bonded by thermal compression.

p.

204.

Ho, C.E.

Yang, C.H.

Chen, C.T.

and

Chen, B.Z.

2015.

Abnormal depletion of Cu metallization pads in line–bump–line solder joints under electron current stressing.

Thin Solid Films,

Vol. 596,

Issue. ,

p.

216.

Chen, Chih

Yu, Doug

and

Chen, Kuan-Neng

2015.

Vertical interconnects of microbumps in 3D integration.

MRS Bulletin,

Vol. 40,

Issue. 3,

p.

257.

Chen, Hongtao

Hang, Chunjin

Fu, Xing

and

Li, Mingyu

2015.

Microstructure and Grain Orientation Evolution in Sn-3.0Ag-0.5Cu Solder Interconnects Under Electrical Current Stressing.

Journal of Electronic Materials,

Vol. 44,

Issue. 10,

p.

3880.

Chen, Jian-Qiang

Guo, Jing-Dong

Ma, Hui-Cai

Liu, Kai-Lang

Zhu, Qing-sheng

and

Shang, Jian Ku

2015.

Magnetic-field induced anisotropy in electromigration behavior of Sn–Ag–Cu solder interconnects.

Journal of Materials Research,

Vol. 30,

Issue. 8,

p.

1065.

Mertens, J.C.E.

Kirubanandham, A.

and

Chawla, N.

2016.

Electromigration mechanisms in Sn-0.7Cu/Cu couples by four dimensional (4D) X-ray microtomography and electron backscatter diffraction (EBSD).

Acta Materialia,

Vol. 102,

Issue. ,

p.

220.

Bashir, M. Nasir

Haseeb, A.S.M.A.

Rahman, Abu Zayed Mohammad Saliqur

and

Fazal, M.A.

2016.

Effect of Cobalt Doping on the Microstructure and Tensile Properties of Lead Free Solder Joint Subjected to Electromigration.

Journal of Materials Science & Technology,

Vol. 32,

Issue. 11,

p.

1129.