1. Introduction

There are many examples of collapsible tubes in the human body, including the blood vessels, airways and intestines. These vessels are typically sensitive to changes in internal pressure, so a variety of interesting physiological phenomena can arise when a flow is driven through them. For example, in veins above the heart the transmural (internal–external) pressure is often negative due to the hydrostatic pressure decrease with height, and so these vessels can spontaneously collapse (Moreno et al. Reference Moreno, Katz, Gold and Reddy1970; Wild, Pedley & Riley Reference Wild, Pedley and Riley1977). Furthermore, forced expiration of air from the lungs can induce airway collapse, significantly reducing the flow rate that can be expelled, a phenomenon known as ‘flow limitation’ (Grotberg & Gavriely Reference Grotberg and Gavriely1989). This study is motivated by another physiological example, where the onset of self-excited oscillations in rapid flow along the brachial artery manifest as Korotkoff sounds during blood pressure measurement (Ur & Gordon Reference Ur and Gordon1970; Bertram, Raymond & Butcher Reference Bertram, Raymond and Butcher1989). More expansive reviews of the interesting phenomena that can arise from flow through collapsible vessels are provided elsewhere (Grotberg & Jensen Reference Grotberg and Jensen2004; Heil & Hazel Reference Heil and Hazel2011).

Flow in collapsible tubes can be investigated experimentally using a Starling resistor, where liquid is driven through a segment of externally pressurised flexible tubing mounted between two rigid tubes (e.g. Bertram & Pedley Reference Bertram and Pedley1982; Bertram Reference Bertram1986; Bertram, Raymond & Pedley Reference Bertram, Raymond and Pedley1990, Reference Bertram, Raymond and Pedley1991; Bertram & Tscherry Reference Bertram and Tscherry2006). A typical experiment drives flow along the tube with either a fixed upstream flow rate or a fixed upstream pressure. The experiments demonstrate that the system can adopt a steady configuration with a non-uniform wall profile, while for some operating conditions the system can even exhibit multiple (stable) steady states in a so-called ‘open-to-closed’ transition (Bertram et al. Reference Bertram, Raymond and Pedley1991). On top of this static behaviour, a wide variety of different classes of self-excited oscillation have been observed. These oscillations fall into distinct frequency bands (Bertram et al. Reference Bertram, Raymond and Pedley1990) and exhibit complex nonlinear limit cycles, characterised by phase portraits of quantities such as pressure or flow rate at different points along the tube (Bertram et al. Reference Bertram, Raymond and Pedley1990, Reference Bertram, Raymond and Pedley1991). However, the mechanisms which generate these oscillations are still not well understood.

Theoretical study of the Starling resistor experiment began with lumped parameter models (e.g. Katz, Chen & Moreno Reference Katz, Chen and Moreno1969; Bertram & Pedley Reference Bertram and Pedley1982), formed from a small number of ordinary differential equations. Such models qualitatively capture the static deformation of the tube observed in experiments, predicting that over a narrow window of the parameter space the system can exhibit three co-existing steady states: an upper branch (where the wall is inflated), a lower branch (where the wall is collapsed) connected by an (unstable) intermediate branch by a pair of limit point bifurcations (Armitstead, Bertram & Jensen Reference Armitstead, Bertram and Jensen1996). These lumped models further predict the onset of self-excited oscillations from the collapsed (lower) static branch (Bertram & Pedley Reference Bertram and Pedley1982) and elucidate possible global interactions between the oscillatory limit cycles and the additional static solutions (Armitstead et al. Reference Armitstead, Bertram and Jensen1996).

In more recent years these theoretical studies have gradually increased in complexity, beginning with cross-sectionally averaged one-dimensional models (e.g. Cancelli & Pedley Reference Cancelli and Pedley1985; Jensen Reference Jensen1990) all the way to full three-dimensional models of the static (Hazel & Heil Reference Hazel and Heil2003; Marzo, Luo & Bertram Reference Marzo, Luo and Bertram2005; Zhang, Luo & Cai Reference Zhang, Luo and Cai2018) and oscillatory behaviour (Heil Reference Heil1997; Heil & Boyle Reference Heil and Boyle2010; Whittaker et al. Reference Whittaker, Heil, Jensen and Waters2010) of the tube. However, numerical solution of the latter requires immense computational resources and so it has not yet been possible to fully map out the different classes of oscillatory behaviour across the parameter space.

For simplicity in probing the underlying mechanisms of instability, theoretical attention has also focused on a planar analogue of the Starling resistor set-up, formed by removing a segment of one wall of a rigid channel and replacing it by an externally pressurised flexible membrane (Pedley Reference Pedley1992). This channel system has subsequently been studied using fully nonlinear simulations (Luo & Pedley Reference Luo and Pedley1995, Reference Luo and Pedley1996; Jensen & Heil Reference Jensen and Heil2003; Xu, Billingham & Jensen Reference Xu, Billingham and Jensen2014), where many of the predictions are analogous to those from the lumped parameter models. For example, for the flexible wall modelled as either a thin membrane or a nonlinearly elastic shell, the system can exhibit multiple co-existing steady states provided the Reynolds number is large enough to collapse the channel through the Bernoulli effect (Luo & Pedley Reference Luo and Pedley2000; Heil Reference Heil2004). Furthermore, the lower branch of static solutions is unstable to oscillations when the channel becomes sufficiently collapsed (Heil Reference Heil2004). In addition, recent work by Herrada et al. (Reference Herrada, Blanco-Trejo, Eggers and Stewart2021) has shown that the upper branch of static solutions can also become unstable to oscillations provided the external pressure is sufficiently low (so the flexible wall bulges outwards).

Further insight into the mechanisms of instability has been provided by spatially one-dimensional models of the collapsible channel system, derived using a flow profile assumption (Stewart, Waters & Jensen Reference Stewart, Waters and Jensen2009; Xu, Billingham & Jensen Reference Xu, Billingham and Jensen2013). Using the approach, Stewart (Reference Stewart2017) described two families of self-excited oscillations arising from the lower branch of static solutions in the limit of large external pressure, where the primary global instability is to a low-frequency mode from a static state which is inflated along most of the compliant segment, but collapsed along a narrow layer adjacent to the downstream rigid segment. Similarly, Xu et al. (Reference Xu, Billingham and Jensen2013) considered a similar system with an imposed gradient in external pressure on the flexible segment (which ensures that the flat wall is always a steady state of the system); this results in a rather different static structure to those reported with constant external pressure, where non-trivial static modes emerge via a transcritical bifurcation in the inviscid limit at particular values of the pre-stress parameter. Self-excited oscillations then arise as a resonance between two modes, which can be explored in the limit of large downstream channel length (Xu et al. Reference Xu, Billingham and Jensen2014), where the oscillations eventually grow to exhibit vigorous ‘slamming’ oscillations (Xu & Jensen Reference Xu and Jensen2015).

This study focuses on the planar channel analogue of the Starling resistor, but instead models the elastic wall as a plane-strained nonlinear beam that is materially linear but geometrically nonlinear (Gere Reference Gere2003); this beam has resistance to both bending and stretching. This model was first introduced by Cai & Luo (Reference Cai and Luo2003) and has subsequently been explored in depth by Luo and coworkers, examining flow driven by either prescribed upstream flux (Luo et al. Reference Luo, Cai, Li and Pedley2008; Hao et al. Reference Hao, Cai, Roper and Luo2016) or prescribed upstream pressure (Liu, Luo & Cai Reference Liu, Luo and Cai2012; Hao et al. Reference Hao, Cai, Roper and Luo2016). In this study we focus on the flow driven system, where it has been shown that the system admits multiple families of self-excited oscillations in a novel cascade structure: the system has isolated regions of stability between unstable regions which each correspond to a different number of extrema in the wall profile (Luo et al. Reference Luo, Cai, Li and Pedley2008). Their neutral stability curve, plotted in the parameter space spanned by the Reynolds number and the dimensionless resistance to beam stretching (![]() $c_\lambda$), is plotted in figure 5 below. In this paper we revisit the model of Luo et al. (Reference Luo, Cai, Li and Pedley2008), making a small correction to the constitutive law for the beam to ensure that it is energetically conservative. We explore the structure of the underling static solutions and show that this is analogous to those described above, with regions of parameter space which exhibit three co-existing steady states. We examine the stability of these static states using fully nonlinear simulations, predicting an additional mode of oscillation not noted by Luo et al. (Reference Luo, Cai, Li and Pedley2008), arising as an instability of the upper branch of static solutions (analogous to upper branch instability recently reported by Herrada et al. Reference Herrada, Blanco-Trejo, Eggers and Stewart2021). We investigate the saturated limit cycles of this oscillatory mode and its subsequent interaction with the other static solutions.

$c_\lambda$), is plotted in figure 5 below. In this paper we revisit the model of Luo et al. (Reference Luo, Cai, Li and Pedley2008), making a small correction to the constitutive law for the beam to ensure that it is energetically conservative. We explore the structure of the underling static solutions and show that this is analogous to those described above, with regions of parameter space which exhibit three co-existing steady states. We examine the stability of these static states using fully nonlinear simulations, predicting an additional mode of oscillation not noted by Luo et al. (Reference Luo, Cai, Li and Pedley2008), arising as an instability of the upper branch of static solutions (analogous to upper branch instability recently reported by Herrada et al. Reference Herrada, Blanco-Trejo, Eggers and Stewart2021). We investigate the saturated limit cycles of this oscillatory mode and its subsequent interaction with the other static solutions.

Analysing the energy budget of the flow has proved to be a useful tool for probing the mechanism of self-excited oscillations, particularly for oscillations driven by a prescribed upstream pressure (Jensen & Heil Reference Jensen and Heil2003; Stewart et al. Reference Stewart, Waters and Jensen2009, Reference Stewart, Heil, Waters and Jensen2010). The approach is similar to the classical derivation of the Reynolds–Orr equation (Schmid & Henningson Reference Schmid and Henningson2001), where we take the scalar product between the fluid momentum equations and the corresponding fluid velocity and integrate over the channel area to construct a rate of energy balance; for incompressible flow the terms appearing in this energy rate equation can be written in the form

where ![]() ${\mathcal {K}}$ is the rate of change of kinetic energy,

${\mathcal {K}}$ is the rate of change of kinetic energy, ![]() ${\mathcal {E}}$ is the rate at which fluid does work on the flexible wall,

${\mathcal {E}}$ is the rate at which fluid does work on the flexible wall, ![]() ${\mathcal {F}}$ is the net rate of energy extraction from the mean flow,

${\mathcal {F}}$ is the net rate of energy extraction from the mean flow, ![]() ${\mathcal {P}}$ is the rate of working of the upstream driving pressure and

${\mathcal {P}}$ is the rate of working of the upstream driving pressure and ![]() ${\mathcal {D}}$ is the rate of working of viscous dissipation. The overall energy change arising from each term can be obtained by taking the time average over a period of fully developed oscillation; throughout this paper we denote this integral with the superscript

${\mathcal {D}}$ is the rate of working of viscous dissipation. The overall energy change arising from each term can be obtained by taking the time average over a period of fully developed oscillation; throughout this paper we denote this integral with the superscript ![]() $^{(avg)}$. For a conservative wall model (where no work is done on the wall, so

$^{(avg)}$. For a conservative wall model (where no work is done on the wall, so ![]() ${\mathcal {E}}^{(avg)}=0$), the time-averaged energy budget can be expressed as the sum of two sources, the time-averaged work done by the upstream driving pressure (

${\mathcal {E}}^{(avg)}=0$), the time-averaged energy budget can be expressed as the sum of two sources, the time-averaged work done by the upstream driving pressure (![]() ${\mathcal {P}}^{(avg)}$) and the time-averaged energy flux extracted from the mean flow (

${\mathcal {P}}^{(avg)}$) and the time-averaged energy flux extracted from the mean flow (![]() ${\mathcal {F}}^{(avg)}$), balanced by the energy consumed by the time-averaged working of viscous dissipation (

${\mathcal {F}}^{(avg)}$), balanced by the energy consumed by the time-averaged working of viscous dissipation (![]() ${\mathcal {D}}^{(avg)}$), so that

${\mathcal {D}}^{(avg)}$), so that

The net energy flux ![]() ${\mathcal {F}}^{(avg)}$ is extremely important for some flows driven by upstream pressure. For example, for ‘sloshing’ oscillations, found in both flexible-walled channels (Jensen & Heil Reference Jensen and Heil2003; Stewart et al. Reference Stewart, Waters and Jensen2009, Reference Stewart, Heil, Waters and Jensen2010) and collapsible tubes (Whittaker et al. Reference Whittaker, Heil, Jensen and Waters2010), it has been shown that, in in the limit of large wall pre-stress, the time-averaged dissipation can be decomposed into the sum of two components, the energy lost due to dissipation in the mean flow (denoted

${\mathcal {F}}^{(avg)}$ is extremely important for some flows driven by upstream pressure. For example, for ‘sloshing’ oscillations, found in both flexible-walled channels (Jensen & Heil Reference Jensen and Heil2003; Stewart et al. Reference Stewart, Waters and Jensen2009, Reference Stewart, Heil, Waters and Jensen2010) and collapsible tubes (Whittaker et al. Reference Whittaker, Heil, Jensen and Waters2010), it has been shown that, in in the limit of large wall pre-stress, the time-averaged dissipation can be decomposed into the sum of two components, the energy lost due to dissipation in the mean flow (denoted ![]() ${\mathcal {D}}^{(avg)}_P$) and the energy lost due to dissipation in the oscillation (denoted

${\mathcal {D}}^{(avg)}_P$) and the energy lost due to dissipation in the oscillation (denoted ![]() ${\mathcal {D}}^{(avg)}_S$). It emerges that exactly two thirds of the energy flux is consumed by dissipative effects in the oscillation (

${\mathcal {D}}^{(avg)}_S$). It emerges that exactly two thirds of the energy flux is consumed by dissipative effects in the oscillation (![]() ${\mathcal {D}}_S^{(avg)}= \tfrac {2}{3}{\mathcal {F}}^{(avg)}$), while the remaining one third increases the mean flow. However, there is evidence to suggest that

${\mathcal {D}}_S^{(avg)}= \tfrac {2}{3}{\mathcal {F}}^{(avg)}$), while the remaining one third increases the mean flow. However, there is evidence to suggest that ![]() ${\mathcal {F}}^{(avg)}$ may become negative for lower pre-stress (Stewart et al. Reference Stewart, Heil, Waters and Jensen2010), indicating a different mechanism entirely. In this study we explore the mechanism of energy transfer in flux-driven oscillations and show that

${\mathcal {F}}^{(avg)}$ may become negative for lower pre-stress (Stewart et al. Reference Stewart, Heil, Waters and Jensen2010), indicating a different mechanism entirely. In this study we explore the mechanism of energy transfer in flux-driven oscillations and show that ![]() ${\mathcal {F}}^{(avg)}$ plays no role in the mechanism of instability.

${\mathcal {F}}^{(avg)}$ plays no role in the mechanism of instability.

In this paper we revisit the nonlinear fluid-beam model presented by Luo et al. (Reference Luo, Cai, Li and Pedley2008), reformulating the nonlinear governing equations to derive the full nonlinear energy budget for oscillatory limit cycles (§ 2), adjusting the Kirchhoff constitutive law for the beam to ensure the elastic wall is energetically conservative. In § 3 we examine the behaviour of our new fluid-beam model along two slices of the parameter space (shown in figure 5), characterising both the steady (§ 3.1) and unsteady (§ 3.2) behaviour of the system and provide an overview of the parameter space for fixed external pressure (§ 3.3). In particular, we elucidate an instability of the upper branch of static solutions (§ 3.4) which is similar to that found by Herrada et al. (Reference Herrada, Blanco-Trejo, Eggers and Stewart2021), explore the nonlinear bifurcation structure of the system (§ 3.5), the resulting interaction between the oscillatory limit cycles and the folding point associated with the upper branch of static solutions (§ 3.6) and the energy budget of self-excited oscillations (§ 3.7). Finally, in § 4 we compare the predictions of our new Kirchhoff law with the previous law used by Luo et al. (Reference Luo, Cai, Li and Pedley2008), showing that the change makes very little difference to the predictions.

2. The model

We consider a planar rigid channel of finite length ![]() $L_0$ and uniform width

$L_0$ and uniform width ![]() $D$ containing a viscous fluid. An internal segment of length

$D$ containing a viscous fluid. An internal segment of length ![]() $L$ of one wall is replaced by a planar elastic beam in a state of plane strain. The corresponding lengths of the upstream and downstream rigid segments are denoted

$L$ of one wall is replaced by a planar elastic beam in a state of plane strain. The corresponding lengths of the upstream and downstream rigid segments are denoted ![]() $L_u$ and

$L_u$ and ![]() $L_d$, respectively, so

$L_d$, respectively, so ![]() $L_0=L_u+L+L_d$. This elastic beam is initially of uniform thickness

$L_0=L_u+L+L_d$. This elastic beam is initially of uniform thickness ![]() $h$, which we assume to be much less than the channel width (

$h$, which we assume to be much less than the channel width (![]() $h \ll D$). We denote the two-dimensional fluid domain by

$h \ll D$). We denote the two-dimensional fluid domain by ![]() $\varOmega$ and use

$\varOmega$ and use ![]() $\partial \varOmega _u$,

$\partial \varOmega _u$, ![]() $\partial \varOmega _d$,

$\partial \varOmega _d$, ![]() $\partial \varOmega _b$ to denote the upstream fluid inlet, the downstream fluid outlet and the elastic beam, respectively. This set-up is similar to the system introduced by Pedley (Reference Pedley1992) and has been analysed extensively by Cai & Luo (Reference Cai and Luo2003) and Luo et al. (Reference Luo, Cai, Li and Pedley2008).

$\partial \varOmega _b$ to denote the upstream fluid inlet, the downstream fluid outlet and the elastic beam, respectively. This set-up is similar to the system introduced by Pedley (Reference Pedley1992) and has been analysed extensively by Cai & Luo (Reference Cai and Luo2003) and Luo et al. (Reference Luo, Cai, Li and Pedley2008).

We consider a parabolic inlet flow to the channel with flux ![]() $Q$ (per unit width in the out-of-plane direction) with average velocity

$Q$ (per unit width in the out-of-plane direction) with average velocity ![]() $Q/D$. We choose the outlet pressure along

$Q/D$. We choose the outlet pressure along ![]() $\partial \varOmega _d$ to be zero, our pressure to which all other pressures and stresses are compared. The fluid is assumed to be Newtonian and incompressible with constant density

$\partial \varOmega _d$ to be zero, our pressure to which all other pressures and stresses are compared. The fluid is assumed to be Newtonian and incompressible with constant density ![]() $\rho$ and viscosity

$\rho$ and viscosity ![]() $\mu$. The elastic beam is subject to a uniform external pressure, denoted

$\mu$. The elastic beam is subject to a uniform external pressure, denoted ![]() $p_e$.

$p_e$.

We establish two coordinate systems to describe the motion, as shown in figure 1. Firstly, ![]() ${\boldsymbol{g}}_1, {\boldsymbol{g}}_2, {\boldsymbol{g}}_3$ are the unit vectors of the Cartesian coordinate system in the (undeformed) reference configuration, such that

${\boldsymbol{g}}_1, {\boldsymbol{g}}_2, {\boldsymbol{g}}_3$ are the unit vectors of the Cartesian coordinate system in the (undeformed) reference configuration, such that ![]() ${\boldsymbol{g}}_1$ is oriented along the entirely rigid wall,

${\boldsymbol{g}}_1$ is oriented along the entirely rigid wall, ![]() ${\boldsymbol{g}}_2$ is normal to

${\boldsymbol{g}}_2$ is normal to ![]() ${\boldsymbol{g}}_1$ in the plane of the channel (pointing into the channel) and

${\boldsymbol{g}}_1$ in the plane of the channel (pointing into the channel) and ![]() ${\boldsymbol{g}}_3$ is in the out-of-plane direction. Conversely,

${\boldsymbol{g}}_3$ is in the out-of-plane direction. Conversely, ![]() ${\boldsymbol{e}}_1, {\boldsymbol{e}}_2, {\boldsymbol{e}}_3$ are unit vectors of the material coordinates in the (deformed) current configuration of the beam, where

${\boldsymbol{e}}_1, {\boldsymbol{e}}_2, {\boldsymbol{e}}_3$ are unit vectors of the material coordinates in the (deformed) current configuration of the beam, where ![]() ${\boldsymbol{e}}_1$ is the local tangent to the beam,

${\boldsymbol{e}}_1$ is the local tangent to the beam, ![]() ${\boldsymbol{e}}_2$ is the local normal to the beam (pointing out of the channel) and

${\boldsymbol{e}}_2$ is the local normal to the beam (pointing out of the channel) and ![]() ${\boldsymbol{e}}_3$ is normal to the plane of the channel (

${\boldsymbol{e}}_3$ is normal to the plane of the channel (![]() ${\boldsymbol{g}}_3={\boldsymbol{e}}_3$). In what follows, we ignore deflections in the out-of-plane direction and so consider all vectors as two-dimensional.

${\boldsymbol{g}}_3={\boldsymbol{e}}_3$). In what follows, we ignore deflections in the out-of-plane direction and so consider all vectors as two-dimensional.

Figure 1. Schematic of the fluid-beam model.

In the absence of fluid loading we assume the elastic beam is flat and parallel to the entirely rigid wall. Following Liu et al. (Reference Liu, Luo and Cai2012), we consider a massless elastic beam and denote the axial pre-stress along the beam as ![]() $T$. Further, we denote

$T$. Further, we denote ![]() $EA$ and

$EA$ and ![]() $EJ$ as the extensional stiffness and bending stiffness of the beam, respectively, where

$EJ$ as the extensional stiffness and bending stiffness of the beam, respectively, where ![]() $E$ is the Young's modulus of the material while

$E$ is the Young's modulus of the material while ![]() $A$ and

$A$ and ![]() $J$ are the cross-sectional area and the second moment of inertia of the cross-sectional area of the beam with respect to the

$J$ are the cross-sectional area and the second moment of inertia of the cross-sectional area of the beam with respect to the ![]() ${\boldsymbol{g}}_1$ axis, respectively.

${\boldsymbol{g}}_1$ axis, respectively.

We denote an arbitrary point on the (flat) beam in the reference configuration as

After deformation this point moves to,

where we use the subscript ![]() $b$ to denote points on the beam. The principal stretch of the beam is then

$b$ to denote points on the beam. The principal stretch of the beam is then

\begin{equation} \lambda=\left[{\left(\frac{\partial x_b}{\partial l}\right)^{2} +\left(\frac{\partial y_b}{\partial l}\right)^{2}}\right]^{1/2}, \quad (0\le l\le L). \end{equation}

\begin{equation} \lambda=\left[{\left(\frac{\partial x_b}{\partial l}\right)^{2} +\left(\frac{\partial y_b}{\partial l}\right)^{2}}\right]^{1/2}, \quad (0\le l\le L). \end{equation}

We denote ![]() $\theta$ as the angle between the tangent to the deformed beam

$\theta$ as the angle between the tangent to the deformed beam ![]() ${\boldsymbol{e}}_1$ and the unit vector

${\boldsymbol{e}}_1$ and the unit vector ![]() ${\boldsymbol{g}_1}$ (see figure 1), hence we have

${\boldsymbol{g}_1}$ (see figure 1), hence we have

The arc-length coordinate, denoted ![]() $s$, is measured along the beam from the upstream intersection with the rigid wall, computed as

$s$, is measured along the beam from the upstream intersection with the rigid wall, computed as

The total length of the deformed beam is therefore ![]() $S=s(L,t)$.

$S=s(L,t)$.

2.1. Governing equations

We introduce dimensionless variables by scaling all lengths on the channel width ![]() $D$, velocities on the mean inlet flow

$D$, velocities on the mean inlet flow ![]() $Q/D$, time on

$Q/D$, time on ![]() $D^{2}/Q$ and pressures on the inertial pressure scale

$D^{2}/Q$ and pressures on the inertial pressure scale ![]() $\rho Q^{2}/D^{2}$ (where the fluid outlet pressure is set to zero without loss of generality). Under the scaling we obtain four dimensionless parameters associated with the geometry of the channel in the form

$\rho Q^{2}/D^{2}$ (where the fluid outlet pressure is set to zero without loss of generality). Under the scaling we obtain four dimensionless parameters associated with the geometry of the channel in the form

the dimensionless lengths of the upstream, downstream and collapsible segments of the channel and the dimensionless beam thickness, respectively. We also obtain three dimensionless parameters associated with the elasticity of the beam, in the form

the dimensionless extensional and bending stiffnesses and the dimensionless beam pre-tension, respectively. Finally, the flow is also governed by the Reynolds number and the dimensionless external pressure, which take the form

We henceforth focus on the dimensionless quantities and drop the tildes for simplicity.

The governing equations for the (two-dimensional) fluid velocity ![]() ${\boldsymbol{u}}({\boldsymbol{x}},t)$ and pressure

${\boldsymbol{u}}({\boldsymbol{x}},t)$ and pressure ![]() $p({\boldsymbol{x}},t)$ follow from the incompressible Navier–Stokes equations in the form,

$p({\boldsymbol{x}},t)$ follow from the incompressible Navier–Stokes equations in the form,

For the Newtonian fluid we have

where ![]() ${\boldsymbol{I}}$ is the identity matrix and the superscript

${\boldsymbol{I}}$ is the identity matrix and the superscript ![]() $^\textrm {{T}}$ represents the matrix transpose.

$^\textrm {{T}}$ represents the matrix transpose.

To establish governing equations for the massless beam we consider a virtual displacement of a differential element and impose conservation of linear and angular momentum, following the derivation of Cai & Luo (Reference Cai and Luo2003). We denote the internal force acting on a cross-section of the beam as ![]() ${\boldsymbol{F}}=F_1{\boldsymbol{e}_1}+F_2{\boldsymbol{e}_2}$ and the external force acting on the beam as

${\boldsymbol{F}}=F_1{\boldsymbol{e}_1}+F_2{\boldsymbol{e}_2}$ and the external force acting on the beam as ![]() ${\boldsymbol{q}} ={\sigma }_1{\boldsymbol{e}}_1+({\sigma }_2-p_e){\boldsymbol{e}}_2$, where

${\boldsymbol{q}} ={\sigma }_1{\boldsymbol{e}}_1+({\sigma }_2-p_e){\boldsymbol{e}}_2$, where ![]() ${\sigma _1}$ and

${\sigma _1}$ and ![]() ${\sigma _2}$ are the tangent and normal components of the fluid traction on the beam,

${\sigma _2}$ are the tangent and normal components of the fluid traction on the beam,

Denoting ![]() $\partial f$ as a virtual displacement of the variable

$\partial f$ as a virtual displacement of the variable ![]() $f$, conservation of linear momentum takes the form

$f$, conservation of linear momentum takes the form

Similarly, denoting ![]() ${\boldsymbol{M}}=M{\boldsymbol{e}_3}$ as the moment acting on the beam, conservation of angular momentum for the beam element takes the form

${\boldsymbol{M}}=M{\boldsymbol{e}_3}$ as the moment acting on the beam, conservation of angular momentum for the beam element takes the form

The commonly used linear constitutive laws for elastic beams (Gere Reference Gere2003), which were adopted in the previous fluid-beam model (Cai & Luo Reference Cai and Luo2003), take the form

where ![]() $\kappa$ is the dimensionless curvature of the beam defined as

$\kappa$ is the dimensionless curvature of the beam defined as

However, to ensure that our approach is suitable to describe large deformations we instead formulate these constitutive laws with respect to the reference configuration of the beam (parameterised by ![]() $l$) and we replace (2.14a,b) with a modified form

$l$) and we replace (2.14a,b) with a modified form

where we can also prove the identity (Wang Reference Wang2019)

These new expressions (2.16a,b) reduce to (2.14a,b) in the limit of small displacements. The advantages of introducing these constitutive laws will become clearer below. Using either of these two constitutive laws, we can eliminate the unknown ![]() $F_2$ between the (2.12) and (2.13) and end up with a closed system.

$F_2$ between the (2.12) and (2.13) and end up with a closed system.

The dimensionless governing equations for the beam can be written as

For flow boundary conditions along the channel inlet (![]() $\partial \varOmega _u$) we prescribe a parabolic inlet flow with unit flux in the form

$\partial \varOmega _u$) we prescribe a parabolic inlet flow with unit flux in the form ![]() ${\boldsymbol{u}}=6y(1-y){\boldsymbol{g}}_1$. Along the channel outlet we impose a stress free condition in the form

${\boldsymbol{u}}=6y(1-y){\boldsymbol{g}}_1$. Along the channel outlet we impose a stress free condition in the form ![]() ${\boldsymbol {\sigma }}{\boldsymbol{g}}_2={\boldsymbol{0}}$. Note that this is not formally identical to imposing zero pressure along the outlet, but we assume that the downstream rigid segment is sufficiently long so that the outflow is approximately parallel and the normal viscous stress terms are negligible (a similar approach was used by Jensen & Heil Reference Jensen and Heil2003). We assume the no-slip condition along the rigid walls as well as continuity of velocity between the elastic beam and the fluid in the form

${\boldsymbol {\sigma }}{\boldsymbol{g}}_2={\boldsymbol{0}}$. Note that this is not formally identical to imposing zero pressure along the outlet, but we assume that the downstream rigid segment is sufficiently long so that the outflow is approximately parallel and the normal viscous stress terms are negligible (a similar approach was used by Jensen & Heil Reference Jensen and Heil2003). We assume the no-slip condition along the rigid walls as well as continuity of velocity between the elastic beam and the fluid in the form

The two ends of the elastic beam are attached to the rigid wall at a fixed angle, in the form

2.2. Fully nonlinear energy budget

A useful tool for analysing the mechanism of instability in collapsible channel flows is to formulate the energy budget of the system (e.g. Jensen & Heil Reference Jensen and Heil2003; Stewart et al. Reference Stewart, Waters and Jensen2009, Reference Stewart, Heil, Waters and Jensen2010). Here, we perform the energy budget analysis for our updated fluid-beam model. To formulate the energy equation we begin with the fluid and consider the dot product of the fluid velocity with the fluid momentum equations (2.9a,b). As the fluid is incompressible, we manipulate and integrate this energy equation over the fluid domain ![]() $\varOmega$ to obtain the total energy budget of the system in the form

$\varOmega$ to obtain the total energy budget of the system in the form

\begin{align} &\int_{\varOmega}\frac{1}{2}\frac{\partial({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}})}{\partial t}\,{ \rm d}A+\int_{\varOmega}\frac{1}{2} \boldsymbol{\nabla} \boldsymbol{\cdot} (({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}) {\boldsymbol{u}})\,\textrm{d}A \nonumber\\ &\quad =\int_{\varOmega}\boldsymbol{\nabla} \boldsymbol{\cdot} ({-}p{\boldsymbol{u}})\,\textrm{d}A+\int_{\varOmega}\frac{1}{Re}[\boldsymbol{\nabla} \boldsymbol{\cdot} ((\boldsymbol{\nabla} {\boldsymbol{u}}+\boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}}){\boldsymbol{u}})-Tr ((\boldsymbol{\nabla} {\boldsymbol{u}}+\boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}})\boldsymbol{\nabla} {\boldsymbol{u}})]\,\textrm{d}A. \end{align}

\begin{align} &\int_{\varOmega}\frac{1}{2}\frac{\partial({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}})}{\partial t}\,{ \rm d}A+\int_{\varOmega}\frac{1}{2} \boldsymbol{\nabla} \boldsymbol{\cdot} (({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}) {\boldsymbol{u}})\,\textrm{d}A \nonumber\\ &\quad =\int_{\varOmega}\boldsymbol{\nabla} \boldsymbol{\cdot} ({-}p{\boldsymbol{u}})\,\textrm{d}A+\int_{\varOmega}\frac{1}{Re}[\boldsymbol{\nabla} \boldsymbol{\cdot} ((\boldsymbol{\nabla} {\boldsymbol{u}}+\boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}}){\boldsymbol{u}})-Tr ((\boldsymbol{\nabla} {\boldsymbol{u}}+\boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}})\boldsymbol{\nabla} {\boldsymbol{u}})]\,\textrm{d}A. \end{align}By the Reynolds transport theorem and the divergence theorem, this energy budget can be rearranged as (see Wang (Reference Wang2019) for details)

\begin{align} &\frac{\partial}{\partial t}\int_{\varOmega}\frac{1}{2} {\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}\,\textrm{d}A+ \left[\int_0^{1}\frac{1}{2}({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}) ({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1})\,\textrm{d} y\right]_{x={-}L_u}^{x=L+L_d} \nonumber\\ &\quad =\left[\int_0^{1}-p{\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1}\,\textrm{d} y\right]^{x=L+L_d}_{x={-}L_u} -\frac{1}{Re}\int_{\varOmega}Tr ((\boldsymbol{\nabla} {\boldsymbol{u}}+ \boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}})\boldsymbol{\nabla} {\boldsymbol{u}})\,\textrm{d}A \nonumber\\ &\qquad +\int_{\partial\varOmega_b} \left\{{-}p+\frac{1}{Re} \left(\boldsymbol{\nabla} {\boldsymbol{u}}+\boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}}\right)\right\}{\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{e}}_{2}\, \textrm{d}s, \end{align}

\begin{align} &\frac{\partial}{\partial t}\int_{\varOmega}\frac{1}{2} {\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}\,\textrm{d}A+ \left[\int_0^{1}\frac{1}{2}({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}) ({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1})\,\textrm{d} y\right]_{x={-}L_u}^{x=L+L_d} \nonumber\\ &\quad =\left[\int_0^{1}-p{\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1}\,\textrm{d} y\right]^{x=L+L_d}_{x={-}L_u} -\frac{1}{Re}\int_{\varOmega}Tr ((\boldsymbol{\nabla} {\boldsymbol{u}}+ \boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}})\boldsymbol{\nabla} {\boldsymbol{u}})\,\textrm{d}A \nonumber\\ &\qquad +\int_{\partial\varOmega_b} \left\{{-}p+\frac{1}{Re} \left(\boldsymbol{\nabla} {\boldsymbol{u}}+\boldsymbol{\nabla} {\boldsymbol{u}}^{\text{T}}\right)\right\}{\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{e}}_{2}\, \textrm{d}s, \end{align}

where the final term involves the surface integral of the fluid stress along the deformed beam, parametrised by ![]() $s$. Applying the definition of the fluid stress tensor (2.10) to the integral evaluated on the elastic beam, we write the total energy budget of the system as

$s$. Applying the definition of the fluid stress tensor (2.10) to the integral evaluated on the elastic beam, we write the total energy budget of the system as

where

\begin{gather} {\mathcal{P}}={-}\left[\int_0^{1}p{\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1}\,\textrm{d} y\right]^{x=L+L_d}_{x={-}L_u}, \end{gather}

\begin{gather} {\mathcal{P}}={-}\left[\int_0^{1}p{\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1}\,\textrm{d} y\right]^{x=L+L_d}_{x={-}L_u}, \end{gather} \begin{gather}{\mathcal{F}}={-}\left[\int_0^{1}\frac{1}{2}({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}) ({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1})\,\textrm{d} y\right]_{x={-}L_u}^{x=L+L_d}, \end{gather}

\begin{gather}{\mathcal{F}}={-}\left[\int_0^{1}\frac{1}{2}({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{u}}) ({\boldsymbol{u}}\boldsymbol{\cdot} {\boldsymbol{g}_1})\,\textrm{d} y\right]_{x={-}L_u}^{x=L+L_d}, \end{gather}

Here, ![]() ${\mathcal {P}}$ is the rate of working of pressure at the channel inlet (since

${\mathcal {P}}$ is the rate of working of pressure at the channel inlet (since ![]() $p$ is set to zero along the channel outlet),

$p$ is set to zero along the channel outlet), ![]() ${\mathcal {F}}$ is the net kinetic energy flux extracted from the mean flow between the channel ends,

${\mathcal {F}}$ is the net kinetic energy flux extracted from the mean flow between the channel ends, ![]() ${\mathcal {K}}$ is the rate of working of kinetic energy,

${\mathcal {K}}$ is the rate of working of kinetic energy, ![]() ${\mathcal {E}}$ is the rate of working of fluid stress on the beam and

${\mathcal {E}}$ is the rate of working of fluid stress on the beam and ![]() ${\mathcal {D}}$ is the rate of dissipative energy loss due to fluid viscosity. This dissipation of energy is non-negative, since

${\mathcal {D}}$ is the rate of dissipative energy loss due to fluid viscosity. This dissipation of energy is non-negative, since ![]() ${\mathcal {D}}$ can be alternatively expressed in terms of the velocity components

${\mathcal {D}}$ can be alternatively expressed in terms of the velocity components ![]() ${\boldsymbol{u}}=u_1{\boldsymbol{g}_1}+u_2{\boldsymbol{g}_2}$ as

${\boldsymbol{u}}=u_1{\boldsymbol{g}_1}+u_2{\boldsymbol{g}_2}$ as

\begin{equation} {\mathcal{D}}=\frac{1}{Re}\int_{\varOmega}\left[2\left(\frac{\partial u_1}{\partial x} \right)^{2}+2\left(\frac{\partial u_2}{\partial y}\right)^{2}+ \left(\frac{\partial u_1}{\partial y}+\frac{\partial u_2}{\partial x} \right)^{2}\right]\,\textrm{d}A.\end{equation}

\begin{equation} {\mathcal{D}}=\frac{1}{Re}\int_{\varOmega}\left[2\left(\frac{\partial u_1}{\partial x} \right)^{2}+2\left(\frac{\partial u_2}{\partial y}\right)^{2}+ \left(\frac{\partial u_1}{\partial y}+\frac{\partial u_2}{\partial x} \right)^{2}\right]\,\textrm{d}A.\end{equation}Note that this formulation represents an improvement on the energy budget presented by Stewart et al. (Reference Stewart, Heil, Waters and Jensen2010), since the dissipation term they derived included part of the work done by viscous stresses on the wall and so could take either sign depending on the parameters.

To fully evaluate the work done by the fluid on the wall (![]() ${\mathcal {E}}$) we substitute the beam equations (2.18), (2.19), the identity (2.17) and boundary conditions (2.20)–(2.22a–e) into (2.29) to obtain

${\mathcal {E}}$) we substitute the beam equations (2.18), (2.19), the identity (2.17) and boundary conditions (2.20)–(2.22a–e) into (2.29) to obtain

where,

Here, ![]() ${\mathcal {U}}_{\kappa }$ is the rate of working of bending stresses,

${\mathcal {U}}_{\kappa }$ is the rate of working of bending stresses, ![]() ${\mathcal {U}}_{\lambda }$ is the rate of working of extensional stresses and

${\mathcal {U}}_{\lambda }$ is the rate of working of extensional stresses and ![]() ${\mathcal {P}}_e$ is the rate of working of external pressure. Note that the rate of working of external pressure

${\mathcal {P}}_e$ is the rate of working of external pressure. Note that the rate of working of external pressure ![]() ${\mathcal {P}}_e$ has been manipulated using the boundary condition (2.22a–e); for details see Appendix A.

${\mathcal {P}}_e$ has been manipulated using the boundary condition (2.22a–e); for details see Appendix A.

Using the fluid-beam model proposed by Cai & Luo (Reference Cai and Luo2003) with constitutive law (2.14a,b), Liu et al. (Reference Liu, Luo and Cai2012) established a similar energy budget, but in this case the rate of working of bending stresses (![]() ${\mathcal {U}}_{\kappa }$) could not be written as a complete time derivative and so their system is not energetically conservative when averaged over a period of self-excited oscillation. On the other hand, applying the nonlinear constitutive law (2.16a,b) for the beam makes the system energetically conservative. This difference will also result in minor changes to the other energy terms in (2.32).

${\mathcal {U}}_{\kappa }$) could not be written as a complete time derivative and so their system is not energetically conservative when averaged over a period of self-excited oscillation. On the other hand, applying the nonlinear constitutive law (2.16a,b) for the beam makes the system energetically conservative. This difference will also result in minor changes to the other energy terms in (2.32).

We now summarise the fully nonlinear energy budget for the coupled fluid-beam system in the form

where the left-hand side represents the sources of energy into the system and the right-hand side represents the losses of energy.

2.3. Energetics of steady flow

In the steady state, in which all variables are independent of time, we denote the flow velocity and pressure as ![]() ${\boldsymbol{u}}^{(0)}$ and

${\boldsymbol{u}}^{(0)}$ and ![]() $p^{(0)}$, respectively. In this case the terms

$p^{(0)}$, respectively. In this case the terms ![]() ${\mathcal {P}}_e$,

${\mathcal {P}}_e$, ![]() ${\mathcal {K}}$,

${\mathcal {K}}$, ![]() ${\mathcal {U}}_{\kappa }$ and

${\mathcal {U}}_{\kappa }$ and ![]() ${\mathcal {U}}_{\lambda }$ all vanish. Therefore, the energy budget for the steady system can be expressed simply as,

${\mathcal {U}}_{\lambda }$ all vanish. Therefore, the energy budget for the steady system can be expressed simply as,

with

\begin{gather} {\mathcal{F}}^{(0)}={-}\left[\int_0^{1}\left(\tfrac{1}{2}({\boldsymbol{u}}^{(0)}\boldsymbol{\cdot} {\boldsymbol{u}}^{(0)})({\boldsymbol{u}}^{(0)}\boldsymbol{\cdot} {\boldsymbol{g}}_1)\right)\,\textrm{d} y\right]_{x={-}L_u}^{x=L+L_d}, \end{gather}

\begin{gather} {\mathcal{F}}^{(0)}={-}\left[\int_0^{1}\left(\tfrac{1}{2}({\boldsymbol{u}}^{(0)}\boldsymbol{\cdot} {\boldsymbol{u}}^{(0)})({\boldsymbol{u}}^{(0)}\boldsymbol{\cdot} {\boldsymbol{g}}_1)\right)\,\textrm{d} y\right]_{x={-}L_u}^{x=L+L_d}, \end{gather} \begin{gather}{\mathcal{P}}^{(0)}={-}\left[\int_0^{1}(p^{(0)}{\boldsymbol{u}}^{(0)}\boldsymbol{\cdot} {\boldsymbol{g}}_1) \,\textrm{d} y\right]^{x=L+L_d}_{x={-}L_u}, \end{gather}

\begin{gather}{\mathcal{P}}^{(0)}={-}\left[\int_0^{1}(p^{(0)}{\boldsymbol{u}}^{(0)}\boldsymbol{\cdot} {\boldsymbol{g}}_1) \,\textrm{d} y\right]^{x=L+L_d}_{x={-}L_u}, \end{gather}

where ![]() $\varOmega ^{(0)}$ denotes the fluid domain in the steady state.

$\varOmega ^{(0)}$ denotes the fluid domain in the steady state.

2.4. Energetics of fully developed oscillations

For an unsteady oscillation which has saturated into a nonlinear (finite-amplitude) limit cycle (see § 3.2) we average over a period of oscillation. For example for quantity ![]() $f(t)$, we compute the time average as

$f(t)$, we compute the time average as

where ![]() $\tau$ is the period of oscillation. In this case, the rate of working of external pressure,

$\tau$ is the period of oscillation. In this case, the rate of working of external pressure, ![]() ${\mathcal {P}}_e^{(avg)}$, the average rate of working of fluid kinetic energy,

${\mathcal {P}}_e^{(avg)}$, the average rate of working of fluid kinetic energy, ![]() ${\mathcal {K}}^{(avg)}$, and the average of the rate of working of bending and extensional stiffness,

${\mathcal {K}}^{(avg)}$, and the average of the rate of working of bending and extensional stiffness, ![]() ${\mathcal {U}}_{\kappa }^{(avg)}$ and

${\mathcal {U}}_{\kappa }^{(avg)}$ and ![]() ${\mathcal {U}}_{\lambda }^{(avg)}$, all vanish. Therefore, the energy budget of the unsteady system (2.36) averaged over one period of oscillation becomes simply

${\mathcal {U}}_{\lambda }^{(avg)}$, all vanish. Therefore, the energy budget of the unsteady system (2.36) averaged over one period of oscillation becomes simply

where ![]() ${\mathcal {P}}^{(avg)}$ denotes the average rate of working of the upstream pressure over a period,

${\mathcal {P}}^{(avg)}$ denotes the average rate of working of the upstream pressure over a period, ![]() ${\mathcal {F}}^{(avg)}$ is the average of the kinetic energy flux extracted from the mean flow over a period and

${\mathcal {F}}^{(avg)}$ is the average of the kinetic energy flux extracted from the mean flow over a period and ![]() ${\mathcal {D}}^{(avg)}$ denotes the average rate of energy loss due to viscosity over a period.

${\mathcal {D}}^{(avg)}$ denotes the average rate of energy loss due to viscosity over a period.

In analysing self-excited oscillations, it is useful to consider the excess energy due to oscillation by subtracting the corresponding steady components in the form

These energy terms are all computed in § 3.7 below.

2.5. The finite element method

A finite element method is used to solve the coupled beam-fluid system and construct the corresponding energy budget. We divide the fluid domain into three sections, denoted as A, B and C for the upstream, compliant and downstream compartments, respectively, as described in Luo & Pedley (Reference Luo and Pedley1996) (see also Luo et al. Reference Luo, Cai, Li and Pedley2008). We use an adaptive mesh in section B (where the beam is deformable), while we use a fixed mesh for sections A and C. The flow is described using an Eulerian description for sections A and C, whereas the flow is described using an arbitrary Lagrangian–Eulerian method for section B (Donea, Giuliani & Halleux Reference Donea, Giuliani and Halleux1982).

Across the elastic segment (section B) we employ rotating spines following Cai & Luo (Reference Cai and Luo2003), where we seed nodes along the rigid wall and connect these to nodes on the beam by spines; nodes are then seeded along these spines covering the entirety of region B. Each spine can rotate around its fixed node on the rigid wall, while all the nodes along each spine can move with this spine as the elastic beam is deformed. This allows the mesh to adapt during deformation of the beam.

The Pertrov–Galerkin weighted residual method is used to discretise the system governing equations (2.9a,b), (2.18), (2.19), (2.4a,b) and (2.17). We use 6-node triangular elements with second-order shape functions for the fluid velocity components ![]() $u_1$ and

$u_1$ and ![]() $u_2$, and linear shape functions for the fluid pressure

$u_2$, and linear shape functions for the fluid pressure ![]() $p$. The beam variables

$p$. The beam variables ![]() $x_b,y_b,\theta ,\lambda$ and

$x_b,y_b,\theta ,\lambda$ and ![]() $\kappa$ are all discretised using second-order shape functions evaluated on 3-node beam elements (Huyakorn et al. Reference Huyakorn, Taylor, Lee and Gresho1978). The weighted residuals method is used to discretise the system to determine the nodal values of all variables, where we obtain the discretised matrix equation in the form

$\kappa$ are all discretised using second-order shape functions evaluated on 3-node beam elements (Huyakorn et al. Reference Huyakorn, Taylor, Lee and Gresho1978). The weighted residuals method is used to discretise the system to determine the nodal values of all variables, where we obtain the discretised matrix equation in the form

where ![]() ${\boldsymbol{\varTheta} }=(u_{xi},p_{i},u_{yi},x_{bi},y_{bi},\theta _{i},\lambda _i,\kappa _{i})^\textrm {{T}}$ is the global vector of unknowns with dimension

${\boldsymbol{\varTheta} }=(u_{xi},p_{i},u_{yi},x_{bi},y_{bi},\theta _{i},\lambda _i,\kappa _{i})^\textrm {{T}}$ is the global vector of unknowns with dimension ![]() $N=n_{total} \times 8$,

$N=n_{total} \times 8$, ![]() $i=1,\ldots n_{total}$ is the

$i=1,\ldots n_{total}$ is the ![]() $i$th nodal number of the total

$i$th nodal number of the total ![]() $n_{total}$ nodes and the number of degrees of freedom per node is 8;

$n_{total}$ nodes and the number of degrees of freedom per node is 8; ![]() ${\boldsymbol{M}}$ and

${\boldsymbol{M}}$ and ![]() ${\boldsymbol{K}}$ are the

${\boldsymbol{K}}$ are the ![]() $N \times N$ mass and stiffness matrices,

$N \times N$ mass and stiffness matrices, ![]() ${\boldsymbol{F}}$ is the external force vector and

${\boldsymbol{F}}$ is the external force vector and ![]() ${\boldsymbol{R}}$ is the residual vector.

${\boldsymbol{R}}$ is the residual vector.

An implicit finite difference scheme is used for time integration of the discrete nonlinear matrix equation. At each timestep, a frontal method is used to assemble the global matrix equation and a Newton–Raphson iteration scheme is applied to solve the global matrix equation for ![]() ${\boldsymbol{\varTheta} }$ (Luo & Pedley Reference Luo and Pedley1996; Hao et al. Reference Hao, Cai, Roper and Luo2016). The numerical method enables us to evaluate the terms in the fully nonlinear energy budget in (2.36) by post-processing. As in Luo et al. (Reference Luo, Cai, Li and Pedley2008), we use 36 657 second-order 6-node triangle elements for the fluid domain and 140 second-order 3-node elements for the beam. The convergence of the numerical method is demonstrated in Appendix B.

${\boldsymbol{\varTheta} }$ (Luo & Pedley Reference Luo and Pedley1996; Hao et al. Reference Hao, Cai, Roper and Luo2016). The numerical method enables us to evaluate the terms in the fully nonlinear energy budget in (2.36) by post-processing. As in Luo et al. (Reference Luo, Cai, Li and Pedley2008), we use 36 657 second-order 6-node triangle elements for the fluid domain and 140 second-order 3-node elements for the beam. The convergence of the numerical method is demonstrated in Appendix B.

3. Results

Following Luo et al. (Reference Luo, Cai, Li and Pedley2008), throughout this study we fix the dimensionless parameters to be ![]() $L_u=L=5$,

$L_u=L=5$, ![]() $L_d=30$,

$L_d=30$, ![]() $h=0.01$,

$h=0.01$, ![]() $T=0$,

$T=0$, ![]() $c_{\kappa }=(h^{2}/12)c_\lambda$ and

$c_{\kappa }=(h^{2}/12)c_\lambda$ and ![]() $p_e=1.95$. In what follows, we focus mainly on a small parameter region with either

$p_e=1.95$. In what follows, we focus mainly on a small parameter region with either ![]() $c_\lambda =500$ or

$c_\lambda =500$ or ![]() $c_\lambda =1600$ and

$c_\lambda =1600$ and ![]() $190 < Re \leq 400$ (although we also briefly summarise the parameter space spanned by

$190 < Re \leq 400$ (although we also briefly summarise the parameter space spanned by ![]() $c_\lambda$ and

$c_\lambda$ and ![]() $Re$ for fixed

$Re$ for fixed ![]() $p_e$). For

$p_e$). For ![]() $c_\lambda =1600$, Luo et al. (Reference Luo, Cai, Li and Pedley2008) identified an unsteady mode-2 oscillation in this region using the linear constitutive fluid-beam model of the same geometrical configuration with critical Reynolds number

$c_\lambda =1600$, Luo et al. (Reference Luo, Cai, Li and Pedley2008) identified an unsteady mode-2 oscillation in this region using the linear constitutive fluid-beam model of the same geometrical configuration with critical Reynolds number ![]() $Re_l\approx 212.0$. We first focus on a slice through this parameter space for fixed

$Re_l\approx 212.0$. We first focus on a slice through this parameter space for fixed ![]() $c_\lambda$, considering the steady (§ 3.1) and unsteady behaviour of the system (§ 3.2). We then provide an overview of the regions of instability in the parameter space spanned by the extensional stiffness and Reynolds number (§ 3.3), summarise the dynamics of oscillations which grow from the upper branch of static solutions (§ 3.4), elucidate the nonlinear bifurcation structure of the system (§ 3.5) and examine the possibility of homoclinic orbits (§ 3.6). Finally, we summarise the associated energy budget of fully developed oscillations (§ 3.7).

$c_\lambda$, considering the steady (§ 3.1) and unsteady behaviour of the system (§ 3.2). We then provide an overview of the regions of instability in the parameter space spanned by the extensional stiffness and Reynolds number (§ 3.3), summarise the dynamics of oscillations which grow from the upper branch of static solutions (§ 3.4), elucidate the nonlinear bifurcation structure of the system (§ 3.5) and examine the possibility of homoclinic orbits (§ 3.6). Finally, we summarise the associated energy budget of fully developed oscillations (§ 3.7).

3.1. Steady solutions for  $c_{\lambda }=1600$

$c_{\lambda }=1600$

In order to assess the static behaviour of the system for fixed elastic properties of the beam, figure 2 summarises steady solutions of beam deflection with ![]() $c_{\lambda }=1600$. In particular, we consider the maximal (

$c_{\lambda }=1600$. In particular, we consider the maximal (![]() $y_{max}$) and minimal (

$y_{max}$) and minimal (![]() $y_{min}$) steady beam positions as a function of Reynolds number in figure 2(a), with a zoom in around the region with multiple steady solutions shown in figure 2(b). For low Reynolds numbers the steady beam is entirely inflated (hence

$y_{min}$) steady beam positions as a function of Reynolds number in figure 2(a), with a zoom in around the region with multiple steady solutions shown in figure 2(b). For low Reynolds numbers the steady beam is entirely inflated (hence ![]() $y_{min}=1$). As the Reynolds number increases the channel becomes increasingly constricted as the beam is drawn toward the rigid wall by the Bernoulli effect. For

$y_{min}=1$). As the Reynolds number increases the channel becomes increasingly constricted as the beam is drawn toward the rigid wall by the Bernoulli effect. For ![]() $Re\approx 201.5$ the steady beam shape becomes so-called mode-2, with two extrema, which are inflated at the upstream end and collapsed at the downstream end, i.e.

$Re\approx 201.5$ the steady beam shape becomes so-called mode-2, with two extrema, which are inflated at the upstream end and collapsed at the downstream end, i.e. ![]() $y_{min} < 1$. As the Reynolds number increases further the steady solution abruptly changes at

$y_{min} < 1$. As the Reynolds number increases further the steady solution abruptly changes at ![]() $Re\approx 202.316$, transitioning to a much more collapsed configuration. This collapsed configuration persists as the Reynolds number decreases until a second transition at

$Re\approx 202.316$, transitioning to a much more collapsed configuration. This collapsed configuration persists as the Reynolds number decreases until a second transition at ![]() $Re\approx 201.834$, resulting in a narrow region of parameter space with more than one steady solution. In line with Stewart (Reference Stewart2017), we term the steady solution which persists to low Reynolds numbers as the upper branch solution (where the channel wall is inflated), and the solution which persists to large Reynolds numbers as the lower branch solution (where the channel wall is collapsed). These two transition points take the form of limit point bifurcations and are termed the upper and lower limit points, respectively. The upper and lower branches are connected by an intermediate branch. A three branch static structure has previously been reported for the collapsible channel system, both using a full two-dimensional model for the flow with a simplified wall model (Luo & Pedley Reference Luo and Pedley2000; Heil Reference Heil2004), as well as using a reduced one-dimensional model for the flow (Stewart Reference Stewart2010, Reference Stewart2017). Such three branch behaviour was also recently demonstrated by Herrada et al. (Reference Herrada, Blanco-Trejo, Eggers and Stewart2021) using a hyperelastic (neo-Hookean) wall of finite thickness. In summary, this figure demonstrates that the steady system exhibits at least one static solution across the parameter space, with a narrow region where it can exhibit three static configurations.

$Re\approx 201.834$, resulting in a narrow region of parameter space with more than one steady solution. In line with Stewart (Reference Stewart2017), we term the steady solution which persists to low Reynolds numbers as the upper branch solution (where the channel wall is inflated), and the solution which persists to large Reynolds numbers as the lower branch solution (where the channel wall is collapsed). These two transition points take the form of limit point bifurcations and are termed the upper and lower limit points, respectively. The upper and lower branches are connected by an intermediate branch. A three branch static structure has previously been reported for the collapsible channel system, both using a full two-dimensional model for the flow with a simplified wall model (Luo & Pedley Reference Luo and Pedley2000; Heil Reference Heil2004), as well as using a reduced one-dimensional model for the flow (Stewart Reference Stewart2010, Reference Stewart2017). Such three branch behaviour was also recently demonstrated by Herrada et al. (Reference Herrada, Blanco-Trejo, Eggers and Stewart2021) using a hyperelastic (neo-Hookean) wall of finite thickness. In summary, this figure demonstrates that the steady system exhibits at least one static solution across the parameter space, with a narrow region where it can exhibit three static configurations.

Figure 2. Static solutions of the model for ![]() $c_{\lambda }=1600$ plotting: (a) the minimal (

$c_{\lambda }=1600$ plotting: (a) the minimal (![]() $y_{min}$) and maximal (

$y_{min}$) and maximal (![]() $y_{max}$) channel widths as a function of Reynolds number, plotted with dot-dashed and solid lines, respectively, where the upper and lower static branches are labelled; (b) zoom-in of the region with multiple static solutions marked by a red square in panel (a); (c) the steady beam shape for operating points U7, I2 and L2.

$y_{max}$) channel widths as a function of Reynolds number, plotted with dot-dashed and solid lines, respectively, where the upper and lower static branches are labelled; (b) zoom-in of the region with multiple static solutions marked by a red square in panel (a); (c) the steady beam shape for operating points U7, I2 and L2.

To illustrate the behaviour of the system for ![]() $c_\lambda =1600$ we select eight points on the upper branch of static solutions, which we term U1–U8, two points on the intermediate branch, which we term I1 and I2, and eight points on the lower branch of static solutions, which we term L1–L8. These points are labelled in figure 2 and their corresponding values of Reynolds number are listed in table 1 below.

$c_\lambda =1600$ we select eight points on the upper branch of static solutions, which we term U1–U8, two points on the intermediate branch, which we term I1 and I2, and eight points on the lower branch of static solutions, which we term L1–L8. These points are labelled in figure 2 and their corresponding values of Reynolds number are listed in table 1 below.

Table 1. Computed terms in the static, time-averaged and excess energy budgets, considering 8 operating points on the upper static branch (U1–U8), 2 points on the intermediate static branch (I1–I2) and 8 points on the lower static branch (L1–L8). Points with a dash do not exhibit an oscillatory limit cycle.

To assess these static configurations in detail, figure 2(c) illustrates the three possible steady beam shapes for ![]() $Re=202.1$,

$Re=202.1$, ![]() $c_\lambda =1600$ (operating points U7, I2 and L2). On each branch of steady solutions the wall shape is so-called mode-2, bulged out near the upstream and collapsed at the downstream end of the channel. The upper branch is more inflated than the intermediate branch, which is itself more inflated than the lower branch. Similarly, the lower branch is more collapsed than the intermediate branch, which is in turn more collapsed than the upper branch.

$c_\lambda =1600$ (operating points U7, I2 and L2). On each branch of steady solutions the wall shape is so-called mode-2, bulged out near the upstream and collapsed at the downstream end of the channel. The upper branch is more inflated than the intermediate branch, which is itself more inflated than the lower branch. Similarly, the lower branch is more collapsed than the intermediate branch, which is in turn more collapsed than the upper branch.

We will analyse the stability and the energy budget of these branches in later sections. The region of parameter space with more than one static solution is shown in figure 5 below.

3.2. Unsteady solutions for  $c_{\lambda }=1600$

$c_{\lambda }=1600$

In order to test the stability of the system to time-dependent perturbations, we apply a small increment to the steady solution to generate an initial condition for the computations (here, we use the steady solution along the same branch with a ![]() $1\,\%$ increase in

$1\,\%$ increase in ![]() $c_{\lambda }$). As is conventional in hydrodynamic stability theory, the system is deemed stable if the unsteady solution converges to the corresponding steady solution following the perturbation, and unstable if the perturbation grows with time (Drazin Reference Drazin2002). The boundary between these two behaviours is termed neutrally stable. In plotting the unsteady behaviour of the system we generally illustrate only the fully developed limit cycle of the oscillations, truncating the period of transient growth from the initial condition. Exceptions to this are given in figures 4 and 10(b) below, where we show the full dynamics from the imposed initial condition.

$c_{\lambda }$). As is conventional in hydrodynamic stability theory, the system is deemed stable if the unsteady solution converges to the corresponding steady solution following the perturbation, and unstable if the perturbation grows with time (Drazin Reference Drazin2002). The boundary between these two behaviours is termed neutrally stable. In plotting the unsteady behaviour of the system we generally illustrate only the fully developed limit cycle of the oscillations, truncating the period of transient growth from the initial condition. Exceptions to this are given in figures 4 and 10(b) below, where we show the full dynamics from the imposed initial condition.

In order to assess the stability of the upper and lower branches of the static solution (identified in figure 2), in figure 3 we plot time traces of the fluid pressure on the elastic wall at the mid-point of the beam (![]() $x=L/2$) for various values of the Reynolds number with

$x=L/2$) for various values of the Reynolds number with ![]() $c_\lambda =1600$. We further illustrate various unsteady perturbation wall profiles over the period of fully developed oscillation by subtracting the corresponding steady wall profile, i.e.

$c_\lambda =1600$. We further illustrate various unsteady perturbation wall profiles over the period of fully developed oscillation by subtracting the corresponding steady wall profile, i.e. ![]() ${\textrm {d} y}=y_b-y_b^{(0)}$. For sufficiently low Reynolds numbers, the upper branch static solutions are stable (not shown). The steady configuration on the upper branch becomes unstable at

${\textrm {d} y}=y_b-y_b^{(0)}$. For sufficiently low Reynolds numbers, the upper branch static solutions are stable (not shown). The steady configuration on the upper branch becomes unstable at ![]() $Re\approx 192.2$ (figure 3a), just outside the region with multiple static states. This oscillation grows in amplitude as the Reynolds number increases (figure 3b), becoming increasingly non-sinusoidal/irregular (figure 3c). Above the critical value of Reynolds number the oscillatory wall profile is mode-2 (two extrema across the compliant segment, shown below the corresponding time traces in figure 3a–c), although the beam profile is mode-3 as it moves through the static configuration (eg profile labelled 1 in figure 3a). Proceeding along the upper branch, the amplitude of oscillation reaches a maximum at

$Re\approx 192.2$ (figure 3a), just outside the region with multiple static states. This oscillation grows in amplitude as the Reynolds number increases (figure 3b), becoming increasingly non-sinusoidal/irregular (figure 3c). Above the critical value of Reynolds number the oscillatory wall profile is mode-2 (two extrema across the compliant segment, shown below the corresponding time traces in figure 3a–c), although the beam profile is mode-3 as it moves through the static configuration (eg profile labelled 1 in figure 3a). Proceeding along the upper branch, the amplitude of oscillation reaches a maximum at ![]() $Re \approx 199.0$ (see profiles below) and then decreases again (figure 3d–f). The unstable branch eventually enters the region with multiple static solutions and approaches zero amplitude and re-stabilises as the steady branch becomes close to the upper branch limit point (

$Re \approx 199.0$ (see profiles below) and then decreases again (figure 3d–f). The unstable branch eventually enters the region with multiple static solutions and approaches zero amplitude and re-stabilises as the steady branch becomes close to the upper branch limit point (![]() $Re\approx 202.316$). The wall profiles in this region are again mostly mode-2 (although some of the profiles are mode-3), shown below the corresponding time traces (figure 3d–f). We explore the interaction between the upper branch limit cycles and the upper branch limit point in § 3.6 below. Conversely, the lower branch of static solutions is stable to oscillations as it emerges from the lower limit point (

$Re\approx 202.316$). The wall profiles in this region are again mostly mode-2 (although some of the profiles are mode-3), shown below the corresponding time traces (figure 3d–f). We explore the interaction between the upper branch limit cycles and the upper branch limit point in § 3.6 below. Conversely, the lower branch of static solutions is stable to oscillations as it emerges from the lower limit point (![]() $Re\approx 201.834$). As the Reynolds number increases, the lower branch steady solution eventually becomes unstable at

$Re\approx 201.834$). As the Reynolds number increases, the lower branch steady solution eventually becomes unstable at ![]() $Re\approx 212.65$, outside the region with multiple steady states; the oscillation profile increases in amplitude as the Reynolds number increases (figure 3h,i) and is again mostly mode-2 (see profiles below the corresponding time traces in figure 3g–i, although the wall profile can be mode-3 as it moves through the static configuration). In summary, this figure demonstrates that both the upper and lower static branches can become unstable to oscillations in the neighbourhood of (but just outside) the region of parameter space with multiple static solutions.

$Re\approx 212.65$, outside the region with multiple steady states; the oscillation profile increases in amplitude as the Reynolds number increases (figure 3h,i) and is again mostly mode-2 (see profiles below the corresponding time traces in figure 3g–i, although the wall profile can be mode-3 as it moves through the static configuration). In summary, this figure demonstrates that both the upper and lower static branches can become unstable to oscillations in the neighbourhood of (but just outside) the region of parameter space with multiple static solutions.

Figure 3. Dynamics of self-excited oscillations arising from the upper and lower static branches for ![]() $c_{\lambda }=1600$, showing time traces of the wall mid-point pressure (upper plot for each panel) and the corresponding perturbation wall shape

$c_{\lambda }=1600$, showing time traces of the wall mid-point pressure (upper plot for each panel) and the corresponding perturbation wall shape ![]() ${\textrm {d} y} = y_b-y_b^{(0)}$ at five selected time instances labelled 1–5 (lower plot in each panel) for operating points: (a) U1,

${\textrm {d} y} = y_b-y_b^{(0)}$ at five selected time instances labelled 1–5 (lower plot in each panel) for operating points: (a) U1, ![]() $Re=192.21$; (b) U2,

$Re=192.21$; (b) U2, ![]() $Re=193$; (c) U3,

$Re=193$; (c) U3, ![]() $Re=195$; (d) U5,

$Re=195$; (d) U5, ![]() $Re=201.5$; (e) U7,

$Re=201.5$; (e) U7, ![]() $Re=202.1$; (f) U8,

$Re=202.1$; (f) U8, ![]() $Re=202.3$; (g) L5,

$Re=202.3$; (g) L5, ![]() $Re=212.71$; (h) L6,

$Re=212.71$; (h) L6, ![]() $Re=213$; (i) L8,

$Re=213$; (i) L8, ![]() $Re=216$.

$Re=216$.

In order to test the stability of the intermediate static branch (identified in figure 2), in figure 4(a) we plot time traces of the fluid pressure on the elastic wall at the mid-point of the beam (![]() $x=L/2$) initiated at operating point I2. Initially the mid-point pressure increases toward the upper static branch, where the corresponding beam profile gradually expands toward the upper branch static state (figure 4b). Since the upper branch of static solutions is unstable for these parameters (see figure 3), the system evolves toward the upper branch oscillatory limit cycle; five snapshots of the beam over an oscillation are shown in figure 4(c), analogous to the beam profiles identified for the upper branch limit cycle around operating point U2 (figure 3b). It emerges that, for this model, the intermediate branch is always unstable for all the parameters tested, consistent with earlier predictions in flow through flexible-walled channels (Stewart Reference Stewart2017; Herrada et al. Reference Herrada, Blanco-Trejo, Eggers and Stewart2021), with the profile evolving to the upper branch limit cycle.

$x=L/2$) initiated at operating point I2. Initially the mid-point pressure increases toward the upper static branch, where the corresponding beam profile gradually expands toward the upper branch static state (figure 4b). Since the upper branch of static solutions is unstable for these parameters (see figure 3), the system evolves toward the upper branch oscillatory limit cycle; five snapshots of the beam over an oscillation are shown in figure 4(c), analogous to the beam profiles identified for the upper branch limit cycle around operating point U2 (figure 3b). It emerges that, for this model, the intermediate branch is always unstable for all the parameters tested, consistent with earlier predictions in flow through flexible-walled channels (Stewart Reference Stewart2017; Herrada et al. Reference Herrada, Blanco-Trejo, Eggers and Stewart2021), with the profile evolving to the upper branch limit cycle.

Figure 4. Unsteady solutions at ![]() $Re=202.1$,

$Re=202.1$, ![]() $c_{\lambda }=1600$ (operating points U7, I2 and L2) showing: (a) time trace of the wall mid-point pressure

$c_{\lambda }=1600$ (operating points U7, I2 and L2) showing: (a) time trace of the wall mid-point pressure ![]() $p_{mid}$ initiated close to the intermediate static branch point I2; (b) five wall profiles as the system evolves from the intermediate static branch toward the upper branch static state, where the corresponding times are labelled in panel (a); (c) five wall profiles over a period of self-excited oscillation growing from the upper static branch, with the corresponding times labelled in the inset to panel (a). The dashed (dot-dashed) lines in (a) show the maximal (minimal) mid-point pressure from the upper branch limit cycle U7, while the blue dot-dashed line shows the time trace of the wall mid-point pressure

$p_{mid}$ initiated close to the intermediate static branch point I2; (b) five wall profiles as the system evolves from the intermediate static branch toward the upper branch static state, where the corresponding times are labelled in panel (a); (c) five wall profiles over a period of self-excited oscillation growing from the upper static branch, with the corresponding times labelled in the inset to panel (a). The dashed (dot-dashed) lines in (a) show the maximal (minimal) mid-point pressure from the upper branch limit cycle U7, while the blue dot-dashed line shows the time trace of the wall mid-point pressure ![]() $p_{mid}$ initiated close to the lower static branch point L2. The beam profile plotted with open squares (circles) in (b) shows the corresponding intermediate (upper) static configurations.

$p_{mid}$ initiated close to the lower static branch point L2. The beam profile plotted with open squares (circles) in (b) shows the corresponding intermediate (upper) static configurations.

3.3. Overview of the parameter space

Following Luo et al. (Reference Luo, Cai, Li and Pedley2008), in figure 5 we present an overview of the stability of the system in the parameter space spanned by the Reynolds number (![]() $Re$) and extensional stiffness (

$Re$) and extensional stiffness (![]() $c_\lambda$), where they showed that the space could be partitioned into a number of unstable tongues. These predictions were updated slightly by Hao et al. (Reference Hao, Cai, Roper and Luo2016) using a global stability eigensolver, and their neutral stability curve is shown as a solid black line in figure 5. The corresponding neutral stability points from the lower static branch computed using our numerical method are shown as filled black circles. These points agree well with the neutral stability curve of Hao et al. (Reference Hao, Cai, Roper and Luo2016), and the slight differences are attributed to the difference between the two constitutive laws (the critical Reynolds number is displaced by less than 1 % for all points tested). In general, the lower static branch becomes unstable as the Reynolds number increases (similar to Heil Reference Heil2004; Stewart Reference Stewart2017; Herrada et al. Reference Herrada, Blanco-Trejo, Eggers and Stewart2021). However, Luo et al. (Reference Luo, Cai, Li and Pedley2008) (see also Hao et al. Reference Hao, Cai, Roper and Luo2016) showed that this neutral stability curve is non-monotonic and for large

$c_\lambda$), where they showed that the space could be partitioned into a number of unstable tongues. These predictions were updated slightly by Hao et al. (Reference Hao, Cai, Roper and Luo2016) using a global stability eigensolver, and their neutral stability curve is shown as a solid black line in figure 5. The corresponding neutral stability points from the lower static branch computed using our numerical method are shown as filled black circles. These points agree well with the neutral stability curve of Hao et al. (Reference Hao, Cai, Roper and Luo2016), and the slight differences are attributed to the difference between the two constitutive laws (the critical Reynolds number is displaced by less than 1 % for all points tested). In general, the lower static branch becomes unstable as the Reynolds number increases (similar to Heil Reference Heil2004; Stewart Reference Stewart2017; Herrada et al. Reference Herrada, Blanco-Trejo, Eggers and Stewart2021). However, Luo et al. (Reference Luo, Cai, Li and Pedley2008) (see also Hao et al. Reference Hao, Cai, Roper and Luo2016) showed that this neutral stability curve is non-monotonic and for large ![]() $c_\lambda$ the system restabilises again as the Reynolds number becomes sufficiently large, although we did not investigate this regime.

$c_\lambda$ the system restabilises again as the Reynolds number becomes sufficiently large, although we did not investigate this regime.

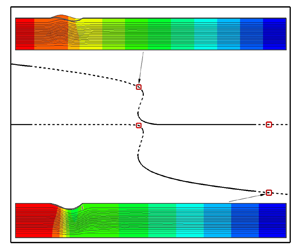

Figure 5. An overview of the parameter space spanned by the Reynolds number and extensional stiffness, summarising the steady and unsteady solutions of the model. The limit points of the upper and lower static branches are plotted as red and black dot-dashed lines, respectively, and the region with multiple static solutions is shaded in light blue. The neutral stability curve initially identified by Luo et al. (Reference Luo, Cai, Li and Pedley2008) and refined by Hao et al. (Reference Hao, Cai, Roper and Luo2016) is plotted as a solid line (associated with the lower static branch). The computed neutral points from the current model are marked as filled black circles. The neutral stability curve associated with the upper static branch is estimated as the dotted line between the computed neutral points. The regions where the system is stable to self-excited oscillations are shaded in grey.

However, as noted in figure 3, the upper branch of static solutions can also become unstable to oscillations. The corresponding computed neutral stability points for the upper static branch are plotted in figure 5, revealing a new region of instability to the left of the region noted by Luo et al. (Reference Luo, Cai, Li and Pedley2008) and Hao et al. (Reference Hao, Cai, Roper and Luo2016).

To extend our understanding of this parameter space, in figure 5 we also highlight the region of parameter space with more than one static solution, by tracing the upper and lower branch limit points as a function of the Reynolds number and the extensional stiffness ![]() $c_\lambda$ for all other parameters held fixed. It emerges that the region which admits multiple static solutions (shaded in figure 5) is very narrow. As

$c_\lambda$ for all other parameters held fixed. It emerges that the region which admits multiple static solutions (shaded in figure 5) is very narrow. As ![]() $c_\lambda$ increases, the upper and lower limit points approach each other and, for

$c_\lambda$ increases, the upper and lower limit points approach each other and, for ![]() $c_\lambda \gtrsim 3500$, the static solution becomes unique for all Reynolds numbers (not shown). Conversely, the width of the region with multiple static states expands slightly as

$c_\lambda \gtrsim 3500$, the static solution becomes unique for all Reynolds numbers (not shown). Conversely, the width of the region with multiple static states expands slightly as ![]() $c_\lambda$ decreases, but is confined to

$c_\lambda$ decreases, but is confined to ![]() $202.495\leq Re \leq 204.554$ for

$202.495\leq Re \leq 204.554$ for ![]() $c_\lambda =500$.

$c_\lambda =500$.