1. Introduction

Bursting bubbles at a liquid–gas interface is a fundamental hydrodynamic process that has piqued interest in various fields across multiple scales ranging from food processing industry (Woodcock et al. Reference Woodcock, Kientzler, Arons and Blanchard1953; MacIntyre Reference MacIntyre1972) to oceanic wave breaking (Veron Reference Veron2015; Blanco-Rodríguez & Gordillo Reference Blanco-Rodríguez and Gordillo2020; Deike Reference Deike2022). A typical daily realization of bubble bursting occurs in a glass of champagne or other sparkling wine and is often credited for enhancing the mouthfeel of the taster (Ghabache et al. Reference Ghabache, Antkowiak, Josserand and Séon2014, Reference Ghabache, Liger-Belair, Antkowiak and Séon2016; Séon & Liger-Belair Reference Séon and Liger-Belair2017). Bubble bursting also plays a wider role in liquid fragmentation (Villermaux Reference Villermaux2020) and serves as a significant mechanism in facilitating the mass transfer of substances across the liquid–gas interface including transporting pathogens from contaminated water (Blanchard & Syzdek Reference Blanchard and Syzdek1970; Poulain & Bourouiba Reference Poulain and Bourouiba2018; Bourouiba Reference Bourouiba2021a; Ji, Singh & Feng Reference Ji, Singh and Feng2022). The interactions of such bubbles with complex rheological fluids abound in nature. For example, the elastic and plastic fluid properties govern and influence pathogen transmission, and the pathogens might even adapt to or manipulate the chemical properties of the carrier fluids to benefit their own transmission (Bourouiba Reference Bourouiba2021b). Additionally, the presence of contaminants, surfactants and oils in the marine boundary layer alters the bursting phenomenon and thereby affects the production of fine marine spray (Ji, Yang & Feng Reference Ji, Yang and Feng2021; Néel, Erinin & Deike Reference Néel, Erinin and Deike2022; Pierre, Poujol & Séon Reference Pierre, Poujol and Séon2022; Ji et al. Reference Ji, Yang, Wang, Ewoldt and Feng2023). The rheological response of food products (Ahmed & Basu Reference Ahmed and Basu2016; Mathijssen et al. Reference Mathijssen, Lisicki, Prakash and Mossige2023) exemplifies yet another instance of the importance of understanding the mechanisms of bubble bursting in rheologically complex fluids. Such an understanding will also improve our knowledge of other natural phenomena, such as volcanic eruptions and underwater gas seep (Gonnermann & Manga Reference Gonnermann and Manga2007).

Unlike the rheologically simpler Newtonian fluids, elastic and plastic properties of the complex fluid govern the bubble bursting in addition to other factors such as buoyancy, surface tension and viscosity. As an air bubble rises within the surrounding medium due to difference in density and approaches the liquid–air interface (figure 1a), the thin liquid film gradually drains (Allan, Charles & Mason Reference Allan, Charles and Mason1961) and subsequently ruptures, resulting in the formation of an open cavity (as illustrated in figure 1b) (Mason Reference Mason1954; Zhang, Cui & Wang Reference Zhang, Cui and Wang2013). The open cavity is unstable due to large surface energy. It thereby collapses, leading to a sequence of dynamic events, including the propagation of capillary waves, which can potentially result in a Worthington jet (Gekle & Gordillo Reference Gekle and Gordillo2010; Gordillo & Rodríguez-Rodríguez Reference Gordillo and Rodríguez-Rodríguez2019). The Worthington jet may destabilize due to the Rayleigh–Plateau instability, leading to the formation of small droplets (Gordillo & Gekle Reference Gordillo and Gekle2010; Ghabache et al. Reference Ghabache, Antkowiak, Josserand and Séon2014).

Figure 1. Initial condition for bubble bursting: (a) gas bubble approaches the free interface forming a film of thickness ![]() $\delta$; (b) the thin film is removed, resulting in a bubble cavity which is considered as the initial condition in our simulations.

$\delta$; (b) the thin film is removed, resulting in a bubble cavity which is considered as the initial condition in our simulations.

Early studies of bubble bursting began with a combination of experimental investigations and theoretical analyses, laying the foundation for identifying the underlying physics of the bursting mechanism in Newtonian fluids. With the progress in direct numerical simulation of multiphase flows (Popinet Reference Popinet2003, Reference Popinet2009), Deike et al. (Reference Deike, Ghabache, Liger-Belair, Das, Zaleski, Popinet and Séon2018) provided quantitative cross-validation of numerical and experimental studies. Further studies through a combination of experimental, numerical and theoretical predictions (Duchemin et al. Reference Duchemin, Popinet, Josserand and Zaleski2002; Walls, Henaux & Bird Reference Walls, Henaux and Bird2015; Berny et al. Reference Berny, Deike, Séon and Popinet2020) revealed that the formation of droplets from the jet in the bubble-bursting process is primarily determined by the viscous and gravitational effects.

On the other hand, the behaviour of bubble bursting in a different rheological medium has received less attention. Very recently, researchers have focused on studying the behaviour of such bubbles in non-Newtonian fluids (Sanjay, Lohse & Jalaal Reference Sanjay, Lohse and Jalaal2021; Ji et al. Reference Ji, Yang, Wang, Ewoldt and Feng2023; Rodríguez-Díaz et al. Reference Rodríguez-Díaz, Rubio, Montanero, Gañán-Calvo and Cabezas2023; Dixit et al. Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024), as they exhibit unique flow characteristics that can significantly affect the bursting dynamics. Notably, Rodríguez-Díaz et al. (Reference Rodríguez-Díaz, Rubio, Montanero, Gañán-Calvo and Cabezas2023) explored the phenomenon of bubble bursting in the presence of polymeric molecules, accounting for elastic effects induced by polymers. Their study revealed that the droplet emission is hindered due to extensional thickening in the jet. Another class of non-Newtonian fluids, called yield-stress fluids, exhibits a combination of solid and fluid behaviours. A thorough description and review of yield-stress fluids can be found in, for example, Balmforth, Frigaard & Ovarlez (Reference Balmforth, Frigaard and Ovarlez2014). Within the category of yield-stress fluids, a specific type known as viscoplastic fluid acts as a rigid solid below the yield stress and flows like a viscous fluid when the shear stress exceeds the material's yield stress. The capillary flows of viscoplastic fluids have been studied for various droplets (Jalaal, Stoeber & Balmforth Reference Jalaal, Stoeber and Balmforth2021; van der Kolk, Tieman & Jalaal Reference van der Kolk, Tieman and Jalaal2023) and bubble problems (Jalaal & Balmforth Reference Jalaal and Balmforth2016; Pourzahedi et al. Reference Pourzahedi, Chaparian, Roustaei and Frigaard2022; Shemilt et al. Reference Shemilt, Horsley, Jensen, Thompson and Whitfield2022, Reference Shemilt, Horsley, Jensen, Thompson and Whitfield2023). Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) studied the bubble-bursting process in a viscoplastic fluid and revealed how viscoplasticity influences the inertiocapillary waves that drive the bubble-bursting mechanism. Unlike Newtonian liquids, the cavity can sustain shear stress (and a non-flat final shape) if the driving stresses inside the pool fall below the yield stress.

Yield-stress liquids often exhibit elastic behaviour below the yield criterion and also after yielding (Larson Reference Larson1999). This characteristic gives rise to a distinct subset within the category of yield-stress fluids, referred to as elastoviscoplastic (EVP) fluids, which behaves akin to an elastic solid below the critical stress identified by the yield stress while exhibiting a viscoelastic fluid behaviour above the yield stress. Different models have been proposed to constitute the behaviour of EVP fluids based on various steady and unsteady flow responses. In the present study, we utilize the EVP model proposed by Saramito (Reference Saramito2007). This model behaves as a Kelvin–Voigt viscoelastic solid prior to yielding and transitions to a nonlinear viscoelastic liquid in the yielded region, exhibiting Oldroyd-B viscoelastic behaviour far beyond the yield point. A detailed review of different EVP models can be found in Fraggedakis, Dimakopoulos & Tsamopoulos (Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016). The physics of EVP fluids have been explored in a variety of problem sets, such as droplet deformation, deformation in shear flow (Izbassarov & Tammisola Reference Izbassarov and Tammisola2020), particle migration (Chaparian et al. Reference Chaparian, Ardekani, Brandt and Tammisola2020a), channel flow (Izbassarov et al. Reference Izbassarov, Rosti, Brandt and Tammisola2021), bubble migration (Feneuil et al. Reference Feneuil, Iqbal, Jensen, Brandt, Tammisola and Carlson2023), porous media flow (Chaparian et al. Reference Chaparian, Izbassarov, de Vita, Brandt and Tammisola2020b), rising bubble (Moschopoulos et al. Reference Moschopoulos, Spyridakis, Varchanis, Dimakopoulos and Tsamopoulos2021) and droplet spreading (França, Jalaal & Oishi Reference França, Jalaal and Oishi2024).

Given that a yield-stress fluid exhibits elastic behaviour, it becomes imperative to understand the role of elastic-stress-relaxation in driving capillary wave propagation, which, in turn, influences the formation of jets and droplets, which are the critical characteristics observed in the bubble-bursting process. This study expands the present understanding of bubble bursting (and in general interfacial flows) of EVP fluids, towards more realistic situations, which may exhibit additional phenomena such as shear thinning and complex initial bubble shape.

The paper is organized as follows. The methodology and the description of the problem are introduced in § 2. In § 3, the results obtained with different combinations of dimensionless elastic stress relaxation time and dimensionless yield stress of the EVP fluid are discussed. The §§ 3.1–3.6 delve into identifying the influence of the fluid properties on key bursting characteristics. The different modes of energy transfer are presented in § 3.7. The summary and conclusions of the present work are highlighted in § 4. Additional details about the derivation of governing equations, the log-conformation technique to solve for the extra stress in EVP, grid convergence of results, comparison between Bingham and EVP model at the viscoplastic limit, derivation of energy budget terms, energy-based analysis to understand the behaviour of maximum jet height can be, respectively, found in Appendices A–F.

2. Numerical framework

2.1. Conservation laws and constitutive equations

A small axisymmetric bubble with an initial radius of ![]() $R_0$ is placed on the surface of an incompressible EVP fluid (see § 2.3). For the considered problem, the dimensionless governing equations are

$R_0$ is placed on the surface of an incompressible EVP fluid (see § 2.3). For the considered problem, the dimensionless governing equations are

where the velocity field ![]() $\boldsymbol {u}$ and the time

$\boldsymbol {u}$ and the time ![]() $t$ are normalized using the inertiocapillary velocity (

$t$ are normalized using the inertiocapillary velocity (![]() $V_\gamma = \sqrt {\gamma /\rho _l R_0}$) and time (

$V_\gamma = \sqrt {\gamma /\rho _l R_0}$) and time (![]() $T_\gamma = \sqrt {\rho _lR_0^3/\gamma }$) scales, respectively, (here,

$T_\gamma = \sqrt {\rho _lR_0^3/\gamma }$) scales, respectively, (here, ![]() $\gamma$ and

$\gamma$ and ![]() $\rho _l$ are the surface tension and density of the liquid medium, respectively, see Appendix A for details). The pressure

$\rho _l$ are the surface tension and density of the liquid medium, respectively, see Appendix A for details). The pressure ![]() $p$, the solvent stress

$p$, the solvent stress ![]() $\boldsymbol {\tau _s}$ and the elastic stress

$\boldsymbol {\tau _s}$ and the elastic stress ![]() $\boldsymbol {\tau _p}$ are normalized using the capillary stress

$\boldsymbol {\tau _p}$ are normalized using the capillary stress ![]() $p_\gamma = \gamma /R_0$. Lastly,

$p_\gamma = \gamma /R_0$. Lastly, ![]() $\boldsymbol {f} = \boldsymbol {f}_g + \boldsymbol {f}_\gamma$ contains the contributions from gravity

$\boldsymbol {f} = \boldsymbol {f}_g + \boldsymbol {f}_\gamma$ contains the contributions from gravity ![]() $\boldsymbol {f}_g = -{\textit {Bo}}\boldsymbol {\hat {e}_z}$, where the Bond number

$\boldsymbol {f}_g = -{\textit {Bo}}\boldsymbol {\hat {e}_z}$, where the Bond number

with ![]() $g$ as acceleration due to gravity, is the ratio between hydrostatic and capillary pressures, and surface tension

$g$ as acceleration due to gravity, is the ratio between hydrostatic and capillary pressures, and surface tension ![]() $\boldsymbol {f}_\gamma = \kappa \delta _s \boldsymbol {\hat {n}}$. Here,

$\boldsymbol {f}_\gamma = \kappa \delta _s \boldsymbol {\hat {n}}$. Here, ![]() $\kappa$ is the curvature of the liquid–gas interface having a normal vector

$\kappa$ is the curvature of the liquid–gas interface having a normal vector ![]() $\boldsymbol {\hat {n}}$, and

$\boldsymbol {\hat {n}}$, and ![]() $\delta _s$ is a Dirac delta function concentrated at the interface.

$\delta _s$ is a Dirac delta function concentrated at the interface.

In (2.2), the deviatoric viscous stress tensor is

where ![]() $\boldsymbol {\mathcal {D}} = (\boldsymbol {\nabla } \boldsymbol {u} + (\boldsymbol {\nabla } \boldsymbol {u})^{\rm T})/2$ is the deformation rate tensor and

$\boldsymbol {\mathcal {D}} = (\boldsymbol {\nabla } \boldsymbol {u} + (\boldsymbol {\nabla } \boldsymbol {u})^{\rm T})/2$ is the deformation rate tensor and ![]() ${{\textit {Oh}}}_s$ denotes the solvent-Ohnesorge number which measures the inertial-capillary time scale compared with the inertial-viscous time scale as defined by

${{\textit {Oh}}}_s$ denotes the solvent-Ohnesorge number which measures the inertial-capillary time scale compared with the inertial-viscous time scale as defined by

Here, ![]() $\mu _s$ identifies the solvent-viscosity of the fluid with the total viscosity of the fluid

$\mu _s$ identifies the solvent-viscosity of the fluid with the total viscosity of the fluid ![]() $(\mu _l = \mu _s + \mu _p)$ including the contribution from polymeric-viscosity term

$(\mu _l = \mu _s + \mu _p)$ including the contribution from polymeric-viscosity term ![]() $(\mu _p)$. We can also define a polymeric-Ohnesorge number

$(\mu _p)$. We can also define a polymeric-Ohnesorge number ![]() ${{\textit {Oh}}}_p$ given by

${{\textit {Oh}}}_p$ given by

based on polymeric viscosity. Consequently, the ratio of solvent to total viscosity is

where ![]() ${{\textit {Oh}}} = {{\textit {Oh}}}_s + {{\textit {Oh}}}_p$ corresponds to the Ohnesorge number based on the total viscosity of the fluid.

${{\textit {Oh}}} = {{\textit {Oh}}}_s + {{\textit {Oh}}}_p$ corresponds to the Ohnesorge number based on the total viscosity of the fluid.

The extra stress tensor ![]() $\boldsymbol {\tau _p}$ embeds the elastic and plastic behaviour of the EVP fluid and is modelled with the constitutive relationship proposed by Saramito (Reference Saramito2007). Using an order parameter

$\boldsymbol {\tau _p}$ embeds the elastic and plastic behaviour of the EVP fluid and is modelled with the constitutive relationship proposed by Saramito (Reference Saramito2007). Using an order parameter ![]() $\boldsymbol {A}$ (conformation tensor) tracking the stretch of the EVP matrix (Snoeijer et al. Reference Snoeijer, Pandey, Herrada and Eggers2020; Stone, Shelley & Boyko Reference Stone, Shelley and Boyko2023) with a base state

$\boldsymbol {A}$ (conformation tensor) tracking the stretch of the EVP matrix (Snoeijer et al. Reference Snoeijer, Pandey, Herrada and Eggers2020; Stone, Shelley & Boyko Reference Stone, Shelley and Boyko2023) with a base state ![]() $\boldsymbol {A} = \boldsymbol {I}$ (here,

$\boldsymbol {A} = \boldsymbol {I}$ (here, ![]() $\boldsymbol {I}$ is the identity tensor), this constitutive model can be summarized as

$\boldsymbol {I}$ is the identity tensor), this constitutive model can be summarized as

and

Here, the Deborah number

is the dimensionless relaxation time ![]() $\lambda$ of the EVP matrix to its base state

$\lambda$ of the EVP matrix to its base state ![]() $\boldsymbol {A} = \boldsymbol {I}$, normalized using the inertial-capillary time scale

$\boldsymbol {A} = \boldsymbol {I}$, normalized using the inertial-capillary time scale ![]() $T_\gamma$. In (2.8),

$T_\gamma$. In (2.8), ![]() $\boldsymbol {\overset {\nabla }{A}}$ is the upper-convected time derivative and

$\boldsymbol {\overset {\nabla }{A}}$ is the upper-convected time derivative and ![]() $\|\boldsymbol {\tau _d}\|$ is the second invariant of the deviatoric part of the elastic stress tensor and are defined as

$\|\boldsymbol {\tau _d}\|$ is the second invariant of the deviatoric part of the elastic stress tensor and are defined as

and

respectively. Here, ![]() $\boldsymbol {\nabla } \boldsymbol {u} := \partial u_j/x_i$ in Einstein notation. The deviatoric part of the elastic stress tensor is calculated as

$\boldsymbol {\nabla } \boldsymbol {u} := \partial u_j/x_i$ in Einstein notation. The deviatoric part of the elastic stress tensor is calculated as ![]() $\boldsymbol {\tau _d} = \boldsymbol {\tau _p} - (\mathrm {tr} (\boldsymbol {\tau _p})/\mathrm {tr}(\boldsymbol {I}))\boldsymbol {I}$. Lastly, the plastocapillary number

$\boldsymbol {\tau _d} = \boldsymbol {\tau _p} - (\mathrm {tr} (\boldsymbol {\tau _p})/\mathrm {tr}(\boldsymbol {I}))\boldsymbol {I}$. Lastly, the plastocapillary number ![]() $(\mathcal {J})$ accounts for the competition between the yield stress

$(\mathcal {J})$ accounts for the competition between the yield stress ![]() $\tau _y$ and the Laplace pressure

$\tau _y$ and the Laplace pressure ![]() $\gamma /R_0$ as

$\gamma /R_0$ as

In (2.8), ![]() $K$ is a dimensionless function that acts as a stress-dependent switch, controlling the transition from viscoelastic solid-like to viscoelastic fluid-like behaviour in the EVP fluid. Consequently, in the yielded state

$K$ is a dimensionless function that acts as a stress-dependent switch, controlling the transition from viscoelastic solid-like to viscoelastic fluid-like behaviour in the EVP fluid. Consequently, in the yielded state ![]() ${{\textit {De}}}/K$ can be interpreted as the effective relaxation time. Consequently, below the yield stress (

${{\textit {De}}}/K$ can be interpreted as the effective relaxation time. Consequently, below the yield stress (![]() $K = 0$),

$K = 0$), ![]() $\boldsymbol {\overset {\nabla }{A}} = \boldsymbol {0}$ and the EVP matrix deform according to the flow field (see (2.11) and Stone et al. (Reference Stone, Shelley and Boyko2023)) but do not relax. Additionally, the stress

$\boldsymbol {\overset {\nabla }{A}} = \boldsymbol {0}$ and the EVP matrix deform according to the flow field (see (2.11) and Stone et al. (Reference Stone, Shelley and Boyko2023)) but do not relax. Additionally, the stress ![]() $\boldsymbol {\tau _p} = {{\textit {Oh}}}_p(\boldsymbol {A} - \boldsymbol {I})/{{\textit {De}}}$ depends only on the elastic (polymeric) deformation and the elastocapillary number

$\boldsymbol {\tau _p} = {{\textit {Oh}}}_p(\boldsymbol {A} - \boldsymbol {I})/{{\textit {De}}}$ depends only on the elastic (polymeric) deformation and the elastocapillary number

where ![]() $G = \mu _p/\lambda$ is the elastic modulus. Above the yield stress (

$G = \mu _p/\lambda$ is the elastic modulus. Above the yield stress (![]() $K > 0$), the EVP fluid behaves like a viscoelastic liquid following the constitutive relation given by combining (2.8)–(2.9) to give

$K > 0$), the EVP fluid behaves like a viscoelastic liquid following the constitutive relation given by combining (2.8)–(2.9) to give

We also model the gas-phase with the corresponding conservation laws, which are similar to (2.1) and (2.2) (see Appendix A). We keep the gas–liquid density ratio ![]() $\rho _r$

$\rho _r$ ![]() $(=\rho _g/\rho _l)$ fixed at

$(=\rho _g/\rho _l)$ fixed at ![]() $10^{-3}$. Similarly, the viscosity ratio

$10^{-3}$. Similarly, the viscosity ratio ![]() $\mu _r$

$\mu _r$ ![]() $(=\mu _g/\mu _l)$ is set constant at

$(=\mu _g/\mu _l)$ is set constant at ![]() $2\times 10^{-2}$ throughout the work.

$2\times 10^{-2}$ throughout the work.

2.2. Simulation set-up

The direct numerical simulations are performed with the open-source software language Basilisk C (Popinet Reference Popinet2009; Popinet & Collaborators Reference Popinet2024), which offers adaptive mesh refinement (AMR) based on wavelet estimated discretization errors, making it well-suited for singular interfacial flows (Berny et al. Reference Berny, Deike, Séon and Popinet2020; Sanjay Reference Sanjay2022; Yang et al. Reference Yang, Ji, Ault and Feng2023). Basilisk C uses a volume of fluid technique to track the interface with the help of a colour function ![]() $c$ (

$c$ (![]() $c = 1$ in liquid and

$c = 1$ in liquid and ![]() $c = 0$ in gas), which satisfies the scalar-advection equation. The geometrical features of the interface such as its unit vector normal

$c = 0$ in gas), which satisfies the scalar-advection equation. The geometrical features of the interface such as its unit vector normal ![]() $\boldsymbol {\hat {n}}$ and the curvature

$\boldsymbol {\hat {n}}$ and the curvature ![]() $\kappa$ (

$\kappa$ (![]() $= \boldsymbol {\nabla }\boldsymbol {\cdot }\hat {\boldsymbol {n}}$) are calculated using the height-function method (Popinet Reference Popinet2009, Reference Popinet2018). The governing equations for the gas and the fluid are solved using a one-fluid approximation (Prosperetti & Tryggvason Reference Prosperetti and Tryggvason2009; Tryggvason, Scardovelli & Zaleski Reference Tryggvason, Scardovelli and Zaleski2011), where the singular surface tension is approximated as

$= \boldsymbol {\nabla }\boldsymbol {\cdot }\hat {\boldsymbol {n}}$) are calculated using the height-function method (Popinet Reference Popinet2009, Reference Popinet2018). The governing equations for the gas and the fluid are solved using a one-fluid approximation (Prosperetti & Tryggvason Reference Prosperetti and Tryggvason2009; Tryggvason, Scardovelli & Zaleski Reference Tryggvason, Scardovelli and Zaleski2011), where the singular surface tension is approximated as ![]() $\boldsymbol {f}_\gamma = \kappa \delta _s\boldsymbol {\hat {n}} \approx \kappa \boldsymbol {\nabla }c$ (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992). Note that the time step in our simulations is restricted by the oscillation period of the smallest wavelength of the capillary wave because the surface tension scheme is explicit in time (Popinet Reference Popinet2009; Popinet & Collaborators Reference Popinet2024).

$\boldsymbol {f}_\gamma = \kappa \delta _s\boldsymbol {\hat {n}} \approx \kappa \boldsymbol {\nabla }c$ (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992). Note that the time step in our simulations is restricted by the oscillation period of the smallest wavelength of the capillary wave because the surface tension scheme is explicit in time (Popinet Reference Popinet2009; Popinet & Collaborators Reference Popinet2024).

Utilizing the AMR feature of Basilisk C, the errors in the volume of fluid tracer and interface curvature are minimized by applying a tolerance threshold of ![]() $10^{-3}$ and

$10^{-3}$ and ![]() $10^{-4}$, respectively. In addition, the refinement of the grid is also performed based on the velocity (tolerance threshold,

$10^{-4}$, respectively. In addition, the refinement of the grid is also performed based on the velocity (tolerance threshold, ![]() $10^{-2}$), conformation tensor

$10^{-2}$), conformation tensor ![]() $\boldsymbol {A}$ (tolerance threshold,

$\boldsymbol {A}$ (tolerance threshold, ![]() $10^{-2}$) and yielded region identified by

$10^{-2}$) and yielded region identified by ![]() $K$ (tolerance threshold,

$K$ (tolerance threshold, ![]() $10^{-3}$) to accurately resolve the regions of low strain rates and elastic deformation. These tolerance threshold values can be interpreted as the maximum error associated with the subsequent application of volume-averaged downsampling of fine-resolution-solution and bilinear upscaling of coarse-level-solution (Popinet Reference Popinet2015; van Hooft et al. Reference van Hooft, Popinet, van Heerwaarden, van der Linden, de Roode and van de Wiel2018). We highlight that these refinements offer the advantage of an almost uniform grid in key regions of interest (see also van Hooft (Reference van Hooft2019)) and acknowledge that the efficacy of such refinement criteria as employed in this study needs further investigation. For AMR, we employ a grid resolution ensuring a minimum cell size of

$10^{-3}$) to accurately resolve the regions of low strain rates and elastic deformation. These tolerance threshold values can be interpreted as the maximum error associated with the subsequent application of volume-averaged downsampling of fine-resolution-solution and bilinear upscaling of coarse-level-solution (Popinet Reference Popinet2015; van Hooft et al. Reference van Hooft, Popinet, van Heerwaarden, van der Linden, de Roode and van de Wiel2018). We highlight that these refinements offer the advantage of an almost uniform grid in key regions of interest (see also van Hooft (Reference van Hooft2019)) and acknowledge that the efficacy of such refinement criteria as employed in this study needs further investigation. For AMR, we employ a grid resolution ensuring a minimum cell size of ![]() $\varDelta = R_0/1024$, corresponding to 1024 cells across the initial bubble radius. However, when

$\varDelta = R_0/1024$, corresponding to 1024 cells across the initial bubble radius. However, when ![]() ${{\textit {De}}} \ge 1$, we switch to

${{\textit {De}}} \ge 1$, we switch to ![]() $\varDelta = R_0/2048$. Comprehensive grid-independence studies were conducted to confirm that the results remain unaffected by the chosen grid size (see Appendix C). We consider a square domain measuring

$\varDelta = R_0/2048$. Comprehensive grid-independence studies were conducted to confirm that the results remain unaffected by the chosen grid size (see Appendix C). We consider a square domain measuring ![]() $8R_0$ on each side, representing only one slice of the three-dimensional bursting bubble process leveraging the axisymmetric flow assumption. For both liquid and gas, free-slip and no-penetration boundary conditions are applied at the domain boundaries, while a zero-gradient condition is used for pressure. To ensure that ejected droplets, which arise from the breakup of the Worthington jet, can leave the domain, an outflow boundary condition is employed at the top boundary. The chosen domain size ensures that the boundaries do not influence the bubble-bursting process. Lastly, the solution of the constitutive relations ((2.8)–(2.9)) require the log-conformation approach proposed by Fattal & Kupferman (Reference Fattal and Kupferman2004) (also see López-Herrera, Popinet & Castrejón-Pita (Reference López-Herrera, Popinet and Castrejón-Pita2019), Dixit et al. (Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024) and França et al. (Reference França, Jalaal and Oishi2024); and Appendix B). For details of our implementation in Basilisk C, we refer the readers to Balasubramanian (Reference Balasubramanian2023).

$8R_0$ on each side, representing only one slice of the three-dimensional bursting bubble process leveraging the axisymmetric flow assumption. For both liquid and gas, free-slip and no-penetration boundary conditions are applied at the domain boundaries, while a zero-gradient condition is used for pressure. To ensure that ejected droplets, which arise from the breakup of the Worthington jet, can leave the domain, an outflow boundary condition is employed at the top boundary. The chosen domain size ensures that the boundaries do not influence the bubble-bursting process. Lastly, the solution of the constitutive relations ((2.8)–(2.9)) require the log-conformation approach proposed by Fattal & Kupferman (Reference Fattal and Kupferman2004) (also see López-Herrera, Popinet & Castrejón-Pita (Reference López-Herrera, Popinet and Castrejón-Pita2019), Dixit et al. (Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024) and França et al. (Reference França, Jalaal and Oishi2024); and Appendix B). For details of our implementation in Basilisk C, we refer the readers to Balasubramanian (Reference Balasubramanian2023).

2.3. Initial condition

The initial shape of the bubble is obtained by solving the Young–Laplace equations to find the quasistatic equilibrium state for a specified Bond number, ![]() ${\textit {Bo}}$ (see Lhuissier & Villermaux Reference Lhuissier and Villermaux2012; Deike et al. Reference Deike, Ghabache, Liger-Belair, Das, Zaleski, Popinet and Séon2018; Sanjay et al. Reference Sanjay, Lohse and Jalaal2021). In this study, we focus more on the capillary effects than gravitational effects, and hence the value of

${\textit {Bo}}$ (see Lhuissier & Villermaux Reference Lhuissier and Villermaux2012; Deike et al. Reference Deike, Ghabache, Liger-Belair, Das, Zaleski, Popinet and Séon2018; Sanjay et al. Reference Sanjay, Lohse and Jalaal2021). In this study, we focus more on the capillary effects than gravitational effects, and hence the value of ![]() $\mathcal {B}$o is set to

$\mathcal {B}$o is set to ![]() $10^{-3}$. At low values of

$10^{-3}$. At low values of ![]() $\mathcal {B}$o, the initial shape of the bubble closely approximates a sphere within the surrounding Newtonian medium. However, for the EVP medium considered in this study, we make a significant assumption by retaining the spherical bubble shape. It is important to note that this assumption is a crucial aspect of our investigation. Given the EVP behaviour of the liquid medium in our work, the bubble shape close to the fluid–air interface would exhibit a different interface profile than that in the Newtonian medium. The shapes of the bubble rising in an EVP medium constitute an active area of research (see Izbassarov et al. Reference Izbassarov, Rosti, Ardekani, Sarabian, Hormozi, Brandt and Tammisola2018; Lopez, Naccache & de Souza Mendes Reference Lopez, Naccache and de Souza Mendes2018; Moschopoulos et al. Reference Moschopoulos, Spyridakis, Varchanis, Dimakopoulos and Tsamopoulos2021).

$\mathcal {B}$o, the initial shape of the bubble closely approximates a sphere within the surrounding Newtonian medium. However, for the EVP medium considered in this study, we make a significant assumption by retaining the spherical bubble shape. It is important to note that this assumption is a crucial aspect of our investigation. Given the EVP behaviour of the liquid medium in our work, the bubble shape close to the fluid–air interface would exhibit a different interface profile than that in the Newtonian medium. The shapes of the bubble rising in an EVP medium constitute an active area of research (see Izbassarov et al. Reference Izbassarov, Rosti, Ardekani, Sarabian, Hormozi, Brandt and Tammisola2018; Lopez, Naccache & de Souza Mendes Reference Lopez, Naccache and de Souza Mendes2018; Moschopoulos et al. Reference Moschopoulos, Spyridakis, Varchanis, Dimakopoulos and Tsamopoulos2021).

Further, the bubble's shape at the fluid–air interface depends not only on the material behaviour of the surrounding medium in which the bubble rises but also on the generation and dynamics before reaching the free surface. The bubble rise depends on the buoyancy forces, which should be strong enough to yield the EVP medium. Hence, one might expect a non-trivial shape as suggested by Lopez et al. (Reference Lopez, Naccache and de Souza Mendes2018) and Deoclecio, Soares & Popinet (Reference Deoclecio, Soares and Popinet2023). However, in the present study, we consider the small spherical bubbles trapped at the interface rather than rising bubbles reaching the free surface to be consistent with the previous investigations. It should be pointed out that the bubble cap breakup is also sensitive to the employed numerical method. For a comparative analysis to understand the transient effects of elasticity on the bubble bursting in an EVP medium, we consider the same initial condition as employed by Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) for the case of bubble bursting in a viscoplastic medium. Hence, an initial stress-free condition is employed in the present computations, which would otherwise correspond to some presheared state if the bubble rose close to the free surface and burst instantly.

The bubble-bursting problem could also be coupled with the bubble rise in an EVP medium with a free surface to obtain a more realistic initial condition. However, such a coupling is limited by the numerical methodology to treat the breakup of bubble cap ![]() $\delta$ (as the thin initial film between the bubble and air drains). Moreover, the bubbles usually sit on the free surface before the cap bursts (Bartlett et al. Reference Bartlett, Oratis, Santin and Bird2023), allowing enough time for the elastic stresses to relax if the drainage time is much longer than the relaxation time. Hence, as a simplification in this work, the open cavity is considered as the initial condition, as shown in figure 1. In this figure,

$\delta$ (as the thin initial film between the bubble and air drains). Moreover, the bubbles usually sit on the free surface before the cap bursts (Bartlett et al. Reference Bartlett, Oratis, Santin and Bird2023), allowing enough time for the elastic stresses to relax if the drainage time is much longer than the relaxation time. Hence, as a simplification in this work, the open cavity is considered as the initial condition, as shown in figure 1. In this figure, ![]() $(\mathcal {R},\mathcal {Z})$ represent the radial and axial coordinate system, and

$(\mathcal {R},\mathcal {Z})$ represent the radial and axial coordinate system, and ![]() $\mathcal {H}_i \approx 2$ denotes the initial bubble depth, while

$\mathcal {H}_i \approx 2$ denotes the initial bubble depth, while ![]() $\theta _i$ indicates the initial location of the cavity-free surface intersection. We incorporate a finite curvature

$\theta _i$ indicates the initial location of the cavity-free surface intersection. We incorporate a finite curvature ![]() $\kappa _0=100$ at the intersection of bubble and free surface to regularize the curvature singularity, consistent with Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021), which has been demonstrated to have no significant influence on the bubble-bursting dynamics.

$\kappa _0=100$ at the intersection of bubble and free surface to regularize the curvature singularity, consistent with Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021), which has been demonstrated to have no significant influence on the bubble-bursting dynamics.

3. Results

3.1. Validation

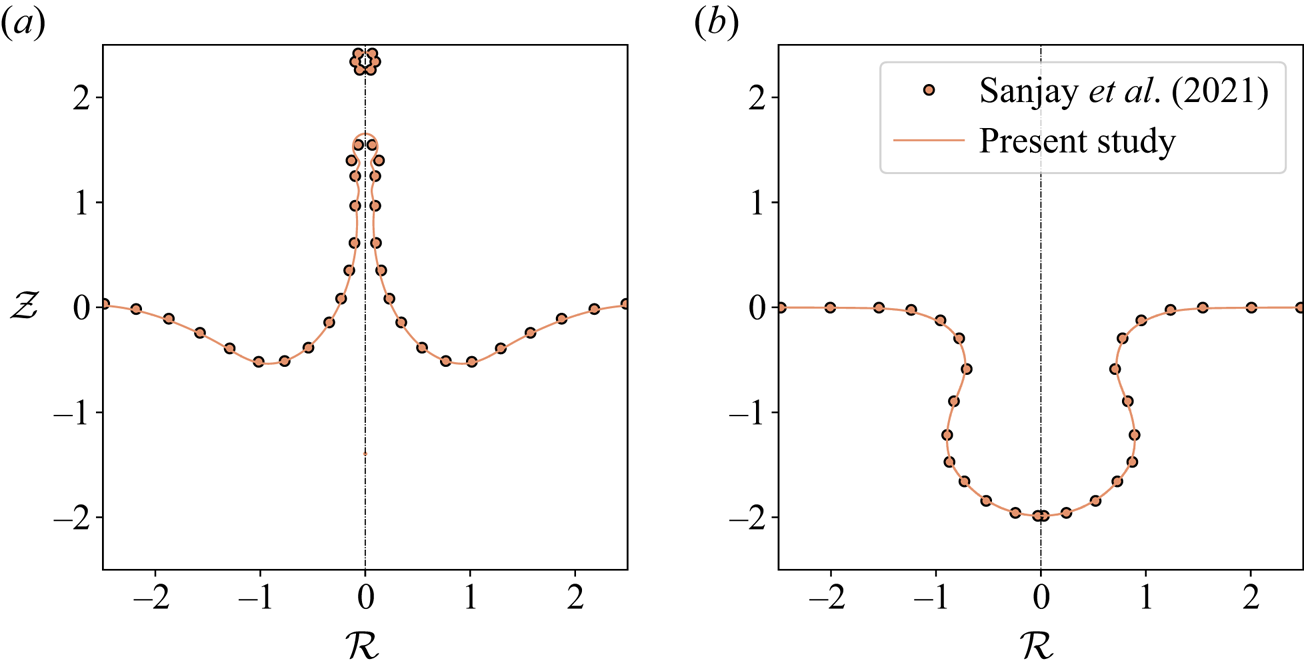

This section compares our results with Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021), who used a regularized Bingham model to study bubble bursting in a viscoplastic medium. In such a viscoplastic model, the fluid features a rigid body motion (![]() $\boldsymbol {\mathcal {D}} = \boldsymbol {0}$) below the yield stress and flows like a viscous liquid above the yield stress. The EVP model used in this work ((2.4) and (2.15)) reduces to the Bingham model if

$\boldsymbol {\mathcal {D}} = \boldsymbol {0}$) below the yield stress and flows like a viscous liquid above the yield stress. The EVP model used in this work ((2.4) and (2.15)) reduces to the Bingham model if ![]() ${{\textit {De}}} = 0$ and

${{\textit {De}}} = 0$ and ![]() ${{\textit {Oh}}}_s = 0$ (see also Appendix D), giving

${{\textit {Oh}}}_s = 0$ (see also Appendix D), giving

where ![]() $({{\textit {Oh}}}_s + {{\textit {Oh}}}_p/K) = {{\textit {Oh}}}_p/K$ is the apparent viscosity. Figures 2 and 3 illustrate the comparison between Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) and our simulations with

$({{\textit {Oh}}}_s + {{\textit {Oh}}}_p/K) = {{\textit {Oh}}}_p/K$ is the apparent viscosity. Figures 2 and 3 illustrate the comparison between Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) and our simulations with ![]() ${{\textit {De}}}=10^{-4}$,

${{\textit {De}}}=10^{-4}$, ![]() ${{\textit {Oh}}}_p = 9.5 \times 10^{-3}$ and

${{\textit {Oh}}}_p = 9.5 \times 10^{-3}$ and ![]() ${{\textit {Oh}}}_s=5\times 10^{-4}$. For a low plastocapillary number (

${{\textit {Oh}}}_s=5\times 10^{-4}$. For a low plastocapillary number (![]() $\mathcal {J} = 0.1$), the capillary waves meet at the bottom of the bubble cavity, leading to an inertial flow-focusing that forms a Worthington jet, which subsequently breaks into droplets (figure 2a).

$\mathcal {J} = 0.1$), the capillary waves meet at the bottom of the bubble cavity, leading to an inertial flow-focusing that forms a Worthington jet, which subsequently breaks into droplets (figure 2a).

Figure 2. Validation of interface shapes obtained with EVP fluid at very low Deborah number of ![]() ${{\textit {De}}}=10^{-4}$ against the results obtained by Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) with viscoplastic fluid at (a)

${{\textit {De}}}=10^{-4}$ against the results obtained by Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) with viscoplastic fluid at (a) ![]() $t=1.0,\mathcal {J}=0.1$ and (b)

$t=1.0,\mathcal {J}=0.1$ and (b) ![]() $t=0.75,\mathcal {J}=1.0$.

$t=0.75,\mathcal {J}=1.0$.

Figure 3. Comparison of the deformation-rate tensor obtained with (a i) viscoplastic fluid by Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) and (a ii) EVP fluid at ![]() $\mathcal {J} = 1.0,{{\textit {De}}}=10^{-4}$ at

$\mathcal {J} = 1.0,{{\textit {De}}}=10^{-4}$ at ![]() $t=1.0$. Time evolution of deformation tensor in EVP fluid at (b i)

$t=1.0$. Time evolution of deformation tensor in EVP fluid at (b i) ![]() $t=1.0$ and (b ii)

$t=1.0$ and (b ii) ![]() $t=1.6$ for

$t=1.6$ for ![]() $\mathcal {J} = 1.0,{{\textit {De}}}=10^{-4}$.

$\mathcal {J} = 1.0,{{\textit {De}}}=10^{-4}$.

On the other hand, at high ![]() $\mathcal {J}$ (i.e. at

$\mathcal {J}$ (i.e. at ![]() $\mathcal {J} = 1$), at comparable time scales between the two models, the bubble cavities are identical (figures 2b and 3a). Nonetheless, the two cases show different

$\mathcal {J} = 1$), at comparable time scales between the two models, the bubble cavities are identical (figures 2b and 3a). Nonetheless, the two cases show different ![]() $\|\boldsymbol {\mathcal {D}}\|$. This apparent discrepancy can be attributed to the different behaviours of the unyielded region in the Bingham viscoplastic and the Saramito (Reference Saramito2007) EVP models. Notably, in the case of the regularized Bingham model employed for simulating bubble bursting in viscoplastic fluid by Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021), at the stoppage time, the entire medium is unyielded (

$\|\boldsymbol {\mathcal {D}}\|$. This apparent discrepancy can be attributed to the different behaviours of the unyielded region in the Bingham viscoplastic and the Saramito (Reference Saramito2007) EVP models. Notably, in the case of the regularized Bingham model employed for simulating bubble bursting in viscoplastic fluid by Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021), at the stoppage time, the entire medium is unyielded (![]() $K \approx 0$ throughout the bulk) and the fluid flow ceases due to stresses falling below the yield stress. Consequently, the deformation tensor

$K \approx 0$ throughout the bulk) and the fluid flow ceases due to stresses falling below the yield stress. Consequently, the deformation tensor ![]() $\|\boldsymbol {\mathcal {D}}\|$ is zero (rigid body rotation or no flow). For the EVP model, nearly the entire liquid remains unyielded as regions with

$\|\boldsymbol {\mathcal {D}}\|$ is zero (rigid body rotation or no flow). For the EVP model, nearly the entire liquid remains unyielded as regions with ![]() $K \neq 0$ are predominantly situated close to the fluid interface. However, the bulk exhibits a Kelvin–Voigt viscoelastic solid behaviour (

$K \neq 0$ are predominantly situated close to the fluid interface. However, the bulk exhibits a Kelvin–Voigt viscoelastic solid behaviour (![]() $\boldsymbol {\overset {\nabla }{A}} = \boldsymbol {0}$ and

$\boldsymbol {\overset {\nabla }{A}} = \boldsymbol {0}$ and ![]() $\boldsymbol {\tau _p} = Ec(\boldsymbol {A} - \boldsymbol {I})$, see Saramito Reference Saramito2007). Consequently, even below the yield stress, the deformation tensor

$\boldsymbol {\tau _p} = Ec(\boldsymbol {A} - \boldsymbol {I})$, see Saramito Reference Saramito2007). Consequently, even below the yield stress, the deformation tensor ![]() $\|\boldsymbol {\mathcal {D}}\|$ can be non-zero. Note that, for the Kelvin–Voigt viscoelastic rigid body motion (

$\|\boldsymbol {\mathcal {D}}\|$ can be non-zero. Note that, for the Kelvin–Voigt viscoelastic rigid body motion (![]() $\|\boldsymbol {\mathcal {D}}\| = 0$) occurs in the limit of very large elastic modulus (i.e.

$\|\boldsymbol {\mathcal {D}}\| = 0$) occurs in the limit of very large elastic modulus (i.e. ![]() $Ec = {{\textit {Oh}}}_p/{{\textit {De}}} \to \infty$). The simulations are stopped at

$Ec = {{\textit {Oh}}}_p/{{\textit {De}}} \to \infty$). The simulations are stopped at ![]() $t=2$ and the final interface shape of the bubble, where the extra stress balances the capillary stress, are not investigated in this study.

$t=2$ and the final interface shape of the bubble, where the extra stress balances the capillary stress, are not investigated in this study.

3.2. Regime map

We investigate the dynamics of bubble bursting in an EVP medium by exploring the influence of elastic stress relaxation and yield stress, quantified by the Deborah ![]() ${{\textit {De}}}$ and the plastocapillary

${{\textit {De}}}$ and the plastocapillary ![]() $\mathcal {J}$ numbers, respectively (see França et al. Reference França, Jalaal and Oishi2024). Our exploration spans a parameter space with

$\mathcal {J}$ numbers, respectively (see França et al. Reference França, Jalaal and Oishi2024). Our exploration spans a parameter space with ![]() ${{\textit {De}}}\in [10^{-3},20]$ and

${{\textit {De}}}\in [10^{-3},20]$ and ![]() $\mathcal {J} \in [10^{-2},1]$ while maintaining a fixed Ohnesorge number of

$\mathcal {J} \in [10^{-2},1]$ while maintaining a fixed Ohnesorge number of ![]() ${{\textit {Oh}}}=10^{-2}$,

${{\textit {Oh}}}=10^{-2}$, ![]() $\beta$ of 0.5 and Bond number of

$\beta$ of 0.5 and Bond number of ![]() ${\textit {Bo}}=10^{-3}$. The value of

${\textit {Bo}}=10^{-3}$. The value of ![]() ${{\textit {Oh}}}_s = {{\textit {Oh}}}_p = 0.005$ (which fixes

${{\textit {Oh}}}_s = {{\textit {Oh}}}_p = 0.005$ (which fixes ![]() $\beta$ at 0.5) is applicable for all the discussions except for § 3.6 (see § 3.6 to identify the variation of regime map with

$\beta$ at 0.5) is applicable for all the discussions except for § 3.6 (see § 3.6 to identify the variation of regime map with ![]() $\beta$). All the simulations were carried out until

$\beta$). All the simulations were carried out until ![]() $t\ge 1.2$, as this time was seen to be sufficient to capture the key dynamics of the bursting process. This investigation leads us to a regime map, presented in figure 4. We identify four distinct regimes, namely (i) droplet formation from the tip of the Worthington jet (Droplet–A), (ii) no Worthington jet formation, (iii) no pinch-off of the Worthington jet and no droplet, (iv) pinch-off at the base of the Worthington jet to form a droplet (Droplet–B). Note that in the context of this study, we characterize a jet formed by inertial flow-focusing as the Worthington jet if it crosses the equilibrium surface

$t\ge 1.2$, as this time was seen to be sufficient to capture the key dynamics of the bursting process. This investigation leads us to a regime map, presented in figure 4. We identify four distinct regimes, namely (i) droplet formation from the tip of the Worthington jet (Droplet–A), (ii) no Worthington jet formation, (iii) no pinch-off of the Worthington jet and no droplet, (iv) pinch-off at the base of the Worthington jet to form a droplet (Droplet–B). Note that in the context of this study, we characterize a jet formed by inertial flow-focusing as the Worthington jet if it crosses the equilibrium surface ![]() $\mathcal {Z}=0$ at the axis

$\mathcal {Z}=0$ at the axis ![]() $(\mathcal {R}=0)$.

$(\mathcal {R}=0)$.

Figure 4. Regime map in terms of the plastocapillarity number ![]() $\mathcal {J}$ and the Deborah number

$\mathcal {J}$ and the Deborah number ![]() ${{\textit {De}}}$, distinguishing the droplet formation (Droplet–I), no jet formation, jet pinch-off (Droplet–II) and no-pinch-off regimes. All the cases correspond to

${{\textit {De}}}$, distinguishing the droplet formation (Droplet–I), no jet formation, jet pinch-off (Droplet–II) and no-pinch-off regimes. All the cases correspond to ![]() ${{\textit {Oh}}}_s = {{\textit {Oh}}}_p = 0.005$. The four series of insets illustrate typical cases in these regimes, namely (b)

${{\textit {Oh}}}_s = {{\textit {Oh}}}_p = 0.005$. The four series of insets illustrate typical cases in these regimes, namely (b) ![]() $(\mathcal {J}, {{\textit {De}}}) = (0.1, 20)$, (c) (0.01, 0.01), (d) (0.8, 0.1) and (e) (1, 2). Different markers identify the viscoelastic limit corresponding to

$(\mathcal {J}, {{\textit {De}}}) = (0.1, 20)$, (c) (0.01, 0.01), (d) (0.8, 0.1) and (e) (1, 2). Different markers identify the viscoelastic limit corresponding to ![]() $\mathcal {J}=0$.

$\mathcal {J}=0$.

3.2.1. Droplet formation regime, Droplet–A (low elastic stress relaxation time and yield-stress limit,  $\mathcal {J} \rightarrow 0,\,{{\textit {De}}}\rightarrow 0$)

$\mathcal {J} \rightarrow 0,\,{{\textit {De}}}\rightarrow 0$)

For small Deborah and plastocapillary numbers (![]() ${{\textit {De}}} \le 0.05$ and

${{\textit {De}}} \le 0.05$ and ![]() $\mathcal {J} \le 0.4$), we observe a Newtonian-like behaviour where the initial capillary waves collapse at the bottom of the bubble cavity resulting in a Worthington jet formation (Gordillo & Blanco-Rodríguez Reference Gordillo and Blanco-Rodríguez2023; Dixit et al. Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024). Further, due to the higher capillary forces compared with the viscous and elastic forces, the jet breaks up, resulting in droplets (Walls et al. Reference Walls, Henaux and Bird2015). This regime often features multiple drops similar to the case of the Newtonian bubble-bursting process (Berny et al. Reference Berny, Deike, Séon and Popinet2020).

$\mathcal {J} \le 0.4$), we observe a Newtonian-like behaviour where the initial capillary waves collapse at the bottom of the bubble cavity resulting in a Worthington jet formation (Gordillo & Blanco-Rodríguez Reference Gordillo and Blanco-Rodríguez2023; Dixit et al. Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024). Further, due to the higher capillary forces compared with the viscous and elastic forces, the jet breaks up, resulting in droplets (Walls et al. Reference Walls, Henaux and Bird2015). This regime often features multiple drops similar to the case of the Newtonian bubble-bursting process (Berny et al. Reference Berny, Deike, Séon and Popinet2020).

For the viscoplastic fluid, Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) had identified this regime to fall below ![]() $\mathcal {J} \approx 0.3$ for small

$\mathcal {J} \approx 0.3$ for small ![]() ${{\textit {Oh}}}$ and

${{\textit {Oh}}}$ and ![]() ${{\textit {De}}} = 0$, beyond which the jet breakup is suppressed owing to an increase in the apparent viscosity which critically dampens the capillary waves. Figure 4 identifies this transition at

${{\textit {De}}} = 0$, beyond which the jet breakup is suppressed owing to an increase in the apparent viscosity which critically dampens the capillary waves. Figure 4 identifies this transition at ![]() $\mathcal {J} \approx 0.5$ for

$\mathcal {J} \approx 0.5$ for ![]() ${{\textit {De}}} \to 0$. This delayed droplet–no-droplet transition is attributed to a reduction in the effective viscosity of the EVP matrix in comparison with the purely Bingham fluid (refer to Appendix D). The effective viscosity in the limit of vanishing

${{\textit {De}}} \to 0$. This delayed droplet–no-droplet transition is attributed to a reduction in the effective viscosity of the EVP matrix in comparison with the purely Bingham fluid (refer to Appendix D). The effective viscosity in the limit of vanishing ![]() ${{\textit {De}}}$ is

${{\textit {De}}}$ is ![]() ${{\textit {Oh}}}_p/K$ contrary to

${{\textit {Oh}}}_p/K$ contrary to ![]() ${{\textit {Oh}}}/K$ for a purely Bingham fluid (Sanjay et al. Reference Sanjay, Lohse and Jalaal2021). This delay in stress relaxation delays the transition to the plastic behaviour within the EVP matrix. Consequently, at finite

${{\textit {Oh}}}/K$ for a purely Bingham fluid (Sanjay et al. Reference Sanjay, Lohse and Jalaal2021). This delay in stress relaxation delays the transition to the plastic behaviour within the EVP matrix. Consequently, at finite ![]() ${{\textit {De}}}$, a critical increase in the apparent viscosity occurs at a higher value of

${{\textit {De}}}$, a critical increase in the apparent viscosity occurs at a higher value of ![]() $\mathcal {J}$.

$\mathcal {J}$.

Furthermore, as ![]() ${{\textit {De}}}$ increases further, even for low

${{\textit {De}}}$ increases further, even for low ![]() $\mathcal {J}$, jet breakup into droplets is suppressed. This observation agrees with that of Rodríguez-Díaz et al. (Reference Rodríguez-Díaz, Rubio, Montanero, Gañán-Calvo and Cabezas2023) and Dixit et al. (Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024): adding polymers hinders droplet ejection even for the small solvent-to-polymer viscosity ratio. We attribute this observation to a delay in elastic stress relaxation at higher

$\mathcal {J}$, jet breakup into droplets is suppressed. This observation agrees with that of Rodríguez-Díaz et al. (Reference Rodríguez-Díaz, Rubio, Montanero, Gañán-Calvo and Cabezas2023) and Dixit et al. (Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024): adding polymers hinders droplet ejection even for the small solvent-to-polymer viscosity ratio. We attribute this observation to a delay in elastic stress relaxation at higher ![]() ${{\textit {De}}}$, increasing the elastic stresses that counteract capillarity to prevent both the end-pinching and Rayleigh–Plateau instabilities (Pandey et al. Reference Pandey, Kansal, Herrada, Eggers and Snoeijer2021).

${{\textit {De}}}$, increasing the elastic stresses that counteract capillarity to prevent both the end-pinching and Rayleigh–Plateau instabilities (Pandey et al. Reference Pandey, Kansal, Herrada, Eggers and Snoeijer2021).

3.2.2. No-jet regime (viscoplastic limit,  $\mathcal {J} \gg 0,\,{{\textit {De}}}\rightarrow 0$)

$\mathcal {J} \gg 0,\,{{\textit {De}}}\rightarrow 0$)

In the case of a purely viscoplastic fluid, Sanjay et al. (Reference Sanjay, Lohse and Jalaal2021) observed that for ![]() $\mathcal {J} \ge 0.65$, the surface tension fails to yield the entire cavity, and the capillary wave freezes before reaching the bottom of the cavity, leading to a non-flat final equilibrium shape. In this work, the no jet regime commences at

$\mathcal {J} \ge 0.65$, the surface tension fails to yield the entire cavity, and the capillary wave freezes before reaching the bottom of the cavity, leading to a non-flat final equilibrium shape. In this work, the no jet regime commences at ![]() $\mathcal {J} \approx 0.7$ in the limit of

$\mathcal {J} \approx 0.7$ in the limit of ![]() ${{\textit {De}}} \to 0$, characterized by the absence of a jet crossing the free surface (

${{\textit {De}}} \to 0$, characterized by the absence of a jet crossing the free surface (![]() $\mathcal {Z} = 0$). This finding aligns with the increased plasticity effect at higher

$\mathcal {Z} = 0$). This finding aligns with the increased plasticity effect at higher ![]() $\mathcal {J}$.

$\mathcal {J}$.

However, our results diverge from the case of a purely viscoplastic fluid in one critical aspect: we find that despite the increasing plasticity, the bubble cavity consistently yields, albeit slowly. In the context of purely viscoplastic fluids, the yield surface is stationary and aligns with the cavity boundary, resulting in a zero deformation rate (![]() $\|\boldsymbol {\mathcal {D}}\| = 0$), independent of resultant stress fields that are below the yield stress. However, under EVP conditions, the medium behaves akin to a Kelvin–Voigt solid below the yield stress, leading to a slow deformation of the cavity over extended time scales depending on the elastocapillary number

$\|\boldsymbol {\mathcal {D}}\| = 0$), independent of resultant stress fields that are below the yield stress. However, under EVP conditions, the medium behaves akin to a Kelvin–Voigt solid below the yield stress, leading to a slow deformation of the cavity over extended time scales depending on the elastocapillary number ![]() $Ec = {{\textit {Oh}}}_p/{{\textit {De}}} = (1-\beta ) {{\textit {Oh}}}/{{\textit {De}}}$, as indicated by a non-zero deformation rate (

$Ec = {{\textit {Oh}}}_p/{{\textit {De}}} = (1-\beta ) {{\textit {Oh}}}/{{\textit {De}}}$, as indicated by a non-zero deformation rate (![]() $\|\boldsymbol {\mathcal {D}}\| \ne 0$, see § 3.1). For an infinite

$\|\boldsymbol {\mathcal {D}}\| \ne 0$, see § 3.1). For an infinite ![]() $Ec$, a rigid body motion of the unyielded region is recovered.

$Ec$, a rigid body motion of the unyielded region is recovered.

3.2.3. No pinch-off regime (viscoelastocapillary limit,  ${{\textit {De}}} \sim O(1)$)

${{\textit {De}}} \sim O(1)$)

At large values of ![]() $\mathcal {J}$, as we increase the Deborah number (

$\mathcal {J}$, as we increase the Deborah number (![]() ${{\textit {De}}} \sim O(1)$), we notice that a Worthington jet forms irrespective of

${{\textit {De}}} \sim O(1)$), we notice that a Worthington jet forms irrespective of ![]() $\mathcal {J}$. This

$\mathcal {J}$. This ![]() $\mathcal {J}$–independent behaviour is due to a decrease in the elastocapillary number

$\mathcal {J}$–independent behaviour is due to a decrease in the elastocapillary number ![]() $Ec = {{\textit {Oh}}}_p/{{\textit {De}}} = (1-\beta ) {{\textit {Oh}}}/{{\textit {De}}}$ with an increase in

$Ec = {{\textit {Oh}}}_p/{{\textit {De}}} = (1-\beta ) {{\textit {Oh}}}/{{\textit {De}}}$ with an increase in ![]() ${{\textit {De}}}$ at fixed

${{\textit {De}}}$ at fixed ![]() ${{\textit {Oh}}}_p$. Consequently, for a considered deformation of the EVP matrix the maximum elastic energy decreases with

${{\textit {Oh}}}_p$. Consequently, for a considered deformation of the EVP matrix the maximum elastic energy decreases with ![]() ${{\textit {De}}}$ at fixed

${{\textit {De}}}$ at fixed ![]() ${{\textit {Oh}}}_p$ (refer to figure 19c), leading to the formation of the jet. This jet development is significantly influenced by the variations in the ratio of polymer to total viscosity (

${{\textit {Oh}}}_p$ (refer to figure 19c), leading to the formation of the jet. This jet development is significantly influenced by the variations in the ratio of polymer to total viscosity (![]() $\beta$, see § 3.6), which modifies the elastocapillary number at fixed

$\beta$, see § 3.6), which modifies the elastocapillary number at fixed ![]() ${{\textit {Oh}}}$ and

${{\textit {Oh}}}$ and ![]() ${{\textit {De}}}$. Nonetheless, the elastic forces still dominate over capillary, resulting in the prevention of droplet formation from the jet even at small

${{\textit {De}}}$. Nonetheless, the elastic forces still dominate over capillary, resulting in the prevention of droplet formation from the jet even at small ![]() $\mathcal {J}$ (see § 3.2.1). The role of elastocapillary number in jet formation is further explained in 3.3.

$\mathcal {J}$ (see § 3.2.1). The role of elastocapillary number in jet formation is further explained in 3.3.

3.2.4. Droplet formation regime, Droplet–B (Newtonian-like limit,  ${{\textit {De}}}\gg 1$)

${{\textit {De}}}\gg 1$)

For very high values of Deborah numbers (![]() ${{\textit {De}}} \gg 1$), the bursting bubble dynamics appear to be independent of

${{\textit {De}}} \gg 1$), the bursting bubble dynamics appear to be independent of ![]() $\mathcal {J}$. However, in contrast to the ‘no pinch-off of the Worthington jet and no droplet regime’, the Worthington jet breaks up at the base to form one droplet. In this regime, the yield surface is still very close to the liquid–gas interface (refer to figure 5d and 7c), and most of the EVP fluid remains unyielded. At such high values of

$\mathcal {J}$. However, in contrast to the ‘no pinch-off of the Worthington jet and no droplet regime’, the Worthington jet breaks up at the base to form one droplet. In this regime, the yield surface is still very close to the liquid–gas interface (refer to figure 5d and 7c), and most of the EVP fluid remains unyielded. At such high values of ![]() ${{\textit {De}}}$, the elastocapillary number becomes too small, and the elastic stresses fail to prevent either the formation of the Worthington jet or its subsequent breakup at the base. Such a Newtonian-like regime with vanishing elastic stresses was also found by França et al. (Reference França, Jalaal and Oishi2024).

${{\textit {De}}}$, the elastocapillary number becomes too small, and the elastic stresses fail to prevent either the formation of the Worthington jet or its subsequent breakup at the base. Such a Newtonian-like regime with vanishing elastic stresses was also found by França et al. (Reference França, Jalaal and Oishi2024).

Figure 5. Variation of the dynamics of bubble bursting in (a) a Newtonian medium compared with EVP medium for ![]() $\mathcal {J}=0.1$,

$\mathcal {J}=0.1$, ![]() ${{\textit {Oh}}}=10^{-2}$ at (b)

${{\textit {Oh}}}=10^{-2}$ at (b) ![]() ${{\textit {De}}}=0.02$, (c)

${{\textit {De}}}=0.02$, (c) ![]() ${{\textit {De}}}=1$, (d)

${{\textit {De}}}=1$, (d) ![]() ${{\textit {De}}}=20$. The left-hand part of each subpanel shows the flow topology parameter

${{\textit {De}}}=20$. The left-hand part of each subpanel shows the flow topology parameter ![]() $\mathcal {Q}$ and the right-hand part of the subpanel shows the trace of elastic stress on a

$\mathcal {Q}$ and the right-hand part of the subpanel shows the trace of elastic stress on a ![]() $\log _{10}$ scale. The yielded regions are marked by a grey line, which corresponds to

$\log _{10}$ scale. The yielded regions are marked by a grey line, which corresponds to ![]() $\mathcal {J}\approxeq \|\boldsymbol {\tau _d}\|$. For the Newtonian medium, both subpanels show the flow topology parameter.

$\mathcal {J}\approxeq \|\boldsymbol {\tau _d}\|$. For the Newtonian medium, both subpanels show the flow topology parameter.

3.3. Bubble-bursting dynamics

In the previous section, we identified different regimes as a function of ![]() ${{\textit {De}}}$ and

${{\textit {De}}}$ and ![]() $\mathcal {J}$. Here, we analyse the transient development of the bubble-bursting process. To demystify the different stages of the bubble-bursting process, we will compare the dynamics of bubble bursting in an EVP medium with that of a Newtonian fluid. The latter is well documented in Duchemin et al. (Reference Duchemin, Popinet, Josserand and Zaleski2002), Ghabache & Séon (Reference Ghabache and Séon2016), Deike et al. (Reference Deike, Ghabache, Liger-Belair, Das, Zaleski, Popinet and Séon2018), Gordillo & Rodríguez-Rodríguez (Reference Gordillo and Rodríguez-Rodríguez2019) and Berny et al. (Reference Berny, Deike, Séon and Popinet2020). The bubble bursting in a Newtonian liquid (

$\mathcal {J}$. Here, we analyse the transient development of the bubble-bursting process. To demystify the different stages of the bubble-bursting process, we will compare the dynamics of bubble bursting in an EVP medium with that of a Newtonian fluid. The latter is well documented in Duchemin et al. (Reference Duchemin, Popinet, Josserand and Zaleski2002), Ghabache & Séon (Reference Ghabache and Séon2016), Deike et al. (Reference Deike, Ghabache, Liger-Belair, Das, Zaleski, Popinet and Séon2018), Gordillo & Rodríguez-Rodríguez (Reference Gordillo and Rodríguez-Rodríguez2019) and Berny et al. (Reference Berny, Deike, Séon and Popinet2020). The bubble bursting in a Newtonian liquid (![]() $\mathcal {J} = 0$,

$\mathcal {J} = 0$, ![]() ${{\textit {De}}} = 0$) is characterized by the retraction of the rim leading to the formation of capillary waves. The capillary waves travel towards the bottom of the bubble cavity resulting in the formation of a Worthington jet, which can then break into multiple droplets owing to the end-pinching and Rayleigh–Plateau instabilities (Walls et al. Reference Walls, Henaux and Bird2015). Furthermore, owing to the conservation of momentum, a high-velocity jet is also formed in an opposite direction to the Worthington jet, inside the liquid pool. Figure 5(a) illustrates the process of bubble bursting in a Newtonian fluid medium and identifies the state of flow inside the liquid medium using the flow topology parameter

${{\textit {De}}} = 0$) is characterized by the retraction of the rim leading to the formation of capillary waves. The capillary waves travel towards the bottom of the bubble cavity resulting in the formation of a Worthington jet, which can then break into multiple droplets owing to the end-pinching and Rayleigh–Plateau instabilities (Walls et al. Reference Walls, Henaux and Bird2015). Furthermore, owing to the conservation of momentum, a high-velocity jet is also formed in an opposite direction to the Worthington jet, inside the liquid pool. Figure 5(a) illustrates the process of bubble bursting in a Newtonian fluid medium and identifies the state of flow inside the liquid medium using the flow topology parameter ![]() $\mathcal {Q}$ defined as

$\mathcal {Q}$ defined as

where ![]() $\|\boldsymbol {\mathcal {D}}\| = \sqrt {(\boldsymbol {\mathcal {D}} \colon \boldsymbol {\mathcal {D}})/2}$ and

$\|\boldsymbol {\mathcal {D}}\| = \sqrt {(\boldsymbol {\mathcal {D}} \colon \boldsymbol {\mathcal {D}})/2}$ and ![]() $\|\boldsymbol {\mathcal {S}}\| = \sqrt {(\boldsymbol {\mathcal {S}}:\boldsymbol {\mathcal {S}})/2}$, with

$\|\boldsymbol {\mathcal {S}}\| = \sqrt {(\boldsymbol {\mathcal {S}}:\boldsymbol {\mathcal {S}})/2}$, with ![]() $\boldsymbol {\mathcal {S}}$ denoting the rate of rotation tensor defined as

$\boldsymbol {\mathcal {S}}$ denoting the rate of rotation tensor defined as ![]() $\boldsymbol {\mathcal {S}} = ((\boldsymbol {\nabla } \boldsymbol {u})^{\rm T} - \boldsymbol {\nabla } \boldsymbol {u})/2$. When

$\boldsymbol {\mathcal {S}} = ((\boldsymbol {\nabla } \boldsymbol {u})^{\rm T} - \boldsymbol {\nabla } \boldsymbol {u})/2$. When ![]() $\mathcal {Q} = -1$, the flow is purely rotational, whereas regions with

$\mathcal {Q} = -1$, the flow is purely rotational, whereas regions with ![]() $\mathcal {Q}=0$ represent pure shear flow and

$\mathcal {Q}=0$ represent pure shear flow and ![]() $\mathcal {Q} = 1$ corresponds to either elongational flow or no flow (i.e.

$\mathcal {Q} = 1$ corresponds to either elongational flow or no flow (i.e. ![]() $\|\boldsymbol {\mathcal {D}}\| \rightarrow 0, \|\boldsymbol {\mathcal {S}}\| \rightarrow 0$).

$\|\boldsymbol {\mathcal {D}}\| \rightarrow 0, \|\boldsymbol {\mathcal {S}}\| \rightarrow 0$).

Bursting bubble in an EVP fluid exhibits a non-monotonic behaviour in the jet development process, as shown in figure 5(b–d). The figure illustrates three representative cases, identifying the effects of elastic stress relaxation on the bubble bursting process in an EVP fluid (supplementary movies are available at Balasubramanian (Reference Balasubramanian2023)) for a given plastocapillary number of ![]() $\mathcal {J}=0.1$. The left-hand and right-hand subpanels of figure 5(b–d) show the flow topology parameter

$\mathcal {J}=0.1$. The left-hand and right-hand subpanels of figure 5(b–d) show the flow topology parameter ![]() $\mathcal {Q}$ and the trace of elastic stresses on a

$\mathcal {Q}$ and the trace of elastic stresses on a ![]() $\mathrm {log_{10}}$ scale, respectively. Note that the early-time dynamics (

$\mathrm {log_{10}}$ scale, respectively. Note that the early-time dynamics (![]() $t \lessapprox 0.4$) appear similar in figure 5(b–d), but exhibit qualitatively different behaviour at later times. At low

$t \lessapprox 0.4$) appear similar in figure 5(b–d), but exhibit qualitatively different behaviour at later times. At low ![]() ${{\textit {De}}}$, droplet formation is observed which is eventually suppressed by elastic stresses for intermediate values of

${{\textit {De}}}$, droplet formation is observed which is eventually suppressed by elastic stresses for intermediate values of ![]() ${{\textit {De}}}$. For large relaxation time (i.e. at higher

${{\textit {De}}}$. For large relaxation time (i.e. at higher ![]() ${{\textit {De}}}$), the elastic stresses persist and are concentrated close to the jet. The jet is characterized by larger axial stress in the elongational flow region of the jet (characterized by high shear

${{\textit {De}}}$), the elastic stresses persist and are concentrated close to the jet. The jet is characterized by larger axial stress in the elongational flow region of the jet (characterized by high shear ![]() $\mathcal {Q}\approx 0$), and extra stress opposes the capillary stress, inhibiting the droplet formation from the jet. This observation of droplet prevention due to the addition of polymers was also discussed by Rodríguez-Díaz et al. (Reference Rodríguez-Díaz, Rubio, Montanero, Gañán-Calvo and Cabezas2023) and Dixit et al. (Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024). At even higher values of

$\mathcal {Q}\approx 0$), and extra stress opposes the capillary stress, inhibiting the droplet formation from the jet. This observation of droplet prevention due to the addition of polymers was also discussed by Rodríguez-Díaz et al. (Reference Rodríguez-Díaz, Rubio, Montanero, Gañán-Calvo and Cabezas2023) and Dixit et al. (Reference Dixit, Oratis, Zinelis, Lohse and Sanjay2024). At even higher values of ![]() ${{\textit {De}}}$ (i.e.

${{\textit {De}}}$ (i.e. ![]() ${{\textit {De}}}=20$), we observe again a persistent Worthington jet that thins appreciatively over time (see figure 5c). Due to low elastocapillary number, the bulk medium remains unyielded and behaves as a Kelvin–Voigt viscoelastic solid with negligible

${{\textit {De}}}=20$), we observe again a persistent Worthington jet that thins appreciatively over time (see figure 5c). Due to low elastocapillary number, the bulk medium remains unyielded and behaves as a Kelvin–Voigt viscoelastic solid with negligible ![]() $\mathrm {tr}(\boldsymbol {\tau _p})$. In contrast, the axial region of the jet experiences significant extra stress, and as the jet continues to thin, it eventually pinches off when its thickness becomes smaller than the grid size.

$\mathrm {tr}(\boldsymbol {\tau _p})$. In contrast, the axial region of the jet experiences significant extra stress, and as the jet continues to thin, it eventually pinches off when its thickness becomes smaller than the grid size.

It is essential to note that the appearance of the yielded region (![]() $K \neq 0$) is influenced not only by the plasticity of the fluid but also by the elastic stress (

$K \neq 0$) is influenced not only by the plasticity of the fluid but also by the elastic stress (![]() $\tau _p$), which affects the yield criterion (refer to (2.8)). For

$\tau _p$), which affects the yield criterion (refer to (2.8)). For ![]() $\mathcal {J}=0.1$, at low

$\mathcal {J}=0.1$, at low ![]() ${{\textit {De}}}$, we observe a large yielded region exhibiting significant elastic deformation from the base state (i.e.

${{\textit {De}}}$, we observe a large yielded region exhibiting significant elastic deformation from the base state (i.e. ![]() $A \neq I$). Hence, the resulting elastic stresses relax more rapidly due to shorter relaxation times. This fast extra stress relaxation, especially at low

$A \neq I$). Hence, the resulting elastic stresses relax more rapidly due to shorter relaxation times. This fast extra stress relaxation, especially at low ![]() ${{\textit {De}}}$, causes the EVP medium to behave similarly to a Newtonian fluid, as evidenced by the similar busting bubble dynamics. However, it is worth noting that the resulting jet formation differs from the Newtonian case at

${{\textit {De}}}$, causes the EVP medium to behave similarly to a Newtonian fluid, as evidenced by the similar busting bubble dynamics. However, it is worth noting that the resulting jet formation differs from the Newtonian case at ![]() ${{\textit {Oh}}}=10^{-2}$ as the introduction of yield stress increases the apparent viscosity (see § 3.1) of the fluid and alters the flow. Note that the maximum magnitude of elastic deformation occurs mainly in the region of high shear around the time when capillary waves converge at the bottom of the bubble cavity, resulting in jet formation. With increasing

${{\textit {Oh}}}=10^{-2}$ as the introduction of yield stress increases the apparent viscosity (see § 3.1) of the fluid and alters the flow. Note that the maximum magnitude of elastic deformation occurs mainly in the region of high shear around the time when capillary waves converge at the bottom of the bubble cavity, resulting in jet formation. With increasing ![]() ${{\textit {De}}}$ at fixed

${{\textit {De}}}$ at fixed ![]() ${{\textit {Oh}}}_p$, the elastocapillary number decreases, indicating lower elastic energy in the EVP fluid (refer to § 3.7) and thereby, the yielded region appears in the proximity of the jet. The elastic stresses are lower in the majority of the bulk, which remains unyielded (

${{\textit {Oh}}}_p$, the elastocapillary number decreases, indicating lower elastic energy in the EVP fluid (refer to § 3.7) and thereby, the yielded region appears in the proximity of the jet. The elastic stresses are lower in the majority of the bulk, which remains unyielded (![]() $K = 0$) and exhibits a Kelvin–Voigt viscoelastic solid behaviour (

$K = 0$) and exhibits a Kelvin–Voigt viscoelastic solid behaviour (![]() $\boldsymbol {\overset {\nabla }{A}} = \boldsymbol {0}$). (Note that the higher elastic stresses can be found in the yielded region of the EVP fluid where

$\boldsymbol {\overset {\nabla }{A}} = \boldsymbol {0}$). (Note that the higher elastic stresses can be found in the yielded region of the EVP fluid where ![]() $\mathrm {tr}(\boldsymbol {A})$ can be larger.) At high

$\mathrm {tr}(\boldsymbol {A})$ can be larger.) At high ![]() ${{\textit {De}}}$, a significant portion of the EVP fluid behaves as an elastic solid with very low elastic modulus, which allows the development of a high and thin jet, leading to capillary-type instability and pearl or drop formation. At

${{\textit {De}}}$, a significant portion of the EVP fluid behaves as an elastic solid with very low elastic modulus, which allows the development of a high and thin jet, leading to capillary-type instability and pearl or drop formation. At ![]() ${{\textit {De}}} = 20$ (refer to figure 5c), we observe jet formation reminiscent of the bead-on-a-string instability, which has been suggested to be the elastic counterpart of the Rayleigh–Plateau instability, and is observed in both viscoelastic fluids and elastic solids (Kibbelaar et al. Reference Kibbelaar, Deblais, Burla, Koenderink, Velikov and Bonn2020).

${{\textit {De}}} = 20$ (refer to figure 5c), we observe jet formation reminiscent of the bead-on-a-string instability, which has been suggested to be the elastic counterpart of the Rayleigh–Plateau instability, and is observed in both viscoelastic fluids and elastic solids (Kibbelaar et al. Reference Kibbelaar, Deblais, Burla, Koenderink, Velikov and Bonn2020).

The effects of increasing plasticity (via plastocapillary number ![]() $\mathcal {J}$) are shown in figure 6, at a small Deborah number (

$\mathcal {J}$) are shown in figure 6, at a small Deborah number (![]() ${{\textit {De}}}=0.04$). We observe that with the addition of plasticity, jet formation is monotonically suppressed. This is due to the increased apparent viscosity, as discussed in § 3.1.

${{\textit {De}}}=0.04$). We observe that with the addition of plasticity, jet formation is monotonically suppressed. This is due to the increased apparent viscosity, as discussed in § 3.1.

Figure 6. Variation of the dynamics of bubble bursting in an EVP medium with respect to ![]() $\mathcal {J}$ at

$\mathcal {J}$ at ![]() ${{\textit {De}}}=0.04$: (a)

${{\textit {De}}}=0.04$: (a) ![]() $\mathcal {J}=0.01$; (b)

$\mathcal {J}=0.01$; (b) ![]() $\mathcal {J}=0.1$; (c)

$\mathcal {J}=0.1$; (c) ![]() $\mathcal {J}=0.8$. The left-hand part of each subpanel shows the flow topology parameter

$\mathcal {J}=0.8$. The left-hand part of each subpanel shows the flow topology parameter ![]() $\mathcal {Q}$ and the right-hand part of the subpanel shows the trace of elastic stress on a

$\mathcal {Q}$ and the right-hand part of the subpanel shows the trace of elastic stress on a ![]() $\log _{10}$ scale. The yielded regions are marked by a grey line, which corresponds to

$\log _{10}$ scale. The yielded regions are marked by a grey line, which corresponds to ![]() $\mathcal {J}\approxeq \|\boldsymbol {\tau _d}\|$.

$\mathcal {J}\approxeq \|\boldsymbol {\tau _d}\|$.

For a lower ![]() ${{\textit {De}}}$, the elastic stresses relax quickly, and the material behaves as a viscous fluid when the elastic stresses are negligible. Here, for the considered

${{\textit {De}}}$, the elastic stresses relax quickly, and the material behaves as a viscous fluid when the elastic stresses are negligible. Here, for the considered ![]() ${{\textit {De}}}\sim O(0.01)$, the elastocapillary number is higher, indicating that most of the EVP fluid region is yielded and the magnitude of elastic energy is high as observed from figure 6(a–c). Then, for a lower

${{\textit {De}}}\sim O(0.01)$, the elastocapillary number is higher, indicating that most of the EVP fluid region is yielded and the magnitude of elastic energy is high as observed from figure 6(a–c). Then, for a lower ![]() $\mathcal {J}$,

$\mathcal {J}$, ![]() $K \neq 0$ over a significant portion of the EVP fluid, indicating a larger yielded region around the axis of cavity and jet. With an increase in the plasticity of the EVP fluid, the yielded region decreases for a given

$K \neq 0$ over a significant portion of the EVP fluid, indicating a larger yielded region around the axis of cavity and jet. With an increase in the plasticity of the EVP fluid, the yielded region decreases for a given ![]() ${{\textit {De}}}$. However, as mentioned earlier, it is essential to note that the elastic stress also plays a role in influencing the yield criterion

${{\textit {De}}}$. However, as mentioned earlier, it is essential to note that the elastic stress also plays a role in influencing the yield criterion ![]() $K$.

$K$.

Finally, we examine the combination of moderate to considerable plasticity (![]() $\mathcal {J}=1$) and different relaxation time of elastic stresses (see figure 7). The behaviour is qualitatively similar to that observed at

$\mathcal {J}=1$) and different relaxation time of elastic stresses (see figure 7). The behaviour is qualitatively similar to that observed at ![]() $\mathcal {J} = 0.1$. However, at low

$\mathcal {J} = 0.1$. However, at low ![]() ${{\textit {De}}}$ (figure 7a), jet formation is wholly suppressed, indicating that the EVP fluid takes on the characteristics of a viscoplastic fluid. The deformation of the bubble cavity is significantly dampened by both the yielded region (with increased apparent viscosity) and the unyielded region (with high elastic modulus because of high

${{\textit {De}}}$ (figure 7a), jet formation is wholly suppressed, indicating that the EVP fluid takes on the characteristics of a viscoplastic fluid. The deformation of the bubble cavity is significantly dampened by both the yielded region (with increased apparent viscosity) and the unyielded region (with high elastic modulus because of high ![]() $Ec$). For

$Ec$). For ![]() ${{\textit {De}}}\ge 1$, the jet is pronounced due to lower elastic energy than capillary energy (low elastocapillary numbers). Further, for

${{\textit {De}}}\ge 1$, the jet is pronounced due to lower elastic energy than capillary energy (low elastocapillary numbers). Further, for ![]() ${{\textit {De}}}=20$ at

${{\textit {De}}}=20$ at ![]() $t=0.95$ the growth of elastic instability compensated by the surface tension forces in the jet hints at the appearance of bead-in-a-string characteristic. At medium

$t=0.95$ the growth of elastic instability compensated by the surface tension forces in the jet hints at the appearance of bead-in-a-string characteristic. At medium ![]() ${{\textit {De}}}$, however, the elastic stresses and plasticity acts together to broaden and suppress the jet formation. In the forthcoming subsections, we will scrutinize the effect of EVP rheology on each stage of the bubble-bursting process.

${{\textit {De}}}$, however, the elastic stresses and plasticity acts together to broaden and suppress the jet formation. In the forthcoming subsections, we will scrutinize the effect of EVP rheology on each stage of the bubble-bursting process.

Figure 7. Variation of the dynamics of bubble bursting in an EVP medium with respect to ![]() ${{\textit {De}}}$ at

${{\textit {De}}}$ at ![]() $\mathcal {J}=1$: (a)

$\mathcal {J}=1$: (a) ![]() ${{\textit {De}}}=0.01$; (b)

${{\textit {De}}}=0.01$; (b) ![]() ${{\textit {De}}}=16$; (c)