1. Introduction

Debris flows consist of a concentrated mixture of water and rock fragments that range widely in size and tend to segregate during shear (Iverson Reference Iverson1997). Large grains tend to rise to the free surface, while small grains percolate down towards the base (Gray Reference Gray2018). Since the downslope velocity is greatest at the free surface, large rocks and boulders are preferentially transported to the front, where they are overrun by the bulk flow. As finer grained material is sheared over the top of them, these large particles segregate upwards and are eventually transported forwards, towards the front again, by the bulk flow field. In two-dimensional flows (that are sheared through the flow depth), this process leads to the recirculation and accumulation of large grains at the flow front (Gray & Kokelaar Reference Gray and Kokelaar2010). Since the large rock fragments tend to be more resistive to motion than the finer grained material, the front becomes increasingly resistive and the flow can stop. In three-dimensions, this increased frontal resistance can be alleviated by pushing the large particles out of plane, towards the sides of the flow, to form static levees (Sharp & Nobles Reference Sharp and Nobles1953; Costa & Williams Reference Costa and Williams1984; Pierson Reference Pierson1986; Iverson Reference Iverson1997; Major Reference Major1997; Iverson & Vallance Reference Iverson and Vallance2001; Félix & Thomas Reference Félix and Thomas2004; Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012; Laigle & Bardou Reference Laigle and Bardou2022). This process generates a self-channelized flow, with a coarse-grained snout and a more mobile, finer-grained flow in the channel which pushes the front downslope. The central channel is bounded on either side by static large-rich levees, as shown schematically in figure 1.

Figure 1. Schematic diagram showing the different parts of a typical debris-flow surge (reproduced from Laigle & Bardou Reference Laigle and Bardou2022). The flow develops a bouldery snout which is pushed along by the concentrated mixture of water and finer grains behind. There are a wide range of grain sizes within this mixture and larger grains segregate to the surface of the flow. Since the downslope velocity is greatest at the free-surface, there is a continual supply of relatively large fragments to the front, and, rather than accumulating there, these are shouldered aside to form static levees on either side of the central channel. As the flow wanes, the tail of the flow is a less concentrated mixture of finer grains and water that is typically more turbulent. Several surges are generally observed during a single event. The body is longer than appears on the figure (represented by the broken arrow).

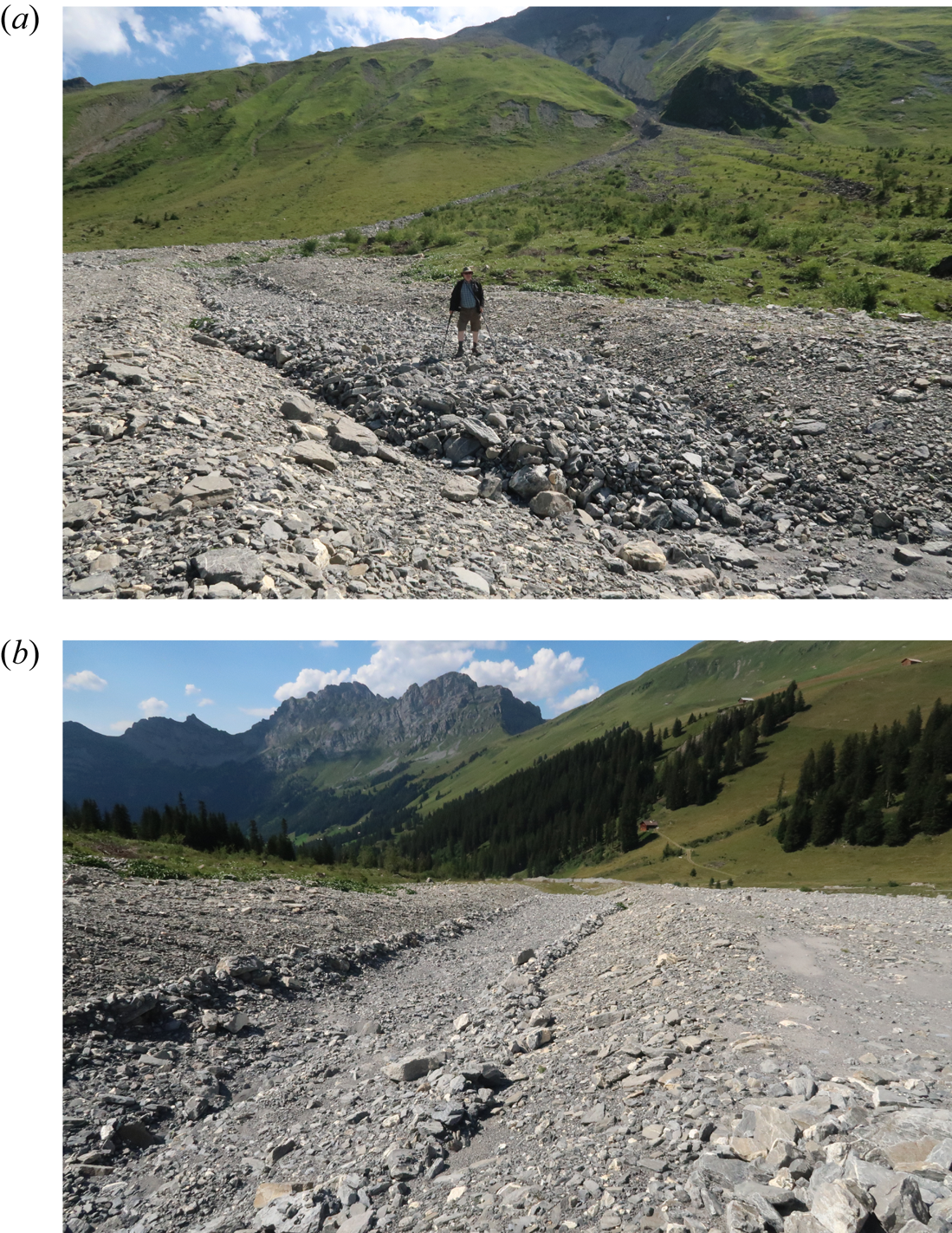

The self-channelization process is important because it prevents lateral spreading, maintaining the flow depth and hence the flow mobility for longer. This can significantly extend the overall run-out distance (Goujon, Dalloz-Dubrujeaud & Thomas Reference Goujon, Dalloz-Dubrujeaud and Thomas2007; Kokelaar et al. Reference Kokelaar, Graham, Gray and Vallance2014). Coarse-fragment-rich debris flows commonly self-channelize as they move on to shallower slopes (Iverson & Vallance Reference Iverson and Vallance2001; Félix & Thomas Reference Félix and Thomas2004; Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012). Figure 2(a) shows an example from the bottom of the Biregrabe on the Albristore, near Färmelberg, Switzerland. There is a coarse-grained snout, as well as parallel-sided levees that are almost entirely composed of similar material. The levees are approximately 4 m apart and extend about 217 m upstream on a ![]() $10^\circ$ slope, to where this small flow was diverted out of the main channel. As the flow waned, the central channel drained almost completely, leaving just the levees as evidence of the debris flow's path (figure 2b). Much larger debris flows occurred in this area on the 20 August 2012 and 24 July 2015, due to melting permafrost and high rainfall (C. Berger, personal communication). The deposits shown in figure 2 are interesting because the snout (which is often washed out by subsequent rainfall) has been almost perfectly preserved. It was deposits such as this and other observations of flowing debris flows that inspired Laigle & Bardou (Reference Laigle and Bardou2022) to draw their schematic diagram shown here in figure 1.

$10^\circ$ slope, to where this small flow was diverted out of the main channel. As the flow waned, the central channel drained almost completely, leaving just the levees as evidence of the debris flow's path (figure 2b). Much larger debris flows occurred in this area on the 20 August 2012 and 24 July 2015, due to melting permafrost and high rainfall (C. Berger, personal communication). The deposits shown in figure 2 are interesting because the snout (which is often washed out by subsequent rainfall) has been almost perfectly preserved. It was deposits such as this and other observations of flowing debris flows that inspired Laigle & Bardou (Reference Laigle and Bardou2022) to draw their schematic diagram shown here in figure 1.

Figure 2. (a) Self-channelized flow front deposited at the bottom of the Biregrabe on the Albristore, near Färmelberg, Switzerland (latitude ![]() $46^\circ 30'43.43"$ N, longitude

$46^\circ 30'43.43"$ N, longitude ![]() $7^\circ 29'40.17"$ E, elevation 1775 m, slope

$7^\circ 29'40.17"$ E, elevation 1775 m, slope ![]() ${\sim }10^\circ$). This area experienced large debris flows on the 20 August 2012 and 24 July 2015 due to melting permafrost and high rainfall (C. Berger, personal communication). This smaller deposit formed between 2017 and 2018. (b) Parallel-sided levees (approximately 4 m apart) left stranded at the side of the central channel as the flow waned.

${\sim }10^\circ$). This area experienced large debris flows on the 20 August 2012 and 24 July 2015 due to melting permafrost and high rainfall (C. Berger, personal communication). This smaller deposit formed between 2017 and 2018. (b) Parallel-sided levees (approximately 4 m apart) left stranded at the side of the central channel as the flow waned.

Self-channelization also occurs in other geophysical mass flows, such as in the dense basal layer of pyroclastic flows, water-saturated lahars and wet snow avalanches (Rowley, Kuntz & MacLeod Reference Rowley, Kuntz and MacLeod1981; Wilson & Head Reference Wilson and Head1981; Branney & Kokelaar Reference Branney and Kokelaar1992; Calder, Sparks & Gardeweg Reference Calder, Sparks and Gardeweg2000; Vallance Reference Vallance2000; Jomelli & Bertran Reference Jomelli and Bertran2001; Jessop et al. Reference Jessop, Kelfoun, Labazuy, Mangeney, Roche and Tillier2012; Ancey Reference Ancey2012; Bartelt et al. Reference Bartelt, Glover, Feistl, Bühler and Buser2012; Schweizer, Bartelt & Van Herwijnen Reference Schweizer, Bartelt and Van Herwijnen2014; Vallance & Iverson Reference Vallance and Iverson2015). Although these flows contain fluid, which helps to mobilize them, self-channelization is not dependent on the presence of the fluid. Kokelaar et al. (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017) identified strongly leveed, fingered rock avalanche deposits in the southeast sector of Bessel crater in Mare Serenitatis on the Moon (see their figure 10). The fronts of these flows came to rest on a ![]() ${\sim }31.5^\circ$ slope, and all of them look remarkably similar to the Biregrabe deposit in figure 2. These flows occurred in the complete absence of water or atmosphere. Interstitial fluids may therefore modify the frictional properties and significantly enhance the flow's mobility (Iverson & George Reference Iverson and George2014; Meng, Johnson & Gray Reference Meng, Johnson and Gray2022), but they are not necessary for a flow to self channelize on a suitably inclined slope.

${\sim }31.5^\circ$ slope, and all of them look remarkably similar to the Biregrabe deposit in figure 2. These flows occurred in the complete absence of water or atmosphere. Interstitial fluids may therefore modify the frictional properties and significantly enhance the flow's mobility (Iverson & George Reference Iverson and George2014; Meng, Johnson & Gray Reference Meng, Johnson and Gray2022), but they are not necessary for a flow to self channelize on a suitably inclined slope.

Félix & Thomas (Reference Félix and Thomas2004) were able to generate leveed channels in small-scale analogue experiments with monodisperse dry grains. This showed that although particle-size segregation commonly occurs (and may be very important), it is not fundamentally necessary to generate a self-channelized flow. The coexistence of layers of static and flowing grains of similar thickness and at the same inclination angle, led Félix & Thomas (Reference Félix and Thomas2004) to suggest that self-channelization was related to frictional hysteresis. Frictional hysteresis (Daerr & Douady Reference Daerr and Douady1999) is responsible for the effect that when a steady uniform flow is brought to rest on a rough bed, a layer of grains of thickness ![]() $h=h_{stop}(\zeta )$ is deposited at a slope angle

$h=h_{stop}(\zeta )$ is deposited at a slope angle ![]() $\zeta$, but this layer does not start to flow again until the chute is inclined to a higher angle

$\zeta$, but this layer does not start to flow again until the chute is inclined to a higher angle ![]() $\zeta _{start}(h)>\zeta$. Pouliquen & Forterre (Reference Pouliquen and Forterre2002) showed how to capture this phenomenon by defining a non-monotonic basal friction law in a depth-averaged avalanche model. This friction law had (i) a multivalued static regime, (ii) a monotonically decreasing intermediate regime and (iii) a monotonically increasing dynamic regime, as a function of Froude number over the flow thickness. This friction law allowed static and flowing states to coexist for thicknesses in the range

$\zeta _{start}(h)>\zeta$. Pouliquen & Forterre (Reference Pouliquen and Forterre2002) showed how to capture this phenomenon by defining a non-monotonic basal friction law in a depth-averaged avalanche model. This friction law had (i) a multivalued static regime, (ii) a monotonically decreasing intermediate regime and (iii) a monotonically increasing dynamic regime, as a function of Froude number over the flow thickness. This friction law allowed static and flowing states to coexist for thicknesses in the range ![]() $h\in [h_{stop}(\zeta ), h_{start}(\zeta )]$, where

$h\in [h_{stop}(\zeta ), h_{start}(\zeta )]$, where ![]() $h_{start}(\zeta )$ is the inverse function of

$h_{start}(\zeta )$ is the inverse function of ![]() $\zeta _{start}(h)$.

$\zeta _{start}(h)$.

Mangeney et al. (Reference Mangeney, Bouchut, Thomas, Vilotte and Bristeau2007) incorporated Pouliquen & Forterre's (Reference Pouliquen and Forterre2002) friction law into a depth-averaged avalanche model, and solved the system of equations numerically to show that it could generate a self-channelized flow with static levees. However, it was unclear what selected the width and height of the ensuing channel, which had multiple steady-state solutions. This contradicted the experimental evidence, which shows that for a given mass flux there is a well-defined channel width and height (Félix & Thomas Reference Félix and Thomas2004; Deboeuf et al. Reference Deboeuf, Lajeunesse, Dauchot and Andreotti2006; Takagi, McElwaine & Huppert Reference Takagi, McElwaine and Huppert2011; Rocha, Johnson & Gray Reference Rocha, Johnson and Gray2019). This conundrum was solved by Rocha et al. (Reference Rocha, Johnson and Gray2019), who incorporated additional depth-averaged in-plane viscous terms (Gray & Edwards Reference Gray and Edwards2014; Baker, Barker & Gray Reference Baker, Barker and Gray2016a), which generate a downslope velocity profile across the central channel. This provides the missing length scale that selects the steady-state flow height and the channel width. Rocha et al. (Reference Rocha, Johnson and Gray2019) showed that the resulting model was able to quantitatively capture experimental measurements of flow height and channel width as a function of the mass flux for quasi-monodisperse (![]() $0.45\pm 0.15$ mm) dry sand (Félix & Thomas Reference Félix and Thomas2004; Takagi et al. Reference Takagi, McElwaine and Huppert2011). Moreover, at low mass fluxes, Rocha et al. (Reference Rocha, Johnson and Gray2019) also correctly showed that self-channelized flows become unstable, and break down into a series of ‘erosion–deposition’ waves (Takagi et al. Reference Takagi, McElwaine and Huppert2011; Edwards & Gray Reference Edwards and Gray2015; Edwards et al. Reference Edwards, Viroulet, Kokelaar and Gray2017, Reference Edwards, Russell, Johnson and Gray2019). Similar surge waves that progressively erode and deposit previously fluidized material along their path are also commonly observed in debris flows (McArdell Reference McArdell2016).

$0.45\pm 0.15$ mm) dry sand (Félix & Thomas Reference Félix and Thomas2004; Takagi et al. Reference Takagi, McElwaine and Huppert2011). Moreover, at low mass fluxes, Rocha et al. (Reference Rocha, Johnson and Gray2019) also correctly showed that self-channelized flows become unstable, and break down into a series of ‘erosion–deposition’ waves (Takagi et al. Reference Takagi, McElwaine and Huppert2011; Edwards & Gray Reference Edwards and Gray2015; Edwards et al. Reference Edwards, Viroulet, Kokelaar and Gray2017, Reference Edwards, Russell, Johnson and Gray2019). Similar surge waves that progressively erode and deposit previously fluidized material along their path are also commonly observed in debris flows (McArdell Reference McArdell2016).

The dynamic part of the non-monotonic friction law is intimately linked to the ![]() $\mu (I)$ rheology for dry granular flows (GDR-Midi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005, Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014; Baker et al. Reference Baker, Barker and Gray2016a). Rather than having a constant Coulomb friction, the

$\mu (I)$ rheology for dry granular flows (GDR-Midi 2004; Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2005, Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014; Baker et al. Reference Baker, Barker and Gray2016a). Rather than having a constant Coulomb friction, the ![]() $\mu (I)$ rheology introduces rate dependence by making the friction

$\mu (I)$ rheology introduces rate dependence by making the friction ![]() $\mu$ a function of the inertial number

$\mu$ a function of the inertial number

where ![]() $\dot {\gamma }$ is the shear rate,

$\dot {\gamma }$ is the shear rate, ![]() $d$ is the particle diameter,

$d$ is the particle diameter, ![]() $p$ is the granular pressure and

$p$ is the granular pressure and ![]() $\rho _*$ is the intrinsic density of the grains. This has spawned intense interest in the rheology of dry granular flows, as it provides a promising way of modelling chute flows, column collapses, silos and flows in rotating drums (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006; Lagrée, Staron & Popinet Reference Lagrée, Staron and Popinet2011; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2012; Barker et al. Reference Barker, Schaeffer, Bohórquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). The

$\rho _*$ is the intrinsic density of the grains. This has spawned intense interest in the rheology of dry granular flows, as it provides a promising way of modelling chute flows, column collapses, silos and flows in rotating drums (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006; Lagrée, Staron & Popinet Reference Lagrée, Staron and Popinet2011; Staron, Lagrée & Popinet Reference Staron, Lagrée and Popinet2012; Barker et al. Reference Barker, Schaeffer, Bohórquez and Gray2015; Barker & Gray Reference Barker and Gray2017; Martin et al. Reference Martin, Ionescu, Mangeney, Bouchut and Farin2017; Schaeffer et al. Reference Schaeffer, Barker, Tsuji, Gremaud, Shearer and Gray2019; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). The ![]() $\mu (I)$ rheology does not, however, capture the formation of

$\mu (I)$ rheology does not, however, capture the formation of ![]() $h_{stop}$ or

$h_{stop}$ or ![]() $h_{start}$ layers. This phenomenology appears to be a non-local effect in which the ability of grains to flow, or not, is affected by motion some distance away (Schall & Van Hecke Reference Schall and Van Hecke2010). In the case of

$h_{start}$ layers. This phenomenology appears to be a non-local effect in which the ability of grains to flow, or not, is affected by motion some distance away (Schall & Van Hecke Reference Schall and Van Hecke2010). In the case of ![]() $h_{stop}$ and

$h_{stop}$ and ![]() $h_{start}$ layers, it is the proximity of the fixed basal boundary to the free surface that has a strong effect on the ability of the grains to remain stable. An alternative approach (to the depth-averaged one used in this paper) is therefore to use one of the non-local models for granular flow (Pouliquen & Forterre Reference Pouliquen and Forterre2009; Kamrin & Koval Reference Kamrin and Koval2012; Bouzid et al. Reference Bouzid, Trulsson, Claudin, Clément and Andreotti2013, Reference Bouzid, Izzet, Trulsson, Clément, Claudin and Andreotti2015; Kamrin & Henann Reference Kamrin and Henann2015). In particular, Mowlavi & Kamrin (Reference Mowlavi and Kamrin2021) have recently captured both the

$h_{start}$ layers, it is the proximity of the fixed basal boundary to the free surface that has a strong effect on the ability of the grains to remain stable. An alternative approach (to the depth-averaged one used in this paper) is therefore to use one of the non-local models for granular flow (Pouliquen & Forterre Reference Pouliquen and Forterre2009; Kamrin & Koval Reference Kamrin and Koval2012; Bouzid et al. Reference Bouzid, Trulsson, Claudin, Clément and Andreotti2013, Reference Bouzid, Izzet, Trulsson, Clément, Claudin and Andreotti2015; Kamrin & Henann Reference Kamrin and Henann2015). In particular, Mowlavi & Kamrin (Reference Mowlavi and Kamrin2021) have recently captured both the ![]() $h_{stop}$,

$h_{stop}$, ![]() $h_{start}$ phenomenology in one-dimensional time-dependent simulations with a non-local model that includes hysteresis. Applying such models in three dimensions to capture self-channelization and levee formation remains, however, a significant challenge for the future.

$h_{start}$ phenomenology in one-dimensional time-dependent simulations with a non-local model that includes hysteresis. Applying such models in three dimensions to capture self-channelization and levee formation remains, however, a significant challenge for the future.

If the relatively simple monodisperse depth-averaged model of Rocha et al. (Reference Rocha, Johnson and Gray2019) can quantitatively capture the self-channelization process, one may reasonably ask: (i) what is the role of particle segregation and (ii) does the small-scale experimental evidence have any bearing on large-scale geophysical flows? Interestingly, the strongly leveed, fingered rock avalanche deposits that Kokelaar et al. (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017) identified in the Bessel crater, look almost identical to small-scale segregation induced fingering experiments of Pouliquen, Delour & Savage (Reference Pouliquen, Delour and Savage1997), Woodhouse et al. (Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012) and Baker, Johnson & Gray (Reference Baker, Johnson and Gray2016b). This led Kokelaar et al. (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017) to develop a scaling argument to show that the depth-averaged system of equations used by Baker et al. (Reference Baker, Johnson and Gray2016b) (which is similar to the model of Rocha et al. (Reference Rocha, Johnson and Gray2019), but includes the depth-averaged effect of segregation) scales with gravity ![]() $g$ and a typical grain diameter

$g$ and a typical grain diameter ![]() $d$. Large-scale segregating bouldery dry flows on the Moon are therefore closely similar to small-scale dry flows with millimetre-sized particles on Earth.

$d$. Large-scale segregating bouldery dry flows on the Moon are therefore closely similar to small-scale dry flows with millimetre-sized particles on Earth.

In geophysical flows, the range of particle sizes is very wide, with particle diameters varying by several orders of magnitude. This allows particles to pack much more densely than monodisperse flows even during shear, which reduces the rate of segregation, and can lead to intermediate and reverse segregation for very large intruders (Thomas Reference Thomas2000). Such effects not only introduce bulk compressibility, but are still well beyond the scope of current granular rheologies and polydisperse particle-size segregation models (Gray & Ancey Reference Gray and Ancey2011; Marks, Rognon & Einav Reference Marks, Rognon and Einav2012; Gray Reference Gray2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021). Indeed, until recently the segregation and diffusion rates in bidisperse segregation models (even with relatively small grains-size ratios) were poorly constrained (Golick & Daniels Reference Golick and Daniels2009; Thornton et al. Reference Thornton, Weinhart, Luding and Bokhove2012; Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Hill & Tan Reference Hill and Tan2014; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019). As one of the first papers to investigate particle segregation in a non-trivial three-dimensional flow field, this paper uses a simple bidisperse model with the empirical segregation law of Trewhela, Ancey & Gray (Reference Trewhela, Ancey and Gray2021). Trewhela et al. (Reference Trewhela, Ancey and Gray2021) used refractive-index-matched shear-box experiments to track the segregation of large and small intruders as a function of time, and determined a scaling law that could collapse all their data. For grain-size ratios close to unity, they found that the segregation velocity magnitude is linearly dependent on the shear rate, the intrinsic particle density, the gravitational acceleration, the square of the average grain diameter and the deviation of the grain-size ratio away from unity, and inversely proportional to the pressure. Additional corrections, which are necessary at moderate grain-size ratios when the percolation of small intruders can be enhanced due to the spontaneous percolation, are ignored here, as are enhanced packing effects at large size ratios.

The inclusion of interstitial fluid also introduces additional complexity. For example, differentially fluidized regions of the flow will produce differential friction, which provides another mechanism to generate self-channelization without invoking frictional hysteresis. In particular, drier coarse-grained flow fronts and lateral levees will experience more friction than the fluid-saturated channel (Sharp & Nobles Reference Sharp and Nobles1953; Wilson & Head Reference Wilson and Head1981; Costa & Williams Reference Costa and Williams1984; Iverson & Vallance Reference Iverson and Vallance2001; Iverson Reference Iverson2003). This inhomogeneous rheology may well prove to be crucial at geophysical scale. In general, mixtures of grains and water can form suspensions whose friction ![]() $\mu =\mu (J)$ is dependent on the viscous inertial number

$\mu =\mu (J)$ is dependent on the viscous inertial number ![]() $J=\eta _f\dot {\gamma }/p^p$, where

$J=\eta _f\dot {\gamma }/p^p$, where ![]() $\eta _f$ is the fluid viscosity and

$\eta _f$ is the fluid viscosity and ![]() $p^p$ is the particle pressure (Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011). This constitutive law is valid for slow flows or small non-colloidal particles. As the shear rate is increased, the flow can transition from viscous inertial to granular inertial regimes with the friction

$p^p$ is the particle pressure (Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011). This constitutive law is valid for slow flows or small non-colloidal particles. As the shear rate is increased, the flow can transition from viscous inertial to granular inertial regimes with the friction ![]() $\mu =\mu (K)$, where

$\mu =\mu (K)$, where ![]() $K=J+\alpha I^2$ is a combination of the viscous and granular inertial numbers and

$K=J+\alpha I^2$ is a combination of the viscous and granular inertial numbers and ![]() $\alpha$ is a constant, approximately equal to

$\alpha$ is a constant, approximately equal to ![]() $0.1$ (Tapia et al. Reference Tapia, Ichihara, Pouliquen and Guazzelli2022). The ratio

$0.1$ (Tapia et al. Reference Tapia, Ichihara, Pouliquen and Guazzelli2022). The ratio ![]() $I^2/J=\rho _*d^2\dot {\gamma }/\eta _f$ defines a Stokes number

$I^2/J=\rho _*d^2\dot {\gamma }/\eta _f$ defines a Stokes number ![]() $St$, which is particle-size dependent, and governs the extent to which the particles are affected by the fluid. If

$St$, which is particle-size dependent, and governs the extent to which the particles are affected by the fluid. If ![]() $St\gg 1/\alpha$, then the particles are affected by fluid buoyancy, but do not closely follow fluid streamlines and in dense flows, they are in the inertial granular regime (Maurin, Chauchat & Frey Reference Maurin, Chauchat and Frey2016). Particles with

$St\gg 1/\alpha$, then the particles are affected by fluid buoyancy, but do not closely follow fluid streamlines and in dense flows, they are in the inertial granular regime (Maurin, Chauchat & Frey Reference Maurin, Chauchat and Frey2016). Particles with ![]() $St\ll 1/\alpha$ are strongly affected by the fluid and are in the viscous inertial regime. For debris flows, where there is a wide range of grain sizes, it is likely that the rocks and coarse-grained sand are in the inertial granular regime, while the very finest grains will be in the viscous inertial regime. The implicit assumption in this paper is that the larger grains dominate the overall debris-flow response, and hence the

$St\ll 1/\alpha$ are strongly affected by the fluid and are in the viscous inertial regime. For debris flows, where there is a wide range of grain sizes, it is likely that the rocks and coarse-grained sand are in the inertial granular regime, while the very finest grains will be in the viscous inertial regime. The implicit assumption in this paper is that the larger grains dominate the overall debris-flow response, and hence the ![]() $\mu (I)$ rheology is most appropriate (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014).

$\mu (I)$ rheology is most appropriate (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014).

In depth-averaged two-phase-flow models, the primary effect of the fluid is the buoyancy-induced reduction in the granular friction, which may additionally be enhanced by excess pore-pressure effects (Iverson & Denlinger Reference Iverson and Denlinger2001; Pitman & Le Reference Pitman and Le2005; Pelanti, Bouchut & Mangeney Reference Pelanti, Bouchut and Mangeney2008; Pudasaini Reference Pudasaini2012; Iverson & George Reference Iverson and George2014; Meng & Wang Reference Meng and Wang2016; Meng et al. Reference Meng, Johnson and Gray2022). These allow debris flows to propagate over much shallower slopes than dry granular materials, as in the debris flow at Färmelberg (figure 2). However, on these shallower slopes, the resulting flow dynamics and observed deposit morphologies are closely similar to the dry small-scale experiments (Sharp & Nobles Reference Sharp and Nobles1953; Wilson & Head Reference Wilson and Head1981; Costa & Williams Reference Costa and Williams1984; Branney & Kokelaar Reference Branney and Kokelaar1992; Iverson Reference Iverson1997; Major Reference Major1997; Major & Iverson Reference Major and Iverson1999; Calder et al. Reference Calder, Sparks and Gardeweg2000; Iverson & Vallance Reference Iverson and Vallance2001; Iverson Reference Iverson2003; Félix & Thomas Reference Félix and Thomas2004; Iverson et al. Reference Iverson, Logan, LaHusen and Berti2010; Takagi et al. Reference Takagi, McElwaine and Huppert2011; Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012; Kokelaar et al. Reference Kokelaar, Graham, Gray and Vallance2014; Rocha et al. Reference Rocha, Johnson and Gray2019).

The aim of this paper is to study the segregation in a representative three-dimensional self-channelizing flow field (Rocha et al. Reference Rocha, Johnson and Gray2019). A specific example is chosen which scales up (Kokelaar et al. Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017) to look qualitatively similar to the large-scale experimental debris flows at the United States Geological Survey (USGS) flume (Iverson et al. Reference Iverson, Logan, LaHusen and Berti2010; Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012). This flow field therefore provides a generic test case. In § 2, the depth-averaged theory of Rocha et al. (Reference Rocha, Johnson and Gray2019) is introduced, and this is used in § 3 to compute a two-dimensional travelling wave solution for the process of self-channelization. In § 4, incompressibility and assumed velocity profiles are used to reconstruct a realistic flow field for self-channelization in three dimensions. This flow field is then held fixed for the remainder of the paper.

Our study is motivated by the USGS debris-flow experiments (Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012) and the experiments of Kokelaar et al. (Reference Kokelaar, Graham, Gray and Vallance2014), which both had quite tightly constrained particle-size distributions. In the bidisperse small-scale experiments, Kokelaar et al. (Reference Kokelaar, Graham, Gray and Vallance2014) used mixtures of glass ballotini and carborundum, and glass ballotini and sand, with size ratios of approximately 1.81 and 1.63, respectively. The flume experiments had a more realistic continuous grain-size distribution ranging from ![]() $100\ \mathrm {\mu }{\rm m}$ to 32 mm, but the most pronounced segregation occurred between grains of modest size ratio (

$100\ \mathrm {\mu }{\rm m}$ to 32 mm, but the most pronounced segregation occurred between grains of modest size ratio (![]() ${<}5$). Kokelaar et al. (Reference Kokelaar, Graham, Gray and Vallance2014) used a resin impregnation and sectioning technique to reveal the internal particle-size distribution within the levees and the central channel. The levees were not entirely composed of large grains, as one might anticipate from surface observations, but had an inner core of fine grains. Fine grains also line the inside of the channel. Experimental measurements of the run-out distance as a function of flow composition led Kokelaar et al. (Reference Kokelaar, Graham, Gray and Vallance2014) to infer that it was the formation of levees and a fine particle channel lining that led to the maximum run out with 60–70 % fines. This was first because the

${<}5$). Kokelaar et al. (Reference Kokelaar, Graham, Gray and Vallance2014) used a resin impregnation and sectioning technique to reveal the internal particle-size distribution within the levees and the central channel. The levees were not entirely composed of large grains, as one might anticipate from surface observations, but had an inner core of fine grains. Fine grains also line the inside of the channel. Experimental measurements of the run-out distance as a function of flow composition led Kokelaar et al. (Reference Kokelaar, Graham, Gray and Vallance2014) to infer that it was the formation of levees and a fine particle channel lining that led to the maximum run out with 60–70 % fines. This was first because the ![]() $\mu (I)$ rheology implies that a finer-grained flow experiences less friction (for grains of the same shape), and can flow further and faster, than a larger grained flow of the same depth (GDR-Midi 2004; Rognon et al. Reference Rognon, Roux, Naaim and Chevoir2007; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021), and second because lateral confinement maintains flow depth, and hence mobility, for longer. Flows of pure fine grains at the same slope angle do not self-channelize, instead spreading laterally and stopping more rapidly (Kokelaar et al. Reference Kokelaar, Graham, Gray and Vallance2014). In debris flows and pyroclastic flows, fine grains additionally hinder the escape of water and gas, and thereby help to maintain high pore pressures, which also convey mobility to the flow (Iverson Reference Iverson2003). The particle-size distribution can therefore have a profound effect on the bulk flow behaviour, and this paper seeks to understand how it develops in the three-dimensional self-channelizing flow field developed in § 4. In § 5, a state-of-the-art particle segregation model (Gray Reference Gray2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021) is introduced that uses Trewhela et al.'s (Reference Trewhela, Ancey and Gray2021) empirical segregation law. Fully three-dimensional, time-dependent, numerical solutions for the particle-size distribution in the vicinity of the moving front are then computed in § 6. The dependence on the grain-size ratio and the inflow concentration are investigated in § 7, and § 8 concludes.

$\mu (I)$ rheology implies that a finer-grained flow experiences less friction (for grains of the same shape), and can flow further and faster, than a larger grained flow of the same depth (GDR-Midi 2004; Rognon et al. Reference Rognon, Roux, Naaim and Chevoir2007; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021), and second because lateral confinement maintains flow depth, and hence mobility, for longer. Flows of pure fine grains at the same slope angle do not self-channelize, instead spreading laterally and stopping more rapidly (Kokelaar et al. Reference Kokelaar, Graham, Gray and Vallance2014). In debris flows and pyroclastic flows, fine grains additionally hinder the escape of water and gas, and thereby help to maintain high pore pressures, which also convey mobility to the flow (Iverson Reference Iverson2003). The particle-size distribution can therefore have a profound effect on the bulk flow behaviour, and this paper seeks to understand how it develops in the three-dimensional self-channelizing flow field developed in § 4. In § 5, a state-of-the-art particle segregation model (Gray Reference Gray2018; Barker et al. Reference Barker, Rauter, Maguire, Johnson and Gray2021) is introduced that uses Trewhela et al.'s (Reference Trewhela, Ancey and Gray2021) empirical segregation law. Fully three-dimensional, time-dependent, numerical solutions for the particle-size distribution in the vicinity of the moving front are then computed in § 6. The dependence on the grain-size ratio and the inflow concentration are investigated in § 7, and § 8 concludes.

2. Depth-averaged model for self-channelization

2.1. Governing equations

Granular material is supplied from a point source onto a rough plane that is inclined at an angle ![]() $\zeta$ to the horizontal. A Cartesian coordinate system

$\zeta$ to the horizontal. A Cartesian coordinate system ![]() $Oxyz$ is defined with the origin

$Oxyz$ is defined with the origin ![]() $O$ located at the top centre of the plane. The

$O$ located at the top centre of the plane. The ![]() $x$-axis points downslope, the

$x$-axis points downslope, the ![]() $y$-axis points across the slope and the

$y$-axis points across the slope and the ![]() $z$-axis is the upward pointing normal. The unit normals are

$z$-axis is the upward pointing normal. The unit normals are ![]() $\boldsymbol {e}_x$,

$\boldsymbol {e}_x$, ![]() $\boldsymbol {e}_y$ and

$\boldsymbol {e}_y$ and ![]() $\boldsymbol {e}_z$, and the velocity

$\boldsymbol {e}_z$, and the velocity ![]() $\boldsymbol {u}$ has components

$\boldsymbol {u}$ has components ![]() $(u,v,w)$ in each of these three directions, respectively. The equations are integrated through the flow depth

$(u,v,w)$ in each of these three directions, respectively. The equations are integrated through the flow depth ![]() $h$, measured normal to the plane, and the depth-averaged velocity

$h$, measured normal to the plane, and the depth-averaged velocity ![]() $\bar {\boldsymbol {u}}$ has components

$\bar {\boldsymbol {u}}$ has components

in the downslope and cross-slope directions, respectively. The granular material is assumed to be incompressible with a constant-uniform bulk density ![]() $\rho$. It follows that the depth-averaged mass and momentum balance equations (Gray & Edwards Reference Gray and Edwards2014; Baker et al. Reference Baker, Barker and Gray2016a; Edwards et al. Reference Edwards, Viroulet, Kokelaar and Gray2017) are

$\rho$. It follows that the depth-averaged mass and momentum balance equations (Gray & Edwards Reference Gray and Edwards2014; Baker et al. Reference Baker, Barker and Gray2016a; Edwards et al. Reference Edwards, Viroulet, Kokelaar and Gray2017) are

where ![]() $\otimes$ is the dyadic product and

$\otimes$ is the dyadic product and ![]() $g$ is the constant of gravitational acceleration. Note that the two-dimensional divergence and gradient operators,

$g$ is the constant of gravitational acceleration. Note that the two-dimensional divergence and gradient operators, ![]() $\hbox {div}$ and

$\hbox {div}$ and ![]() $\hbox {grad}$, are used here to distinguish them from their three-dimensional counterparts, which are written in terms of the

$\hbox {grad}$, are used here to distinguish them from their three-dimensional counterparts, which are written in terms of the ![]() $\boldsymbol {\nabla }$ operator in § 5. In the source term on the right-hand side of (2.3), the non-dimensional net acceleration,

$\boldsymbol {\nabla }$ operator in § 5. In the source term on the right-hand side of (2.3), the non-dimensional net acceleration,

consists of the component of gravity pulling the avalanche downslope along the direction of the unit vector ![]() $\boldsymbol {e}_x$ and the effective basal friction

$\boldsymbol {e}_x$ and the effective basal friction ![]() $\mu _b$. The hysteretic effective basal friction law for

$\mu _b$. The hysteretic effective basal friction law for ![]() $\mu _b$ is introduced in § 2.2. It is a generalization of Pouliquen's (Reference Pouliquen1999a) dynamic friction law, which is directly linked to the

$\mu _b$ is introduced in § 2.2. It is a generalization of Pouliquen's (Reference Pouliquen1999a) dynamic friction law, which is directly linked to the ![]() $\mu (I)$ rheology for granular flows (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2005, Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014; Baker et al. Reference Baker, Barker and Gray2016a). If the avalanche is in motion, the direction of the friction,

$\mu (I)$ rheology for granular flows (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2005, Reference Jop, Forterre and Pouliquen2006; Gray & Edwards Reference Gray and Edwards2014; Baker et al. Reference Baker, Barker and Gray2016a). If the avalanche is in motion, the direction of the friction, ![]() $\boldsymbol {e}$, opposes the motion, and when the grains are static, the friction opposes the downslope component of gravitational acceleration and the depth-averaged pressure gradient, which implies that

$\boldsymbol {e}$, opposes the motion, and when the grains are static, the friction opposes the downslope component of gravitational acceleration and the depth-averaged pressure gradient, which implies that

\begin{equation} \boldsymbol{e} = \begin{cases} \dfrac{\bar{\boldsymbol{u}}}{|\bar{\boldsymbol{u}}|} & \text{if $|\bar{\boldsymbol{u}}|>0$},\\[10pt] \dfrac{\tan\zeta\,\boldsymbol{e}_x-\hbox{grad}\,h}{|\tan\zeta\,\boldsymbol{e}_x-\hbox{grad}\,h|} & \text{if $|\bar{\boldsymbol{u}}|=0$}. \end{cases} \end{equation}

\begin{equation} \boldsymbol{e} = \begin{cases} \dfrac{\bar{\boldsymbol{u}}}{|\bar{\boldsymbol{u}}|} & \text{if $|\bar{\boldsymbol{u}}|>0$},\\[10pt] \dfrac{\tan\zeta\,\boldsymbol{e}_x-\hbox{grad}\,h}{|\tan\zeta\,\boldsymbol{e}_x-\hbox{grad}\,h|} & \text{if $|\bar{\boldsymbol{u}}|=0$}. \end{cases} \end{equation}

The final term on the right-hand side of (2.3) arises from the inclusion of depth-averaged in-plane deviatoric stresses, which are neglected in most theories. Here, however, they play a crucial role in selecting a unique solution for the steady-state channel width and height. Gray & Edwards (Reference Gray and Edwards2014) and Baker et al. (Reference Baker, Barker and Gray2016a) derived the specific form for this second-order-gradient depth-averaged viscous term from the ![]() $\mu (I)$ rheology. It consists of a depth-averaged viscosity

$\mu (I)$ rheology. It consists of a depth-averaged viscosity ![]() $\nu h^{1/2}/2$ that multiplies the depth-integrated strain-rate tensor

$\nu h^{1/2}/2$ that multiplies the depth-integrated strain-rate tensor

where ![]() $\bar {\boldsymbol {L}}=\hbox {grad}\,\bar {\boldsymbol {u}}$ is the two-dimensional gradient of the depth-averaged velocity. The coefficient

$\bar {\boldsymbol {L}}=\hbox {grad}\,\bar {\boldsymbol {u}}$ is the two-dimensional gradient of the depth-averaged velocity. The coefficient ![]() $\nu$ is determined from the

$\nu$ is determined from the ![]() $\mu (I)$ friction law (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) and an explicit formula will be given for it in § 2.3.

$\mu (I)$ friction law (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006) and an explicit formula will be given for it in § 2.3.

2.2. The hysteretic friction law

This paper uses the hysteretic friction law of Edwards et al. (Reference Edwards, Russell, Johnson and Gray2019), which is a generalization of Pouliquen & Forterre's (Reference Pouliquen and Forterre2002) original law. It consists of three cases that are known as the dynamic, intermediate and static friction regimes

\begin{equation}

\mu_b(h/d,Fr)=\left\{ \begin{array}{@{}ll@{}} \mu_{D}, & Fr

\geqslant \beta_*, \\ \mu_{I}, & 0 < Fr \leqslant

\beta_*,\\ \mu_{S}, & Fr=0. \end{array}\right.

\end{equation}

\begin{equation}

\mu_b(h/d,Fr)=\left\{ \begin{array}{@{}ll@{}} \mu_{D}, & Fr

\geqslant \beta_*, \\ \mu_{I}, & 0 < Fr \leqslant

\beta_*,\\ \mu_{S}, & Fr=0. \end{array}\right.

\end{equation}These regimes are defined respectively by the functions

where ![]() $\mu _1=\tan \zeta _1$,

$\mu _1=\tan \zeta _1$, ![]() $\mu _2=\tan \zeta _2$ and

$\mu _2=\tan \zeta _2$ and ![]() $\mu _3=\tan \zeta _3$ are the tangents of the friction angles

$\mu _3=\tan \zeta _3$ are the tangents of the friction angles ![]() $\zeta _1$,

$\zeta _1$, ![]() $\zeta _2$ and

$\zeta _2$ and ![]() $\zeta _3$. These parameters are determined from experimental fits to the deposit depth

$\zeta _3$. These parameters are determined from experimental fits to the deposit depth ![]() $h_{stop}(\zeta )$ and initiation thickness

$h_{stop}(\zeta )$ and initiation thickness ![]() $h_{start}(\zeta )$ as a function of

$h_{start}(\zeta )$ as a function of ![]() $\zeta$. The fitting functions contain a frictional length scale

$\zeta$. The fitting functions contain a frictional length scale ![]() $\mathscr {L}$, which Forterre & Pouliquen (Reference Forterre and Pouliquen2003) showed scales with the grain size

$\mathscr {L}$, which Forterre & Pouliquen (Reference Forterre and Pouliquen2003) showed scales with the grain size ![]() $d$. This grain-size dependence has explicitly been included in (2.8)–(2.10) by defining the non-dimensional friction length scale

$d$. This grain-size dependence has explicitly been included in (2.8)–(2.10) by defining the non-dimensional friction length scale ![]() $\mathcal {L}=\mathscr {L}/d$. The regime boundaries are determined by the Froude number

$\mathcal {L}=\mathscr {L}/d$. The regime boundaries are determined by the Froude number ![]() $Fr$, which is the ratio of the flow speed to the gravity wave speed

$Fr$, which is the ratio of the flow speed to the gravity wave speed

If ![]() $Fr$ is above the minimum Froude number

$Fr$ is above the minimum Froude number ![]() $\beta _*$ for steady-uniform flow, then the flow is in the dynamic regime, if the Froude number equals zero, it is in the static regime and if

$\beta _*$ for steady-uniform flow, then the flow is in the dynamic regime, if the Froude number equals zero, it is in the static regime and if ![]() $Fr\in (0,\beta _*)$, then it is in the intermediate regime. The remaining non-dimensional constants

$Fr\in (0,\beta _*)$, then it is in the intermediate regime. The remaining non-dimensional constants ![]() $\beta$ and

$\beta$ and ![]() $\varGamma$ are determined from a pair of best fits to the steady-uniform-flow law for angular particles (Forterre & Pouliquen Reference Forterre and Pouliquen2003)

$\varGamma$ are determined from a pair of best fits to the steady-uniform-flow law for angular particles (Forterre & Pouliquen Reference Forterre and Pouliquen2003)

Edwards et al. (Reference Edwards, Russell, Johnson and Gray2019) assumed that the minimum observable steady-uniform flow occurs at the same Froude number ![]() $Fr=\beta _*$ at all slope angles. It follows from (2.12) that the minimum steady-uniform-flow depth

$Fr=\beta _*$ at all slope angles. It follows from (2.12) that the minimum steady-uniform-flow depth

which implies that ![]() $h_*$ is a multiple of

$h_*$ is a multiple of ![]() $h_{stop}$. The frictional parameters must be chosen so that

$h_{stop}$. The frictional parameters must be chosen so that ![]() $h_{stop}< h_*< h_{start}$ for the hysteretic friction law to be well defined. A necessary, but not sufficient condition is that

$h_{stop}< h_*< h_{start}$ for the hysteretic friction law to be well defined. A necessary, but not sufficient condition is that ![]() $\mu _1<\mu _3<\mu _2$. This paper adopts the parameters for sand used by Rocha et al. (Reference Rocha, Johnson and Gray2019), except for

$\mu _1<\mu _3<\mu _2$. This paper adopts the parameters for sand used by Rocha et al. (Reference Rocha, Johnson and Gray2019), except for ![]() $\zeta _3$, which is increased from

$\zeta _3$, which is increased from ![]() $31^\circ$ to

$31^\circ$ to ![]() $33^\circ$. This increases the maximum static friction and hence the thickness range

$33^\circ$. This increases the maximum static friction and hence the thickness range ![]() $(h\in [h_{stop},h_{start}])$ with coexisting flowing and static states. Increasing

$(h\in [h_{stop},h_{start}])$ with coexisting flowing and static states. Increasing ![]() $\mu _3$ gives the levees slightly greater stability than in the simulations of Rocha et al. (Reference Rocha, Johnson and Gray2019), which suppresses the periodically upslope propagating erosion-deposition waves seen in their movie 5. All the parameters (see table 1) are tightly constrained by existing experiments in the literature and are typical of those for sand flowing on a bed of glass beads. Rocha et al. (Reference Rocha, Johnson and Gray2019) also gave parameters for flows of glass beads, which also form levees even though

$\mu _3$ gives the levees slightly greater stability than in the simulations of Rocha et al. (Reference Rocha, Johnson and Gray2019), which suppresses the periodically upslope propagating erosion-deposition waves seen in their movie 5. All the parameters (see table 1) are tightly constrained by existing experiments in the literature and are typical of those for sand flowing on a bed of glass beads. Rocha et al. (Reference Rocha, Johnson and Gray2019) also gave parameters for flows of glass beads, which also form levees even though ![]() $\varGamma =0$ (Félix & Thomas Reference Félix and Thomas2004). The values of

$\varGamma =0$ (Félix & Thomas Reference Félix and Thomas2004). The values of ![]() $\mu _1$ and

$\mu _1$ and ![]() $\mu _3$ are, however, very close to one another, which leads to weak non-monotonic dependence of the friction

$\mu _3$ are, however, very close to one another, which leads to weak non-monotonic dependence of the friction ![]() $\mu$ on the Froude number

$\mu$ on the Froude number ![]() $Fr$, as shown in figure 6(b) of Rocha et al. (Reference Rocha, Johnson and Gray2019). This leads to very weak levees. Indeed, Deboeuf et al. (Reference Deboeuf, Lajeunesse, Dauchot and Andreotti2006) have observed experimentally that levees of glass beads slowly creep outwards over very long periods of time, which is not the case for sand.

$Fr$, as shown in figure 6(b) of Rocha et al. (Reference Rocha, Johnson and Gray2019). This leads to very weak levees. Indeed, Deboeuf et al. (Reference Deboeuf, Lajeunesse, Dauchot and Andreotti2006) have observed experimentally that levees of glass beads slowly creep outwards over very long periods of time, which is not the case for sand.

Table 1. Material properties for flows of sand with a mean diameter of ![]() $0.45$ mm. The values of

$0.45$ mm. The values of ![]() $\zeta _1$,

$\zeta _1$, ![]() $\zeta _2$ and

$\zeta _2$ and ![]() $\mathcal {L}$ were calculated from the

$\mathcal {L}$ were calculated from the ![]() $h_{stop}$ curve of Takagi et al. (Reference Takagi, McElwaine and Huppert2011) by Rocha et al. (Reference Rocha, Johnson and Gray2019). The values of

$h_{stop}$ curve of Takagi et al. (Reference Takagi, McElwaine and Huppert2011) by Rocha et al. (Reference Rocha, Johnson and Gray2019). The values of ![]() $\beta$ and

$\beta$ and ![]() $\varGamma$ differ from those in Pouliquen & Forterre (Reference Pouliquen and Forterre2002) and Forterre & Pouliquen (Reference Forterre and Pouliquen2003) to account for the factor

$\varGamma$ differ from those in Pouliquen & Forterre (Reference Pouliquen and Forterre2002) and Forterre & Pouliquen (Reference Forterre and Pouliquen2003) to account for the factor ![]() $\sqrt {\cos \zeta }$ in the Froude number (2.11). All the values are the same as those used by Rocha et al. (Reference Rocha, Johnson and Gray2019) except for

$\sqrt {\cos \zeta }$ in the Froude number (2.11). All the values are the same as those used by Rocha et al. (Reference Rocha, Johnson and Gray2019) except for ![]() $\zeta _3$, which is increased from

$\zeta _3$, which is increased from ![]() $31^\circ$ to

$31^\circ$ to ![]() $33^\circ$ to give the sand slightly more stability in the hysteretic flow regime.

$33^\circ$ to give the sand slightly more stability in the hysteretic flow regime.

2.3. The coefficient  $\nu$

$\nu$

Gray & Edwards (Reference Gray and Edwards2014) and Baker et al. (Reference Baker, Barker and Gray2016a) derived the depth-averaged viscous terms in (2.3) from the ![]() $\mu (I)$ rheology (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006). In this equation, the coefficient

$\mu (I)$ rheology (GDR-Midi 2004; Jop et al. Reference Jop, Forterre and Pouliquen2006). In this equation, the coefficient

is explicitly determined during the integration process in terms of the existing friction parameters, summarized in table 1, and the slope angle ![]() $\zeta$. Equation (2.14) is valid for slope inclinations in the range

$\zeta$. Equation (2.14) is valid for slope inclinations in the range ![]() $\zeta \in [\zeta _1,\zeta _2]$, when steady-uniform flows are predicted to exist by the dynamic frictional law (2.8). In reality, the lowest observable steady-uniform flow occurs at

$\zeta \in [\zeta _1,\zeta _2]$, when steady-uniform flows are predicted to exist by the dynamic frictional law (2.8). In reality, the lowest observable steady-uniform flow occurs at ![]() $Fr=\beta _*$ and one might anticipate that the form of

$Fr=\beta _*$ and one might anticipate that the form of ![]() $\nu$ might change when the flow is in the intermediate (2.9) and static (2.10) regimes. However, in the computations presented in this paper, (2.14) is assumed to apply to all regimes.

$\nu$ might change when the flow is in the intermediate (2.9) and static (2.10) regimes. However, in the computations presented in this paper, (2.14) is assumed to apply to all regimes.

2.4. Particle size and gravitational dependence

The governing equations can be made non-dimensional by introducing scalings based on a typical particle diameter ![]() $d$ and gravity

$d$ and gravity ![]() $g$

$g$

\begin{equation}

\left.\begin{array}{@{}c@{}} (x,y,z,h)=d\,(\tilde{x}, \tilde{y},

\tilde{z}, \tilde{h}),\quad t=\sqrt{d/g}\,\tilde{t},\\

\bar{\boldsymbol{u}}=\sqrt{gd}\,\tilde{\bar{\boldsymbol{u}}},\quad

\bar{\boldsymbol{D}}=\sqrt{g/d}\,\tilde{\bar{\boldsymbol{D}}},\quad

\nu=d\sqrt{g}\,\tilde{\nu}, \end{array}\right\}

\end{equation}

\begin{equation}

\left.\begin{array}{@{}c@{}} (x,y,z,h)=d\,(\tilde{x}, \tilde{y},

\tilde{z}, \tilde{h}),\quad t=\sqrt{d/g}\,\tilde{t},\\

\bar{\boldsymbol{u}}=\sqrt{gd}\,\tilde{\bar{\boldsymbol{u}}},\quad

\bar{\boldsymbol{D}}=\sqrt{g/d}\,\tilde{\bar{\boldsymbol{D}}},\quad

\nu=d\sqrt{g}\,\tilde{\nu}, \end{array}\right\}

\end{equation}where the tilde is used to indicate a non-dimensional variable. It follows that the non-dimensional form of the mass and momentum balances (2.2) and (2.3) are

respectively, where ![]() $\widetilde {\hbox {div}}$ and

$\widetilde {\hbox {div}}$ and ![]() $\widetilde {\hbox {grad}}$ are the non-dimensionalized divergence and gradient operators and the non-dimensional coefficient in the viscous term

$\widetilde {\hbox {grad}}$ are the non-dimensionalized divergence and gradient operators and the non-dimensional coefficient in the viscous term

Moreover, the non-dimensional net acceleration ![]() $\boldsymbol {S}$, the unit vector

$\boldsymbol {S}$, the unit vector ![]() $\boldsymbol {e}$ and the friction

$\boldsymbol {e}$ and the friction ![]() $\mu _b$, defined in (2.4), (2.5) and (2.7), respectively, are already written in dimensionless form, since

$\mu _b$, defined in (2.4), (2.5) and (2.7), respectively, are already written in dimensionless form, since ![]() $\bar {\boldsymbol {u}}/|\bar {\boldsymbol {u}}|=\tilde {\bar {\boldsymbol {u}}}/|\tilde {\bar {\boldsymbol {u}}}|$,

$\bar {\boldsymbol {u}}/|\bar {\boldsymbol {u}}|=\tilde {\bar {\boldsymbol {u}}}/|\tilde {\bar {\boldsymbol {u}}}|$, ![]() $\hbox {grad}\,h=\widetilde {\hbox {grad}}\,\tilde {h}$ and

$\hbox {grad}\,h=\widetilde {\hbox {grad}}\,\tilde {h}$ and ![]() $\mu _b(h/d,Fr)=\mu _b(\tilde {h},Fr)$. The non-dimensional system of equations is therefore independent of any additional non-dimensional groups involving

$\mu _b(h/d,Fr)=\mu _b(\tilde {h},Fr)$. The non-dimensional system of equations is therefore independent of any additional non-dimensional groups involving ![]() $d$ or

$d$ or ![]() $g$ dependence. These non-dimensionalized equations are therefore scale and gravity independent. This remarkable result is due to Kokelaar et al. (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017), and implies that provided all the length scales (height, width and length) scale up with the particle size, the results will be the same. A self-channelized geophysical flow of large boulders, such as that shown in figure 2, may therefore be exactly equivalent to a small-scale experimental flow involving millimetre-sized grains (Rocha et al. Reference Rocha, Johnson and Gray2019). This scaling on the particle size relies on the fact that the frictional length scale

$g$ dependence. These non-dimensionalized equations are therefore scale and gravity independent. This remarkable result is due to Kokelaar et al. (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017), and implies that provided all the length scales (height, width and length) scale up with the particle size, the results will be the same. A self-channelized geophysical flow of large boulders, such as that shown in figure 2, may therefore be exactly equivalent to a small-scale experimental flow involving millimetre-sized grains (Rocha et al. Reference Rocha, Johnson and Gray2019). This scaling on the particle size relies on the fact that the frictional length scale ![]() $\mathscr {L}=\mathcal {L}d$ scales linearly on

$\mathscr {L}=\mathcal {L}d$ scales linearly on ![]() $d$. Forterre & Pouliquen (Reference Forterre and Pouliquen2003) showed that

$d$. Forterre & Pouliquen (Reference Forterre and Pouliquen2003) showed that ![]() $\mathscr {L}=1.65d$ for glass beads and

$\mathscr {L}=1.65d$ for glass beads and ![]() $\mathscr {L}=2.03d$ for sand. In this paper, the non-dimensional frictional length

$\mathscr {L}=2.03d$ for sand. In this paper, the non-dimensional frictional length ![]() $\mathcal {L}=\mathscr {L}/d$ is assumed to be equal to

$\mathcal {L}=\mathscr {L}/d$ is assumed to be equal to ![]() $2$ (table 1).

$2$ (table 1).

Kokelaar et al. (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017) applied these ideas to large-scale dry granular flows on the Moon, which occur during crater wall collapses. The reduced gravity on the Moon implies that the velocities will be slower than an equivalent sized flow on Earth and the flows would therefore have taken correspondingly longer to run out. However, Kokelaar et al.'s (Reference Kokelaar, Bahia, Joy, Viroulet and Gray2017) figure 10 shows self-channelized fingered deposits in the Bessel crater in Mare Serenitatis (latitude 21.8![]() $^\circ$N, longitude 17.9

$^\circ$N, longitude 17.9![]() $^\circ$E) that are closely analogous to the small-scale segregation induced fingering experiments of Pouliquen et al. (Reference Pouliquen, Delour and Savage1997), Woodhouse et al. (Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012) and Baker et al. (Reference Baker, Johnson and Gray2016b). The presence of water in debris flows on Earth modifies the friction law and the scaling properties. However, the essential flow dynamics and morphological features remain closely similar as demonstrated by the USGS debris-flow-flume experiments (Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012).

$^\circ$E) that are closely analogous to the small-scale segregation induced fingering experiments of Pouliquen et al. (Reference Pouliquen, Delour and Savage1997), Woodhouse et al. (Reference Woodhouse, Thornton, Johnson, Kokelaar and Gray2012) and Baker et al. (Reference Baker, Johnson and Gray2016b). The presence of water in debris flows on Earth modifies the friction law and the scaling properties. However, the essential flow dynamics and morphological features remain closely similar as demonstrated by the USGS debris-flow-flume experiments (Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012).

3. Depth-averaged simulations of a self-channelized flow

The governing equations in § 2 are now solved numerically to generate thickness and depth-averaged velocity fields that quantitatively capture the small-scale self-channelized flow experiments of Takagi et al. (Reference Takagi, McElwaine and Huppert2011) and Rocha et al. (Reference Rocha, Johnson and Gray2019). The scaling behaviour with particle size (see § 2.4) ensures that this solution is also appropriate for geophysical flows, whose average grain size is much larger than that in the small-scale experiments. The solution is then transformed to a frame of reference moving with the flow front, to show that over longer integration periods, a travelling-wave solution develops that is steady in the moving frame.

3.1. Continuous release of grains on an inclined plane

A numerical simulation is first performed to capture the continuous release of sand from a point source onto a rough plane inclined at ![]() $\zeta =32^{\circ }$. The values of the critical thicknesses

$\zeta =32^{\circ }$. The values of the critical thicknesses ![]() $h_{stop}$,

$h_{stop}$, ![]() $h_*$ and

$h_*$ and ![]() $h_{start}$ as well as

$h_{start}$ as well as ![]() $\nu$ are therefore constant, and their specific values are summarized in table 2. The computational domain consists of a rectangle covering the area

$\nu$ are therefore constant, and their specific values are summarized in table 2. The computational domain consists of a rectangle covering the area ![]() $0\ {\rm m} \leqslant x \leqslant 2.5$ m and

$0\ {\rm m} \leqslant x \leqslant 2.5$ m and ![]() $-10\ {\rm cm} \leqslant y \leqslant 10$ cm, discretized to

$-10\ {\rm cm} \leqslant y \leqslant 10$ cm, discretized to ![]() $2500\times 200$ finite volume cells (1 grid point per mm in both directions). The conservation equations (2.2) and (2.3) are solved numerically with a semi-discrete non-oscillatory central (NOC) scheme, which uses a generalized minmod limiter with

$2500\times 200$ finite volume cells (1 grid point per mm in both directions). The conservation equations (2.2) and (2.3) are solved numerically with a semi-discrete non-oscillatory central (NOC) scheme, which uses a generalized minmod limiter with ![]() $\theta =2$ (Kurganov & Tadmor Reference Kurganov and Tadmor2000). The time-stepping is performed with a second-order Runge–Kutta method, with the step size determined by a CFL (Courant–Friedrichs–Lewy) number of

$\theta =2$ (Kurganov & Tadmor Reference Kurganov and Tadmor2000). The time-stepping is performed with a second-order Runge–Kutta method, with the step size determined by a CFL (Courant–Friedrichs–Lewy) number of ![]() $0.225$ and limited to a maximum of

$0.225$ and limited to a maximum of ![]() $\Delta t = 10^{-4}$ s (LeVeque Reference LeVeque2002) to minimize the creep in the levees.

$\Delta t = 10^{-4}$ s (LeVeque Reference LeVeque2002) to minimize the creep in the levees.

Table 2. Critical layer thicknesses ![]() $h_{stop}$,

$h_{stop}$, ![]() $h_*$ and

$h_*$ and ![]() $h_{start}$ as well as the coefficient

$h_{start}$ as well as the coefficient ![]() $\nu$ (in the depth-averaged viscosity

$\nu$ (in the depth-averaged viscosity ![]() $\nu h^{1/2}/2$) for the material properties for sand in table 1 and the fixed slope angle of

$\nu h^{1/2}/2$) for the material properties for sand in table 1 and the fixed slope angle of ![]() $\zeta =32.0^{\circ }$ used in the numerical computations.

$\zeta =32.0^{\circ }$ used in the numerical computations.

The initial conditions at ![]() $t=0$ are

$t=0$ are ![]() $h=h_0=0.01$ mm (around 50 times smaller than the mean particle diameter) and

$h=h_0=0.01$ mm (around 50 times smaller than the mean particle diameter) and ![]() $\bar {\boldsymbol {u}}=\boldsymbol {0}\ {\rm m}\ {\rm s}^{-1}$ everywhere. This thin static layer is required to mitigate numerical errors caused by the degeneracy of the governing equations at

$\bar {\boldsymbol {u}}=\boldsymbol {0}\ {\rm m}\ {\rm s}^{-1}$ everywhere. This thin static layer is required to mitigate numerical errors caused by the degeneracy of the governing equations at ![]() $h=0$. Following Rocha et al. (Reference Rocha, Johnson and Gray2019), a source term

$h=0$. Following Rocha et al. (Reference Rocha, Johnson and Gray2019), a source term ![]() $S_{inflow}$ is included on the right-hand side of (2.2) to give

$S_{inflow}$ is included on the right-hand side of (2.2) to give

which allows grains to be added in a small circular region of radius ![]() $r_0=2.5$ cm centred at

$r_0=2.5$ cm centred at ![]() $(x_0,y_0)=(15$ cm

$(x_0,y_0)=(15$ cm![]() $,0)$ at a flow rate of

$,0)$ at a flow rate of ![]() $Q_m = 130\ {\rm g}\ {\rm s}^{-1}$, i.e.

$Q_m = 130\ {\rm g}\ {\rm s}^{-1}$, i.e.

\begin{equation} S_{inflow}=\left\{\begin{array}{@{}ll@{}} \displaystyle\dfrac{3 Q_M}{{\rm \pi} \rho r_0^6} \left(r_0^2 - \left((x-x_0)^2 + y^2\right) \right)^2, & (x-x_0)^2 + y^2 \leqslant r_0^2,\\[10pt] 0, & (x-x_0)^2 + y^2 > r_0^2. \end{array}\right. \end{equation}

\begin{equation} S_{inflow}=\left\{\begin{array}{@{}ll@{}} \displaystyle\dfrac{3 Q_M}{{\rm \pi} \rho r_0^6} \left(r_0^2 - \left((x-x_0)^2 + y^2\right) \right)^2, & (x-x_0)^2 + y^2 \leqslant r_0^2,\\[10pt] 0, & (x-x_0)^2 + y^2 > r_0^2. \end{array}\right. \end{equation}

The inflowing particles move downslope and some of them eventually reach the downstream boundary ![]() $x=2.5$ m, where a free outflow condition is imposed by linear extrapolation of the values of

$x=2.5$ m, where a free outflow condition is imposed by linear extrapolation of the values of ![]() $h$ and

$h$ and ![]() $h\bar {u}$ from the final two columns of interior cells. The conditions

$h\bar {u}$ from the final two columns of interior cells. The conditions ![]() $h=h_0$ and

$h=h_0$ and ![]() $\bar {\boldsymbol {u}}=\boldsymbol {0}\ {\rm m}\ {\rm s}^{-1}$ are trivially satisfied at the top

$\bar {\boldsymbol {u}}=\boldsymbol {0}\ {\rm m}\ {\rm s}^{-1}$ are trivially satisfied at the top ![]() $x=0$ and sides

$x=0$ and sides ![]() $y= \pm 10$ cm of the domain where no flow reaches.

$y= \pm 10$ cm of the domain where no flow reaches.

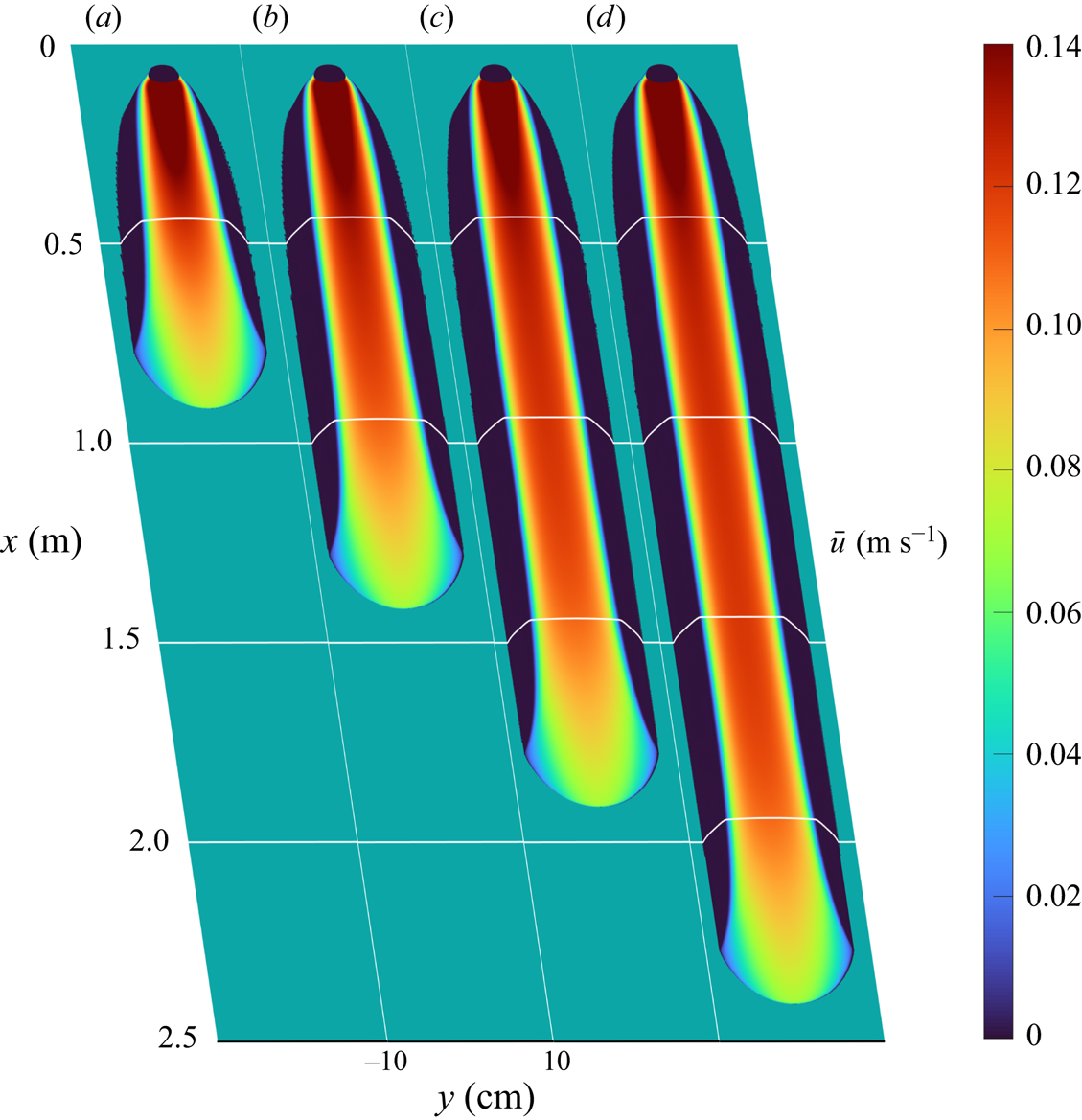

The results of this numerical simulation are plotted in figure 3 at times ![]() $t=7$,

$t=7$, ![]() $14$,

$14$, ![]() $21$ and

$21$ and ![]() $28$ s. The continuous release of grains is shown to quickly form a self-channelized flow with static levees. In the central flowing channel, which is of approximately constant thickness

$28$ s. The continuous release of grains is shown to quickly form a self-channelized flow with static levees. In the central flowing channel, which is of approximately constant thickness ![]() $9$ mm and uniform width

$9$ mm and uniform width ![]() $16$ cm, material is transported towards the flow front. When it reaches the front, the lateral confinement is lost and the flow spreads out, rapidly coming to rest and building up new sections of the levees just behind the flow front. The levees are approximately

$16$ cm, material is transported towards the flow front. When it reaches the front, the lateral confinement is lost and the flow spreads out, rapidly coming to rest and building up new sections of the levees just behind the flow front. The levees are approximately ![]() $2.5$ cm wide and have a thickness that starts at the flowing channel depth and decreases to zero. As a result, the front in figure 3 appears to propagate steadily downslope at constant velocity

$2.5$ cm wide and have a thickness that starts at the flowing channel depth and decreases to zero. As a result, the front in figure 3 appears to propagate steadily downslope at constant velocity ![]() $u_F \simeq 0.07\ {\rm m}\ {\rm s}^{-1}$, suggesting that a two-dimensional travelling wave is generated.

$u_F \simeq 0.07\ {\rm m}\ {\rm s}^{-1}$, suggesting that a two-dimensional travelling wave is generated.

Figure 3. Surface plots of the flow thickness ![]() $h$ for the numerical simulation of a release of particles at a flow rate of

$h$ for the numerical simulation of a release of particles at a flow rate of ![]() $Q_m = 130\ {\rm g}\ {\rm s}^{-1}$ on a plane inclined at

$Q_m = 130\ {\rm g}\ {\rm s}^{-1}$ on a plane inclined at ![]() $\zeta =32^{\circ }$, coloured by the downslope component of depth-averaged velocity

$\zeta =32^{\circ }$, coloured by the downslope component of depth-averaged velocity ![]() $\bar {u}$ and shown at times (a)

$\bar {u}$ and shown at times (a) ![]() $t = 7$, (b)

$t = 7$, (b) ![]() $14$, (c)

$14$, (c) ![]() $21$ and (d)

$21$ and (d) ![]() $28$ s. The filled black circles indicate the non-zero source region where

$28$ s. The filled black circles indicate the non-zero source region where ![]() $S_{inflow}$ is given by (3.2) and the solid horizontal white lines indicate cross-slope flow thickness, mimicking the displacement of an experimental laser line. The online supplementary movie 1 available at https://doi.org/10.1017/jfm.2022.1089 shows the time dependent evolution of the flow.

$S_{inflow}$ is given by (3.2) and the solid horizontal white lines indicate cross-slope flow thickness, mimicking the displacement of an experimental laser line. The online supplementary movie 1 available at https://doi.org/10.1017/jfm.2022.1089 shows the time dependent evolution of the flow.

3.2. Depth-averaged travelling frame simulation

For the travelling wave to be fully realised, it is useful to perform simulations in a frame moving at the front speed ![]() $u_F$. Using the change of coordinates

$u_F$. Using the change of coordinates

the mass and momentum conservation laws (2.2) and (2.3) can be written

where ![]() $\hbox {div}'$ and

$\hbox {div}'$ and ![]() $\hbox {grad}'$ are now the two-dimensional divergence and gradient operators in the moving frame

$\hbox {grad}'$ are now the two-dimensional divergence and gradient operators in the moving frame ![]() $(\xi,y)$. The depth-averaged velocity in the moving frame is equal to

$(\xi,y)$. The depth-averaged velocity in the moving frame is equal to ![]() $\bar {\boldsymbol {u}}^{\prime } = \bar {\boldsymbol {u}}-u_F\boldsymbol {e}_x$. The strain-rate tensor is unchanged in the moving frame, i.e.

$\bar {\boldsymbol {u}}^{\prime } = \bar {\boldsymbol {u}}-u_F\boldsymbol {e}_x$. The strain-rate tensor is unchanged in the moving frame, i.e. ![]() $\bar {\boldsymbol {D}}^\prime =\bar {\boldsymbol {D}}$. Note that the elimination of

$\bar {\boldsymbol {D}}^\prime =\bar {\boldsymbol {D}}$. Note that the elimination of ![]() $\bar {\boldsymbol {u}}$ in the transformed momentum balance (3.5) relies on subtracting

$\bar {\boldsymbol {u}}$ in the transformed momentum balance (3.5) relies on subtracting ![]() $u_F$ times the moving frame mass balance (3.4) from the transformed downslope momentum balance.

$u_F$ times the moving frame mass balance (3.4) from the transformed downslope momentum balance.

Since (3.4) and (3.5) have the same structure as the original mass and momentum balance equations (2.2) and (2.3), the numerical method described in § 3.1 can be used to compute the flow in the moving frame. This time, the computational domain is a rectangle covering the area ![]() $-0.8\ {\rm m} \leqslant \xi \leqslant 0.8$ m and

$-0.8\ {\rm m} \leqslant \xi \leqslant 0.8$ m and ![]() $-10\ {\rm cm} \leqslant y \leqslant 10$ cm, discretized to

$-10\ {\rm cm} \leqslant y \leqslant 10$ cm, discretized to ![]() $1600\times 200$ finite volume cells (with the same resolution of 1 grid point per mm in both directions as the continuous release simulation). The initial conditions at

$1600\times 200$ finite volume cells (with the same resolution of 1 grid point per mm in both directions as the continuous release simulation). The initial conditions at ![]() $\tau = 0$ are the

$\tau = 0$ are the ![]() $t = t_0 = 28$ s state of the continuous release simulation, which is shown in figure 3(d). At the downstream boundary, at

$t = t_0 = 28$ s state of the continuous release simulation, which is shown in figure 3(d). At the downstream boundary, at ![]() $\xi = 0.8$ m, the precursor layer enters the domain with thickness

$\xi = 0.8$ m, the precursor layer enters the domain with thickness ![]() $h=h_0$ and velocity

$h=h_0$ and velocity ![]() $\bar {\boldsymbol {u}}^\prime =-u_F\boldsymbol {e}_x$, which is equivalent to zero velocity in the stationary frame. This condition is also trivially satisfied at the sides

$\bar {\boldsymbol {u}}^\prime =-u_F\boldsymbol {e}_x$, which is equivalent to zero velocity in the stationary frame. This condition is also trivially satisfied at the sides ![]() $y= \pm 10$ cm.

$y= \pm 10$ cm.

The upstream boundary condition is more complex. Physically, this is because some of the grains in the central channel are moving downslope towards the front, and therefore must enter the domain at ![]() $\xi =-0.8$ m, whilst other grains at the sides and base of the central channel, as well as in the static levees, are moving slower than the front and leave the domain. This has to be accounted for in a depth-averaged model by allowing an inflow along part of the upstream boundary and an outflow along the rest. To achieve this, a novel procedure has been developed. First, the net mass flux leaving the domain across the upstream boundary is calculated by evaluating the integral

$\xi =-0.8$ m, whilst other grains at the sides and base of the central channel, as well as in the static levees, are moving slower than the front and leave the domain. This has to be accounted for in a depth-averaged model by allowing an inflow along part of the upstream boundary and an outflow along the rest. To achieve this, a novel procedure has been developed. First, the net mass flux leaving the domain across the upstream boundary is calculated by evaluating the integral

\begin{equation} Q_{out} ={-}\rho\int_{{-}W/2}^{{+}W/2} h\bar{u}^{\prime} \rvert_{\xi={-}0.8\ {\rm m}}\, \mathrm{d}y. \end{equation}

\begin{equation} Q_{out} ={-}\rho\int_{{-}W/2}^{{+}W/2} h\bar{u}^{\prime} \rvert_{\xi={-}0.8\ {\rm m}}\, \mathrm{d}y. \end{equation}

At steady state, the inflowing and outflowing grains should be in exact balance and ![]() $Q_{out}$ should equal zero. However, the initial state is not yet quite in steady state and therefore

$Q_{out}$ should equal zero. However, the initial state is not yet quite in steady state and therefore ![]() $Q_{out}$ is non-zero. To correct for the net loss/gain of particles across

$Q_{out}$ is non-zero. To correct for the net loss/gain of particles across ![]() $\xi =-0.8$ m, a mass source term (similar to that applied in (3.1)) is applied across the first row of interior grid cells. The new source term in the moving frame simulations is therefore

$\xi =-0.8$ m, a mass source term (similar to that applied in (3.1)) is applied across the first row of interior grid cells. The new source term in the moving frame simulations is therefore

\begin{equation} S'_{inflow} = \dfrac{Q_{out}h\rvert_{\xi={-}0.8\ \mathrm{m}}}{\rho\Delta x \displaystyle\int\nolimits_{{-}W/2}^{{+}W/2} h\rvert_{\xi={-}0.8\ \mathrm{m}}\,\mathrm{d} y} \end{equation}

\begin{equation} S'_{inflow} = \dfrac{Q_{out}h\rvert_{\xi={-}0.8\ \mathrm{m}}}{\rho\Delta x \displaystyle\int\nolimits_{{-}W/2}^{{+}W/2} h\rvert_{\xi={-}0.8\ \mathrm{m}}\,\mathrm{d} y} \end{equation}

inside the first grid cell and zero otherwise, where ![]() $\Delta x = 10^{-3}$ m is the length of a grid cell in the downslope direction. The inflow is weighted so that more mass is supplied in thicker parts of the flow. It follows that when (3.7) is integrated over the domain

$\Delta x = 10^{-3}$ m is the length of a grid cell in the downslope direction. The inflow is weighted so that more mass is supplied in thicker parts of the flow. It follows that when (3.7) is integrated over the domain ![]() $(-0.8,-0.8+\Delta x~\mathrm {m})\times (-W,W)$, it resupplies the material lost through the upstream boundary. An iterative procedure is required to refine the initial guess of

$(-0.8,-0.8+\Delta x~\mathrm {m})\times (-W,W)$, it resupplies the material lost through the upstream boundary. An iterative procedure is required to refine the initial guess of ![]() $u_F=0.07065\ {\rm m}\ {\rm s}^{-1}$ to ensure convergence towards a steady state. Figure 4 shows the results of a numerical simulation with

$u_F=0.07065\ {\rm m}\ {\rm s}^{-1}$ to ensure convergence towards a steady state. Figure 4 shows the results of a numerical simulation with ![]() $u_F=0.07053\ {\rm m}\ {\rm s}^{-1}$. Figure 4(a,b) show that the initial thickness is almost indistinguishable from the final thickness 100 s later, implying that by

$u_F=0.07053\ {\rm m}\ {\rm s}^{-1}$. Figure 4(a,b) show that the initial thickness is almost indistinguishable from the final thickness 100 s later, implying that by ![]() $t=28$ s, the simulations in figure 3(d) were already close to steady state. The temporal evolution of

$t=28$ s, the simulations in figure 3(d) were already close to steady state. The temporal evolution of ![]() $Q_{out}$ is shown in figure 4(c). By

$Q_{out}$ is shown in figure 4(c). By ![]() $\tau =100$ s, the simulation has converged on a steady state with

$\tau =100$ s, the simulation has converged on a steady state with ![]() $Q_{out}=0$, and this is now used to reconstruct the three-dimensional velocity field near the front of a self-channelized flow with static levees.

$Q_{out}=0$, and this is now used to reconstruct the three-dimensional velocity field near the front of a self-channelized flow with static levees.

Figure 4. Colour maps of flow thickness ![]() $h$ in a frame moving with the front speed

$h$ in a frame moving with the front speed ![]() $u_F = 0.07053\ {\rm m}\ {\rm s}^{-1}$ plotted (a) at the initial time

$u_F = 0.07053\ {\rm m}\ {\rm s}^{-1}$ plotted (a) at the initial time ![]() $\tau = 0$ s (equivalent to

$\tau = 0$ s (equivalent to ![]() $t=t_0=28$ s of the continuous release simulation shown in figure 3d) and (b) after

$t=t_0=28$ s of the continuous release simulation shown in figure 3d) and (b) after ![]() $\tau = 100$ s in the travelling frame simulation. (c) Mass flux

$\tau = 100$ s in the travelling frame simulation. (c) Mass flux ![]() $Q_{out}$ leaving the domain as a function of time

$Q_{out}$ leaving the domain as a function of time ![]() $\tau$. This tends to zero for large times confirming that a travelling wave solution is achieved.

$\tau$. This tends to zero for large times confirming that a travelling wave solution is achieved.

4. Reconstruction of the three-dimensional velocity field

4.1. Reconstruction of the bulk flow velocity components