1. Introduction

Significant advances have been achieved in recent years in understanding the structure and motion of freely propagating premixed flames, including the role of intrinsic flame instabilities and flame-turbulence interactions, using a hydrodynamic theory. Following the multi-scale approach proposed by Clavin & Williams (Reference Clavin and Williams1982), a general theory of multi-dimensional flames in arbitrary flow fields has been derived systematically from the general governing equations by Matalon & Matkowsky (Reference Matalon and Matkowsky1982, Reference Matalon and Matkowsky1983), and generalized by Matalon, Cui & Bechtold (Reference Matalon, Cui and Bechtold2003) to account for salient physical properties, including temperature-dependent transport, differential and preferential diffusion (i.e. anon-unity and distinct Lewis numbers for the fuel and oxidizer), and effects due to stoichiometry and reaction orders. The main assumption behind this theory is that the flame is thin relative to all other fluid dynamic length scales and can be treated as a surface of density discontinuity when determining the flow field. The instantaneous shape and location of the flame surface, and expressions relating the pressure and velocities across this surface were obtained by asymptotic matching. Of paramount importance is the flame speed-flame stretch relation that has captivated the interest of experimentalists whose raw data from measurements in laboratory configurations was found to correlate well with this prediction. The hydrodynamic theory has been used in analytical and numerical studies to successfully unravel mechanisms of flame instability, their onset and their nonlinear growth. Moreover, since the complexity of the chemistry is captured elegantly by fewer physicochemical parameters, the restriction on numerical time step and mesh size in turbulent flame calculations is alleviated making it an ideal model for fundamental understanding, which is free of turbulence modelling assumptions, empiricism and/or ad hoc adjustable parameters. The approach was successfully implemented in two and three dimensions for planar and spherically expanding turbulent flames (Creta & Matalon Reference Creta and Matalon2011; Fogla, Creta & Matalon Reference Fogla, Creta and Matalon2015; Patyal & Matalon Reference Patyal and Matalon2018; Mohan & Matalon Reference Mohan and Matalon2021, Reference Mohan and Matalon2022; Patyal & Matalon Reference Patyal and Matalon2022), capturing many important morphological features, such as multiply folded and disjoint surfaces, pinching of surface elements and the creation of pockets of unburned gas, all of which are commonly observed in laboratory flames. Additionally, predictions of flame characteristics, including the turbulent flame speed that is arguably one of the most important properties, were found to compare well with empirical correlations suggested in the literature (Fogla, Creta & Matalon Reference Fogla, Creta and Matalon2017).

The objective of this study is the derivation of a hydrodynamic theory of premixed flames propagating in closed vessels. There are significant differences when the flame propagates in an open or closed space. Consider, for example, a flame initiated from a small ignition source at the centre of a spherical vessel containing a combustible mixture. The outwardly propagating flame appears at first smooth and spherical but, after reaching a critical size, it spontaneously turns into a highly cellular structure. For mixtures deficient in their more mobile component (sub-unity Lewis numbers), such as lean hydrogen–air, the critical flame size at the onset of instability is of the order of the flame thickness and the observed instability is thermo-diffusive in nature. In mixtures for which the Lewis number is greater than one, such as rich hydrogen–air, the critical flame size at the onset of instability is of the order of several flame thicknesses. The average cell size of the developing flame is significantly larger, with the flame surface bearing resemblance to that of a soccer ball. Such mixtures are thermo-diffusively stable, and the observed instability is hydrodynamic in nature. It is the well-known Darrieus–Landau instability (Darrieus Reference Darrieus1938; Landau Reference Landau1944) induced by gas expansion that results from the heat released by the chemical reactions (Istratov & Librovich Reference Istratov and Librovich1969; Bechtold & Matalon Reference Bechtold and Matalon1987; Addabbo, Bechtold & Matalon Reference Addabbo, Bechtold and Matalon2002). The increase in surface area of the corrugated flame, further augmented by the continuous creation of cells as the flame grows bigger, results in enhanced fuel consumption and an increased propagation speed. In open space, this development occurs under nearly isobaric conditions; the mean pressure remains virtually constant and equal to the ambient pressure. In a closed vessel, the mean pressure increases in time, the gas is compressed and its temperature rises, leading to higher flame temperatures and a subsequent increase in propagation speed. The self-acceleration of the flame would be significantly affected by combustion instabilities and, in a turbulent environment, by the highly vortical field within which the flame is propagating. The role of intrinsic combustion instabilities and flame-turbulence interactions when the flame is propagating in a confined environment have not been thoroughly investigated. Fundamental understanding of the flame morphology, the dependence of the burning rate on the state of the gas, the onset of instabilities, self-wrinkling and self-acceleration of the flame surface, and the effects of turbulence all have practical implications on the design of engineering devices. It is also important from a safety perspective, to prevent undesirable phenomena such as knocking or the onset of detonations.

Expanding flames in spherical chambers are frequently used in the laboratory to ascertain the laminar flame speeds and Markstein lengths of various fuel mixtures experimentally, owing to a well-defined stretch rate that diminishes as the flame grows bigger. The continuously changing temperature and pressure of the unburned mixture, the unknown effect of pressure buildup and the onset of flame instabilities poses significant challenges in the accuracy of data reduction and limit the range of mixtures that can be studied. Moreover, the measurements are prone to yielding widely different values of burning velocities (Andrews & Bradley Reference Andrews and Bradley1972). Some investigators addressed these issues by modifying their experimental device to alleviate the rapid changes in pressure and allowing nearly constant-pressure measurements (Tse, Zhu & Law Reference Tse, Zhu and Law2000, Reference Tse, Zhu and Law2004). Others have limited measurements to the initial stages of flame propagation by assuming a negligible pressure rise and unconfined conditions (Bradley et al. Reference Bradley, Hicks, Lawes, Sheppard and Woolley1998). The accuracy of the burning velocity values determined by the confined flame method compared with those obtained from unconfined conditions were recently examined, noting that a slight pressure rise contributes to an increase in burned gas density and an inward flow of the expanded burned gas (Chen, Burke & Ju Reference Chen, Burke and Ju2009; Omari & Tartakovsky Reference Omari and Tartakovsky2016), both of which significantly affect the measured data. Fundamental understanding of the fluid dynamical consequences when the flame propagates in a closed vessel, the dependence of the burning rate on pressure buildup and the onset or delay of instabilities and cellularity will contribute greatly to the experimental effort.

Earlier hydrodynamic studies of confined flames, including the original work of Sivashinsky (Reference Sivashinsky1979) and the stability analyses of McGreevy & Matalon (Reference McGreevy and Matalon1994a,Reference McGreevy and Matalonb), treated the flame as a structureless surface of discontinuity. The present work is the first asymptotic theory that resolves the structure of the thin but finite flame zone, and captures the effect of pressure rise, flow conditions and mixture properties on the flame speed; it follows a previous exploration by Bechtold & Matalon (Reference Bechtold and Matalon2000) that sowed the seeds of this paper. The analysis shows that the flame speed of confined flames is modified not only by flame stretch, representing the distortion of an element of the flame surface, but also by variations of the flame thickness that combine to describe the deformation of a volume element of the flame zone, or the voluminal stretch. This concept, first introduced by Buckmaster (Reference Buckmaster1979) in the context of slowly varying flames, has not been apparent in the hydrodynamic theory of freely propagating flames owing to the assumption of a constant flame thickness. Elements of this idea, referred to as mass-based flame stretch, were exploited by de-Goey and co-workers (van Oijen et al. Reference van Oijen, Donini, Bastiaans, ten Thije Boonkkamp and de Goey2016) in their numerical simulations. In addition to the voluminal stretch, the flame speed is shown to be also modified by the rate of pressure increase. The two ingredients, voluminal stretch and pressure rise, arising from physicochemical influences associated with the internal flame structure, are modulated when cast in dimensional form by two pressure-dependent Markstein lengths of the order of the flame thickness. Since the increase in burning rate as the pressure rises causes the flame to become thinner, their effects diminish during combustion and become negligible in the latter stages of propagation. While this assertion has been phenomenologically recognized, it is the first time that it has been quantified in a detailed analysis.

Flame stretch is an asymptotic concept that is unambiguously defined when the flame is confined to a surface. It measures the distortion of the flame that results from its motion and from the fluid velocity gradient it experiences, and can be expressed in terms of properties of the flame surface, such as curvature and propagation speed, and of the underlying velocity field (Matalon Reference Matalon1983). For freely propagating flames, it may be also expressed as a combination of the curvature of the flame front and the hydrodynamic strain it experiences. This representation is particularly convenient in general computational studies because the strain rate is implemented in most fluid dynamical codes. However, it requires specifying an isosurface within the flame zone that represents the flame front, and accommodating for the velocity divergence that, although it vanishes on either side of the flame, is not zero within the numerically resolved flame zone due to gas expansion (Giannakopoulos et al. Reference Giannakopoulos, Gatzoulis, Frouzakis, Matalon and Tomboulides2015). It is shown that under confinement, flame stretch is not a simple combination of the surface curvature and hydrodynamic strain, because the velocity divergence is not zero even outside the flame zone owing to adiabatic compression. Even in the hydrodynamic limit, when the flame is confined to a surface, the contribution of the velocity divergence at the flame front is essential to balance the local strain rate and properly evaluate the stretch rate.

In the freely propagating flame theory, the chemical activity is confined to a thin layer embedded within the flame zone and centred near the location where the temperature reaches its maximum value – the adiabatic flame temperature. For a given mixture, the adiabatic flame temperature is a constant that depends on the total heat release. In a closed vessel the flame temperature exceeds the adiabatic value and varies in time as a consequence of pressure rise. Moreover, the temperature in the burned gas continues to increase due to adiabatic compression. These conditions preclude the use of the standard activation energy asymptotic approximation, which has greatly facilitated analyses of combustion problems by confining the chemical activity to a reaction sheet. The temporal change of flame temperature requires readjusting the reaction zone thickness from one time to the next, while the continual increase in temperature in the burned gas prevents expressing the jump in temperature gradient across the reaction sheet in closed form. Consequently, we employ a delta-function model that has been used in the literature when encountering similar technical difficulties (Matkowsky & Sivashinsky Reference Matkowsky and Sivashinsky1978; Buckmaster & Ludford Reference Buckmaster and Ludford1983; Margolis & Matkowsky Reference Margolis and Matkowsky1983). In this approach, the reaction rate takes the form of a Dirac delta function with a strength expressed as an Arrhenius form of the instantaneous flame temperature. The jump conditions across the reaction sheet are then determined by direct integration of the governing equations. We demonstrate that a formal asymptotic approach can be carried out by adopting the Newtonian approximation (Van Dyke Reference Van Dyke1954; Cole Reference Cole1957), whereby the ratio of specific heats is assumed near unity. In this limit the flame temperature is near its adiabatic value, delaying the aforementioned difficulties to higher orders. The restriction placed on the ratio of specific heats leads to a description of flame propagation that is not as rich as the more general case, but provides justification for the delta-function model employed without this limitation.

2. Governing equations

A homogeneous combustible mixture consisting of two reactants, both appearing in small quantities relative to an abundant inert gas, resides in a closed vessel. The mass fraction of the deficient and excess reactants in the mixture are ![]() $Y_{D_0}$ and

$Y_{D_0}$ and ![]() $Y_{E_0}$, respectively, with the index

$Y_{E_0}$, respectively, with the index ![]() $i=D,E$ representing the deficient/excess reactant and the subscript 0 identifying conditions of the given initial mixture. In a lean mixture, the fuel is the deficient component, while in a rich mixture the deficient component is the oxidizer. Upon ignition, a flame separating the fresh mixture from the burned products propagates throughout the vessel. The chemical activity is modelled by a single overall step:

$i=D,E$ representing the deficient/excess reactant and the subscript 0 identifying conditions of the given initial mixture. In a lean mixture, the fuel is the deficient component, while in a rich mixture the deficient component is the oxidizer. Upon ignition, a flame separating the fresh mixture from the burned products propagates throughout the vessel. The chemical activity is modelled by a single overall step:

Here ![]() $\mathcal {C}_{i}$ represents the chemical symbol and

$\mathcal {C}_{i}$ represents the chemical symbol and ![]() $\nu _{i}$ the stoichiometric coefficient of species

$\nu _{i}$ the stoichiometric coefficient of species ![]() $i$. The reaction rate is given by

$i$. The reaction rate is given by

where ![]() $\tilde \rho$ is the density and

$\tilde \rho$ is the density and ![]() $\tilde T$ the temperature of the mixture,

$\tilde T$ the temperature of the mixture, ![]() $Y_i$ and

$Y_i$ and ![]() $W_{i}$ are the mass fraction and molecular weight of species

$W_{i}$ are the mass fraction and molecular weight of species ![]() $i$,

$i$, ![]() $E$ is the overall activation energy,

$E$ is the overall activation energy, ![]() $\mathcal {R}$ is the gas constant and

$\mathcal {R}$ is the gas constant and ![]() $\mathcal {B}$ a pre-exponential factor. To allow for mixture compositions ranging from lean to rich conditions, we introduce the excess-to-deficient reactant mass ratio

$\mathcal {B}$ a pre-exponential factor. To allow for mixture compositions ranging from lean to rich conditions, we introduce the excess-to-deficient reactant mass ratio

where ![]() $\nu =\nu _{E}W_{E}/\nu _{D}W_{D}$ is the mass-weighted stoichiometric coefficient ratio. As defined,

$\nu =\nu _{E}W_{E}/\nu _{D}W_{D}$ is the mass-weighted stoichiometric coefficient ratio. As defined, ![]() $\varPhi$ is always larger than one, with

$\varPhi$ is always larger than one, with ![]() $\varPhi = 1$ corresponding to a stoichiometric mixture. Hence,

$\varPhi = 1$ corresponding to a stoichiometric mixture. Hence, ![]() $\varPhi$ is equal to the equivalence ratio for fuel-rich mixtures and to the reciprocal of the equivalence ratio for fuel-lean mixtures.

$\varPhi$ is equal to the equivalence ratio for fuel-rich mixtures and to the reciprocal of the equivalence ratio for fuel-lean mixtures.

Deflagrative combustion phenomena are highly subsonic and a low-Mach-number approximation may be employed for their description; the characteristic Mach number ![]() ${Ma}$ is defined as the ratio of the laminar flame speed to the speed of sound in the initial fresh mixture. For

${Ma}$ is defined as the ratio of the laminar flame speed to the speed of sound in the initial fresh mixture. For ![]() ${Ma} \ll 1$, the pressure in the vessel is rapidly equalized such that spatial variations remain relatively small. The pressure may then be decomposed into the mean pressure

${Ma} \ll 1$, the pressure in the vessel is rapidly equalized such that spatial variations remain relatively small. The pressure may then be decomposed into the mean pressure ![]() $\tilde P = \tilde P(t)$ and small fluctuations of

$\tilde P = \tilde P(t)$ and small fluctuations of ![]() $O({Ma}^2)$ that balance the small changes in momentum. The temporal variations of the mean pressure

$O({Ma}^2)$ that balance the small changes in momentum. The temporal variations of the mean pressure ![]() $\tilde P(t)$ are determined by integrating the energy equation throughout the entire domain, after neglecting the small viscous dissipation term. For impermeable walls, and in the absence of heat losses, one finds that

$\tilde P(t)$ are determined by integrating the energy equation throughout the entire domain, after neglecting the small viscous dissipation term. For impermeable walls, and in the absence of heat losses, one finds that

where ![]() $t$ is the time variable,

$t$ is the time variable, ![]() $P_0, \rho _0,T_0$ the pressure, density and temperature of the fresh unburned mixture,

$P_0, \rho _0,T_0$ the pressure, density and temperature of the fresh unburned mixture, ![]() $Q$ the total heat release,

$Q$ the total heat release, ![]() $c_v$ the specific heat at constant volume (assumed constant) and

$c_v$ the specific heat at constant volume (assumed constant) and ![]() $\tilde {\mathbb {V}}$ the volume of the vessel. A consequence of this quasi-isobaric approximation is the simplification of the equation of state to

$\tilde {\mathbb {V}}$ the volume of the vessel. A consequence of this quasi-isobaric approximation is the simplification of the equation of state to

where ![]() $\bar W$ is the mean molecular weight of the mixture (assumed constant).

$\bar W$ is the mean molecular weight of the mixture (assumed constant).

The equations governing the combustion process consist of the Navier–Stokes equations supplemented by mass balance equations for the two reactants and an energy equation for the mixture. To express these equations in dimensionless form, the hydrodynamic length scale ![]() $l$ is used as a unit length, the laminar flame speed

$l$ is used as a unit length, the laminar flame speed ![]() $S_{L}$ as a unit speed and the ratio

$S_{L}$ as a unit speed and the ratio ![]() $l/S_{L}$ as a unit of time. The hydrodynamic length characterizes the lateral size of the flame or the average wavelength of corrugations evolving on its surface. Diffusion processes introduce an additional length scale

$l/S_{L}$ as a unit of time. The hydrodynamic length characterizes the lateral size of the flame or the average wavelength of corrugations evolving on its surface. Diffusion processes introduce an additional length scale ![]() $l_d = \mathcal {D}_{th} /S_{L}$, where

$l_d = \mathcal {D}_{th} /S_{L}$, where ![]() $\mathcal {D}_{th} = \lambda _{{0}}/\rho _{0} c_p$ is the thermal diffusivity of the initial fresh mixture with

$\mathcal {D}_{th} = \lambda _{{0}}/\rho _{0} c_p$ is the thermal diffusivity of the initial fresh mixture with ![]() $\lambda _0$ the thermal conductivity and

$\lambda _0$ the thermal conductivity and ![]() $c_p$ the specific heat at constant pressure (assumed constant). The ratio of the diffusion-to-hydrodynamic length scales,

$c_p$ the specific heat at constant pressure (assumed constant). The ratio of the diffusion-to-hydrodynamic length scales, ![]() $\delta \equiv l_d/l$, is a representative measure of the flame thickness. Pressure, density and temperature are scaled with respect to their values in the initial fresh mixture

$\delta \equiv l_d/l$, is a representative measure of the flame thickness. Pressure, density and temperature are scaled with respect to their values in the initial fresh mixture ![]() $P_0, \rho _0,T_0$. The transport coefficients, including the viscosity

$P_0, \rho _0,T_0$. The transport coefficients, including the viscosity ![]() $\tilde \mu$ and thermal conductivity

$\tilde \mu$ and thermal conductivity ![]() $\tilde \lambda$ of the mixture, and the diffusion coefficients

$\tilde \lambda$ of the mixture, and the diffusion coefficients ![]() $\tilde \rho \mathcal {D}_i$ where

$\tilde \rho \mathcal {D}_i$ where ![]() $\mathcal {D}_i$ is the molecular diffusivity of species

$\mathcal {D}_i$ is the molecular diffusivity of species ![]() $i$ (into the inert gas), depend on temperature. Scaled by their values in the initial fresh mixture, the dimensionless coefficients

$i$ (into the inert gas), depend on temperature. Scaled by their values in the initial fresh mixture, the dimensionless coefficients

are assumed to have the same temperature dependence such that their ratios, consisting of the Prandtl ![]() $\Pr \equiv \tilde \mu c_p/\tilde \lambda$ and Lewis

$\Pr \equiv \tilde \mu c_p/\tilde \lambda$ and Lewis ![]() ${{Le}_i \equiv \tilde \lambda / \tilde \rho \mathcal {D}_i c_p}$ numbers, remain constant. The common transport coefficient (in dimensionless form) takes the form

${{Le}_i \equiv \tilde \lambda / \tilde \rho \mathcal {D}_i c_p}$ numbers, remain constant. The common transport coefficient (in dimensionless form) takes the form ![]() $\lambda (T) = T^a$, with

$\lambda (T) = T^a$, with ![]() $1/2 \le a \le 1$. The laminar flame speed for a two-reactant model obeying (2.2) in the large activation energy limit (Bechtold & Matalon Reference Bechtold and Matalon1999), is given by

$1/2 \le a \le 1$. The laminar flame speed for a two-reactant model obeying (2.2) in the large activation energy limit (Bechtold & Matalon Reference Bechtold and Matalon1999), is given by

\begin{equation} S_{L} = \sqrt{4 \left(\frac{\tilde \rho_a}{\rho_{{0}}}\right)^{2} \frac{\tilde \lambda_a}{\lambda_{{0}}} \frac{\mathcal{D}_{th} {(1 + \beta ( \varPhi - 1)/2{Le}_E)}} {\beta^{3} {\nu_{E}^{{-}1} {\nu_{D}^{{-}1} }} {Le}_E^{{-}1}{Le}_D^{{-}1} } \frac{\rho_0 Y_{D_0} \mathcal{B}}{ \nu_D W_{D}}} \exp({-E/2\mathcal{R} \tilde T_{a}}), \end{equation}

\begin{equation} S_{L} = \sqrt{4 \left(\frac{\tilde \rho_a}{\rho_{{0}}}\right)^{2} \frac{\tilde \lambda_a}{\lambda_{{0}}} \frac{\mathcal{D}_{th} {(1 + \beta ( \varPhi - 1)/2{Le}_E)}} {\beta^{3} {\nu_{E}^{{-}1} {\nu_{D}^{{-}1} }} {Le}_E^{{-}1}{Le}_D^{{-}1} } \frac{\rho_0 Y_{D_0} \mathcal{B}}{ \nu_D W_{D}}} \exp({-E/2\mathcal{R} \tilde T_{a}}), \end{equation}where

\begin{equation} \beta = \frac{E(\tilde T_a - T_0) }{ \mathcal{R} \tilde T_{a}^{2} },\quad \tilde T_a =T_0 + \frac {(Q/c_p) Y_{D_0} }{ \nu_{D}W_{D} } \end{equation}

\begin{equation} \beta = \frac{E(\tilde T_a - T_0) }{ \mathcal{R} \tilde T_{a}^{2} },\quad \tilde T_a =T_0 + \frac {(Q/c_p) Y_{D_0} }{ \nu_{D}W_{D} } \end{equation}

are, respectively, the Zel'dovich number and adiabatic flame temperature. The subscript ![]() $a$ stands for values evaluated at the adiabatic temperature, namely

$a$ stands for values evaluated at the adiabatic temperature, namely ![]() $\tilde \lambda _a = \tilde \lambda (\tilde T_a)$ and

$\tilde \lambda _a = \tilde \lambda (\tilde T_a)$ and ![]() $\tilde \rho _a/\rho _{{0}} = T_0 / \tilde T_a$. Below, only when the same symbols are used for both dimensional and dimensionless variables, the dimensional quantities are distinguished by a ‘tilde’ accent.

$\tilde \rho _a/\rho _{{0}} = T_0 / \tilde T_a$. Below, only when the same symbols are used for both dimensional and dimensionless variables, the dimensional quantities are distinguished by a ‘tilde’ accent.

In dimensionless form, the governing equations are

where ![]() $\mathrm {D}/\mathrm {D} t \equiv \partial /\partial t + \boldsymbol v \boldsymbol {\cdot } \boldsymbol \nabla$ is the convective derivative,

$\mathrm {D}/\mathrm {D} t \equiv \partial /\partial t + \boldsymbol v \boldsymbol {\cdot } \boldsymbol \nabla$ is the convective derivative, ![]() $\boldsymbol v$ is the gas velocity,

$\boldsymbol v$ is the gas velocity, ![]() $\boldsymbol {\varSigma }$ is the viscous stress tensor given by

$\boldsymbol {\varSigma }$ is the viscous stress tensor given by

with ![]() $\boldsymbol E$ and

$\boldsymbol E$ and ![]() $\boldsymbol I$ the strain rate and unit tensors (the superscript

$\boldsymbol I$ the strain rate and unit tensors (the superscript ![]() $\mathrm {T}$ denoting the transpose) and

$\mathrm {T}$ denoting the transpose) and

the reaction rate. Consistent with the low-Mach-number approximation, the pressure has been expressed as ![]() $P(t) + \gamma {Ma}^2 p(\boldsymbol x,t)$, where

$P(t) + \gamma {Ma}^2 p(\boldsymbol x,t)$, where ![]() $P$ is the spatially uniform (or mean) pressure in the vessel and

$P$ is the spatially uniform (or mean) pressure in the vessel and ![]() $p$ is the dynamic pressure. In view of (2.4), the overall or mean pressure is obtained from

$p$ is the dynamic pressure. In view of (2.4), the overall or mean pressure is obtained from

where the integration is performed over the entire volume ![]() ${\mathbb {V}}$ expressed in units of the hydrodynamic length

${\mathbb {V}}$ expressed in units of the hydrodynamic length ![]() $l$. In addition to the Prandtl number

$l$. In addition to the Prandtl number ![]() $\Pr$ and Lewis number

$\Pr$ and Lewis number ![]() ${Le}_D, {Le}_E$, the parameters appearing in these equations are: the ratio of specific heats

${Le}_D, {Le}_E$, the parameters appearing in these equations are: the ratio of specific heats ![]() $\gamma = {c_p/ c_v}$, the heat release parameter

$\gamma = {c_p/ c_v}$, the heat release parameter ![]() $q = (Q Y_{D_{{0}}} / \nu _{D}W_{D})/ c_p T_0$ that represents the ratio of the total heat released per unit mass of the deficient reactant to the enthalpy of the initial mixture, the adiabatic flame temperature

$q = (Q Y_{D_{{0}}} / \nu _{D}W_{D})/ c_p T_0$ that represents the ratio of the total heat released per unit mass of the deficient reactant to the enthalpy of the initial mixture, the adiabatic flame temperature ![]() $T_a = 1+ q$ and the activation energy parameter

$T_a = 1+ q$ and the activation energy parameter ![]() $\beta _0 = E/\mathcal {R}T_0$ related to the Zel'dovich number

$\beta _0 = E/\mathcal {R}T_0$ related to the Zel'dovich number ![]() $\beta$ via

$\beta$ via ![]() $\beta _0 = (T_a^2/q) \beta$. The Damköhler number

$\beta _0 = (T_a^2/q) \beta$. The Damköhler number ![]() $\mathbb {D}$, representing the ratio of the flow to the chemical reaction times, is given by

$\mathbb {D}$, representing the ratio of the flow to the chemical reaction times, is given by

where ![]() $\tilde {\mathcal {B}}$ is the scaled pre-exponential factor (in units of s

$\tilde {\mathcal {B}}$ is the scaled pre-exponential factor (in units of s![]() $^{-1}$). When substituting for the laminar flame speed (2.7), the Damköhler number simplifies to

$^{-1}$). When substituting for the laminar flame speed (2.7), the Damköhler number simplifies to

For a stoichiometric mixture, ![]() $\varPhi = 1$, the Damköhler number depends on the Lewis numbers of both reactants, while for a mixture remote from stoichiometry, it depends primarily on the Lewis number of the deficient reactant.

$\varPhi = 1$, the Damköhler number depends on the Lewis numbers of both reactants, while for a mixture remote from stoichiometry, it depends primarily on the Lewis number of the deficient reactant.

An expression for the end pressure ![]() $P = P_{e}$, defined as the mean pressure in the vessel at time

$P = P_{e}$, defined as the mean pressure in the vessel at time ![]() $t= t_e$, namely the time when the flame has consumed all the available reactant, can be obtained by integrating the combined energy and appropriate species equations

$t= t_e$, namely the time when the flame has consumed all the available reactant, can be obtained by integrating the combined energy and appropriate species equations

\begin{align} & \frac{\partial}{\partial t} \left(\rho \left(\frac{qY_{D}}{{Y_{D_{0}}}}+T \right) \right) + \boldsymbol\nabla \boldsymbol{\cdot} \left({\rho {\boldsymbol v} \left(\frac{qY_{D}}{{Y_{D_{0}}} }+T \right) } \right) - \delta \boldsymbol\nabla \boldsymbol{\cdot}\left(\lambda \boldsymbol\nabla \left(\frac{qY_{D} }{{Y_{D_{0}}} } {Le}_D^{{-}1}+T \right) \right) \nonumber\\ &\quad =\frac{\gamma -1}{\gamma} \frac{\mathrm{d}P}{\mathrm{d}t} \end{align}

\begin{align} & \frac{\partial}{\partial t} \left(\rho \left(\frac{qY_{D}}{{Y_{D_{0}}}}+T \right) \right) + \boldsymbol\nabla \boldsymbol{\cdot} \left({\rho {\boldsymbol v} \left(\frac{qY_{D}}{{Y_{D_{0}}} }+T \right) } \right) - \delta \boldsymbol\nabla \boldsymbol{\cdot}\left(\lambda \boldsymbol\nabla \left(\frac{qY_{D} }{{Y_{D_{0}}} } {Le}_D^{{-}1}+T \right) \right) \nonumber\\ &\quad =\frac{\gamma -1}{\gamma} \frac{\mathrm{d}P}{\mathrm{d}t} \end{align}over the entire volume. For impermeable and rigid walls, and in the absence of heat losses, it simplifies to

which can be integrated in time from ![]() $t = 0$ to

$t = 0$ to ![]() $t= t_e$, to give

$t= t_e$, to give ![]() $P_{e} = 1 + \gamma q$. If combustion was to occur uniformly throughout the vessel as in a stirred reactor, such that

$P_{e} = 1 + \gamma q$. If combustion was to occur uniformly throughout the vessel as in a stirred reactor, such that ![]() $\rho = 1$, the final temperature would be the constant-volume adiabatic temperature

$\rho = 1$, the final temperature would be the constant-volume adiabatic temperature ![]() $1 + \gamma q$. However, owing to the fluid dynamics associated with the flame propagation, neither the density nor the temperature remain spatially uniform. It should be noted that in determining

$1 + \gamma q$. However, owing to the fluid dynamics associated with the flame propagation, neither the density nor the temperature remain spatially uniform. It should be noted that in determining ![]() $P_{e}$ we have assumed that a flame already exists at

$P_{e}$ we have assumed that a flame already exists at ![]() $t=0$. In other words, the theory does not describe the short ignition event that is expected to have a minor effect on the end pressure level.

$t=0$. In other words, the theory does not describe the short ignition event that is expected to have a minor effect on the end pressure level.

The governing equations (2.9)–(2.17) will be analysed using a multi-scale approach that exploits the disparity in length scales associated with the fluid dynamics, diffusion and chemical reactions. The flame zone consisting of the region where diffusion and chemical reactions occur may be treated as an internal layer of ![]() $O(\delta )$, with

$O(\delta )$, with ![]() $\delta \ll 1$, that separates the unburned gas from the burned products. Consequently, the governing equations in the hydrodynamic regions on either side of the flame zone are greatly simplified, but they remain dependent on the instantaneous shape and location of the flame surface, or equivalently, on the flame propagation speed. The latter, which is the focus of the subsequent analysis, depends on the diffusion and chemical processes occurring inside the flame zone, on the pressure buildup and on the interaction of the flame with the local flow conditions.

$\delta \ll 1$, that separates the unburned gas from the burned products. Consequently, the governing equations in the hydrodynamic regions on either side of the flame zone are greatly simplified, but they remain dependent on the instantaneous shape and location of the flame surface, or equivalently, on the flame propagation speed. The latter, which is the focus of the subsequent analysis, depends on the diffusion and chemical processes occurring inside the flame zone, on the pressure buildup and on the interaction of the flame with the local flow conditions.

In the following sections we start by examining the simplifications that result in the hydrodynamic zones. We then analyse the physicochemical processes occurring in the thin but finite flame zone and derive explicit expressions for the flame speed and overall pressure rise. Following a general discussion of the results, applicable to general time-dependent multi-dimensional flames in vessels of arbitrary geometry, we provide a complete description of planar and spherical flames. We conclude with general comments about and future applications of the derived hydrodynamic theory.

3. The hydrodynamic zones

In the limit ![]() $\delta \to 0$, the flame zone shrinks to a surface described by

$\delta \to 0$, the flame zone shrinks to a surface described by ![]() $\psi (\boldsymbol x,t) = 0$ and referred to as the flame front. It separates the unburned gas in the region

$\psi (\boldsymbol x,t) = 0$ and referred to as the flame front. It separates the unburned gas in the region ![]() $\psi (\boldsymbol x, t) < 0$ from the burned products in the region

$\psi (\boldsymbol x, t) < 0$ from the burned products in the region ![]() $\psi (\boldsymbol x,t) > 0$, and is characterized by the geometric factors

$\psi (\boldsymbol x,t) > 0$, and is characterized by the geometric factors

defined to represent the unit normal pointing towards the burned gas region and the propagation speed (in the laboratory frame) of the flame surface back along its normal. The determination of the instantaneous shape and location of the flame front and/or the propagation speed depend on the diffusion and reaction processes occurring inside the flame zone, as discussed in the next section.

To leading order in ![]() $\delta$, diffusion and chemical reactions are negligible on either side of the flame front, i.e.

$\delta$, diffusion and chemical reactions are negligible on either side of the flame front, i.e. ![]() $\psi (\boldsymbol x,t) \lessgtr 0$, and the governing equations reduce to

$\psi (\boldsymbol x,t) \lessgtr 0$, and the governing equations reduce to

The combination of the continuity (3.2) and energy (3.5) equations implies that the volume dilatation rate is

namely, fluid elements on either side of the flame are progressively compressed. Integrating (2.9)–(2.13) across the flame zone and taking the limit ![]() $\delta \to 0$ yield the Rankine–Hugoniot (RH) jump conditions

$\delta \to 0$ yield the Rankine–Hugoniot (RH) jump conditions

where the bracket ![]() $[\![ \,\,]\!]$ denotes the jump across the flame front, i.e.

$[\![ \,\,]\!]$ denotes the jump across the flame front, i.e. ![]() $[\![ \varTheta ]\!]=\varTheta |_{{\psi =0^+}} - \varTheta |_{{\psi =0^-}}$. Comments regarding the

$[\![ \varTheta ]\!]=\varTheta |_{{\psi =0^+}} - \varTheta |_{{\psi =0^-}}$. Comments regarding the ![]() $O(\delta )$ corrections will be discussed below, following the flame zone analysis.

$O(\delta )$ corrections will be discussed below, following the flame zone analysis.

Given that the fresh mixture in the vessel is initially homogeneous, and assuming that the deficient reactant is completely consumed in the flame zone, (3.4a,b) yield

The energy equation (3.5), when combined with the equation of state (3.6), shows that the function

referred to as the entropy function (the entropy of the gas is proportional to ![]() $\ln \mathcal {E}$), satisfies

$\ln \mathcal {E}$), satisfies

Since the state of the fresh gas is initially uniform and the entropy ahead of the flame is conserved along particle paths, ![]() $\mathcal {E} = 1$ in the unburned gas region. In the burned gas region

$\mathcal {E} = 1$ in the unburned gas region. In the burned gas region ![]() $\mathcal {E}=\mathcal {E}(\boldsymbol x, t)$ is determined by solving (3.13). As a consequence,

$\mathcal {E}=\mathcal {E}(\boldsymbol x, t)$ is determined by solving (3.13). As a consequence,

The temperature and density of the unburned gas remain spatially uniform, but their values increase in time because of gas compression, a conclusion that remains true to all orders in ![]() $\delta$. By contrast, the temporally varying temperature and density at the moving front,

$\delta$. By contrast, the temporally varying temperature and density at the moving front,

are advected with the flow downstream such that the burned gas is no longer spatially uniform. Here and below, subscripts ![]() $b$ and

$b$ and ![]() $u$ will be used to denote conditions on the burned/unburned side of the flame front; i.e. at

$u$ will be used to denote conditions on the burned/unburned side of the flame front; i.e. at ![]() $\psi = 0^{\pm }$, respectively. The flame temperature

$\psi = 0^{\pm }$, respectively. The flame temperature ![]() $T_{f}$, defined as the temperature at

$T_{f}$, defined as the temperature at ![]() $\psi = 0^+$, is given to leading order by

$\psi = 0^+$, is given to leading order by ![]() $T_b$ and is seen to exceed the adiabatic flame temperature

$T_b$ and is seen to exceed the adiabatic flame temperature ![]() $T_a$ as a result of adiabatic compression. On the other hand, the extent of gas expansion across the flame,

$T_a$ as a result of adiabatic compression. On the other hand, the extent of gas expansion across the flame,

diminishes as the pressure rises.

To complete the formulation, an equation describing the evolution of the flame surface ![]() $\psi (\boldsymbol x,t)=0$ or, equivalently, the propagation speed

$\psi (\boldsymbol x,t)=0$ or, equivalently, the propagation speed ![]() $V_{f}$, must be derived. It is customary to use instead of the propagation speed, the flame speed, which is defined as the propagation speed relative to the flow of fresh mixture, namely

$V_{f}$, must be derived. It is customary to use instead of the propagation speed, the flame speed, which is defined as the propagation speed relative to the flow of fresh mixture, namely

where the ![]() $^*$ denotes conditions at

$^*$ denotes conditions at ![]() $\psi =0^-$. The local mass burning rate

$\psi =0^-$. The local mass burning rate

refers to the normal mass flux at the cold edge of the flame zone as viewed from an observer moving with the flame front. The flame speed, burning rate and mean pressure rise depend on the physicochemical processes occurring inside the flame zone, as discussed next.

4. The flame zone

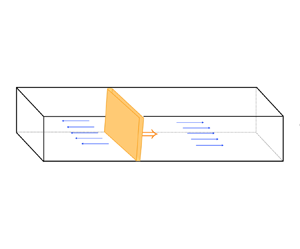

It is convenient in the following analysis to introduce a curvilinear coordinate system attached to the flame front, as shown in figure 1. The flame front is parametrized by the surface coordinates ![]() $(\xi _1,\xi _2)$ aligned with the principal directions of curvature at each point of the surface, and

$(\xi _1,\xi _2)$ aligned with the principal directions of curvature at each point of the surface, and ![]() ${\boldsymbol e_1}, {\boldsymbol e_2}$ denote unit vectors tangential to the parametric curves

${\boldsymbol e_1}, {\boldsymbol e_2}$ denote unit vectors tangential to the parametric curves ![]() $\xi _2 = {\rm const.}$ and

$\xi _2 = {\rm const.}$ and ![]() $\xi _1 = {\rm const.}$, respectively. The three vectors

$\xi _1 = {\rm const.}$, respectively. The three vectors ![]() $\boldsymbol e_{1},\boldsymbol e_{2},\boldsymbol n$, with

$\boldsymbol e_{1},\boldsymbol e_{2},\boldsymbol n$, with ![]() $\boldsymbol n = \boldsymbol e_1 \times \boldsymbol e_2$, form an orthogonal triad of unit vectors and (

$\boldsymbol n = \boldsymbol e_1 \times \boldsymbol e_2$, form an orthogonal triad of unit vectors and (![]() $\xi _1, \xi _2, n$) may be taken as the coordinates of an arbitrary point P in space at time

$\xi _1, \xi _2, n$) may be taken as the coordinates of an arbitrary point P in space at time ![]() $t$. The vector position

$t$. The vector position ![]() $\boldsymbol r$ of the point P with respect to the fixed rectangular coordinate system may be expressed in terms of the distance

$\boldsymbol r$ of the point P with respect to the fixed rectangular coordinate system may be expressed in terms of the distance ![]() $n$ from the flame front and the position vector

$n$ from the flame front and the position vector ![]() $\boldsymbol r_f$ of the projection of P on the surface, namely

$\boldsymbol r_f$ of the projection of P on the surface, namely

which serves as the transformation from the rectangular to the moving intrinsic surface coordinate system. The unit vectors ![]() $\boldsymbol e_1$ and

$\boldsymbol e_1$ and ![]() $\boldsymbol e_2$ are given by

$\boldsymbol e_2$ are given by

where ![]() $a_i = |\partial \boldsymbol r_f /\partial \xi _i|$. The gas velocity may be decomposed as

$a_i = |\partial \boldsymbol r_f /\partial \xi _i|$. The gas velocity may be decomposed as ![]() $\boldsymbol v = \boldsymbol v_{\perp } + v_n \boldsymbol n$, where

$\boldsymbol v = \boldsymbol v_{\perp } + v_n \boldsymbol n$, where ![]() $v_n$ is the velocity component oriented normal to the flame surface and

$v_n$ is the velocity component oriented normal to the flame surface and ![]() $\boldsymbol v_{\perp } = v_1 \boldsymbol e_1 + v_2 \boldsymbol e_2$. Consequently,

$\boldsymbol v_{\perp } = v_1 \boldsymbol e_1 + v_2 \boldsymbol e_2$. Consequently, ![]() $m \equiv \rho (v_n - V_{f} )$ is the normal mass flux. Computation of the vector differential operators involve the scale factors

$m \equiv \rho (v_n - V_{f} )$ is the normal mass flux. Computation of the vector differential operators involve the scale factors

where ![]() $\kappa _1$ and

$\kappa _1$ and ![]() $\kappa _2$ are the principal curvatures in the

$\kappa _2$ are the principal curvatures in the ![]() $\xi _1$ and

$\xi _1$ and ![]() $\xi _2$ directions, respectively. The sum

$\xi _2$ directions, respectively. The sum ![]() $\kappa = \kappa _1 + \kappa _2$ is referred below as the curvature of the flame surface. The gradient operator then takes the form

$\kappa = \kappa _1 + \kappa _2$ is referred below as the curvature of the flame surface. The gradient operator then takes the form

where ![]() $\boldsymbol \nabla _{s}$ is its surface component. The divergence of a vector

$\boldsymbol \nabla _{s}$ is its surface component. The divergence of a vector ![]() $\boldsymbol b$, with components

$\boldsymbol b$, with components ![]() $(b_1,b_2,b_3)$ in the directions

$(b_1,b_2,b_3)$ in the directions ![]() $\boldsymbol e_1$,

$\boldsymbol e_1$, ![]() $\boldsymbol e_2$ and

$\boldsymbol e_2$ and ![]() $\boldsymbol n$ respectively, is given by

$\boldsymbol n$ respectively, is given by

and the Laplacian of a scalar ![]() $\varphi$ is

$\varphi$ is

Transforming the governing equations also requires expressing time derivatives in the moving frame, using

with ![]() $\dot {\boldsymbol {\xi }} = l_1 \dot \xi _1 \boldsymbol e_1 + l_2 \dot \xi _2 \boldsymbol e_2$, where the ‘dot’ corresponds to differentiation with respect to time, and

$\dot {\boldsymbol {\xi }} = l_1 \dot \xi _1 \boldsymbol e_1 + l_2 \dot \xi _2 \boldsymbol e_2$, where the ‘dot’ corresponds to differentiation with respect to time, and ![]() $V_{f} = - \partial n/\partial t$. We will avoid writing the general equations in the moving curvilinear system and express only the relevant terms at each stage of the analysis. Further details can be found in Matalon et al. (Reference Matalon, Cui and Bechtold2003, appendix B).

$V_{f} = - \partial n/\partial t$. We will avoid writing the general equations in the moving curvilinear system and express only the relevant terms at each stage of the analysis. Further details can be found in Matalon et al. (Reference Matalon, Cui and Bechtold2003, appendix B).

Figure 1. The intrinsic curvilinear coordinates (![]() $\xi _1, \xi _2, n$) to the flame surface. The blue and magenta vectors correspond to the normal component of the gas velocity

$\xi _1, \xi _2, n$) to the flame surface. The blue and magenta vectors correspond to the normal component of the gas velocity ![]() $v_n \boldsymbol n$ and normal propagation velocity

$v_n \boldsymbol n$ and normal propagation velocity ![]() $- V_{f} \boldsymbol n$, respectively.

$- V_{f} \boldsymbol n$, respectively.

To examine the internal structure of the flame zone, centred near the surface along which ![]() $n=0$, we introduce the stretched conductivity-weighted coordinate

$n=0$, we introduce the stretched conductivity-weighted coordinate

with ![]() $\delta \ll 1$, and seek solutions that match those in the hydrodynamic zones as

$\delta \ll 1$, and seek solutions that match those in the hydrodynamic zones as ![]() $\eta \to \mp \infty$. Although it is straightforward to simplify the governing equations in the flame zone using this transformation, they remain intractable analytically due to the highly nonlinear reaction rate term. A common simplification that has paved the way to most of the theoretical advances in combustion is the activation energy asymptotic approximation. The activation energy of chemical reactions occurring in combustion systems is typically large compared with the thermal energy of the fresh mixture, such that

$\eta \to \mp \infty$. Although it is straightforward to simplify the governing equations in the flame zone using this transformation, they remain intractable analytically due to the highly nonlinear reaction rate term. A common simplification that has paved the way to most of the theoretical advances in combustion is the activation energy asymptotic approximation. The activation energy of chemical reactions occurring in combustion systems is typically large compared with the thermal energy of the fresh mixture, such that ![]() $\beta _0 \gg 1$ or, equivalently, the Zel'dovich number

$\beta _0 \gg 1$ or, equivalently, the Zel'dovich number ![]() $\beta = q \beta _0/T_a^2 \gg 1$ (in the following analysis it is more convenient to use

$\beta = q \beta _0/T_a^2 \gg 1$ (in the following analysis it is more convenient to use ![]() $\beta _0$). As a result, the chemical activity is confined to a thin layer embedded within the flame zone and centred about the location where the temperature is near its maximum value – the flame temperature

$\beta _0$). As a result, the chemical activity is confined to a thin layer embedded within the flame zone and centred about the location where the temperature is near its maximum value – the flame temperature ![]() $T_{f}$. In the limit

$T_{f}$. In the limit ![]() $\beta _0 \to \infty$, the reaction rate

$\beta _0 \to \infty$, the reaction rate ![]() $\omega$ takes the form of a Dirac delta function of strength

$\omega$ takes the form of a Dirac delta function of strength ![]() ${\sim }\exp {(-\beta _0/T_{f}})$; i.e. an Arrhenius form of temperature

${\sim }\exp {(-\beta _0/T_{f}})$; i.e. an Arrhenius form of temperature ![]() $T_{f}$. This approximation has been implemented in one of two ways: as a formal asymptotic approach, in which the solution is expressed in terms of gauge functions that depend on

$T_{f}$. This approximation has been implemented in one of two ways: as a formal asymptotic approach, in which the solution is expressed in terms of gauge functions that depend on ![]() $\beta _0$, or as a model – the delta-function model with

$\beta _0$, or as a model – the delta-function model with ![]() $\beta _0$ treated as a finite parameter (Matkowsky & Sivashinsky Reference Matkowsky and Sivashinsky1978; Buckmaster & Ludford Reference Buckmaster and Ludford1983; Margolis & Matkowsky Reference Margolis and Matkowsky1983). The latter, which captures the essence of activation energy asymptotics, was used primarily when encountering technical difficulties that prevented the use of a formal approach.

$\beta _0$ treated as a finite parameter (Matkowsky & Sivashinsky Reference Matkowsky and Sivashinsky1978; Buckmaster & Ludford Reference Buckmaster and Ludford1983; Margolis & Matkowsky Reference Margolis and Matkowsky1983). The latter, which captures the essence of activation energy asymptotics, was used primarily when encountering technical difficulties that prevented the use of a formal approach.

A systematic asymptotic approach was used to describe the dynamics of freely propagating flames (Matalon & Matkowsky Reference Matalon and Matkowsky1982; Matalon et al. Reference Matalon, Cui and Bechtold2003). In this case, the flame temperature is constant and equal to ![]() $T_a$ and the reaction zone spans the region where

$T_a$ and the reaction zone spans the region where ![]() $T - T_a = O(1/\beta _0)$ such that

$T - T_a = O(1/\beta _0)$ such that ![]() $\omega = O(1)$. The reaction rate (2.16) is exponentially small, and hence, negligible in the preheat zone where

$\omega = O(1)$. The reaction rate (2.16) is exponentially small, and hence, negligible in the preheat zone where ![]() $T < T_a$, and vanishes identically in the post-reaction zone where the deficient reactant or both reactants for a stoichiometric mixture are completely consumed. The solution in the reaction zone that constitutes a balance between the diffusion and chemical reaction rates provides, through asymptotic matching, jump conditions across the reaction sheet that can be used to facilitate the determination of the solution in the flame zone. The analysis also requires adopting a near-equidiffusion formulation (Buckmaster & Ludford Reference Buckmaster and Ludford1982), whereby

$T < T_a$, and vanishes identically in the post-reaction zone where the deficient reactant or both reactants for a stoichiometric mixture are completely consumed. The solution in the reaction zone that constitutes a balance between the diffusion and chemical reaction rates provides, through asymptotic matching, jump conditions across the reaction sheet that can be used to facilitate the determination of the solution in the flame zone. The analysis also requires adopting a near-equidiffusion formulation (Buckmaster & Ludford Reference Buckmaster and Ludford1982), whereby ![]() ${Le}_i^{-1} = 1 - {le}_i/\beta _0$, and a near-stoichiometric mixture limit (Bechtold & Matalon Reference Bechtold and Matalon1999) where

${Le}_i^{-1} = 1 - {le}_i/\beta _0$, and a near-stoichiometric mixture limit (Bechtold & Matalon Reference Bechtold and Matalon1999) where ![]() $Y_{E_0} - \nu Y_{D_0} = O(1/\beta _0)$, such that

$Y_{E_0} - \nu Y_{D_0} = O(1/\beta _0)$, such that ![]() $\varPhi = 1 + \varphi /\beta _0$ with

$\varPhi = 1 + \varphi /\beta _0$ with ![]() $\varphi = O(1)$ representing the deviation from stoichiometry.

$\varphi = O(1)$ representing the deviation from stoichiometry.

When propagating in a closed vessel, the flame temperature ![]() $T_{f}$ varies in time and exceeds the adiabatic flame temperature

$T_{f}$ varies in time and exceeds the adiabatic flame temperature ![]() $T_a$. The reaction rate may then be expressed in the form

$T_a$. The reaction rate may then be expressed in the form

ensuring that the chemical reaction remains confined to a thin layer where ![]() $T - T_{f} = O(1/\beta _0)$. Retaining a reaction–diffusion balance inside the thin reaction layer, however, requires rescaling the equations from one time to the next by readjusting the reaction zone thickness with an exponentially small scale that balances the factor

$T - T_{f} = O(1/\beta _0)$. Retaining a reaction–diffusion balance inside the thin reaction layer, however, requires rescaling the equations from one time to the next by readjusting the reaction zone thickness with an exponentially small scale that balances the factor ![]() $\exp {(\beta _0/T_a - \beta _0/T_{f})}$. This constitutes a technical difficulty that prevents the use of a formal asymptotic approach. A resolution can be obtained if one adopts a Newtonian approximation (Van Dyke Reference Van Dyke1954; Cole Reference Cole1957), whereby

$\exp {(\beta _0/T_a - \beta _0/T_{f})}$. This constitutes a technical difficulty that prevents the use of a formal asymptotic approach. A resolution can be obtained if one adopts a Newtonian approximation (Van Dyke Reference Van Dyke1954; Cole Reference Cole1957), whereby ![]() $(\gamma - 1)/\gamma$ is treated as a small parameter. In this limit,

$(\gamma - 1)/\gamma$ is treated as a small parameter. In this limit, ![]() $T_{f} \sim T_a$ and the factor

$T_{f} \sim T_a$ and the factor ![]() $\exp {(\beta _0/T_a - \beta _0/T_{f})}$ remains, to leading order, an

$\exp {(\beta _0/T_a - \beta _0/T_{f})}$ remains, to leading order, an ![]() $O(1)$ quantity. This approach is implemented in § 7. Although the Newtonian approximation accounts for gas compression, the increase in density translates entirely into a pressure rise, with the temperature minimally affected. To allow for gas compression to modify both the temperature and pressure, as anticipated physically, and circumvent the aforementioned difficulty, we use instead the delta-function approach.

$O(1)$ quantity. This approach is implemented in § 7. Although the Newtonian approximation accounts for gas compression, the increase in density translates entirely into a pressure rise, with the temperature minimally affected. To allow for gas compression to modify both the temperature and pressure, as anticipated physically, and circumvent the aforementioned difficulty, we use instead the delta-function approach.

The reaction rate in the governing equations is now replaced by the Dirac delta function of strength ![]() ${\sim }\exp {(-\beta _0/T_{f})}$, and

${\sim }\exp {(-\beta _0/T_{f})}$, and ![]() $\beta _0$ is subsequently treated as a finite parameter. The chemical reaction is now confined to a surface located, without loss of generality, at

$\beta _0$ is subsequently treated as a finite parameter. The chemical reaction is now confined to a surface located, without loss of generality, at ![]() $\eta = 0$. For consistency with earlier studies, we retain the near-equidiffusion and near-stoichiometric assumptions and use the same scaling for the temperature–mass fraction coupling functions, namely

$\eta = 0$. For consistency with earlier studies, we retain the near-equidiffusion and near-stoichiometric assumptions and use the same scaling for the temperature–mass fraction coupling functions, namely

\begin{equation} \left.\begin{gathered} T + qY_{D}/Y_{D_0} = H + \beta_0^{{-}1} h_{D} + \cdots, \\ T +qY_{E}/\nu Y_{D_0} = H + \beta_0^{{-}1} (h_{E} + q \varphi) + \cdots, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} T + qY_{D}/Y_{D_0} = H + \beta_0^{{-}1} h_{D} + \cdots, \\ T +qY_{E}/\nu Y_{D_0} = H + \beta_0^{{-}1} (h_{E} + q \varphi) + \cdots, \end{gathered}\right\} \end{equation}where the enthalpy functions satisfy

\begin{equation} \left.\begin{gathered} \rho \frac{\mathrm{D}H}{\mathrm{D}t} - \delta \boldsymbol\nabla \boldsymbol{\cdot} (\lambda \boldsymbol\nabla H ) = \frac{\gamma - 1}{\gamma} \frac{\mathrm{d}P}{\mathrm{d}t}, \\ \rho \frac{\mathrm{D}h_i}{\mathrm{D}t} - \delta \boldsymbol\nabla \boldsymbol{\cdot} (\lambda \boldsymbol\nabla h_i ) ={-} \delta {le}_i \boldsymbol\nabla \boldsymbol{\cdot} (\lambda \boldsymbol\nabla (H - T)). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \rho \frac{\mathrm{D}H}{\mathrm{D}t} - \delta \boldsymbol\nabla \boldsymbol{\cdot} (\lambda \boldsymbol\nabla H ) = \frac{\gamma - 1}{\gamma} \frac{\mathrm{d}P}{\mathrm{d}t}, \\ \rho \frac{\mathrm{D}h_i}{\mathrm{D}t} - \delta \boldsymbol\nabla \boldsymbol{\cdot} (\lambda \boldsymbol\nabla h_i ) ={-} \delta {le}_i \boldsymbol\nabla \boldsymbol{\cdot} (\lambda \boldsymbol\nabla (H - T)). \end{gathered}\right\} \end{equation}

The enthalpy perturbations ![]() $h_{D}$ and

$h_{D}$ and ![]() $h_{E}$ may then be used as the dependent variables replacing the mass fractions. Since the deficient reactant is depleted by the chemical reaction,

$h_{E}$ may then be used as the dependent variables replacing the mass fractions. Since the deficient reactant is depleted by the chemical reaction,

in the burned gas region ![]() $(\eta \ge 0)$. At the reaction sheet (

$(\eta \ge 0)$. At the reaction sheet (![]() $\eta =0$),

$\eta =0$),

representing, respectively, the flame temperature and the mass of unconsumed reactant leaking through the reaction sheet. A direct integration of the governing equations across ![]() $\eta = 0$ yields the following jump relations:

$\eta = 0$ yields the following jump relations:

\begin{gather} \left.\begin{gathered} {}[\rho] = [T] = [H] = [h_i] = [\boldsymbol v] = 0, \\ [p] = \frac{4}{3} \Pr \left[\lambda \frac{\partial v_n}{\partial\eta}\right],\quad \left[\frac{\partial\boldsymbol v_{{\perp}}}{\partial\eta}\right] = 0, \\ \left[\frac{\partial H}{\partial\eta}\right] = 0,\quad \left[\frac{\partial h_i}{\partial\eta}\right] ={-}{le}_i \left[\frac{\partial T}{\partial\eta}\right], \end{gathered}\right\} \end{gather}

\begin{gather} \left.\begin{gathered} {}[\rho] = [T] = [H] = [h_i] = [\boldsymbol v] = 0, \\ [p] = \frac{4}{3} \Pr \left[\lambda \frac{\partial v_n}{\partial\eta}\right],\quad \left[\frac{\partial\boldsymbol v_{{\perp}}}{\partial\eta}\right] = 0, \\ \left[\frac{\partial H}{\partial\eta}\right] = 0,\quad \left[\frac{\partial h_i}{\partial\eta}\right] ={-}{le}_i \left[\frac{\partial T}{\partial\eta}\right], \end{gathered}\right\} \end{gather} \begin{gather} \left[\frac{\partial T}{\partial\eta}\right] ={-} qP \left(\frac{T_{f}}{T_a}\right)^{2} \sqrt\frac{\lambda_b}{\lambda_a}\sqrt {\frac{1 + (h_{E}^{{\ast}} - h_{D}^{{\ast}} + q \varphi)/2T_{f}^{2} } { 1 + q\varphi /2T_a^2}} \exp\left({\frac{\beta_0}{2T_a} - \frac{\beta_0}{2T_{f}}}\right). \end{gather}

\begin{gather} \left[\frac{\partial T}{\partial\eta}\right] ={-} qP \left(\frac{T_{f}}{T_a}\right)^{2} \sqrt\frac{\lambda_b}{\lambda_a}\sqrt {\frac{1 + (h_{E}^{{\ast}} - h_{D}^{{\ast}} + q \varphi)/2T_{f}^{2} } { 1 + q\varphi /2T_a^2}} \exp\left({\frac{\beta_0}{2T_a} - \frac{\beta_0}{2T_{f}}}\right). \end{gather}

Here ![]() $\lambda _b = \lambda (T_b)$ and the bracket

$\lambda _b = \lambda (T_b)$ and the bracket ![]() $[\,\,]$ denotes the jump, i.e.

$[\,\,]$ denotes the jump, i.e. ![]() $[\varTheta ] =\varTheta |_{{\eta =0^+}} - \varTheta |_{{\eta =0^-}}$. To avoid confusion, we note the distinction between the single brackets

$[\varTheta ] =\varTheta |_{{\eta =0^+}} - \varTheta |_{{\eta =0^-}}$. To avoid confusion, we note the distinction between the single brackets ![]() $[\,\,]$ used here to represent the jump across the reaction zone from the double brackets

$[\,\,]$ used here to represent the jump across the reaction zone from the double brackets ![]() $[\![ \,\,]\!]$ used earlier that represent the jump across the entire flame zone. The relations (4.14)–(4.15) constitute an obvious generalization of those derived systematically in the Newtonian limit (§ 7), and reduce to the corresponding relations for freely propagation flames (Matalon et al. Reference Matalon, Cui and Bechtold2003) when

$[\![ \,\,]\!]$ used earlier that represent the jump across the entire flame zone. The relations (4.14)–(4.15) constitute an obvious generalization of those derived systematically in the Newtonian limit (§ 7), and reduce to the corresponding relations for freely propagation flames (Matalon et al. Reference Matalon, Cui and Bechtold2003) when ![]() $P=1$. Although the jump in temperature gradient includes the factor

$P=1$. Although the jump in temperature gradient includes the factor ![]() $\exp {(\beta _0/2 T_a - \beta _0/2T_{f})}$, which is exponentially large when

$\exp {(\beta _0/2 T_a - \beta _0/2T_{f})}$, which is exponentially large when ![]() $\beta _0$ is formally treated as a large parameter, this factor is quite moderate, approximately 1–2 for practical values of the physical parameters.

$\beta _0$ is formally treated as a large parameter, this factor is quite moderate, approximately 1–2 for practical values of the physical parameters.

To describe the combustion field in the flame zone (![]() $-\infty < \eta < \infty$), all variables are expanded in power series of

$-\infty < \eta < \infty$), all variables are expanded in power series of ![]() $\delta$, namely

$\delta$, namely

\begin{equation} \left.\begin{gathered} m = m^{(0)}(\eta, \xi_1,\xi_2,t) + \delta m^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ T = T^{(0)}(\eta, \xi_1,\xi_2,t) + \delta T^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ H = H^{(0)}(\eta, \xi_1,\xi_2,t) + \delta H^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ h_i = h_i^{(0)}(\eta, \xi_1,\xi_2,t) + \delta h_i^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ v_n = v_n^{(0)}(\eta, \xi_1,\xi_2,t) + \delta v_n^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ \boldsymbol v_{{\perp}} = \boldsymbol v_{{\perp}}^{(0)}(\eta, \xi_1,\xi_2,t) + \delta \boldsymbol v_{{\perp}}^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ p = p^{(0)}(\eta, \xi_1,\xi_2,t) + \delta p^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} m = m^{(0)}(\eta, \xi_1,\xi_2,t) + \delta m^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ T = T^{(0)}(\eta, \xi_1,\xi_2,t) + \delta T^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ H = H^{(0)}(\eta, \xi_1,\xi_2,t) + \delta H^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ h_i = h_i^{(0)}(\eta, \xi_1,\xi_2,t) + \delta h_i^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ v_n = v_n^{(0)}(\eta, \xi_1,\xi_2,t) + \delta v_n^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ \boldsymbol v_{{\perp}} = \boldsymbol v_{{\perp}}^{(0)}(\eta, \xi_1,\xi_2,t) + \delta \boldsymbol v_{{\perp}}^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots, \\ p = p^{(0)}(\eta, \xi_1,\xi_2,t) + \delta p^{(1)}(\eta, \xi_1,\xi_2,t) + \cdots. \end{gathered}\right\} \end{equation}

The mean pressure ![]() $P(t)$ has not been explicitly expanded, but it too will be determined to

$P(t)$ has not been explicitly expanded, but it too will be determined to ![]() $O(\delta )$ when evaluating the integral in (2.17). The equations that need to be solved at each order are obtained by applying the transformation

$O(\delta )$ when evaluating the integral in (2.17). The equations that need to be solved at each order are obtained by applying the transformation ![]() $(n,\xi _1,\xi _2,t) \mapsto (\eta,\xi _1,\xi _2,t)$ to the governing equations, noting that

$(n,\xi _1,\xi _2,t) \mapsto (\eta,\xi _1,\xi _2,t)$ to the governing equations, noting that

They must be solved for ![]() $\eta \lessgtr 0$ subject to the jump conditions (4.14) across

$\eta \lessgtr 0$ subject to the jump conditions (4.14) across ![]() $\eta = 0$. The matching conditions for the state variables are readily available from (3.11) and (3.14), namely

$\eta = 0$. The matching conditions for the state variables are readily available from (3.11) and (3.14), namely

\begin{equation} \left.\begin{gathered} Y_D \sim \left\{\begin{array}{@{}ll@{}} {Y_{D_{0}}}, \\ 0, \end{array}\right.\quad Y_E \sim \left\{\begin{array}{@{}ll@{}} {Y_{E_{0}}} & \text{as}\ \eta \to -\infty, \\ \nu {Y_{D_{0}}} \varphi/\beta_0 & \text{as}\ \eta \to +\infty, \end{array}\right.\\ \rho \sim \left\{\begin{array}{@{}ll@{}} P^{1/\gamma}, \\ P / T_b, \end{array}\right.\quad T \sim \left\{\begin{array}{@{}ll@{}} P^{(\gamma -1)/\gamma} & \text{as}\ \eta \to -\infty, \\ T_b & \text{as}\ \eta \to +\infty, \end{array}\right. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} Y_D \sim \left\{\begin{array}{@{}ll@{}} {Y_{D_{0}}}, \\ 0, \end{array}\right.\quad Y_E \sim \left\{\begin{array}{@{}ll@{}} {Y_{E_{0}}} & \text{as}\ \eta \to -\infty, \\ \nu {Y_{D_{0}}} \varphi/\beta_0 & \text{as}\ \eta \to +\infty, \end{array}\right.\\ \rho \sim \left\{\begin{array}{@{}ll@{}} P^{1/\gamma}, \\ P / T_b, \end{array}\right.\quad T \sim \left\{\begin{array}{@{}ll@{}} P^{(\gamma -1)/\gamma} & \text{as}\ \eta \to -\infty, \\ T_b & \text{as}\ \eta \to +\infty, \end{array}\right. \end{gathered}\right\} \end{equation}

where ![]() $T_b = T_b^{(0)}(t) + \delta T_b^{(1)}(t) + \cdots$, with

$T_b = T_b^{(0)}(t) + \delta T_b^{(1)}(t) + \cdots$, with ![]() $T_b^{(0)} = P^{(\gamma -1)/ \gamma } + q$. Consequently,

$T_b^{(0)} = P^{(\gamma -1)/ \gamma } + q$. Consequently, ![]() $H \sim T_b$ as

$H \sim T_b$ as ![]() $\eta \to \pm \infty$, but the enthalpy perturbations that satisfy

$\eta \to \pm \infty$, but the enthalpy perturbations that satisfy ![]() $h_D = h_E \sim 0$ as

$h_D = h_E \sim 0$ as ![]() $\eta \to - \infty$ remain to be determined on the burned side as

$\eta \to - \infty$ remain to be determined on the burned side as ![]() $\eta \to + \infty$.

$\eta \to + \infty$.

To leading order,

\begin{equation} \left.\begin{gathered} \frac{\partial m^{(0)}}{\partial \eta }=0, \\ m^{(0)}\frac{\partial T^{(0)}}{\partial \eta} - \frac{\partial^{2}T^{(0)}}{\partial \eta ^{2}} = 0, \\ m^{(0)}\frac{\partial H^{(0)}}{\partial \eta } - \frac{\partial^{2}H^{(0)}}{\partial \eta ^{2}} =0, \\ m^{(0)}\frac{\partial h_i^{(0)}}{\partial \eta } - \frac{\partial^{2}h_i^{(0)}}{\partial \eta ^{2}} ={-} {le}_i \left( \frac{\partial ^{2} H^{(0)}}{\partial \eta ^{2}} - \frac{\partial ^{2} T^{(0)}}{\partial \eta ^{2}} \right), \\ m^{(0)}\frac{\partial v_n^{(0)}}{\partial \eta } - \frac{4}{3}\Pr \frac{\partial ^{2}v_n^{(0)}}{\partial \eta ^{2}} ={-}\frac{\partial p^{(0)} }{\partial \eta }, \\ m^{(0)}\frac{\partial \boldsymbol v_{{\perp}}^{(0)}}{\partial \eta } -\Pr \frac{\partial^{2}\boldsymbol v_{{\perp}}^{(0)}}{\partial \eta ^{2}} = 0. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \frac{\partial m^{(0)}}{\partial \eta }=0, \\ m^{(0)}\frac{\partial T^{(0)}}{\partial \eta} - \frac{\partial^{2}T^{(0)}}{\partial \eta ^{2}} = 0, \\ m^{(0)}\frac{\partial H^{(0)}}{\partial \eta } - \frac{\partial^{2}H^{(0)}}{\partial \eta ^{2}} =0, \\ m^{(0)}\frac{\partial h_i^{(0)}}{\partial \eta } - \frac{\partial^{2}h_i^{(0)}}{\partial \eta ^{2}} ={-} {le}_i \left( \frac{\partial ^{2} H^{(0)}}{\partial \eta ^{2}} - \frac{\partial ^{2} T^{(0)}}{\partial \eta ^{2}} \right), \\ m^{(0)}\frac{\partial v_n^{(0)}}{\partial \eta } - \frac{4}{3}\Pr \frac{\partial ^{2}v_n^{(0)}}{\partial \eta ^{2}} ={-}\frac{\partial p^{(0)} }{\partial \eta }, \\ m^{(0)}\frac{\partial \boldsymbol v_{{\perp}}^{(0)}}{\partial \eta } -\Pr \frac{\partial^{2}\boldsymbol v_{{\perp}}^{(0)}}{\partial \eta ^{2}} = 0. \end{gathered}\right\} \end{equation}

Conservation of mass implies that ![]() $m^{(0)} = M$ independent of

$m^{(0)} = M$ independent of ![]() $\eta$. The solution of the state variables that satisfies the jump relations at

$\eta$. The solution of the state variables that satisfies the jump relations at ![]() $\eta =0$ and the matching conditions as

$\eta =0$ and the matching conditions as ![]() $\eta \rightarrow \pm \infty$ is

$\eta \rightarrow \pm \infty$ is

with ![]() $H^{(0)} = T_b^{(0)}$ independent of

$H^{(0)} = T_b^{(0)}$ independent of ![]() $\eta$. The top and bottom expressions correspond to

$\eta$. The top and bottom expressions correspond to ![]() $\eta < 0$ and

$\eta < 0$ and ![]() $\eta > 0$, respectively, a notation that is also kept below. The solution of the velocity and pressure that satisfies the jump relations at

$\eta > 0$, respectively, a notation that is also kept below. The solution of the velocity and pressure that satisfies the jump relations at ![]() $\eta = 0$ is given by

$\eta = 0$ is given by

\begin{equation} \left.\begin{gathered} v_n^{(0)} = v_n^{(0)}|_{{\eta ={-}\infty}} + \frac{1}{P} \left\{\begin{array}{@{}l@{}} q M \,\text{e}^{M \eta} \\ q M \end{array}\right.,\quad \boldsymbol v_{{\perp}}^{(0)} =\boldsymbol v_{{\perp}}^{(0)}|_{{\eta ={-}\infty}},\\ p^{(0)}= p^{(0)}|_{{\eta ={-}\infty}} + \frac{1}{P} \left\{\begin{array}{@{}l@{}} \left(\dfrac{4}{3} \Pr -1\right) qM^2 \,\text{e}^{M \eta}, \\ - q M^2, \end{array}\right. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} v_n^{(0)} = v_n^{(0)}|_{{\eta ={-}\infty}} + \frac{1}{P} \left\{\begin{array}{@{}l@{}} q M \,\text{e}^{M \eta} \\ q M \end{array}\right.,\quad \boldsymbol v_{{\perp}}^{(0)} =\boldsymbol v_{{\perp}}^{(0)}|_{{\eta ={-}\infty}},\\ p^{(0)}= p^{(0)}|_{{\eta ={-}\infty}} + \frac{1}{P} \left\{\begin{array}{@{}l@{}} \left(\dfrac{4}{3} \Pr -1\right) qM^2 \,\text{e}^{M \eta}, \\ - q M^2, \end{array}\right. \end{gathered}\right\} \end{equation}

where it can be verified that the behaviour as ![]() $\eta \to \pm \infty$ confirms the RH relations across the flame. Finally, the jump relation for the temperature gradient yields an expression for the burning rate, given by

$\eta \to \pm \infty$ confirms the RH relations across the flame. Finally, the jump relation for the temperature gradient yields an expression for the burning rate, given by

\begin{equation} M = P \left(\frac{T_{f}}{T_a}\right)^{2} \sqrt\frac{\lambda_b}{\lambda_a} \sqrt {\frac{1 + q \varphi / 2T_{f}^{2}} {1 + q\varphi /2 T_a^2}} \exp\left({\frac{\beta_0}{2T_a} - \frac{\beta_0}{2T_{f}}}\right), \end{equation}

\begin{equation} M = P \left(\frac{T_{f}}{T_a}\right)^{2} \sqrt\frac{\lambda_b}{\lambda_a} \sqrt {\frac{1 + q \varphi / 2T_{f}^{2}} {1 + q\varphi /2 T_a^2}} \exp\left({\frac{\beta_0}{2T_a} - \frac{\beta_0}{2T_{f}}}\right), \end{equation}

where here, ![]() $T_{f} = T_b^{(0)}$. Below, we will use

$T_{f} = T_b^{(0)}$. Below, we will use ![]() $T_{f}$ and

$T_{f}$ and ![]() $T_b^{(0)}$ interchangeably when only the leading order of flame temperature is needed in a given expression. Equation (4.22) shows that, to leading order, the burning rate depends only on time and simplifies to

$T_b^{(0)}$ interchangeably when only the leading order of flame temperature is needed in a given expression. Equation (4.22) shows that, to leading order, the burning rate depends only on time and simplifies to ![]() $M=1$ for a freely propagating flame, as it should.

$M=1$ for a freely propagating flame, as it should.

We now proceed to the next order in the perturbation scheme. Before writing the simplified equations to ![]() $O(\delta )$ we note that since

$O(\delta )$ we note that since ![]() $\lambda = \lambda (T)$ and

$\lambda = \lambda (T)$ and ![]() $T \sim T^{(0)}(\eta, t)$, the transformation (4.17a–c) implies that

$T \sim T^{(0)}(\eta, t)$, the transformation (4.17a–c) implies that

\begin{equation} \left.\begin{gathered} \frac{\partial}{\partial t} = \frac{\partial}{\partial t} + \frac{\partial \eta}{\partial t} \frac{\partial}{\partial \eta} + O(\delta), \qquad \boldsymbol\nabla_{s} = \boldsymbol\nabla_{s} + O(\delta), \\ \lambda \frac{\partial \eta}{\partial t} = \int^0_{\eta} \lambda_T \frac{\partial T}{\partial t} \mathrm{d} \eta' = \left\{\begin{array}{@{}l@{}} \dot T_{f} \displaystyle\int^0_{\eta} \lambda_T \,\mathrm{d} \eta' - \dfrac{\dot M}{M} \left(\lambda \eta + \displaystyle\int^0_{\eta} \lambda \, \mathrm{d} \eta' \right), \\ - \lambda_T \dot T_{f} \eta, \end{array}\right. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \frac{\partial}{\partial t} = \frac{\partial}{\partial t} + \frac{\partial \eta}{\partial t} \frac{\partial}{\partial \eta} + O(\delta), \qquad \boldsymbol\nabla_{s} = \boldsymbol\nabla_{s} + O(\delta), \\ \lambda \frac{\partial \eta}{\partial t} = \int^0_{\eta} \lambda_T \frac{\partial T}{\partial t} \mathrm{d} \eta' = \left\{\begin{array}{@{}l@{}} \dot T_{f} \displaystyle\int^0_{\eta} \lambda_T \,\mathrm{d} \eta' - \dfrac{\dot M}{M} \left(\lambda \eta + \displaystyle\int^0_{\eta} \lambda \, \mathrm{d} \eta' \right), \\ - \lambda_T \dot T_{f} \eta, \end{array}\right. \end{gathered}\right\} \end{equation}

where ![]() $\lambda _T = \mathrm {d} \lambda /\mathrm {d} T$ and the ‘dot’, here and thereafter, signifies differentiation with respect to

$\lambda _T = \mathrm {d} \lambda /\mathrm {d} T$ and the ‘dot’, here and thereafter, signifies differentiation with respect to ![]() $t$.

$t$.

The continuity equation takes the form

where ![]() $\kappa$ is the local curvature of the flame surface taken to be positive when the surface is concave towards the burned gas, as per the convention adopted earlier, and

$\kappa$ is the local curvature of the flame surface taken to be positive when the surface is concave towards the burned gas, as per the convention adopted earlier, and

\begin{equation} {\mathbb{K}} ={-} V_{f} \kappa +\underbrace{\frac{1}{a_1 a_2} \left(\frac{\partial(a_2v_1)}{\partial\xi_1} + \frac{\partial(a_1v_2)}{\partial\xi_2}\right)}_{\boldsymbol\nabla_{s}\ \boldsymbol{\cdot}\ \boldsymbol v_{{\perp}}} \end{equation}

\begin{equation} {\mathbb{K}} ={-} V_{f} \kappa +\underbrace{\frac{1}{a_1 a_2} \left(\frac{\partial(a_2v_1)}{\partial\xi_1} + \frac{\partial(a_1v_2)}{\partial\xi_2}\right)}_{\boldsymbol\nabla_{s}\ \boldsymbol{\cdot}\ \boldsymbol v_{{\perp}}} \end{equation}

is the (dimensionless) stretch rate experienced by the flame (Matalon et al. Reference Matalon, Cui and Bechtold2003, appendix A), both being independent of ![]() $\eta$. Its influence on the flame propagation will be discussed in § 5. The solution of (4.24), which satisfies continuity at

$\eta$. Its influence on the flame propagation will be discussed in § 5. The solution of (4.24), which satisfies continuity at ![]() $\eta =0$, takes the form

$\eta =0$, takes the form

\begin{equation} m^{(1)} = A + \left\{\begin{array}{@{}l@{}} g(\eta), \\ \lambda_b \left(M \kappa - \dfrac{P}{T_{f}} \mathbb{K} - \dfrac{ \dot P}{T_{f}} + \dfrac{\gamma - 1}{\gamma} \dfrac{T_{u} \dot P}{T_{f}^2} \right) \eta, \end{array}\right. \end{equation}

\begin{equation} m^{(1)} = A + \left\{\begin{array}{@{}l@{}} g(\eta), \\ \lambda_b \left(M \kappa - \dfrac{P}{T_{f}} \mathbb{K} - \dfrac{ \dot P}{T_{f}} + \dfrac{\gamma - 1}{\gamma} \dfrac{T_{u} \dot P}{T_{f}^2} \right) \eta, \end{array}\right. \end{equation}

where ![]() $A = A(\xi _1,\xi _2,t)$ remains to be determined, and

$A = A(\xi _1,\xi _2,t)$ remains to be determined, and

\begin{align} g(\eta) &= \left(M \kappa - \frac{\dot M P}{ M \vartheta(\eta)}\right) \mathcal{J}_1(\eta) + \left(\frac{\dot M P}{M} - P \mathbb{K} - \dot P \right) \mathcal{J}_2(\eta) \nonumber\\ &\quad + \frac{\gamma -1}{\gamma}\dot P T_{u} \left(\frac{\mathcal{J}_3(\eta)}{\vartheta} - \mathcal{J}_4(\eta)\right). \end{align}

\begin{align} g(\eta) &= \left(M \kappa - \frac{\dot M P}{ M \vartheta(\eta)}\right) \mathcal{J}_1(\eta) + \left(\frac{\dot M P}{M} - P \mathbb{K} - \dot P \right) \mathcal{J}_2(\eta) \nonumber\\ &\quad + \frac{\gamma -1}{\gamma}\dot P T_{u} \left(\frac{\mathcal{J}_3(\eta)}{\vartheta} - \mathcal{J}_4(\eta)\right). \end{align}Here

\begin{equation} \left.\begin{gathered} \mathcal{J}_1 (\eta) = \int_{0}^{\eta} \lambda(\eta') \, \mathrm{d} \eta',\quad \mathcal{J}_2 (\eta) = \int_{0}^{\eta} \frac{\lambda(\eta')}{\vartheta(\eta')} \mathrm{d}\eta', \\ \mathcal{J}_3 (\eta) = \int_{0}^{\eta} \frac{\mathrm{d}}{\mathrm{d}\vartheta} (\lambda(\eta')) \, \mathrm{d} \eta',\quad \mathcal{J}_4 (\eta) = \int_{0}^{\eta} \frac{\mathrm{d}}{\mathrm{d}\vartheta} \left(\frac{\lambda(\eta')}{\vartheta(\eta')}\right)\mathrm{d} \eta', \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \mathcal{J}_1 (\eta) = \int_{0}^{\eta} \lambda(\eta') \, \mathrm{d} \eta',\quad \mathcal{J}_2 (\eta) = \int_{0}^{\eta} \frac{\lambda(\eta')}{\vartheta(\eta')} \mathrm{d}\eta', \\ \mathcal{J}_3 (\eta) = \int_{0}^{\eta} \frac{\mathrm{d}}{\mathrm{d}\vartheta} (\lambda(\eta')) \, \mathrm{d} \eta',\quad \mathcal{J}_4 (\eta) = \int_{0}^{\eta} \frac{\mathrm{d}}{\mathrm{d}\vartheta} \left(\frac{\lambda(\eta')}{\vartheta(\eta')}\right)\mathrm{d} \eta', \end{gathered}\right\} \end{equation}

where ![]() $\vartheta$ is the leading-order temperature in the preheat zone, namely

$\vartheta$ is the leading-order temperature in the preheat zone, namely ![]() $\vartheta (\eta ) = T_{u} + q \,\text{e}^{M \eta }$, and

$\vartheta (\eta ) = T_{u} + q \,\text{e}^{M \eta }$, and ![]() $T_{u} = P^{(\gamma -1)/ \gamma }$ is the temperature on the unburned side of the flame zone. For simplicity of notation, we have displayed explicitly only the dependence on

$T_{u} = P^{(\gamma -1)/ \gamma }$ is the temperature on the unburned side of the flame zone. For simplicity of notation, we have displayed explicitly only the dependence on ![]() $\eta$, which is needed for integration, although

$\eta$, which is needed for integration, although ![]() $g$ is a function of

$g$ is a function of ![]() $\xi _1, \xi _2, \eta$ and

$\xi _1, \xi _2, \eta$ and ![]() $t$ and the integrals

$t$ and the integrals ![]() $\mathcal {J}_i$ depend on both

$\mathcal {J}_i$ depend on both ![]() $\eta$ and

$\eta$ and ![]() $t$. The same notation is adopted below.

$t$. The same notation is adopted below.

The remaining equations describing the combustion field are

and

\begin{align} M

\frac{\partial{h_i^{(1)}} }{\partial\eta} -

\frac{\partial^2{h_i^{(1)}}}{\partial\eta^2} &={-} (m^{(1)}

+\lambda \kappa ) \frac{\partial {h_i^{(0)}}}{\partial

\eta} - \lambda \rho^{(0)}

\left(\frac{\partial{h_i^{(0)}}}{\partial t} +

\frac{\partial \eta}{\partial t} \frac{\partial

h_i^{(0)}}{\partial \eta}\right) \nonumber\\ &\quad +{le}_i

\left(\frac{\partial^2~T^{(1)}}{\partial\eta^2} -

\frac{\partial^2H^{(1)}}{\partial\eta^2} - \lambda \kappa

\frac{\partial T^{(0)}}{\partial\eta}\right),

\end{align}

\begin{align} M