1. Introduction

The impact of a structure on a wavy or quiescent water surface is a complex phenomenon in which many physical processes are involved. Typically, the impact generates highly transient impact loads, rapid structural deformation and violent water surface motion, including the formation of waves and high-speed sprays. These physical processes interact with each other over short time scales and the rates of change of many physical quantities are substantial. In addition, under certain circumstances, air can be entrained into the flow system and the resulting two-phase flow may affect the flow dynamics and acoustics. In an effort to study the physics of impact phenomena, investigators have taken advantage of simplified structure geometries and motions typically during impact with calm water surfaces. A number of these studies are discussed briefly below.

The classic problem of the vertical water entry of a rigid wedge at high Froude number has been studied extensively in a two-dimensional potential flow framework; see, for example, Wagner (Reference Wagner1932), Dobrovol'Skaya (Reference Dobrovol'Skaya1969) and Zhao & Faltinsen (Reference Zhao and Faltinsen1993). These models explain the dynamics of this flow in which the water surface overturns as it rises along the tilted surface of the wedge. The region where the flow overturns is called the spray root. The theory is based on the assumption of a self-similar flow with constant wedge velocity and predicts a high pressure ridge that moves along the wedge surface with the spray root. Extended mathematical models for the water entry of rigid objects of various geometry were developed in studies such as Howison, Ockendon & Wilson (Reference Howison, Ockendon and Wilson1991), Vorus (Reference Vorus1996), Xu et al. (Reference Xu, Troesch and Vorus1998), de Divitiis & de Socio (Reference de Divitiis and de Socio2002), Moore et al. (Reference Moore, Howison, Ockendon and Oliver2012) and Wu & Sun (Reference Wu and Sun2014).

The physics of the impact of rigid objects on a water surface has also been studied through experiments. Early experimental studies on the gravity-driven free drop of a rigid wedge or three-dimensional objects on a water surface were reported by Chuang (Reference Chuang1966), Chuang & Milne (Reference Chuang and Milne1971) and Chuang (Reference Chuang1973). These studies largely confirm the theoretical findings discussed above. Experiments performed by Judge, Troesch & Perlin (Reference Judge, Troesch and Perlin2004) on the vertical/oblique impact of a tilted wedge on a water surface illustrated the effects of the wedge's initial velocity ratio and the level of asymmetry from the vertical axis at its vertex on the symmetry of the spray root propagation as well as on the flow separation from the wedge's surface. Mathematical models for the water entry of an asymmetric wedge are developed in studies such as Semenov & Iafrati (Reference Semenov and Iafrati2006) and Semenov & Wu (Reference Semenov and Wu2018). Breton, Tassin & Jacques (Reference Breton, Tassin and Jacques2020) performed an experimental study on the vertical water entry/exit of axisymmetric bodies. The evolution of the wetted surface under the body and the force on the body during the process were measured. The effect of gravity on the impact at low initial impact velocity is pointed out by the authors. Experimental investigations on the vertical impact of an inclined nearly rigid plate with prescribed impact velocity on a water surface were performed by Wang et al. (Reference Wang, Wang, Balaras, Conroy, O'Shea and Duncan2016) and Wang & Duncan (Reference Wang and Duncan2019). In Wang & Duncan (Reference Wang and Duncan2019) the effect of gravity on the evolution of the spray over time was characterized by an instantaneous Froude number associated with the temporally varying nominal submerged length of the plate. Iafrati (Reference Iafrati2016) performed an experimental study on the ditching of a rectangular plate of negligible deformation into the water surface with substantial horizontal velocities just before the impact. The study shows that the propagation speed of the pressure peak on the plate relative to the geometrical intersection of the plate with the still water surface varies over time and the impact load scales favourably with the velocity normal to the plate. It is also worth noting that if the local inclination of the impactor is small near the touchdown point, due to the flow induced by the air cushion between the impactor and the water surface, the water surface can deform before the impact. The effect of the air cushion is especially important for phenomena at the very initial stage, when the instantaneous Froude number is tremendously large. The detailed behaviour of the air cushion and its effect on various aspects of the impact, such as splash, pressure and force, are studied in, for example, Bouwhuis et al. (Reference Bouwhuis, Hendrix, van der Meer and Snoeijer2015), Jain et al. (Reference Jain, Gauthier, Lohse and van der Meer2021), Moore (Reference Moore2021), Hicks et al. (Reference Hicks, Ermanyuk, Gavrilov and Purvis2012).

The impact of a vertically moving flexible wedge on a water surface was also investigated extensively in the past (see, for example, Maki et al. Reference Maki, Lee, Troesch and Vlahopoulos2011; Luo, Wang & Soares Reference Luo, Wang and Soares2012; Khabakhpasheva & Korobkin Reference Khabakhpasheva and Korobkin2013; Panciroli, Abrate & Minak Reference Panciroli, Abrate and Minak2013; Piro & Maki Reference Piro and Maki2013; Shams & Porfiri Reference Shams and Porfiri2015; Shams, Zhao & Porfiri Reference Shams, Zhao and Porfiri2017; Yu, Li & Ong Reference Yu, Li and Ong2019; Zhang et al. Reference Zhang, Feng, Zhang, Chen, Sun and Zong2021). Panciroli (Reference Panciroli2013) indicated that the deformation of a flexible wedge can cause the separation of the spray sheet from the wedge surface. The results shown in Shams et al. (Reference Shams, Zhao and Porfiri2017) by model and experiments on the free falling of a rigid/flexible wedge on a water surface indicate a very limited effect of hydroelasticity on the spray root propagation during the water entry stage. However, the results indicate that the impact force is reduced as the structural deformation increases during the water entry stage of the gravity-driven wedge. The reduction of the impact force during the gravity-driven vertical impact of a wedge with flexible panels is also illustrated by Ren et al. (Reference Ren, Wang, Stern, Judge and Ikeda-Gilbert2019) and Ren, Javaherian & Gilbert (Reference Ren, Javaherian and Gilbert2021). It should be pointed out that in a gravity-driven impact, the variation of the hydrodynamic force induced by deformation also modifies the rigid body motion of the impactor and in turn changes the flow characteristics and impact force. Therefore, it is difficult to decouple the effect of the deformation on the impact force.

During the vertical water entry of a flexible wedge, an important parameter that characterizes the effect of hydroelasticity is the ratio between the characteristic impact time (wetting time) to the natural period of the panel (Faltinsen Reference Faltinsen1999; Panciroli et al. Reference Panciroli, Abrate and Minak2013). For a gravity-driven vertical impact of a flexible wedge on a water surface, the wetting time is also associated with the mass of the wedge, in addition to the initial impact speed, the deadrise angle and the distance between the vertex and the chine.

Faltinsen & Semenov (Reference Faltinsen and Semenov2008) performed a theoretical study on the oblique water entry of a rigid two-dimensional (2-D) plate. The oblique impact calculations presented in the work of Faltinsen & Semenov (Reference Faltinsen and Semenov2008) cover a range with relatively small horizontal-to-vertical entry velocity ratios (smaller than 2.75) as well as a relatively large pitch angle (greater than 15![]() $^\circ$). The variation of the pressure and normal force coefficients are shown under various combinations of the velocity ratio and the plate pitch angle. Reinhard, Korobkin & Cooker (Reference Reinhard, Korobkin and Cooker2013) performed a theoretical study on the oblique impact of an elastic 2-D plate with free ends on a water surface at large horizontal speed. The calculation indicates that the elastic deformation of the plate may increase the impact force and the chance of cavitation, both due to the low fluid pressure induced by the plate vibration. It should be noted that the calculation is performed with a free-end boundary condition and rigid body motion of the plate is not prescribed.

$^\circ$). The variation of the pressure and normal force coefficients are shown under various combinations of the velocity ratio and the plate pitch angle. Reinhard, Korobkin & Cooker (Reference Reinhard, Korobkin and Cooker2013) performed a theoretical study on the oblique impact of an elastic 2-D plate with free ends on a water surface at large horizontal speed. The calculation indicates that the elastic deformation of the plate may increase the impact force and the chance of cavitation, both due to the low fluid pressure induced by the plate vibration. It should be noted that the calculation is performed with a free-end boundary condition and rigid body motion of the plate is not prescribed.

In the experimental investigation on the impact of a fuselage specimen on a water surface by Iafrati & Grizzi (Reference Iafrati and Grizzi2019), cavitation and ventilation, triggered by the curved shape of the specimen, were observed when the horizontal velocity is sufficiently large. It is pointed out that the cavitation and ventilation have a significant influence on the impact load. In a computational study on the 2-D oblique impact of an elastic plate (beam) with free-free boundary condition at both ends on a thin liquid layer, Khabakhpasheva & Korobkin (Reference Khabakhpasheva and Korobkin2020) also show the possibility of air entrainment as a consequence of plate deformation and rotational motion. Spinosa & Iafrati (Reference Spinosa and Iafrati2021) conducted an experimental study of the water impact of aluminum plates at large horizontal speed and it is pointed out that the structural deformation causes a reduction in peak pressure and an increase in the total load. Faltinsen (Reference Faltinsen1999) proposed an orthotropic plate theory for the coupled analysis of the structural dynamics and the flow motion during the vertical water entry of a ship panel. It is pointed out that the hydroelastic response increases as the ratio of the wetting time to the lowest order natural period of the panel decreases. Wang et al. (Reference Wang, Kim, Wong, Yu, Kiger and Duncan2019) performed an experimental study on the oblique impact of a flexible and a rigid plate with non-zero pitch and roll angles. Under the same motion trajectory, it is found that the maximum deformation of the flexible plate occurs at a more downstream location for a greater impact speed. It is also found that the outboard spray generation during the impact is influenced by the plate deformation.

The impact of a horizontally oriented elastic flat plate falling on a wave crest is studied theoretically by Kvålsvold & Faltinsen (Reference Kvålsvold and Faltinsen1995), Faltinsen (Reference Faltinsen1997), Faltinsen, Kvålsvold & Aarsnes (Reference Faltinsen, Kvålsvold and Aarsnes1997) and Korobkin & Khabakhpasheva (Reference Korobkin and Khabakhpasheva2006). Faltinsen (Reference Faltinsen1997) suggested that the impact process can be categorized into an initial structural inertial phase, which is a very short period during which the plate does not have enough time to rebound before the plate is completely wet, and a subsequent free vibration phase of the plate with associated added mass. It is also shown experimentally by Faltinsen (Reference Faltinsen1997) and Faltinsen et al. (Reference Faltinsen, Kvålsvold and Aarsnes1997) that the maximum bending stress in the plate is not sensitive to the relative location of the wave crest on the plate nor the radius of curvature of the wave crest in the impact region. It is pointed out by both Faltinsen (Reference Faltinsen1997) and Korobkin & Khabakhpasheva (Reference Korobkin and Khabakhpasheva2006) that cavitation and/or ventilation can occur during the impact, as a result of the plate deformation.

In the present study the oblique and vertical impact of flexible plates on a quiescent water surface is investigated experimentally. This study includes several features that have not been examined in the above-mentioned experimental studies. First, the plate is driven into the water surface while its velocity is held constant during the time interval between the passage of the plate's trailing (lower) and leading (upper) edges through the still water level (SWL). (The plate is pitched at a 10![]() $^\circ$ angle.) Second, the force and moment required to maintain the steady plate motion are measured during the impact. And finally, the plate flexibility is varied from stiff, creating maximum deflections of only a few millimetres even at the highest impact speeds, to the very flexible, creating large maximum deflections, on the order of 50 mm. These large deflections create two-way fluid–structure interactions in which the hydrodynamic force and moment change compared with those found during a rigid plate impact at the same velocity. Also, the set-up and wide range of highly controlled experimental conditions allow for a parametric investigation of the interaction between the structural response and the fluid motion.

$^\circ$ angle.) Second, the force and moment required to maintain the steady plate motion are measured during the impact. And finally, the plate flexibility is varied from stiff, creating maximum deflections of only a few millimetres even at the highest impact speeds, to the very flexible, creating large maximum deflections, on the order of 50 mm. These large deflections create two-way fluid–structure interactions in which the hydrodynamic force and moment change compared with those found during a rigid plate impact at the same velocity. Also, the set-up and wide range of highly controlled experimental conditions allow for a parametric investigation of the interaction between the structural response and the fluid motion.

Some of the data from the present study were used in Wu & Earls (Reference Wu and Earls2021) and Pellegrini et al. (Reference Pellegrini, Diez, Wang, Stern, Wang, Wong, Yu, Kiger and Duncan2020) for validation of fluid–structure interaction numerical codes.

In the remainder of this paper, the details of the experimental set-up, measurement techniques and experimental conditions are described first in § 2. In § 3 the experimental results are presented along with analysis and discussions. Finally, the concluding remarks are given in § 4.

2. Experimental details

In this section the details of the experimental set-up, procedures and conditions are described in detail. This description is divided into a series of subsections with the experimental facilities, the force and moment measurements, the flexible plates, the plate deflection measurements, the under-plate spray root measurements, the measurements of the plates’ free vibration frequencies and the experimental conditions and procedures given in § 2.1 to § 2.7, respectively.

2.1. Experimental facilities: towing tank and two-axis carriage

The experiments were performed in the towing tank facility in the hydrodynamics laboratory at the University of Maryland. A schematic of the facility is given in figure 1. The tank is 13.41 m long, 2.45 m wide and 1.33 m tall and consists of a series of 35 mm-thick transparent acrylic side and bottom panels that are bolted to a steel superstructure frame. The frame is in turn bolted to the concrete floor of the laboratory. Another steel superstructure frame (herein called the carriage support frame) is positioned next to one of the long sidewalls of the tank and spans its entire length. The frame is 3.7 m tall and is bolted to the laboratory's concrete floor and sidewall. Two precision horizontal rails, which span the length of the tank, are bolted to two very stiff steel box beams which are in turn bolted to the carriage support frame. A two-axis towing carriage, designed and built for the present experiments, runs along the two horizontal rails. The horizontal motion of the carriage is driven by a belt that is in turn driven by two hydraulic servo motors that are attached to the carriage support frame and powered by a 44 kw hydraulic power unit. The carriage support frame is not in contact with the towing tank, thus avoiding any undesired tank vibration or water surface motion induced by the motion of the carriage.

Figure 1. Schematic drawing of the towing tank and high-speed carriage system. The interior side and bottom panels of the tank are made of clear acrylic to allow for flow visualization. The flexible plates are attached to the two-axis carriage that is driven horizontally along one side of the towing tank by a belt and hydraulic servo motor system. The vertical carriage rides on rails that are attached to the horizontal carriage and is driven by a belt and electric servo motor system. Camera 1 is installed under the tank for the measurement of the under-plate water surface motion. Cameras 2–4 are installed along the tank's side wall for the measurement of the plate deflection.

The two-axis towing carriage, as shown in figure 2(a), is made of 304 stainless steel and consists of a horizontal carriage, which moves along the two horizontal rails described above, and a vertical carriage, which moves along two vertical precision rails that are bolted to the horizontal carriage. The horizontal and vertical carriages are constructed from stiff frames, composed from a series of I-beams and bulkhead stiffeners, with a sheet metal skin (12 and 14 gauge thickness) riveted to the frames. The horizontal carriage carries an electric servo motor and a belt-sprocket motion system that drives the vertical carriage. The instantaneous positions of the horizontal and vertical carriages are measured with an absolute rotary encoder (model 1037504, SICK Sensor Intelligence) and a linear position sensor (Temposonics R-series model RH, MTS, Inc.), respectively, at a sample rate of 1024 Hz. Motions of both axes are controlled by a position feedback control system through a computer.

Figure 2. Schematics drawings of the carriage and flexible plate. In (a) the structure of the two-axis high-speed carriage and the dynamometer system are shown. The coordinate system of the undeformed plate is denoted. The origin of the coordinate system is at the undeformed plate's centre, ![]() $O$, and the longitudinal, transverse and normal coordinates are denoted as

$O$, and the longitudinal, transverse and normal coordinates are denoted as ![]() $\hat l$,

$\hat l$, ![]() $\hat t$ and

$\hat t$ and ![]() $\hat n$, respectively. In (b) a side view of the dynamometer system and some details of the plate mounting mechanism are shown. The direction of the horizontal and vertical carriage velocities,

$\hat n$, respectively. In (b) a side view of the dynamometer system and some details of the plate mounting mechanism are shown. The direction of the horizontal and vertical carriage velocities, ![]() $U$ and

$U$ and ![]() $W$, and the orientation of the water surface, are denoted. The pitch angle of the plate is denoted as

$W$, and the orientation of the water surface, are denoted. The pitch angle of the plate is denoted as ![]() $\alpha$. The five locations where the out-of-plane deflection is measured are denoted as

$\alpha$. The five locations where the out-of-plane deflection is measured are denoted as ![]() $R_i$ (

$R_i$ (![]() $i=1,\ldots,5$). The locations of

$i=1,\ldots,5$). The locations of ![]() $R_i$ are at the transverse mid plane (

$R_i$ are at the transverse mid plane (![]() $t=0$) and are equally spaced between the axes of the two shafts, with

$t=0$) and are equally spaced between the axes of the two shafts, with ![]() $R_3$ at the plate centre. In (c) the projected view of the dynamometer system and the plate is shown when viewed toward the positive longitudinal direction. The numerical values of the dimensions labelled in the figure are as following:

$R_3$ at the plate centre. In (c) the projected view of the dynamometer system and the plate is shown when viewed toward the positive longitudinal direction. The numerical values of the dimensions labelled in the figure are as following: ![]() $\alpha =10^\circ$,

$\alpha =10^\circ$, ![]() $L=1080$ mm,

$L=1080$ mm, ![]() $L_s=1016$ mm,

$L_s=1016$ mm, ![]() $l_1=L_s/6=169.3$ mm,

$l_1=L_s/6=169.3$ mm, ![]() $d_1=38.1$ mm,

$d_1=38.1$ mm, ![]() $d_2=28.6$ mm,

$d_2=28.6$ mm, ![]() $B=406$ mm and

$B=406$ mm and ![]() $B_s=269$ mm. In (d) a detailed schematic of a single deflection sensor is shown.

$B_s=269$ mm. In (d) a detailed schematic of a single deflection sensor is shown.

2.2. Plate mounting structure and force/moment measurement system

The impact plate is installed under the vertical carriage through a mounting structure that includes four struts, a dynamometer and two rotary bearing systems, as shown in figure 2. The struts are right angle beams made of aluminum alloy. In the present experiments the lengths of the four struts are chosen to create a 10![]() $^\circ$ pitch angle and 0

$^\circ$ pitch angle and 0![]() $^\circ$ roll angle for the plate. The dynamometer includes two parallel frames made of square box beams and stiffeners. The upper and lower dynamometer frames are connected at each of the four frame corners through a dynamic three-component load cell with thick steel mounting blocks (Kistler 9367C, 60 kN range, with 5080A multichannel charge amplifier); see figure 2(a). With this configuration, the dynamometer can measure all three components (

$^\circ$ roll angle for the plate. The dynamometer includes two parallel frames made of square box beams and stiffeners. The upper and lower dynamometer frames are connected at each of the four frame corners through a dynamic three-component load cell with thick steel mounting blocks (Kistler 9367C, 60 kN range, with 5080A multichannel charge amplifier); see figure 2(a). With this configuration, the dynamometer can measure all three components (![]() $l$-longitudinal,

$l$-longitudinal, ![]() $t$-transverse and

$t$-transverse and ![]() $n$-normal; see figure 2a) of the total force and the total moment, exerted by the lower frame and its attachments to the upper frame.

$n$-normal; see figure 2a) of the total force and the total moment, exerted by the lower frame and its attachments to the upper frame.

The impact plate is connected to the lower frame of the dynamometer using a linear bearing system (SRB2-08SS-016, PBC Linear) at the forward and aft ends of the dynamometer frame; see figure 2. In this configuration, one bearing is centred on and bolted to the bottom of each load cell unit. Near each of the transverse plate edges, herein called the leading edge or the trailing edge (labelled in figure 2b), an aluminum T-rail that is bolted to a stainless steel round shaft (diameter 12.7 mm) is bolted to the plate. The relatively thick T-rail covers the entire plate width and is bolted to the plate with pairs of machine screws placed every 50.8 mm across the plate width. The flat heads of the screws are counter sunk into the bottom surface of the plate so as to minimize their effect on the water flow during the experiments. With this configuration, the plate bending along the two transverse edges is believed to be small under a nearly uniformly distributed load along the transverse direction, as in the present experiments. Each round shaft goes through two rotary bearings described above and is free to rotate about the axis of the shaft. The translation of each shaft along its axis is prevented by shaft collars. With this configuration, the shaft, which is centred 28.6 mm (![]() $d_2$, see figure 2) above the upper surface of the plate and at a longitudinal distance of 32 mm away from the plate's leading/trailing edge, is only allowed to rotate about its axis while rotation about other directions and translation along any directions are prohibited. This mounting configuration is analogous in some way to a plate simply supported at two opposite edges and free at the other two opposite edges. However, one should keep in mind that the rotational axis of the present configuration is above the plate and inward of the plate's leading and trailing edges.

$d_2$, see figure 2) above the upper surface of the plate and at a longitudinal distance of 32 mm away from the plate's leading/trailing edge, is only allowed to rotate about its axis while rotation about other directions and translation along any directions are prohibited. This mounting configuration is analogous in some way to a plate simply supported at two opposite edges and free at the other two opposite edges. However, one should keep in mind that the rotational axis of the present configuration is above the plate and inward of the plate's leading and trailing edges.

The impact plates used in the present experiments are all made of aluminum 6061-T651 alloy (density of ![]() $\rho _p=2700\,{\rm kg}\,{\rm m}^{-3}$; elastic modulus of

$\rho _p=2700\,{\rm kg}\,{\rm m}^{-3}$; elastic modulus of ![]() $E=68.9$ GPa; Poisson's ratio

$E=68.9$ GPa; Poisson's ratio ![]() $\nu _p=0.3$). Three impact plates are used in the present experiments. All plates are

$\nu _p=0.3$). Three impact plates are used in the present experiments. All plates are ![]() $L=1080$ mm long by

$L=1080$ mm long by ![]() $B=406$ mm wide while their thicknesses varied from plate to plate. Next to the port edge of the plate, a very stiff vertical wall that reaches the tank bottom is installed along the tank. The distance between the vertical wall and the plate's port edge is 2 mm and remains nearly constant along the length of the wall.

$B=406$ mm wide while their thicknesses varied from plate to plate. Next to the port edge of the plate, a very stiff vertical wall that reaches the tank bottom is installed along the tank. The distance between the vertical wall and the plate's port edge is 2 mm and remains nearly constant along the length of the wall.

The impact force and moment are sampled using an A/D system (PXIe-4497, National Instrument) with a sample rate of 40.96 kHz. Double shielded cables are used to avoid the electrical noise contamination from the vertical carriage servo motor system. The manufacturer's calibration data of each load cell was verified and the total force/moment measured by the dynamometer was also verified by applying standard weights to the individual load cells and to the dynamometer frame at various locations, respectively.

2.3. Thickness of the impact plates

In order to evaluate the uniformity of the plates and to obtain a statistical description of each plate's thickness, an ultrasonic thickness meter (GE CL5 Krautkramer, with Alpha2-DFR probe) was used to measure the plate thickness at both the edges and the interior of the plate. Before measuring the thickness of each plate, the ultrasonic meter was calibrated by the thickness at the edge of the same plate which was also measured with a high-precision micrometre in a small section where the paint on the lower surface was removed. The ultrasonic probe was then placed at a series of ![]() $22 \times 8$ grid points with 50.8 mm spacing on the upper side of the plates for the measurements, so that only the aluminum thickness was captured by the ultrasonic meter; in this configuration the thickness of the very thin layer of paint on the lower side of the plates does not affect the measurements. The measurement resolution of the ultrasonic meter is 0.001 mm. The statistics of the thicknesses at a total of 176 measured locations for each plate are listed in table 1. The results indicate that the thickness of each impact plate is highly uniform with a range of variation of approximately 0.1 mm and a standard deviation of approximately 0.02 mm. In the following discussion, the mean thicknesses of the three plates will be used in the data analysis.

$22 \times 8$ grid points with 50.8 mm spacing on the upper side of the plates for the measurements, so that only the aluminum thickness was captured by the ultrasonic meter; in this configuration the thickness of the very thin layer of paint on the lower side of the plates does not affect the measurements. The measurement resolution of the ultrasonic meter is 0.001 mm. The statistics of the thicknesses at a total of 176 measured locations for each plate are listed in table 1. The results indicate that the thickness of each impact plate is highly uniform with a range of variation of approximately 0.1 mm and a standard deviation of approximately 0.02 mm. In the following discussion, the mean thicknesses of the three plates will be used in the data analysis.

Table 1. Statistics of the thicknesses of the three impact plates, measured by an ultrasonic thickness meter at 176 grid points on each plate.

2.4. Plate deformation measurement

The out-of-plane deflection of the plates is measured at five locations along the longitudinal plate centreline. All five measurement locations lie between the axes of the two plate mounting shafts and are equally spaced by a distance of 169.3 mm (![]() $l_1$, see figure 2). The out-of-plane deflection gauge employed in this study consists of a metal rod whose lower end connects to a swivel joint that is glued to the plate's upper surface; see figure 2. The rod goes through a hole on a ball joint fixed on a frame that is in turn bolted to the four dynamometer mounting struts. An imaging target, a white board with a random black dot pattern printed on it, is installed at the tip of each metal rod and at the fixed ball joint. As the plate deforms, the relative distance from the target at the rod tip to the target on the fixed ball joint varies. Three high-speed cameras (cameras 2–4 in figure 1, model V640, V641, VEO 640L, Vision Research Inc.) are installed along the side of the tank to record the motion of these imaging targets at a frame rate of 1024 Hz and a field of view of 98 cm by 61 cm. Flood lights were installed along the side of the tank to provide illumination for the imaging. The camera image sensors measure 2560 by 1600 pixels resulting in a 0.38 mm pixel

$l_1$, see figure 2). The out-of-plane deflection gauge employed in this study consists of a metal rod whose lower end connects to a swivel joint that is glued to the plate's upper surface; see figure 2. The rod goes through a hole on a ball joint fixed on a frame that is in turn bolted to the four dynamometer mounting struts. An imaging target, a white board with a random black dot pattern printed on it, is installed at the tip of each metal rod and at the fixed ball joint. As the plate deforms, the relative distance from the target at the rod tip to the target on the fixed ball joint varies. Three high-speed cameras (cameras 2–4 in figure 1, model V640, V641, VEO 640L, Vision Research Inc.) are installed along the side of the tank to record the motion of these imaging targets at a frame rate of 1024 Hz and a field of view of 98 cm by 61 cm. Flood lights were installed along the side of the tank to provide illumination for the imaging. The camera image sensors measure 2560 by 1600 pixels resulting in a 0.38 mm pixel![]() $^{-1}$ resolution. Each black dot on the imaging target is 2.25 mm (5.9 pixel) in diameter and there are 25 dots in each image of the target. The processing aims at finding the relative displacement vector of the same target between the first image of the target in each camera and the current image of the target by using cross-correlation values of the image intensity map between the two images. A three-point Gaussian peak fit to the three highest cross-correlation values around the peak was used to achieve sub-pixel accuracy of the displacement. Calibration experiments were performed in which one of the dot-pattern targets was attached to a linear translation stage with an accuracy of 0.0127 mm and photographed at 100 successive locations separated by 0.0254 mm (total displacement

$^{-1}$ resolution. Each black dot on the imaging target is 2.25 mm (5.9 pixel) in diameter and there are 25 dots in each image of the target. The processing aims at finding the relative displacement vector of the same target between the first image of the target in each camera and the current image of the target by using cross-correlation values of the image intensity map between the two images. A three-point Gaussian peak fit to the three highest cross-correlation values around the peak was used to achieve sub-pixel accuracy of the displacement. Calibration experiments were performed in which one of the dot-pattern targets was attached to a linear translation stage with an accuracy of 0.0127 mm and photographed at 100 successive locations separated by 0.0254 mm (total displacement ![]() $= 2.54$ mm). Using various combinations of pairs of images, correlations were performed for at least 50 pairs of images for relative target displacements (

$= 2.54$ mm). Using various combinations of pairs of images, correlations were performed for at least 50 pairs of images for relative target displacements (![]() $\varDelta$) ranging from 0.0254 mm to 1.27 mm. It was found that a displacement of 0.1 mm was measured by this system with a standard deviation of

$\varDelta$) ranging from 0.0254 mm to 1.27 mm. It was found that a displacement of 0.1 mm was measured by this system with a standard deviation of ![]() $\pm$7 %.

$\pm$7 %.

2.5. Under-plate water surface measurement

The water surface evolution under the flexible plates was also recorded during the impact experiments. For this purpose, a high-speed camera (camera 1 in figure 1, model V640, Vision Research Inc. 2500 by 1600 pixel sensor), a flat mirror oriented at a 45![]() $^\circ$ angle from the horizontal plane, and two flood lights were installed under the towing tank near the impact site, as illustrated in figure 1. With this configuration, the camera views the plate's lower surface and the under-plate water surface, through the transparent tank bottom panel. Flat white paint was sprayed uniformly over the lower surface of each flexible plate in order to provide a uniformly illuminated background for observing the water surface evolution. Grid lines were then added to each painted surface with spacing of 50.8 mm to inform the location of water surface features relative to the plate surface.

$^\circ$ angle from the horizontal plane, and two flood lights were installed under the towing tank near the impact site, as illustrated in figure 1. With this configuration, the camera views the plate's lower surface and the under-plate water surface, through the transparent tank bottom panel. Flat white paint was sprayed uniformly over the lower surface of each flexible plate in order to provide a uniformly illuminated background for observing the water surface evolution. Grid lines were then added to each painted surface with spacing of 50.8 mm to inform the location of water surface features relative to the plate surface.

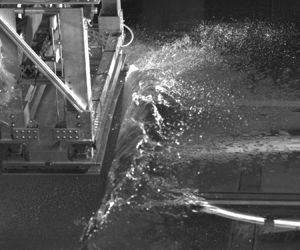

A sample image taken from one of the high-speed movies during an impact of the thinnest plate is given figure 3. The location of the spray root, defined in the following, is extracted from each image. During impact, the water surface rises between the plate's geometrical intersection with the SWL and the plate's leading edge, and, via a region called the spray root, overturns to join a thin spray sheet which extends over time along the plate's lower surface as the impact proceeds (see, for example, studies of the vertical impact of a wedge/plate on a water surface, Zhao & Faltinsen Reference Zhao and Faltinsen1993; Wang & Duncan Reference Wang and Duncan2019). The under-plate spray root line is a spatial curve consisting of points on the under-plate water surface where the surface normal becomes horizontal. In the region between the spray root line and the plate's trailing edge, the left side of the image in figure 3, the camera views the lower side of the plate only through the water phase. Thus, this region appears smooth in the images. In the region between the spray root line and the plate's leading edge, to the right in figure 3, the image of the plate appears rough, due to the rough surface of the under-plate spray sheet (caused by the growing turbulent boundary layer within the spray sheet and gravitational instability) and the rough lower water surface (caused by splashes due to falling droplets and ligaments). In the images, the spray root line separating these two regions appears as a narrow opaque band, due to the total internal reflection of the subsurface light rays that reach the spray root region. The edge of the band closest to the plate trailing edge is taken as the location of the spray root line, and is marked in figure 3. Using measurements of the actual distance of the spray root from the surface of a wedge during vertical impact, Wang & Duncan (Reference Wang and Duncan2019), and the camera viewing angle relative to the normal to the plate surface in the present experiments (4![]() $^\circ$ to 24

$^\circ$ to 24![]() $^\circ$), it is estimated that the error between the true position of the spray root and that measured by the above method is at most

$^\circ$), it is estimated that the error between the true position of the spray root and that measured by the above method is at most ![]() $0.004L$.

$0.004L$.

Figure 3. An image from a high-speed movie taken looking up from under the tank during an impact of the thinnest plate for ![]() ${Fr} = 0.43$ and

${Fr} = 0.43$ and ![]() $UW^{-1}=8.33$. The spray root line is visible as marked in the image. The camera and flood lights set-up is shown in figure 1. The plate is moving from left to right and the image was taken at

$UW^{-1}=8.33$. The spray root line is visible as marked in the image. The camera and flood lights set-up is shown in figure 1. The plate is moving from left to right and the image was taken at ![]() $t/T_s = 0.50$.

$t/T_s = 0.50$.

The coordinates of the spray root line in the reference frame of the plate's lower surface at a set of equally spaced times during impact are obtained by the following method. The times when the spray root line crosses each grid point are first extracted from the high-speed movies. Then an interpolation is applied at uniformly distributed time steps to the longitudinal position data. Finally, at each time step, with the interpolated longitudinal position and the known transverse position of each longitudinal line, a fourth-order polynomial is applied to approximate the instantaneous shape of the spray root line.

2.6. Measurements of the plates’ free vibration frequencies

The natural frequencies and damping coefficients of the three plates were measured in free vibration experiments. During the plate-water impact experiments, the upper surface of the plate remains in air while the portion of the wetted lower surface between the trailing edge and the spray root drives the motion of the flow. This wetted plate area ranges from zero at initial impact to the entire underside of the plate when the spray root reaches the plate's leading edge. In order to evaluate the influence of the added mass of the water on the structural dynamics, the free vibration experiments were performed under two conditions for each plate. In both conditions, the plates were oriented horizontally. The first condition is the free vibration of the entire plate in air (the condition at the beginning of the plate-water impact) while the second condition is the free vibration of the plate when its upper surface is dry and its entire lower surface is located slightly below the water surface (mimicking in some ways the condition at the end of the plate-water impact).

To perform the free vibration experiments under the two conditions described above, the following set-up and procedure was used. To orient the plate horizontally, both forward supporting struts, which connect the dynamometer frame to the vertical carriage, were replaced with struts of equal length to the two aft struts. The symmetry wall was located next to the port edge of the plate with the same gap width used in the impact experiments. The SWL in the tank was also kept the same as that during the impact experiments. The free vibration was excited by an impulsive impact near the plate centre by a rubber hammer. An optical switch was used to trigger the data recording, which starts just before the impact occurs. Five targets, with random dot patters printed on each of them, were glued to the plate along its centreline and the starboard plate edge, as shown in figure 4. Two synchronized high-speed cameras were used to record the motion of the targets during the impact. The position of each target at every instant is extracted from the high-speed movies by the image correlation method used in the plate deflection measurements. The resolutions of the two cameras for the centreline and edge targets are 6.48 and 7.20 pixels mm![]() $^{-1}$, respectively, and all movies were taken at 3600 pps. High-speed movies taken simultaneously by a third camera, which was installed under the tank and viewed the lower surface of the plate, were used to ensure that no air pockets were trapped between the water surface and the plate's lower surface during the vibration experiments. In addition to these displacement measurements, records of the normal (vertical for this plate orientation) force were also recorded. For each plate under each vibration condition, the measurements were repeated at least five times.

$^{-1}$, respectively, and all movies were taken at 3600 pps. High-speed movies taken simultaneously by a third camera, which was installed under the tank and viewed the lower surface of the plate, were used to ensure that no air pockets were trapped between the water surface and the plate's lower surface during the vibration experiments. In addition to these displacement measurements, records of the normal (vertical for this plate orientation) force were also recorded. For each plate under each vibration condition, the measurements were repeated at least five times.

Figure 4. Top and side views of the set-up for the free vibration experiments are shown in (a,b), respectively. In the depicted configuration, the lower side of the plate is slightly below the water surface while the upper side is dry. The carriage structure above the dynamometer frame is omitted.

Spectral analysis of the displacement vs time data was then used to examine the plate response in the frequency domain. For the same plate, it is found that the power spectral density of the displacement at all five measurement locations is prominent at two frequencies for each experimental condition. These two natural frequency components also consistently appear with prominent power in the spectrum of the normal force data. At the lower frequency (![]() $f_1$), it is found that the vibration at all five measurement locations are in phase, indicating a dominant first-order mode shape in the longitudinal direction. At the higher frequency (

$f_1$), it is found that the vibration at all five measurement locations are in phase, indicating a dominant first-order mode shape in the longitudinal direction. At the higher frequency (![]() $f_2$), the three locations along the centreline vibrate at an approximately 180

$f_2$), the three locations along the centreline vibrate at an approximately 180![]() $^\circ$ phase lag from the two locations along the edge, indicating a dominant first-order mode shape in the transverse direction. Qualitative observations indicate that longitudinal bending dominates the plate's deformation during the water impact experiments. Numerical values of the two dominant frequencies and their damping characteristics were obtained by fitting the solution of the linear damping equation,

$^\circ$ phase lag from the two locations along the edge, indicating a dominant first-order mode shape in the transverse direction. Qualitative observations indicate that longitudinal bending dominates the plate's deformation during the water impact experiments. Numerical values of the two dominant frequencies and their damping characteristics were obtained by fitting the solution of the linear damping equation,

where ![]() $\omega = 2{\rm \pi} f$ and

$\omega = 2{\rm \pi} f$ and ![]() $\zeta$ is the damping ratio, to the deflection vs time records obtained by band-pass filtering the raw data at the frequencies of the above-mentioned two spectral peaks. The results for dry and wet conditions for each of the three plates are given in table 2. The solution of the linear oscillator equation was not a good fit to the lowest mode wet plate data, which has an unusual decay pattern. Thus, no values of

$\zeta$ is the damping ratio, to the deflection vs time records obtained by band-pass filtering the raw data at the frequencies of the above-mentioned two spectral peaks. The results for dry and wet conditions for each of the three plates are given in table 2. The solution of the linear oscillator equation was not a good fit to the lowest mode wet plate data, which has an unusual decay pattern. Thus, no values of ![]() $\zeta$ are given for these cases. As can be seen from the table, the dry and wet natural frequencies for both modes increase with increasing plate thickness. Also, the lowest order wet natural frequency (

$\zeta$ are given for these cases. As can be seen from the table, the dry and wet natural frequencies for both modes increase with increasing plate thickness. Also, the lowest order wet natural frequency (![]() $f_{1w}$) is approximately

$f_{1w}$) is approximately ![]() $1/3$ of the lowest order dry natural frequency (

$1/3$ of the lowest order dry natural frequency (![]() $f_{1a}$) for all three plates.

$f_{1a}$) for all three plates.

Table 2. Natural frequencies (![]() $f$) and damping ratios (

$f$) and damping ratios (![]() $\zeta$) of each plate for modes one and two, denoted by subscripts 1 and 2, respectively. Data are given for cases with the plate in air, denoted by subscript

$\zeta$) of each plate for modes one and two, denoted by subscripts 1 and 2, respectively. Data are given for cases with the plate in air, denoted by subscript ![]() $a$, and with the plate's lower surface slightly below the water surface while the upper surface remains in air, denoted by subscript

$a$, and with the plate's lower surface slightly below the water surface while the upper surface remains in air, denoted by subscript ![]() $w$. The data are obtained from the free vibration experiments described in § 2.6.

$w$. The data are obtained from the free vibration experiments described in § 2.6.

In the plate-water impact experiments, the submergence time, defined as the time interval between the passage of the plate's trailing and leading edges through the SWL, ![]() $T_s = L\sin \alpha /W$, ranges from 0.21 s to 0.78 s. In the current experiments, the lowest order natural period when the plate's lower side is wet (

$T_s = L\sin \alpha /W$, ranges from 0.21 s to 0.78 s. In the current experiments, the lowest order natural period when the plate's lower side is wet (![]() $1/f_{w1}$) ranges from 0.07 s for

$1/f_{w1}$) ranges from 0.07 s for ![]() $h=13.22$ mm to 0.13 s for

$h=13.22$ mm to 0.13 s for ![]() $h=6.61$ mm. Thus, the ratio of the submergence time scale to the wet natural period,

$h=6.61$ mm. Thus, the ratio of the submergence time scale to the wet natural period, ![]() $R_T=T_s/T_{1w}$, ranges from 1.59 for the thinnest plate at the highest vertical velocity to 10.70 for the thickest plate at the slowest vertical velocity. As the ratio approaches its lower boundary, the two time scales are of the same order and an increased coupling effect between the structural dynamics and the flow dynamics is expected.

$R_T=T_s/T_{1w}$, ranges from 1.59 for the thinnest plate at the highest vertical velocity to 10.70 for the thickest plate at the slowest vertical velocity. As the ratio approaches its lower boundary, the two time scales are of the same order and an increased coupling effect between the structural dynamics and the flow dynamics is expected.

2.7. Experimental procedures and conditions

In each experimental run with oblique motion (![]() $U>0$), the carriage starts at a position near one end of the tank with the vertical carriage position set so that the plate's trailing (lower) edge is 117.3 mm above the still water surface. The horizontal carriage is then accelerated over a travel distance of 1.52 m to a horizontal speed,

$U>0$), the carriage starts at a position near one end of the tank with the vertical carriage position set so that the plate's trailing (lower) edge is 117.3 mm above the still water surface. The horizontal carriage is then accelerated over a travel distance of 1.52 m to a horizontal speed, ![]() $U$, which is held constant until after the leading edge of the plate passes through the SWL. A laser-trip system, which consists of a sharp knife edge installed on the horizontal carriage, a HeNe laser beam that is directed across the width of the tank at a fixed position (carriage travel distance of 1.96 m), and a photodiode placed at a fixed position to receive the laser beam, is used to create a time reference for triggering the vertical carriage motion; see figure 1. When the knife edge interrupts the laser beam, the change in state of the photodiode is detected by a pulse delay generator (Model 577, Berkeley Nucleonics Corp.) which, after an adjustable time delay, sends a signal to initiate the vertical carriage motion. Using this triggering system, the run-to-run variation of the streamwise tank position where the impact plate first makes contact with the water surface varies by no more than

$U$, which is held constant until after the leading edge of the plate passes through the SWL. A laser-trip system, which consists of a sharp knife edge installed on the horizontal carriage, a HeNe laser beam that is directed across the width of the tank at a fixed position (carriage travel distance of 1.96 m), and a photodiode placed at a fixed position to receive the laser beam, is used to create a time reference for triggering the vertical carriage motion; see figure 1. When the knife edge interrupts the laser beam, the change in state of the photodiode is detected by a pulse delay generator (Model 577, Berkeley Nucleonics Corp.) which, after an adjustable time delay, sends a signal to initiate the vertical carriage motion. Using this triggering system, the run-to-run variation of the streamwise tank position where the impact plate first makes contact with the water surface varies by no more than ![]() $\pm 2.5$ mm from run to run. Starting just before the plate's trailing (lower) edge makes contact with the still water surface, despite the hydrodynamic load exerted on the plate, the horizontal and vertical carriage speeds,

$\pm 2.5$ mm from run to run. Starting just before the plate's trailing (lower) edge makes contact with the still water surface, despite the hydrodynamic load exerted on the plate, the horizontal and vertical carriage speeds, ![]() $U$ and

$U$ and ![]() $W$, remain at nearly constant values, which are programmed and controlled by a feedback system, until the plate's leading (higher) edge reaches the SWL. Subsequently, the horizontal and vertical carriages undergo constant deceleration to zero speed. For runs with vertical motion only, the horizontal carriage is placed at the centre of the symmetry wall and the vertical carriage motion is triggered manually.

$W$, remain at nearly constant values, which are programmed and controlled by a feedback system, until the plate's leading (higher) edge reaches the SWL. Subsequently, the horizontal and vertical carriages undergo constant deceleration to zero speed. For runs with vertical motion only, the horizontal carriage is placed at the centre of the symmetry wall and the vertical carriage motion is triggered manually.

The procedure for each experimental run was as follows. After the previous run, the filtration system of the tank is turned on for 15 min. Then the fluid motion in the tank is allowed to die away over a period of approximately 40 min. The SWL is then measured (using a mechanical point gauge, Lory Type-C, resolution: 0.1 mm) to ensure its consistency throughout the entire experimental campaign. The surface tension was measured two times each day with a Wilhelmy plate device and was maintained at that of clean water at room temperature, ![]() $73\pm 0.5\,{\rm dyne}\,{\rm cm}^{-1}$, via water surface skimming and filtration.

$73\pm 0.5\,{\rm dyne}\,{\rm cm}^{-1}$, via water surface skimming and filtration.

The following experimental conditions were used in the present study. Throughout the impact experiments, the pitch angles of the undeformed plates, ![]() $\alpha$, are set to 10

$\alpha$, are set to 10![]() $^\circ$ and the deadrise (roll) angles of the plates,

$^\circ$ and the deadrise (roll) angles of the plates, ![]() $\beta$, are set to zero. The constant horizontal and vertical speeds of the carriage during impact,

$\beta$, are set to zero. The constant horizontal and vertical speeds of the carriage during impact, ![]() $U$ and

$U$ and ![]() $W$, respectively, are varied from one impact condition to another as shown in figure 5. In the primary set of the impact conditions, for the same plate,

$W$, respectively, are varied from one impact condition to another as shown in figure 5. In the primary set of the impact conditions, for the same plate, ![]() $U$ and

$U$ and ![]() $W$ are varied simultaneously so that either the normal impact speed,

$W$ are varied simultaneously so that either the normal impact speed, ![]() $V_n=U\sin {\alpha }+W\cos {\alpha }$, or the cotangent of the angle between the carriage motion trajectory and the still water surface,

$V_n=U\sin {\alpha }+W\cos {\alpha }$, or the cotangent of the angle between the carriage motion trajectory and the still water surface, ![]() $UW^{-1}$, is changed while the other quantity remains a constant. With this concept, five values of

$UW^{-1}$, is changed while the other quantity remains a constant. With this concept, five values of ![]() $V_n$ ranging from 0.58

$V_n$ ranging from 0.58 ![]() ${\rm m}\,{\rm s}^{-1}$ to 1.39

${\rm m}\,{\rm s}^{-1}$ to 1.39 ![]() ${\rm m}\,{\rm s}^{-1}$ are chosen and for each value of

${\rm m}\,{\rm s}^{-1}$ are chosen and for each value of ![]() $V_n$, four values of

$V_n$, four values of ![]() $UW^{-1}$ ranging from 4.50 to 8.33 are chosen. Besides the primary experimental matrix described above, impact with only vertical motion (

$UW^{-1}$ ranging from 4.50 to 8.33 are chosen. Besides the primary experimental matrix described above, impact with only vertical motion (![]() $UW^{-1}=0$) was performed for

$UW^{-1}=0$) was performed for ![]() $V_n=0.58$ and 0.88 m. In addition, the impact condition with

$V_n=0.58$ and 0.88 m. In addition, the impact condition with ![]() $V_n=1.39\,{\rm m}\,{\rm s}^{-1}$ and

$V_n=1.39\,{\rm m}\,{\rm s}^{-1}$ and ![]() $UW^{-1}=8.33$ is chosen as a baseline for an additional set of conditions with the same vertical impact speed but different values of

$UW^{-1}=8.33$ is chosen as a baseline for an additional set of conditions with the same vertical impact speed but different values of ![]() $UW^{-1}$ and

$UW^{-1}$ and ![]() $V_n$. Three impact plates with different thicknesses are used for each of the impact conditions described above. All of the experimental conditions are listed in table 4 of the Appendix.

$V_n$. Three impact plates with different thicknesses are used for each of the impact conditions described above. All of the experimental conditions are listed in table 4 of the Appendix.

Figure 5. The impact conditions plotted in ![]() $U$–

$U$–![]() $W$ space, where

$W$ space, where ![]() $U$ and

$U$ and ![]() $W$ are the horizontal and vertical carriage speed during the impact, respectively. Plotting symbols:

$W$ are the horizontal and vertical carriage speed during the impact, respectively. Plotting symbols: ![]() $\circ$, the primary set of the oblique impact conditions;

$\circ$, the primary set of the oblique impact conditions; ![]() $\square$, the set of vertical impact conditions (

$\square$, the set of vertical impact conditions (![]() $UW^{-1}=0$);

$UW^{-1}=0$); ![]() $\triangle$, the set of impact conditions with the same

$\triangle$, the set of impact conditions with the same ![]() $W$. The primary conditions with the same

$W$. The primary conditions with the same ![]() $UW^{-1}$ are connected with blue dashed lines and the primary conditions with the same

$UW^{-1}$ are connected with blue dashed lines and the primary conditions with the same ![]() ${Fr}$ (and

${Fr}$ (and ![]() $V_n$) are connected with red dash-dotted lines. The four conditions with the same

$V_n$) are connected with red dash-dotted lines. The four conditions with the same ![]() $W$ are connected with a green dashed line. The Froude number is given by

$W$ are connected with a green dashed line. The Froude number is given by ![]() ${Fr}=V_n(gL)^{-0.5}$, where

${Fr}=V_n(gL)^{-0.5}$, where ![]() $V_n=U\sin {\alpha }+W\cos {\alpha }$ is the component of the carriage velocity normal to the undeformed plate. For each condition presented in this plot, the experiments were performed for three plates with thicknesses shown in table 1.

$V_n=U\sin {\alpha }+W\cos {\alpha }$ is the component of the carriage velocity normal to the undeformed plate. For each condition presented in this plot, the experiments were performed for three plates with thicknesses shown in table 1.

Measurements for each experimental condition were repeated for at least two runs for the deflection and spray root measurements, while the force and moment measurements were recorded in all runs and so repeated six or more times. In figure 6 the normal force, ![]() $F_n$, the transverse moment about the plate centre,

$F_n$, the transverse moment about the plate centre, ![]() $M_{to}$, the deflection at the plate centre,

$M_{to}$, the deflection at the plate centre, ![]() $\delta _c$, and the horizontal and vertical carriage speeds,

$\delta _c$, and the horizontal and vertical carriage speeds, ![]() $U$ and

$U$ and ![]() $W$, are plotted vs the time for three runs in panels (a–d), respectively, for the thinnest plate,

$W$, are plotted vs the time for three runs in panels (a–d), respectively, for the thinnest plate, ![]() $h=6.61$ mm. It can be seen from the figure that

$h=6.61$ mm. It can be seen from the figure that ![]() $U$ and

$U$ and ![]() $W$ are nearly constant during the impact for all runs and that the run-to-run repeatability of all quantities is excellent. In view of these results, the data for each experimental condition in all plots given below is from one experimental run.

$W$ are nearly constant during the impact for all runs and that the run-to-run repeatability of all quantities is excellent. In view of these results, the data for each experimental condition in all plots given below is from one experimental run.

Figure 6. Typical data set for multiple experimental runs: (a) normal force, ![]() $F_n$; (b) transverse moment about plate's centre,

$F_n$; (b) transverse moment about plate's centre, ![]() $M_{to}$; (c) out-of-plane deflection at the plate's centre,

$M_{to}$; (c) out-of-plane deflection at the plate's centre, ![]() $\delta _c$; and (d) horizontal and vertical impact speeds,

$\delta _c$; and (d) horizontal and vertical impact speeds, ![]() $U$ and

$U$ and ![]() $W$, vs time since initial impact at

$W$, vs time since initial impact at ![]() $t=0$ for

$t=0$ for ![]() $h=6.61$ mm,

$h=6.61$ mm, ![]() $V_n = 1.31\,{\rm m}\,{\rm s}^{-1}$ and

$V_n = 1.31\,{\rm m}\,{\rm s}^{-1}$ and ![]() $U/W=8.33$. The dash-dotted (left) and dashed (right) vertical lines represent, respectively, the instants when the trailing edge and leading edge reach the SWL.

$U/W=8.33$. The dash-dotted (left) and dashed (right) vertical lines represent, respectively, the instants when the trailing edge and leading edge reach the SWL.

3. Results and discussion

In this section the experimental results from the oblique and vertical impact of the three elastic plates will be presented and discussed. The section is organized into three subsections with the impact force and moment results in § 3.1, the spray root results in § 3.2 and the plate deformation results in § 3.3. Since the fluid and structure dynamics are strongly coupled in the impact process, the depth of the discussion increases as more of the data is presented.

The water surface behaviour in these flexible plate experiments is quite similar to that found in theoretical and experimental studies of the vertical impact of a rigid wedge/plate on a quiescent water surface (see, for example, Zhao & Faltinsen Reference Zhao and Faltinsen1993). In particular, at a high Froude number in both cases after the lower structural edge makes first contact with the water surface, the water surface rises under the plate/wedge surface and forms a region called the spray root, where the water surface locally becomes vertical. Between the spray root and the higher edge (chine) of the wedge/plate, the water surface turns over and creates a spray sheet that is attached to the wedge/plate surface. In the case of 2-D rigid plate/wedge impacts, when gravity is ignored, theoretical studies support the idea that the pressure distribution between the lower wedge/plate edge and the spray root is self-similar in time as the spray root moves along the surface of the wedge/plate. In addition, these studies show that the magnitude and gradient of the pressure distribution on the rigid plate/wedge surface near the spray root are substantially greater than that at regions far away from it. Given that the water surface behaviour is similar in both the rigid plate/wedge impact and the present flexible plate impact, it seems reasonable that the general behaviour of the pressure distribution would be qualitatively similar as well. Thus, in the following, the pressure distribution concepts from the rigid plate/wedge studies will be used to help interpret the present experimental results.

The presentation and interpretation of the data is somewhat complicated by the large number of parameters describing the experimental conditions. While the experimental conditions matrix was chosen as a set of ![]() $V_n$,

$V_n$, ![]() $U/W$ and

$U/W$ and ![]() $h$ values, the dimensionless parameters include the Froude number; the ratio of the hydrodynamic pressure force to the plate's stiffness, called the stiffness ratio

$h$ values, the dimensionless parameters include the Froude number; the ratio of the hydrodynamic pressure force to the plate's stiffness, called the stiffness ratio ![]() $R_D$; and the ratio of the submergence time to the plate's wet natural period, called the submergence time ratio

$R_D$; and the ratio of the submergence time to the plate's wet natural period, called the submergence time ratio ![]() $R_T$. The definitions of these parameters are given in table 3 to aid the reader in following the detailed discussion below. The values of all of these dimensionless ratios are given along with the dimensional experimental conditions in the Appendix, table 4 and are highlighted in the captions and titles of the figures.

$R_T$. The definitions of these parameters are given in table 3 to aid the reader in following the detailed discussion below. The values of all of these dimensionless ratios are given along with the dimensional experimental conditions in the Appendix, table 4 and are highlighted in the captions and titles of the figures.

Table 3. Definitions of the bending stiffness and three dimensionless ratios.

The explanation of the significance of the parameters ![]() $R_T$ and

$R_T$ and ![]() $R_D$ is aided by considering qualitatively the linearized equation of motion for the deflection of a simply supported beam (length

$R_D$ is aided by considering qualitatively the linearized equation of motion for the deflection of a simply supported beam (length ![]() $L_b$, width

$L_b$, width ![]() $B_b$, moment of inertia about neutral axis

$B_b$, moment of inertia about neutral axis ![]() $I_b$, elastic modulus

$I_b$, elastic modulus ![]() $E_b$ and density

$E_b$ and density ![]() $\rho _b$). In this model the beam deflection is excited by a moving load (qb) of prescribed self-similar distribution, where

$\rho _b$). In this model the beam deflection is excited by a moving load (qb) of prescribed self-similar distribution, where ![]() $q_b(x_b,t_b)$ has units of force per unit length and

$q_b(x_b,t_b)$ has units of force per unit length and ![]() $t_b$ and

$t_b$ and ![]() $x_b$ denote the time from initial impact and the distance from one end of the beam, respectively, which is qualitatively like that found for rigid wedge vertical impact. The beam is considered to have a vertical velocity,

$x_b$ denote the time from initial impact and the distance from one end of the beam, respectively, which is qualitatively like that found for rigid wedge vertical impact. The beam is considered to have a vertical velocity, ![]() $W_b$, and a pitch angle

$W_b$, and a pitch angle ![]() $\alpha _b$ relative to a quiescent water surface; the low end of the beam is designated

$\alpha _b$ relative to a quiescent water surface; the low end of the beam is designated ![]() $\tilde {x}_b = 0$. The non-dimensional form of this deflection equation is

$\tilde {x}_b = 0$. The non-dimensional form of this deflection equation is

\begin{equation} \frac{\partial^4\tilde{\delta}_b\left(\tilde{x}_b,\tilde{t}_b\right)}{\partial\tilde{x}_b^4}+\frac{1}{R_{Tb}^2}\frac{\partial^2\tilde{\delta}_b\left(\tilde{x}_b,\tilde{t}_b\right)}{\partial\tilde{t}_b^2}=\tilde{p}_b\left(\frac{\tilde{x}_b}{\tilde{t}_b}\right), \end{equation}

\begin{equation} \frac{\partial^4\tilde{\delta}_b\left(\tilde{x}_b,\tilde{t}_b\right)}{\partial\tilde{x}_b^4}+\frac{1}{R_{Tb}^2}\frac{\partial^2\tilde{\delta}_b\left(\tilde{x}_b,\tilde{t}_b\right)}{\partial\tilde{t}_b^2}=\tilde{p}_b\left(\frac{\tilde{x}_b}{\tilde{t}_b}\right), \end{equation}

where dimensionless quantities are denoted with a ![]() $\tilde {\ }$,

$\tilde {\ }$, ![]() $\tilde {x}_b=x_b/L_b$,

$\tilde {x}_b=x_b/L_b$, ![]() $\tilde {t}_b=t_b/T_{sb}$,

$\tilde {t}_b=t_b/T_{sb}$, ![]() $T_{sb} = L_b\sin \alpha _b/W$,

$T_{sb} = L_b\sin \alpha _b/W$,

\begin{gather} R_{Tb}=\sqrt{\frac{E_bI_b}{\rho_bA_bL_b^4}T_{sb}^2}=\frac{2}{\rm \pi} \left(\frac{T_{sb}}{T_{1b}}\right), \end{gather}

\begin{gather} R_{Tb}=\sqrt{\frac{E_bI_b}{\rho_bA_bL_b^4}T_{sb}^2}=\frac{2}{\rm \pi} \left(\frac{T_{sb}}{T_{1b}}\right), \end{gather}

where ![]() $T_{1b}$ is the lowest order natural period of the dry beam. The parameters

$T_{1b}$ is the lowest order natural period of the dry beam. The parameters ![]() $R_{Tb}$ and

$R_{Tb}$ and ![]() $R_{Db}$ are similar to

$R_{Db}$ are similar to ![]() $R_T$ and

$R_T$ and ![]() $R_D$, respectively, in the present plate impact experiments. In this simple model, in the limit that

$R_D$, respectively, in the present plate impact experiments. In this simple model, in the limit that ![]() $R_{Tb}\rightarrow \infty$, i.e. the submergence time,

$R_{Tb}\rightarrow \infty$, i.e. the submergence time, ![]() $T_{sb}$, is much larger than the beam's natural period, one finds a quasi-static response limit in which the deflection at any instant is the static response of the beam to the instantaneous hydrodynamic pressure distribution. In this case, due to the combined effects of the non-uniform instantaneous pressure distribution (a high pressure ridge followed by a region of more moderate pressure), the increasing area over which the pressure distribution is applied as time increases, and the zero-deflection end conditions, the maximum deflection occurs after the pressure ridge passes the beam's centre but well before the pressure ridge emerges from the beam at

$T_{sb}$, is much larger than the beam's natural period, one finds a quasi-static response limit in which the deflection at any instant is the static response of the beam to the instantaneous hydrodynamic pressure distribution. In this case, due to the combined effects of the non-uniform instantaneous pressure distribution (a high pressure ridge followed by a region of more moderate pressure), the increasing area over which the pressure distribution is applied as time increases, and the zero-deflection end conditions, the maximum deflection occurs after the pressure ridge passes the beam's centre but well before the pressure ridge emerges from the beam at ![]() $\tilde {x}_b=1$. As

$\tilde {x}_b=1$. As ![]() $R_{Tb}$ approaches 1, a dynamic response occurs in which the value of

$R_{Tb}$ approaches 1, a dynamic response occurs in which the value of ![]() $\tilde {t}_b$ corresponding to peak deflection increases from its value in the static response case. For sufficiently small

$\tilde {t}_b$ corresponding to peak deflection increases from its value in the static response case. For sufficiently small ![]() $R_{Tb}$, the peak deflection occurs after the pressure ridge emerges from the beam. According to the above one-way beam model,

$R_{Tb}$, the peak deflection occurs after the pressure ridge emerges from the beam. According to the above one-way beam model, ![]() $\delta _b = R_{Db}L_b\tilde {\delta }_b$, where the distribution

$\delta _b = R_{Db}L_b\tilde {\delta }_b$, where the distribution ![]() $\tilde {\delta }_b$ is a function of

$\tilde {\delta }_b$ is a function of ![]() $R_{Tb}$. Numerical solutions of (3.1) indicate that the maximum value of

$R_{Tb}$. Numerical solutions of (3.1) indicate that the maximum value of ![]() $\delta _b$ in a given calculation is a function of both

$\delta _b$ in a given calculation is a function of both ![]() $R_{Tb}$ and

$R_{Tb}$ and ![]() $R_{Db}$, but is dominated by its linear proportionality with

$R_{Db}$, but is dominated by its linear proportionality with ![]() $R_{Db}$; see (3.2). It should be kept in mind that this model represents a one-way fluid–structure interaction. In a two-way interaction the deflection is large enough to affect the flow and, therefore, the hydrodynamic pressure distribution. In the remainder of the paper, variables used in the 2-D beam model described above (with a subscript

$R_{Db}$; see (3.2). It should be kept in mind that this model represents a one-way fluid–structure interaction. In a two-way interaction the deflection is large enough to affect the flow and, therefore, the hydrodynamic pressure distribution. In the remainder of the paper, variables used in the 2-D beam model described above (with a subscript ![]() $b$) will no longer be used. Instead, their counterparts of the same physical meaning for the flexible plate, such as

$b$) will no longer be used. Instead, their counterparts of the same physical meaning for the flexible plate, such as ![]() $R_D$,

$R_D$, ![]() $R_T$ (defined where they first appear in the text and in tables 3 and 4), will be used in the discussion of the present experimental results.

$R_T$ (defined where they first appear in the text and in tables 3 and 4), will be used in the discussion of the present experimental results.

3.1. Impact force and moment

In this subsection the normal component of the transient impact force and the transverse component of the moment during the impact of the three flexible plates under various values of ![]() $V_n$ and

$V_n$ and ![]() $UW^{-1}$ will be presented and discussed. The remaining force and moment components are at most 3 % and 10 % of the maximum values of

$UW^{-1}$ will be presented and discussed. The remaining force and moment components are at most 3 % and 10 % of the maximum values of ![]() $F_n$ and

$F_n$ and ![]() $M_{to}$, respectively, for the most extreme impact condition and are not presented here. The normal impact force,

$M_{to}$, respectively, for the most extreme impact condition and are not presented here. The normal impact force, ![]() $F_n$, and the transverse moment about the plate centre,

$F_n$, and the transverse moment about the plate centre, ![]() $M_{to}$, are plotted against time

$M_{to}$, are plotted against time ![]() $t$ in figure 7(a,b), respectively, for the highest speed,

$t$ in figure 7(a,b), respectively, for the highest speed, ![]() $V_n=1.39\,{\rm m}\,{\rm s}^{-1}$ (

$V_n=1.39\,{\rm m}\,{\rm s}^{-1}$ (![]() ${Fr} =0.43$,

${Fr} =0.43$, ![]() $R_D=1.33$), the thinnest plate (

$R_D=1.33$), the thinnest plate (![]() $h=6.61$ mm) and the four non-zero values of

$h=6.61$ mm) and the four non-zero values of ![]() $UW^{-1}$. The time

$UW^{-1}$. The time ![]() $t=0$ is chosen as the instant when the plate's trailing edge first makes contact with the still water surface. The large-scale features of the normal force and transverse moment curves are described as follows. The normal force increases at a variable rate over time during the impact until it reaches a maximum, ranging from approximately 2700 to 2900 N, and then suddenly decreases. The overall increase in force is qualitatively consistent with previous theoretical and experimental studies of vertical impact of rigid plates and wedges and is thought to be primarily due to the increasing wet plate area, which is under hydrodynamic pressure. The transverse moment,

$t=0$ is chosen as the instant when the plate's trailing edge first makes contact with the still water surface. The large-scale features of the normal force and transverse moment curves are described as follows. The normal force increases at a variable rate over time during the impact until it reaches a maximum, ranging from approximately 2700 to 2900 N, and then suddenly decreases. The overall increase in force is qualitatively consistent with previous theoretical and experimental studies of vertical impact of rigid plates and wedges and is thought to be primarily due to the increasing wet plate area, which is under hydrodynamic pressure. The transverse moment, ![]() $M_{to}$, also initially increases with time but quickly reaches a maximum value before decreasing, crossing zero and reaching a sharp negative peak value ranging from

$M_{to}$, also initially increases with time but quickly reaches a maximum value before decreasing, crossing zero and reaching a sharp negative peak value ranging from ![]() $-400$ Nm to

$-400$ Nm to ![]() $-530$ Nm. The times of the negative peak values of

$-530$ Nm. The times of the negative peak values of ![]() $M_{to}$ match the times of the positive peak values of

$M_{to}$ match the times of the positive peak values of ![]() $F_n$ at the same impact conditions. As will be discussed in the following subsection, the times of these extreme values of

$F_n$ at the same impact conditions. As will be discussed in the following subsection, the times of these extreme values of ![]() $F_n$ and

$F_n$ and ![]() $M_{to}$ correspond to the times when the spray root reaches the leading edge of the plate, which is denoted in the following as

$M_{to}$ correspond to the times when the spray root reaches the leading edge of the plate, which is denoted in the following as ![]() $t=t_e$. At this instant, the leading edge of the plate begins to go under the local water surface. The temporal behaviour of

$t=t_e$. At this instant, the leading edge of the plate begins to go under the local water surface. The temporal behaviour of ![]() $M_{to}$ is consistent with a temporally increasing magnitude of the total normal force and a centre of hydrodynamic pressure that moves from the trailing to the leading edge of the plate during the impact, as it does in the case of vertical impact of a rigid wedge or plate. Because of these competing effects, the moment reaches a maximum and then decreases to zero as the moment arm goes to zero when the centre of pressure moves across the middle of the plate. After this point, the moment becomes negative and continuously increases in magnitude (due to the increasing force and moment arm) until the spray root reaches the plate's leading edge; see § 3.2.

$M_{to}$ is consistent with a temporally increasing magnitude of the total normal force and a centre of hydrodynamic pressure that moves from the trailing to the leading edge of the plate during the impact, as it does in the case of vertical impact of a rigid wedge or plate. Because of these competing effects, the moment reaches a maximum and then decreases to zero as the moment arm goes to zero when the centre of pressure moves across the middle of the plate. After this point, the moment becomes negative and continuously increases in magnitude (due to the increasing force and moment arm) until the spray root reaches the plate's leading edge; see § 3.2.

Figure 7. The normal force, ![]() $F_n$, and the transverse moment about the plate centre,

$F_n$, and the transverse moment about the plate centre, ![]() $M_{to}$, are plotted vs time,

$M_{to}$, are plotted vs time, ![]() $t$, in panels (a,b), respectively, for a single plate thickness (

$t$, in panels (a,b), respectively, for a single plate thickness (![]() $h=6.61$ mm),

$h=6.61$ mm), ![]() $V_n=1.39\,{\rm m}\,{\rm s}^{-1}$ and various values of

$V_n=1.39\,{\rm m}\,{\rm s}^{-1}$ and various values of ![]() $U/W$. The time

$U/W$. The time ![]() $t=0$ is the instant when the plate's trailing (low) edge first makes contact with the quiescent water surface. For these experimental conditions,

$t=0$ is the instant when the plate's trailing (low) edge first makes contact with the quiescent water surface. For these experimental conditions, ![]() ${Fr}=0.43$,

${Fr}=0.43$, ![]() $R_D= 1.33$ and

$R_D= 1.33$ and ![]() $R_T$ ranges from 2.47 at

$R_T$ ranges from 2.47 at ![]() $U/W = 8.33$ to 1.79 at

$U/W = 8.33$ to 1.79 at ![]() $U/W = 4.5$.

$U/W = 4.5$.

In addition to the general features of the ![]() $F_n(t)$ and