Published online by Cambridge University Press: 28 September 2015

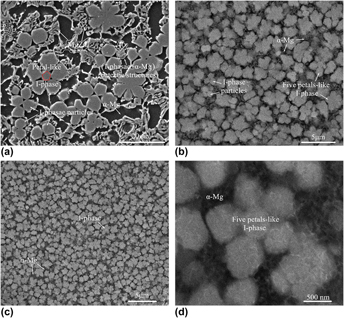

The influence of cooling rates on the solidification and microstructure of rapidly solidified quasicrystal alloys with a nominal compositions of Mg57Zn37Y6 (at.%) prepared by melt spinning method was investigated. The microstructure, phase constitution, phase transition, and phase structure of the alloys were examined by means of scanning electron microscopy, x-ray diffraction, energy dispersive spectrometer, differential scanning calorimetry, and transmission electron microscopy. The results show that rapid solidification refines and homogenizes the microstructure of Mg57Zn37Y6 alloys, compared to the conventionally-cast master alloy. With the increasing cooling rate of rapid solidification, the thickness of the ribbon decreases greatly and a larger amount of I-phase can be formed. α-Mg, MgZn, and icosahedral phases are found in the as-cast alloy, but the MgZn phase is absent from rapidly solidified alloys. The I-phase in both as-cast and rapidly solidified alloys can precipitate directly from the melt during the solidification process. A higher cooling rate can lead to a large degree of supercooling, resulting in a decreased phase transition temperature and a large number of icosahedral short-range orders (ISROs). ISROs can act as templates in liquid and promote the nucleation of I-phase.

Contributing Editor: Yang-T. Cheng