1. Introduction

Viscoplastic materials are a branch of non-Newtonian fluids showing a threshold for the applied stress, called the yield stress. For applied stresses larger than the yield stress, the material deforms as a viscous fluid; when the applied stresses are smaller than the yield stress, the material behaves as a rigid solid (Bonn et al. Reference Bonn, Denn, Berthier, Divoux and Manneville2017). In this context, the term ‘viscoplastic materials’ refers typically to those that exhibit only viscous and plastic properties. On the other hand, as discussed in detail by Thompson, Sica & de Souza Mendes (Reference Thompson, Sica and de Souza Mendes2018), the term ‘yield stress materials’ may refer to those that show additional properties beside the yield stress threshold, such as elasticity, thixotropy and so on. There are many fluids with proven yield stress behaviour, including waxy crude oils, foamed cement and cement slurries, many food products (e.g. chocolate cream and jam), cosmetic products (e.g. moisturizing cream) and so on (Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014). Biological materials (e.g. mucus and mammalian blood) also exhibit the yield stress rheology, suggesting new problems in physiological sciences, biomedical applications and microfluidic technologies (Balmforth et al. Reference Balmforth, Frigaard and Ovarlez2014; Burinaru et al. Reference Burinaru, Avram, Avram, Marculescu, Tincu, Tucureanu, Matei and Militaru2018; Horner, Wagner & Beris Reference Horner, Wagner and Beris2021).

Superhydrophobic (SH) surfaces are created via adding micro- and nano-scale protrusions onto hydrophobic surfaces, in order to decrease the surface wettability and, hence, improve the slippery motion (Koch & Barthlott Reference Koch and Barthlott2009). Groovy structures are among most well-known protrusions, experimentally created on hydrophobic surfaces (Lee, Choi & Kim Reference Lee, Choi and Kim2016), allowing us to trap gas (usually air), causing a fluid slippage on these surfaces (Rothstein Reference Rothstein2010; Lee et al. Reference Lee, Choi and Kim2016). Considering an SH wall, the condition at which air is trapped between the liquid and the groovy wall is called the Cassie state. However, in some conditions, the trapped air escapes and the liquid penetrates into the groove, fills the cavity and forms the Wenzel state (Lee et al. Reference Lee, Choi and Kim2016; Hardt & McHale Reference Hardt and McHale2022). In this context, there are several possible scenarios for the liquid/air interface, summarized as follows: (i) the liquid/air interface is nearly flat and pinned at the edges of the groove (ideal Cassie state) (Hodes et al. Reference Hodes, Kirk, Karamanis and MacLachlan2017; Arenas et al. Reference Arenas, García, Fu, Orlandi, Hultmark and Leonardi2019; Tomlinson & Papageorgiou Reference Tomlinson and Papageorgiou2022); (ii) the interface is deformed towards the groove or towards the main flow while it is pinned at the groove edges (Crowdy Reference Crowdy2017b; Game, Hodes & Papageorgiou Reference Game, Hodes and Papageorgiou2019); (iii) the liquid partially fills the groove and the liquid/air interface is in contact with the side and bottom walls of the groove (and the interface is not anymore pinned to the groove edges) (Giacomello et al. Reference Giacomello, Chinappi, Meloni and Casciola2012; Papadopoulos et al. Reference Papadopoulos, Mammen, Deng, Vollmer and Butt2013; He et al. Reference He, Zhang, Wang, Wang, Yang, Wang and Lee2021). The occurrence of these situations is mostly dependent on the flow parameters and the surface properties, including the system pressure, surface tension and the fluid's rheology (Tsai et al. Reference Tsai, Peters, Pirat, Wessling, Lammertink and Lohse2009; Papadopoulos et al. Reference Papadopoulos, Mammen, Deng, Vollmer and Butt2013; Annavarapu et al. Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019; Rofman et al. Reference Rofman, Dehe, Frumkin, Hardt and Bercovici2020; He et al. Reference He, Zhang, Wang, Wang, Yang, Wang and Lee2021).

Several experimental studies (Manukyan et al. Reference Manukyan, Oh, Van Den Ende, Lammertink and Mugele2011; Papadopoulos et al. Reference Papadopoulos, Mammen, Deng, Vollmer and Butt2013) have found large deformations and deflections of the liquid/air interface at the SH wall. However, in several other experiments, small values for the deflection of the liquid/air interface have been reported (Ou, Perot & Rothstein Reference Ou, Perot and Rothstein2004; Ou & Rothstein Reference Ou and Rothstein2005; Kirk, Hodes & Papageorgiou Reference Kirk, Hodes and Papageorgiou2017). In a series of experiments conducted by Ou et al. (Reference Ou, Perot and Rothstein2004), the pressure drop and flow rate have been measured for a pressure-driven flow through a microchannel with one SH wall decorated with cubic micro-posts (![]() $30$

$30$ ![]() $\mathrm {\mu }$m tall,

$\mathrm {\mu }$m tall, ![]() $30$

$30$ ![]() $\mathrm {\mu }$m thick and spaced at

$\mathrm {\mu }$m thick and spaced at ![]() $30$

$30$ ![]() $\mathrm {\mu }$m), with the channel height varying between 76 and 257

$\mathrm {\mu }$m), with the channel height varying between 76 and 257 ![]() $\mathrm {\mu }$m. They have found the maximum deflection to be

$\mathrm {\mu }$m. They have found the maximum deflection to be ![]() ${\sim }3$

${\sim }3$ ![]() $\mathrm {\mu }$m for the liquid/air interface, i.e. relatively small compared with the period of the micro-posts (which is

$\mathrm {\mu }$m for the liquid/air interface, i.e. relatively small compared with the period of the micro-posts (which is ![]() $60$

$60$ ![]() $\mathrm {\mu }$m). Presenting a universal law, Annavarapu et al. (Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019) have demonstrated that the shape and geometry of the SH microstructures can affect the deflection of the liquid/air interface. They have shown that the deflection of the liquid/air interface is proportional to the second power of the microstructure edge to the edge length. They have also proven that the critical Laplace pressure at which the wetting transition occurs changes with the microstructure geometry and shape (Annavarapu et al. Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019). In particular, the Cassie state can be stabilized with having larger microstructure depths and smaller widths of the liquid/air interface (smaller slip area fractions) (He, Patankar & Lee Reference He, Patankar and Lee2003; Zhao & Yuan Reference Zhao and Yuan2015; Annavarapu et al. Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019). In another series of studies, the channel height has been carefully adjusted to maintain a flat liquid/air interface in molecular dynamics simulations (Bao, Priezjev & Hu Reference Bao, Priezjev and Hu2020; Ren et al. Reference Ren, Hu, Bao, Zhang, Wen and Xie2021). Using certain microtrench SH surfaces, the Cassie state has been stabilized for turbulent flows (Xu et al. Reference Xu, Grabowski, Yu, Kerezyte, Lee, Pfeifer and Kim2020, Reference Xu, Yu, Kim and Kim2021). In addition, Choi et al. (Reference Choi, Kang, Park, Jeong and Lee2021) have proposed flexible overhangs of re-entrant structures to stabilize the Cassie state. Also, Zhang et al. (Reference Zhang, Klittich, Gao and Dhinojwala2017) have tuned the roughness of a carbon nanotube surface, producing a new surface showing SH properties with a stable Cassie state. It has also been demonstrated that SH surfaces with low intrinsic wettability show high resistance to the undesired Wenzel state; this is due to a weak attractive force between the fluid molecules and the substrate atoms (Verplanck et al. Reference Verplanck, Galopin, Camart, Thomy, Coffinier and Boukherroub2007; Zhang, Wang & Wang Reference Zhang, Wang and Wang2019). These recent studies have demonstrated the important role of the shape and geometry of the microstructures, the surface intrinsic wettability and the channel height for confined flows in controlling the deflection of the liquid/air interface and maintaining a stable Cassie state.

$\mathrm {\mu }$m). Presenting a universal law, Annavarapu et al. (Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019) have demonstrated that the shape and geometry of the SH microstructures can affect the deflection of the liquid/air interface. They have shown that the deflection of the liquid/air interface is proportional to the second power of the microstructure edge to the edge length. They have also proven that the critical Laplace pressure at which the wetting transition occurs changes with the microstructure geometry and shape (Annavarapu et al. Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019). In particular, the Cassie state can be stabilized with having larger microstructure depths and smaller widths of the liquid/air interface (smaller slip area fractions) (He, Patankar & Lee Reference He, Patankar and Lee2003; Zhao & Yuan Reference Zhao and Yuan2015; Annavarapu et al. Reference Annavarapu, Kim, Wang, Hart and Sojoudi2019). In another series of studies, the channel height has been carefully adjusted to maintain a flat liquid/air interface in molecular dynamics simulations (Bao, Priezjev & Hu Reference Bao, Priezjev and Hu2020; Ren et al. Reference Ren, Hu, Bao, Zhang, Wen and Xie2021). Using certain microtrench SH surfaces, the Cassie state has been stabilized for turbulent flows (Xu et al. Reference Xu, Grabowski, Yu, Kerezyte, Lee, Pfeifer and Kim2020, Reference Xu, Yu, Kim and Kim2021). In addition, Choi et al. (Reference Choi, Kang, Park, Jeong and Lee2021) have proposed flexible overhangs of re-entrant structures to stabilize the Cassie state. Also, Zhang et al. (Reference Zhang, Klittich, Gao and Dhinojwala2017) have tuned the roughness of a carbon nanotube surface, producing a new surface showing SH properties with a stable Cassie state. It has also been demonstrated that SH surfaces with low intrinsic wettability show high resistance to the undesired Wenzel state; this is due to a weak attractive force between the fluid molecules and the substrate atoms (Verplanck et al. Reference Verplanck, Galopin, Camart, Thomy, Coffinier and Boukherroub2007; Zhang, Wang & Wang Reference Zhang, Wang and Wang2019). These recent studies have demonstrated the important role of the shape and geometry of the microstructures, the surface intrinsic wettability and the channel height for confined flows in controlling the deflection of the liquid/air interface and maintaining a stable Cassie state.

Considering numerous applications of SH surfaces in microfluidic technology (Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Tsai Reference Tsai2013; Lee et al. Reference Lee, Choi and Kim2016; Qi et al. Reference Qi, Niu, Ruck and Zhao2019), in some scenarios, the rheology of fluids flowing in microfluidic devices exhibits yield stress characteristics (Burinaru et al. Reference Burinaru, Avram, Avram, Marculescu, Tincu, Tucureanu, Matei and Militaru2018; Gao et al. Reference Gao2020). For example, human blood is a prevalent fluid synthesized in microfluidic devices, e.g. for disease diagnosis (Choi et al. Reference Choi, Ng, Fobel and Wheeler2012; Burinaru et al. Reference Burinaru, Avram, Avram, Marculescu, Tincu, Tucureanu, Matei and Militaru2018). Human blood's yield stress originates from complex interactions between red blood cells, leading to the formation of a three-dimensional network of rouleaux at low shear rates. Rouleaux formation and break up is also responsible for blood's thixotropy (Giannokostas et al. Reference Giannokostas, Moschopoulos, Varchanis, Dimakopoulos and Tsamopoulos2020, Reference Giannokostas, Dimakopoulos, Anayiotos and Tsamopoulos2021; Beris et al. Reference Beris, Horner, Jariwala, Armstrong and Wagner2021; Horner et al. Reference Horner, Wagner and Beris2021). New rheometers have been designed by the use of microfluidic technologies, e.g. to analyse the rheology of concentrated solutions of microgel particles in microchannels involving a yield stress (Nghe et al. Reference Nghe, Terriac, Schneider, Li, Cloitre, Abecassis and Tabeling2011).

Let us briefly mention some of the existing studies on viscoplastic fluid flows with homogeneous slip boundary conditions, which can occur on a hydrophobic or hydrophilic surface, assuming that the viscoplastic fluid slides on the solid wall. The flow of Herschel–Bulkley fluids in channels with wall slip has been analytically studied for symmetric (Ferrás, Nóbrega & Pinho Reference Ferrás, Nóbrega and Pinho2012) and asymmetric (Panaseti & Georgiou Reference Panaseti and Georgiou2017; Panaseti et al. Reference Panaseti, Vayssade, Georgiou and Cloitre2017) slip configurations. These works have analysed the viscoplastic fluid velocity profile using different slip models, including the linear and nonlinear Navier, empirical asymptotic and Hatzikiriakos slip models. The axial flow of a Bingham fluid through concentric annulus with wall slip has been analytically addressed by Kalyon & Malik (Reference Kalyon and Malik2012). Taghavi (Reference Taghavi2018) has studied multilayer flows of viscoplastic fluids in a narrow channel with symmetric and asymmetric wall slip conditions, evaluating the role of the different slip configurations on the overall flow picture. The stability of plane Poiseuille flow of Bingham fluids with wall slip has been recently studied, revealing stabilizing and destabilizing effects of the streamwise and spanwise slip conditions, respectively (Rahmani & Taghavi Reference Rahmani and Taghavi2020).

Regardless of the boundary conditions (e.g. slip or no slip), viscoplastic fluid flows are numerically studied using two main approaches i.e. the regularization and augmented Lagrangian methods, both of which are typically implemented in finite element/volume discretizations (Saramito & Wachs Reference Saramito and Wachs2017). Knowing the fact that, for an ideal viscoplastic fluid, the effective viscosity becomes infinite at the yield surface and within the plug, in the regularization approach the infinite viscosity is replaced by a very high value, following a viscosity function (Frigaard Reference Frigaard2019; Wachs Reference Wachs2019), e.g. as implemented in the well-known Papanastasiou regularization model (Putz, Frigaard & Martinez Reference Putz, Frigaard and Martinez2009). In the augmented Lagrangian method, on the other hand, the motion equations are formulated based on variational calculus and the flow solution is determined via an optimization algorithm (Saramito & Roquet Reference Saramito and Roquet2001). The augmented Lagrangian method has been enhanced in recent years to provide a faster solution convergence (Saramito Reference Saramito2016; Treskatis, Moyers-González & Price Reference Treskatis, Moyers-González and Price2016; Dimakopoulos et al. Reference Dimakopoulos, Makrigiorgos, Georgiou and Tsamopoulos2018). For instance, a fast converging and efficient algorithm based on a monolithic Newton solver for the augmented Lagrangian is proposed by Dimakopoulos et al. (Reference Dimakopoulos, Makrigiorgos, Georgiou and Tsamopoulos2018) and tested via solving for five benchmark problems. Recently proposed accelerated augmented Lagrangian methods have been evaluated by Treskatis et al. (Reference Treskatis, Roustaei, Frigaard and Wachs2018) and practical guides for efficient simulation of viscoplastic fluid flows have been presented.

While the augmented Lagrangian method is more accurate in capturing yield surfaces (Putz et al. Reference Putz, Frigaard and Martinez2009; Balmforth et al. Reference Balmforth, Frigaard and Ovarlez2014), the regularization method is generally faster (Muravleva et al. Reference Muravleva, Muravleva, Georgiou and Mitsoulis2010; Dimakopoulos, Pavlidis & Tsamopoulos Reference Dimakopoulos, Pavlidis and Tsamopoulos2013; Saramito & Wachs Reference Saramito and Wachs2017), making it suitable to deal with a large number of simulations. The Papanastasiou regularization model has been successfully used in numerous studies, e.g. to address the Poiseuille flow of viscoplastic fluids in ducts with wall slip (Damianou et al. Reference Damianou, Philippou, Kaoullas and Georgiou2014; Damianou & Georgiou Reference Damianou and Georgiou2014; Damianou, Kaoullas & Georgiou Reference Damianou, Kaoullas and Georgiou2016); in these works, the yield surfaces appearing at the centre and corners of the duct have been accurately captured.

The slip modelling for Newtonian fluid flows over SH groovy surfaces has been typically studied for two special cases, i.e. longitudinal and transverse groove configurations. In the former case, the flow direction is the same as that of the grooves and the effective slip length is given typically by ![]() ${\hat {b}_{{eff}}^\parallel }$. However, in the transverse groove configuration, the flow direction is perpendicular to that of the grooves and the effective slip length is usually symbolized by

${\hat {b}_{{eff}}^\parallel }$. However, in the transverse groove configuration, the flow direction is perpendicular to that of the grooves and the effective slip length is usually symbolized by ![]() ${\hat {b}_{{eff}}^\bot }$. For an ideal slippery condition on a liquid/gas interface (the Cassie state with no meniscus curvature), the pressure-driven flow has been studied by several researchers (Philip Reference Philip1972; Lauga & Stone Reference Lauga and Stone2003; Cottin-Bizonne et al. Reference Cottin-Bizonne, Barentin, Charlaix, Bocquet and Barrat2004) and the effective slip length has been formulated as

${\hat {b}_{{eff}}^\bot }$. For an ideal slippery condition on a liquid/gas interface (the Cassie state with no meniscus curvature), the pressure-driven flow has been studied by several researchers (Philip Reference Philip1972; Lauga & Stone Reference Lauga and Stone2003; Cottin-Bizonne et al. Reference Cottin-Bizonne, Barentin, Charlaix, Bocquet and Barrat2004) and the effective slip length has been formulated as ![]() $\hat {b}_{{eff}}^ \bot = ({\hat {L}}/{{2{\rm \pi} }})\ln [\sec({\rm \pi} \varphi/2)]$ (Belyaev & Vinogradova Reference Belyaev and Vinogradova2010), where

$\hat {b}_{{eff}}^ \bot = ({\hat {L}}/{{2{\rm \pi} }})\ln [\sec({\rm \pi} \varphi/2)]$ (Belyaev & Vinogradova Reference Belyaev and Vinogradova2010), where ![]() ${\hat {L}}$ is the periodicity length of the grooves and

${\hat {L}}$ is the periodicity length of the grooves and ![]() ${{\varphi }}$ is the fraction of the liquid/gas interface. A more realistic model called the gas cushion model has been originally presented by Vinogradova (Reference Vinogradova1995) to predict the local slip at the slipping area (i.e. the liquid/gas interface), in the form of

${{\varphi }}$ is the fraction of the liquid/gas interface. A more realistic model called the gas cushion model has been originally presented by Vinogradova (Reference Vinogradova1995) to predict the local slip at the slipping area (i.e. the liquid/gas interface), in the form of ![]() $\hat {b} = \hat {e}( {{\hat {\mu } }/{{{\hat {\mu } _a}}} - 1} ) \approx \hat {e}({\hat {\mu }}/{{{\hat {\mu }_a}}})$, where

$\hat {b} = \hat {e}( {{\hat {\mu } }/{{{\hat {\mu } _a}}} - 1} ) \approx \hat {e}({\hat {\mu }}/{{{\hat {\mu }_a}}})$, where ![]() ${\hat {e}}$ is the gas layer thickness, and

${\hat {e}}$ is the gas layer thickness, and ![]() ${\hat {\mu }}$ and

${\hat {\mu }}$ and ![]() ${\hat {\mu }_a}$ represent the liquid and gas viscosities, respectively. An effective slip length model for the pressure-driven flow of Newtonian fluids over rectangular stripes has been presented by Belyaev & Vinogradova (Reference Belyaev and Vinogradova2010), solving the Poisson and Laplace equations for the slip-induced perturbations of the streamfunction and vorticity, respectively, leading to formulas for the longitudinal and transverse slip lengths. The limits of thick and thin channels have been considered in the modelling of flows over groovy surfaces, albeit mainly for Newtonian fluids. For thick channels, Asmolov et al. (Reference Asmolov, Zhou, Schmid and Vinogradova2013b) have developed an effective slip length model for a Newtonian shear-driven flow over weakly slipping rectangular stripes. Assuming the local slip length to be small in comparison with the scale of the heterogeneities, they have perturbed the Stokes equation, considered a linear Navier slip model, and developed a Fourier series solution for the perturbation velocity, eventually allowing them to calculate the slip velocity and lengths using a stick–slip boundary condition. Schmieschek et al. (Reference Schmieschek, Belyaev, Harting and Vinogradova2012) have generalized a tensorial effective slip theory, initially developed for thick channels, to any channel thickness. They have considered an asymmetric flow (i.e. no slip at the upper wall and groovy structures at the lower wall), along with the perturbed Stokes equation and the Navier slip law, as the governing equations; this has led to a Fourier series solution yielding trigonometric dual series (with exact solutions at the limit of thin and thick channels), describing the complete physics of the slip. Several other analytical efforts have been made to address the flow of Newtonian fluids over SH surfaces, to which an interested reader can refer (Asmolov & Vinogradova Reference Asmolov and Vinogradova2012; Asmolov et al. Reference Asmolov, Schmieschek, Harting and Vinogradova2013a; Schönecker, Baier & Hardt Reference Schönecker, Baier and Hardt2014; Asmolov, Nizkaya & Vinogradova Reference Asmolov, Nizkaya and Vinogradova2020).

${\hat {\mu }_a}$ represent the liquid and gas viscosities, respectively. An effective slip length model for the pressure-driven flow of Newtonian fluids over rectangular stripes has been presented by Belyaev & Vinogradova (Reference Belyaev and Vinogradova2010), solving the Poisson and Laplace equations for the slip-induced perturbations of the streamfunction and vorticity, respectively, leading to formulas for the longitudinal and transverse slip lengths. The limits of thick and thin channels have been considered in the modelling of flows over groovy surfaces, albeit mainly for Newtonian fluids. For thick channels, Asmolov et al. (Reference Asmolov, Zhou, Schmid and Vinogradova2013b) have developed an effective slip length model for a Newtonian shear-driven flow over weakly slipping rectangular stripes. Assuming the local slip length to be small in comparison with the scale of the heterogeneities, they have perturbed the Stokes equation, considered a linear Navier slip model, and developed a Fourier series solution for the perturbation velocity, eventually allowing them to calculate the slip velocity and lengths using a stick–slip boundary condition. Schmieschek et al. (Reference Schmieschek, Belyaev, Harting and Vinogradova2012) have generalized a tensorial effective slip theory, initially developed for thick channels, to any channel thickness. They have considered an asymmetric flow (i.e. no slip at the upper wall and groovy structures at the lower wall), along with the perturbed Stokes equation and the Navier slip law, as the governing equations; this has led to a Fourier series solution yielding trigonometric dual series (with exact solutions at the limit of thin and thick channels), describing the complete physics of the slip. Several other analytical efforts have been made to address the flow of Newtonian fluids over SH surfaces, to which an interested reader can refer (Asmolov & Vinogradova Reference Asmolov and Vinogradova2012; Asmolov et al. Reference Asmolov, Schmieschek, Harting and Vinogradova2013a; Schönecker, Baier & Hardt Reference Schönecker, Baier and Hardt2014; Asmolov, Nizkaya & Vinogradova Reference Asmolov, Nizkaya and Vinogradova2020).

Using computational fluid dynamics tools (e.g. in-house codes, Fluent, COMSOL Multiphysics, OpenFOAM, etc.), there are several numerical studies addressing the flow of Newtonian fluids over SH textures. For instance, Cheng, Teo & Khoo (Reference Cheng, Teo and Khoo2009) have addressed a pressure-driven flow through channels with SH surfaces (patterned with square posts), using a combined finite volume–finite difference method. Davies et al. (Reference Davies, Maynes, Webb and Woolford2006) have performed numerical simulations of the flow through microchannels with SH walls having transverse ribs, reporting a significant decrease in the frictional pressure drop and an increase in the slip velocity compared with the classical Poiseuille flow with smooth walls. Ou & Rothstein (Reference Ou and Rothstein2005) have analysed similar flows over SH surfaces, finding good agreement between the results of their numerical simulations and those of micro-particle image velocimetry experiments. Priezjev, Darhuber & Troian (Reference Priezjev, Darhuber and Troian2005) have simulated Newtonian Couette flow with an SH patterned stationary wall, using both the finite element method (for solving the Navier–Stokes equations) and the molecular dynamics method (to quantify the effective slip length). They have reported a reasonable agreement between the results of these simulation methods when the ratio of the slip region width to the molecular diameter is large. A few studies have also considered shear-thinning flows over SH surfaces. For instance, using the Carreau–Yasuda model, Patlazhan & Vagner (Reference Patlazhan and Vagner2017) have numerically studied the apparent slip of shear-thinning fluids in microchannels with SH groovy walls. They have simplified the flow into three regions, i.e. the core region as well as the stick and slip thin regions, each with a different viscosity, resulting in an estimation of the effective slip length. Haase et al. (Reference Haase, Wood, Sprakel and Lammertink2017) have performed numerical simulations of a pressure-driven flow of a shear-thinning fluid over a bubble mattress, representing an SH surface on which no-slip walls and no-shear gas bubbles are transversely positioned. They have found a general increase in the effective slip length for their shear-thinning fluid in comparison with a Newtonian fluid. In addition to the aforementioned numerical studies, there are several other works attempting to numerically model the slip phenomenon over SH surfaces using molecular dynamics simulations (Cottin-Bizonne et al. Reference Cottin-Bizonne, Barentin, Charlaix, Bocquet and Barrat2004), dissipative particle dynamics methods (Asmolov et al. Reference Asmolov, Zhou, Schmid and Vinogradova2013b) and lattice Boltzmann simulations (Schmieschek et al. Reference Schmieschek, Belyaev, Harting and Vinogradova2012).

Our brief review of the relevant studies so far has revealed that the literature of fluid flows over SH surfaces is well developed for Newtonian fluids, covering various flow scenarios and SH surface configurations, using analytical, numerical and experimental approaches. However, in spite of numerous applications of non-Newtonian fluids over SH surfaces (Crowdy Reference Crowdy2017a; Haase et al. Reference Haase, Wood, Sprakel and Lammertink2017; Kim et al. Reference Kim, Lee, Kim and Kwak2021), the relevant literature is limited only to a few shear-thinning fluid studies. In fact, to the best of our knowledge, the flow of viscoplastic materials over SH surfaces, as an important category of non-Newtonian fluids, has not yet been fundamentally studied, despite its existing and potential applications (Burinaru et al. Reference Burinaru, Avram, Avram, Marculescu, Tincu, Tucureanu, Matei and Militaru2018; Gao et al. Reference Gao2020; Ijaola, Farayibi & Asmatulu Reference Ijaola, Farayibi and Asmatulu2020; Li et al. Reference Li, Tian, Gao, Qin, Pi, Li and Yang2021). Via analysing plane Poiseuille flow of a Bingham fluid in a channel with an SH groovy lower wall, in the current work, we attempt to address this problem for the first time. In particular, assuming a flat liquid/air interface (i.e. the Cassie state), we develop a semi-analytical model based on considering infinitesimal wall-induced perturbations in the flow system and, then, solving the resulting equations using the Fourier series expansion method. We also use complementary OpenFOAM direct numerical simulations (DNSs), to validate our semi-analytical model results and elucidate the flow details and physics. Our analysis, including a combination of semi-analytical and DNS solutions, is fairly comprehensive, as it considers a range of thicknesses for thick channels and both creeping and inertial flow regimes, while providing regime classifications. In our analysis, the channel thickness is defined using the ratio between the dimensional values of the groove period (![]() $\hat L$) and the half-channel height (

$\hat L$) and the half-channel height (![]() $\hat H$, see figure 1); when

$\hat H$, see figure 1); when ![]() $\hat H \gg \hat L$ the channel is assumed to be thick, while for

$\hat H \gg \hat L$ the channel is assumed to be thick, while for ![]() $\hat H \ll \hat L$ the channel is thin.

$\hat H \ll \hat L$ the channel is thin.

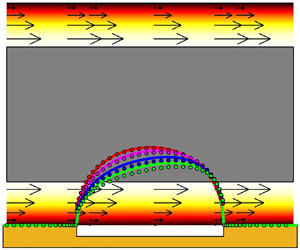

Figure 1. Schematic of the flow configuration. In this figure, dimensional geometrical parameters are shown. Here, and throughout the text, the dimensional parameters and variables are marked with ‘![]() $\hat {\ }$’ and the dimensionless ones without.

$\hat {\ }$’ and the dimensionless ones without.

The outline of the present work is as follows. Section 2 introduces the governing equations of our flow system. In § 3, the semi-analytical model is first developed for the perturbation fields of the creeping and inertial flow regimes, for the thick channel limit. The total flow profile is then calculated at the end of this section. Section 4 presents the method for the complementary DNSs, including the numerical schemes and set-up (the computational mesh is presented in § 3 of online supplementary material available at https://doi.org/10.1017/jfm.2022.700). The results of our analysis are presented in § 5, for the thick channel limit (via the semi-analytical and DNS solutions). Afterwards, a criterion for the unyielded plug zone formation at the SH wall, followed by a regime classification, are presented. Finally, § 6 presents the summary and concluding remarks of the paper.

2. Governing equations

This section presents the governing equations for our plane Poiseuille flow of a Bingham fluid, in a two-dimensional (2-D) channel with an SH lower wall. This asymmetric flow configuration (with the lower boundary as an SH groovy wall and the upper wall with the no-slip condition) is studied due to practical considerations: in practice, a channel with two symmetrically aligned groovy walls (typically micro-nano sized grooves) is difficult to construct (Schmieschek et al. Reference Schmieschek, Belyaev, Harting and Vinogradova2012). At the SH wall, the transverse groovy structure is considered, while the main flow direction is normal to the groove direction. The schematic of the flow under study is presented in figure 1. Based on this figure, ![]() $\hat L$ is the periodicity length of the grooves,

$\hat L$ is the periodicity length of the grooves, ![]() $\hat \delta$ represents the width of the liquid/air interface,

$\hat \delta$ represents the width of the liquid/air interface, ![]() $\hat h$ and

$\hat h$ and ![]() $\hat h^u$ are the SH wall distances from the lower and upper yield surfaces (i.e. the boundaries between the yielded zones and the unyielded centre plug zone), respectively, and

$\hat h^u$ are the SH wall distances from the lower and upper yield surfaces (i.e. the boundaries between the yielded zones and the unyielded centre plug zone), respectively, and ![]() $\hat H$ is the half-channel height. The coordinate origin is placed at the centre of the liquid/air interface on the SH wall.

$\hat H$ is the half-channel height. The coordinate origin is placed at the centre of the liquid/air interface on the SH wall.

The dimensionless continuity and momentum balance equations in two dimensions are presented as

where ![]() $t$ is the time and

$t$ is the time and ![]() ${\boldsymbol {U} = U {\boldsymbol {e}_x} + V {\boldsymbol {e}_y}}$ is the dimensionless velocity vector for which

${\boldsymbol {U} = U {\boldsymbol {e}_x} + V {\boldsymbol {e}_y}}$ is the dimensionless velocity vector for which ![]() $U$ and

$U$ and ![]() $V$ are the velocity components in the

$V$ are the velocity components in the ![]() $\boldsymbol {e}_x$ and

$\boldsymbol {e}_x$ and ![]() $\boldsymbol {e}_y$ directions, respectively. In addition, the other variables are the pressure (

$\boldsymbol {e}_y$ directions, respectively. In addition, the other variables are the pressure (![]() $P$) and the deviatoric stress tensor (

$P$) and the deviatoric stress tensor (![]() ${\boldsymbol {\tau }}$). To obtain the dimensionless form of the equations of motion, the half-channel height (

${\boldsymbol {\tau }}$). To obtain the dimensionless form of the equations of motion, the half-channel height (![]() $\hat H$) has been considered as the characteristic length and the average velocity (

$\hat H$) has been considered as the characteristic length and the average velocity (![]() $\hat U_{ave}$) as the characteristic velocity; the pressure and stress fields have been made dimensionless using the characteristic viscous stress, i.e.

$\hat U_{ave}$) as the characteristic velocity; the pressure and stress fields have been made dimensionless using the characteristic viscous stress, i.e. ![]() $\hat \tau _{ch}=\hat \mu _p ({\hat U_{ave}}/{\hat H})$, where

$\hat \tau _{ch}=\hat \mu _p ({\hat U_{ave}}/{\hat H})$, where ![]() $\hat \mu _p$ is the plastic viscosity. Subsequently, the Reynolds number is defined as

$\hat \mu _p$ is the plastic viscosity. Subsequently, the Reynolds number is defined as

where ![]() $\hat \rho$ is the fluid density.

$\hat \rho$ is the fluid density.

To model the viscoplastic fluid rheology, the Bingham constitutive equation is used. The dimensionless form of the Bingham model is presented as

\begin{equation}

\left. \begin{array}{c@{}} {\boldsymbol{\tau }} = \left( {1 +

\dfrac{Bi}{{\dot \gamma }}} \right) {\dot{\boldsymbol \gamma

}},\quad \tau > Bi,\\

\dot \gamma = 0, \quad \tau \le Bi,

\end{array} \right\}

\end{equation}

\begin{equation}

\left. \begin{array}{c@{}} {\boldsymbol{\tau }} = \left( {1 +

\dfrac{Bi}{{\dot \gamma }}} \right) {\dot{\boldsymbol \gamma

}},\quad \tau > Bi,\\

\dot \gamma = 0, \quad \tau \le Bi,

\end{array} \right\}

\end{equation}

where ![]() ${\dot {\boldsymbol \gamma } = \boldsymbol {\nabla } \boldsymbol {u} + {( {\boldsymbol {\nabla } \boldsymbol {u}} )^T}}$ is the strain-rate tensor, and

${\dot {\boldsymbol \gamma } = \boldsymbol {\nabla } \boldsymbol {u} + {( {\boldsymbol {\nabla } \boldsymbol {u}} )^T}}$ is the strain-rate tensor, and ![]() ${\tau = \sqrt {{{{\tau _{ij}}{\tau _{ij}}} /2}}}$ and

${\tau = \sqrt {{{{\tau _{ij}}{\tau _{ij}}} /2}}}$ and ![]() ${\dot \gamma = \sqrt {{{{{\dot \gamma }_{ij}}{{\dot \gamma }_{ij}}}/2}}}$ are the magnitudes of the stress and strain-rate tensors, respectively. The Bingham number, representing the ratio of the yield stress (

${\dot \gamma = \sqrt {{{{{\dot \gamma }_{ij}}{{\dot \gamma }_{ij}}}/2}}}$ are the magnitudes of the stress and strain-rate tensors, respectively. The Bingham number, representing the ratio of the yield stress (![]() ${{{\hat \tau _0}}}$) to the characteristic viscous stress (

${{{\hat \tau _0}}}$) to the characteristic viscous stress (![]() $\hat \tau _{ch}$), is defined as

$\hat \tau _{ch}$), is defined as

\begin{equation} Bi = \frac{{{\hat \tau _0}\hat H}}{{{{\hat \mu }_p}{{\hat U}_{ave}}}}. \end{equation}

\begin{equation} Bi = \frac{{{\hat \tau _0}\hat H}}{{{{\hat \mu }_p}{{\hat U}_{ave}}}}. \end{equation}2.1. No-slip Poiseuille–Bingham flow profile

For a laminar 2-D channel Poiseuille flow with no-slip conditions at both walls, the flow pressure (![]() $P_0$) and velocity (

$P_0$) and velocity (![]() $U_0$) can be analytically obtained, by solving the dimensionless equations (2.1) and (2.2). Due to the symmetry with respect to the channel axis in the no-slip condition case, it suffices to derive the solution for the lower half of the channel

$U_0$) can be analytically obtained, by solving the dimensionless equations (2.1) and (2.2). Due to the symmetry with respect to the channel axis in the no-slip condition case, it suffices to derive the solution for the lower half of the channel

where ![]() $C_1=\tau _w - Bi$,

$C_1=\tau _w - Bi$, ![]() $C_2=-{\tau _w}/{2}$ and

$C_2=-{\tau _w}/{2}$ and ![]() $C_3={(\tau _w - Bi)^2}/{2\tau _w}$. Here,

$C_3={(\tau _w - Bi)^2}/{2\tau _w}$. Here, ![]() $h$ is the location of the lower yield surface with respect to the lower wall. The wall shear stress,

$h$ is the location of the lower yield surface with respect to the lower wall. The wall shear stress, ![]() $\tau _w$ (at

$\tau _w$ (at ![]() $y=0$), is the largest positive root of the following equation (refer to Frigaard & Ryan (Reference Frigaard and Ryan2004) for a similar equation):

$y=0$), is the largest positive root of the following equation (refer to Frigaard & Ryan (Reference Frigaard and Ryan2004) for a similar equation):

After finding the wall shear stress (![]() $\tau _w$), the location of the lower yield surface (

$\tau _w$), the location of the lower yield surface (![]() $h$), representing the boundary between the lower yielded zone and the unyielded centre plug zone, can be calculated by

$h$), representing the boundary between the lower yielded zone and the unyielded centre plug zone, can be calculated by

2.2. Slip modelling

2.2.1. Slip origin

In our flow configuration, a layer of air trapped inside the wall grooves causes the bulk flow slippage on the liquid/air interface. On the other hand, the no-slip condition is considered for the liquid/solid contact at the SH wall and the upper wall. Shear stress at the flat liquid/air interface (i.e. the Cassie state assumption) is obtained as

where ![]() $\hat \tau _{la}$ and

$\hat \tau _{la}$ and ![]() ${{\hat u}_s}$ are the shear stress and the slip velocity at the liquid/air interface, respectively. Also,

${{\hat u}_s}$ are the shear stress and the slip velocity at the liquid/air interface, respectively. Also, ![]() $\hat \mu _a$ is the dynamic viscosity of air and

$\hat \mu _a$ is the dynamic viscosity of air and ![]() ${\hat \varepsilon }$ represents an average characteristic length for the air layer through which the air velocity reaches zero. Based on (2.10), the linear Navier slip law at the liquid/air interface is retrieved

${\hat \varepsilon }$ represents an average characteristic length for the air layer through which the air velocity reaches zero. Based on (2.10), the linear Navier slip law at the liquid/air interface is retrieved

In our study, ![]() $\hat b$ is called the dimensional slip number and, as a parameter, it is generally dependent on the air flow dynamics inside the grooves. In particular, the slip number is strongly dependent on the value of

$\hat b$ is called the dimensional slip number and, as a parameter, it is generally dependent on the air flow dynamics inside the grooves. In particular, the slip number is strongly dependent on the value of ![]() $\hat \varepsilon$, while this value is under the influence of the Poiseuille flow dynamics inside the channel. To be more specific, the shear stress at the liquid/air interface affects the air flow dynamics inside the grooves; thus, it changes the values of

$\hat \varepsilon$, while this value is under the influence of the Poiseuille flow dynamics inside the channel. To be more specific, the shear stress at the liquid/air interface affects the air flow dynamics inside the grooves; thus, it changes the values of ![]() $\hat \varepsilon$ and, eventually, the slip number. Considering a groove as a cavity inside which air flows,

$\hat \varepsilon$ and, eventually, the slip number. Considering a groove as a cavity inside which air flows, ![]() $\hat \varepsilon$ can be affected by the groove dimensions as well. Throughout our study, we simply work with the slip number and use a wide range of values for it, to be able to cover any possible scenario regarding the values/ranges of

$\hat \varepsilon$ can be affected by the groove dimensions as well. Throughout our study, we simply work with the slip number and use a wide range of values for it, to be able to cover any possible scenario regarding the values/ranges of ![]() $\hat \varepsilon$.

$\hat \varepsilon$.

2.2.2. Slip model

Considering the continuity of the shear stress at the liquid/air interface, we rewrite equation (2.11) based on the shear stress of the Bingham fluid at the liquid/air interface, i.e. ![]() ${\hat \tau _{la}} = {\hat \mu _{la}}{\hat {\dot {\gamma }}_{xy}}$, to find the following equation:

${\hat \tau _{la}} = {\hat \mu _{la}}{\hat {\dot {\gamma }}_{xy}}$, to find the following equation:

where ![]() ${\hat {\dot {\gamma }}_{xy}}$ is the flow shear strain rate at the liquid/air interface for the Bingham fluid. In addition,

${\hat {\dot {\gamma }}_{xy}}$ is the flow shear strain rate at the liquid/air interface for the Bingham fluid. In addition, ![]() ${\hat \mu _{la}}$ is the general viscosity of the Bingham fluid at the liquid/air interface, defined as

${\hat \mu _{la}}$ is the general viscosity of the Bingham fluid at the liquid/air interface, defined as

where ![]() ${\hat {\dot {\gamma }}_{la}}$ is the magnitude of the flow strain rate at the liquid/air interface (for the Bingham fluid). Substituting equation (2.13) into (2.12), the following relation is obtained:

${\hat {\dot {\gamma }}_{la}}$ is the magnitude of the flow strain rate at the liquid/air interface (for the Bingham fluid). Substituting equation (2.13) into (2.12), the following relation is obtained:

Making the above equation dimensionless, one can obtain

where the dimensionless slip number, ![]() $b$, is defined as:

$b$, is defined as:

3. Semi-analytical model

In this section, our semi-analytical model is developed, at the steady-state condition, for plane Poiseuille flow of a Bingham fluid, considering an SH groovy lower wall. The model is developed for the flow in the thick channel limit, where the lower yield surface is assumed to be flat. The solution is obtained based on perturbing the lower yielded zone, via infinitesimal perturbations. Consequently, the perturbed governing equations for the lower yielded zone are solved. To be comprehensive and systematic, a semi-analytical model is first developed for the creeping flow regime (§ 3.1), where the inertial terms are negligible in the momentum balance equation. Then, the semi-analytical model is extended to include the inertial flow regime (§ 3.2), where a simplified version of the momentum balance equation is assumed to govern the flow physics. After presenting the perturbation fields in both creeping and inertial regimes, the total velocity profile is presented (§ 3.3). For the simplicity of the analysis, throughout our semi-analytical derivation, the Bingham fluid is assumed to have only a single unyielded region, i.e. the plug formed around the channel centreline. Therefore, the solutions derived in §§ 3.1 and 3.2 concern the yielded region only, while § 3.3 gives the total velocity for both yielded and unyielded regions.

3.1. Creeping flow

At small Reynolds numbers (![]() $Re \ll 1$), the momentum balance equation governs a creeping flow motion. The SH groovy wall induces infinitesimal perturbations in the flow, which eventually vanish at the lower yield surface (which is assumed to be flat for the thick channel limit). The flow field can be perturbed based on the no-slip Poiseuille flow, i.e.

$Re \ll 1$), the momentum balance equation governs a creeping flow motion. The SH groovy wall induces infinitesimal perturbations in the flow, which eventually vanish at the lower yield surface (which is assumed to be flat for the thick channel limit). The flow field can be perturbed based on the no-slip Poiseuille flow, i.e. ![]() $\boldsymbol {U}=\boldsymbol {U}_0+\epsilon \boldsymbol {u}$ and

$\boldsymbol {U}=\boldsymbol {U}_0+\epsilon \boldsymbol {u}$ and ![]() $P=P_0 +\epsilon p$, where

$P=P_0 +\epsilon p$, where ![]() $\boldsymbol {u}$ and

$\boldsymbol {u}$ and ![]() $p$ are the perturbation velocity and pressure, respectively, and

$p$ are the perturbation velocity and pressure, respectively, and ![]() $\boldsymbol {U}$ and

$\boldsymbol {U}$ and ![]() $P$ are the total velocity and pressure, respectively. The perturbation velocity vector, i.e.

$P$ are the total velocity and pressure, respectively. The perturbation velocity vector, i.e. ![]() $\boldsymbol {u}=u {\boldsymbol {e}_x}+v {\boldsymbol {e}_y}$, has two components in the

$\boldsymbol {u}=u {\boldsymbol {e}_x}+v {\boldsymbol {e}_y}$, has two components in the ![]() $x$ and

$x$ and ![]() $y$ directions, i.e.

$y$ directions, i.e. ![]() $u$ and

$u$ and ![]() $v$, respectively. For the thick channel limit, the perturbation parameter can be defined as

$v$, respectively. For the thick channel limit, the perturbation parameter can be defined as ![]() $\epsilon = \kappa ^{-1}$, where

$\epsilon = \kappa ^{-1}$, where ![]() $\kappa$ is the wavenumber of the groovy SH wall (

$\kappa$ is the wavenumber of the groovy SH wall (![]() $\kappa =2{\rm \pi} /\ell$ and

$\kappa =2{\rm \pi} /\ell$ and ![]() $\ell =\hat L/\hat H$).

$\ell =\hat L/\hat H$).

Considering infinitesimal wall-induced perturbations, an anisotropic perturbation stress tensor for the Bingham fluid can be derived, for which the components are shown at the leading order as (Frigaard, Howison & Sobey Reference Frigaard, Howison and Sobey1994; Nouar et al. Reference Nouar, Kabouya, Dusek and Mamou2007)

where ![]() $d$ is the ordinary derivative operator and

$d$ is the ordinary derivative operator and ![]() $i,j$ refer to the components of the coordinate system.

$i,j$ refer to the components of the coordinate system.

Imposing infinitesimal wall-induced perturbations in the momentum balance equation and having the perturbation stress components for the Bingham fluid (shown in (3.1) and (3.2)), we can derive the perturbation equations in the ![]() $x$ and

$x$ and ![]() $y$ directions. We should recall that the perturbation parameter is dropped in the obtained perturbation equations; thus, we do not consider it in the following formulations and calculations. Taking the curl of the perturbed equations and using the definition of the streamfunction for the perturbation field (

$y$ directions. We should recall that the perturbation parameter is dropped in the obtained perturbation equations; thus, we do not consider it in the following formulations and calculations. Taking the curl of the perturbed equations and using the definition of the streamfunction for the perturbation field (![]() $u = {{\partial \psi }}/{{\partial y}}$ and

$u = {{\partial \psi }}/{{\partial y}}$ and ![]() $v = - {{\partial \psi }}/{{\partial x}}$), we obtain a fourth-order partial differential equation for the perturbation streamfunction

$v = - {{\partial \psi }}/{{\partial x}}$), we obtain a fourth-order partial differential equation for the perturbation streamfunction

It is assumed that the perturbation field is periodic in the ![]() $x$ direction, with the period of the SH wall, i.e.

$x$ direction, with the period of the SH wall, i.e. ![]() $\ell ={\hat L}/{\hat H}$; thus, the solution for the perturbation streamfunction can be written in a Fourier series form for the

$\ell ={\hat L}/{\hat H}$; thus, the solution for the perturbation streamfunction can be written in a Fourier series form for the ![]() $x$ component

$x$ component

\begin{equation} \psi (x,y) = \sum_{n ={-} \infty }^\infty {A_n}{\hat \psi } (n,y)\,{{\rm e}^{{\rm i}n\kappa x}}, \end{equation}

\begin{equation} \psi (x,y) = \sum_{n ={-} \infty }^\infty {A_n}{\hat \psi } (n,y)\,{{\rm e}^{{\rm i}n\kappa x}}, \end{equation}

where ![]() $\kappa ={2{\rm \pi} }/{\ell }$, representing the wavenumber for the SH groovy wall and

$\kappa ={2{\rm \pi} }/{\ell }$, representing the wavenumber for the SH groovy wall and ![]() $A_n$ are the unknown coefficients.

$A_n$ are the unknown coefficients.

Before proceeding, note that in our analysis we have assumed that the period of the perturbed flow is the same as the period of the SH surface. This assumption follows several previous studies through the literature regarding the flow of Newtonian fluids over SH surfaces with periodic microstructures (Lauga & Stone Reference Lauga and Stone2003; Belyaev & Vinogradova Reference Belyaev and Vinogradova2010; Asmolov & Vinogradova Reference Asmolov and Vinogradova2012; Schmieschek et al. Reference Schmieschek, Belyaev, Harting and Vinogradova2012; Schnitzer & Yariv Reference Schnitzer and Yariv2017). However, we should also mention that this assumption may not be always valid. In other words, considering the flow period to be the same as the period of geometry is an assumption that requires further examination, e.g. through the Floquet–Bloch theory (Pettas et al. Reference Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2019; Marousis et al. Reference Marousis, Pettas, Karapetsas, Dimakopoulos and Tsamopoulos2021; Rohan, Nguyen & Naili Reference Rohan, Nguyen and Naili2021).

Substituting equation (3.4) into (3.3), while substituting for ![]() ${{{\textrm {d}{U_0}}/{\textrm {d}y}}}$ and

${{{\textrm {d}{U_0}}/{\textrm {d}y}}}$ and ![]() ${{{{\textrm {d}^2}{U_0}}/{\textrm {d}{y^2}}}}$ from (2.7), we obtain a fourth-order ordinary differential equation for

${{{{\textrm {d}^2}{U_0}}/{\textrm {d}{y^2}}}}$ from (2.7), we obtain a fourth-order ordinary differential equation for ![]() ${\hat \psi }$

${\hat \psi }$

\begin{equation} \frac{{{{\rm d}^4}\hat \psi }}{{{\rm d}{y^4}}} - \left( {2 + \frac{{4Bi}}{{{C_1} + 2{C_2}y}}} \right){n^2}{\kappa^2} \frac{{{{\rm d}^2}\hat \psi }}{{{\rm d}{y^2}}} + 8Bi{n^2}{\kappa ^2}\frac{{{C_2}}}{{{{( {{C_1} + 2{C_2}y} )}^2}}} \frac{{{\rm d}\hat \psi }}{{{\rm d} y}} + {n^4}{\kappa ^4} \hat \psi = 0.\end{equation}

\begin{equation} \frac{{{{\rm d}^4}\hat \psi }}{{{\rm d}{y^4}}} - \left( {2 + \frac{{4Bi}}{{{C_1} + 2{C_2}y}}} \right){n^2}{\kappa^2} \frac{{{{\rm d}^2}\hat \psi }}{{{\rm d}{y^2}}} + 8Bi{n^2}{\kappa ^2}\frac{{{C_2}}}{{{{( {{C_1} + 2{C_2}y} )}^2}}} \frac{{{\rm d}\hat \psi }}{{{\rm d} y}} + {n^4}{\kappa ^4} \hat \psi = 0.\end{equation}

To close the boundary value problem, the following boundary conditions are considered (![]() $n \ne 0$):

$n \ne 0$):

Let us clarify the boundary conditions introduced above in (3.6a–d), which are derived for non-zero modes of the Fourier expansion, i.e. ![]() $n \ne 0$. Generally, the boundary conditions for our problem originate from the following: (i) the no-penetration condition at the SH wall (i.e.

$n \ne 0$. Generally, the boundary conditions for our problem originate from the following: (i) the no-penetration condition at the SH wall (i.e. ![]() $v=0$ at

$v=0$ at ![]() $y=0$); (ii) the zero perturbation velocity at the lower yield surface, i.e.

$y=0$); (ii) the zero perturbation velocity at the lower yield surface, i.e. ![]() $u=0$ and

$u=0$ and ![]() $v=0$ at

$v=0$ at ![]() $y=h$ (Frigaard et al. Reference Frigaard, Howison and Sobey1994; Nouar et al. Reference Nouar, Kabouya, Dusek and Mamou2007); (iii) the slip–stick condition at the SH wall. For

$y=h$ (Frigaard et al. Reference Frigaard, Howison and Sobey1994; Nouar et al. Reference Nouar, Kabouya, Dusek and Mamou2007); (iii) the slip–stick condition at the SH wall. For ![]() $n=0$, (3.5) reduces to

$n=0$, (3.5) reduces to ![]() ${{{\textrm {d}^4}\hat \psi }}/{{\textrm {d} {y^4}}}=0$, which has a quadratic function solution, the general form of which can be obtained using the no-penetration condition at

${{{\textrm {d}^4}\hat \psi }}/{{\textrm {d} {y^4}}}=0$, which has a quadratic function solution, the general form of which can be obtained using the no-penetration condition at ![]() $y=0$ and the zero perturbation velocities at

$y=0$ and the zero perturbation velocities at ![]() ${y=h}$, as boundary conditions. The first condition in (3.6a–d) satisfies the no-penetration requirement at the SH wall for the non-zero Fourier terms. Since the zero-term solution of

${y=h}$, as boundary conditions. The first condition in (3.6a–d) satisfies the no-penetration requirement at the SH wall for the non-zero Fourier terms. Since the zero-term solution of ![]() $\psi$ is only a function of

$\psi$ is only a function of ![]() $y$, the zero-term solution of

$y$, the zero-term solution of ![]() $v$ is always zero. Therefore, the first condition that is applied to the non-zero Fourier modes is sufficient to satisfy the no-penetration requirement at the SH wall. In a same way, the second boundary condition ensures having

$v$ is always zero. Therefore, the first condition that is applied to the non-zero Fourier modes is sufficient to satisfy the no-penetration requirement at the SH wall. In a same way, the second boundary condition ensures having ![]() $v=0$ at the lower yield surface. The third boundary condition also ensures a zero streamwise perturbation velocity (

$v=0$ at the lower yield surface. The third boundary condition also ensures a zero streamwise perturbation velocity (![]() $u=0$) at the lower yield surface. Finally, the fourth boundary condition implies that the perturbation field rapidly decays away from the SH wall in the

$u=0$) at the lower yield surface. Finally, the fourth boundary condition implies that the perturbation field rapidly decays away from the SH wall in the ![]() $y$ direction for the flow in the thick channel limit, consistent with the assumption of a flat lower yield surface. In other words, assuming a flat lower yield surface and a zero strain-rate magnitude at the yield surface for the Bingham fluids (see (2.4)) implies that each single non-zero Fourier mode of the perturbation shear gradient at the lower yield surface must vanish (as the yield surface is flat and its location is independent of

$y$ direction for the flow in the thick channel limit, consistent with the assumption of a flat lower yield surface. In other words, assuming a flat lower yield surface and a zero strain-rate magnitude at the yield surface for the Bingham fluids (see (2.4)) implies that each single non-zero Fourier mode of the perturbation shear gradient at the lower yield surface must vanish (as the yield surface is flat and its location is independent of ![]() $x$).

$x$).

Equation (3.5) with the boundary conditions (3.6a–d) can be solved numerically for thick channels. For the numerical scheme, a system of nonlinear equations is set up and solved using a Runge–Kutta collocation method combined with a Newton method, which is a fourth-order integration scheme to solve boundary value problems. The bvp4c routine in MATLAB R2020a is used to implement the method and discretize our system of nonlinear equations. Note that, as explained further below, in our flow configuration, ![]() $h$ is generally unknown and it is found based on an iterative method, using an initial value based on the no-slip Poiseuille–Bingham channel flow.

$h$ is generally unknown and it is found based on an iterative method, using an initial value based on the no-slip Poiseuille–Bingham channel flow.

Considering ![]() $\hat \psi _n (y) = f_n(y)$ (for

$\hat \psi _n (y) = f_n(y)$ (for ![]() $n > 0$) and combining the zero and non-zero Fourier mode solutions, we write the simplified closed form solution of the perturbation streamfunction and velocities as

$n > 0$) and combining the zero and non-zero Fourier mode solutions, we write the simplified closed form solution of the perturbation streamfunction and velocities as

\begin{gather} \psi (x,y) = {A_0}\left( {y - \frac{{{y^2}}}{{2h}}} \right) + \sum_{n = 1}^\infty {{A_n}} {f_n}(y)\cos ( {n\kappa x} ), \end{gather}

\begin{gather} \psi (x,y) = {A_0}\left( {y - \frac{{{y^2}}}{{2h}}} \right) + \sum_{n = 1}^\infty {{A_n}} {f_n}(y)\cos ( {n\kappa x} ), \end{gather} \begin{gather}u(x,y) = {A_0}\left( {1 - \frac{y}{h}} \right) + \sum_{n = 1}^\infty {{A_n}} {{f'_n}}(y)\cos ( {n\kappa x} ), \end{gather}

\begin{gather}u(x,y) = {A_0}\left( {1 - \frac{y}{h}} \right) + \sum_{n = 1}^\infty {{A_n}} {{f'_n}}(y)\cos ( {n\kappa x} ), \end{gather} \begin{gather}v(x,y) = \sum_{n = 1}^\infty {{A_n}n\kappa } {f_n}(y)\sin ( {n\kappa x} ), \end{gather}

\begin{gather}v(x,y) = \sum_{n = 1}^\infty {{A_n}n\kappa } {f_n}(y)\sin ( {n\kappa x} ), \end{gather}

where ![]() $'$ denotes the first derivative with respect to

$'$ denotes the first derivative with respect to ![]() $y$; also,

$y$; also, ![]() $A_n (n=0,1,2,\ldots$) are unknown coefficients, which are obtained based on the slip–stick boundary condition.

$A_n (n=0,1,2,\ldots$) are unknown coefficients, which are obtained based on the slip–stick boundary condition.

The linear Navier slip law with a local slip number (![]() $b$) is considered for the liquid/air interface at the groovy wall, while the no-slip condition is assumed for the liquid/solid interface. Consequently, the following boundary conditions are obtained at the groovy wall:

$b$) is considered for the liquid/air interface at the groovy wall, while the no-slip condition is assumed for the liquid/solid interface. Consequently, the following boundary conditions are obtained at the groovy wall:

where ![]() $\varphi = {\hat \delta }/{\hat L}$ represents the fraction of one groove that is exposed to slip (also called the slip area fraction). Substituting equations (2.7) and (3.8) into (3.10) and (3.11), we have

$\varphi = {\hat \delta }/{\hat L}$ represents the fraction of one groove that is exposed to slip (also called the slip area fraction). Substituting equations (2.7) and (3.8) into (3.10) and (3.11), we have

\begin{gather}

{A_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^\infty

{{A_n}} [ {{{f'_n}}(0) - b{{f''_n}}(0)} ]\cos ( {n\kappa x}

) = b( {Bi + {C_1}} ), \quad 0 \leq x \leq \frac{\varphi

\ell}{2}, \end{gather}

\begin{gather}

{A_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^\infty

{{A_n}} [ {{{f'_n}}(0) - b{{f''_n}}(0)} ]\cos ( {n\kappa x}

) = b( {Bi + {C_1}} ), \quad 0 \leq x \leq \frac{\varphi

\ell}{2}, \end{gather} \begin{gather}{A_0} +

\sum_{n = 1}^\infty {{A_n}} {{f'_n}}(0)\cos ( {n\kappa x} )

= 0, \quad \frac{\varphi \ell}{2} \leq x \leq

\frac{\ell}{2},

\end{gather}

\begin{gather}{A_0} +

\sum_{n = 1}^\infty {{A_n}} {{f'_n}}(0)\cos ( {n\kappa x} )

= 0, \quad \frac{\varphi \ell}{2} \leq x \leq

\frac{\ell}{2},

\end{gather}

where ![]() $''$ refers to the second derivative with respect to

$''$ refers to the second derivative with respect to ![]() $y$.

$y$.

Equations (3.12) and (3.13) represent a dual series problem and, in contrast to their corresponding dual series for Newtonian fluids in the thick and thin channel limits, they have no closed form solution in their present form (see Sneddon Reference Sneddon1966; Belyaev & Vinogradova Reference Belyaev and Vinogradova2010). However, (3.12) and (3.13) can be solved using a similar technique to that used in Schmieschek et al. (Reference Schmieschek, Belyaev, Harting and Vinogradova2012):

(i) Equation (3.12) is integrated in

$[0\ x]$ and then multiplied by

$[0\ x]$ and then multiplied by  ${\sin }(m\kappa x)$, where

${\sin }(m\kappa x)$, where  $m$ is a positive integer. Afterwards, the obtained equation is integrated in

$m$ is a positive integer. Afterwards, the obtained equation is integrated in  $[0\ {\varphi \ell }/{2}]$.

$[0\ {\varphi \ell }/{2}]$.(ii) Equation (3.13) is multiplied by

${\cos }(m\kappa x)$ and then integrated in

${\cos }(m\kappa x)$ and then integrated in  $[{\varphi \ell }/{2}\ {\ell }/{2}]$.

$[{\varphi \ell }/{2}\ {\ell }/{2}]$.

Subsequently, a system of linear equations is obtained

\begin{equation} \sum_{n = 0}^N {{P_{mn}}{A_n}} = {M_m},\end{equation}

\begin{equation} \sum_{n = 0}^N {{P_{mn}}{A_n}} = {M_m},\end{equation}

in which ![]() $A_n (n=0,\ldots,N$) are the unknown coefficients. The coefficient and constant matrices for (3.14) are obtained as follows:

$A_n (n=0,\ldots,N$) are the unknown coefficients. The coefficient and constant matrices for (3.14) are obtained as follows:

\begin{gather} {P_{m0}} = \left( {1 + \frac{b}{h}} \right)\int_0^{{\varphi \ell}/{2}} {x\sin (m\kappa x)\,{{\rm d}\,x} }+ \int_{{\varphi\ell}/{2}}^{{\ell}/{2}}{\cos (m\kappa x)\,{{\rm d}\,x}}, \end{gather}

\begin{gather} {P_{m0}} = \left( {1 + \frac{b}{h}} \right)\int_0^{{\varphi \ell}/{2}} {x\sin (m\kappa x)\,{{\rm d}\,x} }+ \int_{{\varphi\ell}/{2}}^{{\ell}/{2}}{\cos (m\kappa x)\,{{\rm d}\,x}}, \end{gather} \begin{gather}{P_{mn}}

= \frac{1}{{n\kappa }}[ {{{f'_n}}(0) - b{{f''_n}}(0)} ]

\int_0^{{{\varphi \ell}}/{2}} \sin ( {n\kappa x} ) \sin

(m\kappa x)\,{{\rm d}\,x}\nonumber\\

\quad + {{f'_n}}(0)\int_{{{\varphi

\ell}}/{2}}^{{\ell}/{2}} {\cos ( {n\kappa x} )\cos (m\kappa

x)\,{{\rm d}\,x}},

\end{gather}

\begin{gather}{P_{mn}}

= \frac{1}{{n\kappa }}[ {{{f'_n}}(0) - b{{f''_n}}(0)} ]

\int_0^{{{\varphi \ell}}/{2}} \sin ( {n\kappa x} ) \sin

(m\kappa x)\,{{\rm d}\,x}\nonumber\\

\quad + {{f'_n}}(0)\int_{{{\varphi

\ell}}/{2}}^{{\ell}/{2}} {\cos ( {n\kappa x} )\cos (m\kappa

x)\,{{\rm d}\,x}},

\end{gather} Solving the system of linear equations (3.14), we can calculate the unknown coefficients of the solution, i.e. ![]() $A_n$. However, for our viscoplastic flow configuration, we need an extra iterative approach in order to calculate the location of the lower yield surface (

$A_n$. However, for our viscoplastic flow configuration, we need an extra iterative approach in order to calculate the location of the lower yield surface (![]() $h$), which is affected by the slip condition at the SH wall; as we increase the slip number, we may expect the yield surface to move towards the SH wall.

$h$), which is affected by the slip condition at the SH wall; as we increase the slip number, we may expect the yield surface to move towards the SH wall.

Considering the total flow obtained for the lower yielded zone, the magnitude of the strain rate is now calculated as

\begin{equation} \dot \gamma = \sqrt {{{\left( {\frac{{\partial U}}{{\partial y}} + \frac{{\partial V}}{{\partial x}}} \right)}^2} + 4{{\left( {\frac{{\partial U}}{{\partial x}}}\right)}^2}},\end{equation}

\begin{equation} \dot \gamma = \sqrt {{{\left( {\frac{{\partial U}}{{\partial y}} + \frac{{\partial V}}{{\partial x}}} \right)}^2} + 4{{\left( {\frac{{\partial U}}{{\partial x}}}\right)}^2}},\end{equation}

where ![]() $U=U_0+u$ and

$U=U_0+u$ and ![]() $V=v$.

$V=v$.

According to the Bingham model, at the yield surface, ![]() $\dot \gamma$ must vanish. Having zero perturbation velocities at the lower yield surface implies that

$\dot \gamma$ must vanish. Having zero perturbation velocities at the lower yield surface implies that ![]() ${{\partial U}/{\partial x}}$ and

${{\partial U}/{\partial x}}$ and ![]() ${{\partial V}/{\partial x}}$ are always zero at

${{\partial V}/{\partial x}}$ are always zero at ![]() $y=h$. Therefore, the only requirement at the yield surface is to have

$y=h$. Therefore, the only requirement at the yield surface is to have ![]() ${{\partial U}/{\partial y}}=0$. To obtain this, in every iteration we start the solution process from (3.5) and, after solving the followed system of linear equations (3.14), we then check for the new location of the yield surface (new

${{\partial U}/{\partial y}}=0$. To obtain this, in every iteration we start the solution process from (3.5) and, after solving the followed system of linear equations (3.14), we then check for the new location of the yield surface (new ![]() $h$) at which

$h$) at which ![]() ${{\partial U}/{\partial y}}=0$; we subsequently update the value of

${{\partial U}/{\partial y}}=0$; we subsequently update the value of ![]() $h$. This iterative approach continues until reaching a converged value for

$h$. This iterative approach continues until reaching a converged value for ![]() $h$ such that

$h$ such that ![]() $\left|{{h_{new}} - {h_{old}}}\right|<eps$. We realize that for

$\left|{{h_{new}} - {h_{old}}}\right|<eps$. We realize that for ![]() $eps=10^{-6}$, only five to six iterations and for

$eps=10^{-6}$, only five to six iterations and for ![]() $eps=10^{-4}$ only two to three iterations are required in most cases to obtain the converged solution.

$eps=10^{-4}$ only two to three iterations are required in most cases to obtain the converged solution.

Before we proceed, let us note that certain flow assumptions may allow us to develop an approximate solution for the thick channel flows, presented in § 1 of the online supplementary material, for the sake of completeness of the current study.

3.2. Inertial flow

In this section, we extend the semi-analytical model to account for inertial flows in the thick channel limit. To do so, we take advantage of the same method developed for the creeping flow regime (§ 3.1) to calculate the perturbation field. Therefore, we again consider the solution to be a superposition of the no-slip profile and the infinitesimal perturbation field induced by the SH groovy wall. Perturbing equations (2.1) and (2.2) with infinitesimal wall-induced perturbations and solving for the leading-order terms (i.e. by ignoring the nonlinear perturbed advection terms), we end up with the following equation for the perturbation streamfunction in the (![]() $x,y$) coordinate:

$x,y$) coordinate:

\begin{align} &Re\left( {{U_0}\left( {\frac{{{\partial^3}\psi }}{{\partial x\partial {y^2}}} + \frac{{{\partial^3}\psi }}{{\partial {x^3}}}} \right) - \frac{{{{\rm d}^2}{U_0}}}{{{\rm d} {y^2}}} \frac{{\partial \psi }}{{\partial x}}} \right) = \frac{{{\partial^4}\psi }}{{\partial {x^4}}} + \frac{{{\partial^4}\psi }}{{\partial {y^4}}}\nonumber\\ &\quad + \left( {2 + \frac{{4Bi}}{{| {{{{\rm d}{U_0}}/{{\rm d} y}}} |}}} \right)\frac{{{\partial^4}\psi }}{{\partial {x^2}\partial {y^2}}}- 4Bi\frac{{{{{{\rm d}^2}{U_0}}/{{\rm d} {y^2}}}}}{{{{({{{{\rm d}{U_0}} /{{\rm d} y}}})}^2}}}\frac{{{\partial^3}\psi }}{{\partial{x^2} \partial y}}. \end{align}

\begin{align} &Re\left( {{U_0}\left( {\frac{{{\partial^3}\psi }}{{\partial x\partial {y^2}}} + \frac{{{\partial^3}\psi }}{{\partial {x^3}}}} \right) - \frac{{{{\rm d}^2}{U_0}}}{{{\rm d} {y^2}}} \frac{{\partial \psi }}{{\partial x}}} \right) = \frac{{{\partial^4}\psi }}{{\partial {x^4}}} + \frac{{{\partial^4}\psi }}{{\partial {y^4}}}\nonumber\\ &\quad + \left( {2 + \frac{{4Bi}}{{| {{{{\rm d}{U_0}}/{{\rm d} y}}} |}}} \right)\frac{{{\partial^4}\psi }}{{\partial {x^2}\partial {y^2}}}- 4Bi\frac{{{{{{\rm d}^2}{U_0}}/{{\rm d} {y^2}}}}}{{{{({{{{\rm d}{U_0}} /{{\rm d} y}}})}^2}}}\frac{{{\partial^3}\psi }}{{\partial{x^2} \partial y}}. \end{align}

Assuming a periodic flow in the ![]() $x$ direction (with the same period as that of the SH wall), we rely on a Fourier series solution in the form of (3.4). Therefore, (3.19) is converted to an ordinary differential equation

$x$ direction (with the same period as that of the SH wall), we rely on a Fourier series solution in the form of (3.4). Therefore, (3.19) is converted to an ordinary differential equation

\begin{align} &\frac{{{{\rm d}^4}\hat \psi }}{{{\rm d} {y^4}}} - \left[ {\left( {2 + \frac{{4Bi}}{{{C_1} + 2{C_2}y}}} \right){n^2}{\kappa ^2} + {\rm i}n\kappa Re ( {{C_1}y + {C_2}{y^2}} )} \right]\frac{{{{\rm d}^2}\hat \psi }}{{{\rm d} {y^2}}} \nonumber\\ &\quad + 8Bi{n^2}{\kappa ^2}\frac{{{C_2}}}{{{{( {{C_1} + 2{C_2}y} )}^2}}}\frac{{{\rm d} \hat \psi }}{{{\rm d} y}} + [{{n^4}{\kappa ^4} + i{n^3}{\kappa ^3}Re( {{C_1}y + {C_2}{y^2}} ) + i2n\kappa {C_2}Re} ]\hat \psi = 0. \end{align}

\begin{align} &\frac{{{{\rm d}^4}\hat \psi }}{{{\rm d} {y^4}}} - \left[ {\left( {2 + \frac{{4Bi}}{{{C_1} + 2{C_2}y}}} \right){n^2}{\kappa ^2} + {\rm i}n\kappa Re ( {{C_1}y + {C_2}{y^2}} )} \right]\frac{{{{\rm d}^2}\hat \psi }}{{{\rm d} {y^2}}} \nonumber\\ &\quad + 8Bi{n^2}{\kappa ^2}\frac{{{C_2}}}{{{{( {{C_1} + 2{C_2}y} )}^2}}}\frac{{{\rm d} \hat \psi }}{{{\rm d} y}} + [{{n^4}{\kappa ^4} + i{n^3}{\kappa ^3}Re( {{C_1}y + {C_2}{y^2}} ) + i2n\kappa {C_2}Re} ]\hat \psi = 0. \end{align} Equation (3.20) together with the boundary conditions of (3.6a–d) is solved using the same algorithm explained earlier (see § 3.1). For ![]() $n=0$, we have the same quadratic solution for

$n=0$, we have the same quadratic solution for ![]() $\hat \psi$ as in the previous section. For

$\hat \psi$ as in the previous section. For ![]() $n>0$, we assume that the solution of (3.20) can be written as

$n>0$, we assume that the solution of (3.20) can be written as ![]() $\hat \psi _n (y) = f_n(y) + i g_n(y)$; therefore, we obtain the function

$\hat \psi _n (y) = f_n(y) + i g_n(y)$; therefore, we obtain the function ![]() $\psi$

$\psi$

\begin{align} \psi

(x,y) &= {A_0}\left( {y - \frac{{{y^2}}}{{2h}}} \right) +

\sum_{n = 1}^\infty {{A_n}( {{f_n}(y) + i{g_n}(y)} )}\,

{{\rm e}^{{\rm i} n\kappa x}}\nonumber\\

&\quad + \sum_{n = 1}^\infty {A_n^*[

{{f_n}(y) - i{g_n}(y)} ]} \,{{\rm e}^{ - {\rm i}n\kappa

x}}.\end{align}

\begin{align} \psi

(x,y) &= {A_0}\left( {y - \frac{{{y^2}}}{{2h}}} \right) +

\sum_{n = 1}^\infty {{A_n}( {{f_n}(y) + i{g_n}(y)} )}\,

{{\rm e}^{{\rm i} n\kappa x}}\nonumber\\

&\quad + \sum_{n = 1}^\infty {A_n^*[

{{f_n}(y) - i{g_n}(y)} ]} \,{{\rm e}^{ - {\rm i}n\kappa

x}}.\end{align}

The rightmost term in the right-hand side of (3.21) represents the negative modes of the Fourier series solution (see (3.4)), written for simplicity based on the positive values of ![]() $n$. Based on this simplification, one can easily show that

$n$. Based on this simplification, one can easily show that ![]() $A_n^*$ must be the complex conjugate of

$A_n^*$ must be the complex conjugate of ![]() $A_n$. Therefore, the following solution can be derived for

$A_n$. Therefore, the following solution can be derived for ![]() $\psi$:

$\psi$:

\begin{align} \psi (x,y) &= {A_0}\left( {y - \frac{{{y^2}}}{{2h}}} \right) + \sum_{n = 1}^\infty {A_n^r[ {{f_n}(y)\sin ( {n\kappa x} ) + {g_n}(y)\cos ( {n\kappa x} )} ]} \nonumber\\ & \quad + \sum_{n = 1}^\infty {A_n^i[ {{g_n}(y)\sin ( {n\kappa x} ) - {f_n}(y)\cos ( {n\kappa x} )} ]}, \end{align}

\begin{align} \psi (x,y) &= {A_0}\left( {y - \frac{{{y^2}}}{{2h}}} \right) + \sum_{n = 1}^\infty {A_n^r[ {{f_n}(y)\sin ( {n\kappa x} ) + {g_n}(y)\cos ( {n\kappa x} )} ]} \nonumber\\ & \quad + \sum_{n = 1}^\infty {A_n^i[ {{g_n}(y)\sin ( {n\kappa x} ) - {f_n}(y)\cos ( {n\kappa x} )} ]}, \end{align}

where ![]() $A_0$,

$A_0$, ![]() $A_n^r$ and

$A_n^r$ and ![]() $A_n^i$ are unknown coefficients. Therefore, the perturbation velocities (

$A_n^i$ are unknown coefficients. Therefore, the perturbation velocities (![]() $u,v$) are obtained as

$u,v$) are obtained as

\begin{align} u(x,y)

&= {A_0}\left( {1 - \frac{y}{h}} \right) + \sum_{n =

1}^\infty {A_n^r[ {{{f'_n}}(y)\sin ( {n\kappa x} ) +

{{g'_n}}(y)\cos ( {n\kappa x} )} ]} \nonumber\\

&\quad + \sum_{n = 1}^\infty {A_n^i[ {{{g'_n}}(y)\sin ( {n\kappa x}

) - {{f'_n}}(y)\cos ( {n\kappa x} )} ]}.

\end{align}

\begin{align} u(x,y)

&= {A_0}\left( {1 - \frac{y}{h}} \right) + \sum_{n =

1}^\infty {A_n^r[ {{{f'_n}}(y)\sin ( {n\kappa x} ) +

{{g'_n}}(y)\cos ( {n\kappa x} )} ]} \nonumber\\

&\quad + \sum_{n = 1}^\infty {A_n^i[ {{{g'_n}}(y)\sin ( {n\kappa x}

) - {{f'_n}}(y)\cos ( {n\kappa x} )} ]}.

\end{align} \begin{align}

v(x,y) &= \sum_{n = 1}^\infty {A_n^rn\kappa [ {{g_n}(y)\sin (

{n\kappa x} ) - {f_n}(y)\cos ( {n\kappa x} )} ]}

\nonumber\\

& \quad - \sum_{n = 1}^\infty {A_n^in\kappa [{{g_n}(y)\cos (

{n\kappa x} ) + {f_n}(y)\sin ( {n\kappa x})}]}.

\end{align}

\begin{align}

v(x,y) &= \sum_{n = 1}^\infty {A_n^rn\kappa [ {{g_n}(y)\sin (

{n\kappa x} ) - {f_n}(y)\cos ( {n\kappa x} )} ]}

\nonumber\\

& \quad - \sum_{n = 1}^\infty {A_n^in\kappa [{{g_n}(y)\cos (

{n\kappa x} ) + {f_n}(y)\sin ( {n\kappa x})}]}.

\end{align} By comparing the streamwise perturbation velocity (![]() $u$) for the inertial flow regime, shown in (3.23), with the corresponding solution for the creeping flow regime, shown in (3.8), we can realize that the inertial effects (amplified by increasing

$u$) for the inertial flow regime, shown in (3.23), with the corresponding solution for the creeping flow regime, shown in (3.8), we can realize that the inertial effects (amplified by increasing ![]() $Re$) are responsible for an asymmetry of the velocity profile in

$Re$) are responsible for an asymmetry of the velocity profile in ![]() $x \in [-{\ell }/{2} \ {\ell }/{2}]$; i.e.

$x \in [-{\ell }/{2} \ {\ell }/{2}]$; i.e. ![]() $u(x,y_0) \ne u(-x,y_0)$, where

$u(x,y_0) \ne u(-x,y_0)$, where ![]() $y_0$ represents a fixed value of

$y_0$ represents a fixed value of ![]() $y$. Consequently, we can separate the flow profiles into even and odd functions, in

$y$. Consequently, we can separate the flow profiles into even and odd functions, in ![]() $x \in [-{\ell }/{2} \ {\ell }/{2}]$, which for the streamwise perturbation velocity leads to

$x \in [-{\ell }/{2} \ {\ell }/{2}]$, which for the streamwise perturbation velocity leads to

\begin{gather} {u_e}(x,y) = {A_0}\left( {1 - \frac{y}{h}} \right) + \sum_{n = 1}^\infty {[ {A_n^r{{g'_n}}(y) - A_n^i{{f'_n}}(y)} ]} \cos ( {n\kappa x} ), \end{gather}

\begin{gather} {u_e}(x,y) = {A_0}\left( {1 - \frac{y}{h}} \right) + \sum_{n = 1}^\infty {[ {A_n^r{{g'_n}}(y) - A_n^i{{f'_n}}(y)} ]} \cos ( {n\kappa x} ), \end{gather} \begin{gather}{u_o}(x,y) = \sum_{n = 1}^\infty {[ {A_n^r{{f'_n}}(y) + A_n^i{{g'_n}}(y)} ]} \sin ( {n\kappa x} ), \end{gather}

\begin{gather}{u_o}(x,y) = \sum_{n = 1}^\infty {[ {A_n^r{{f'_n}}(y) + A_n^i{{g'_n}}(y)} ]} \sin ( {n\kappa x} ), \end{gather}

where the subscripts ![]() $e$ and

$e$ and ![]() $o$ refer to even and odd functions, respectively. Since the no-slip shear stress (

$o$ refer to even and odd functions, respectively. Since the no-slip shear stress (![]() ${Bi + {{\textrm {d} {U_0}}}/{{\textrm {d} y}}}$) is always an even function in

${Bi + {{\textrm {d} {U_0}}}/{{\textrm {d} y}}}$) is always an even function in ![]() $x \in [-{\ell }/{2} \ {\ell }/{2}]$, we can write the Navier slip law separately for the even and odd contributions of the velocity profile as

$x \in [-{\ell }/{2} \ {\ell }/{2}]$, we can write the Navier slip law separately for the even and odd contributions of the velocity profile as

Substituting equations (3.25) and (3.26) in (3.27) to (3.30), we find

\begin{gather}

{A_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^N {[ {A_n^r( {{{g'_n}}(0) - b{{g''_n}}(0)} ) -

A_n^i ( {{{f'_n}}(0) - b{{f''_n}}(0)})}]} \cos ({n\kappa x} )\nonumber\\

= b( {Bi + {C_1}} ),\quad 0 \le x \le \frac{{\varphi \ell}}{2},

\end{gather}

\begin{gather}

{A_0}\left( {1 + \frac{b}{h}} \right) + \sum_{n = 1}^N {[ {A_n^r( {{{g'_n}}(0) - b{{g''_n}}(0)} ) -

A_n^i ( {{{f'_n}}(0) - b{{f''_n}}(0)})}]} \cos ({n\kappa x} )\nonumber\\

= b( {Bi + {C_1}} ),\quad 0 \le x \le \frac{{\varphi \ell}}{2},

\end{gather} \begin{gather}0 = {{A_0} + \sum_{n = 1}^N {( {A_n^r{{g'_n}}(0) - A_n^i{{f'_n}}(0)} )} \cos ( {n\kappa x} ), \quad \frac{\varphi \ell}{2} \le x \le \frac{\ell}{2}}, \end{gather}

\begin{gather}0 = {{A_0} + \sum_{n = 1}^N {( {A_n^r{{g'_n}}(0) - A_n^i{{f'_n}}(0)} )} \cos ( {n\kappa x} ), \quad \frac{\varphi \ell}{2} \le x \le \frac{\ell}{2}}, \end{gather}and

\begin{gather} \sum_{n = 1}^N {[ {A_n^r( {{{f'_n}}(0) - b{{f''_n}}(0)} ) + A_n^i( {{{g'_n}}(0) - b{{g''_n}}(0)} )} ]} \sin ( {n\kappa x} ) = 0,\quad 0 \le x \le \frac{{\varphi \ell}}{2}, \end{gather}

\begin{gather} \sum_{n = 1}^N {[ {A_n^r( {{{f'_n}}(0) - b{{f''_n}}(0)} ) + A_n^i( {{{g'_n}}(0) - b{{g''_n}}(0)} )} ]} \sin ( {n\kappa x} ) = 0,\quad 0 \le x \le \frac{{\varphi \ell}}{2}, \end{gather} \begin{gather}\sum_{n = 1}^N {( {A_n^r{{f'_n}}(0) + A_n^i{{g'_n}}(0)} ) } \sin ( {n\kappa x} ) = 0, \quad \frac{\varphi \ell}{2} \le x \le \frac{\ell}{2}, \end{gather}

\begin{gather}\sum_{n = 1}^N {( {A_n^r{{f'_n}}(0) + A_n^i{{g'_n}}(0)} ) } \sin ( {n\kappa x} ) = 0, \quad \frac{\varphi \ell}{2} \le x \le \frac{\ell}{2}, \end{gather}

where the series are truncated to the ![]() $N$th terms.

$N$th terms.

Based on (3.33) and (3.34), a relation between the coefficients ![]() $A_n^r$ and

$A_n^r$ and ![]() $A_n^i$ is calculable. To do so, the same method as used in § 3.1 is employed: (3.33) is integrated with respect to

$A_n^i$ is calculable. To do so, the same method as used in § 3.1 is employed: (3.33) is integrated with respect to ![]() $x$ in

$x$ in ![]() $[0 \; x]$ and, then, the resulting equation is multiplied with

$[0 \; x]$ and, then, the resulting equation is multiplied with ![]() $\cos (m\kappa x)$ (where

$\cos (m\kappa x)$ (where ![]() $m$ is a positive integer) and again integrated in

$m$ is a positive integer) and again integrated in ![]() $x \in [0 \ {\varphi \ell }/{2}]$. Equation (3.34) is multiplied by

$x \in [0 \ {\varphi \ell }/{2}]$. Equation (3.34) is multiplied by ![]() $\sin (m\kappa x)$ and, then, it is integrated in

$\sin (m\kappa x)$ and, then, it is integrated in ![]() $x \in [{\varphi \ell }/{2} \ {\ell }/{2}]$. The combination of the resulting equations and some algebra leads to the following relation between the unknown coefficients:

$x \in [{\varphi \ell }/{2} \ {\ell }/{2}]$. The combination of the resulting equations and some algebra leads to the following relation between the unknown coefficients:

\begin{equation} A_m^i = \sum_{n = 1}^N {{{[ {{{( {{P^i}} )}^{ - 1}}{P^r}} ]}_{m,n}}A_n^r}, \end{equation}

\begin{equation} A_m^i = \sum_{n = 1}^N {{{[ {{{( {{P^i}} )}^{ - 1}}{P^r}} ]}_{m,n}}A_n^r}, \end{equation}

where the matrices ![]() $\boldsymbol{\mathsf{P}}^r$ and