Introduction: a different approach to metalworking

Archaeological approaches to metallurgy and the results of its production usually tend to focus on the technical characteristics of the process. Despite the validity of different methodologies of ‘archaeometallurgical’ analysis, this paper does not focus on technical development or the characteristics of production, but on the role of the blacksmith and the social role of metallurgy. Thus, the goal is not to analyse only the ‘technological dimension’ of this activity, but rather how metallurgy and its interactions with other forms of expressions helped shape the social ethos of a community. As Ingold argues (Reference Ingold2000, 312–14), these ‘technological activities’ cannot be understood without other social expressions. Indeed, the very concept of technology, in a contemporary sense, is not applicable to pre-industrial societies. Therefore, a contemporary perspective on metallurgy could raise significant issues, since neither a continuous state of development from the perspective of ‘scientific discovery’ should be taken for granted, nor should different cultural assumptions be accepted from a contemporary perspective (Budd & Taylor Reference Budd and Taylor1995, 133–4).

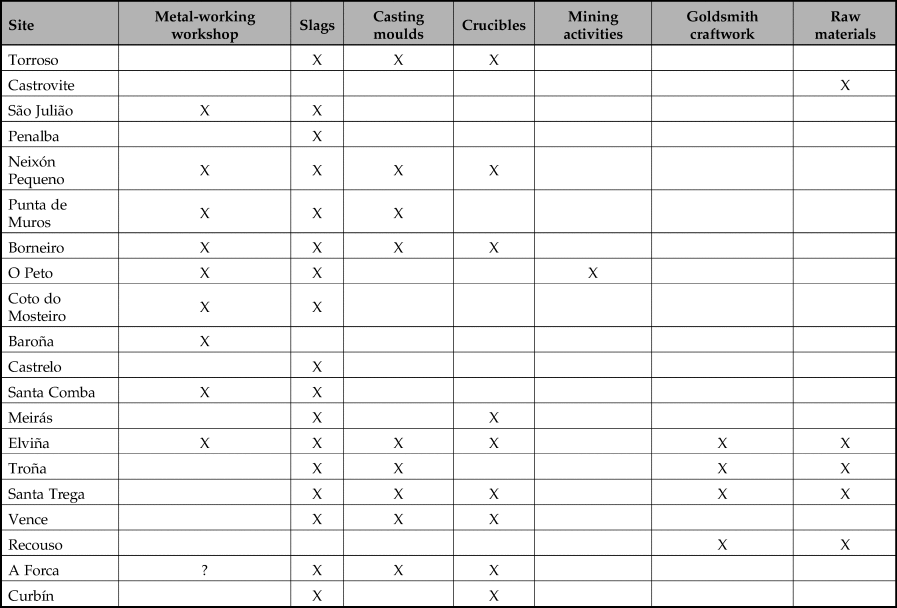

Table 1. Archaeological sites studied and metalworking evidence identified.

Following a necessary review of the application of contemporary concepts into prehistory, as has already been proposed, for instance, in economic terms (e.g. Clastres Reference Clastres1989; Polanyi Reference Polanyi2001; Sahlins Reference Sahlins1972), this work intends to move away from an exclusively technical approach to metallurgy rationalized from a contemporary criterion (Welbourn Reference Welbourn, Champion and Megaw1985, 129). Reinterpreting Maurice Godelier's (Reference Godelier2014) ideas about cultural perception of human conception, a blacksmith and a forge are not enough to produce a metallic object: its creation, especially in terms of ironworking, requires the intervention of other actors, be they material, immaterial, technological, or spiritual. From the perspective of the communities of the past, all these concepts were necessary and equally important. In the same way that the ‘spiritual’ requires a technical application, the relevance of the ‘technological’ field also requires a ‘symbolic’ justification (Ingold Reference Ingold2000, 316). The activities that could be labelled ‘technical’, in the same way as any other activity, are social phenomena, linked to technical but also social and symbolic aspects (Pfaffenberger Reference Pfaffenberger1988, 236). Their study indeed demands a perspective that comprehends the ways of the societies that produce and use them. Esoteric and symbolic values, albeit elusive from an archaeological perspective, must be considered, as they were indispensable to any artisanal metallurgical production process (Budd & Taylor Reference Budd and Taylor1995; Childs Reference Childs, Dobres and Hoffman1999). This approach, commonly used in different anthropological studies (especially in Africa: e.g. Barndon Reference Barndon2004; Childs Reference Childs1998; Herbert Reference Herbert1993; Schmidt & Mapunda Reference Schmidt and Mapunda1997), has not been particularly exploited in archaeological studies of European protohistory, with some exceptions in regions such as the British Isles (Dolan Reference Dolan2016; Giles Reference Giles2007; Hingley Reference Hingley and Gwilt1997; Reference Hingley2009) or Scandinavia (Barndon Reference Barndon, Andrén, Jennbert and Raudvere2006; Gansum Reference Gansum2004; Haaland Reference Haaland2004; Reference Haaland2007–8).

Nevertheless, it is true that the difficulties in drawing lines between materiality, symbolism and the imaginary (sensu Godelier Reference Godelier2014, 40–44) make this kind of approach demanding. In this regard, this paper will focus on identifying the social role of the blacksmith, analysing the evidence that allows us to identify both the characteristics of this activity and its possible symbolic role. However, all those interpretations of this symbolism—that is, the ‘imaginary’ behind the symbols—will be considered from a ‘hypothetical’ point of view in the absence of further studies.

From this perspective, a holistic and diachronic perspective of metallurgical work is addressed. The objective is to assess the importance of these activities in communities and the role of those who preserve their knowledge as part of their own community. This perspective observes the structuring of societies through changes in their relationships, as proposed by Actor-Network-Theory (Callon Reference Callon, Law and Hassard1999; Latour Reference Latour2005). However, it should be noted that these changes have their own sociocultural limits, defined by Bourdieu as habitus (Reference Bourdieu1990). While changes in the forms of relationship shape transformations in the social ethos, their scope is limited by the boundaries of their own cultural, social and cognitive frameworks (see further Nión-Alvarez Reference Nión-Álvarez2021, 46–51).

Focusing on those studies that have explored the relationship between political identity and metallurgy, the development of different metalworking techniques and skills has commonly been understood as representative of the emergence of social inequalities (Budd & Taylor Reference Budd and Taylor1995, 137; Helms Reference Helms1993; Rowlands Reference Rowlands1971), although there are also critical voices (Hingley Reference Hingley and Gwilt1997; Welbourn Reference Welbourn, Champion and Megaw1985). Some of these interpretations have probably been influenced by the traditional model of ‘Celtic societies’ (Arnold & Gibson Reference Arnold and Gibson1995; Brun Reference Brun, Arnold and Gibson1995), whose ‘triangular’ models emphasize prestige goods and metal production. I consider this idea, however, to be heavily influenced by remarkable economistic perspectives, mainly based on the divisions of society established by Emile Durkheim (Reference Durkheim1984). Durkheim established a distinction between societies based on kinship and those based on productive specialization. The main difference was the switch from domestic production to production and services relationships. These approaches raise two significant issues.

Firstly, this kind of wide-ranging division can obscure the nuances that allow the categorization and understanding of non-industrialized societies. Labour or productive specialization does not represent inequalities, but reflects a deep level of productive specialization that is only possible in much more complex societies or even early states. If the historical narratives set a discourse duality only between ‘state societies’ and ‘the others’, the lack of significant inequalities in the absence of labour specialization is implicitly assumed. As has been asserted on different occasions (Clastres Reference Clastres1989; Giddens Reference Giddens1984, 250), social inequality in non-industrial societies cannot be traced from an exclusively economic point of view; it should be recognized in other elements and expressed through other ‘kinds of capital’ (not only economic, but also cultural, social, political and symbolic: Bourdieu Reference Bourdieu1990). Approaching prehistoric societies exclusively from the perspective of economic change, especially from such a large-scale one, may imply an oversimplification of social reality.

Secondly, the ‘specialization’ of blacksmiths, as will be discussed below, does not necessarily imply their exclusive dedication. An increase in the specialization of production does not necessarily imply a greater degree of social complexity, but rather refers to the ability to obtain and preserve knowledge—technical and esoteric—that is not widely disseminated among the rest of the community. The emergence of complex metallurgical techniques (especially with the spread of iron) must have implied significant changes at multiple scales of daily life. Depending on the context, it is also possible, eventually, to relate them to the emergence of inequalities, although there is not always a causal relationship. Nevertheless, the fact that the activity requires the existence of a ‘specialist’ does not reflect the emergence of internal hierarchies or an economic system based on the provision of services. This sort of interpretation, from an industrial and contemporary perception of metallurgy, does not correspond to prehistoric societies (Budd & Taylor Reference Budd and Taylor1995, 143). The specialization of blacksmiths, according to these approaches, should not define their exclusive dedication or their working status, but their role in preserving and applying a technical and esoteric knowledge of great value that few individuals knew about. Even in the Middle Ages, blacksmiths do not have an exclusive dedication: in most cases, they are still involved in agricultural and other subsistence activities (Fossier Reference Fossier2002, 159). As Childs argues (Reference Childs1998; Reference Childs, Dobres and Hoffman1999), metallurgy in non-state societies is a seasonal activity carried out by a specialist (and eventual collaborators) in the more technical production stages, but which includes collective activities in certain processes. One way or another, the social position of the metalworker will vary depending on their cultural framework: in some cases, such as the Tanzanian Fipa (Haaland Reference Haaland2004, 10) or the Kuba of the southwest of the current Democratic Republic of Congo (Vansina Reference Vansina1978, 67), the metalworker holds a predominant and privileged position, akin to Helms's definition of ‘elite crafts’ (Reference Helms1993, 13); in other African communities, such as the Toumala of northern Chad (Baumann & Westermann Reference Baumann and Westermann1970) or the Kenyan Maasai (Childs & Herbert Reference Childs, Herbert and Stahl2005, 288), their status is marginal and implies social contempt. Their role in the community is eminently cultural, and it would be wrong to assume a dominant position or to establish an unbreakable bond between ironwork specialization in these terms and a higher degree of hierarchization.

This approach overcomes an exclusively technical and productive view of metallurgy, focusing on other issues such as symbolism and ritualism, which are more difficult to measure, but equally relevant to the craft process (Childs & Killick Reference Childs and Killick1993, 319). Apart from considering these variables, an analytical framework that encompasses the technical, the symbolic and the functional as an active and representative part of social dynamics at varying degrees must be drawn up. Thus, this paper considers all kinds of metallurgical creation as a key element for understanding the development of Iron Age communities, analysing changes and continuities diachronically as part of a common process.

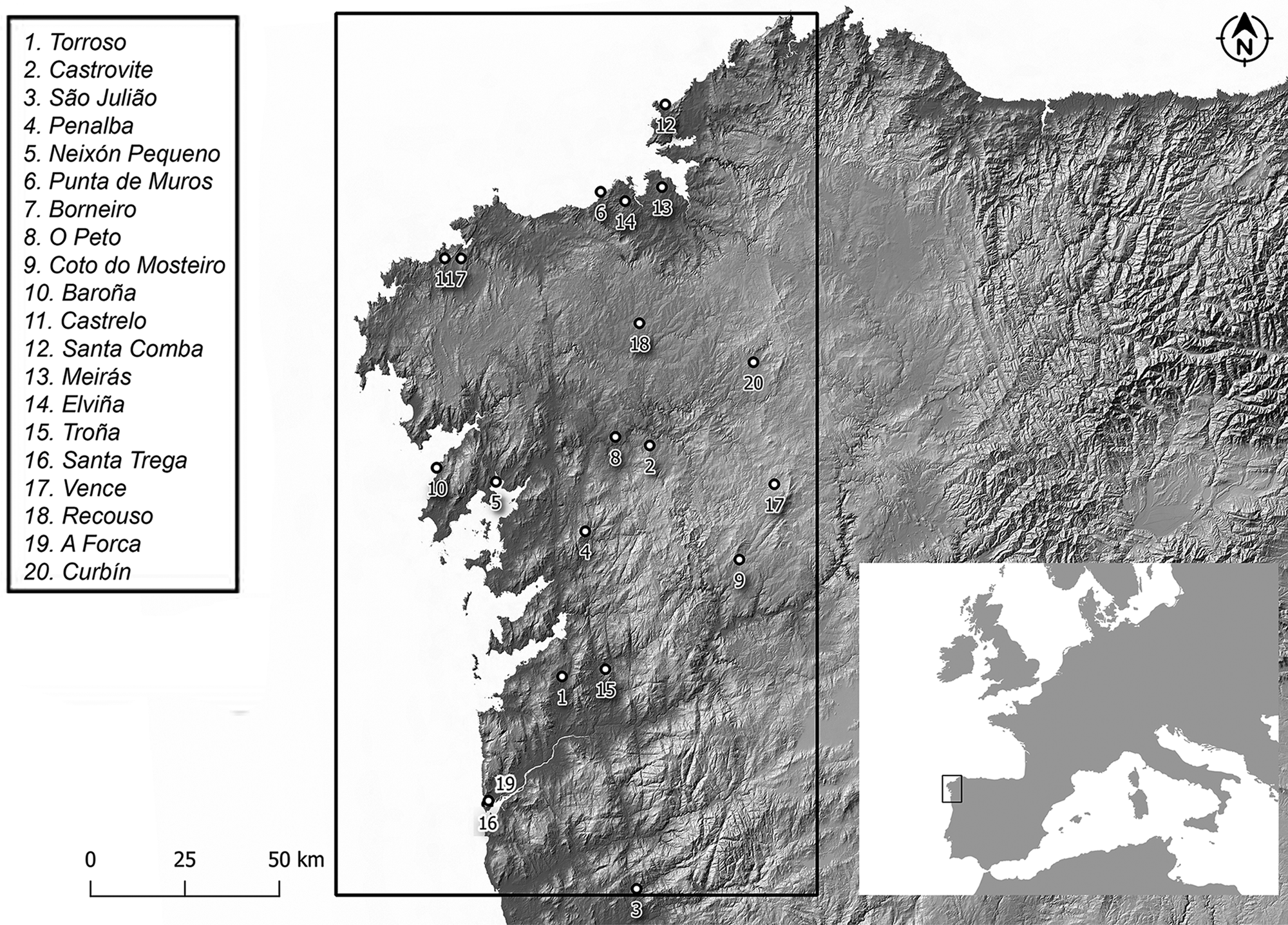

In this paper, the Atlantic façade of the northwest Iberian peninsula has been chosen to develop these considerations (Fig. 1). In this area, the outstanding role of the exchange and production of metal throughout prehistory has been stressed in several studies (Armada Pita et al. Reference Armada Pita, Rafel Fontanals, Montero Ruiz, Celestino Pérez, Rafel Fontanals and Armada Pita2008; Comendador Rey Reference Comendador Rey1999; Sánchez-Palencia et al. Reference Sánchez-Palencia, Plácido Suarez, Orejas Saco del Valle and Fernández-Posse1999). Nonetheless, despite remarkable archaeometallurgical studies (such as Armada Pita & García-Vuelta Reference Armada Pita and García-Vuelta2015; Fanjul Peraza & Marín Suárez Reference Fanjul Peraza and Marín Suárez2006), hardly anything has been written about the influence of changes in the metallurgical scale on social organization (exceptionally Nión-Álvarez & González García forthcoming; see also González-Ruibal Reference González-Ruibal2006–7, 490–96) or to assess the role of the blacksmith in these transformations over time. Therefore, this region presents an undeniable potential for exploring the links between metallurgy and society.

Figure 1. Study area.

Finally, it should be noted that the goal of this research is not to analyse the social use of metal objects, a usual discussion in the context of the northwestern Iron Age (mainly focused on gold objects: Armada & García-Vuelta 2018; Armbruster & Perea Reference Armbruster and Perea2000), but rather the role of the agents involved in their production.

The end of the Atlantic Bronze Age and the dawn of a new fortified world: the First Iron Age (ninth–sixth centuries bce)

Throughout the ninth and eighth centuries bce, the communities of the northwest of the Iberian peninsula underwent a deep process of social and habitational reconfiguration. This process reached its apex by setting up a new way of life that brought along the fortification and monumentalization of the physical boundaries of settlements. It seems that these communities, maybe as a response to the social inequalities of the Final Bronze Age (González García et al. Reference González García, Parcero-Oubiña, Ayán-Vila, Armada Pita and Moore2011), were societies with undivided social values (in terms of Clastres Reference Clastres1989, 203–9) and reluctant to develop internal inequalities. The development of this process of fortification and political fragmentation of the landscape implied (or perhaps was a consequence of) a complete disruption of previous cultural symbols. The decline or disappearance of characteristic Bronze Age expressions, such as some rock-art designs or the hoarding of certain bronze objects, can be highlighted. In fact, this progressive decrease of the structured deposition of bronze objects in liminal spaces (Parcero-Oubiña et al. Reference Parcero-Oubiña, Armada Pita, Nión-Álvarez, González Insua, Currás and Sastre2020) seems to be related to the virtual disappearance of the Atlantic interaction networks and to the substantial decrease in the exchange and production of metal objects in this period (Comendador Rey Reference Comendador Rey1999).

The disappearance of these cultural forms and the reduction in metal exchange and production might have caused a change in the role of the blacksmith, although, due to the lack of documentation from previous production areas it is not possible to verify this. In any case, most of the metal objects are still made of bronze, mainly in ternary alloys, showing a slight continuity of production from the Late Bronze Age (Armada Pita et al. Reference Armada Pita, Rafel Fontanals, Montero Ruiz, Celestino Pérez, Rafel Fontanals and Armada Pita2008). Iron, despite being documented in some sites as Torroso (Peña Santos Reference Peña Santos1992) or Castrovite (Carballo Arceo Reference Carballo Arceo1987), was not widespread in the northwest until the fifth century bce (González-Ruibal Reference González-Ruibal2006–7, 490–91). Indeed, iron metalworking has been acknowledged around similar dates in most of the northern area of the Iberian peninsula (Camino Mayor & Villa Valdés Reference Camino Mayor and Villa Valdés2014, 65; Fanjul Peraza & Marín Suárez Reference Fanjul Peraza and Marín Suárez2006, 115).

The metalworking workshops identified throughout this period are characterized by their limited extent. Workshops probably stood inside the settlement, separated from any kind of construction, as has been shown in settlements such as São Julião (Bettencourt Reference Bettencourt2000) or Torroso (Peña Santos Reference Peña Santos1992), but close to the dwelling area. Similar production areas have been found in Neixón Pequeno (Ayán-Vila Reference Ayán-Vila2008, 269–93), although one of them is clearly linked to a household (Ayán-Vila Reference Ayán-Vila2012, 472). Another example has been documented in Punta de Muros (see Figure 2). In this settlement, the complete technical-operational chain of metallurgical production could be reconstructed (Cano Pan Reference Cano Pan2012, 132). However, as we shall see, metallurgical production areas underwent significant changes throughout their occupation. While the characteristics of metal production are very akin to those already mentioned, in this case, certain production structures (Structures I–III or XXXII) have been exhumed within different domestic areas (Cano Pan Reference Cano Pan2012, 446–61). Initially understood as specialized metalworking areas (Cano Pan Reference Cano Pan2012, 735), recent research suggests their functionality as different small household spaces in which multiple activities were carried out, especially the production of bronze (Ayán-Vila Reference Ayán-Vila2012, 397). This assertion is supported by the presence of cooking and dining pottery in all the rooms, as well as other tools such as quernstones, related to the domestic sphere (Nión-Álvarez Reference Nión-Álvarez2021, 181–2). These features match the dynamics of the settlement, characterized by small multifunctional households that suggest an egalitarian and autarchic ethos in Punta de Muros in this period (Nión-Álvarez Reference Nión-Álvarez2021, 170).

Figure 2. Structures I–III of Punta de Muros. (* = metalworking area; + = domestic area).

Thus, metallurgy seems to have been part of household activities, or, at least, completely integrated into the daily life of the community. The blacksmith seems to have played neither a predominant role, nor a marginal one. Despite apparently widespread metallurgical activities in the domestic sphere, not all dwellings might have been familiar with these techniques. Still, as discussed below, this knowledge seems to have been more widespread than in later periods.

Metallurgy as an agent of social change? (Sixth–fourth centuries bce)

Throughout the sixth century bce, notable changes took place in the northern sector of the Atlantic façade, suggesting a far-reaching change in the social ethos of its communities towards a higher degree of internal inequality. This change also seems to have happened in other areas of the northwest of the Iberian peninsula in the fifth and fourth centuries bce (González-Ruibal Reference González-Ruibal2006–7, 269; Reference González-Ruibal, Stoddart and Cifani2012) without excluding the possibility that these processes began earlier. In any case, changes in the social paradigm would be generalized between the fifth and fourth centuries bce, reproducing a significant social transformation that would bring about new settlement patterns and new ways of understanding social relations. Metallurgy and the role of the blacksmith, as we will see, will be important for the emergence of these transformations. It should be noted that these changes seem to appear mainly on the coast. Inland communities, on the other hand, seem to have preserved a social model similar to those previously defined for the First Iron Age.

Punta de Muros provides the most remarkable example of these processes. Between the sixth and fourth centuries bce, the settlement underwent a complete internal transformation (Nión-Álvarez Reference Nión-Álvarez2021, 190). Among other aspects, this determined the complete restructuring of different buildings, emphasizing the appearance of potential inequalities between different family units. Large households with compartmentalized spaces could be noted (sometimes exceeding 150 sq. m), either through new construction or through the aggregation of previously separate dwellings. At the same time, smaller dwellings (between 30 and 40 sq. m) with similar characteristics to those previously described were still inhabited. To a certain extent, the rise of social inequalities in Punta de Muros could be similar to other processes, such as those suggested by Ian Hodder (Reference Hodder2014) at Çatalhöyük. In both cases, changes towards an aggregation of domestic spaces, the emergence of religious spaces and the centralization and specialization of productive activities begin to be documented with the arising of significant social transformations.

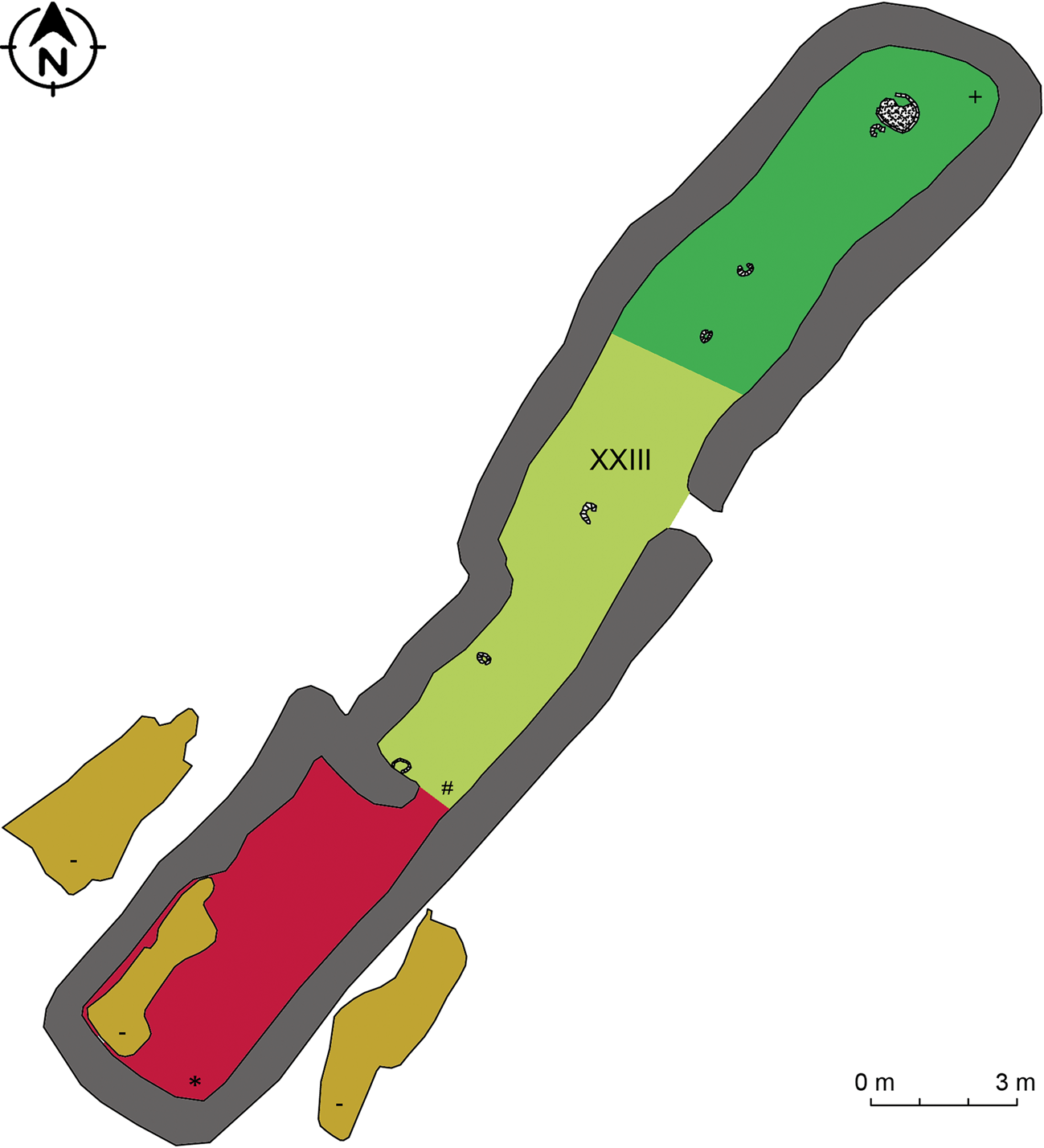

While it is difficult to identify the factors that led to the emergence of social inequality in Punta de Muros, the value of control and knowledge of certain activities such as metallurgy can be inferred. Parallel to the social transformation of the settlement, there seems to be a clear trend towards specialization and individualization of metal production. Thus, there are several buildings exclusively devoted to metal production, like Structures XXIX and XXX. In contrast to previous metal workshops, these spaces are specialized areas, without any evidence of habitation. In some cases, production does remain under domestic control. The most characteristic example is Structure XXIII, one of the most prominent households in the settlement (around 150 sq. m) with a specialized workshop in its Sector W (Cano Pan Reference Cano Pan2012, 299; Fig. 3). However, differences are clear from earlier production stages. These workshops were not part of domestic life, even when located in a household, and display a significant degree of specialization. Metalworking workshops were located in areas of specialized production, with no evidence of domestic activities, and reproducing completely dedicated areas from previous multi-functional domestic units.

Figure 3. Structure XXIII of Punta de Muros. (* = metalworking area; # = storage area; + = domestic area; - = bronze-production specific areas).

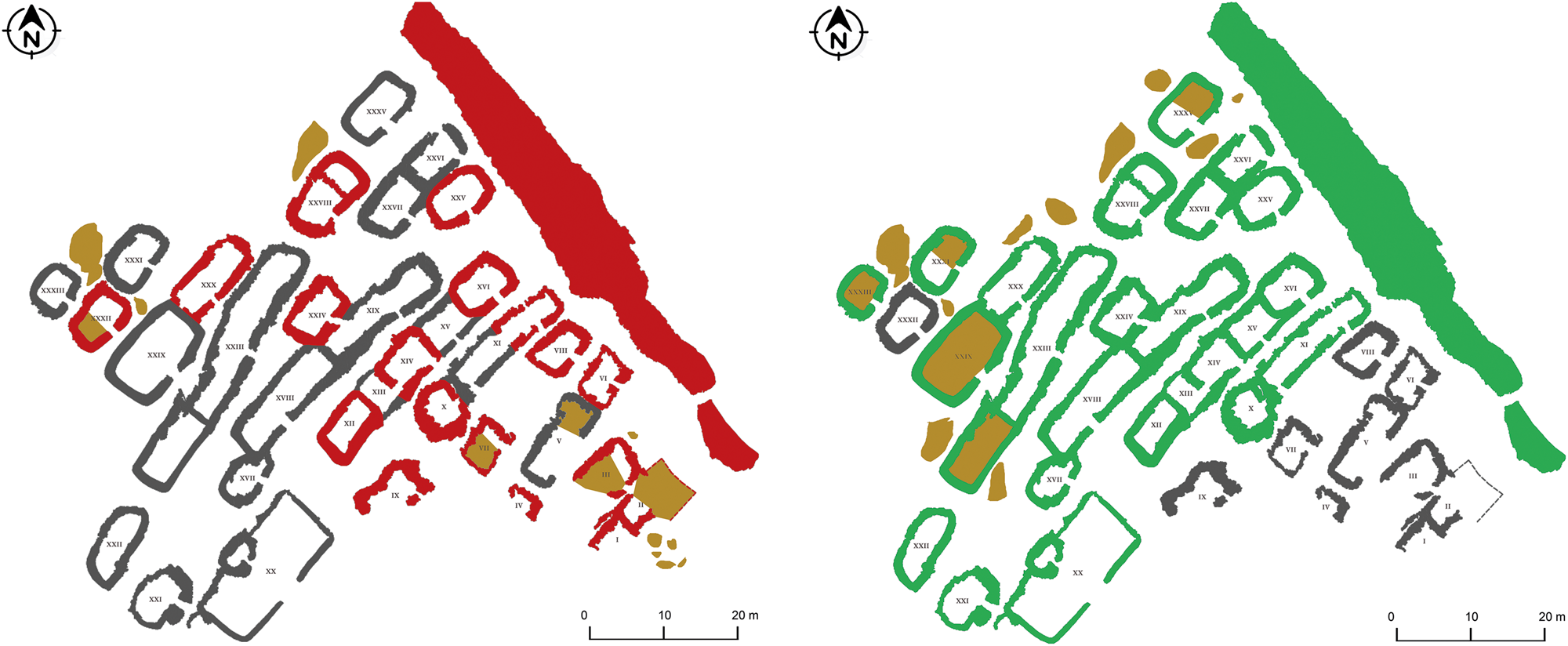

Thus, metalworkers could be acquiring a specific position, expressed through a higher degree of specialization that allows them to be defined accordingly. Although there is no significant transformation in terms of technical production (ternary alloys are still used, while iron remains scarce or inexistent), there do indeed seem to be changes in their social position. There are individualized metalworking spaces in two of the six large households located in the settlement (Structures XXV–XVII and XXIII: see Figure 4). This could show that the blacksmith and their activities held a privileged position in the settlement. Being a metalworker could give greater prestige and a higher status, but it was not necessary to achieve a privileged position.

Figure 4. Punta de Muros. Settlement changes between first (ninth–sixth centuries bce, above) and second (sixth–fourth centuries bce, below) phases of occupation. Metalworking specific areas are also coloured.

Although it depends on their sociocultural context, metalworking can provide prestige and power in many different ways (Reid & MacLean Reference Reid and MacLean1995, 145), by providing symbols (Sassoon Reference Sassoon1983), as esoteric and exclusive knowledge (Barndon Reference Barndon2004, 41; Childs Reference Childs1998, 112), or through the value retained by certain objects (Hingley Reference Hingley2009). However, this relationship between metallurgy and power is usually only explored through the symbolism of iron production (Green Reference Green, Green and Webster2002, 8; Haaland Reference Haaland2007–8, 203), leaving aside the production of other objects. It is true that, as we will see below, iron production has a symbolic relevance that, in certain conditions, favours a particular cosmogony. However, this symbolic value is also characteristic of other activities that do not require such a specialized process. In regions such as India, the symbolic and cultural predominance of unalloyed copper metallurgy, as well as that of its craftsmen, has been highlighted in comparison to other tasks (Lahiri Reference Lahiri1995). Undoubtedly, the particulars of their production would lead to very different symbols, but their influence should not be underestimated or ignored.

It has recently been suggested that the symbolic and technical knowledge of certain activities related to metallurgical production may have been related to the deep transformation in Punta de Muros (Nión-Álvarez Reference Nión-Álvarez2021, 209). Although it is not possible to confirm this cause-effect relationship, the shift in the social position of the blacksmith is nonetheless significant. As we have seen, metallurgy acquired a greater degree of specialization through the creation of certain specialized areas in parallel to the emergence of social inequalities. This, however, is not necessarily understood as a labour specialization of the metalworker. As happens in societies such as the Ugandan Toro, the existence of one or more metalworkers in a hierarchical society does not imply their exclusive dedication, nor does it reduce the collective dimension of certain stages of their activity (Childs Reference Childs1998). However, there might be hints of a change in their social position. In contrast to the previous domestic role, metallurgy acquires its own spaces outside the domestic sphere, and, more interestingly, it also belongs to some of the most prominent household settings. The presence of specific production spaces in individualized spaces or associated with domestic units raises two main questions.

On the one hand, this ‘specialization’ might be related to the necessity of separating this activity to preserve some technical and symbolic aspects of manufacture metal secret. This has been proposed in diverse societies, such as the Bamana of West Africa (Herbert Reference Herbert1993, 110) or, recently, in protohistoric Ireland (Dolan Reference Dolan2016, 43–4). Thus, metallurgy is kept away from anyone that should not access such information. As a hypothesis, this type of activity can be related to the emergence of new forms of religious expression. In this process of social transformation, culturally oriented buildings (Structure XX), with access and visual restrictions, are constructed (Cano Pan Reference Cano Pan2012, 769–72).

On the other hand, as mentioned earlier, the presence of certain spaces under the control of some of the most important domestic households could suggest the high social position of the blacksmith. Those who know and practise metallurgy were not segregated or marginalized, but formed part of the most prominent households. However, it should be noted that not all the prominent households crafted metal. This could suggest that metallurgy was not the only means for social promotion.

Fourth–first centuries bce: the spread of iron and the establishment of inequalities

After a brief period of instability during the fifth century bce, a process of consolidation of social inequality had begun in several spots along the Atlantic coast throughout the fourth century (González García Reference González García2017, 297). This process encompassed a significant shift in the forms of settlements, with a greater proximity to the valley, a demographic increase (in each hillfort as well as in the overall settlement numbers) and a development of defensive and domestic architecture (Parcero-Oubiña Reference Parcero-Oubiña2003). Between the fifth and fourth centuries bce, it can be observed that iron metallurgy became widespread in the northwest (González-Ruibal Reference González-Ruibal2006–7, 490–91), albeit late in relation to other Atlantic territories (Hingley Reference Hingley and Gwilt1997, 14). Within the same period, there was also an exponential increase in gold production (Armada Pita & García-Vuelta Reference Armada Pita and García-Vuelta2015). Nevertheless, a significant reduction in bronze production is not documented.

Regarding the link between the increase in social inequality and the emergence of new production techniques, there is no evidence of a causal relation. While these new techniques were similarly widespread in northwestern Iberia during this period, significant divergences in the social ethos of coastal and inland communities (Parcero-Oubiña & Nión-Álvarez Reference Parcero-Oubiña and Nión-Álvarez2021), as well as between south and north (González-Ruibal Reference González-Ruibal, Stoddart and Cifani2012), can be highlighted. As has been already pointed out, metallurgical activity by itself does not allow us to define or understand any kind of society, but its relation to other social and cultural expressions must be considered to understand its influence.

Despite this remarkable stabilization of social inequality, the position of the blacksmith seems to symbolize a significant change from earlier periods. Three distinct categories to understand the changes in the role of metallurgy and the blacksmith during these periods can be established.

Liminalization

As Turner stated (Reference Turner1969), the concept of ‘liminalization’ defines the condition of ‘in-betweenness’ amid two well-defined stages of existence, usually overcome through various rites of passage. The social condition of metalworkers in this period would respond to this depiction. Far from holding a prestigious place in society, they could be defined as individuals between ‘the spiritual and the marginal’, a position that, to a certain extent, can be labelled as ‘liminal’.

The first hint of this ‘liminal’ position is the location of the working area. At this time, metalworking started to be individualized and segregated from other common activities, in contrast with previous periods. Workshops were usually located far from the main living areas, either outside the settlement, as in O Peto (Aboal Fernández et al. Reference Aboal Fernández, Ayán-Vila and Prieto Martínez2003) or Vence (Naveiro López Reference Naveiro López1991, 79), or by the walls, as in Borneiro (Nión-Álvarez Reference Nión-Álvarez2021, 316), Coto do Mosteiro (Orero Grandal Reference Orero Grandal1986, 39–40) and perhaps A Forca (Carballo Arceo Reference Carballo Arceo1987, 16). This trend of separating metal workshops from the dwelling enviroment seems to be common throughout the northwest (González-Ruibal Reference González-Ruibal2006–7, 496; Sánchez-Palencia et al. Reference Sánchez-Palencia, Plácido Suarez, Orejas Saco del Valle and Fernández-Posse1999) and, perhaps, other regions of Europe (Giles Reference Giles2007, 399; Hingley Reference Hingley and Gwilt1997, 12), a process that responded to both symbolic and productive factors. It is possible to bridge this segregation between daily activities and the emergence of iron, which completely changed the way of understanding metal production. Ironworking required a complex production process, a deep insight and a thorough control of different techniques, (Hingley Reference Hingley2009), many of which were hazardous for human health (Álvarez-Sanchís et al. Reference Álvarez-Sanchís, Lorrio Alvarado and Ruiz Zapatero2016). These technical changes and the consequences of their production might have influenced the significant change in their location in the settlement. At the same time, they would also have led to the creation of a new set of symbols and meanings related to their craft, and, perhaps, also to the movement of the blacksmith towards a ‘liminal position’. A particularly significant example of this liminality could be the workshop of Structure IX at Baroña (Porto do Son, A Coruña), along a strong partition wall that divides the settlement into two neighbourhoods (Calo Lourido & Soeiro Reference Calo Lourido and Soeiro1986, 13). There is not any kind of structure in its immediate surroundings, apart from an open space to produce metal. Its individualization and its location in a space of ‘transit’ may have influenced its liminality, both spatial and social.

Ritualization

The knowledge required to produce metal is not limited to procedures that, from a contemporary perspective, could be described as technical. Metallurgy, far from our industrialized vision, would be codified through different symbolic and esoteric elements, a fundamental and inseparable aspect of metalworking (Budd & Taylor Reference Budd and Taylor1995; Childs Reference Childs, Dobres and Hoffman1999; Hingley Reference Hingley2009). This kind of knowledge implies that individuals who preserve that knowledge not only know how to craft metal, but also mediate in conflicts and sanction activities that affect the production process.

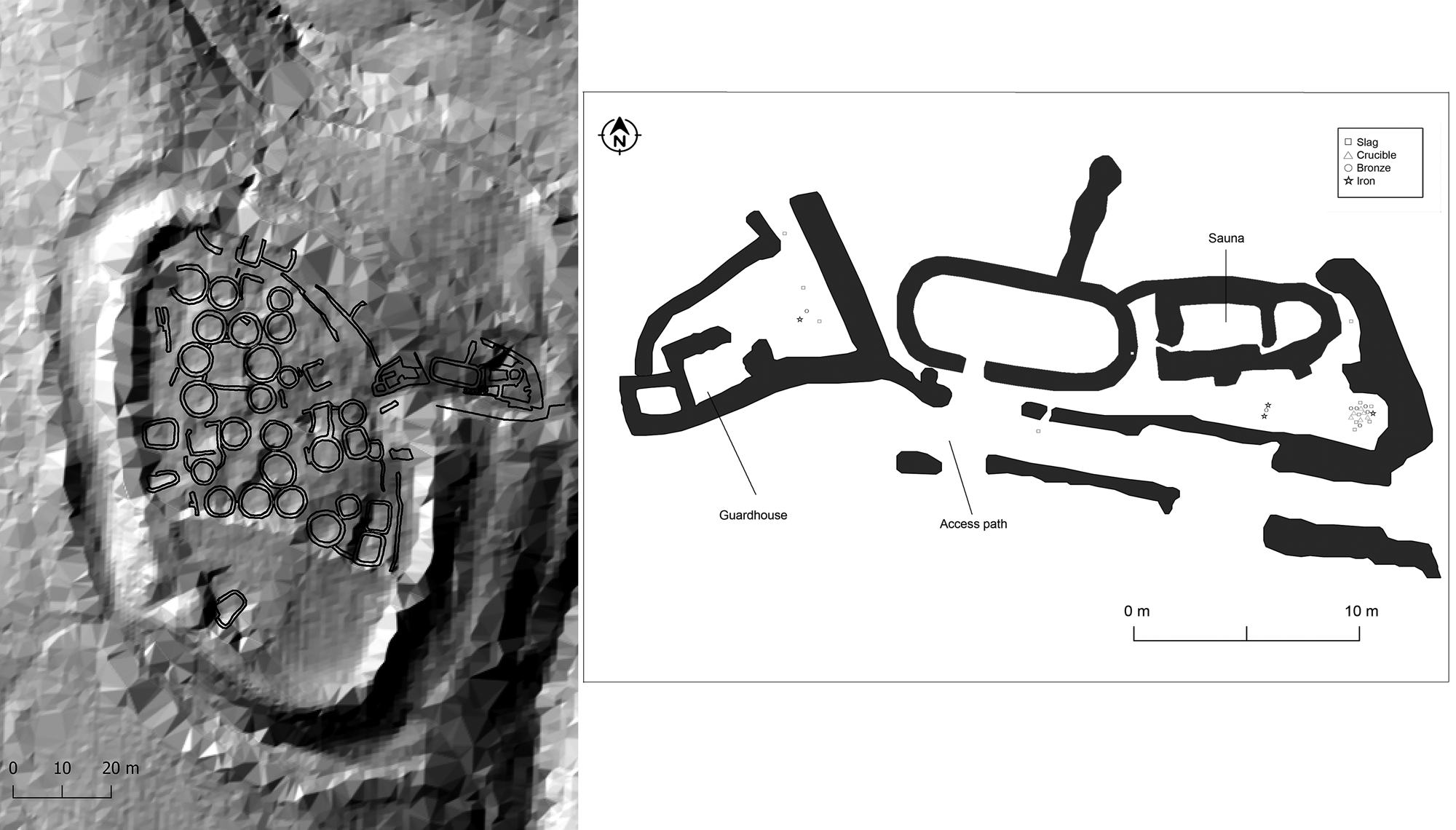

This bond between the technical and the spiritual, especially in terms of iron production, has been stressed in almost every broad study of non-industrial metallurgy (Barndon Reference Barndon2004; Haaland Reference Haaland2004; Helms Reference Helms1993; Herbert Reference Herbert1993). Among several examples previously mentioned, A Cidá de Borneiro could provide some particularly representative evidence to determine the symbolism of the blacksmith (Fig. 5).

Figure 5. Metalworking evidence in the surroundings of the Borneiro sauna.

The first example emphasizes the relationship between cultural and metallurgical activities. Around the entrance to the settlement, known as ‘Barrio de Extramuros’, a bath structure has been documented (Álvarez-Sanchís & Almagro Gorbea Reference Álvarez-Sanchís and Almagro Gorbea1993, 187; González-Ruibal Reference González-Ruibal2006–7, 557). Some authors have refused to accept this function (Ríos González Reference Ríos González2017; Romero Masiá Reference Romero Masiá1987), arguing, mainly, the existence of evidence of metalworking in the immediate surroundings. Though its construction characteristics emphasize its thermal use (Prociuk Reference Prociuk2019; Villa Valdés Reference Villa Valdés2011), remnants of metalworking (crucibles, traces of iron slag, amorphous objects in bronze and iron, mostly found in a river sand level) are also noteworthy (Romero Masiá Reference Romero Masiá1987). Considering the extensive usage of silica sand in these periods—as reported in hillforts such as that of Santa Comba (Gómez Filgueiras de Brage Reference Gómez Filgueiras de Brage and Columba2003)—metal smelting was probably carried out in this area.

Recently, a joint understanding of both aspects has been proposed (Nión-Álvarez Reference Nión-Álvarez2021, 351). From this point of view, the location of certain specific activities related to iron smelting in culturally important space could not be incidental. Looking at other contexts, and without drawing a straight comparison, the relationship between ritual activities and smelting is widespread in non-industrial metallurgy. The Ugandan Toro, among other rituals that will be discussed later, perform a plethora of activities related to metallurgy to contact spiritual entities (Childs Reference Childs1998, 114). This relationship between the ancestors and smelting is, in fact, constant throughout sub-Saharan Africa (Herbert Reference Herbert1993, 27). Such processes of ritualization of smelting have also been reported in Iron Age Europe: in Norway, the deliberate amortization of certain parts of smelting furnaces has been interpreted as a symbolic expression (Haaland Reference Haaland2004, 14); in Ireland, a close bond between smelting furnaces and spiritual spaces has been pointed out (Dolan Reference Dolan2016, 44). Looking back to the northwest Iberian peninsula, the existence of different ritual activities related to the founding of smithies, even in modern times, is well known (Rodriguez Migués Reference Rodriguez Migués1995–6). These examples, without intending to apply homogeneous determinisms between cultures, could help express the symbolic value of certain production processes and their codification in different cultures.

It is possible to go a step further and analyse what might have been the motivation behind this relationship between saunas and iron smelting. Although current data are insufficient to make a statement, also considering the difficulties of interpreting certain symbolic acts, some of these ideas may provide some guidance for understanding this connection. Iron Age saunas are usually related to different rites of passage, perhaps linked to the warrior world, and probably associated with the transition to a new ‘state of existence’ (Álvarez-Sanchís & Almagro Gorbea Reference Álvarez-Sanchís and Almagro Gorbea1993, 209–15; García Quintela Reference García Quintela2016; González-Ruibal Reference González-Ruibal2006–7, 568). A connection between both realities would not be surprising. Herbert (Reference Herbert1993, 86–91) has pointed out how smelting areas are fertile spaces that must preserve their natural conditions to ensure fertility. The deployment of efforts to avoid any presence or activity that could disrupt it, such as limiting the access of women during their menstruation, should not be unusual indeed. This prohibition is relatively common in many ethnic groups, such as the Ugandan Toro (Childs Reference Childs1998, 30), the communities of southwest Ethiopia (Haaland Reference Haaland2004, 3–5) or, on a broader scale, most communities of central and eastern Africa (Herbert Reference Herbert1993, 86). In other cases, such as the Pangwa or the Tanzanian Fipa, a connection is also set between the smelting furnace and the womb (Barndon Reference Barndon2004, 35). According to its own specific characteristics, smelting is highly prone to generate a symbolic leitmotif around different life-creating processes: agriculture, procreation, or fertility. This idea has already been confirmed in different Iron Age sites in the British Isles (Dolan Reference Dolan2016, 33; Giles Reference Giles2007, 400; Hingley Reference Hingley and Gwilt1997, 14). Thus, it is not surprising that spatial and symbolic connections were forged between smelting activities and Iron Age saunas.

Considering the above, a second example can be suggested that also involves technical production. Some archaeometallurgical and osteological studies would be appropriate to support these preliminary theories. Taking into account the archaeological evidence of the forging areas in Borneiro (constructions C10–C11), a remarkable presence of bone remains among slag, ashes and charcoal has been documented as part of a set of traces of metalworking (Romero Masiá Reference Romero Masiá1987, 8). These bones are heavily crushed, mostly unidentifiable at a taxonomic level.

The finding of these crushed bone remains in forging areas may indicate their use as bonecoal used to refine iron through carbonization. This was a common technique in the Scandinavian Iron Age (Back Danielsson Reference Back Danielsson and Jones2008; Gansum Reference Gansum2004), although it may have been used in several regions of the world (Khojiev et al. Reference Khojiev, Alamova, Rakhmonaliev, Imomnazaroc, Sattorova and Khojiev2020). Through this procedure, partially burnt bones are reused and placed in a furnace at temperatures above 1328° F. At this temperature, carbon is transferred from the furnace to the iron, penetrating its surface up to 3 mm deep. This process enables the hardening of the iron, facilitating the making of a solid edge that could be properly sharpened. The strengthening of iron is essential for many of the objects thus made (Back Danielsson Reference Back Danielsson and Jones2008, 320), especially weapons (Gansum Reference Gansum2004, 43). This process is usually carried out in a clay oven (Gansum Reference Gansum2004, 42), which poses difficulties in its documentation due to post-depositional processes. It should be mentioned, however, that in room C10, where most bones were recovered, the remains of several clay ovens have been found, which fits the description (Nión-Álvarez Reference Nión-Álvarez2021, 332). Another example of this technical process can be found in Meirás (Sada, A Coruña), with remarkable evidence of significant metalworking and crushed bones unearthed (Luengo Martínez Reference Luengo Martínez1950, 106), but current data prevent relating these findings with metal-processing works.

The use of such techniques has been explained to evoke a transition between life and death (Gansum Reference Gansum2004, 45). Considering the reuse of bones for a technical process that allows the giving and reinforcing of the life of an object, the need to justify its effectiveness in the symbolic field seems particularly evident. In this regard, while this technique may be widespread, its contextualization and cultural identification may differ, especially depending on the source of the bone remains. In the case of Borneiro, nearby burial sites are not known, nor has it been possible to identify the bone remains taxonomically. At this point, these facts prevent any further questions about the significance of this evidence.

In both cases, the presence of this technique and its clear symbolic value show, given its characteristics, a certain level of ritualization. Even though the use of bones can be understood as part of a ‘technical’ process from a contemporary point of view, the original explanation would differ. In this respect, and regardless of their origin, the use of remains of living beings to strengthen new metal objects has significant symbolic implications. The existence of this technique and its effectiveness would have required a ‘ritualized’ explanation to justify its relevance, highlighting, once again, the value of the spiritual and the natural in metal production.

‘Specialization’

An increase in specialization in metal production, as previously mentioned, may not necessarily have implied labour specialization. The expansion of iron metallurgy implies more complex procedures as well as the need to acquire, preserve and transmit knowledge (Childs Reference Childs, Dobres and Hoffman1999, 24–6). These skills would not necessarily be related to an increase of social inequalities or productive specialization, nor to its emergence. A holistic perspective of social processes is necessary to understand the extent of the emergence of social inequalities, and, subsequently, to explore whether metallurgy has played a significant role in this process. In the case of the northwest Iberian peninsula, iron metallurgy was widespread during this period; however, the gradual implementation of inequalities experienced on the Atlantic coast does not seem to have the same prevalence inland.

On the Atlantic façade, it is possible to highlight the development of a specialized knowledge that seems to distinguish blacksmiths from the rest of the inhabitants; this specialization refers exclusively to the knowledge that enables them to produce metal and the ability to apply it. Smiths must also know how to sanction those activities considered beneficial or detrimental to the metalworking process. Everything seems to indicate, as has been suggested, that their dedication is not exclusive, and that they still need to guarantee their own subsistence, as can be traced in the household in Borneiro (Nión-Álvarez Reference Nión-Álvarez2021, 324).

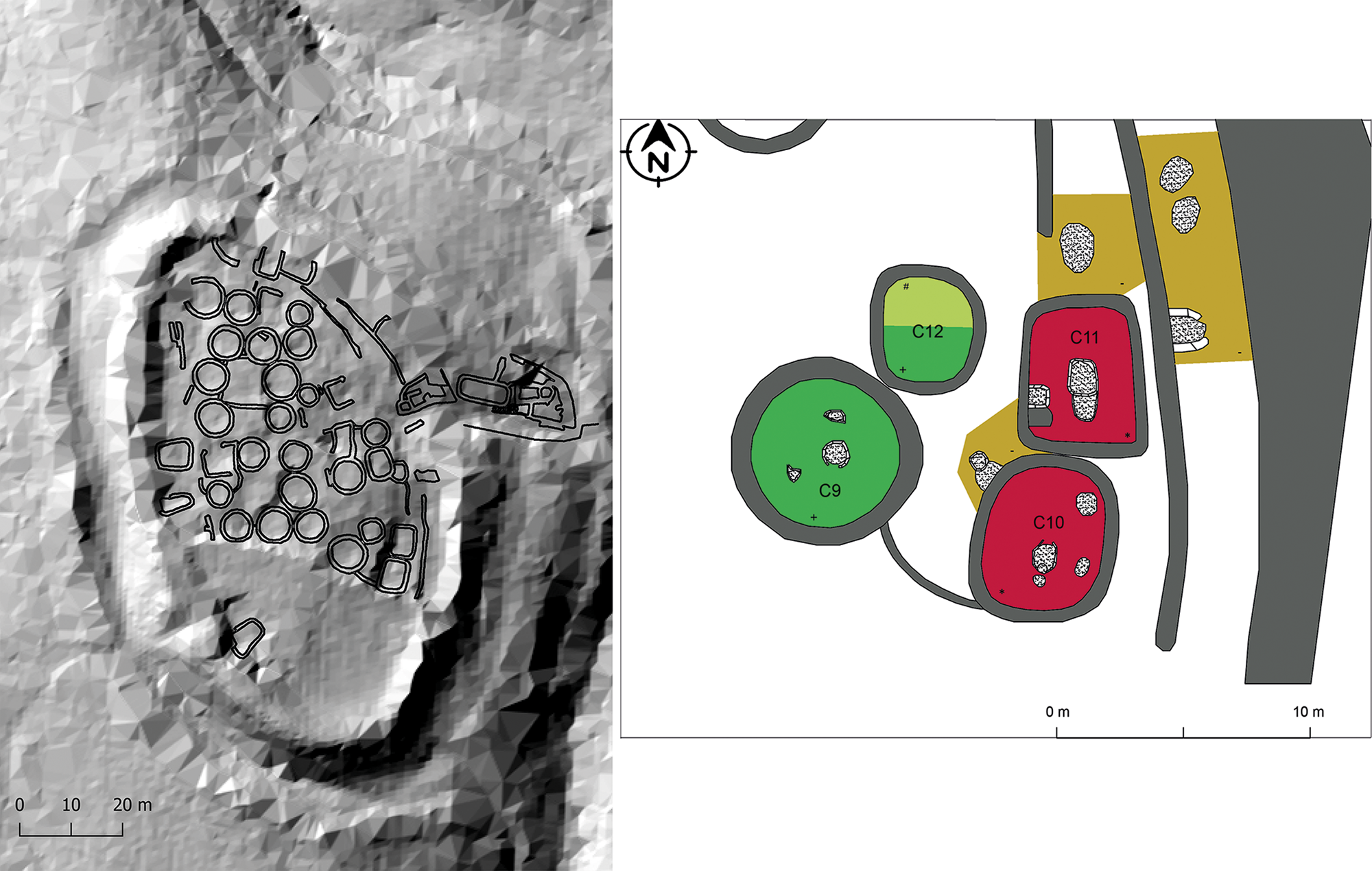

At Borneiro, a domestic setting with specific traces of metalworking activities has been unearthed (Fig. 6). This domestic unit consists of four rooms, the first of which (C9) is the largest and most carefully constructed. It has a clear domestic use, perhaps together with another dwelling (C12). The other chambers, as well as the open spaces to the east and south of the household, were related to different stages of the metalworking process (Nión-Álvarez Reference Nión-Álvarez2021, 318). The presence of a specialized space for metal production in one specific household suggests, on the one hand, that blacksmiths acquire a specific role and social position, which is expressed through the materialization of a space of their own; on the other hand, considering the social context of the settlement, it seems that their role is no longer linked to the main spaces of power. Differing from previous settlements, such as Punta de Muros, the production of metal is disengaged from the predominant domestic units. These households, placed in a privileged space, no longer show any evidence of metal production. Thus, the social role of blacksmiths seems to become secondary, parallel to their new domestic status. Nevertheless, no evidence suggests that they had a marginal role, or that they belonged to the lowest levels of the social scale. If we focus on the whole urban structure, this domestic unit is on a second level, lower than the largest domestic complexes, but above many smaller dwellings that do hold a peripheral and marginal role. It should be noted, however, that some activities may have taken place in outlying locations.

Figure 6. ‘Courtyard’ house C9-12 (Borneiro) (* = metalworking; + = domestic area; # = storage area; - = metalworking activities outside the rooms).

It should be mentioned that no strong parallels have yet been found in other regions of the Atlantic façade. The identified metal workshops, such as that of Baroña, do not seem to have a specific location in relation to a domestic unit. Though it could have been linked to a household called ‘Structure VI’, joined to the workshop by two walls that border the settlement wall (Luengo Martínez Reference Luengo Martínez1999), data are too scarce to support this assertion. Other metalworking workshops, such as at Santa Comba, do not allow extrapolation of their case to other domestic spaces due to the significant degradation of the surroundings (Gómez Filgueiras de Brage Reference Gómez Filgueiras de Brage and Columba2003). Far from the social dynamics of the Atlantic façade, metalworking activities inland, in sites such as Corona de Corporales or Castrelín de San Juan de Paluezas, have been documented as part of the household (Fernández-Posse & Sánchez-Palencia Reference Fernández-Posse and Sánchez-Palencia1998). Although this significant homogeneity between domestic units does not allow analysis of the social role of the metalworker, it does suggest different ways of understanding social relations in different regions of the northwest, as has already been highlighted (González-Ruibal Reference González-Ruibal, Stoddart and Cifani2012). In fact, the social models proposed for the region of El Bierzo (León) suggest the development of less complex social forms (Sastre Reference Sastre2002). On the contrary, in neighbouring areas such as the northern plateau, the outstanding role of metalworker and the specialization of his production have already been highlighted to underline an apparently social inequality (Ruiz Zapatero & Álvarez-Sanchís Reference Ruiz Zapatero and Álvarez-Sanchís2015, 220).

In any case, as already outlined, the heterogeneous nature of the blacksmiths’ role reflects exclusively how their social position depends on the cultural context. Even in a narrow geographical context such as the Atlantic façade, their rank may vary according to local dynamics. Only by identifying this heterogeneity in social ethos and political identity, which has only recently begun to be addressed (González Álvarez Reference González Álvarez2011; González-Ruibal Reference González-Ruibal, Stoddart and Cifani2012; Parcero-Oubiña & Nión-Álvarez Reference Parcero-Oubiña and Nión-Álvarez2021), will it be possible to identify the role and influence of different collectives such as metalworkers.

Metalworking in the emergence of the oppida

During the last centuries before the change of era (second–first centuries bce), a process of hierarchization and social aggregation spread throughout several European regions (Collis Reference Collis1984; Fernández Götz Reference Fernández Götz2017), mainly characterized by the emergence of fortified central spaces, usually known as oppida. Nevertheless, it is possible to trace alternative modes of social structure (Moore Reference Moore2017; Salač Reference Salač, Fernández-Götz, Wendling and Winger2014). This is not a homogenous process at all: several communities have not experienced significant changes and have even reinforced egalitarian values (González Álvarez Reference González Álvarez2016; Thurston Reference Thurston2009). With some nuances, this depiction can be verified in the northwest territory (Álvarez González et al. Reference Álvarez González, López González, Fernández-Götz and García Quintela2018; González-Ruibal Reference González-Ruibal2006). The emergence of complex settlements on a social and political level seems to occur in very specific regions: the Rías Baixas, some parts of the Bracarense and, as has recently been suggested, certain areas in the region of the Artabrii (Nión-Álvarez Reference Nión-Álvarez2021, 561). Considering the development of these notable transformations, it is necessary to assess whether the role of the blacksmith may also have experienced certain changes, as has been suggested in the northern plateau of the Iberian peninsula (Ruiz Zapatero & Álvarez-Sanchís Reference Ruiz Zapatero and Álvarez-Sanchís2015, 224).

The first question to analyse is the continuity of the detachment of bronze and iron production from the large domestic assemblages or ‘courtyard houses’. A trend towards its definitive separation from the domestic sphere, especially in the case of oppida, can be identified. Evidence of iron, bronze or gold production is particularly significant, as settlements such as Troña, Santa Trega or Elviña show (Fig. 7). In the first two cases, notable examples of production have been found: crucibles with residues of bronze and iron, tongs, sistula moulds, etc. (Carballo Arceo Reference Carballo Arceo1989; Hidalgo Cuñarro Reference Hidalgo Cuñarro1985). However, metalworking areas have not been documented in either settlement. In Elviña, nevertheless, metalworking workshops have been found outside the acropolis, within a specialized area without signs of domestic spaces nearby (López González Reference López González2018). Another example, although outside the study area, could be Campa Torres. Like Elviña, it is a complex settlement far from the social aggregation dynamics of the southern Galician region (Fanjul Peraza & Marín Suárez Reference Fanjul Peraza and Marín Suárez2006, 125). Its smithy is placed outside the walls, completely dissociated from any kind of dwelling (Maya González & Cuesta Toribio Reference Maya González and Cuesta Toribio2001, 238). This trend towards metallurgical specialization may have been accompanied by an increase in goldsmith production. Although its production is relatively widespread throughout the northwestern territory, latest radiocarbon dating could suggest that most gold objects were produced from the fourth century bce onwards (Armada Pita & García-Vuelta Reference Armada Pita and García-Vuelta2015). However, the available data concerning their production areas are particularly scarce.

Figure 7. Gold production evidence found in settlements. (Above) Objects and melting mass from Recouso (Armada Pita & García Vuelta Reference Armada Pita and García-Vuelta2015, used with permission); (Below) ‘Treasure of Elviña’ (Museo of A Coruña, used with permission).

Some researchers have suggested technique-production diversification and specialization between bronze-workers and goldsmiths (Armbruster & Perea Reference Armbruster and Perea2000, 109), but the record of production areas currently available does not permit verification of these assertions. However, the evidence of goldsmith production seems to be mainly located in large and complex settlements. Most of the examples in the Atlantic façade (Troña, Elviña, Santa Trega, etc.; see Figure 1) correspond to oppida. It should be noted, however, that in areas where social inequality is not so accentuated, far from the coast, evidence of goldsmith production has also been found, such as in Foxados or Recadieira (Pérez Outeiriño Reference Pérez Outeiriño and Acuña Castroviejo1992). This concentration of goldsmithing in the oppida might hint at the control of the production of certain prestige goods, but current data are too scarce to confirm this hypothesis.

Despite the contextual limitations, a step towards the specialization of the metalworker can be identified. Production adopts a place of its own separated from the household (at least in bronze and iron forges). Possibly, the level of specialization of metalworkers was higher, according to the social dynamics of the region, which does not imply that blacksmiths had an exclusive dedication, nor that they achieved a predominant position in society. It is necessary to stress again that the role of blacksmiths is eminently cultural, and their role in the cultural development of different communities can vary greatly.

Conclusions

In this study, the changes and continuities in the role of the blacksmith throughout the northwest Iberian Iron Age have been presented. Metalworking has been approached from a holistic perspective, understood as a multidimensional activity in which the technical and the symbolic are parts of the same set of meanings. Instead of analysing the value of metal objects in society, this work has focused on analysing the social position of prehistoric metalworkers, examining their role in the community within the social dynamics of the area and avoiding a technical or economic perspective on metalworking, the most usual concerns in archaeological research. Instead, the value of the technical and symbolic as inherent parts of metalworking has been addressed, focusing on their value in structuring and defining intra-community relations. At the same time, the need to avoid an excessively economistic or presentist approach to these activities is emphasized, adopting conceptualizations more akin to non-industrial societies. Thus, metalworking is understood from a social perspective, considering its relevance in the framework of the internal development of Iron Age societies and its value in identifying certain transformations.

Thus, it has been possible to appreciate a remarkable transformation of their social position during the first millennium bce. During the first centuries of the Iron Age, metallurgy was a common activity in different domestic spheres that became part of daily life in the village. In settlements with a remarkable development of social inequality, metallurgy achieved a higher level of specialization in new individualized spaces and, at the same time, linked to some outstanding domestic units.

From the fifth–fourth centuries bce, ironworking was widespread throughout northwestern Iberia, which implies considerable changes in the ways of working and interpreting metal production. The blacksmith may have acquired a higher level of specialization (not in labour or economic terms, but in its technical aspect), which would have led to defining new relationships within the community. The symbolism and ritualism of iron and of the role of metalworkers were significantly transformed. The characteristics of their activity have been classified in liminalization, specialization and ritualization. At this time, metal production was detached from the most prestigious households, becoming part of secondary domestic units or independent workshops. This may reflect a secondary or even marginal status of blacksmiths, although their position might have changed considerably depending on regional dynamics. The spread of ironworking has also triggered the emergence of new symbolic and religious expressions. Thus, metalworking was embedded in new cultural spaces and ways of perceiving its craft, perhaps linked to different rites of passage. Therefore, the blacksmith may have acquired a new role, holding greater control of both the technical and the spiritual, embodying the need to encompass both aspects of the craft as part of a whole.

With the emergence of the oppida, metalworking could have gone a step further towards specialization. In fortified central spaces, metal workshops seem to be completely dissociated from any domestic space, which could suggest a greater degree of individualization related to a greater control over the production of symbolic objects (especially gold objects), more common in the oppida. But evidence of their working areas is still elusive.

This brief review of the role of the blacksmith in recent prehistory is a starting-point for exploring new interpretations of metalworking beyond technical production. The crafting of iron, bronze or gold was a ritualized activity with a significant impact on the development of Iron Age communities that requires a holistic and multidisciplinary approach to analyse all its facets properly.

Acknowledgements

I would like to thank Dr Tamara Barreiro Neira for reviewing and proofreading the text and also the anonymous reviewers for their insightful comments and suggestions.