1. Introduction

Drying-driven redistribution of dirt within filters and textiles is a common problem, with practical industrial importance. For instance, after the rinsing of filters used in vacuum cleaners or washing machines, the filter dries and any remaining dirt or cloth fibres are left in the filter (Ji & Sanaei Reference Ji and Sanaei2023), reducing its capacity for the next filtration cycle. Waterproof clothing such as coats and boots will dry after use, and impurities or dirt may similarly be left within the pores of the textile and waterproof membrane (Breward et al. Reference Breward2020; Sanaei et al. Reference Sanaei2022).

A key question in these filtration and waterproof-clothing applications is to determine where within the porous material the dirt is deposited once the liquid has all evaporated. We might also ask whether all of the liquid can indeed be evaporated, or whether it becomes trapped in regions of pore space clogged by the deposited dirt. In the applications of interest, it is important that the dirt does not clog the material, as this leads to reduced filter efficacy, or reduced breathability of the waterproof garment. Furthermore, trapped water in a washing machine filter may contribute to the growth of bacteria or mould, and should be avoided for hygiene reasons (Abney et al. Reference Abney, Ijaz, McKinney and Gerba2021). A paradigm situation encompassing these processes is that of a porous material containing a mixture of a liquid, such as water, and an impurity or dirt that is suspended in the liquid. As the liquid evaporates, an evaporation front moves into the porous material from its surface. The dirt is left behind in the liquid as the liquid evaporates, and may deposit into a layer on the walls of the pore space.

A related problem is the deposition of suspended particles when a droplet of liquid dries on an impermeable substrate. This is known to lead to a coffee-ring effect, in which the coffee particles are transported by evaporation-induced flow of liquid to the edge of the droplet. This coffee-ring effect is well studied, for instance, by Deegan et al. (Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten1997, Reference Deegan, Bakajin, Dupont, Huber, Nagel and Witten2000), Karapetsas, Sahu & Matar (Reference Karapetsas, Sahu and Matar2016), Kaplan & Mahadevan (Reference Kaplan and Mahadevan2015), Moore, Vella & Oliver (Reference Moore, Vella and Oliver2021), Murisic & Kondic (Reference Murisic and Kondic2011), Popov (Reference Popov2005), and recently reviewed by Wilson & D'Ambrosio (Reference Wilson and D'Ambrosio2023). The coffee-ring effect is of practical importance, for instance, in the drying of ink droplets in ink-jet printing (Mampallil & Eral Reference Mampallil and Eral2018; Soltman & Subramanian Reference Soltman and Subramanian2008) and in the manufacture of electronic devices (D'Ambrosio et al. Reference D'Ambrosio, Colosimo, Duffy, Wilson, Yang, Bain and Walker2021).

In a drying porous material, such as a filter membrane or textile, there are several additional complications not present in the coffee-ring set-up. Firstly, the problem is multiscale in nature, in that the fluid flow, evaporation and the transport and deposition of the dirt occur within the pore space, while the depth of porous material to be dried is likely to be significantly larger than an individual pore, even for fairly thin filter membranes. It is not immediately clear how to formulate a model that captures the pore-scale behaviour and yet remains tractable over the scale of the entire drying material. Additionally, dirt deposition may occur throughout the porous domain, not only at the base of the evaporating droplet. This means that there is additional coupling between the drying and the deposition: like in evaporating droplets, the accumulation of suspended dirt at the evaporating interface can reduce the evaporation rate (Karapetsas et al. Reference Karapetsas, Sahu and Matar2016), but additionally the build-up of deposited dirt in the pore space affects the porosity and reduces the rate of diffusive transport of (i) the suspended dirt through the liquid-saturated pore space, and (ii) vapour out through the dry porous material. In extreme cases, the deposited dirt might completely clog the pore space at the evaporation front, terminating the drying before all liquid is evaporated. This phenomenon is not possible in coffee-ring problems. Like the surface tension driven flows in coffee rings, a capillary flow may draw fluid through the porous material, which then evaporates near the surface of the porous material (Lehmann, Assouline & Or Reference Lehmann, Assouline and Or2008). This is typically the case early in the drying process (‘stage I’), while later (‘stage II’) the evaporating interface moves into the porous material, and the transport of vapour out of the porous material limits the evaporation rate (Or et al. Reference Or, Lehmann, Shahraeeni and Shokri2013; Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022).

Drying porous media (without dirt) have been studied in a variety of settings and using various different modelling techniques. Depending on the porous material and fluids, various drying regimes are possible: liquid and gas may coexist within the pore space throughout the entire medium and for the majority of the drying time (so that the majority of the drying is in stage I), or a region in which capillary effects dominate, often referred to as a ‘film region’, may separate a region of porous material saturated with liquid from a multiphase region incorporating unconnected pockets of stationary liquid (Pel, Landman & Kaasschieter Reference Pel, Landman and Kaasschieter2002; Lehmann et al. Reference Lehmann, Assouline and Or2008). Multiphase flow models for drying are derived by, for instance, Whitaker (Reference Whitaker1977) while lumped models, consisting of nonlinear diffusion equations for the ‘moisture’ (combining liquid and vapour) are also often used (Vu & Tsotsas Reference Vu and Tsotsas2018; Pel et al. Reference Pel, Landman and Kaasschieter2002). Evaporation within the pore space may be simulated directly, although this is computationally expensive and limited to sufficiently small domain sizes (Fei et al. Reference Fei, Qin, Zhao, Derome and Carmeliet2022). Pore-network models are a more computationally tractable approximation, although the details of the fluid flow are neglected (Nowicki, Davis & Scriven Reference Nowicki, Davis and Scriven1992; Tsimpanogiannis et al. Reference Tsimpanogiannis, Yortsos, Poulou, Kanellopoulos and Stubos1999).

The transport and trapping of particles in a liquid-saturated porous material when the liquid is flowing is known as deep-bed filtration (Zamani & Maini Reference Zamani and Maini2009). When there is no flow of the liquid, the particles may still be transported by Brownian diffusion (Epstein Reference Epstein1988). Particles may build up in a deposited layer on the pore walls due to several mechanisms, including electrostatic forces in the bulk (Zamani & Maini Reference Zamani and Maini2009). Particles are generally repelled from air–water interfaces unless they are hydrophobic; in the hydrophobic case they might be held at the interface and, thus, transported more effectively with it (Flury & Aramrak Reference Flury and Aramrak2017). Particles may deposit or attach to the walls of the pore space due to adsorption, electrostatic forces or other chemical binding mechanisms (Epstein Reference Epstein1988; Zamani & Maini Reference Zamani and Maini2009; Dressaire & Sauret Reference Dressaire and Sauret2017). Experimental work such as that of Gudipaty et al. (Reference Gudipaty, Stamm, Cheung, Jiang and Zohar2011), Linkhorst et al. (Reference Linkhorst, Beckmann, Go, Kuehne and Wessling2016), Stamm et al. (Reference Stamm, Gudipaty, Rush, Jiang and Zohar2011) seeks to visualise the deposits and quantify their growth rates in terms of the system parameters.

For an evaporating droplet, an evaporative flux is generally prescribed at the droplet surface (Popov Reference Popov2005; Murisic & Kondic Reference Murisic and Kondic2011; Kaplan & Mahadevan Reference Kaplan and Mahadevan2015; Karapetsas et al. Reference Karapetsas, Sahu and Matar2016; Moore et al. Reference Moore, Vella and Oliver2021). This flux may be constant (Moore et al. Reference Moore, Vella and Oliver2021), but typically depends on the distance from the edge of the droplet, accounting for the quasi-steady transport of vapour away from the droplet (Popov Reference Popov2005; Karapetsas et al. Reference Karapetsas, Sahu and Matar2016). When drying from within porous media, a prescribed evaporation rate may be appropriate during stage I (when the evaporation occurs near the surface of the material) but, since the stage II drying of porous media is limited by the removal of vapour from the pore space (Lehmann et al. Reference Lehmann, Assouline and Or2008), like the majority of evaporating drops (Wilson & D'Ambrosio Reference Wilson and D'Ambrosio2023), we expect that the evaporation rate will depend on the position of the evaporating interface within the porous material during this stage.

The deposition of dirt during the drying of a filter has recently been studied by Ji & Sanaei (Reference Ji and Sanaei2023). Here, the suspended dirt is assumed to diffuse through a liquid-saturated region of porous material ahead of an evaporating interface, and deposit at a rate directly proportional to its concentration, causing the local porosity to decrease. The evaporating interface is assumed to move through the porous material at a prescribed speed, dependent only on the local porosity and suspended dirt concentration, and not the location of the front within the filter. Simulations of this model show that the porosity of the filter decreases during the drying, and that the deposited dirt is non-uniformly distributed in the pore space once the drying is complete.

In this paper we systematically derive a homogenised model for the coupled processes of evaporation, transport of liquid vapour, diffusion and deposition of dirt in a drying porous material, starting from a pore-scale model for these processes. This analysis is based on previous work (Luckins et al. Reference Luckins, Breward, Griffiths and Please2023) for evaporation of a pure liquid in a porous material, extended to incorporate dirt transport and deposition. One benefit of the homogenisation approach is that the pore-scale behaviour is included in the homogenised model through averaged terms. This ensures that the model conserves mass of all species, and also results in a different diffusive term in the homogenised equations compared with the model posed by Ji & Sanaei (Reference Ji and Sanaei2023). For simplicity, as in both Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023) and Ji & Sanaei (Reference Ji and Sanaei2023), we assume that capillary flows are negligible and a sharp evaporating interface moves into the porous material. In practice, such systems would be valid when viscous or gravitational forces dominate over surface tension, for instance, if the solid is hydrophobic (Shokri, Lehmann & Or Reference Shokri, Lehmann and Or2008) or the pores are sufficiently large relative to the capillary length scale (Lehmann et al. Reference Lehmann, Assouline and Or2008). Our coupled model for the drying and dirt transport is a type of Stefan problem, with undercooling in certain parameter regimes. We derive our homogenised model in § 2. In § 3 we note that the vapour transport is quasi-steady for physically relevant parameter choices and reduce the vapour-transport problem to a single ordinary differential equation (ODE) for the position of the evaporation front, providing a comparison between this model and that of Ji & Sanaei (Reference Ji and Sanaei2023). In § 4 we study the early time behaviour of our model and describe our numerical solution method. In §§ 5–6 we study the asymptotic limits of slow and fast deposition rates, identifying a distinct mechanism in each case by which the system may clog before the drying is complete. We quantify the parameter regimes for which these clogging phenomena occur in § 7 before concluding in § 8.

2. Model derivation

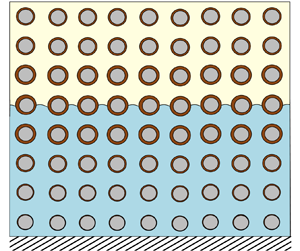

We consider a porous material of finite thickness ![]() $l$, initially with uniform porosity and saturated with a uniform mixture of liquid and suspended dirt. We assume that the dirt particles are small relative to the pore-length scale, and neither interact with each other nor dissolve in the liquid. The dirt–liquid mixture is thus a suspension of these insoluble dirt particles. We suppose the porous material is bounded by an impermeable solid material on one side. The liquid begins to evaporate from the side open to the atmosphere, leaving the dirt behind, and an evaporation front moves into the porous material, with the suspended dirt and liquid ahead of the front, and a mixture of inert gas (drawn in from above the porous material) and liquid vapour behind it. We assume the system is isothermal, with no variation in temperature. A schematic of the situation under consideration is shown in figure 1. We consider a two-dimensional porous material for simplicity, with spatial variables

$l$, initially with uniform porosity and saturated with a uniform mixture of liquid and suspended dirt. We assume that the dirt particles are small relative to the pore-length scale, and neither interact with each other nor dissolve in the liquid. The dirt–liquid mixture is thus a suspension of these insoluble dirt particles. We suppose the porous material is bounded by an impermeable solid material on one side. The liquid begins to evaporate from the side open to the atmosphere, leaving the dirt behind, and an evaporation front moves into the porous material, with the suspended dirt and liquid ahead of the front, and a mixture of inert gas (drawn in from above the porous material) and liquid vapour behind it. We assume the system is isothermal, with no variation in temperature. A schematic of the situation under consideration is shown in figure 1. We consider a two-dimensional porous material for simplicity, with spatial variables ![]() $x$ and

$x$ and ![]() $y$, and with

$y$, and with ![]() $y$ pointing into the porous material and

$y$ pointing into the porous material and ![]() $y=0$ at the surface of the porous material. Although the structure of our model and the homogenisation analysis does not depend on the pore-scale geometry, it is helpful to specify this for simplicity. We choose a square lattice of circular solid inclusions, of radius

$y=0$ at the surface of the porous material. Although the structure of our model and the homogenisation analysis does not depend on the pore-scale geometry, it is helpful to specify this for simplicity. We choose a square lattice of circular solid inclusions, of radius ![]() $r_0$. We account for deposition of the suspended dirt onto the solid structure by considering deposited dirt layers of thickness

$r_0$. We account for deposition of the suspended dirt onto the solid structure by considering deposited dirt layers of thickness ![]() $R(x,y,t)$, on each solid inclusion, which have initial thickness zero. An important assumption is that the liquid–dirt mixture does not flow, and so our model excludes any capillary pressure or surface tension effects (since in order to attain a (quasi-)static meniscus shape, the liquid would need to flow). We first consider the drying behaviour on the microscale – within the pores of the material – before averaging to derive our effective model. We suppose that the evaporating front is located at

$R(x,y,t)$, on each solid inclusion, which have initial thickness zero. An important assumption is that the liquid–dirt mixture does not flow, and so our model excludes any capillary pressure or surface tension effects (since in order to attain a (quasi-)static meniscus shape, the liquid would need to flow). We first consider the drying behaviour on the microscale – within the pores of the material – before averaging to derive our effective model. We suppose that the evaporating front is located at ![]() $y=h(x,t)$, splitting the domain into a region of pore space containing vapour in

$y=h(x,t)$, splitting the domain into a region of pore space containing vapour in ![]() $0\leq y\leq h(x,t)$, where the thickness of the layers of deposited dirt do not change with time, and a region of pore space in

$0\leq y\leq h(x,t)$, where the thickness of the layers of deposited dirt do not change with time, and a region of pore space in ![]() $h(x,t)\leq y\leq l$ containing the liquid–dirt mixture, where the dirt-layer thicknesses vary in time due to deposition or erosion.

$h(x,t)\leq y\leq l$ containing the liquid–dirt mixture, where the dirt-layer thicknesses vary in time due to deposition or erosion.

Figure 1. Schematic showing the evaporation front at ![]() $y=h(x,t)$ moving through the pore space (length scale

$y=h(x,t)$ moving through the pore space (length scale ![]() $d$) of a porous material (of depth

$d$) of a porous material (of depth ![]() $l\gg d$), with dirt depositing in a layer of thickness

$l\gg d$), with dirt depositing in a layer of thickness ![]() $R(x,y,t)$ on the circular solid inclusions with radius

$R(x,y,t)$ on the circular solid inclusions with radius ![]() $r_0$. The unit normal to the solid or dirt boundary of the pore space is

$r_0$. The unit normal to the solid or dirt boundary of the pore space is ![]() $\boldsymbol {n}_s$, while the evaporating interface has unit normal

$\boldsymbol {n}_s$, while the evaporating interface has unit normal ![]() $\boldsymbol {m}$.

$\boldsymbol {m}$.

2.1. Pore-scale model

In the pore space occupied by the vapour–gas mixture (behind the evaporating front, i.e. ![]() $y< h(x,t)$), we expect the Reynolds number to be small (Luckins et al. Reference Luckins, Breward, Griffiths and Please2023) and so we assume that the mixture satisfies the Stokes equations

$y< h(x,t)$), we expect the Reynolds number to be small (Luckins et al. Reference Luckins, Breward, Griffiths and Please2023) and so we assume that the mixture satisfies the Stokes equations

where ![]() $\boldsymbol {u}$ is the mass-averaged velocity of the mixture,

$\boldsymbol {u}$ is the mass-averaged velocity of the mixture, ![]() $p$ is the pressure and

$p$ is the pressure and ![]() $\mu$ is the viscosity (assumed constant). The vapour contained within the mixture is advected with the flow, and also diffuses through the mixture with diffusivity

$\mu$ is the viscosity (assumed constant). The vapour contained within the mixture is advected with the flow, and also diffuses through the mixture with diffusivity ![]() $D_v$, and thus, the density of the vapour,

$D_v$, and thus, the density of the vapour, ![]() $\rho _v$ [

$\rho _v$ [![]() ${\rm kg}\ {\rm m}^{-3}$], satisfies

${\rm kg}\ {\rm m}^{-3}$], satisfies

where the subscript ![]() $t$ denotes partial derivative. The overall density of the inert gas–vapour mixture,

$t$ denotes partial derivative. The overall density of the inert gas–vapour mixture, ![]() $\rho _G$, is given by

$\rho _G$, is given by

Wherever the gas–vapour mixture meets the solid walls of the pore space we suppose there is no flux or slip of the gas–vapour mixture, and no flux vapour into the solid material, so that on the solid–liquid or dirt–liquid boundary, with normal ![]() $\boldsymbol {n}_s$,

$\boldsymbol {n}_s$,

In the liquid–dirt mixture in ![]() $y>h(x,t)$, we assume that there is no net flow of the mixture, and the suspended dirt and liquid diffuse against one another in an ideal mixture, due to Brownian motion. The suspended dirt volume fraction,

$y>h(x,t)$, we assume that there is no net flow of the mixture, and the suspended dirt and liquid diffuse against one another in an ideal mixture, due to Brownian motion. The suspended dirt volume fraction, ![]() $\theta$, therefore satisfies

$\theta$, therefore satisfies

where ![]() $D_d$ is the diffusivity of suspended dirt in liquid. As discussed in Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023), the assumption that the liquid does not flow means that capillary effects are neglected from the model.

$D_d$ is the diffusivity of suspended dirt in liquid. As discussed in Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023), the assumption that the liquid does not flow means that capillary effects are neglected from the model.

At the solid walls of the pore space, we suppose that the suspended dirt can deposit onto the solid microstructure, forming a layer that may also then be eroded away. We suppose that the deposited layer has a dirt volume fraction ![]() $\theta _*$ which is the packing volume fraction of the dirt particles. We expect this to be close to one, as only a small amount of liquid (volume fraction

$\theta _*$ which is the packing volume fraction of the dirt particles. We expect this to be close to one, as only a small amount of liquid (volume fraction ![]() $1-\theta _*$) is trapped within the deposited dirt layer. Conservation of dirt across the interface is given by

$1-\theta _*$) is trapped within the deposited dirt layer. Conservation of dirt across the interface is given by

where ![]() $V_n$ is the normal velocity of the depositing/eroding interface. We note that, in order that there is no flow generated at the depositing interface, we assume that the dirt and liquid have the same mass density, so that the total mixture density is the same on either side of the depositing/eroding interface, while the dirt and liquid fractions can jump (see, for instance, Geng, Kamilova & Luckins Reference Geng, Kamilova and Luckins2023).

$V_n$ is the normal velocity of the depositing/eroding interface. We note that, in order that there is no flow generated at the depositing interface, we assume that the dirt and liquid have the same mass density, so that the total mixture density is the same on either side of the depositing/eroding interface, while the dirt and liquid fractions can jump (see, for instance, Geng, Kamilova & Luckins Reference Geng, Kamilova and Luckins2023).

We suppose that the dirt is deposited at a rate dependent on the local suspended dirt volume fraction, while the erosion rate depends on the (constant) packing volume fraction ![]() $\theta _*$. (If there was a flow of the fluid, we might extend this model and allow the erosion rate to depend on the local shear stress.) Thus, we prescribe

$\theta _*$. (If there was a flow of the fluid, we might extend this model and allow the erosion rate to depend on the local shear stress.) Thus, we prescribe

where the constants ![]() $k_\pm$ have units

$k_\pm$ have units ![]() ${\rm m}\ {\rm s}^{-1}$. This type of law-of-mass-action deposition rate, in which the deposition rate is linear in the quantity of suspended dirt, is common in the phenomenological bed-filtration literature (Zamani & Maini Reference Zamani and Maini2009; Dressaire & Sauret Reference Dressaire and Sauret2017), and is also used by Ji & Sanaei (Reference Ji and Sanaei2023) as a model for adsorption of particles onto the deposit layer.

${\rm m}\ {\rm s}^{-1}$. This type of law-of-mass-action deposition rate, in which the deposition rate is linear in the quantity of suspended dirt, is common in the phenomenological bed-filtration literature (Zamani & Maini Reference Zamani and Maini2009; Dressaire & Sauret Reference Dressaire and Sauret2017), and is also used by Ji & Sanaei (Reference Ji and Sanaei2023) as a model for adsorption of particles onto the deposit layer.

At the evaporating interface ![]() $y=h(x,t)$, we suppose that the inert gas and the dirt do not pass through the interface, while liquid turns into vapour. We thus impose conservation of mass of each of the liquid/vapour, gas, and suspended dirt, namely

$y=h(x,t)$, we suppose that the inert gas and the dirt do not pass through the interface, while liquid turns into vapour. We thus impose conservation of mass of each of the liquid/vapour, gas, and suspended dirt, namely

where ![]() $\rho _l$ and

$\rho _l$ and ![]() $\rho _d$ are the densities of pure liquid and dirt, respectively. Combining these, we derive the more helpful form

$\rho _d$ are the densities of pure liquid and dirt, respectively. Combining these, we derive the more helpful form

interpretable as a condition on each of ![]() $\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {m}$,

$\boldsymbol {u}\boldsymbol {\cdot }\boldsymbol {m}$, ![]() $\rho _v$ and

$\rho _v$ and ![]() $\theta$, respectively, where

$\theta$, respectively, where ![]() $\rho _L=\rho _l(1-\theta )+\rho _d\theta$ is the (assumed constant) liquid–dirt mixture density. The normal velocity of the interface and unit normal to the interface are given by

$\rho _L=\rho _l(1-\theta )+\rho _d\theta$ is the (assumed constant) liquid–dirt mixture density. The normal velocity of the interface and unit normal to the interface are given by

where subscripts ![]() $t$ and

$t$ and ![]() $x$ denote partial derivatives. In addition to (2.9), we also impose a no-slip condition for the gas-mixture velocity

$x$ denote partial derivatives. In addition to (2.9), we also impose a no-slip condition for the gas-mixture velocity

Finally, we must also incorporate a condition that describes the chemistry governing the evaporation. In Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023) the effect of different chemistry conditions were considered, and these were shown to affect the form of macroscale boundary conditions derived through a homogenisation analysis. For simplicity, we assume that the liquid and vapour are in chemical equilibrium at the evaporating interface. The chemical potential on the liquid side of the interface is dependent on the amount of liquid (![]() $1-\theta$) at the interface, while the chemical potential on the gas-mixture side depends on the density of vapour,

$1-\theta$) at the interface, while the chemical potential on the gas-mixture side depends on the density of vapour, ![]() $\rho _v$, at the interface. In general, we may express this chemical equilibrium as

$\rho _v$, at the interface. In general, we may express this chemical equilibrium as

where ![]() $\rho ^*$ is the (constant) saturation vapour density when

$\rho ^*$ is the (constant) saturation vapour density when ![]() $\theta =0$ and there is no suspended dirt, and the function

$\theta =0$ and there is no suspended dirt, and the function ![]() $f(\theta )$ captures the dirt dependence of the saturation vapour density. (We note that therefore

$f(\theta )$ captures the dirt dependence of the saturation vapour density. (We note that therefore ![]() $f(0)=1$.) The presence of particles at the interface are expected to hinder the vaporisation; in both Ji & Sanaei (Reference Ji and Sanaei2023) and Karapetsas et al. (Reference Karapetsas, Sahu and Matar2016) the evaporative flux is modelled as decreasing with increased particles on the fluid surface. We keep

$f(0)=1$.) The presence of particles at the interface are expected to hinder the vaporisation; in both Ji & Sanaei (Reference Ji and Sanaei2023) and Karapetsas et al. (Reference Karapetsas, Sahu and Matar2016) the evaporative flux is modelled as decreasing with increased particles on the fluid surface. We keep ![]() $f(\theta )$ general as far as possible, and in § 5 we investigate the effect of different functional dependencies

$f(\theta )$ general as far as possible, and in § 5 we investigate the effect of different functional dependencies ![]() $f(\theta )$ on the drying rate. However, in our numerical simulations we use the simple linear form

$f(\theta )$ on the drying rate. However, in our numerical simulations we use the simple linear form

to capture the effect of the dirt inhibiting vaporisation. We choose this form so that the saturation vapour density scales with the amount of liquid at the interface.

At the surface of the porous material, we impose a constant atmospheric vapour density and atmospheric pressure

Dirt cannot diffuse through the impermeable boundary and thus so impose that

This depth ![]() $l$ is assumed to be much greater than the typical pore-length scale, so that there is separation between the pore- and macro-length scales.

$l$ is assumed to be much greater than the typical pore-length scale, so that there is separation between the pore- and macro-length scales.

2.2. Non-dimensionalisation

We non-dimensionalise the vapour/gas problem in a similar way to Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023), making the rescalings

where

are dimensionless parameters representing the ratio of vapour density to liquid density, the ratio of pore- to macro-length scales and the ratio of vapour to gas densities, respectively. In particular, we note that we have chosen the time scale associated with the speed of the motion of the evaporating interfaces on the microscale, i.e. the time scale over which sufficient vapour is removed by diffusion to empty the microscale pore space of liquid. Making these rescalings and dropping the hat notation, the dimensionless microscale model is, in ![]() $y< h(x,t)$,

$y< h(x,t)$,

while in ![]() $y>h(x,t)$,

$y>h(x,t)$,

At gas–solid interfaces in ![]() $y< h(x,t)$ (which are stationary),

$y< h(x,t)$ (which are stationary),

and at liquid–solid interfaces in ![]() $y>h(x,t)$ (which move with velocity

$y>h(x,t)$ (which move with velocity ![]() $V_n$),

$V_n$),

while at the evaporating interfaces ![]() $y=h(x,t)$,

$y=h(x,t)$,

At the surface of the porous material,

while at the impermeable surface (or centre of a symmetric porous material),

Here we have introduced the additional dimensionless parameters

that appear in the dirt problem, representing the ratio of the suspended dirt diffusion time scale to the time scale of the evaporation-front motion, the ratio of the dirt-deposition rate to the evaporation rate, the ratio of the dirt erosion rate to deposition rate and the ratio of the atmospheric vapour density to the maximum saturation vapour density, respectively.

The micro- to macro-length scale ratio ![]() $\epsilon$ (defined in (2.17a–f)) is the small parameter we take advantage of in order to homogenise (2.18). As in Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023), we take

$\epsilon$ (defined in (2.17a–f)) is the small parameter we take advantage of in order to homogenise (2.18). As in Luckins et al. (Reference Luckins, Breward, Griffiths and Please2023), we take ![]() $\delta <1$ and

$\delta <1$ and ![]() $\nu <1$ to be order one parameters relative to

$\nu <1$ to be order one parameters relative to ![]() $\epsilon$ for the homogenisation analysis. We note that

$\epsilon$ for the homogenisation analysis. We note that ![]() $\delta \approx 10^{-3}$ for water, so will later consider the additional limit of

$\delta \approx 10^{-3}$ for water, so will later consider the additional limit of ![]() $\delta \rightarrow 0$ (which is equivalent to taking this limit before performing the homogenisation analysis). We require

$\delta \rightarrow 0$ (which is equivalent to taking this limit before performing the homogenisation analysis). We require ![]() $\alpha <1$ but expect

$\alpha <1$ but expect ![]() $\alpha \ll 1$ to be reasonable. Although the diffusion of vapour in air is generally much faster than the diffusion of any kind of molecule through a liquid, so that

$\alpha \ll 1$ to be reasonable. Although the diffusion of vapour in air is generally much faster than the diffusion of any kind of molecule through a liquid, so that ![]() $D_v\gg D_d$, we note that since

$D_v\gg D_d$, we note that since ![]() $\delta \approx 10^{-3}\unicode{x2013}10^{-4}$ is small,

$\delta \approx 10^{-3}\unicode{x2013}10^{-4}$ is small, ![]() $\sigma$ is likely to be order one. For instance, if we take

$\sigma$ is likely to be order one. For instance, if we take ![]() $D_v\approx 2.5\times 10^{-5}\ {\rm m}^2\ {\rm s}^{-1}$ and

$D_v\approx 2.5\times 10^{-5}\ {\rm m}^2\ {\rm s}^{-1}$ and ![]() $D_d\approx 10^{-9}\ {\rm m}^2\ {\rm s}^{-1}$ (Cussler Reference Cussler2009), then with

$D_d\approx 10^{-9}\ {\rm m}^2\ {\rm s}^{-1}$ (Cussler Reference Cussler2009), then with ![]() $\delta =10^{-4}$ we find that

$\delta =10^{-4}$ we find that ![]() $\sigma \approx 2.5$. We consider the distinguished limit of

$\sigma \approx 2.5$. We consider the distinguished limit of ![]() $\sigma =O(1)$ in this paper, but we note there is an alternative, slow-dirt-diffusion, distinguished limit with

$\sigma =O(1)$ in this paper, but we note there is an alternative, slow-dirt-diffusion, distinguished limit with ![]() $\sigma =O(\epsilon ^{-1})$. We discuss this alternative case further in Appendix A.2, and briefly in § 2.3 below. In summary, all of

$\sigma =O(\epsilon ^{-1})$. We discuss this alternative case further in Appendix A.2, and briefly in § 2.3 below. In summary, all of ![]() $\sigma, \kappa, \beta$ and

$\sigma, \kappa, \beta$ and ![]() $\alpha$ are taken to be order one relative to

$\alpha$ are taken to be order one relative to ![]() $\epsilon$ to homogenise the model.

$\epsilon$ to homogenise the model.

2.3. Summary of the homogenised drying model

The homogenisation analysis is described in Appendix A. The result of this analysis is a macroscale model for the vapour density ![]() $\rho$, suspended dirt volume fraction

$\rho$, suspended dirt volume fraction ![]() $\theta$, deposited dirt-layer thickness,

$\theta$, deposited dirt-layer thickness, ![]() $R$, and position,

$R$, and position, ![]() $Y=H(T)$ of the evaporation front, namely

$Y=H(T)$ of the evaporation front, namely

for ![]() $Y< H(T)$, and

$Y< H(T)$, and

for ![]() $Y>H(T)$. At

$Y>H(T)$. At ![]() $Y=H(T)$,

$Y=H(T)$,

while

The porosity, ![]() $\phi (R)=1-{\rm \pi} (r_0+R)^2$, surface area,

$\phi (R)=1-{\rm \pi} (r_0+R)^2$, surface area, ![]() $\mathcal {C}(R)=2{\rm \pi} (r_0+R)$, and effective diffusivity,

$\mathcal {C}(R)=2{\rm \pi} (r_0+R)$, and effective diffusivity, ![]() $\mathcal {D}(R)$ (given by (A4)), all vary with the thickness of the deposited dirt layer.

$\mathcal {D}(R)$ (given by (A4)), all vary with the thickness of the deposited dirt layer.

We assume that, initially, the porous material is entirely saturated with a uniform liquid–dirt mixture, none of which has yet deposited (i.e. the time scale of deposition is assumed longer than the time scale over which the liquid–dirt mixture flooded the material). Thus, at ![]() $T=0$,

$T=0$,

Our homogenised model (2.20) is similar in structure to those proposed in Breward et al. (Reference Breward2020), Sanaei et al. (Reference Sanaei2022) and Ji & Sanaei (Reference Ji and Sanaei2023), with the suspended dirt satisfying a reaction–diffusion equation ahead of a moving evaporation front. However, through the systematic homogenisation analysis, we have found the correct form for the diffusion term in (2.20b), which was erroneously given as ![]() $(D(\phi \theta )_Y)_Y$ (in our notation) by Ji & Sanaei (Reference Ji and Sanaei2023). Additionally, we have quantified the effective parameters

$(D(\phi \theta )_Y)_Y$ (in our notation) by Ji & Sanaei (Reference Ji and Sanaei2023). Additionally, we have quantified the effective parameters ![]() $\mathcal {D}$,

$\mathcal {D}$, ![]() $\mathcal {C}$ and

$\mathcal {C}$ and ![]() $\phi$, which all vary with the deposited dirt-layer thickness

$\phi$, which all vary with the deposited dirt-layer thickness ![]() $R$. We also impose different boundary conditions to Ji & Sanaei (Reference Ji and Sanaei2023), which will result in different drying behaviours, as discussed in § 3 below.

$R$. We also impose different boundary conditions to Ji & Sanaei (Reference Ji and Sanaei2023), which will result in different drying behaviours, as discussed in § 3 below.

A key assumption of our homogenisation analysis was that ![]() $\sigma =O(1)$, which ensured that

$\sigma =O(1)$, which ensured that ![]() $\theta$ (and therefore

$\theta$ (and therefore ![]() $R$) is uniform to leading order on the microscale. As discussed further in Appendix A.2, the extremely slow suspended dirt diffusion limit of

$R$) is uniform to leading order on the microscale. As discussed further in Appendix A.2, the extremely slow suspended dirt diffusion limit of ![]() $\sigma =O(\epsilon ^{-1})$ is not captured by this model: in this case we would expect non-periodic behaviour on the microscale at the evaporating interface, and the homogenisation analysis would break down. We do not consider this situation here.

$\sigma =O(\epsilon ^{-1})$ is not captured by this model: in this case we would expect non-periodic behaviour on the microscale at the evaporating interface, and the homogenisation analysis would break down. We do not consider this situation here.

3. An ODE for the motion of the evaporation front

The parameter ![]() $\delta =\rho ^*/\rho _L$ is generally small; indeed for water evaporating we expect

$\delta =\rho ^*/\rho _L$ is generally small; indeed for water evaporating we expect ![]() $\delta \approx 10^{-3}$. Before studying the full drying problem, we consider the limit of

$\delta \approx 10^{-3}$. Before studying the full drying problem, we consider the limit of ![]() $\delta \rightarrow 0$ in the vapour–gas transport problem, which we show results in a single ODE describing the motion of the evaporation front

$\delta \rightarrow 0$ in the vapour–gas transport problem, which we show results in a single ODE describing the motion of the evaporation front ![]() $H(T)$. This gives insight into the drying dynamics and is interesting as a comparison with other models for the motion of evaporating interfaces in the literature, e.g. Ji & Sanaei (Reference Ji and Sanaei2023). Furthermore, the analysis in this section is helpful for all of the subsequent analysis of the model, including the early time asymptotic analysis in the following section (§ 4), which we use to initialise numerical simulations of the model.

$H(T)$. This gives insight into the drying dynamics and is interesting as a comparison with other models for the motion of evaporating interfaces in the literature, e.g. Ji & Sanaei (Reference Ji and Sanaei2023). Furthermore, the analysis in this section is helpful for all of the subsequent analysis of the model, including the early time asymptotic analysis in the following section (§ 4), which we use to initialise numerical simulations of the model.

For small ![]() $\delta$, we see from (2.20a) that the vapour-density profile is quasi-steady, varying instantaneously with the motion of the evaporation front. Specifically, in the limit

$\delta$, we see from (2.20a) that the vapour-density profile is quasi-steady, varying instantaneously with the motion of the evaporation front. Specifically, in the limit ![]() $\delta \rightarrow 0$, the vapour-transport equation (2.20a) becomes

$\delta \rightarrow 0$, the vapour-transport equation (2.20a) becomes

Integrating twice with respect to ![]() $Y$ and applying the boundary conditions (2.20d) and (2.20g), we obtain

$Y$ and applying the boundary conditions (2.20d) and (2.20g), we obtain

\begin{equation} \rho=\frac{1}{\nu}\left(1-(1-\nu \alpha)\exp\left(-\nu \phi|_H H_T\int_0^Y \frac{1}{\mathcal{D}(R(\hat{Y}))}\,\mathrm{d}\hat{Y}\right)\right). \end{equation}

\begin{equation} \rho=\frac{1}{\nu}\left(1-(1-\nu \alpha)\exp\left(-\nu \phi|_H H_T\int_0^Y \frac{1}{\mathcal{D}(R(\hat{Y}))}\,\mathrm{d}\hat{Y}\right)\right). \end{equation}

By additionally imposing the boundary condition (2.20e) we obtain an equation for the motion of the evaporation front, ![]() $H$, in terms of the suspended dirt volume fraction there,

$H$, in terms of the suspended dirt volume fraction there, ![]() $\theta |_{H}$, namely

$\theta |_{H}$, namely

\begin{equation} H_T\int_0^H \frac{1}{\mathcal{D}(R(\hat{Y}))}\,\mathrm{d}\hat{Y}=\frac{1}{\nu \phi|_H}\log\left(\frac{1-\nu \alpha}{1-\nu f(\theta|_{H})}\right).\end{equation}

\begin{equation} H_T\int_0^H \frac{1}{\mathcal{D}(R(\hat{Y}))}\,\mathrm{d}\hat{Y}=\frac{1}{\nu \phi|_H}\log\left(\frac{1-\nu \alpha}{1-\nu f(\theta|_{H})}\right).\end{equation}

One particular case of interest is if ![]() $\mathcal {D}$ is uniform (for instance, if little dirt has been deposited, so

$\mathcal {D}$ is uniform (for instance, if little dirt has been deposited, so ![]() $R\approx 0$ is constant). In this case (3.3) reduces to

$R\approx 0$ is constant). In this case (3.3) reduces to

If ![]() $\theta |_H$ were constant, we would see a

$\theta |_H$ were constant, we would see a ![]() $\sqrt {T}$ behaviour of the evaporation front, as expected for this type of Stefan problem. For

$\sqrt {T}$ behaviour of the evaporation front, as expected for this type of Stefan problem. For ![]() $\mathcal {D}$ non-uniform in

$\mathcal {D}$ non-uniform in ![]() $Y$, the integral term in (3.3) behaves like an overall resistance to vapour transport. In particular, the integral is dominated by any localised regions of pore space in

$Y$, the integral term in (3.3) behaves like an overall resistance to vapour transport. In particular, the integral is dominated by any localised regions of pore space in ![]() $Y< H$ for which

$Y< H$ for which ![]() $\mathcal {D}$ is very small.

$\mathcal {D}$ is very small.

We see that the ODE (3.4) for ![]() $H$ (with

$H$ (with ![]() $\mathcal {D}$ constant) takes the form

$\mathcal {D}$ constant) takes the form

for an algebraic function ![]() $E_1$, while the more general (3.3) takes the form

$E_1$, while the more general (3.3) takes the form

By comparison, Ji & Sanaei (Reference Ji and Sanaei2023) prescribe an evaporative flux that does not explicitly depend on ![]() $H$, of the form

$H$, of the form

in our notation. Unlike (3.5) and (3.6), the model (3.7) does not explicitly depend on the position ![]() $H$ of the evaporating interface. These different equations for

$H$ of the evaporating interface. These different equations for ![]() $H$ result from different modelling assumptions: Ji & Sanaei (Reference Ji and Sanaei2023) assume that the vaporisation of the liquid molecules is the limiting process in the evaporation, whereas we have assumed that the vaporisation is instantaneous (the vapour is at its saturation point adjacent to

$H$ result from different modelling assumptions: Ji & Sanaei (Reference Ji and Sanaei2023) assume that the vaporisation of the liquid molecules is the limiting process in the evaporation, whereas we have assumed that the vaporisation is instantaneous (the vapour is at its saturation point adjacent to ![]() $Y=H$) and that evaporation is instead limited by the transport of vapour out of the porous material. For sufficiently deep or hydrophobic porous media that there is a moving drying front, it is clear that the evaporation rate should depend on the location

$Y=H$) and that evaporation is instead limited by the transport of vapour out of the porous material. For sufficiently deep or hydrophobic porous media that there is a moving drying front, it is clear that the evaporation rate should depend on the location ![]() $H$ of the drying front (Lehmann et al. Reference Lehmann, Assouline and Or2008; Shokri et al. Reference Shokri, Lehmann and Or2008). Furthermore, we note that our drying model is given in terms of well-defined physical parameters such as the diffusivity and saturation vapour densities, and results in a reasonable drying time scale

$H$ of the drying front (Lehmann et al. Reference Lehmann, Assouline and Or2008; Shokri et al. Reference Shokri, Lehmann and Or2008). Furthermore, we note that our drying model is given in terms of well-defined physical parameters such as the diffusivity and saturation vapour densities, and results in a reasonable drying time scale ![]() $l^2\rho _L/\rho _* D_v\approx 10^{2}$ s (using values for water:

$l^2\rho _L/\rho _* D_v\approx 10^{2}$ s (using values for water: ![]() $\rho _L\approx 10^3\ {\rm kg}\ {\rm m}^{-3}$,

$\rho _L\approx 10^3\ {\rm kg}\ {\rm m}^{-3}$, ![]() $\rho _*\approx 1\ {\rm kg}\ {\rm m}^{-3}$,

$\rho _*\approx 1\ {\rm kg}\ {\rm m}^{-3}$, ![]() $D_v\approx 10^{-5}\ {\rm m}^2\ {\rm s}^{-1}$ and

$D_v\approx 10^{-5}\ {\rm m}^2\ {\rm s}^{-1}$ and ![]() $l\sim 10^{-3}\ {\rm m}$), whereas the coefficients in a prescribed evaporation rate must be fitted in some way.

$l\sim 10^{-3}\ {\rm m}$), whereas the coefficients in a prescribed evaporation rate must be fitted in some way.

We note from (3.3) that evaporation only occurs when ![]() $f(\theta |_H)>\alpha$, so that the vapour density at the liquid–gas interface is greater than the atmospheric vapour density; otherwise if

$f(\theta |_H)>\alpha$, so that the vapour density at the liquid–gas interface is greater than the atmospheric vapour density; otherwise if ![]() $f(\theta |_H)=\alpha$, we see that

$f(\theta |_H)=\alpha$, we see that ![]() $H_T=0$. We define

$H_T=0$. We define ![]() $\hat {\theta }$ such that

$\hat {\theta }$ such that ![]() $f(\hat {\theta })=\alpha$, noting that since

$f(\hat {\theta })=\alpha$, noting that since ![]() $f$ is monotonic in

$f$ is monotonic in ![]() $\theta$, evaporation only occurs for

$\theta$, evaporation only occurs for ![]() $\theta <\hat {\theta }$.

$\theta <\hat {\theta }$.

Our analysis above (and in the remainder of this paper) is for the case that the atmospheric vapour density ![]() $\rho =\alpha$ is prescribed at the surface

$\rho =\alpha$ is prescribed at the surface ![]() $Y=0$. As an aside, we now briefly consider an alternative case, in which the flux,

$Y=0$. As an aside, we now briefly consider an alternative case, in which the flux, ![]() $J$, of vapour out of the material at

$J$, of vapour out of the material at ![]() $Y=0$ is prescribed by a Newton cooling law:

$Y=0$ is prescribed by a Newton cooling law: ![]() $J=m(\rho |_0-a_\infty )$, for some constants

$J=m(\rho |_0-a_\infty )$, for some constants ![]() $a_\infty$ (the far-field ambient vapour density) and

$a_\infty$ (the far-field ambient vapour density) and ![]() $m$ (the mass-transfer coefficient). Since the vapour flux is spatially uniform throughout

$m$ (the mass-transfer coefficient). Since the vapour flux is spatially uniform throughout ![]() $Y< H$ in the limit

$Y< H$ in the limit ![]() $\delta \ll 1$, we find that

$\delta \ll 1$, we find that ![]() $\phi |_H H_T=m(\rho |_0-a_\infty )$. Eliminating

$\phi |_H H_T=m(\rho |_0-a_\infty )$. Eliminating ![]() $\rho |_0$, we find that

$\rho |_0$, we find that ![]() $H_T$ is given by the implicit ODE

$H_T$ is given by the implicit ODE

(We may rearrange (3.8) to give ![]() $H_T$ explicitly in terms of a Lambert-

$H_T$ explicitly in terms of a Lambert-![]() $W$ function, but we consider the form (3.8) more useful as we may compare directly with (3.3).) Clearly in the limit as

$W$ function, but we consider the form (3.8) more useful as we may compare directly with (3.3).) Clearly in the limit as ![]() $m\rightarrow \infty$ (for which vapour is easily removed from the surface of the porous material), and with

$m\rightarrow \infty$ (for which vapour is easily removed from the surface of the porous material), and with ![]() $a_\infty =\alpha$ we regain (3.3). In the case of a bounded mass-transfer coefficient

$a_\infty =\alpha$ we regain (3.3). In the case of a bounded mass-transfer coefficient ![]() $m$, the non-instantaneous removal of vapour from the surface results in a slower evaporation rate

$m$, the non-instantaneous removal of vapour from the surface results in a slower evaporation rate ![]() $H_T$, compared with that given by (3.3).

$H_T$, compared with that given by (3.3).

4. Early time behaviour and numerical method

In this section we first consider the early time behaviour of our model (2.20) in § 4.1, in the limit of ![]() $\delta \ll 1$. This will be necessary in order to accurately initialise numerical simulations of the model, which is then discussed in § 4.2.

$\delta \ll 1$. This will be necessary in order to accurately initialise numerical simulations of the model, which is then discussed in § 4.2.

4.1. Early time analysis

To study the early time behaviour of the system (2.20), we suppose ![]() $T=b\tau$ where

$T=b\tau$ where ![]() $b\ll 1$ is the smallest parameter in the system, and

$b\ll 1$ is the smallest parameter in the system, and ![]() $\tau =O(1)$. From (2.20c), on this time scale we see that

$\tau =O(1)$. From (2.20c), on this time scale we see that ![]() $R_\tau =O(b\kappa )\ll 1$, and so

$R_\tau =O(b\kappa )\ll 1$, and so ![]() $R$ is small, hence, all of

$R$ is small, hence, all of ![]() $\mathcal {D},\phi$ and

$\mathcal {D},\phi$ and ![]() $\mathcal {C}$ are constant to leading order in

$\mathcal {C}$ are constant to leading order in ![]() $b$.

$b$.

We first consider the vapour problem in ![]() $Y< H$. On the short time scale the interface only moves a short distance, and so we rescale

$Y< H$. On the short time scale the interface only moves a short distance, and so we rescale

\begin{equation} H=\sqrt{\frac{b\mathcal{D}}{\phi}}\bar{H}, \quad Y=\sqrt{\frac{b\mathcal{D}}{\phi}}\bar{Y} \end{equation}

\begin{equation} H=\sqrt{\frac{b\mathcal{D}}{\phi}}\bar{H}, \quad Y=\sqrt{\frac{b\mathcal{D}}{\phi}}\bar{Y} \end{equation}in order to balance the mass-flux boundary condition (2.20d). The vapour problem is therefore self-similar in that we regain the same system at early time with these rescalings as the full system (2.20a), (2.20d)–(2.20e) and (2.20g), namely

We have already noted that ![]() $\delta \ll 1$ in general, and we take this limit now to make analytical progress. As in § 3, we find that

$\delta \ll 1$ in general, and we take this limit now to make analytical progress. As in § 3, we find that

where ![]() $\bar {H}(\tau )$ is the solution of

$\bar {H}(\tau )$ is the solution of

The value of ![]() $\theta$ at

$\theta$ at ![]() $\bar {Y}=\bar {H}(\tau )$ depends on the solution of the suspended dirt problem in the domain

$\bar {Y}=\bar {H}(\tau )$ depends on the solution of the suspended dirt problem in the domain ![]() $Y\in (H,1)=(\sqrt {b\mathcal {D}/\phi }\, \bar {H}(\tau ),1)$. On this short time scale, the full dirt problem (2.20b), (2.20f) and (2.20h), with the initial condition (2.21a–c), becomes

$Y\in (H,1)=(\sqrt {b\mathcal {D}/\phi }\, \bar {H}(\tau ),1)$. On this short time scale, the full dirt problem (2.20b), (2.20f) and (2.20h), with the initial condition (2.21a–c), becomes

To leading order in ![]() $b$, we see that

$b$, we see that ![]() $\theta _\tau =0$, so that

$\theta _\tau =0$, so that ![]() $\theta =\theta _{IC}$ is independent of time over the domain. However, in a boundary layer at

$\theta =\theta _{IC}$ is independent of time over the domain. However, in a boundary layer at ![]() $Y=\sqrt {b\mathcal {D}/\phi } \bar {H}$, suspended dirt accumulates due to the motion of the evaporation front. To examine this region, we make the change of variables

$Y=\sqrt {b\mathcal {D}/\phi } \bar {H}$, suspended dirt accumulates due to the motion of the evaporation front. To examine this region, we make the change of variables ![]() $Y=\sqrt {b\mathcal {D}/\phi }(\bar {H}(\tau )+z)$, so that, at leading order in

$Y=\sqrt {b\mathcal {D}/\phi }(\bar {H}(\tau )+z)$, so that, at leading order in ![]() $b$, the equations are

$b$, the equations are

This system (4.6) must be solved with (4.4) to determine ![]() $\theta$ and

$\theta$ and ![]() $\bar {H}$.

$\bar {H}$.

We look for a similarity solution of the form

for some constant ![]() $\lambda$ to be determined. In particular, from (4.4) we see that the suspended dirt volume fraction at the evaporating interface,

$\lambda$ to be determined. In particular, from (4.4) we see that the suspended dirt volume fraction at the evaporating interface, ![]() $\theta |_{\bar {H}}=\varTheta (0)$, must be constant in time for such a similarity solution to exist. Substituting into (4.6), we find the solution

$\theta |_{\bar {H}}=\varTheta (0)$, must be constant in time for such a similarity solution to exist. Substituting into (4.6), we find the solution

\begin{equation} \varTheta=\theta_{IC}+\left(\varTheta(0)-\theta_{IC}\right)\frac{\text{erfc}\left(\lambda+ \dfrac{\sqrt{\sigma}z}{2\sqrt{ \tau}}\right)}{\text{erfc}(\lambda)} ,\end{equation}

\begin{equation} \varTheta=\theta_{IC}+\left(\varTheta(0)-\theta_{IC}\right)\frac{\text{erfc}\left(\lambda+ \dfrac{\sqrt{\sigma}z}{2\sqrt{ \tau}}\right)}{\text{erfc}(\lambda)} ,\end{equation}

where ![]() $\lambda$ and the constant

$\lambda$ and the constant ![]() $\varTheta (0)$ satisfy

$\varTheta (0)$ satisfy

Solutions of (4.9)–(4.10) may be computed numerically, and are shown for various ![]() $\sigma$ and

$\sigma$ and ![]() $\theta _{IC}$ in figure 2.

$\theta _{IC}$ in figure 2.

Figure 2. Early time solution behaviour. Coloured lines show the variation of the solution of (4.9) and (4.10) with the suspended dirt diffusion time scale ![]() $\sigma$. Green dashed lines are the small-

$\sigma$. Green dashed lines are the small-![]() $\sigma$ approximations (4.11), while black dashed lines are the large-

$\sigma$ approximations (4.11), while black dashed lines are the large-![]() $\sigma$ approximations (4.13). Here we use the form

$\sigma$ approximations (4.13). Here we use the form ![]() $f(\theta )=1-\theta$ and set

$f(\theta )=1-\theta$ and set ![]() $\alpha =0$, so that

$\alpha =0$, so that ![]() $\hat {\theta }=1$. We additionally set

$\hat {\theta }=1$. We additionally set ![]() $\nu =0.5$.

$\nu =0.5$.

To establish some intuitive understanding of this early time behaviour, we now consider the sublimits ![]() $\sigma \ll 1$,

$\sigma \ll 1$, ![]() $\theta _{IC}\ll 1$ and

$\theta _{IC}\ll 1$ and ![]() $\sigma \gg 1$ in turn. We show our early time analytic solutions for each case in figure 3 (alongside numerical solutions for comparison, computed using the method described in § 4.2 below), all with excellent agreement. In each, we see that the vapour density

$\sigma \gg 1$ in turn. We show our early time analytic solutions for each case in figure 3 (alongside numerical solutions for comparison, computed using the method described in § 4.2 below), all with excellent agreement. In each, we see that the vapour density ![]() $\rho$ varies from

$\rho$ varies from ![]() $f(\theta |_H)=1-\theta |_H$ at

$f(\theta |_H)=1-\theta |_H$ at ![]() $Y=H$ to

$Y=H$ to ![]() $\alpha =0$ at the surface of the material, according to (4.3). The evaporation front moves with the expected

$\alpha =0$ at the surface of the material, according to (4.3). The evaporation front moves with the expected ![]() $\sqrt {T}$ behaviour, faster if there is a steeper vapour-density gradient. Suspended dirt accumulates in the liquid ahead of the evaporation front, with a spatial maximum in

$\sqrt {T}$ behaviour, faster if there is a steeper vapour-density gradient. Suspended dirt accumulates in the liquid ahead of the evaporation front, with a spatial maximum in ![]() $\theta$ at

$\theta$ at ![]() $Y=H$. The size of the boundary layer at

$Y=H$. The size of the boundary layer at ![]() $H$ over which

$H$ over which ![]() $\theta$ varies is dependent on

$\theta$ varies is dependent on ![]() $\sigma$, which quantifies suspended dirt diffusion. At early times, we expect little dirt deposition, so that the dirt-layer thickness

$\sigma$, which quantifies suspended dirt diffusion. At early times, we expect little dirt deposition, so that the dirt-layer thickness ![]() $R\approx 0$ throughout the porous material.

$R\approx 0$ throughout the porous material.

Figure 3. Early time solutions (4.3), (4.7a,b) and (4.8) (dotted lines) compared with numerical solutions (solid lines) of the full model (2.20), for ![]() $\sigma =0.01$ (a,b)

$\sigma =0.01$ (a,b) ![]() $\sigma =1$, (c,d) and

$\sigma =1$, (c,d) and ![]() $\sigma =10$ (e,f). The profiles of

$\sigma =10$ (e,f). The profiles of ![]() $\rho$,

$\rho$, ![]() $\theta$ and

$\theta$ and ![]() $R$ in figures a, c, and e are at times for which

$R$ in figures a, c, and e are at times for which ![]() $H=0.3$ (towards the end of what we would consider ‘early’ time, especially in the small-

$H=0.3$ (towards the end of what we would consider ‘early’ time, especially in the small-![]() $\sigma$ case). Throughout the figure we take

$\sigma$ case). Throughout the figure we take ![]() $f(\theta )=1-\theta$,

$f(\theta )=1-\theta$, ![]() $\kappa =1$,

$\kappa =1$, ![]() $\theta _{IC}=0.1$,

$\theta _{IC}=0.1$, ![]() $\nu =0.5$,

$\nu =0.5$, ![]() $\delta =10^{-3}$,

$\delta =10^{-3}$, ![]() $r_0=0.2$,

$r_0=0.2$, ![]() $\alpha =0$ and

$\alpha =0$ and ![]() $\beta =0$.

$\beta =0$.

If ![]() $\sigma \ll 1$ so that suspended dirt diffusion is fast relative to the motion of the evaporation front, then we see from (4.9) that

$\sigma \ll 1$ so that suspended dirt diffusion is fast relative to the motion of the evaporation front, then we see from (4.9) that ![]() $\lambda =O(\sqrt {\sigma })$, and so from (4.10) that

$\lambda =O(\sqrt {\sigma })$, and so from (4.10) that ![]() $\theta |_h\sim \theta _{IC}$. Specifically, we find that

$\theta |_h\sim \theta _{IC}$. Specifically, we find that

\begin{equation} \left.\begin{array}{c} \varTheta(0)=\theta_{IC}+O(\sqrt{\sigma}),\\[3pt] \lambda=\sqrt{\sigma}\left(\sqrt{\dfrac{1}{2\nu}\log\left(\dfrac{1-\nu \alpha}{1-\nu f(\theta_{IC})}\right)}+O (\sqrt{\sigma})\right)\end{array}\!\!\right\} \quad \text{as }\sigma\rightarrow 0.\end{equation}

\begin{equation} \left.\begin{array}{c} \varTheta(0)=\theta_{IC}+O(\sqrt{\sigma}),\\[3pt] \lambda=\sqrt{\sigma}\left(\sqrt{\dfrac{1}{2\nu}\log\left(\dfrac{1-\nu \alpha}{1-\nu f(\theta_{IC})}\right)}+O (\sqrt{\sigma})\right)\end{array}\!\!\right\} \quad \text{as }\sigma\rightarrow 0.\end{equation}Thus, reverting to our original variables, the early time evaporating interface is given by

\begin{equation} H=\sqrt{T}\sqrt{\frac{\mathcal{D}}{2\nu\phi}\log\left(\frac{1-\nu \alpha}{1-\nu f(\theta_{IC})}\right)}+O(\sqrt{\sigma}) \quad \text{as }\sigma\rightarrow 0. \end{equation}

\begin{equation} H=\sqrt{T}\sqrt{\frac{\mathcal{D}}{2\nu\phi}\log\left(\frac{1-\nu \alpha}{1-\nu f(\theta_{IC})}\right)}+O(\sqrt{\sigma}) \quad \text{as }\sigma\rightarrow 0. \end{equation}

We also note from the form (4.8) of the solution that the spatial region over which ![]() $\theta$ varies is wide,

$\theta$ varies is wide, ![]() $O(1/\sqrt {\sigma })$. In this small-

$O(1/\sqrt {\sigma })$. In this small-![]() $\sigma$ limit, the diffusion of dirt is fast relative to the motion of the evaporation front, and so the suspended dirt volume fraction

$\sigma$ limit, the diffusion of dirt is fast relative to the motion of the evaporation front, and so the suspended dirt volume fraction ![]() $\theta$ remains close to its initial value

$\theta$ remains close to its initial value ![]() $\theta _{IC}$, only deviating by a small,

$\theta _{IC}$, only deviating by a small, ![]() $O(\sqrt {\sigma })$, amount. For conservation of overall dirt, the region over which the accumulating suspended dirt is spread is wide, of

$O(\sqrt {\sigma })$, amount. For conservation of overall dirt, the region over which the accumulating suspended dirt is spread is wide, of ![]() $O(1/\sqrt {\sigma })$ relative to the early time boundary layer. This may be seen in figure 3(a,b): since

$O(1/\sqrt {\sigma })$ relative to the early time boundary layer. This may be seen in figure 3(a,b): since ![]() $\sigma \ll 1$, the

$\sigma \ll 1$, the ![]() $\theta$ profile is approximately uniform in

$\theta$ profile is approximately uniform in ![]() $Y$, and so close to its initial value of

$Y$, and so close to its initial value of ![]() $\theta _{IC}=0.1$ at early times. The suspended dirt is accumulating due to the evaporation, but spread almost evenly through the domain.

$\theta _{IC}=0.1$ at early times. The suspended dirt is accumulating due to the evaporation, but spread almost evenly through the domain.

Next, we suppose that ![]() $\sigma =O(1)$ but the initial suspended dirt volume fraction

$\sigma =O(1)$ but the initial suspended dirt volume fraction ![]() $\theta _{IC}\ll 1$ is small. In this case, for a balance in both of (4.9) and (4.10), we must have

$\theta _{IC}\ll 1$ is small. In this case, for a balance in both of (4.9) and (4.10), we must have ![]() $\varTheta (0)=O(\theta _{IC})$ and

$\varTheta (0)=O(\theta _{IC})$ and ![]() $\lambda =O(1)$, as we might expect. The solution shown in figure 3(c,d) is for this case, with

$\lambda =O(1)$, as we might expect. The solution shown in figure 3(c,d) is for this case, with ![]() $\theta _{IC}=0.1$: we indeed observe that

$\theta _{IC}=0.1$: we indeed observe that ![]() $\theta |_H=O(0.1)$ (and this effect becomes increasingly clear for smaller

$\theta |_H=O(0.1)$ (and this effect becomes increasingly clear for smaller ![]() $\theta _{IC}$).

$\theta _{IC}$).

Finally, if ![]() $\sigma \gg 1$, so that the diffusion of suspended dirt is slow relative to the motion of the evaporation front, then from (4.9) we see that we must have

$\sigma \gg 1$, so that the diffusion of suspended dirt is slow relative to the motion of the evaporation front, then from (4.9) we see that we must have ![]() $f(\varTheta (0))=\alpha$ to leading order in

$f(\varTheta (0))=\alpha$ to leading order in ![]() $\sigma ^{-1}\ll 1$. At this value,

$\sigma ^{-1}\ll 1$. At this value,

there is no evaporation at leading order, as the vapour density at the atmospheric value is in equilibrium with the liquid–dirt interface, and there is no transport of vapour out of the porous material. Indeed, we see from (4.10) that when ![]() $\theta =\hat {\theta }$,

$\theta =\hat {\theta }$, ![]() $\lambda$ is the solution of

$\lambda$ is the solution of

\begin{equation} \lambda {\rm e}^{\lambda^2}\,\text{erfc}(\lambda)=\frac{\hat{\theta}-\theta_{IC}}{\hat{\theta}\sqrt{\rm \pi}}, \end{equation}

\begin{equation} \lambda {\rm e}^{\lambda^2}\,\text{erfc}(\lambda)=\frac{\hat{\theta}-\theta_{IC}}{\hat{\theta}\sqrt{\rm \pi}}, \end{equation}

which is independent of ![]() $\sigma$ and of

$\sigma$ and of ![]() $O(1)$, so that the position of the evaporating interface, given by

$O(1)$, so that the position of the evaporating interface, given by

\begin{equation} H=\frac{2\lambda}{\sqrt{\sigma}}\sqrt{\frac{\mathcal{D}}{\phi}}\sqrt{T}, \end{equation}

\begin{equation} H=\frac{2\lambda}{\sqrt{\sigma}}\sqrt{\frac{\mathcal{D}}{\phi}}\sqrt{T}, \end{equation}

is of order ![]() $\sigma ^{-1/2}\ll 1$ away from its initial position. Thus, when the suspended dirt diffusion is slow, the diffusion of dirt away from

$\sigma ^{-1/2}\ll 1$ away from its initial position. Thus, when the suspended dirt diffusion is slow, the diffusion of dirt away from ![]() $H$ limits the speed of the evaporation front, so that there is a slower,

$H$ limits the speed of the evaporation front, so that there is a slower, ![]() $O(\sigma )$, drying time scale. We also note from (4.8) that the region over which

$O(\sigma )$, drying time scale. We also note from (4.8) that the region over which ![]() $\theta$ varies is narrow, with width

$\theta$ varies is narrow, with width ![]() $O(1/\sqrt {\sigma })$ relative to the early time boundary layer. The boundary layer is narrow for large

$O(1/\sqrt {\sigma })$ relative to the early time boundary layer. The boundary layer is narrow for large ![]() $\sigma$, so that the early time solution actually remains valid for the majority of the drying process. Indeed, in figure 3(e,f) we see excellent agreement between the early time analytic solution and the numerical solution for

$\sigma$, so that the early time solution actually remains valid for the majority of the drying process. Indeed, in figure 3(e,f) we see excellent agreement between the early time analytic solution and the numerical solution for ![]() $\rho, \theta$ and

$\rho, \theta$ and ![]() $H$ up to the time when the evaporating front is halfway through the domain. This is because the boundary layer at

$H$ up to the time when the evaporating front is halfway through the domain. This is because the boundary layer at ![]() $H$ over which

$H$ over which ![]() $\theta$ varies is narrow, and so the effect of the boundary at

$\theta$ varies is narrow, and so the effect of the boundary at ![]() $Y=1$ is not felt until

$Y=1$ is not felt until ![]() $H$ is close to 1. However, we notice in figure 3(e) that the early time approximation

$H$ is close to 1. However, we notice in figure 3(e) that the early time approximation ![]() $R=0$ ceases to be accurate at these late times. The early time solution would remain valid so long as

$R=0$ ceases to be accurate at these late times. The early time solution would remain valid so long as ![]() $R$ remains relatively small (e.g. if

$R$ remains relatively small (e.g. if ![]() $\kappa$ and

$\kappa$ and ![]() $\theta _{IC}$ are fairly small). We note that, since the boundary layer width scales with

$\theta _{IC}$ are fairly small). We note that, since the boundary layer width scales with ![]() $\sqrt {T}$, it quickly becomes numerically impractical to resolve the solution at small times for large

$\sqrt {T}$, it quickly becomes numerically impractical to resolve the solution at small times for large ![]() $\sigma$. The early time asymptotic solution is therefore very valuable in initialising the simulations accurately for large

$\sigma$. The early time asymptotic solution is therefore very valuable in initialising the simulations accurately for large ![]() $\sigma$.

$\sigma$.

Finally, we note that our early time analysis in this section is equivalent to studying the original problem on a semi-infinite domain ![]() $Y\in (0,\infty )$, in the combined limit

$Y\in (0,\infty )$, in the combined limit ![]() $\kappa,\delta \rightarrow 0$.

$\kappa,\delta \rightarrow 0$.

4.2. Numerical method

We solve the model (2.20) numerically using the method of lines. Specifically, we first transform the model onto two separate fixed domains, setting ![]() $\eta =Y/H(T)$ for the gas–vapour problem, which then holds in

$\eta =Y/H(T)$ for the gas–vapour problem, which then holds in ![]() $\eta \in (0,1)$, and setting

$\eta \in (0,1)$, and setting ![]() $\xi =(Y-H(T))/(1-H(T))$ for the liquid–dirt problem, which then also holds in

$\xi =(Y-H(T))/(1-H(T))$ for the liquid–dirt problem, which then also holds in ![]() $\xi \in (0,1)$. We discretise spatially on these transformed domains, with a uniform mesh, using central differences for diffusive terms and first-order upwinding for advective terms, so that the scheme is overall first order. (The advection for the vapour problem (2.20a), including the artificial advection terms due to the change of variables, is negative; the purely artificial advection in the liquid–dirt problem (2.20b)–(2.20c) is also negative. Upwinding these terms therefore requires forward differences in both cases.) We then use the inbuilt ODE solver ode15s in Matlab for the time stepping. We note that the model is stiff in certain parameter regimes of interest (

$\xi \in (0,1)$. We discretise spatially on these transformed domains, with a uniform mesh, using central differences for diffusive terms and first-order upwinding for advective terms, so that the scheme is overall first order. (The advection for the vapour problem (2.20a), including the artificial advection terms due to the change of variables, is negative; the purely artificial advection in the liquid–dirt problem (2.20b)–(2.20c) is also negative. Upwinding these terms therefore requires forward differences in both cases.) We then use the inbuilt ODE solver ode15s in Matlab for the time stepping. We note that the model is stiff in certain parameter regimes of interest (![]() $\delta \ll 1$ and/or

$\delta \ll 1$ and/or ![]() $\sigma \ll 1$), and that ode15s is specifically designed for stiff systems. Ode15s is a multistep solver, using numerical differentiation formulas of order 1–5 (Shampine & Reichelt Reference Shampine and Reichelt1997). We make use of our early time asymptotic solution of § 4.1 to initialise our numerical simulations. In particular, the spatial mesh must be sufficiently fine to resolve the boundary layer in the suspended dirt problem at

$\sigma \ll 1$), and that ode15s is specifically designed for stiff systems. Ode15s is a multistep solver, using numerical differentiation formulas of order 1–5 (Shampine & Reichelt Reference Shampine and Reichelt1997). We make use of our early time asymptotic solution of § 4.1 to initialise our numerical simulations. In particular, the spatial mesh must be sufficiently fine to resolve the boundary layer in the suspended dirt problem at ![]() $Y=H$ at early times. Our analysis in § 4.1 suggests we require the number of spatial mesh points

$Y=H$ at early times. Our analysis in § 4.1 suggests we require the number of spatial mesh points ![]() $N$ to scale like

$N$ to scale like

\begin{equation} N=O\left(\sqrt{\frac{\mathcal{D}(0)\sigma}{\phi(0)T}}\right) \quad \text{for }T\ll1. \end{equation}

\begin{equation} N=O\left(\sqrt{\frac{\mathcal{D}(0)\sigma}{\phi(0)T}}\right) \quad \text{for }T\ll1. \end{equation}

More efficient solvers might take further advantage of the asymptotic structure of the system and distribute mesh points unevenly through the domain in order to ensure good resolution of the boundary layer while maintaining computational efficiency. However, by making use of our early time asymptotic solution we do not require simulations at particularly small ![]() $T$, and our uniform-mesh formulation suffices.

$T$, and our uniform-mesh formulation suffices.

5. The slow deposition limit  $\kappa \ll 1$ and dry clogging

$\kappa \ll 1$ and dry clogging

Having stated the model and our numerical solution method, we are now in a position to explore solutions of the model. In this section we focus on the limit ![]() $\kappa \ll 1$, for which the dirt-deposition time scale is much longer than the evaporation time scale. We expect that the accumulation of suspended dirt due to evaporation and the effects of suspended dirt diffusion to be dominant.

$\kappa \ll 1$, for which the dirt-deposition time scale is much longer than the evaporation time scale. We expect that the accumulation of suspended dirt due to evaporation and the effects of suspended dirt diffusion to be dominant.

We first consider the leading-order behaviour, taking ![]() $\kappa =0$, and show that the evaporation becomes infinitely slow as suspended dirt accumulates. We then allow

$\kappa =0$, and show that the evaporation becomes infinitely slow as suspended dirt accumulates. We then allow ![]() $\kappa$ to be small but non-zero, and explore our first clogging scenario, which we term ‘dry clogging’.

$\kappa$ to be small but non-zero, and explore our first clogging scenario, which we term ‘dry clogging’.

5.1. Infinitely slow evaporation when  $\kappa =0$

$\kappa =0$

Taking ![]() $\kappa =0$, we see from (2.20c) that we have

$\kappa =0$, we see from (2.20c) that we have ![]() $R=0$ everywhere, and thus,

$R=0$ everywhere, and thus, ![]() $\mathcal {D}=\mathcal {D}_0$,

$\mathcal {D}=\mathcal {D}_0$, ![]() $\mathcal {C}=\mathcal {C}_0$ and

$\mathcal {C}=\mathcal {C}_0$ and ![]() $\phi =\phi _0$ are all constant, equal to their values at

$\phi =\phi _0$ are all constant, equal to their values at ![]() $R=0$. Taking the

$R=0$. Taking the ![]() $\delta \ll 1$ limit as in § 3, the motion of the evaporation front is therefore governed by (3.4), i.e.

$\delta \ll 1$ limit as in § 3, the motion of the evaporation front is therefore governed by (3.4), i.e.

while ![]() $\theta$ satisfies

$\theta$ satisfies

To investigate how the accumulation of suspended dirt affects the evaporation rate, we consider the additional limit of ![]() $\sigma \ll 1$ so that the diffusion of suspended dirt is fast. In this case, we see from (5.2) that

$\sigma \ll 1$ so that the diffusion of suspended dirt is fast. In this case, we see from (5.2) that ![]() $\theta (T)$ is uniform, and so, for overall conservation of dirt, we must have

$\theta (T)$ is uniform, and so, for overall conservation of dirt, we must have

Substituting (5.3) into (5.1) we obtain the single equation for ![]() $H(T)$,

$H(T)$,

As discussed previously, the evaporation shuts down when ![]() $\theta =\hat {\theta }$ so that

$\theta =\hat {\theta }$ so that ![]() $f(\hat {\theta })=\alpha$, since then

$f(\hat {\theta })=\alpha$, since then ![]() $H_T=0$. At this point we see from (5.3) that

$H_T=0$. At this point we see from (5.3) that ![]() $H=1-\theta _{IC}/\hat {\theta }$.

$H=1-\theta _{IC}/\hat {\theta }$.

Numerical solutions of the model (2.20) (with ![]() $\kappa =0$,

$\kappa =0$, ![]() $\delta =10^{-3}$) are shown in figures 4(a) and 4(b), and compared with the solution of (5.4) for the limit of

$\delta =10^{-3}$) are shown in figures 4(a) and 4(b), and compared with the solution of (5.4) for the limit of ![]() $\sigma \rightarrow 0$, with good agreement for

$\sigma \rightarrow 0$, with good agreement for ![]() $\sigma =0.1$ and smaller. We take the functional form

$\sigma =0.1$ and smaller. We take the functional form ![]() $f(\theta )=1-\theta$ for these simulations, and fix

$f(\theta )=1-\theta$ for these simulations, and fix ![]() $\alpha =0$ (so that

$\alpha =0$ (so that ![]() $\hat {\theta }=1$). In figure 4(c) we show solutions of (5.4) for various

$\hat {\theta }=1$). In figure 4(c) we show solutions of (5.4) for various ![]() $\theta _{IC}$. We see that, for larger

$\theta _{IC}$. We see that, for larger ![]() $\theta _{IC}$, the evaporation is slower, with the evaporating interface

$\theta _{IC}$, the evaporation is slower, with the evaporating interface ![]() $H$ moving more slowly into the domain. In particular, we note that when

$H$ moving more slowly into the domain. In particular, we note that when ![]() $\theta _{IC}=0$, the evaporation is completed (with

$\theta _{IC}=0$, the evaporation is completed (with ![]() $H=1$) in finite time

$H=1$) in finite time

(from (5.4) with ![]() $\theta _{IC}=0$), whereas for

$\theta _{IC}=0$), whereas for ![]() $\theta _{IC}>0$, we see that

$\theta _{IC}>0$, we see that ![]() $H$ appears to take infinite time to reach

$H$ appears to take infinite time to reach ![]() $1-\theta _{IC}/\hat {\theta }$.

$1-\theta _{IC}/\hat {\theta }$.

Figure 4. The effect of suspended dirt accumulation on the evaporation, for ![]() $\kappa =0$ and

$\kappa =0$ and ![]() $\sigma \ll 1$. Numerical solutions of (2.20) shown with

$\sigma \ll 1$. Numerical solutions of (2.20) shown with ![]() $\kappa =0$ (no dirt deposition), alongside the solution of (5.4) in the limit

$\kappa =0$ (no dirt deposition), alongside the solution of (5.4) in the limit ![]() $\sigma \rightarrow 0$, (taking

$\sigma \rightarrow 0$, (taking ![]() $f(\theta )=1-\theta$ and

$f(\theta )=1-\theta$ and ![]() $\alpha =0$). Throughout the figure we take

$\alpha =0$). Throughout the figure we take ![]() $\nu =0.5$ and

$\nu =0.5$ and ![]() $r_0=0.2$. (a) Motion of the evaporation front

$r_0=0.2$. (a) Motion of the evaporation front ![]() $H(T)$ for various

$H(T)$ for various ![]() $\sigma$, with

$\sigma$, with ![]() $\theta _{IC}=0.3$. (b) Vapour density and suspended dirt volume fraction profiles at the same time

$\theta _{IC}=0.3$. (b) Vapour density and suspended dirt volume fraction profiles at the same time ![]() $T=0.2$ for various

$T=0.2$ for various ![]() $\sigma$, with

$\sigma$, with ![]() $\theta _{IC}=0.3$. (c) Effect of

$\theta _{IC}=0.3$. (c) Effect of ![]() $\theta _{IC}$ on the evaporating interface motion. Dashed lines are

$\theta _{IC}$ on the evaporating interface motion. Dashed lines are ![]() $1-\theta _{IC}$.

$1-\theta _{IC}$.

We investigate this late time behaviour (within the ![]() $\sigma \ll 1$ limit) by considering the expansion

$\sigma \ll 1$ limit) by considering the expansion

where ![]() $c\ll 1$ is small and

$c\ll 1$ is small and ![]() $\mathcal {H}=O(1)$ is positive. Assuming that

$\mathcal {H}=O(1)$ is positive. Assuming that ![]() $f$ is continuous at

$f$ is continuous at ![]() $\theta =\hat {\theta }$, on substitution of (5.6) into (5.4) we find that (retaining only leading-order terms on either side)

$\theta =\hat {\theta }$, on substitution of (5.6) into (5.4) we find that (retaining only leading-order terms on either side)

\begin{align}

c\left(1-\frac{\theta_{IC}}{\hat{\theta}}\right)\frac{\theta_{IC}}{\hat{\theta}}\mathcal{H}_T&={-}

\frac{\mathcal{D}_0}{\phi_0(1-\nu

\alpha)}\biggl(f\biggl(\frac{\hat{\theta}}{1+c\mathcal{H}}\biggr)-\alpha\biggr)\nonumber\\

&={-}\frac{\mathcal{D}_0}{\phi_0(1-\nu \alpha)}(

f(\hat{\theta}(1-c\mathcal{H}+O(c^2)))-\alpha).

\end{align}

\begin{align}

c\left(1-\frac{\theta_{IC}}{\hat{\theta}}\right)\frac{\theta_{IC}}{\hat{\theta}}\mathcal{H}_T&={-}

\frac{\mathcal{D}_0}{\phi_0(1-\nu

\alpha)}\biggl(f\biggl(\frac{\hat{\theta}}{1+c\mathcal{H}}\biggr)-\alpha\biggr)\nonumber\\

&={-}\frac{\mathcal{D}_0}{\phi_0(1-\nu \alpha)}(

f(\hat{\theta}(1-c\mathcal{H}+O(c^2)))-\alpha).

\end{align}

So long as the gradient of the function ![]() $f$ is bounded at

$f$ is bounded at ![]() $\hat {\theta }$, we may Taylor expand the right-hand side of (5.7) and, thus, find that, to leading order in