Impact Statement

The use of graph neural networks wall models for compressible anisothermal flows has the potential to significantly enhance the accuracy and efficiency of large-eddy simulation in industrial settings. This innovation can lead to improvements in design optimization in various industries, notably in the transportation, aeronautics, and energy sectors, and thus contribute to global sustainability goals by helping to decarbonize these sectors.

1. Introduction

It is often computationally impractical to simulate all scales of motions in turbulent fluid flows. The computational requirements are less stringent if only the larger turbulent scales are resolved, and the smaller ones modeled. This is the basis of large-eddy simulation (LES). By modeling the effect of the more expensive small-scale motions, LESs enable the study of more complex flow configurations than allowed by direct computation. The LES of compressible anisothermal flow, in particular, is useful in many industrial applications, such as combustion chambers, high-pressure turbines, rocket engines, or heat exchangers (Chassaing et al., Reference Chassaing, Antonia, Anselmet, Joly and Sarkar2013). In these flows, the variations of density, viscosity, or heat conductivity with temperature are large and lead to a strong coupling between the fields of temperature and velocity. The near-wall profiles of velocity and temperature are influenced by this coupling (Huang et al., Reference Huang, Coleman and Bradshaw1995; Serra et al., Reference Serra, Toutant, Bataille and Zhou2012; Toutant and Bataille, Reference Toutant and Bataille2013). LES should thus accurately represent the interaction between temperature and turbulence. There are two ways to approach the simulation of wall-bounded compressible anisothermal flow. The first approach, hereafter referred to as wall-resolved large-eddy simulation (WRLES), resolves the large-scale turbulent structures in the entire boundary layer, including the viscous and conductive sublayers. Since the turbulent structures decrease in size near walls, this can be costly at high Reynolds numbers and for complex configurations. The second approach, hereafter referred to as wall-modeled large-eddy simulation (WMLES), models all turbulent structures in the viscous and conductive sublayers. This can be achieved using a wall model that imposes either the shear stress, conductive heat flux, slip velocity, or temperature at the wall as a boundary condition.

Various wall models have been proposed in the literature. Differential wall models can be devised by combining large-eddy simulation with Reynolds-average Navier–Stokes (RANS) near the walls. Hybrid methods based on an embedded grid, zonal methods, and seamless methods such as detached-eddy simulation may fall into this category (Cabot, Reference Cabot1995; Balaras et al., Reference Balaras, Benocci and Piomelli1996; Davidson and Peng, Reference Davidson and Peng2003; Temmerman et al., Reference Temmerman, Hadžiabdić, Leschziner and Hanjalić2005; Piomelli, Reference Piomelli2008). This type of approach can handle non-equilibrium effects (Kawai and Larsson, Reference Kawai and Larsson2013; Park and Moin, Reference Park and Moin2014) and may take into account the effects of compressibility and temperature variations, provided that relevant RANS models are used (Benarafa et al., Reference Benarafa, Cioni, Ducros and Sagaut2007; Rani et al., Reference Rani, Smith and Nix2009; Zhang et al., Reference Zhang, Vicquelin, Gicquel and Taine2013; Mettu and Subbareddy, Reference Mettu and Subbareddy2018; Iyer and Malik, Reference Iyer and Malik2019). However, the computational cost can be large as it requires a mesh that resolves the viscous and conductive sublayers for the RANS computation. To reduce computational costs, an integral wall model based on a parameterized velocity profile was introduced by Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2015) for incompressible flows and extended to compressible anisothermal flows by Catchirayer et al. (Reference Catchirayer, Boussuge, Sagaut, Montagnac, Papadogiannis and Garnaud2018). The family of algebraic wall models includes some of the most widely used and classical wall models (Larsson et al., Reference Larsson, Kawai, Bodart and Bermejo-Moreno2016; Bose and Park, Reference Bose and Park2018). The simplest such model uses the incompressible law of the wall locally and instantaneously, following a statistical equilibrium assumption, to impose the wall shear stress (Deardorff, Reference Deardorff1970; Schumann, Reference Schumann1975). The approach may be adapted to the modeling of the conductive heat flux using a wall function for temperature (Kader and Yaglom, Reference Kader and Yaglom1972; Han and Reitz, Reference Han and Reitz1997; Nichols and Nelson, Reference Nichols and Nelson2004; Berni et al., Reference Berni, Cicalese and Fontanesi2017). The law of the wall for temperature fields has been analyzed by Huang et al. (Reference Huang, Coleman and Bradshaw1995). The article also introduced the semi-local scaling analysis, which is relevant for wall modeling (Patel et al., Reference Patel, Peeters, Boersma and Pecnik2015, Reference Patel, Boersma and Pecnik2016, Reference Patel, Boersma and Pecnik2017). The models for velocity and temperature should necessarily be coupled in flows with strong temperature variations, as for example was proposed by Cabrit and Nicoud (Reference Cabrit and Nicoud2009). This coupled wall model has been validated and compared to uncoupled wall modeling approaches and differential wall models in various physical configurations (Maestro et al., Reference Maestro, Cuenot and Selle2017; Kraus et al., Reference Kraus, Selle and Poinsot2018; Muto et al., Reference Muto, Daimon, Shimizu and Negishi2019, Reference Muto, Daimon, Negishi and Shimizu2021; Indelicato et al., Reference Indelicato, Lapenna, Remiddi and Creta2021; Potier et al., Reference Potier, Duchaine, Cuenot, Saucereau and Pichillou2022). Finally, machine-learning wall models have recently emerged following the development of machine-learning technologies in image classification, speech recognition, natural language processing as well as turbulence simulation and modeling (LeCun et al., Reference LeCun, Bengio and Hinton2015; Duraisamy et al., Reference Duraisamy, Iaccarino and Xiao2019; Brunton et al., Reference Brunton, Noack and Koumoutsakos2020). Data-driven wall-stress models were developed and assessed for various incompressible flow configurations, including fully developed wall turbulence and separated turbulent flows (Huang et al., Reference Huang, Yang and Kunz2019; Yang et al., Reference Yang, Zafar, Wang and Xiao2019; Lozano-Durán and Bae, Reference Lozano-Durán and Bae2020, Reference Lozano-Durán and Bae2022; Bhaskaran et al., Reference Bhaskaran, Kannan, Barr and Priebe2021; Radhakrishnan et al., Reference Radhakrishnan, Adu, Miró, Font, Calafell and Lehmkuhl2021; Zangeneh, Reference Zangeneh2021; Zhou et al., Reference Zhou, He and Yang2021; Bae and Koumoutsakos, Reference Bae and Koumoutsakos2022; Dupuy et al., Reference Dupuy, Odier and Lapeyre2023a). For complex configurations, Dupuy et al. (Reference Dupuy, Odier, Lapeyre and Papadogiannis2023b) introduced a machine-learning wall model that can directly operate on the unstructured grid of a LES, based on a graph neural network (GNN) architecture (Battaglia et al., Reference Battaglia, Hamrick, Bapst, Sanchez-Gonzalez, Zambaldi, Malinowski, Tacchetti, Raposo, Santoro, Faulkner, Gulcehre, Song, Ballard, Gilmer, Dahl, Vaswani, Allen, Nash, Langston, Dyer, Heess, Wierstra, Kohli, Botvinick, Vinyals, Li and Pascanu2018; Pfaff et al., Reference Pfaff, Fortunato, Sanchez-Gonzalez and Battaglia2020; Zhou et al., Reference Zhou, Cui, Hu, Zhang, Yang, Liu, Wang, Li and Sun2020). The relevance of the approach was demonstrated a priori and a posteriori for the modeling of the wall shear stress in incompressible isothermal flows.

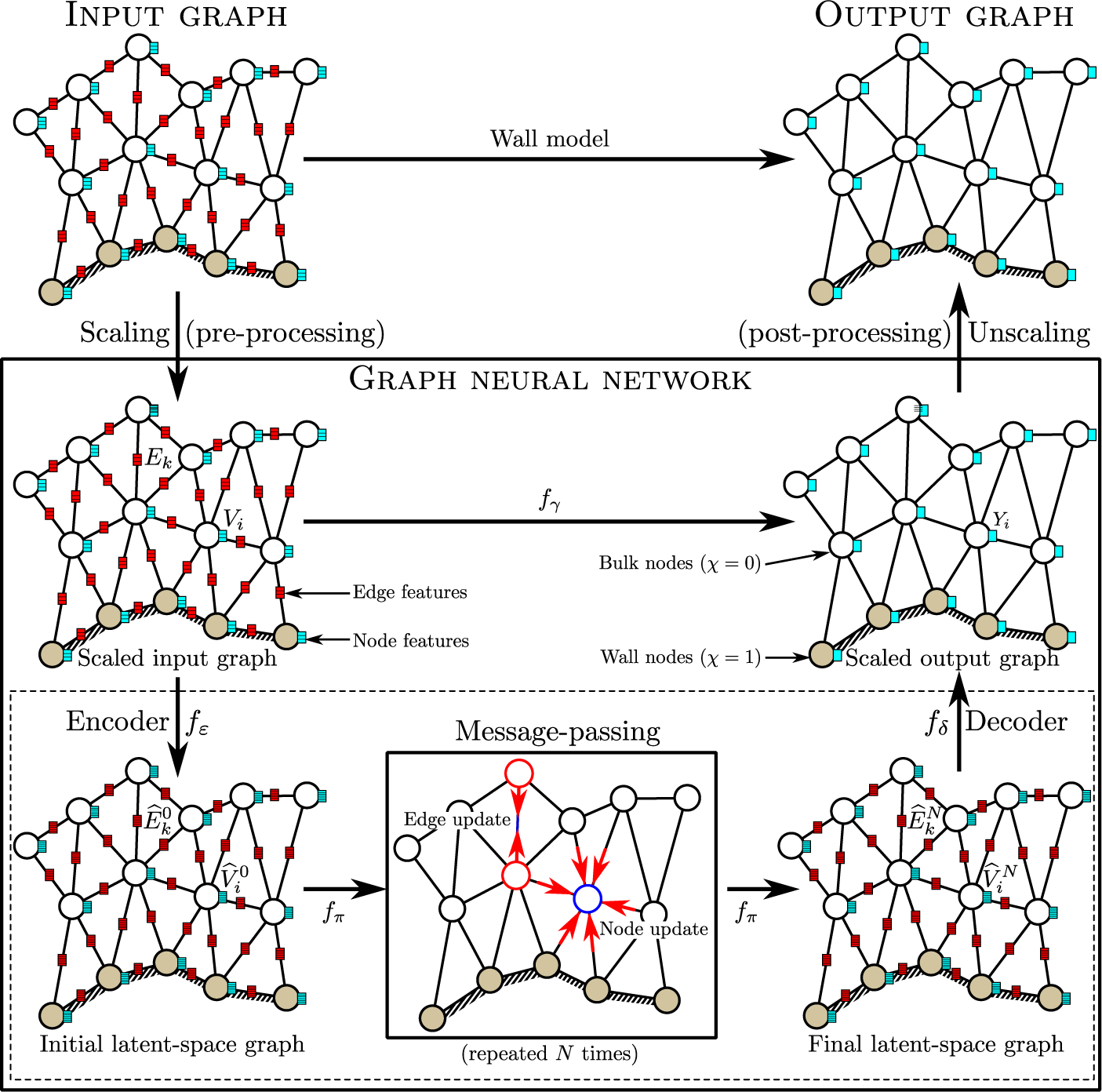

In this article, the GNN wall modeling approach is extended to the modeling of the wall shear stress and wall conductive heat flux in compressible anisothermal flows. The objective is to assess the capability of graph neural network to address the wall modeling of complex anisothermal flows, as well as to evaluate the generalization capabilities of such models. The graph neural networks are based on an Encode-Process-Decode architecture (Battaglia et al., Reference Battaglia, Hamrick, Bapst, Sanchez-Gonzalez, Zambaldi, Malinowski, Tacchetti, Raposo, Santoro, Faulkner, Gulcehre, Song, Ballard, Gilmer, Dahl, Vaswani, Allen, Nash, Langston, Dyer, Heess, Wierstra, Kohli, Botvinick, Vinyals, Li and Pascanu2018) with no global features that ensure the spatial locality of the prediction. Due to the GNN architecture, the model is able to directly operate on unstructured meshes and can be applied in complex geometries with angles or curvature without a prior interpolation of the inputs. Moreover, the GNN architecture encodes the translational invariance of the prediction, is inherently biased toward locality and suited to massively parallel computation. The inputs of the model are augmented and scaled to ensure in addition the Galilean invariance of the model and the equivariance of the model under orthogonal transformations and to Mach number variations. Although the GNN approach is in principle not restrictive in terms of mesh elements, the present analysis is restricted to coarse tetrahedral meshes, as this type of mesh is commonly used to simulate complex industrial flows. The graph neural networks wall models are validated a priori, based on filtered numerical data from direct numerical simulations (DNS) and wall-resolved LESs, and a posteriori, based on wall-modeled LESs coupled with the GNN models. The models are trained and tested on coarse tetrahedral meshes in both cases. We use an uncoupled velocity-temperature algebraic wall model and the coupled velocity-temperature algebraic wall model of Cabrit and Nicoud (Reference Cabrit and Nicoud2009) as baseline wall models in both cases. The a priori database used to train and evaluate the models include six incompressible isothermal flows (two channel flows, a diffuser, two backward-facing steps, and a linear blade cascade) and five compressible anisothermal flows (two symmetrically cooled channel flows, two asymmetrically cooled/heated channels flows, and a cooled high-pressure turbine blade). In a posteriori tests, the model is first assessed for a channel flow to verify that the graph neural network model is able to perform at least as well as algebraic models devised for this type of simulation. The model is then validated a posteriori for the simulation of the high-pressure turbine blade VKI LS1989, specifically for test case MUR235 of Arts et al. (Reference Arts, Rouvroit and Rutherford1990), which features a complex physics that strongly departs from equilibrium wall modeling assumptions. It relies on the coupling strategy of Serhani et al. (Reference Serhani, Xing, Dupuy, Lapeyre and Staffelbach2022) to couple the massively parallel flow solver (Schönfeld and Rudgyard, Reference Schönfeld and Rudgyard1999) to the graph neural network in the wall-modeled LESs.

The article is organized as follows. The dataset and the preparation of the data for the machine-learning model are presented in Section 2. The strategies used to enforce the equivariances of the model are described in Section 3. The baseline wall models and the graph neural network wall model are described in Section 4. The a priori results are discussed in Section 5 and the a posteriori results in Section 6.

2. Database

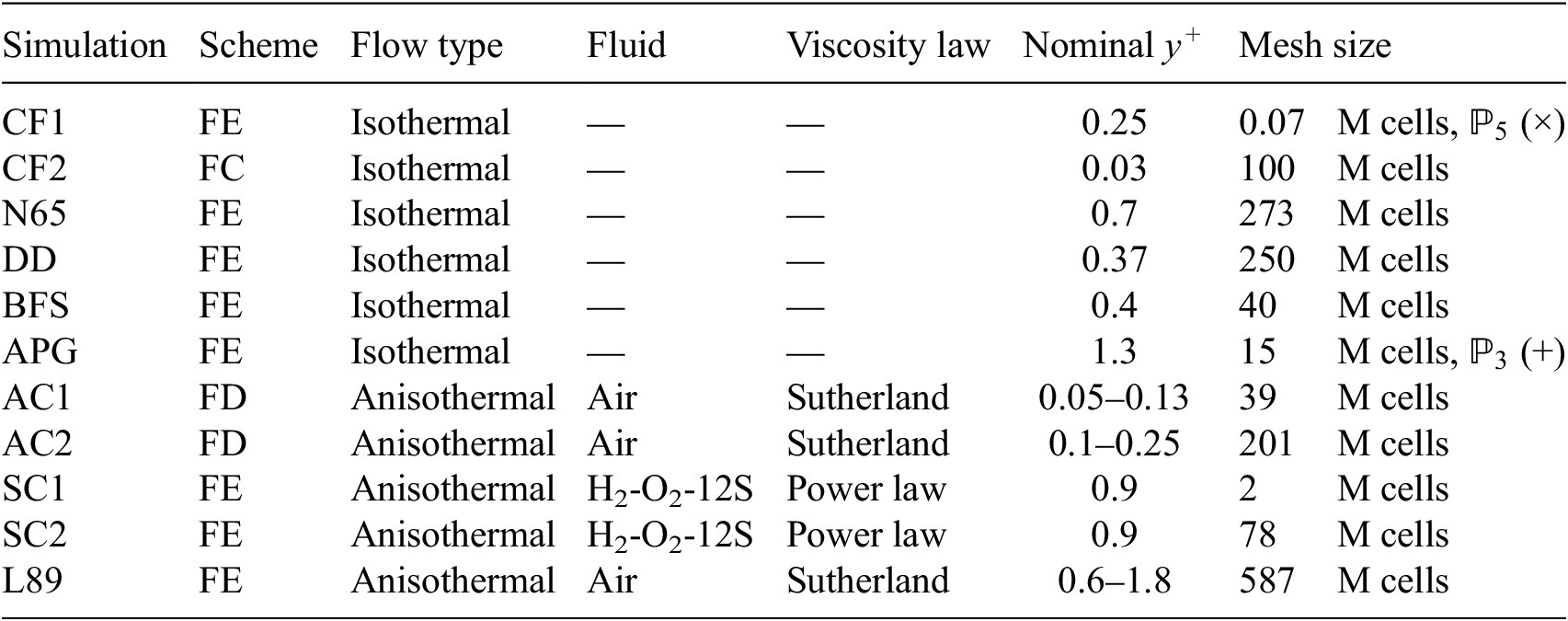

Data-driven wall modeling hinges on the development of datasets that can specify the wall behavior of fluids. These datasets may either be based on high-fidelity experimental or numerical data, and should involve a large diversity of flow phenomena in order to build a model that can operate in a wide variety of configurations. Building such dataset is a challenging task, even if the problem is restricted to incompressible flows. The effect of compressibility and fluid-property variations adds several dimensions to the problem, for instance, the effect of the Prandtl number, the Mach number, the equation of state, or the viscosity law, such that fully specifying the problem is yet elusive. For practical purpose, small regions of the problem space, of practical interest, could however be described by such a dataset. The present study uses a dataset of 12 high-fidelity numerical simulations, 6 incompressible isothermal simulations, and 5 compressible anisothermal simulations. All compressible simulations involve an ideal gas, with properties close to that of air in terms of Prandtl number, assumed constant. The simulations were performed by various research groups using various CFD solvers and numerical methods. Demonstrating an ability to learn from such an heterogeneous database is crucial for the further development of machine-learning wall models with much larger datasets. The six incompressible isothermal simulations are the same as found in Dupuy et al. (Reference Dupuy, Odier, Lapeyre and Papadogiannis2023b), as summarized in Table 1: two fully developed channel flows at friction Reynolds number

![]() $ {\mathit{\operatorname{Re}}}_{\tau }=180 $

(CF1, (Agostini and Vincent, Reference Agostini and Vincent2020) and

$ {\mathit{\operatorname{Re}}}_{\tau }=180 $

(CF1, (Agostini and Vincent, Reference Agostini and Vincent2020) and

![]() $ {\mathit{\operatorname{Re}}}_{\tau }=950 $

(CF2, (Del Álamo and Jiménez, Reference Del Álamo and Jiménez2003; Lozano-Durán and Jiménez, Reference Lozano-Durán and Jiménez2014; Lozano-Durán and Jiménez, Reference Lozano-Durán and Jiménez2015); a three-dimensional diffuser corresponding to the geometry “Diffuser 1” of Cherry et al. (Reference Cherry, Elkins and Eaton2008) (3DD, (Ercoftac, 2022); a backward-facing step (BFS, (Pouech et al., Reference Pouech, Duchaine and Poinsot2019, Reference Pouech, Duchaine and Poinsot2021); a curved backward-facing step (APG, (Ercoftac, 2022); and a NACA 65–009 blade cascade on a flat plate such as studied experimentally by Ma et al. (Reference Ma, Ottavy, Lu, Francis and Gao2011) and Zambonini et al. (Reference Zambonini, Ottavy and Kriegseis2017) at an incidence angle of 4° and 7° (N65) (Dupuy et al., Reference Dupuy, Odier, Lapeyre and Papadogiannis2023b). The five compressible anisothermal simulations are the simulations of two fully developed asymmetrically cooled/heated channel flows at friction Reynolds number

$ {\mathit{\operatorname{Re}}}_{\tau }=950 $

(CF2, (Del Álamo and Jiménez, Reference Del Álamo and Jiménez2003; Lozano-Durán and Jiménez, Reference Lozano-Durán and Jiménez2014; Lozano-Durán and Jiménez, Reference Lozano-Durán and Jiménez2015); a three-dimensional diffuser corresponding to the geometry “Diffuser 1” of Cherry et al. (Reference Cherry, Elkins and Eaton2008) (3DD, (Ercoftac, 2022); a backward-facing step (BFS, (Pouech et al., Reference Pouech, Duchaine and Poinsot2019, Reference Pouech, Duchaine and Poinsot2021); a curved backward-facing step (APG, (Ercoftac, 2022); and a NACA 65–009 blade cascade on a flat plate such as studied experimentally by Ma et al. (Reference Ma, Ottavy, Lu, Francis and Gao2011) and Zambonini et al. (Reference Zambonini, Ottavy and Kriegseis2017) at an incidence angle of 4° and 7° (N65) (Dupuy et al., Reference Dupuy, Odier, Lapeyre and Papadogiannis2023b). The five compressible anisothermal simulations are the simulations of two fully developed asymmetrically cooled/heated channel flows at friction Reynolds number

![]() $ {\mathit{\operatorname{Re}}}_{\tau }=180 $

(AC1, (Dupuy et al., Reference Dupuy, Toutant and Bataille2018) and

$ {\mathit{\operatorname{Re}}}_{\tau }=180 $

(AC1, (Dupuy et al., Reference Dupuy, Toutant and Bataille2018) and

![]() $ {\mathit{\operatorname{Re}}}_{\tau }=395 $

(AC2, (Dupuy et al., Reference Dupuy, Toutant and Bataille2019), with a temperature ratio of 2 between the two walls; two fully developed symmetrically cooled channel flows at friction Reynolds number

$ {\mathit{\operatorname{Re}}}_{\tau }=395 $

(AC2, (Dupuy et al., Reference Dupuy, Toutant and Bataille2019), with a temperature ratio of 2 between the two walls; two fully developed symmetrically cooled channel flows at friction Reynolds number

![]() $ {\mathit{\operatorname{Re}}}_{\tau }=320 $

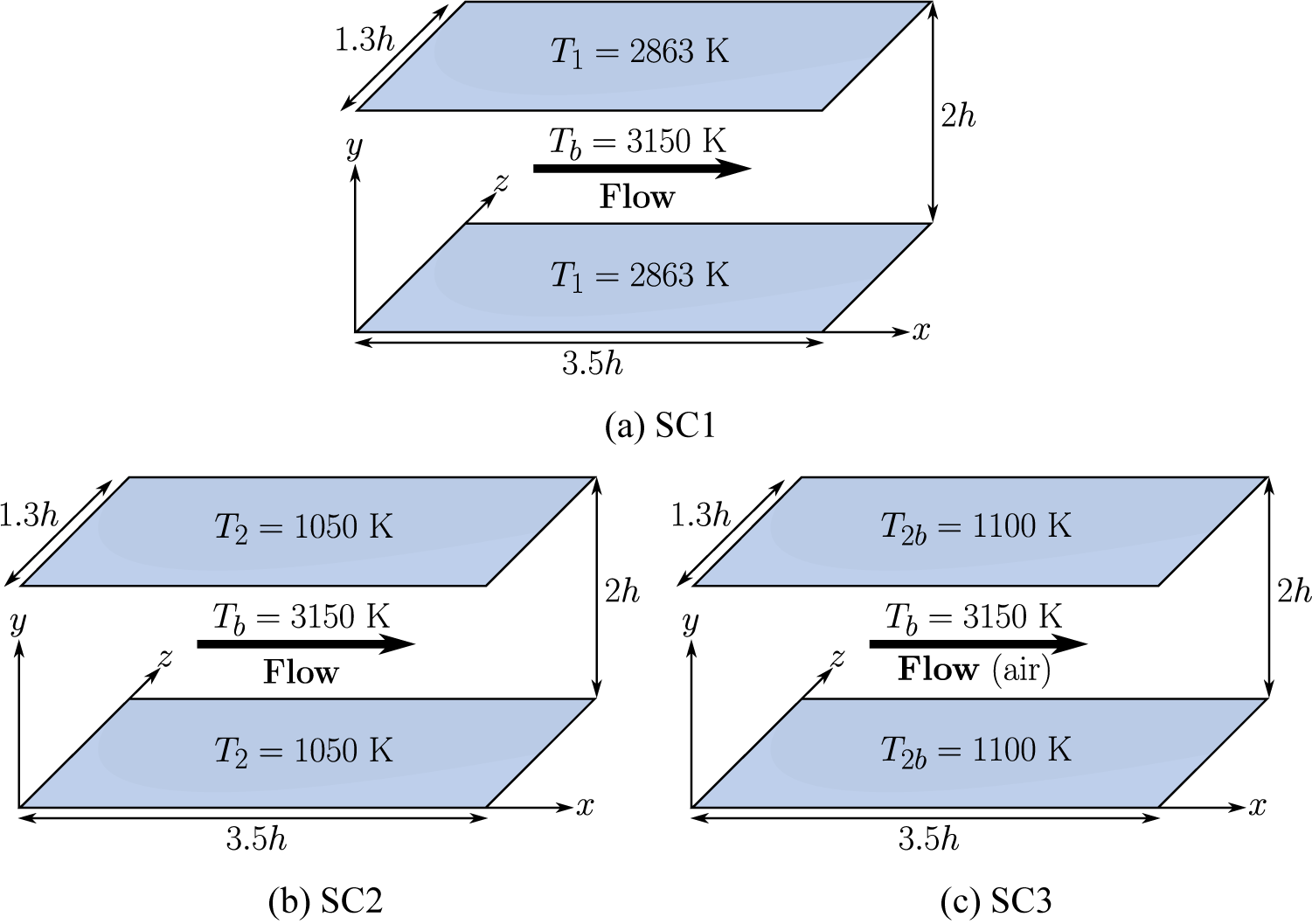

(SC1, Appendix A) and

$ {\mathit{\operatorname{Re}}}_{\tau }=320 $

(SC1, Appendix A) and

![]() $ {\mathit{\operatorname{Re}}}_{\tau }=1150 $

(SC2, Appendix A), with a temperature ratio between the bulk flow and the walls of 1.1 and 3 respectively; and a cooled high-pressure turbine blade which corresponds to the test case MUR235 of Arts et al. (Reference Arts, Rouvroit and Rutherford1990) (L89, (Dupuy et al., Reference Dupuy, Gicquel, Odier, Duchaine and Arts2020). The SC1 simulation aims to provide a case where the coupling between the velocity and temperature fields is small, while the SC2, AC1, and AC2 simulations provide cases where this coupling is strong. The channel flows simulations (CF1, CF2, AC1, AC2, SC1, SC2) provide data for fully developed attached turbulence, whereas the spatially inhomogeneous simulations (3DD, BFS, APG, N65, L89) provide data in non-equilibrium conditions, including regions with adverse pressure gradients, separated boundary layers, and laminar-turbulent transition. The N65 and L89 simulations feature laminar and transitional boundary layers on the blade surface. The 3DD simulation includes an intermittently laminar-separated region (Ohlsson et al., Reference Ohlsson, Schlatter, Fischer and Henningson2010). The numerical parameters of each simulation are summarized in Table 1.

$ {\mathit{\operatorname{Re}}}_{\tau }=1150 $

(SC2, Appendix A), with a temperature ratio between the bulk flow and the walls of 1.1 and 3 respectively; and a cooled high-pressure turbine blade which corresponds to the test case MUR235 of Arts et al. (Reference Arts, Rouvroit and Rutherford1990) (L89, (Dupuy et al., Reference Dupuy, Gicquel, Odier, Duchaine and Arts2020). The SC1 simulation aims to provide a case where the coupling between the velocity and temperature fields is small, while the SC2, AC1, and AC2 simulations provide cases where this coupling is strong. The channel flows simulations (CF1, CF2, AC1, AC2, SC1, SC2) provide data for fully developed attached turbulence, whereas the spatially inhomogeneous simulations (3DD, BFS, APG, N65, L89) provide data in non-equilibrium conditions, including regions with adverse pressure gradients, separated boundary layers, and laminar-turbulent transition. The N65 and L89 simulations feature laminar and transitional boundary layers on the blade surface. The 3DD simulation includes an intermittently laminar-separated region (Ohlsson et al., Reference Ohlsson, Schlatter, Fischer and Henningson2010). The numerical parameters of each simulation are summarized in Table 1.

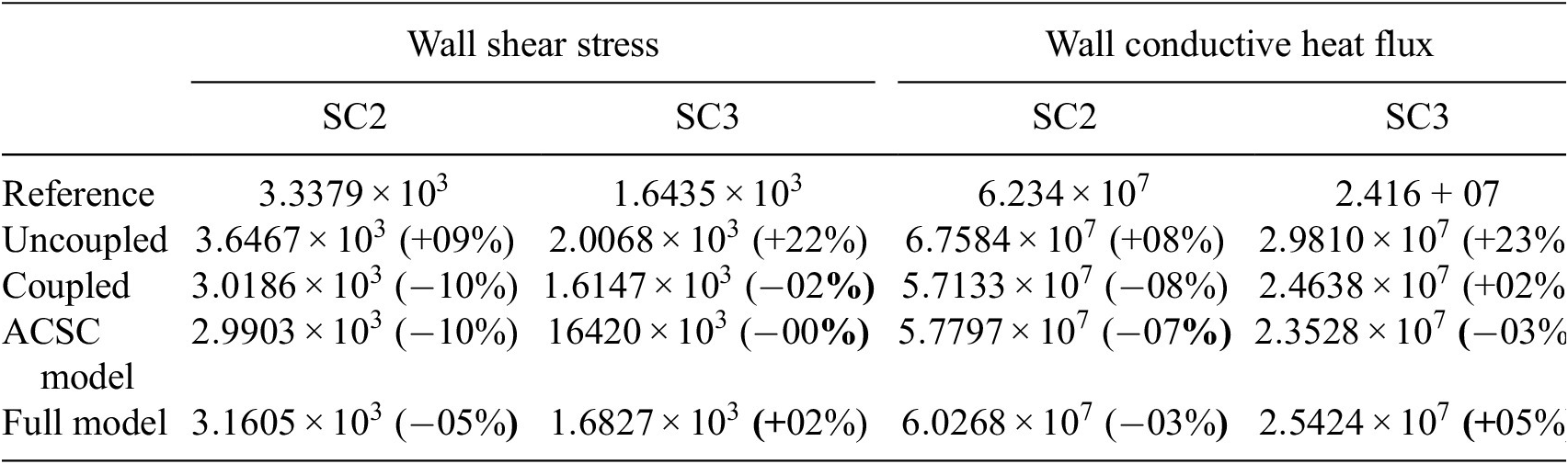

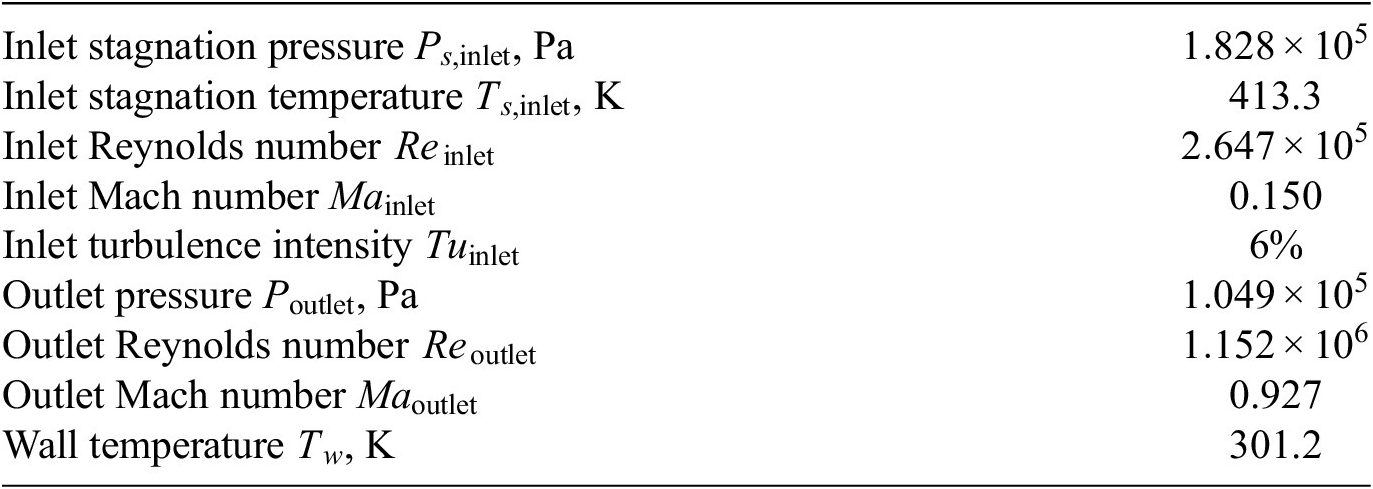

Table 1. Numerical parameters of the numerical simulations are included in the training database

Note. The acronym FC denotes a Fourier-Chebyshev spectral method, FE denotes a finite-element method and FD denotes a finite-difference method.

![]() $ {\mathrm{\mathbb{P}}}_n $

indicates the use of a high-order method with polynomial order

$ {\mathrm{\mathbb{P}}}_n $

indicates the use of a high-order method with polynomial order

![]() $ n $

. The “nominal

$ n $

. The “nominal

![]() $ {y}^{+} $

” is the height of the first point off the wall, in wall units, in the channel (CF1, CF2, SC1, SC2), the boundary layer upstream of the blade (N65), the inlet duct flow (3DD), the boundary layer before the step (BFS, APG), the bottom (cold) and top (hot) walls (AC1, AC2), the blade surface on the pressure and suction sides (L89). An “isothermal” flow type implies that the temperature variations within the flow are negligible but does not imply an incompressible numerical method. In the case where a compressible numerical solver is used to simulate an incompressible isothermal flow, we do not report the fluid and viscosity law since it is not of practical relevance.

$ {y}^{+} $

” is the height of the first point off the wall, in wall units, in the channel (CF1, CF2, SC1, SC2), the boundary layer upstream of the blade (N65), the inlet duct flow (3DD), the boundary layer before the step (BFS, APG), the bottom (cold) and top (hot) walls (AC1, AC2), the blade surface on the pressure and suction sides (L89). An “isothermal” flow type implies that the temperature variations within the flow are negligible but does not imply an incompressible numerical method. In the case where a compressible numerical solver is used to simulate an incompressible isothermal flow, we do not report the fluid and viscosity law since it is not of practical relevance.

2.1. Data preparation

The fields in the numerical database are processed to prepare the data for the machine-learning wall models. The goal of this preprocessing step is to produce fields that are similar in some ways to the fields of a wall-modeled LES. Namely, the fields are filtered to attenuate large frequencies that cannot be resolved in a wall-modeled LES and resampled onto coarse tetrahedral meshes that could be used for WMLES computations. The present machine-learning methodology does not make any assumption regarding the nature of the function that should be learned by the model and can only operate in the range of mesh resolution that was seen during training. This operating range effectively determines the range of Reynolds number that can be addressed a posteriori at moderate computational cost. Since the exact mesh resolution required for unseen test cases is not known, it is important to consider a wide range of mesh refinements to train the model. For each simulation, 12 tetrahedral WMLES meshes with varying mesh resolution are generated using the mesh adaptation library MMG3D (Dobrzynski and Frey, Reference Dobrzynski and Frey2008; Dapogny et al., Reference Dapogny, Dobrzynski and Frey2014; Balarac et al., Reference Balarac, Basile, Bénard, Bordeu, Chapelier, Cirrottola, Caumon, Dapogny, Frey, Froehly, Ghigliotti, Laraufie, Lartigue, Legentil, Mercier, Moureau, Nardoni, Pertant and Zakari2021), with nominal edge length in the range

![]() $ 25\le {e}^{+}\le 80 $

, in wall units, where the classical wall-unit scaling is based on the friction velocity and the kinematic viscosity at the wall, namely

$ 25\le {e}^{+}\le 80 $

, in wall units, where the classical wall-unit scaling is based on the friction velocity and the kinematic viscosity at the wall, namely

![]() $ {e}^{+}={eu}_{\tau }/{\nu}_{\omega } $

, with

$ {e}^{+}={eu}_{\tau }/{\nu}_{\omega } $

, with

![]() $ e $

the nominal edge length,

$ e $

the nominal edge length,

![]() $ {u}_{\tau }={\left(\tau /{\rho}_{\omega}\right)}^{0.5} $

the friction velocity,

$ {u}_{\tau }={\left(\tau /{\rho}_{\omega}\right)}^{0.5} $

the friction velocity,

![]() $ \tau $

the wall shear stress,

$ \tau $

the wall shear stress,

![]() $ {\rho}_{\omega } $

the wall density, and

$ {\rho}_{\omega } $

the wall density, and

![]() $ {\nu}_{\omega } $

the wall kinematic viscosity. This range of

$ {\nu}_{\omega } $

the wall kinematic viscosity. This range of

![]() $ {e}^{+} $

implies that the first point off the wall of the WMLES mesh is typically within the logarithmic layer or the upper part of the buffer layer, in the case of a fully developed turbulent boundary layer. It is suitable for instance in turbomachinery-flow simulations (Leonard et al., Reference Leonard, Sanjose, Moreau and Duchaine2016; Dombard et al., Reference Dombard, Duchaine, Gicquel, Odier, Leroy, Buffaz, Le-Guyader, Démolis, Richard and Grosnickel2020; Odier et al., Reference Odier, Thacker, Harnieh, Staffelbach, Gicquel, Duchaine, Rosa and Müller2021). Indeed, while real turbomachines are typically not instrumented for boundary-layer measurements, experimental measurements, and high-fidelity LESs show that the friction Reynolds number based on boundary-layer thickness is in the range of 600–1000 in academic linear blade cascades with realistic operating conditions in terms of Reynolds and Mach numbers (Arts et al., Reference Arts, Rouvroit and Rutherford1990; Ma et al., Reference Ma, Ottavy, Lu, Francis and Gao2011; Gao et al., Reference Gao, Zambonini, Boudet, Ottavy, Lu and Shao2015; Zambonini et al., Reference Zambonini, Ottavy and Kriegseis2017; Dupuy et al., Reference Dupuy, Gicquel, Odier, Duchaine and Arts2020). However, this implies that the trained models are not applicable for cell sizes larger than

$ {e}^{+} $

implies that the first point off the wall of the WMLES mesh is typically within the logarithmic layer or the upper part of the buffer layer, in the case of a fully developed turbulent boundary layer. It is suitable for instance in turbomachinery-flow simulations (Leonard et al., Reference Leonard, Sanjose, Moreau and Duchaine2016; Dombard et al., Reference Dombard, Duchaine, Gicquel, Odier, Leroy, Buffaz, Le-Guyader, Démolis, Richard and Grosnickel2020; Odier et al., Reference Odier, Thacker, Harnieh, Staffelbach, Gicquel, Duchaine, Rosa and Müller2021). Indeed, while real turbomachines are typically not instrumented for boundary-layer measurements, experimental measurements, and high-fidelity LESs show that the friction Reynolds number based on boundary-layer thickness is in the range of 600–1000 in academic linear blade cascades with realistic operating conditions in terms of Reynolds and Mach numbers (Arts et al., Reference Arts, Rouvroit and Rutherford1990; Ma et al., Reference Ma, Ottavy, Lu, Francis and Gao2011; Gao et al., Reference Gao, Zambonini, Boudet, Ottavy, Lu and Shao2015; Zambonini et al., Reference Zambonini, Ottavy and Kriegseis2017; Dupuy et al., Reference Dupuy, Gicquel, Odier, Duchaine and Arts2020). However, this implies that the trained models are not applicable for cell sizes larger than

![]() $ {\Delta}^{+}=80 $

, which would make their use in flows with a very large friction Reynolds number (

$ {\Delta}^{+}=80 $

, which would make their use in flows with a very large friction Reynolds number (

![]() $ {10}^4 $

or above) impractical. It would in principle be possible to train the model on a wider range of mesh resolutions. However, it should be noted that this range would remain limited by the Reynolds number of the high-fidelity simulations in the training database. For instance, using a direct numerical simulations of a channel with a friction Reynolds number of 10,000 (Hoyas et al., Reference Hoyas, Oberlack, Alcántara-Ávila, Kraheberger and Laux2022), the present method could be used to train a model that can operate up to a cell size in the order of a thousand wall unit, but not an order of magnitude more.

$ {10}^4 $

or above) impractical. It would in principle be possible to train the model on a wider range of mesh resolutions. However, it should be noted that this range would remain limited by the Reynolds number of the high-fidelity simulations in the training database. For instance, using a direct numerical simulations of a channel with a friction Reynolds number of 10,000 (Hoyas et al., Reference Hoyas, Oberlack, Alcántara-Ávila, Kraheberger and Laux2022), the present method could be used to train a model that can operate up to a cell size in the order of a thousand wall unit, but not an order of magnitude more.

To filter the data, the instantaneous fields of the numerical database are first linearly interpolated on fine tetrahedral meshes. The resulting fields are used to compute the filtered variables on the coarse tetrahedral meshes. A surface filter is used for wall quantities while a volume filter is used outside the walls:

-

1. The surface filter (

$ {\underset{\dot{\mkern6mu}}{-}}^S $

) is defined as(1)with

$ {\underset{\dot{\mkern6mu}}{-}}^S $

) is defined as(1)with $$ {\overline{\phi}}^S\left({p}_0\right)=\sum \limits_{p\in {\mathfrak{w}}_{p_0}^S}{C}_{p_0}^S{S}_p{e}^{-\frac{{\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}}{2{\left({\sigma}_{p_0}^S\right)}^2}}\phi (p), $$

$$ {\overline{\phi}}^S\left({p}_0\right)=\sum \limits_{p\in {\mathfrak{w}}_{p_0}^S}{C}_{p_0}^S{S}_p{e}^{-\frac{{\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}}{2{\left({\sigma}_{p_0}^S\right)}^2}}\phi (p), $$

$ {\overline{\phi}}^S\left({p}_0\right) $

a filtered variable on a point

$ {\overline{\phi}}^S\left({p}_0\right) $

a filtered variable on a point

$ {p}_0 $

of the target coarse mesh,

$ {p}_0 $

of the target coarse mesh,

$ \phi (p) $

the corresponding unfiltered variable on a point

$ \phi (p) $

the corresponding unfiltered variable on a point

$ p $

of the source fine mesh,

$ p $

of the source fine mesh,

$ {C}_{p_0}^S $

a normalization constant,

$ {C}_{p_0}^S $

a normalization constant,

$ {S}_p $

the nodal area associated with node

$ {S}_p $

the nodal area associated with node

$ p $

on the source fine mesh,

$ p $

on the source fine mesh,

$ {\boldsymbol{r}}_p $

and

$ {\boldsymbol{r}}_p $

and

$ {\boldsymbol{r}}_{p_0} $

the position vector associated with point

$ {\boldsymbol{r}}_{p_0} $

the position vector associated with point

$ p $

and

$ p $

and

$ {p}_0 $

, respectively,

$ {p}_0 $

, respectively,

$ {\sigma}_{p_0}^S={\tilde{\Delta}}_{p_0}^S/\sqrt{12} $

the standard deviations of the surface Gaussian kernel,

$ {\sigma}_{p_0}^S={\tilde{\Delta}}_{p_0}^S/\sqrt{12} $

the standard deviations of the surface Gaussian kernel,

$ {\tilde{\Delta}}_{p_0}^S={\tilde{S}}_{p_0}^{1/2} $

the local filter width,

$ {\tilde{\Delta}}_{p_0}^S={\tilde{S}}_{p_0}^{1/2} $

the local filter width,

$ {\tilde{S}}_{p_0} $

the nodal area of node

$ {\tilde{S}}_{p_0} $

the nodal area of node

$ {p}_0 $

on the target coarse mesh and

$ {p}_0 $

on the target coarse mesh and

$ {\mathfrak{w}}_{p_0}^S=\left\{p\in {\mathfrak{P}}_{\mathfrak{f}}:\left(\parallel {\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}\parallel \le {\tilde{\Delta}}_{p_0}^S\right)\wedge \left({D}_{\mathfrak{W},p}=0\right)\right\} $

the isotropic window of the surface filter, where

$ {\mathfrak{w}}_{p_0}^S=\left\{p\in {\mathfrak{P}}_{\mathfrak{f}}:\left(\parallel {\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}\parallel \le {\tilde{\Delta}}_{p_0}^S\right)\wedge \left({D}_{\mathfrak{W},p}=0\right)\right\} $

the isotropic window of the surface filter, where

$ {\mathfrak{P}}_{\mathfrak{f}} $

is the set of points of the source mesh and

$ {\mathfrak{P}}_{\mathfrak{f}} $

is the set of points of the source mesh and

$ {D}_{\mathfrak{W},p} $

the shortest distance between

$ {D}_{\mathfrak{W},p} $

the shortest distance between

$ p $

and the target walls

$ p $

and the target walls

$ \mathfrak{W} $

.

$ \mathfrak{W} $

.

-

2. The volume filter (

$ \underset{\dot{\mkern6mu}}{-} $

) is defined as

$ \underset{\dot{\mkern6mu}}{-} $

) is defined as

(2)with $$ \overline{\phi}\left({p}_0\right)=\sum \limits_{p\in {\mathfrak{w}}_{p_0}}{C}_{p_0}{V}_p{e}^{-\frac{{\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}}{2{\left({\sigma}_{p_0}\right)}^2}}\phi (p), $$

$$ \overline{\phi}\left({p}_0\right)=\sum \limits_{p\in {\mathfrak{w}}_{p_0}}{C}_{p_0}{V}_p{e}^{-\frac{{\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}}{2{\left({\sigma}_{p_0}\right)}^2}}\phi (p), $$

$ {C}_{p_0} $

a normalization constant,

$ {C}_{p_0} $

a normalization constant,

$ {V}_p $

the nodal volume associated with node

$ {V}_p $

the nodal volume associated with node

$ p $

on the source fine mesh,

$ p $

on the source fine mesh,

$ {\sigma}_{p_0}={\tilde{\Delta}}_{p_0}/\sqrt{12} $

the standard deviations of the volume Gaussian kernel,

$ {\sigma}_{p_0}={\tilde{\Delta}}_{p_0}/\sqrt{12} $

the standard deviations of the volume Gaussian kernel,

$ {\tilde{\Delta}}_{p_0}={\tilde{V}}_{p_0}^{1/3} $

the volume filter width,

$ {\tilde{\Delta}}_{p_0}={\tilde{V}}_{p_0}^{1/3} $

the volume filter width,

$ {\tilde{V}}_{p_0} $

the nodal volume of node

$ {\tilde{V}}_{p_0} $

the nodal volume of node

$ {p}_0 $

on the target coarse mesh and

$ {p}_0 $

on the target coarse mesh and

$ {\mathfrak{w}}_{p_0}=\left\{p\in {\mathfrak{P}}_{\mathfrak{f}}:\left(\parallel {\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}\parallel \le {\tilde{\Delta}}_{p_0}\right)\wedge \left(|{D}_{\mathfrak{W},p}-{D}_{\mathfrak{W},{p}_0}|\le \frac{1}{2}{\tilde{\Delta}}_{p_0}\right)\right\} $

the window of the volume filter, restricted in the wall-normal direction. The volume Gaussian filter is corrected to compensate any bias on the mean profiles induced by the filter. The corrected filtered field may be expressed as

$ {\mathfrak{w}}_{p_0}=\left\{p\in {\mathfrak{P}}_{\mathfrak{f}}:\left(\parallel {\boldsymbol{r}}_p-{\boldsymbol{r}}_{p_0}\parallel \le {\tilde{\Delta}}_{p_0}\right)\wedge \left(|{D}_{\mathfrak{W},p}-{D}_{\mathfrak{W},{p}_0}|\le \frac{1}{2}{\tilde{\Delta}}_{p_0}\right)\right\} $

the window of the volume filter, restricted in the wall-normal direction. The volume Gaussian filter is corrected to compensate any bias on the mean profiles induced by the filter. The corrected filtered field may be expressed as

$ {\overline{\phi}}^{\ast }=\overline{\phi}+\left\langle \phi \right\rangle -\left\langle \overline{\phi}\right\rangle $

, where

$ {\overline{\phi}}^{\ast }=\overline{\phi}+\left\langle \phi \right\rangle -\left\langle \overline{\phi}\right\rangle $

, where

$ \left\langle \cdot \right\rangle $

denotes a time average.

$ \left\langle \cdot \right\rangle $

denotes a time average.

-

This filtering operation verifies the properties of (1) the conservation of constants

![]() $ {\overline{a}}^{\ast }=a $

, for any constant

$ {\overline{a}}^{\ast }=a $

, for any constant

![]() $ a $

; (2) linearity

$ a $

; (2) linearity

![]() $ {\overline{\phi +\psi}}^{\ast }={\overline{\phi}}^{\ast }+{\overline{\psi}}^{\ast } $

, for any

$ {\overline{\phi +\psi}}^{\ast }={\overline{\phi}}^{\ast }+{\overline{\psi}}^{\ast } $

, for any

![]() $ \phi $

and

$ \phi $

and

![]() $ \psi $

; and (3) DNS-convergence,

$ \psi $

; and (3) DNS-convergence,

![]() $ {\lim}_{{\tilde{\Delta}}_{p_0}\to 0}\overline{\phi}=\phi $

, that is, the filter has no effect in the limit of an arbitrarily small filter size. It should, however, be noted that the filter does not commute with spatial derivation, since it is a discrete approximation of a truncated Gaussian filter (Sagaut, Reference Sagaut2006).

$ {\lim}_{{\tilde{\Delta}}_{p_0}\to 0}\overline{\phi}=\phi $

, that is, the filter has no effect in the limit of an arbitrarily small filter size. It should, however, be noted that the filter does not commute with spatial derivation, since it is a discrete approximation of a truncated Gaussian filter (Sagaut, Reference Sagaut2006).

The filtered fields are partitioned to produce contiguous chunks of consistent size that can be used to train the model. The chunks only include nodes that are separated from the target walls

![]() $ \mathfrak{W} $

by

$ \mathfrak{W} $

by

![]() $ {N}_H=3 $

edges or less. The partitioning is performed using the library METIS (Karypis and Kumar, Reference Karypis and Kumar1998).

$ {N}_H=3 $

edges or less. The partitioning is performed using the library METIS (Karypis and Kumar, Reference Karypis and Kumar1998).

3. Scaling and data augmentation

To develop a model that can operate in a wide variety of flow configurations, it is critical to encode some prior physical knowledge of the flow dependencies in the learning process. Indeed, learning the wall behavior of fluids purely from data is only achievable using a dataset that includes a large diversity of physical phenomena and also encompasses a wide range of scales of length, velocity, temperature, or pressure. The present dataset only involves 10 configurations, which is undeniably too little to properly specify the problem along each of those dimensions purely from data. The present study combines input feature scaling and data augmentation to increase the generalizability of the model to other flows configurations. The approach is based on a low Mach number hypothesis that is only approximately verified in some real flows.

3.1. Mach-number equivariance

First, we give some theoretical background on the behavior of low Mach number flows, that will be relevant to construct the input features. We will show how, under some assumptions, modifying the scales of velocity, density, viscosity, and length does not change the underlying flow physics and thus should accordingly not alter the behavior of the model.

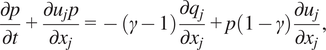

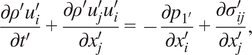

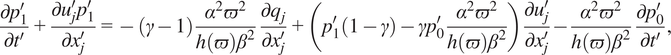

Consider a flow modeled using the compressible Navier–Stokes equations without body forces or heat sources and the ideal gas equation of state,

$$ \frac{\partial p}{\partial t}+\frac{\partial {u}_jp}{\partial {x}_j}=-\left(\gamma -1\right)\frac{\partial {q}_j}{\partial {x}_j}+p\left(1-\gamma \right)\frac{\partial {u}_j}{\partial {x}_j}, $$

$$ \frac{\partial p}{\partial t}+\frac{\partial {u}_jp}{\partial {x}_j}=-\left(\gamma -1\right)\frac{\partial {q}_j}{\partial {x}_j}+p\left(1-\gamma \right)\frac{\partial {u}_j}{\partial {x}_j}, $$

where

![]() $ \rho $

is the density,

$ \rho $

is the density,

![]() $ t $

the time,

$ t $

the time,

![]() $ p $

the pressure,

$ p $

the pressure,

![]() $ \gamma $

the adiabatic index of the fluid,

$ \gamma $

the adiabatic index of the fluid,

![]() $ r $

is the ideal gas-specific constant,

$ r $

is the ideal gas-specific constant,

![]() $ {u}_i $

the

$ {u}_i $

the

![]() $ i $

th component of velocity, and

$ i $

th component of velocity, and

![]() $ {x}_i $

the Cartesian coordinate in

$ {x}_i $

the Cartesian coordinate in

![]() $ i $

th direction. The shear-stress tensor

$ i $

th direction. The shear-stress tensor

![]() $ \sigma $

and the conductive heat flux

$ \sigma $

and the conductive heat flux

![]() $ \boldsymbol{q} $

are assumed to be of the form

$ \boldsymbol{q} $

are assumed to be of the form

![]() $ {\sigma}_{ij}=\mu (T)\left[\left({\partial}_j{u}_i+{\partial}_i{u}_j\right)-\left(2/3\right){\partial}_k{u}_k{\delta}_{ij}\right] $

and

$ {\sigma}_{ij}=\mu (T)\left[\left({\partial}_j{u}_i+{\partial}_i{u}_j\right)-\left(2/3\right){\partial}_k{u}_k{\delta}_{ij}\right] $

and

![]() $ {q}_j=-\lambda (T){\partial}_jT $

respectively, where the dynamic viscosity

$ {q}_j=-\lambda (T){\partial}_jT $

respectively, where the dynamic viscosity

![]() $ \mu (T) $

and the heat conductivity

$ \mu (T) $

and the heat conductivity

![]() $ \lambda (T) $

are functions of temperature. Dissipation has been neglected in the pressure evolution equation (5), as this term vanishes in the low Mach number limit (Paolucci, Reference Paolucci1982). The dynamic viscosity

$ \lambda (T) $

are functions of temperature. Dissipation has been neglected in the pressure evolution equation (5), as this term vanishes in the low Mach number limit (Paolucci, Reference Paolucci1982). The dynamic viscosity

![]() $ \mu (T) $

is monotonous increasing in terms of

$ \mu (T) $

is monotonous increasing in terms of

![]() $ T $

and separable,

$ T $

and separable,

![]() $ \mu (kT)={h}^{-1}(k)\mu (T) $

, which is for instance the case for a power law

$ \mu (kT)={h}^{-1}(k)\mu (T) $

, which is for instance the case for a power law

![]() $ \mu (T)={\mu}_0{\left(T/{T}_0\right)}^k $

. The thermal conductivity is given by

$ \mu (T)={\mu}_0{\left(T/{T}_0\right)}^k $

. The thermal conductivity is given by

![]() $ \lambda (T)=\mu (T){C}_p/\mathit{\Pr} $

, with

$ \lambda (T)=\mu (T){C}_p/\mathit{\Pr} $

, with

![]() $ {C}_p $

the isobaric heat capacity of the fluid and

$ {C}_p $

the isobaric heat capacity of the fluid and

![]() $ \mathit{\Pr} $

the Prandtl number of the fluid, both assumed constant. Suppose that this flow is characterized by a density scale

$ \mathit{\Pr} $

the Prandtl number of the fluid, both assumed constant. Suppose that this flow is characterized by a density scale

![]() $ {\rho}^b $

, a velocity scale

$ {\rho}^b $

, a velocity scale

![]() $ {u}^b $

, and a pressure scale

$ {u}^b $

, and a pressure scale

![]() $ {p}^b $

. The nondimensional numbers associated with the flow are the Reynolds number

$ {p}^b $

. The nondimensional numbers associated with the flow are the Reynolds number

![]() $ \mathit{\operatorname{Re}}={\rho}^b{u}^b{x}^b/\mu \left({T}^b\right) $

, the Prandtl number

$ \mathit{\operatorname{Re}}={\rho}^b{u}^b{x}^b/\mu \left({T}^b\right) $

, the Prandtl number

![]() $ \mathit{\Pr}=\mu \left({T}^b\right){C}_p/\lambda \left({T}^b\right) $

, and the Mach number

$ \mathit{\Pr}=\mu \left({T}^b\right){C}_p/\lambda \left({T}^b\right) $

, and the Mach number

![]() $ Ma={u}^b/{c}^b $

, with

$ Ma={u}^b/{c}^b $

, with

![]() $ {x}^b $

a length scale characterizing the geometry, and

$ {x}^b $

a length scale characterizing the geometry, and

![]() $ {c}^b=\sqrt{\gamma {rT}^b} $

the typical speed of sound.

$ {c}^b=\sqrt{\gamma {rT}^b} $

the typical speed of sound.

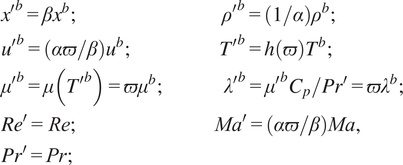

At the low Mach number limit, modifying the scales of the flows does not modify the flow in a nondimensional sense, provided that the Reynolds and Prandtl number are kept constant. Indeed, consider another similar flow with a different Mach number and different scales of length, velocity, and temperature but the same Reynolds and Prandtl number, as follows:

$$ {\displaystyle \begin{array}{l}{x^{\prime}}^b=\beta {x}^b;\hskip11.6em {\rho^{\prime}}^b=\left(1/\alpha \right){\rho}^b;\\ {}{u^{\prime}}^b=\left(\alpha \varpi /\beta \right){u}^b;\hskip7em {T^{\prime}}^b=h\left(\varpi \right){T}^b;\\ {}{\mu^{\prime}}^b=\mu \left({T^{\prime}}^b\right)={\varpi \mu}^b;\hskip4.8em {\lambda^{\prime}}^b={\mu^{\prime}}^b{C}_p/P{r}^{\prime }={\varpi \lambda}^b;\\ {}R{e}^{\prime }=\mathit{\operatorname{Re}};\hskip11em Ma^{\prime }=\left(\alpha \varpi /\beta \right) Ma,\\ {}P{r}^{\prime }=\mathit{\Pr};\end{array}} $$

$$ {\displaystyle \begin{array}{l}{x^{\prime}}^b=\beta {x}^b;\hskip11.6em {\rho^{\prime}}^b=\left(1/\alpha \right){\rho}^b;\\ {}{u^{\prime}}^b=\left(\alpha \varpi /\beta \right){u}^b;\hskip7em {T^{\prime}}^b=h\left(\varpi \right){T}^b;\\ {}{\mu^{\prime}}^b=\mu \left({T^{\prime}}^b\right)={\varpi \mu}^b;\hskip4.8em {\lambda^{\prime}}^b={\mu^{\prime}}^b{C}_p/P{r}^{\prime }={\varpi \lambda}^b;\\ {}R{e}^{\prime }=\mathit{\operatorname{Re}};\hskip11em Ma^{\prime }=\left(\alpha \varpi /\beta \right) Ma,\\ {}P{r}^{\prime }=\mathit{\Pr};\end{array}} $$

where

![]() $ \alpha $

,

$ \alpha $

,

![]() $ \beta $

, and

$ \beta $

, and

![]() $ \varpi $

are constant scalars characterizing the transformation. At low Mach number, the nondimensionalized density and velocity are independent of the Mach number while the Mach number dependence of pressure cannot be neglected. Namely,

$ \varpi $

are constant scalars characterizing the transformation. At low Mach number, the nondimensionalized density and velocity are independent of the Mach number while the Mach number dependence of pressure cannot be neglected. Namely,

![]() $ u/{u}^b\approx {\hat{u}}_0 $

,

$ u/{u}^b\approx {\hat{u}}_0 $

,

![]() $ \rho /{\rho}^b\approx {\hat{\rho}}_0 $

and

$ \rho /{\rho}^b\approx {\hat{\rho}}_0 $

and

![]() $ p/{p}^b\approx {\hat{p}}_0+{Ma}^2{\hat{p}}_1 $

, where

$ p/{p}^b\approx {\hat{p}}_0+{Ma}^2{\hat{p}}_1 $

, where

![]() $ {\hat{u}}_0 $

,

$ {\hat{u}}_0 $

,

![]() $ {\hat{\rho}}_0 $

,

$ {\hat{\rho}}_0 $

,

![]() $ {\hat{p}}_0 $

, and

$ {\hat{p}}_0 $

, and

![]() $ {\hat{p}}_1 $

do not depend on the Mach number (Lions and Moulden, Reference Lions and Moulden1996; Meister, Reference Meister1999; Munz et al., Reference Munz, Dumbser and Zucchini2003). The zeroth-order nondimensionalized pressure

$ {\hat{p}}_1 $

do not depend on the Mach number (Lions and Moulden, Reference Lions and Moulden1996; Meister, Reference Meister1999; Munz et al., Reference Munz, Dumbser and Zucchini2003). The zeroth-order nondimensionalized pressure

![]() $ {\hat{p}}_0 $

can be shown to be constant in space by injecting these asymptotic developments into the Navier–Stokes equations. It is therefore useful to decompose pressure in a thermodynamical pressure

$ {\hat{p}}_0 $

can be shown to be constant in space by injecting these asymptotic developments into the Navier–Stokes equations. It is therefore useful to decompose pressure in a thermodynamical pressure

![]() $ {p}_0={p}^b{\hat{p}}_0 $

and a mechanical pressure

$ {p}_0={p}^b{\hat{p}}_0 $

and a mechanical pressure

![]() $ {p}_1=p-{p}_0={p}^b{Ma}^2{\hat{p}}_1 $

. Hence, the thermodynamical and mechanical pressures are given by

$ {p}_1=p-{p}_0={p}^b{Ma}^2{\hat{p}}_1 $

. Hence, the thermodynamical and mechanical pressures are given by

![]() $ {p}_0^{\prime }={p^{\prime}}^b{\hat{p}}_0=\left(h\left(\varpi \right)/\alpha \right){p}_0 $

and

$ {p}_0^{\prime }={p^{\prime}}^b{\hat{p}}_0=\left(h\left(\varpi \right)/\alpha \right){p}_0 $

and

![]() $ {p}_1^{\prime }={p^{\prime}}^b{\alpha}^2{Ma}^2{\hat{p}}_1=\left({\alpha \varpi}^2/{\beta}^2\right){p}_1 $

.

$ {p}_1^{\prime }={p^{\prime}}^b{\alpha}^2{Ma}^2{\hat{p}}_1=\left({\alpha \varpi}^2/{\beta}^2\right){p}_1 $

.

Based on these insights, let us consider the change of variables

![]() $ x=\left(1/\beta \right){x}^{\prime } $

,

$ x=\left(1/\beta \right){x}^{\prime } $

,

![]() $ t=\left(\alpha \varpi /{\beta}^2\right){t}^{\prime } $

,

$ t=\left(\alpha \varpi /{\beta}^2\right){t}^{\prime } $

,

![]() $ u={u}^{\prime}\beta /\left(\alpha \varpi \right) $

,

$ u={u}^{\prime}\beta /\left(\alpha \varpi \right) $

,

![]() $ \rho =\alpha {\rho}^{\prime } $

,

$ \rho =\alpha {\rho}^{\prime } $

,

![]() $ {p}_0=\left(\alpha /h\left(\varpi \right)\right){p}_0^{\prime } $

,

$ {p}_0=\left(\alpha /h\left(\varpi \right)\right){p}_0^{\prime } $

,

![]() $ {p}_1={p}_1^{\prime }{\beta}^2/\left({\alpha \varpi}^2\right) $

,

$ {p}_1={p}_1^{\prime }{\beta}^2/\left({\alpha \varpi}^2\right) $

,

![]() $ T=\left(1/h\left(\varpi \right)\right){T}^{\prime } $

,

$ T=\left(1/h\left(\varpi \right)\right){T}^{\prime } $

,

![]() $ \mu ={\mu}^{\prime }/\varpi $

, and

$ \mu ={\mu}^{\prime }/\varpi $

, and

![]() $ \lambda ={\lambda}^{\prime }/\varpi $

. Hereafter, we refer to this change of variable as a Mach-number transformation, since this change of variable modifies the Mach number of the flow. Introducing the change of variables in equations (3)–(6) leads to:

$ \lambda ={\lambda}^{\prime }/\varpi $

. Hereafter, we refer to this change of variable as a Mach-number transformation, since this change of variable modifies the Mach number of the flow. Introducing the change of variables in equations (3)–(6) leads to:

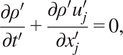

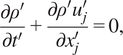

$$ \frac{\partial {\rho}^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }}{\partial {x}_j^{\prime }}=0, $$

$$ \frac{\partial {\rho}^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }}{\partial {x}_j^{\prime }}=0, $$

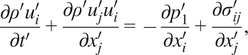

$$ \frac{\partial {\rho}^{\prime }{u}_i^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }{u}_i^{\prime }}{\partial {x}_j^{\prime }}=-\frac{\partial {p}_{1^{\prime }}}{\partial {x}_i^{\prime }}+\frac{\partial {\sigma}_{ij}^{\prime }}{\partial {x}_j^{\prime }}, $$

$$ \frac{\partial {\rho}^{\prime }{u}_i^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }{u}_i^{\prime }}{\partial {x}_j^{\prime }}=-\frac{\partial {p}_{1^{\prime }}}{\partial {x}_i^{\prime }}+\frac{\partial {\sigma}_{ij}^{\prime }}{\partial {x}_j^{\prime }}, $$

$$ \frac{\partial {p}_1^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {u}_j^{\prime }{p}_1^{\prime }}{\partial {x}_j^{\prime }}=-\left(\gamma -1\right)\frac{\alpha^2{\varpi}^2}{h\left(\varpi \right){\beta}^2}\frac{\partial {q}_j}{\partial {x}_j^{\prime }}+\left({p}_1^{\prime}\left(1-\gamma \right)-\gamma {p}_0^{\prime}\frac{\alpha^2{\varpi}^2}{h\left(\varpi \right){\beta}^2}\right)\frac{\partial {u}_j^{\prime }}{\partial {x}_j^{\prime }}-\frac{\alpha^2{\varpi}^2}{h\left(\varpi \right){\beta}^2}\frac{\partial {p}_0^{\prime }}{\partial {t}^{\prime }}, $$

$$ \frac{\partial {p}_1^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {u}_j^{\prime }{p}_1^{\prime }}{\partial {x}_j^{\prime }}=-\left(\gamma -1\right)\frac{\alpha^2{\varpi}^2}{h\left(\varpi \right){\beta}^2}\frac{\partial {q}_j}{\partial {x}_j^{\prime }}+\left({p}_1^{\prime}\left(1-\gamma \right)-\gamma {p}_0^{\prime}\frac{\alpha^2{\varpi}^2}{h\left(\varpi \right){\beta}^2}\right)\frac{\partial {u}_j^{\prime }}{\partial {x}_j^{\prime }}-\frac{\alpha^2{\varpi}^2}{h\left(\varpi \right){\beta}^2}\frac{\partial {p}_0^{\prime }}{\partial {t}^{\prime }}, $$

At the limit of a low Mach number, the terms involving

![]() $ {p}_1^{\prime } $

in equations (9) and (10) vanish and the system of equations (7)–(10) tends to the low Mach number equations of Paolucci (Reference Paolucci1982):

$ {p}_1^{\prime } $

in equations (9) and (10) vanish and the system of equations (7)–(10) tends to the low Mach number equations of Paolucci (Reference Paolucci1982):

$$ \frac{\partial {\rho}^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }}{\partial {x}_j^{\prime }}=0, $$

$$ \frac{\partial {\rho}^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }}{\partial {x}_j^{\prime }}=0, $$

$$ \frac{\partial {\rho}^{\prime }{u}_i^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }{u}_i^{\prime }}{\partial {x}_j^{\prime }}=-\frac{\partial {p}_1^{\prime }}{\partial {x}_i^{\prime }}+\frac{\partial {\sigma}_{ij}^{\prime }}{\partial {x}_j^{\prime }}, $$

$$ \frac{\partial {\rho}^{\prime }{u}_i^{\prime }}{\partial {t}^{\prime }}+\frac{\partial {\rho}^{\prime }{u}_j^{\prime }{u}_i^{\prime }}{\partial {x}_j^{\prime }}=-\frac{\partial {p}_1^{\prime }}{\partial {x}_i^{\prime }}+\frac{\partial {\sigma}_{ij}^{\prime }}{\partial {x}_j^{\prime }}, $$

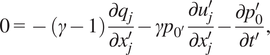

$$ 0=-\left(\gamma -1\right)\frac{\partial {q}_j}{\partial {x}_j^{\prime }}-\gamma {p}_{0^{\prime }}\frac{\partial {u}_j^{\prime }}{\partial {x}_j^{\prime }}-\frac{\partial {p}_0^{\prime }}{\partial {t}^{\prime }}, $$

$$ 0=-\left(\gamma -1\right)\frac{\partial {q}_j}{\partial {x}_j^{\prime }}-\gamma {p}_{0^{\prime }}\frac{\partial {u}_j^{\prime }}{\partial {x}_j^{\prime }}-\frac{\partial {p}_0^{\prime }}{\partial {t}^{\prime }}, $$

This system of equations does not depend on any of the scalar parameters

![]() $ \alpha $

,

$ \alpha $

,

![]() $ \beta $

, or

$ \beta $

, or

![]() $ \varpi $

. Hence, the Mach-number transformation is parameterized by

$ \varpi $

. Hence, the Mach-number transformation is parameterized by

![]() $ \alpha $

,

$ \alpha $

,

![]() $ \beta $

, and

$ \beta $

, and

![]() $ \varpi $

does not modify the system of equations. It follows that the solution of the system of equations (11)–(14) with different scales of velocity, density, viscosity, and length can be deduced from such transformation.

$ \varpi $

does not modify the system of equations. It follows that the solution of the system of equations (11)–(14) with different scales of velocity, density, viscosity, and length can be deduced from such transformation.

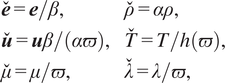

To summarize, a relevant corollary with respect to the machine learning model is that under a Mach-number transformation of its the input features,

$$ {\displaystyle \begin{array}{ll}\overset{\check{}}{\boldsymbol{e}}=\boldsymbol{e}/\beta, & \overset{\check{}}{\rho }=\alpha \rho, \\ {}\overset{\check{}}{\boldsymbol{u}}=\boldsymbol{u}\beta /\left(\alpha \varpi \right),& \overset{\check{}}{T}=T/h\left(\varpi \right),\\ {}\overset{\check{}}{\mu }=\mu /\varpi, & \overset{\check{}}{\lambda }=\lambda /\varpi, \end{array}} $$

$$ {\displaystyle \begin{array}{ll}\overset{\check{}}{\boldsymbol{e}}=\boldsymbol{e}/\beta, & \overset{\check{}}{\rho }=\alpha \rho, \\ {}\overset{\check{}}{\boldsymbol{u}}=\boldsymbol{u}\beta /\left(\alpha \varpi \right),& \overset{\check{}}{T}=T/h\left(\varpi \right),\\ {}\overset{\check{}}{\mu }=\mu /\varpi, & \overset{\check{}}{\lambda }=\lambda /\varpi, \end{array}} $$

the model’s prediction should undergo the same transformation. Namely, the norm of the shear stress vector

![]() $ \tau =\Sigma \cdot {\boldsymbol{e}}_{\boldsymbol{n}}-\left({\boldsymbol{e}}_{\boldsymbol{n}}\cdot \Sigma \cdot {\boldsymbol{e}}_{\boldsymbol{n}}\right){\boldsymbol{e}}_{\boldsymbol{n}} $

, where

$ \tau =\Sigma \cdot {\boldsymbol{e}}_{\boldsymbol{n}}-\left({\boldsymbol{e}}_{\boldsymbol{n}}\cdot \Sigma \cdot {\boldsymbol{e}}_{\boldsymbol{n}}\right){\boldsymbol{e}}_{\boldsymbol{n}} $

, where

![]() $ \Sigma =\mu \left(\nabla \boldsymbol{u}+{\left(\nabla \boldsymbol{u}\right)}^T-\left(2/3\right)\left(\nabla \cdot \boldsymbol{u}\right){\mathbf{I}}_{\mathbf{d}}\right) $

is the viscous stress tensor and

$ \Sigma =\mu \left(\nabla \boldsymbol{u}+{\left(\nabla \boldsymbol{u}\right)}^T-\left(2/3\right)\left(\nabla \cdot \boldsymbol{u}\right){\mathbf{I}}_{\mathbf{d}}\right) $

is the viscous stress tensor and

![]() $ {\boldsymbol{e}}_{\boldsymbol{n}} $

a unit wall-normal vector, and the norm of the heat flux at the wall should undergo the transformation

$ {\boldsymbol{e}}_{\boldsymbol{n}} $

a unit wall-normal vector, and the norm of the heat flux at the wall should undergo the transformation

This property will thereupon will be referred to as the Mach-number equivariance of the model. Particular cases of the Mach-number transformation are the

![]() $ \alpha $

-transformation,

$ \alpha $

-transformation,

![]() $ \beta $

-transformation, and

$ \beta $

-transformation, and

![]() $ \varpi $

-transformation, which respectively correspond to

$ \varpi $

-transformation, which respectively correspond to

![]() $ \beta =\varpi =1 $

,

$ \beta =\varpi =1 $

,

![]() $ \alpha =\varpi =1 $

, and

$ \alpha =\varpi =1 $

, and

![]() $ \alpha =\beta =1 $

. The equivariance of the model under a Mach-number transformation is not exact for real flows, including the flows in the numerical database, as it relies on several approximations, most notably that of a low Mach number and constant adiabatic index. It is nevertheless useful to introduce this approximate equivariance in the learning process to build with limited data a model that can generalize to flows with different scales of velocity, density, viscosity, and length. The a priori results should demonstrate that these approximations are not critical for the performance of the model.

$ \alpha =\beta =1 $

. The equivariance of the model under a Mach-number transformation is not exact for real flows, including the flows in the numerical database, as it relies on several approximations, most notably that of a low Mach number and constant adiabatic index. It is nevertheless useful to introduce this approximate equivariance in the learning process to build with limited data a model that can generalize to flows with different scales of velocity, density, viscosity, and length. The a priori results should demonstrate that these approximations are not critical for the performance of the model.

3.2. Strategies for equivariance enforcement

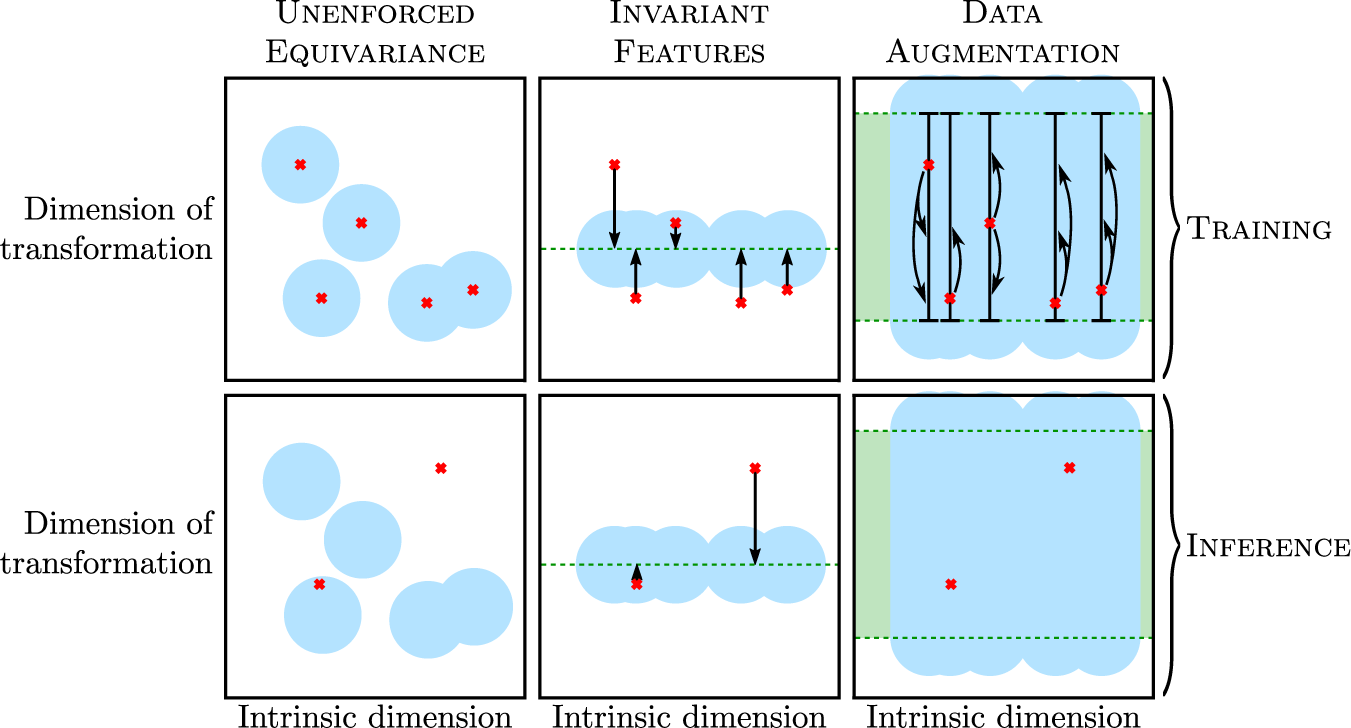

There are at least to two ways to leverage the equivariance of the model to a transformation

![]() $ \mathcal{P} $

within the training process: the invariant feature strategy and the data-augmentation strategy. In the invariant-feature strategy, the model is expressed in terms of invariant trainable functions by algorithmically constructing invariant features from the input data

$ \mathcal{P} $

within the training process: the invariant feature strategy and the data-augmentation strategy. In the invariant-feature strategy, the model is expressed in terms of invariant trainable functions by algorithmically constructing invariant features from the input data

![]() $ \boldsymbol{X} $

(Villar et al., Reference Villar, Storey-Fisher, Yao and Blum-Smith2021, Reference Villar, Yao, Hogg, Blum-Smith and Dumitrascu2022). One particular way to construct these invariant features is to use a reference to restrict the input space of the model. For instance, a privileged direction and an intrinsic velocity reference can be used to enforce rotational invariance and Galilean equivariance respectively. For machine-learning wall modeling, the wall may provide such references for the

$ \boldsymbol{X} $

(Villar et al., Reference Villar, Storey-Fisher, Yao and Blum-Smith2021, Reference Villar, Yao, Hogg, Blum-Smith and Dumitrascu2022). One particular way to construct these invariant features is to use a reference to restrict the input space of the model. For instance, a privileged direction and an intrinsic velocity reference can be used to enforce rotational invariance and Galilean equivariance respectively. For machine-learning wall modeling, the wall may provide such references for the

![]() $ \alpha $

- and

$ \alpha $

- and

![]() $ \varpi $

-transformations. In the data-augmentation strategy, the input space of the model is increased by using the transformation

$ \varpi $

-transformations. In the data-augmentation strategy, the input space of the model is increased by using the transformation

![]() $ \mathcal{P} $

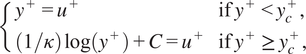

to create modified copies of the training samples. For instance, arbitrary rotations and translations can be used to enforce rotational invariance and Galilean equivariance respectively. The two strategies are represented schematically in Figure 1. The invariant-feature strategy is generally more costly than the data augmentation in terms of training time. However, it adds a pre-processing and post-processing step to the model at inference time, which may hinder its implementation in a CFD code.

$ \mathcal{P} $

to create modified copies of the training samples. For instance, arbitrary rotations and translations can be used to enforce rotational invariance and Galilean equivariance respectively. The two strategies are represented schematically in Figure 1. The invariant-feature strategy is generally more costly than the data augmentation in terms of training time. However, it adds a pre-processing and post-processing step to the model at inference time, which may hinder its implementation in a CFD code.

Figure 1. Schematic representation of the scaling and data augmentation strategies, where the input space is formally decomposed into the dimension of a transformation

![]() $ \mathcal{P} $

, with respect to which the model is assumed equivariant, and an intrinsic dimension, which represents of the physical content of the input data, invariant under

$ \mathcal{P} $

, with respect to which the model is assumed equivariant, and an intrinsic dimension, which represents of the physical content of the input data, invariant under

![]() $ \mathcal{P} $

. The red crosses represent different simulations seen during training or at inference time. The blue areas are the portion of input space seen during training, which for illustrative purpose is assumed to be a sphere in the feature space.

$ \mathcal{P} $

. The red crosses represent different simulations seen during training or at inference time. The blue areas are the portion of input space seen during training, which for illustrative purpose is assumed to be a sphere in the feature space.

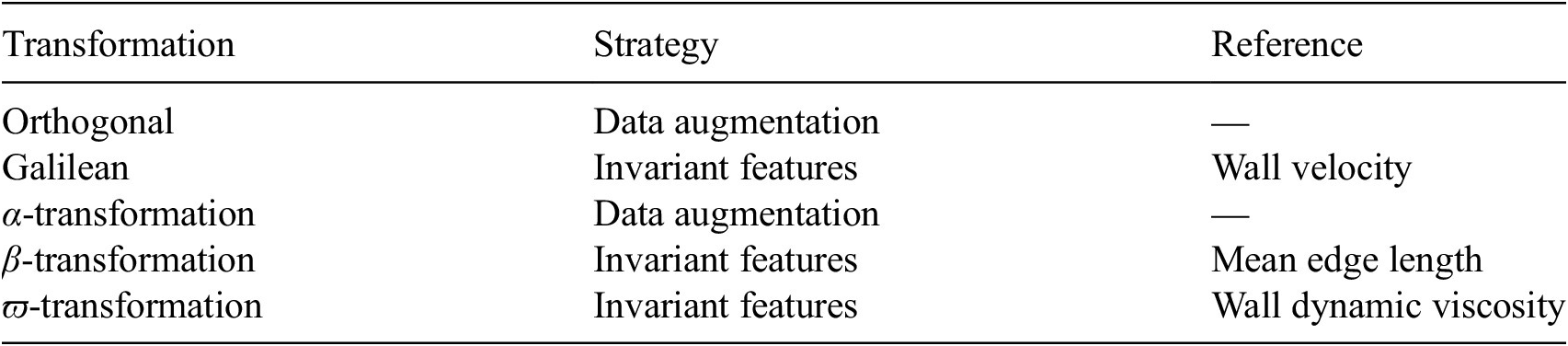

In the present study, the equivariance of the model under an orthogonal transformation, a Galilean transformation, and the

![]() $ \alpha $

-,

$ \alpha $

-,

![]() $ \beta $

-, and

$ \beta $

-, and

![]() $ \varpi $

-transformations defined in Section 3.1 are considered. Since the walls are assumed to be isothermal, the dynamic viscosity is constant at the walls assuming that dynamic viscosity is only function of temperature. Accordingly, it is straightforward to define a

$ \varpi $

-transformations defined in Section 3.1 are considered. Since the walls are assumed to be isothermal, the dynamic viscosity is constant at the walls assuming that dynamic viscosity is only function of temperature. Accordingly, it is straightforward to define a

![]() $ \varpi $

-transformation that scales dynamic viscosity. In contrast, the wall density may vary due to variations of pressure and accordingly, it is difficult to equivocally select a particular value of the wall density to define an

$ \varpi $

-transformation that scales dynamic viscosity. In contrast, the wall density may vary due to variations of pressure and accordingly, it is difficult to equivocally select a particular value of the wall density to define an

![]() $ \alpha $

-transformation that scales density. Indeed, the density at each grid point is used for predictions at several wall locations. In light of the above, a strategy based on data augmentation has been selected to impose the equivariance of the model under a

$ \alpha $

-transformation that scales density. Indeed, the density at each grid point is used for predictions at several wall locations. In light of the above, a strategy based on data augmentation has been selected to impose the equivariance of the model under a

![]() $ \varpi $

-transformation while a strategy based on the scaling of input features has been selected to impose the equivariance of the model under an

$ \varpi $

-transformation while a strategy based on the scaling of input features has been selected to impose the equivariance of the model under an

![]() $ \alpha $

-transformation. Data augmentation is also used to ensure that the prediction of the model does not depend on the coordinate system. Table 2 summarizes the strategy used to enforce the equivariance of the model under each transformation considered:

$ \alpha $

-transformation. Data augmentation is also used to ensure that the prediction of the model does not depend on the coordinate system. Table 2 summarizes the strategy used to enforce the equivariance of the model under each transformation considered:

-

• Orthogonal equivariance is ensured by augmenting the dataset with arbitrary three-dimensional rotations and reflections of the axes.

-

• Galilean equivariance is ensured by expressing the input velocity relatively to the wall motion.

-

•

$ \alpha $

-equivariance is ensured by augmenting the dataset with arbitrary

$ \alpha $

-equivariance is ensured by augmenting the dataset with arbitrary

$ \alpha $

-transformations, with

$ \alpha $

-transformations, with

$ \alpha $

sampled from the log-uniform distribution with range

$ \alpha $

sampled from the log-uniform distribution with range

$ \left[{\rho}_{\mathrm{min}}/{\left\langle \rho \right\rangle}_{\mathfrak{W}},{\rho}_{\mathrm{max}}/{\left\langle \rho \right\rangle}_{\mathfrak{W}}\right] $

, where

$ \left[{\rho}_{\mathrm{min}}/{\left\langle \rho \right\rangle}_{\mathfrak{W}},{\rho}_{\mathrm{max}}/{\left\langle \rho \right\rangle}_{\mathfrak{W}}\right] $

, where

$ {\left\langle \parallel \rho \parallel \right\rangle}_{\mathfrak{W}} $

is the mean wall density and where

$ {\left\langle \parallel \rho \parallel \right\rangle}_{\mathfrak{W}} $

is the mean wall density and where

$ \left[{\rho}_{\mathrm{min}},{\rho}_{\mathrm{max}}\right] $

is the desired density range of the model.

$ \left[{\rho}_{\mathrm{min}},{\rho}_{\mathrm{max}}\right] $

is the desired density range of the model. -

•

$ \beta $

-equivariance is ensured by scaling the input data using the average edge length of the graph, denoted

$ \beta $

-equivariance is ensured by scaling the input data using the average edge length of the graph, denoted

$ {\left\langle \parallel \boldsymbol{e}\parallel \right\rangle}_{\mathfrak{G}} $

, that is by applying a

$ {\left\langle \parallel \boldsymbol{e}\parallel \right\rangle}_{\mathfrak{G}} $

, that is by applying a

$ \beta $

-transformation with

$ \beta $

-transformation with

$ \beta ={\left\langle \parallel \boldsymbol{e}\parallel \right\rangle}_{\mathfrak{G}} $

.

$ \beta ={\left\langle \parallel \boldsymbol{e}\parallel \right\rangle}_{\mathfrak{G}} $

. -

•

$ \varpi $

-equivariance is ensured by scaling the input data using the wall dynamic viscosity

$ \varpi $

-equivariance is ensured by scaling the input data using the wall dynamic viscosity

$ {\mu}_{\mathrm{wall}} $

, that is by applying a

$ {\mu}_{\mathrm{wall}} $

, that is by applying a

$ \varpi $

-transformation with

$ \varpi $

-transformation with

$ \varpi ={\mu}_{\mathrm{wall}} $

.

$ \varpi ={\mu}_{\mathrm{wall}} $

.

Table 2. Strategies used to enforce the equivariance of the machine-learning model to various transformations, and references used to compute the scalings

For ease of interpretation, notice that the scaled input velocity may be expressed as

![]() $ \overset{\check{}}{\boldsymbol{u}}={\overset{\check{}}{\boldsymbol{u}}}^{+}{\left\langle \parallel {\boldsymbol{e}}^{+}\parallel \right\rangle}_{\mathfrak{G}}/\left({\alpha \rho}_{\mathrm{wall}}\right) $

, the scaled target wall shear stress as

$ \overset{\check{}}{\boldsymbol{u}}={\overset{\check{}}{\boldsymbol{u}}}^{+}{\left\langle \parallel {\boldsymbol{e}}^{+}\parallel \right\rangle}_{\mathfrak{G}}/\left({\alpha \rho}_{\mathrm{wall}}\right) $

, the scaled target wall shear stress as

![]() $ \overset{\check{}}{\tau }={\left\langle \parallel {\boldsymbol{e}}^{+}\parallel \right\rangle}_{\mathfrak{G}}^2/\left({\alpha \rho}_{\mathrm{wall}}\right) $

and the scaled wall heat flux

$ \overset{\check{}}{\tau }={\left\langle \parallel {\boldsymbol{e}}^{+}\parallel \right\rangle}_{\mathfrak{G}}^2/\left({\alpha \rho}_{\mathrm{wall}}\right) $

and the scaled wall heat flux

![]() $ \overset{\check{}}{q} $

is proportional to

$ \overset{\check{}}{q} $

is proportional to

![]() $ Cp\left(\left(\overset{\check{}}{T}-{\overset{\check{}}{T}}_{\mathrm{wall}}\right)/{\overset{\check{}}{T}}_{\mathrm{wall}}\right){\left\langle \parallel {\boldsymbol{e}}^{+}\parallel \right\rangle}_{\mathfrak{G}}/{T}^{+} $

, where

$ Cp\left(\left(\overset{\check{}}{T}-{\overset{\check{}}{T}}_{\mathrm{wall}}\right)/{\overset{\check{}}{T}}_{\mathrm{wall}}\right){\left\langle \parallel {\boldsymbol{e}}^{+}\parallel \right\rangle}_{\mathfrak{G}}/{T}^{+} $

, where

![]() $ {}^{+} $

denotes the classical wall-unit scaling, namely

$ {}^{+} $

denotes the classical wall-unit scaling, namely

![]() $ {e}^{+}={eu}_{\tau }/{\nu}_{\omega } $

,

$ {e}^{+}={eu}_{\tau }/{\nu}_{\omega } $

,

![]() $ {\boldsymbol{u}}^{+}=\boldsymbol{u}/{u}_{\tau } $

, and

$ {\boldsymbol{u}}^{+}=\boldsymbol{u}/{u}_{\tau } $

, and

![]() $ {T}^{+}={\rho}_{\omega }{C}_p{u}_{\tau}\left(T-{T}_{\mathrm{wall}}\right)/q $

. This scaling uniformizes the length scale of the various simulations included in the training database, but it does not negate differences in terms of mesh resolution, which implies that ideally a wide range of mesh resolution need to be included in the training dataset. Similarly, the scaling uniformizes the viscosity scale of the various simulations included in the training database, but it does not negate differences in terms of viscosity ratio between the wall and bulk flow, which implies that ideally a wide range of such viscosity ratio should be found in the training dataset.

$ {T}^{+}={\rho}_{\omega }{C}_p{u}_{\tau}\left(T-{T}_{\mathrm{wall}}\right)/q $

. This scaling uniformizes the length scale of the various simulations included in the training database, but it does not negate differences in terms of mesh resolution, which implies that ideally a wide range of mesh resolution need to be included in the training dataset. Similarly, the scaling uniformizes the viscosity scale of the various simulations included in the training database, but it does not negate differences in terms of viscosity ratio between the wall and bulk flow, which implies that ideally a wide range of such viscosity ratio should be found in the training dataset.

4. Wall modeling

This section presents the architecture of the graph neural network wall model and the algebraic wall models used as baselines.

4.1. Baseline wall models

Two algebraic wall models are used as baselines: an uncoupled velocity-temperature algebraic wall model and the coupled velocity-temperature algebraic wall model of Cabrit and Nicoud (Reference Cabrit and Nicoud2009).

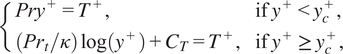

The uncoupled algebraic wall model provides a boundary condition for the wall shear stress and the wall conductive heat flux without taking into account the coupling between the velocity and temperature profiles. Namely, the wall shear stress is obtained by solving the incompressible law of the wall,

$$ \left\{\begin{array}{ll}{y}^{+}={u}^{+}& \mathrm{if}\;{y}^{+}<{y}_c^{+},\\ {}\left(1/\kappa \right)\log \left({y}^{+}\right)+C={u}^{+}& \mathrm{if}\;{y}^{+}\ge {y}_c^{+},\end{array}\right. $$

$$ \left\{\begin{array}{ll}{y}^{+}={u}^{+}& \mathrm{if}\;{y}^{+}<{y}_c^{+},\\ {}\left(1/\kappa \right)\log \left({y}^{+}\right)+C={u}^{+}& \mathrm{if}\;{y}^{+}\ge {y}_c^{+},\end{array}\right. $$

and the wall heat flux is obtained by solving the temperature law

$$ \left\{\begin{array}{ll}{Pry}^{+}={T}^{+},& \mathrm{if}\;{y}^{+}<{y}_c^{+},\\ {}\left({\mathit{\Pr}}_t/\kappa \right)\log \left({y}^{+}\right)+{C}_T={T}^{+},& \mathrm{if}\;{y}^{+}\ge {y}_c^{+},\end{array}\right. $$

$$ \left\{\begin{array}{ll}{Pry}^{+}={T}^{+},& \mathrm{if}\;{y}^{+}<{y}_c^{+},\\ {}\left({\mathit{\Pr}}_t/\kappa \right)\log \left({y}^{+}\right)+{C}_T={T}^{+},& \mathrm{if}\;{y}^{+}\ge {y}_c^{+},\end{array}\right. $$

with

![]() $ \kappa =0.41 $

the von Kármán constant,

$ \kappa =0.41 $

the von Kármán constant,

![]() $ C=5.5 $

a scalar constant,

$ C=5.5 $

a scalar constant,

![]() $ {\mathit{\Pr}}_t=0.85 $

the turbulent Prandtl number and

$ {\mathit{\Pr}}_t=0.85 $

the turbulent Prandtl number and

a function of the Prandtl number (Kader, Reference Kader1981). The threshold

![]() $ {y}_c^{+}=11.445 $

is a critical value of the scaled first point height separating the viscous and inertial sublayers. The scaled wall distance is

$ {y}_c^{+}=11.445 $

is a critical value of the scaled first point height separating the viscous and inertial sublayers. The scaled wall distance is

![]() $ {y}^{+}={yu}_{\tau }/{\nu}_{\omega } $

, the scaled temperature

$ {y}^{+}={yu}_{\tau }/{\nu}_{\omega } $

, the scaled temperature

![]() $ {T}^{+}=\left(T-{T}_{\omega}\right)/{T}_{\tau } $

and the scaled velocity

$ {T}^{+}=\left(T-{T}_{\omega}\right)/{T}_{\tau } $

and the scaled velocity

![]() $ {u}^{+}=u/{u}_{\tau } $

. The wall shear stress and conductive heat flux are solved sequentially from equations (17) then (18) and the friction velocity and friction temperature definitions, namely

$ {u}^{+}=u/{u}_{\tau } $

. The wall shear stress and conductive heat flux are solved sequentially from equations (17) then (18) and the friction velocity and friction temperature definitions, namely

![]() $ \tau ={\rho}_{\omega }{u}_{\tau}^2 $

and

$ \tau ={\rho}_{\omega }{u}_{\tau}^2 $

and

![]() $ {q}_{\omega }={\rho}_{\omega }{C}_p{u}_{\tau }{T}_{\tau } $

. The uncoupled algebraic model does not take into account the effect of the temperature variations to determine the wall shear stress. It is commonly used and accurate in flows with a negligible coupling between the fields of velocity and temperature, for example, when the temperature variations are not large.

$ {q}_{\omega }={\rho}_{\omega }{C}_p{u}_{\tau }{T}_{\tau } $

. The uncoupled algebraic model does not take into account the effect of the temperature variations to determine the wall shear stress. It is commonly used and accurate in flows with a negligible coupling between the fields of velocity and temperature, for example, when the temperature variations are not large.

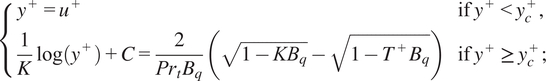

The coupled algebraic wall model of Cabrit and Nicoud (Reference Cabrit and Nicoud2009) is an algebraic model that takes into account the coupling between the fields of velocity and temperature. In the case of a compressible non-reacting flow, the coupled wall model of Cabrit and Nicoud (Reference Cabrit and Nicoud2009) may be expressed by the following system of equations.

-

• Velocity equation:

$$ \left\{\begin{array}{ll}{y}^{+}={u}^{+}& \mathrm{if}\;{y}^{+}<{y}_c^{+},\\ {}\frac{1}{K}\log \left({y}^{+}\right)+C=\frac{2}{{\mathit{\Pr}}_t{B}_q}\left(\sqrt{1-{KB}_q}-\sqrt{1-{T}^{+}{B}_q}\right)& \mathrm{if}\;{y}^{+}\ge {y}_c^{+};\end{array}\right. $$

$$ \left\{\begin{array}{ll}{y}^{+}={u}^{+}& \mathrm{if}\;{y}^{+}<{y}_c^{+},\\ {}\frac{1}{K}\log \left({y}^{+}\right)+C=\frac{2}{{\mathit{\Pr}}_t{B}_q}\left(\sqrt{1-{KB}_q}-\sqrt{1-{T}^{+}{B}_q}\right)& \mathrm{if}\;{y}^{+}\ge {y}_c^{+};\end{array}\right. $$

-

• Temperature equation:

with

![]() $ {B}_q={T}_{\tau }/{T}_{\omega } $

the anisothermicity factor, and

$ {B}_q={T}_{\tau }/{T}_{\omega } $

the anisothermicity factor, and

![]() $ K $

a function of the Prandtl number, given by

$ K $

a function of the Prandtl number, given by

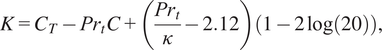

$$ K={C}_T-{\mathit{\Pr}}_tC+\left(\frac{{\mathit{\Pr}}_t}{\kappa }-2.12\right)\left(1-2\log (20)\right), $$

$$ K={C}_T-{\mathit{\Pr}}_tC+\left(\frac{{\mathit{\Pr}}_t}{\kappa }-2.12\right)\left(1-2\log (20)\right), $$

where

![]() $ {C}_T $

is defined in equation (19). To solve this system of equations, a candidate friction velocity is first computed by injecting

$ {C}_T $

is defined in equation (19). To solve this system of equations, a candidate friction velocity is first computed by injecting

![]() $ {y}^{+}={yu}_{\tau }/{\nu}_{\omega } $

and

$ {y}^{+}={yu}_{\tau }/{\nu}_{\omega } $

and

![]() $ {T}^{+}=\left(T-{T}_{\omega}\right)/{T}_{\tau } $

in equation (2

1). This candidate value is discarded if the corresponding scaled first point height

$ {T}^{+}=\left(T-{T}_{\omega}\right)/{T}_{\tau } $

in equation (2

1). This candidate value is discarded if the corresponding scaled first point height

![]() $ {y}^{+} $

is less than

$ {y}^{+} $

is less than

![]() $ {y}_c^{+} $

, in which case

$ {y}_c^{+} $

, in which case

![]() $ {u}_{\tau } $

is solved using (20). In any case, the friction temperature

$ {u}_{\tau } $

is solved using (20). In any case, the friction temperature

![]() $ {T}_{\tau } $

is then computed by injecting

$ {T}_{\tau } $

is then computed by injecting

![]() $ {u}^{+}=u/{u}_{\tau } $

in equation (22). The wall shear stress and conductive heat flux are deduced from the friction velocity and temperature definitions, namely

$ {u}^{+}=u/{u}_{\tau } $

in equation (22). The wall shear stress and conductive heat flux are deduced from the friction velocity and temperature definitions, namely

![]() $ \tau ={\rho}_{\omega }{u}_{\tau}^2 $

and

$ \tau ={\rho}_{\omega }{u}_{\tau}^2 $

and

![]() $ {q}_{\omega }={\rho}_{\omega }{C}_p{u}_{\tau }{T}_{\tau } $

. The coupled algebraic model of Cabrit and Nicoud (Reference Cabrit and Nicoud2009) takes into account the effect of the temperature variations to determine the wall shear stress. It is relevant for fully developed turbulent boundary layers with large temperature variations.

$ {q}_{\omega }={\rho}_{\omega }{C}_p{u}_{\tau }{T}_{\tau } $

. The coupled algebraic model of Cabrit and Nicoud (Reference Cabrit and Nicoud2009) takes into account the effect of the temperature variations to determine the wall shear stress. It is relevant for fully developed turbulent boundary layers with large temperature variations.

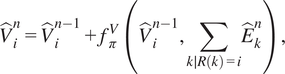

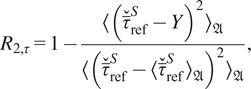

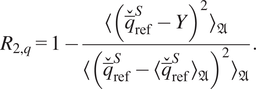

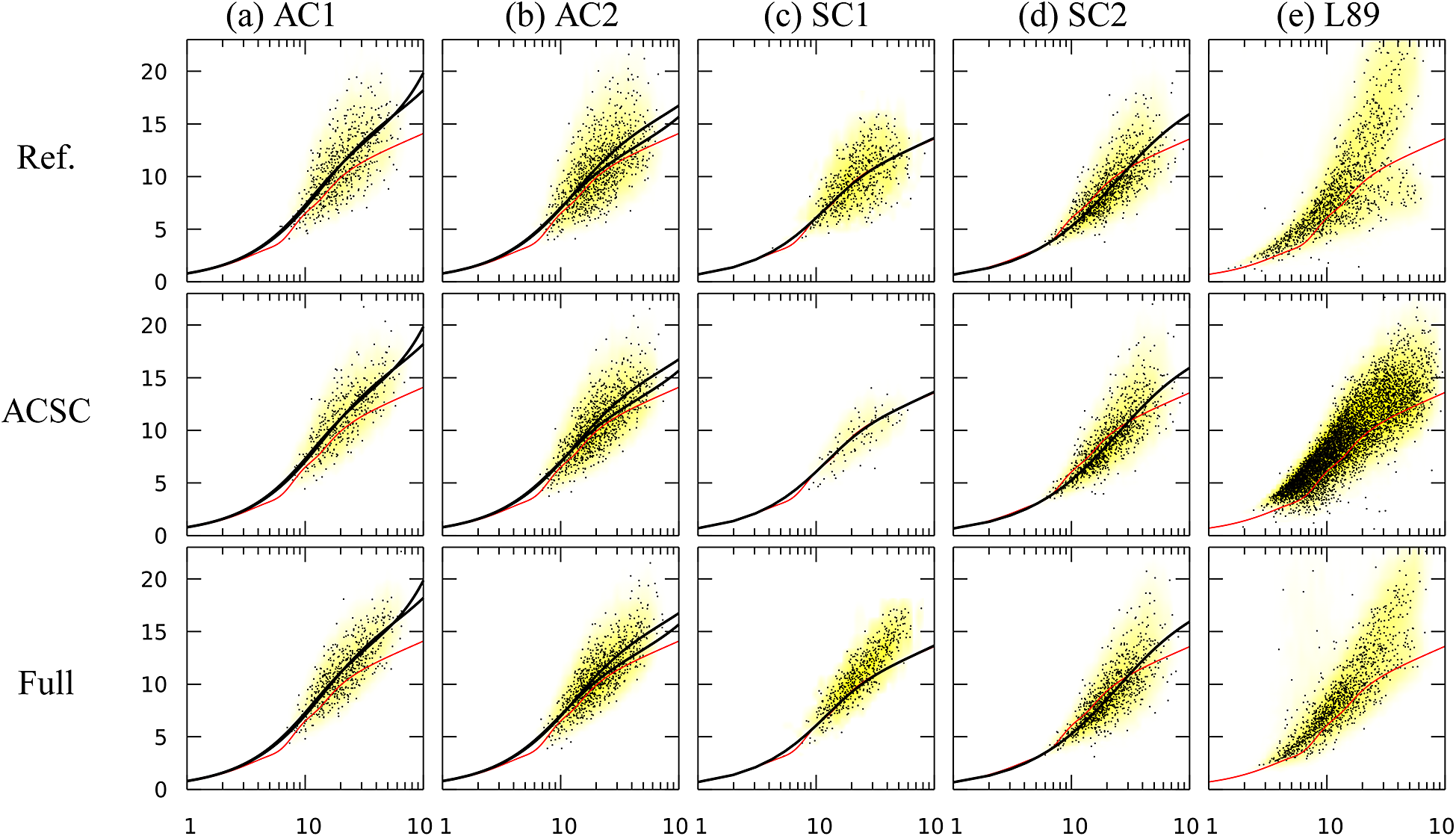

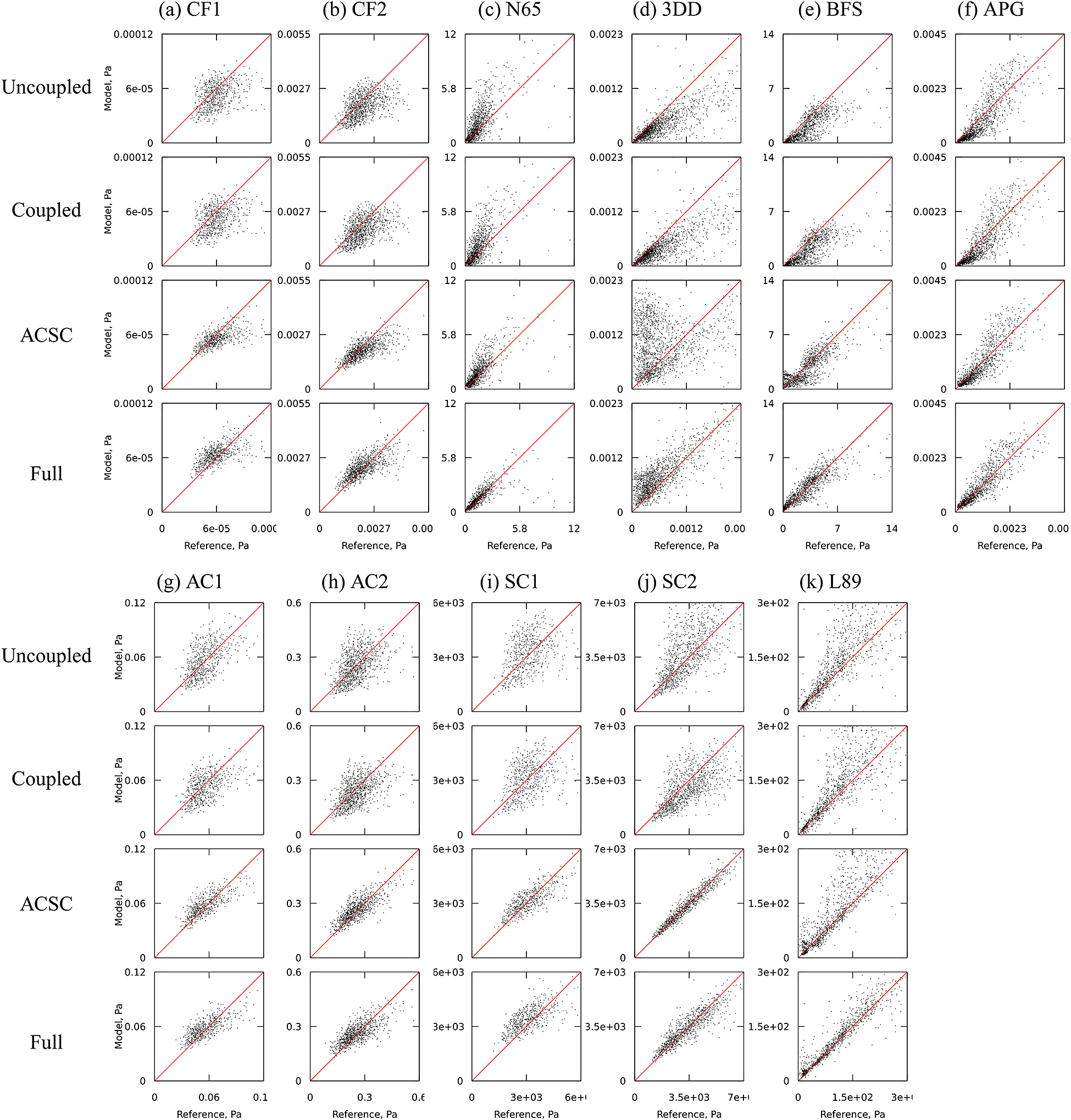

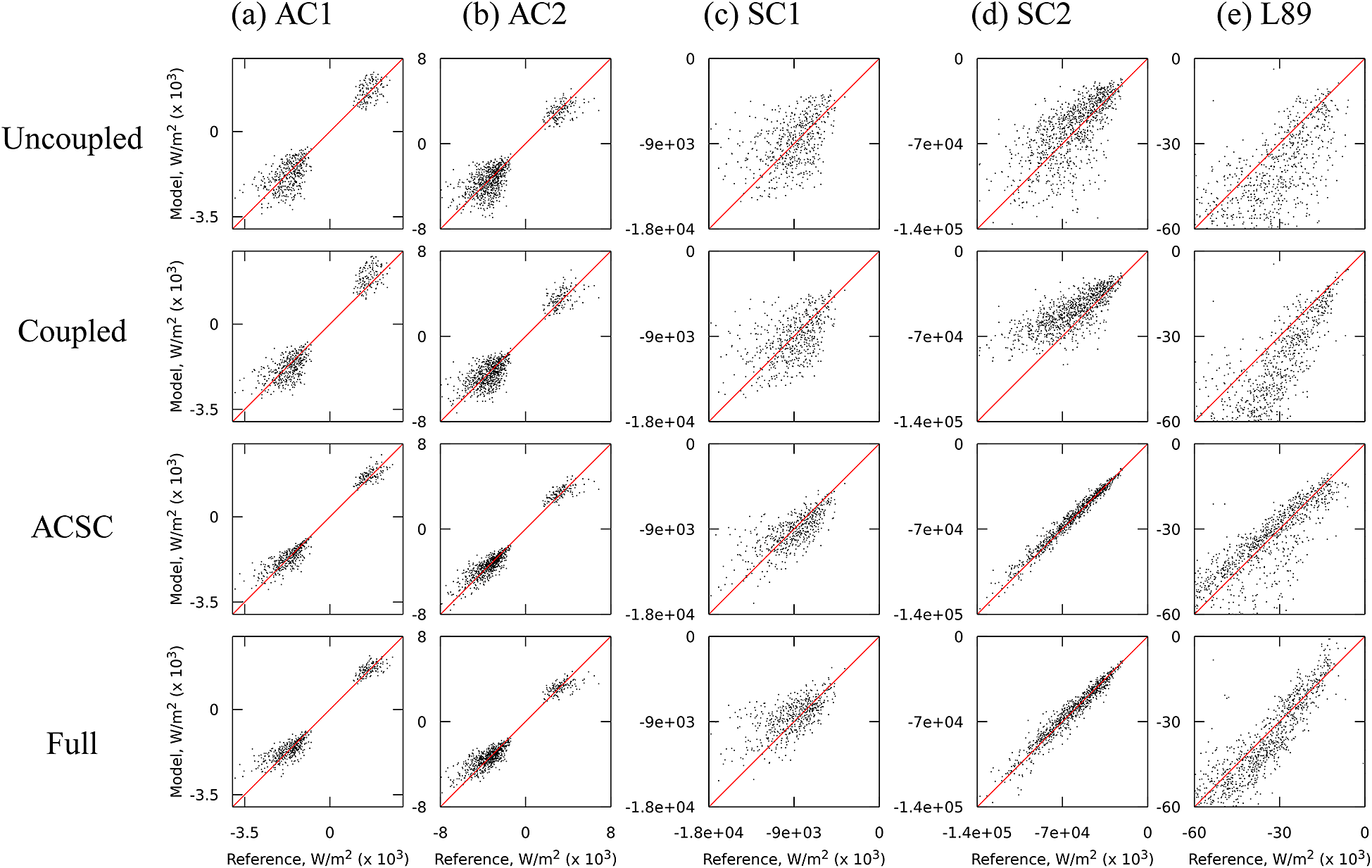

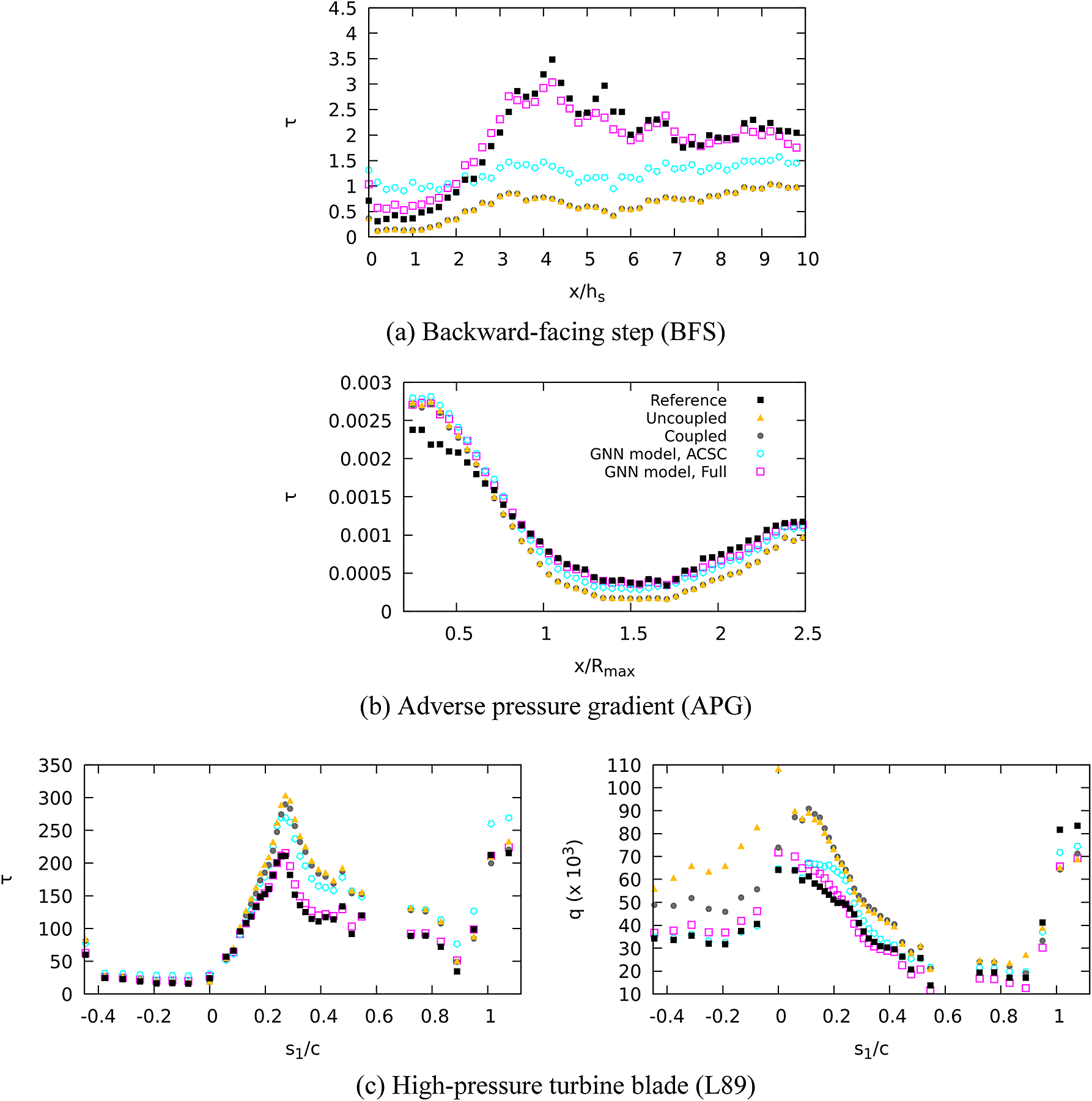

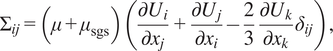

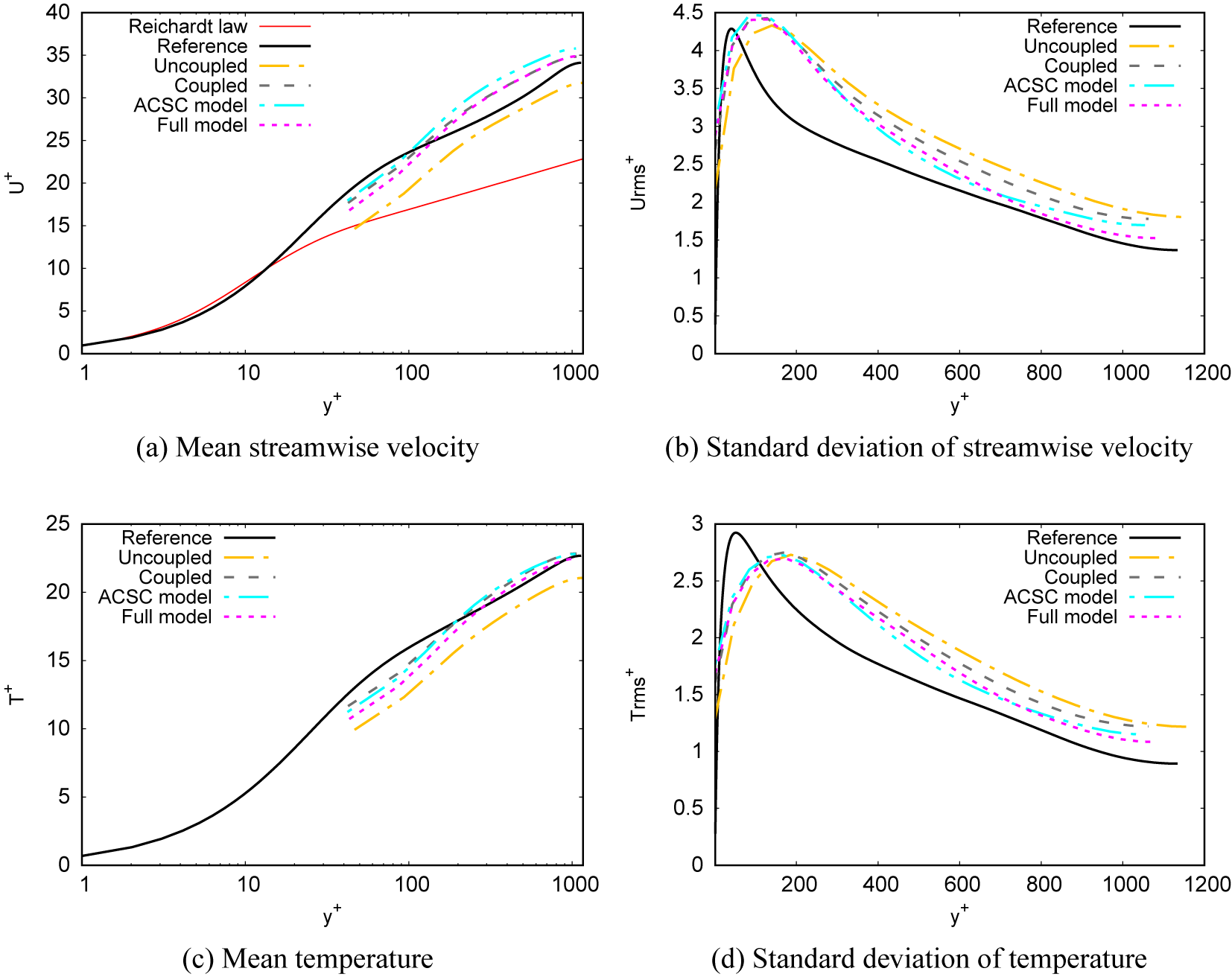

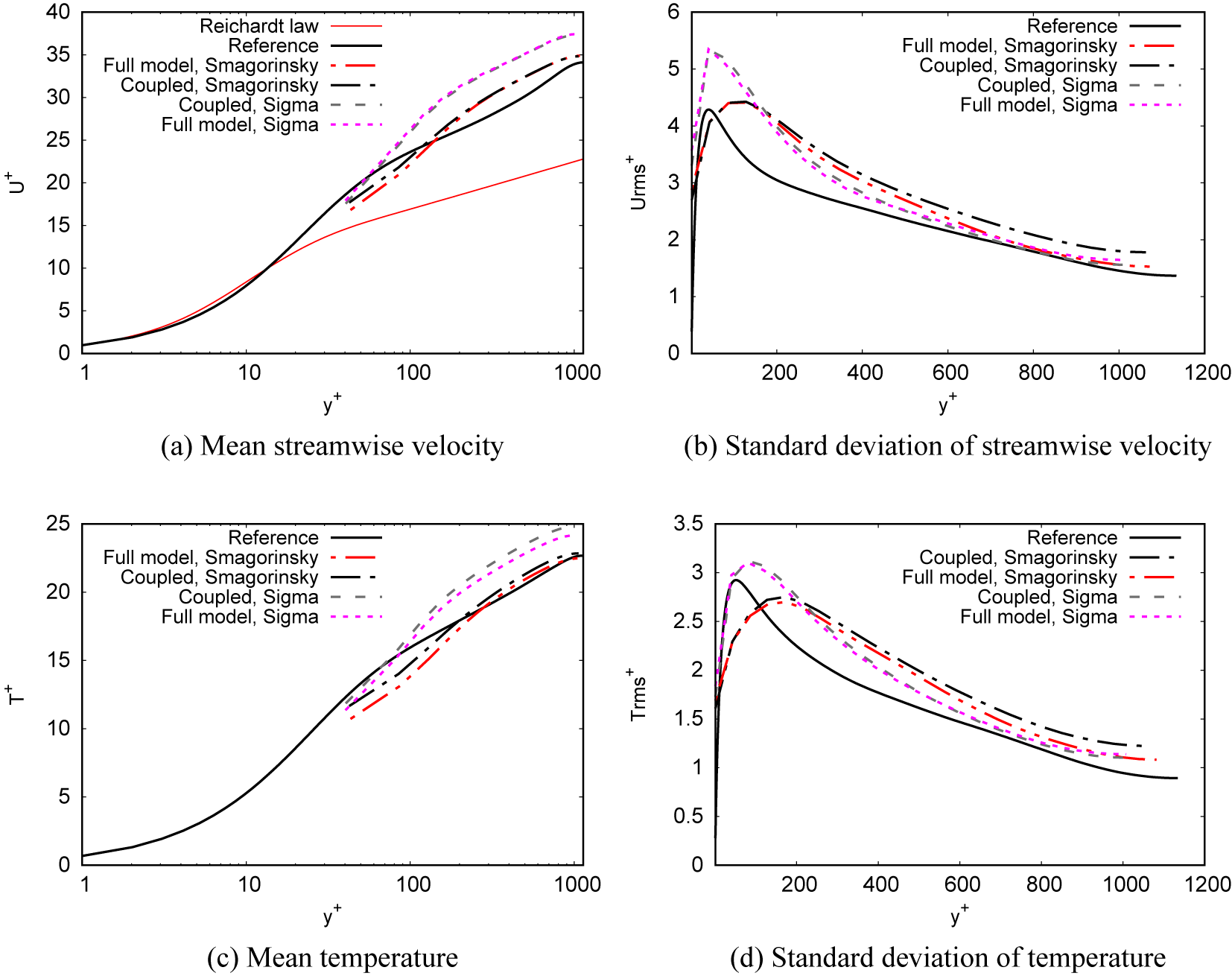

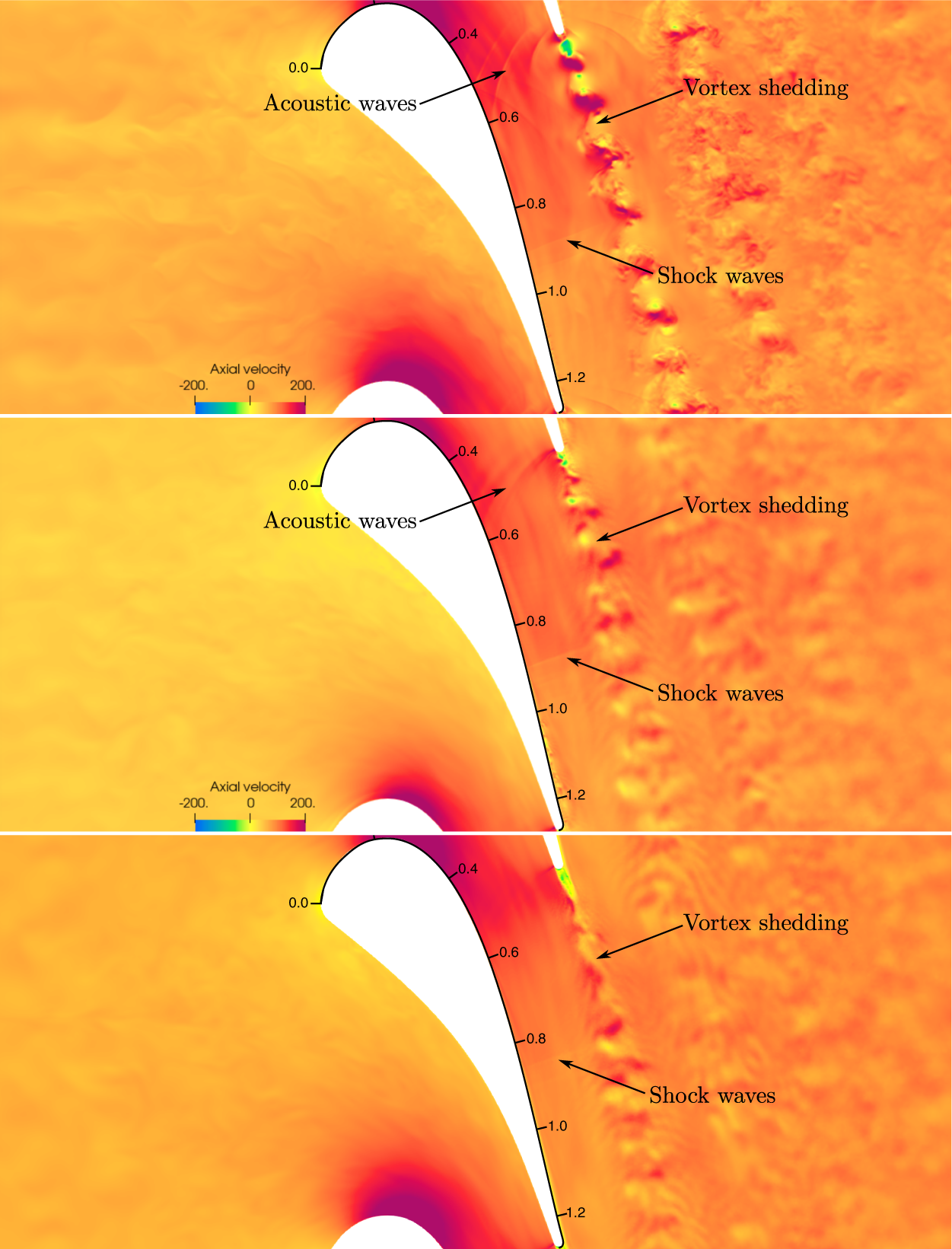

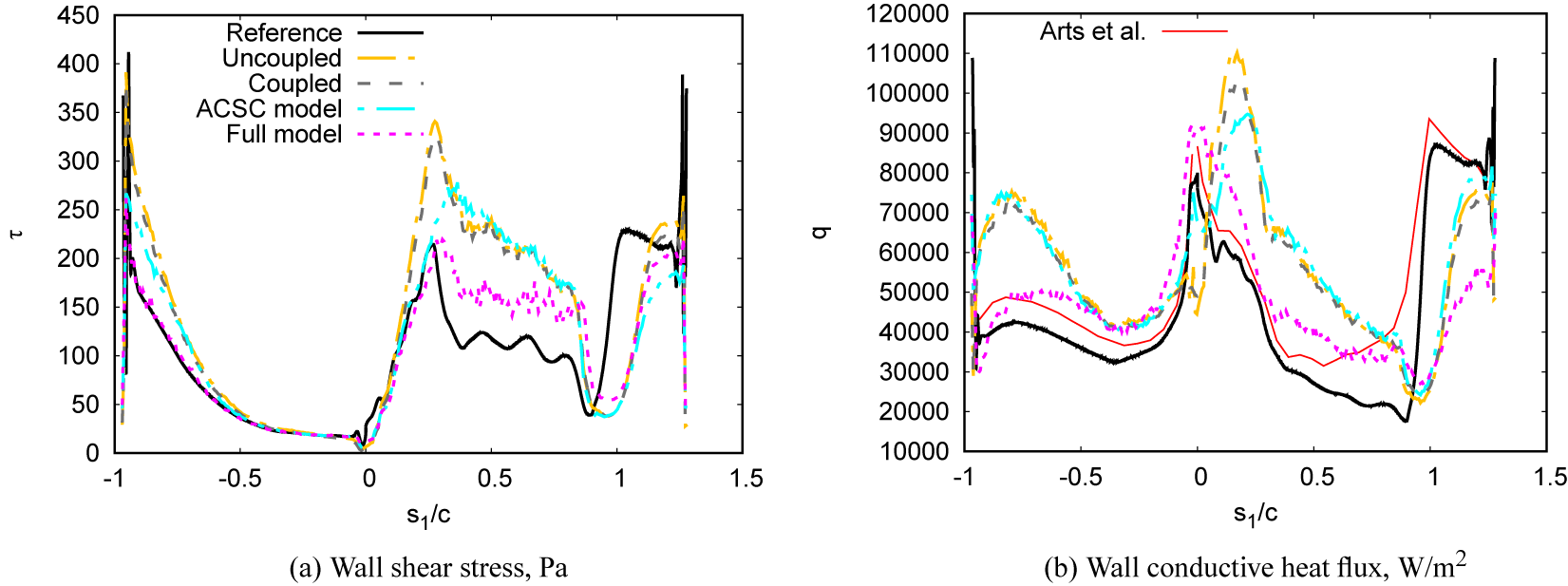

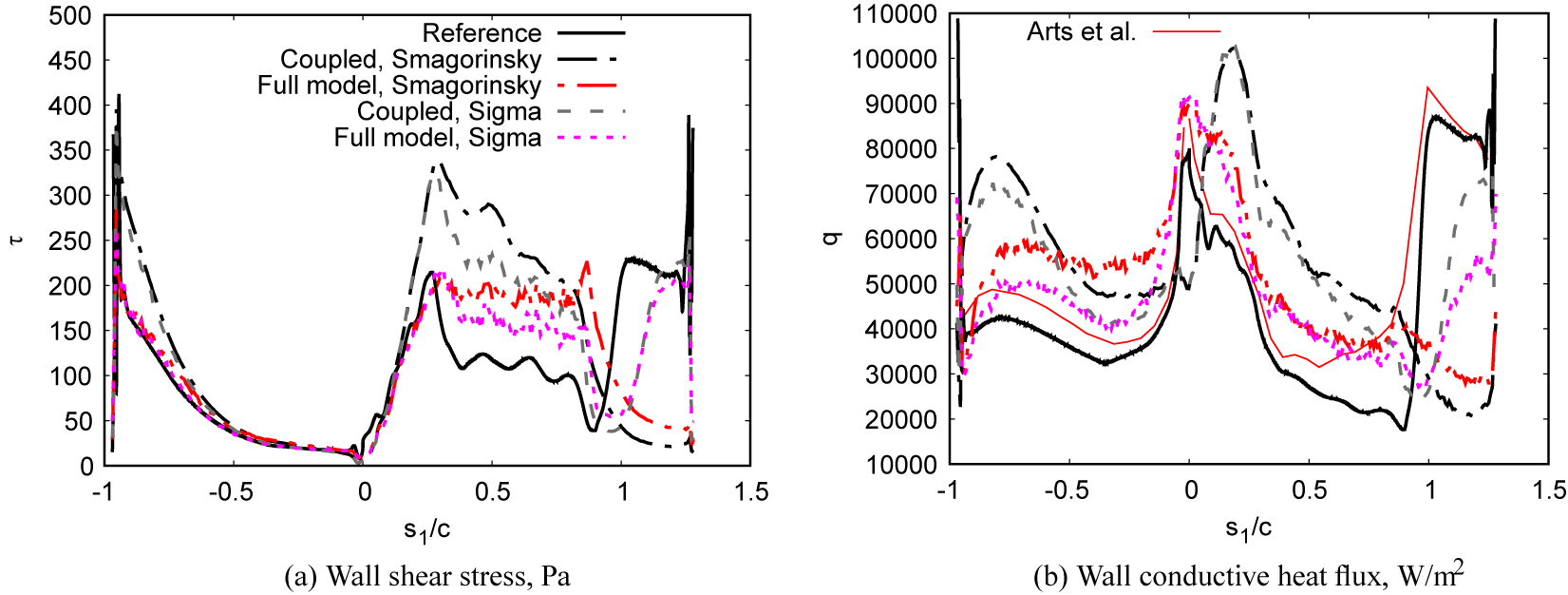

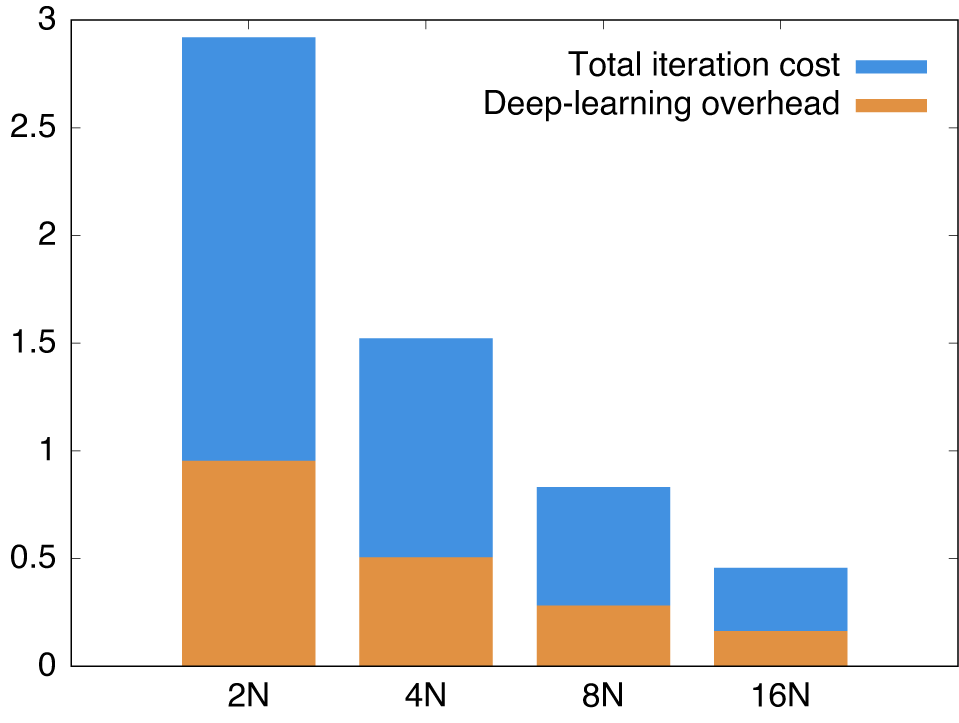

4.2. Graph neural network wall model