Published online by Cambridge University Press: 12 July 2017

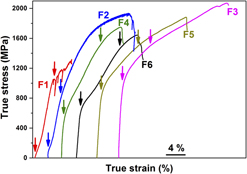

The addition of Co to CuZr-based shape memory bulk metallic glass composites stabilizes the high temperature B2-CuZr and decreases its stacking faulty energy, which promotes an increase in ductility caused by an easier twinning formation. A similar effect is expected for TiCu-based alloys. The present work aims to investigate the effect of Co additions on the phase formation, mechanical properties, and thermal stability of rapidly solidified Ti–Cu-based alloys. Rods of six Ti–Cu-based compositions with different amounts of Co were prepared by Cu-mold suction casting and investigated by X-ray diffraction, differential scanning calorimetry, scanning electron microscopy, dilatometry, and compression tests. The results show that the addition of Co decreases the glass-forming ability of Ti–Cu-based alloys and stabilizes B2 Ti(Cu,Ni,Co) at room temperature. The Co-added alloys exhibit an almost identical phase formation and microstructure, but their mechanical behavior is completely different nonetheless, which is mainly connected with the different composition of the B2 phase. The addition of Co makes the stress-induced martensitic transformation of this phase more difficult, which is one of the main reasons for the increase of the yield strength when a higher amount of Co is added.

This author was an editor of this journal during the review and decision stage. For the JMR policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Contributing Editor: Mathias Göken