1. Introduction

Surface roughness is prevalent in many practical flows. Examples include flow through rough pipes (Allen et al. Reference Allen, Shockling, Kunkel and Smits2007), flow past bio-fouled ship hulls (Utama et al. Reference Utama, Nugroho, Yusuf, Prasetyo, Hakim, Suastika, Ganapathisubramani, Hutchins and Monty2021) and flow over vegetation canopies (Brunet Reference Brunet2020). It is well known that a hydrodynamically rough surface experiences an increased level of drag relative to a smooth surface at matched flow conditions (Moody Reference Moody1944), and that practical surfaces often exhibit irregular roughness across a wide range of length scales, e.g. turbine-blade roughness (Barros & Christensen Reference Barros and Christensen2014), machined surfaces (Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2016) and additively manufactured parts (Townsend et al. Reference Townsend, Senin, Blunt, Leach and Taylor2016). Yet predicting the drag penalty of irregular, multi-scale roughness remains an elusive goal and continues to be a focal point of research (Flack Reference Flack2018; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021).

In practice, the drag penalty due to surface roughness is described using a single parameter: the Nikuradse (Reference Nikuradse1933) sand-grain roughness, ![]() $k_{s}$. However,

$k_{s}$. However, ![]() $k_{s}$ cannot be derived from any direct measure of roughness, e.g. using digital data obtained from a surface scan. Instead, an equivalent value of

$k_{s}$ cannot be derived from any direct measure of roughness, e.g. using digital data obtained from a surface scan. Instead, an equivalent value of ![]() $k_{s}$ must be assigned to a particular surface by exposing it to a range of known flow conditions and then relating measurements of the Hama (Reference Hama1954) roughness function

$k_{s}$ must be assigned to a particular surface by exposing it to a range of known flow conditions and then relating measurements of the Hama (Reference Hama1954) roughness function ![]() $\Delta U^{+}\equiv \Delta U/u_{\tau }$, or the skin-friction coefficient

$\Delta U^{+}\equiv \Delta U/u_{\tau }$, or the skin-friction coefficient ![]() $C_{f}\equiv \tau _{w}/(\frac {1}{2}\rho U_{b}^{2})$, to the Nikuradse (Reference Nikuradse1933) sand-grain data. Here,

$C_{f}\equiv \tau _{w}/(\frac {1}{2}\rho U_{b}^{2})$, to the Nikuradse (Reference Nikuradse1933) sand-grain data. Here, ![]() $\Delta U^{+}$ is the downward shift of the inner-scaled mean streamwise velocity profile in the logarithmic (log) layer, relative to the smooth-wall profile at matched flow conditions, and

$\Delta U^{+}$ is the downward shift of the inner-scaled mean streamwise velocity profile in the logarithmic (log) layer, relative to the smooth-wall profile at matched flow conditions, and ![]() $u_{\tau }\equiv \sqrt {\tau _{w}/\rho }$ is the friction velocity, where

$u_{\tau }\equiv \sqrt {\tau _{w}/\rho }$ is the friction velocity, where ![]() $\tau _{w}$ is the wall shear stress,

$\tau _{w}$ is the wall shear stress, ![]() $\rho$ is the density, and

$\rho$ is the density, and ![]() $U_{b}$ is the streamwise bulk velocity. To express

$U_{b}$ is the streamwise bulk velocity. To express ![]() $k_{s}$ in terms of some measure for the physical roughness height, say

$k_{s}$ in terms of some measure for the physical roughness height, say ![]() $k$, a scaling factor

$k$, a scaling factor ![]() $C=k_{s}/k$ can be determined by collapsing the measured values of

$C=k_{s}/k$ can be determined by collapsing the measured values of ![]() $\Delta U^{+}$ onto Nikuradse's fully rough asymptote,

$\Delta U^{+}$ onto Nikuradse's fully rough asymptote, ![]() $\Delta U_{FR}^{+}(k_{s}^{+})=\kappa ^{-1}\log k_{s}^{+} +A-8.5$, where subscript

$\Delta U_{FR}^{+}(k_{s}^{+})=\kappa ^{-1}\log k_{s}^{+} +A-8.5$, where subscript ![]() $FR$ denotes fully rough conditions,

$FR$ denotes fully rough conditions, ![]() $\kappa$ is the von Kármán constant,

$\kappa$ is the von Kármán constant, ![]() $k_{s}^{+}\equiv k_{s} u_{\tau }/\nu$ is the viscous-scaled sand-grain roughness, and

$k_{s}^{+}\equiv k_{s} u_{\tau }/\nu$ is the viscous-scaled sand-grain roughness, and ![]() $A$ is the smooth-wall intercept. However, the scaling factor

$A$ is the smooth-wall intercept. However, the scaling factor ![]() $C=k_{s}/k$ is surface-specific and must be determined for each type of roughness, e.g. virtual sandpaper roughness (Yuan & Piomelli Reference Yuan and Piomelli2014), egg-carton roughness (Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2015), tube-worm roughness (Monty et al. Reference Monty, Dogan, Hanson, Scardino, Ganapathisubramani and Hutchins2016), grit-blasted roughness (Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2018), irregular near-Gaussian roughness (Jelly & Busse Reference Jelly and Busse2019b), orange-peel roughness (Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021) or industrial grade sandpaper roughness (Berghout et al. Reference Berghout, Bullee, Fuchs, Scharnowski, Kähler, Chung, Lohse and Huisman2021). Models that reliably predict

$C=k_{s}/k$ is surface-specific and must be determined for each type of roughness, e.g. virtual sandpaper roughness (Yuan & Piomelli Reference Yuan and Piomelli2014), egg-carton roughness (Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2015), tube-worm roughness (Monty et al. Reference Monty, Dogan, Hanson, Scardino, Ganapathisubramani and Hutchins2016), grit-blasted roughness (Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2018), irregular near-Gaussian roughness (Jelly & Busse Reference Jelly and Busse2019b), orange-peel roughness (Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021) or industrial grade sandpaper roughness (Berghout et al. Reference Berghout, Bullee, Fuchs, Scharnowski, Kähler, Chung, Lohse and Huisman2021). Models that reliably predict ![]() $k_{s}/k$ (or

$k_{s}/k$ (or ![]() $\Delta U^{+}$) based solely on key topographical parameters are therefore of great value.

$\Delta U^{+}$) based solely on key topographical parameters are therefore of great value.

Whilst the ultimate goal for roughness research is to produce a universal model that correlates key topographical parameters to ![]() $k_{s}/k$ (or

$k_{s}/k$ (or ![]() $\Delta U^{+}$ for transitionally rough flows), a complete exploration of the parameter space that defines the ‘roughness problem’ is simply not feasible. To overcome this challenge, it is widely accepted that a minimal set of key topographical parameters must first be identified (Flack Reference Flack2018; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which can then be used to develop predictive models for

$\Delta U^{+}$ for transitionally rough flows), a complete exploration of the parameter space that defines the ‘roughness problem’ is simply not feasible. To overcome this challenge, it is widely accepted that a minimal set of key topographical parameters must first be identified (Flack Reference Flack2018; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021), which can then be used to develop predictive models for ![]() $k_{s}/k$ or

$k_{s}/k$ or ![]() $\Delta U^{+}$. Eight predictive models for

$\Delta U^{+}$. Eight predictive models for ![]() $k_{s}/k$ and

$k_{s}/k$ and ![]() $\Delta U^{+}$ proposed in past work are listed in table 1. Despite their variety, the models share three common topographical parameters. These include: (i) a measure of the physical roughness height, e.g. the mean absolute height

$\Delta U^{+}$ proposed in past work are listed in table 1. Despite their variety, the models share three common topographical parameters. These include: (i) a measure of the physical roughness height, e.g. the mean absolute height ![]() $S_{a}$, the root-mean-square (r.m.s.) height

$S_{a}$, the root-mean-square (r.m.s.) height ![]() $S_{q}$, or the mean peak-to-valley height

$S_{q}$, or the mean peak-to-valley height ![]() $S_{z,5\times 5}$; (ii) the skewness of the height distribution

$S_{z,5\times 5}$; (ii) the skewness of the height distribution ![]() $Ssk$; and (iii) the streamwise effective slope

$Ssk$; and (iii) the streamwise effective slope ![]() $ES_{x}$. The latter quantity is defined as

$ES_{x}$. The latter quantity is defined as ![]() $ES_{x}={A}^{-1}\int _{A}|{\partial h(x,y)}/{\partial x}|\,\textrm {d}A$ (where

$ES_{x}={A}^{-1}\int _{A}|{\partial h(x,y)}/{\partial x}|\,\textrm {d}A$ (where ![]() $h(x,y)$ is the roughness height distribution, and

$h(x,y)$ is the roughness height distribution, and ![]() $A$ is the planform area of the surface), and is related to frontal solidity through the formula

$A$ is the planform area of the surface), and is related to frontal solidity through the formula ![]() $\textstyle \lambda _{x}\equiv \frac {1}{2}ES_{x}$ (see MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) for details). Although models based on parameters (i)–(iii) have shown promise in predicting the roughness drag penalty (Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlic and Frohnapfel2017), a truly universal correlation will likely depend on additional topographical parameters related to other surface properties such as directionality or anisotropy.

$\textstyle \lambda _{x}\equiv \frac {1}{2}ES_{x}$ (see MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) for details). Although models based on parameters (i)–(iii) have shown promise in predicting the roughness drag penalty (Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlic and Frohnapfel2017), a truly universal correlation will likely depend on additional topographical parameters related to other surface properties such as directionality or anisotropy.

Table 1. Predictive models for ![]() $k_{s}/k$ and

$k_{s}/k$ and ![]() $\Delta U^{+}$ based on topographical parameters, including: generalised Sigal–Danberg parameter

$\Delta U^{+}$ based on topographical parameters, including: generalised Sigal–Danberg parameter ![]() $\varLambda _{s}=(S/S_{f})(S_{f}/S_{s})^{-1.6}$ (where

$\varLambda _{s}=(S/S_{f})(S_{f}/S_{s})^{-1.6}$ (where ![]() $S$ is the planform area of the corresponding smooth surface,

$S$ is the planform area of the corresponding smooth surface, ![]() $S_{f}$ is the total projected frontal area of all the roughness elements, and

$S_{f}$ is the total projected frontal area of all the roughness elements, and ![]() $S_{s}$ is the total area of all roughness elements wetted by the flow

$S_{s}$ is the total area of all roughness elements wetted by the flow ![]() $S$);

$S$); ![]() $n$th spectral moment

$n$th spectral moment ![]() $m_{n}=\int _{0}^{\infty }\kappa _{}^{n}E_{hh}\,{\rm d}\kappa _{}$ (where

$m_{n}=\int _{0}^{\infty }\kappa _{}^{n}E_{hh}\,{\rm d}\kappa _{}$ (where ![]() $E_{hh}$ is the spectrum of surface elevation, and

$E_{hh}$ is the spectrum of surface elevation, and ![]() $\kappa _{}$ is an in-plane wavenumber); r.m.s. forward-facing surface angle

$\kappa _{}$ is an in-plane wavenumber); r.m.s. forward-facing surface angle ![]() $\alpha _{rms}=\sqrt {n_{f}^{-1}\sum _{j=1}^{n_{f}}\alpha ^{2}_{j}}$ (where

$\alpha _{rms}=\sqrt {n_{f}^{-1}\sum _{j=1}^{n_{f}}\alpha ^{2}_{j}}$ (where ![]() $n_{f}$ is the total number of forward-facing roughness elements, the local forward-facing surface angle is

$n_{f}$ is the total number of forward-facing roughness elements, the local forward-facing surface angle is ![]() $\alpha _{j}=\tan ^{-1}(\Delta s^{-1}[h_{j+1}-h_{j}])$, and

$\alpha _{j}=\tan ^{-1}(\Delta s^{-1}[h_{j+1}-h_{j}])$, and ![]() $\Delta s$ is the streamwise spacing of the roughness elements); mean absolute roughness height

$\Delta s$ is the streamwise spacing of the roughness elements); mean absolute roughness height ![]() $S_{a}={A^{-1}\iint |h(x,y)|\,{\rm d} A}$; r.m.s. roughness height

$S_{a}={A^{-1}\iint |h(x,y)|\,{\rm d} A}$; r.m.s. roughness height ![]() $S_{q}=\sqrt {{A^{-1}\iint h(x,y)^{2}\,{\rm d} A}}$; skewness

$S_{q}=\sqrt {{A^{-1}\iint h(x,y)^{2}\,{\rm d} A}}$; skewness ![]() $Ssk=A^{-1}{S_{q}^{-3}}\iint h(x,y)^{3}\,{\rm d} A$; kurtosis

$Ssk=A^{-1}{S_{q}^{-3}}\iint h(x,y)^{3}\,{\rm d} A$; kurtosis ![]() $Sku=A^{-1}{S_{q}^{-4}}\iint h(x,y)^{4}\,{\rm d} A$; streamwise effective slope

$Sku=A^{-1}{S_{q}^{-4}}\iint h(x,y)^{4}\,{\rm d} A$; streamwise effective slope ![]() $ES_{x}={A}^{-1}\int _{A}|{\partial h(x,y)}/{\partial x}|\,\textrm {d}A$; and streamwise correlation length based on a 0.2 cutoff criterion,

$ES_{x}={A}^{-1}\int _{A}|{\partial h(x,y)}/{\partial x}|\,\textrm {d}A$; and streamwise correlation length based on a 0.2 cutoff criterion, ![]() $L_{x,cor}$. Note that

$L_{x,cor}$. Note that ![]() $A$ is the planform area of the height map

$A$ is the planform area of the height map ![]() $h(x,y)$.

$h(x,y)$.

Whilst the drag behaviours of highly directional two-dimensional surfaces have been studied extensively, e.g. streamwise-aligned riblets (Gatti et al. Reference Gatti, von Deyn, Forooghi and Frohnapfel2020; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021), spanwise-aligned bars (Volino, Schultz & Flack Reference Volino, Schultz and Flack2009; Krogstad & Efros Reference Krogstad and Efros2012) and spanwise-alternating rough-to-smooth surfaces (Bakhuis et al. Reference Bakhuis, Ezeta, Berghout, Bullee, Tai, Chung, Verzicco, Lohse, Huisman and Sun2020; Wangsawijaya et al. Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020), systematic studies of surface anisotropy in the context of irregular, three-dimensional roughness remain scarce. One exception to this trend is the work by Busse & Jelly (Reference Busse and Jelly2020), which demonstrated that irregular roughness with spanwise-elongated features induces an over 200 % increase in ![]() $\Delta U^{+}$, relative to roughness with streamwise-elongated features in fully developed turbulent channel flow. In that work, the level of surface anisotropy was quantified using the surface anisotropy ratio (SAR) parameter, which was defined as

$\Delta U^{+}$, relative to roughness with streamwise-elongated features in fully developed turbulent channel flow. In that work, the level of surface anisotropy was quantified using the surface anisotropy ratio (SAR) parameter, which was defined as ![]() $\textrm {SAR}\equiv L_{x,cor}/L_{y,cor}$, where

$\textrm {SAR}\equiv L_{x,cor}/L_{y,cor}$, where ![]() $L_{x,cor}$ and

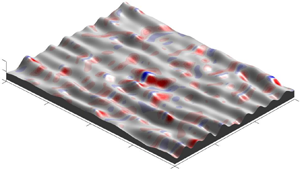

$L_{x,cor}$ and ![]() $L_{y,cor}$ are the streamwise and spanwise correlation lengths based on a 0.2 cutoff criterion (see Thakkar et al. (Reference Thakkar, Busse and Sandham2016) for details). Yet the sensitivity of wall drag with respect to the SAR parameter or other measures of surface anisotropy cannot be predicted using any combination of the topographical parameters included in table 1. This shortcoming is illustrated by the three roughness topographies shown in figure 1, which, based on their mean peak-to-valley height, skewness and streamwise effective slope, are identical in the statistical sense – despite showing obvious differences along the spanwise (

$L_{y,cor}$ are the streamwise and spanwise correlation lengths based on a 0.2 cutoff criterion (see Thakkar et al. (Reference Thakkar, Busse and Sandham2016) for details). Yet the sensitivity of wall drag with respect to the SAR parameter or other measures of surface anisotropy cannot be predicted using any combination of the topographical parameters included in table 1. This shortcoming is illustrated by the three roughness topographies shown in figure 1, which, based on their mean peak-to-valley height, skewness and streamwise effective slope, are identical in the statistical sense – despite showing obvious differences along the spanwise (![]() $y$) direction. Hence further consideration of directional topographical parameters is required to predict the drag penalty of anisotropic surface roughness.

$y$) direction. Hence further consideration of directional topographical parameters is required to predict the drag penalty of anisotropic surface roughness.

Figure 1. Irregular surface roughness with identical mean peak-to-valley height ![]() $S_{z,5\times 5}/\delta =1/6$, skewness

$S_{z,5\times 5}/\delta =1/6$, skewness ![]() $Ssk\approx 0$ and

$Ssk\approx 0$ and ![]() $ES_{x}\approx 0.35$, but differing

$ES_{x}\approx 0.35$, but differing ![]() $ES_{y}$. (a) Isotropic surface with

$ES_{y}$. (a) Isotropic surface with ![]() $ES_{y}/ES_{x}=1$. (b) Spanwise-elongated roughness with

$ES_{y}/ES_{x}=1$. (b) Spanwise-elongated roughness with ![]() $ES_{y}/ES_{x}\approx 0.63$. (c) Spanwise-elongated roughness with

$ES_{y}/ES_{x}\approx 0.63$. (c) Spanwise-elongated roughness with ![]() $ES_{y}/ES_{x}\approx 0.29$. Each surface is shown on a

$ES_{y}/ES_{x}\approx 0.29$. Each surface is shown on a ![]() $(2\times 2)/\delta$ tile, where

$(2\times 2)/\delta$ tile, where ![]() $\delta$ is the mean channel half-height.

$\delta$ is the mean channel half-height.

As a first step, spanwise effective slope ![]() $ES_{y}$ can be considered, which, in analogy to

$ES_{y}$ can be considered, which, in analogy to ![]() $ES_{x}$, is defined as the mean absolute spanwise slope of the height distribution,

$ES_{x}$, is defined as the mean absolute spanwise slope of the height distribution, ![]() $ES_{y}\equiv {A}^{-1}\int _{A}|{\partial h(x,y)}/{\partial y}|\,\textrm {d}A$, and is related to ‘lateral’ solidity through the formula

$ES_{y}\equiv {A}^{-1}\int _{A}|{\partial h(x,y)}/{\partial y}|\,\textrm {d}A$, and is related to ‘lateral’ solidity through the formula ![]() $\varLambda _{y}\equiv \frac {1}{2}ES_{y}$. The degree of surface anisotropy can then be inferred from the ratio of spanwise effective slope to streamwise effective slope, i.e. surfaces with

$\varLambda _{y}\equiv \frac {1}{2}ES_{y}$. The degree of surface anisotropy can then be inferred from the ratio of spanwise effective slope to streamwise effective slope, i.e. surfaces with ![]() $ES_{y}/ES_{x}=1$ are isotropic (figure 1a), surfaces with

$ES_{y}/ES_{x}=1$ are isotropic (figure 1a), surfaces with ![]() $ES_{y}/ES_{x}<1$ are spanwise-elongated (figures 1b,c), and surfaces with

$ES_{y}/ES_{x}<1$ are spanwise-elongated (figures 1b,c), and surfaces with ![]() $ES_{y}/ES_{x}>1$ are streamwise-elongated. The limiting cases are streamwise homogeneous roughness with

$ES_{y}/ES_{x}>1$ are streamwise-elongated. The limiting cases are streamwise homogeneous roughness with ![]() $ES_{x}=0$ and

$ES_{x}=0$ and ![]() $ES_{y}>0$, i.e. two-dimensional riblet-like surfaces with

$ES_{y}>0$, i.e. two-dimensional riblet-like surfaces with ![]() $ES_{y}/ES_{x}\rightarrow \infty$, and spanwise homogeneous roughness with

$ES_{y}/ES_{x}\rightarrow \infty$, and spanwise homogeneous roughness with ![]() $ES_{x}>0$ and

$ES_{x}>0$ and ![]() $ES_{y}=0$, i.e. two-dimensional spanwise bar-like surfaces with

$ES_{y}=0$, i.e. two-dimensional spanwise bar-like surfaces with ![]() $ES_{y}/ES_{x}\rightarrow 0$.

$ES_{y}/ES_{x}\rightarrow 0$.

Whilst systematic studies of irregular anisotropic roughness (![]() $ES_{y}/ES_{x}\neq 1$) remain scarce, the drag penalty of isotropic surface roughness (

$ES_{y}/ES_{x}\neq 1$) remain scarce, the drag penalty of isotropic surface roughness (![]() $ES_{y}/ES_{x}=1$) has been studied for various regular (Bhaganagar, Kim & Coleman Reference Bhaganagar, Kim and Coleman2004; Coceal et al. Reference Coceal, Thomas, Castro and Belcher2006; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2015; Seddighi et al. Reference Seddighi, He, Pokrajac, O'Donoghue and Vardy2015; Ma et al. Reference Ma, Xu, Sung and Huang2020) and irregular (De Marchis et al. Reference De Marchis, Saccone, Milici and Napoli2020; Flack, Schultz & Barros Reference Flack, Schultz and Barros2020; Ma, Alamé & Mahesh Reference Ma, Alamé and Mahesh2021; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021; Portela, Busse & Sandham Reference Portela, Busse and Sandham2021) topographies. The current lack of studies on turbulent flow over surface roughness with systematically varied

$ES_{y}/ES_{x}=1$) has been studied for various regular (Bhaganagar, Kim & Coleman Reference Bhaganagar, Kim and Coleman2004; Coceal et al. Reference Coceal, Thomas, Castro and Belcher2006; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2015; Seddighi et al. Reference Seddighi, He, Pokrajac, O'Donoghue and Vardy2015; Ma et al. Reference Ma, Xu, Sung and Huang2020) and irregular (De Marchis et al. Reference De Marchis, Saccone, Milici and Napoli2020; Flack, Schultz & Barros Reference Flack, Schultz and Barros2020; Ma, Alamé & Mahesh Reference Ma, Alamé and Mahesh2021; Nugroho et al. Reference Nugroho, Monty, Utama, Ganapathisubramani and Hutchins2021; Portela, Busse & Sandham Reference Portela, Busse and Sandham2021) topographies. The current lack of studies on turbulent flow over surface roughness with systematically varied ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ is conveyed in figure 2, where data points from the present study and past work are plotted on the

$ES_{y}$ is conveyed in figure 2, where data points from the present study and past work are plotted on the ![]() $ES_{x}$–

$ES_{x}$–![]() $ES_{y}$ plane. Relative to the combinations of

$ES_{y}$ plane. Relative to the combinations of ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ considered in the present study (shown as filled black circles in figure 2), most past data appear scattered, and few systematic patterns can be discerned. An exception to this trend is the past work of Busse & Jelly (Reference Busse and Jelly2020), although, as was mentioned previously, that study focused on varying the SAR parameter systematically, and did not change

$ES_{y}$ considered in the present study (shown as filled black circles in figure 2), most past data appear scattered, and few systematic patterns can be discerned. An exception to this trend is the past work of Busse & Jelly (Reference Busse and Jelly2020), although, as was mentioned previously, that study focused on varying the SAR parameter systematically, and did not change ![]() $ES_{x}$ or

$ES_{x}$ or ![]() $ES_{y}$ independently (see filled green circles in figure 2). Also, whilst practical roughness often shows appreciable levels of anisotropy (e.g. see surface scan data of Thakkar et al. (Reference Thakkar, Busse and Sandham2016); filled red circles in figure 2), the values of

$ES_{y}$ independently (see filled green circles in figure 2). Also, whilst practical roughness often shows appreciable levels of anisotropy (e.g. see surface scan data of Thakkar et al. (Reference Thakkar, Busse and Sandham2016); filled red circles in figure 2), the values of ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ cannot be specified a priori, which complicates the analysis of results. Combined with the empirical models listed in table 1 and the data points plotted in figure 2, these past studies draw further attention to the lack of available data regarding the impact of

$ES_{y}$ cannot be specified a priori, which complicates the analysis of results. Combined with the empirical models listed in table 1 and the data points plotted in figure 2, these past studies draw further attention to the lack of available data regarding the impact of ![]() $ES_{y}$ upon rough-wall turbulent flows.

$ES_{y}$ upon rough-wall turbulent flows.

Figure 2. Combinations of ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ considered in the present study (black circles) and past work by: Napoli, Armenio & De Marchis (Reference Napoli, Armenio and De Marchis2008), yellow circles; Schultz & Flack (Reference Schultz and Flack2009), grey circles; Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2015), blue circles; Thakkar et al. (Reference Thakkar, Busse and Sandham2016), red circles; Forooghi, Stripf & Frohnapfel (Reference Forooghi, Stripf and Frohnapfel2018a), cyan circles; Busse & Jelly (Reference Busse and Jelly2020), green circles; and Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), white circles. The diagonal grey dotted line demarcates isotropic roughness

$ES_{y}$ considered in the present study (black circles) and past work by: Napoli, Armenio & De Marchis (Reference Napoli, Armenio and De Marchis2008), yellow circles; Schultz & Flack (Reference Schultz and Flack2009), grey circles; Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2015), blue circles; Thakkar et al. (Reference Thakkar, Busse and Sandham2016), red circles; Forooghi, Stripf & Frohnapfel (Reference Forooghi, Stripf and Frohnapfel2018a), cyan circles; Busse & Jelly (Reference Busse and Jelly2020), green circles; and Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), white circles. The diagonal grey dotted line demarcates isotropic roughness ![]() $ES_{y}/ES_{x}=1$.

$ES_{y}/ES_{x}=1$.

To determine whether or not ![]() $ES_{y}$ should be considered an important topographical parameter, the present investigation takes a ‘slice’ through a region of the roughness parameter space that has not hitherto been explored. This is achieved by synthesising a set of ten irregular height maps with specified values of

$ES_{y}$ should be considered an important topographical parameter, the present investigation takes a ‘slice’ through a region of the roughness parameter space that has not hitherto been explored. This is achieved by synthesising a set of ten irregular height maps with specified values of ![]() $ES_{y}$ (whilst holding roughness amplitude, skewness and streamwise effective slope nearly constant), and then performing direct numerical simulations (DNS) of a rough-walled turbulent channel at friction Reynolds number 395 for each surface, corresponding to roughness Reynolds number

$ES_{y}$ (whilst holding roughness amplitude, skewness and streamwise effective slope nearly constant), and then performing direct numerical simulations (DNS) of a rough-walled turbulent channel at friction Reynolds number 395 for each surface, corresponding to roughness Reynolds number ![]() $k^{+}\approx 65.8$ (where

$k^{+}\approx 65.8$ (where ![]() $k$ is the mean peak-to-valley height). The sensitivity of key hydrodynamic parameters, such as the Hama roughness function, and associated physical mechanisms, such as the relative contributions of pressure and viscous drag, are then quantified with respect to systematic variations in

$k$ is the mean peak-to-valley height). The sensitivity of key hydrodynamic parameters, such as the Hama roughness function, and associated physical mechanisms, such as the relative contributions of pressure and viscous drag, are then quantified with respect to systematic variations in ![]() $ES_{y}$ for a fixed value of

$ES_{y}$ for a fixed value of ![]() $k^{+}$. Some observations regarding the levels of outer-layer similarity (or lack thereof) above particular low-

$k^{+}$. Some observations regarding the levels of outer-layer similarity (or lack thereof) above particular low-![]() $ES_{y}$ surfaces are also discussed. The numerical aspects of this study are described in § 2. Results are presented in § 3. Finally, in § 4, the conclusions of this work are given.

$ES_{y}$ surfaces are also discussed. The numerical aspects of this study are described in § 2. Results are presented in § 3. Finally, in § 4, the conclusions of this work are given.

2. Numerical aspects

This section describes the numerical aspects of this work and is divided into three parts. First, a description of the surface synthesis procedure is given. Second, the embedded boundary DNS algorithm used to simulate rough-wall turbulent channel flow is summarised, and key simulation parameters are provided. Finally, the statistical averaging procedure is described.

2.1. Surface synthesis procedure

Irregular three-dimensional surfaces with doubly periodic boundaries were generated by taking linear combinations of Gaussian random number matrices using a weighted moving average process based on past work by Patir (Reference Patir1978). Numerical details of the surface synthesis procedure are provided in Appendix A and/or in the past work of Jelly & Busse (Reference Jelly and Busse2018, Reference Jelly and Busse2019a). The height distribution of each surface is near-Gaussian, i.e. zero mean, negligible skewness (![]() $Ssk\approx 0$), and kurtosis equal to 3 (

$Ssk\approx 0$), and kurtosis equal to 3 (![]() $Sku\approx 3$). The values of

$Sku\approx 3$). The values of ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ for each surface were specified by varying the cutoff length of an exponential autocorrelation function in the streamwise (

$ES_{y}$ for each surface were specified by varying the cutoff length of an exponential autocorrelation function in the streamwise (![]() $x_{1}$) and spanwise (

$x_{1}$) and spanwise (![]() $x_{2}$) directions, and the cutoff wavenumber of a two-dimensional low-pass Fourier filter (Busse, Lützner & Sandham Reference Busse, Lützner and Sandham2015). The filtered height maps were scaled to a common mean peak-to-valley height

$x_{2}$) directions, and the cutoff wavenumber of a two-dimensional low-pass Fourier filter (Busse, Lützner & Sandham Reference Busse, Lützner and Sandham2015). The filtered height maps were scaled to a common mean peak-to-valley height ![]() $S_{z,5\times 5}/\delta =1/6$, where

$S_{z,5\times 5}/\delta =1/6$, where ![]() $\delta$ is the channel half-height. Following Thakkar et al. (Reference Thakkar, Busse and Sandham2016), the mean-peak-to-valley height was calculated by subdividing each height map into

$\delta$ is the channel half-height. Following Thakkar et al. (Reference Thakkar, Busse and Sandham2016), the mean-peak-to-valley height was calculated by subdividing each height map into ![]() $5\times 5$ tiles and then taking the average of the maximum peak-to-valley-heights of the different tiles. Thakkar et al. (Reference Thakkar, Busse and Sandham2018) showed for an irregular, multi-scale rough surface resembling Nikuradse's sand-grain roughness that

$5\times 5$ tiles and then taking the average of the maximum peak-to-valley-heights of the different tiles. Thakkar et al. (Reference Thakkar, Busse and Sandham2018) showed for an irregular, multi-scale rough surface resembling Nikuradse's sand-grain roughness that ![]() $\Delta U^+$ becomes independent of

$\Delta U^+$ becomes independent of ![]() $S_{z,5\times 5}/\delta$ for fixed

$S_{z,5\times 5}/\delta$ for fixed ![]() $S_{z,5\times 5}^+$ when

$S_{z,5\times 5}^+$ when ![]() $S_{z,5\times 5}/\delta \le 1/6$; this criterion is met for all surfaces included in the present study.

$S_{z,5\times 5}/\delta \le 1/6$; this criterion is met for all surfaces included in the present study.

Whilst all surfaces investigated here share a common mean peak-to-valley height, their mean absolute height (![]() $S_{a}$) and r.m.s. roughness height (

$S_{a}$) and r.m.s. roughness height (![]() $S_{q}$) show some variation (see second and third columns in table 2). In particular,

$S_{q}$) show some variation (see second and third columns in table 2). In particular, ![]() $S_{a}$ varies by up to 26 % for Group A surfaces (see below), which could potentially mask the sensitivity of

$S_{a}$ varies by up to 26 % for Group A surfaces (see below), which could potentially mask the sensitivity of ![]() $\Delta U^{+}$ with respect to

$\Delta U^{+}$ with respect to ![]() $ES_{y}$. The impact of variations in

$ES_{y}$. The impact of variations in ![]() $S_{a}$ upon

$S_{a}$ upon ![]() $\Delta U^{+}$ can be estimated by recasting Nikuradse's fully rough asymptote as

$\Delta U^{+}$ can be estimated by recasting Nikuradse's fully rough asymptote as ![]() $\Delta U^{+}_{FR}=\kappa ^{-1} \log (CS_{a})+A-8.5$, where

$\Delta U^{+}_{FR}=\kappa ^{-1} \log (CS_{a})+A-8.5$, where ![]() $C=k_{s}/S_{a}$ is a surface-specific scaling factor. Multiplying

$C=k_{s}/S_{a}$ is a surface-specific scaling factor. Multiplying ![]() $S_{a}$ by a factor 1.26 would therefore change the Hama roughness function by approximately

$S_{a}$ by a factor 1.26 would therefore change the Hama roughness function by approximately ![]() $0.6$ wall units. As will be shown later, this variation is a factor of four smaller than the observed range of

$0.6$ wall units. As will be shown later, this variation is a factor of four smaller than the observed range of ![]() $\Delta U^{+}$ for Group A surfaces. As a result, variations in

$\Delta U^{+}$ for Group A surfaces. As a result, variations in ![]() $S_{a}$ are herein considered to have a negligible effect on

$S_{a}$ are herein considered to have a negligible effect on ![]() $\Delta U^{+}$, relative to the impact of varying

$\Delta U^{+}$, relative to the impact of varying ![]() $ES_{y}$.

$ES_{y}$.

Table 2. Surface statistics, including: mean absolute height ![]() $S_{a}$; r.m.s. height

$S_{a}$; r.m.s. height ![]() $S_{q}$; skewness

$S_{q}$; skewness ![]() $Ssk$; kurtosis

$Ssk$; kurtosis ![]() $Sku$; mean peak-to-valley height

$Sku$; mean peak-to-valley height ![]() $S_{z,{ 5 \times 5 }}$; height of the highest crest

$S_{z,{ 5 \times 5 }}$; height of the highest crest ![]() $h_{max}$; streamwise effective slope

$h_{max}$; streamwise effective slope ![]() $ES_{x}$; spanwise effective slope

$ES_{x}$; spanwise effective slope ![]() $ES_{y}$; ratio of spanwise to streamwise effective slope

$ES_{y}$; ratio of spanwise to streamwise effective slope ![]() $ES_{y}/ES_{x}$; ratio of mean streamwise in-plane wavelength to channel half-height

$ES_{y}/ES_{x}$; ratio of mean streamwise in-plane wavelength to channel half-height ![]() $\bar {\lambda }_{x}/\delta$; ratio of mean spanwise in-plane wavelength to channel half-height

$\bar {\lambda }_{x}/\delta$; ratio of mean spanwise in-plane wavelength to channel half-height ![]() $\bar {\lambda }_{y}/\delta$; and ratio of mean spanwise and streamwise in-plane wavelengths

$\bar {\lambda }_{y}/\delta$; and ratio of mean spanwise and streamwise in-plane wavelengths ![]() $\bar {\lambda }_{y}/\bar {\lambda }_{x}$.

$\bar {\lambda }_{y}/\bar {\lambda }_{x}$.

The ten roughness topographies investigated here are shown in figure 3. Each surface is named using the identification code

where the first three digits represent the value of the streamwise effective slope, e.g. ![]() $ES_{x}=0.10$, and the last three three digits represent the value of the of the spanwise effective slope, e.g.

$ES_{x}=0.10$, and the last three three digits represent the value of the of the spanwise effective slope, e.g. ![]() $ES_{y}=0.35$. Decimal points have been omitted for brevity. The ten surfaces were sorted into three groups according to their

$ES_{y}=0.35$. Decimal points have been omitted for brevity. The ten surfaces were sorted into three groups according to their ![]() $ES_{x}$ value. Group A contains four height maps, with

$ES_{x}$ value. Group A contains four height maps, with ![]() $ES_{x}=0.10$ and

$ES_{x}=0.10$ and ![]() $ES_{y}=\{0.70,0.35,0.22,0.10\}$. Group B contains three height maps, with

$ES_{y}=\{0.70,0.35,0.22,0.10\}$. Group B contains three height maps, with ![]() $ES_{x}\approx 0.22$ and

$ES_{x}\approx 0.22$ and ![]() $ES_{y}=\{0.35,0.22,0.10\}$. Group C contains three height maps, with

$ES_{y}=\{0.35,0.22,0.10\}$. Group C contains three height maps, with ![]() $ES_{x}\approx 0.35$ and

$ES_{x}\approx 0.35$ and ![]() $ES_{y}=\{0.35,0.22,0.10\}$. Further, according to the classification of Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021), Group A surfaces lie on the cusp of the sparse regime (

$ES_{y}=\{0.35,0.22,0.10\}$. Further, according to the classification of Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021), Group A surfaces lie on the cusp of the sparse regime (![]() $ES_{x}\lesssim 0.10$), Group C surfaces fall within the dense regime (

$ES_{x}\lesssim 0.10$), Group C surfaces fall within the dense regime (![]() $ES_{x}\gtrsim 0.30$), and Group B surfaces fall within an intermediate regime (

$ES_{x}\gtrsim 0.30$), and Group B surfaces fall within an intermediate regime (![]() $0.10 \lesssim ES_{x}\lesssim 0.30$). The present study therefore focuses mainly on the sparse and intermediate regimes. This choice was motivated by the surface scan data obtained by Thakkar et al. (Reference Thakkar, Busse and Sandham2016) (filled red circles in figure 2), which shows that many practical surfaces satisfy the criterion

$0.10 \lesssim ES_{x}\lesssim 0.30$). The present study therefore focuses mainly on the sparse and intermediate regimes. This choice was motivated by the surface scan data obtained by Thakkar et al. (Reference Thakkar, Busse and Sandham2016) (filled red circles in figure 2), which shows that many practical surfaces satisfy the criterion ![]() $ES_{x}\lesssim 0.30$.

$ES_{x}\lesssim 0.30$.

Figure 3. Surface topographies under consideration in this study. Streamwise effective slope (![]() $ES_{x}$) remains constant in each column, whereas spanwise effective slope (

$ES_{x}$) remains constant in each column, whereas spanwise effective slope (![]() $ES_{y}$) remains constant along each row. Group A surfaces: (a)

$ES_{y}$) remains constant along each row. Group A surfaces: (a) ![]() $010\_070$, (b)

$010\_070$, (b) ![]() $010\_035$, (c)

$010\_035$, (c) ![]() $010\_022$, and (d)

$010\_022$, and (d) ![]() $010\_010$. Group B surfaces: (e)

$010\_010$. Group B surfaces: (e) ![]() $022\_035$, ( f)

$022\_035$, ( f) ![]() $022\_022$,and (g)

$022\_022$,and (g) ![]() $022\_010$. Group C surfaces: (h)

$022\_010$. Group C surfaces: (h) ![]() $035\_035$, (i)

$035\_035$, (i) ![]() $035\_022$, and (j)

$035\_022$, and (j) ![]() $035\_010$. The spanwise domain width for surfaces

$035\_010$. The spanwise domain width for surfaces ![]() $010\_010$,

$010\_010$, ![]() $022\_010$ and

$022\_010$ and ![]() $035\_010$ has been truncated by a distance

$035\_010$ has been truncated by a distance ![]() $2\delta$ for visualisation purposes.

$2\delta$ for visualisation purposes.

To assign a particular spanwise length scale to each value of ![]() $ES_{y}$, the mean spanwise wavelength

$ES_{y}$, the mean spanwise wavelength ![]() $\bar {\lambda }_{y}$ was obtained from the ratio of spectral moments (Townsin Reference Townsin2003), defined here as

$\bar {\lambda }_{y}$ was obtained from the ratio of spectral moments (Townsin Reference Townsin2003), defined here as ![]() $\bar {\lambda }_{y}/(2{\rm \pi} )\equiv m_{0}/m_{1}$, where the

$\bar {\lambda }_{y}/(2{\rm \pi} )\equiv m_{0}/m_{1}$, where the ![]() $n$th spectral moment is given by

$n$th spectral moment is given by ![]() $m_{n}=\int _{0}^{\infty }\kappa _{y}^{n}E_{hh}\,{\rm d}\kappa _{y}$, with

$m_{n}=\int _{0}^{\infty }\kappa _{y}^{n}E_{hh}\,{\rm d}\kappa _{y}$, with ![]() $\kappa _{y}E_{hh}$ the premultiplied spanwise spectra of the height distribution, and

$\kappa _{y}E_{hh}$ the premultiplied spanwise spectra of the height distribution, and ![]() $\kappa _{y}$ the in-plane spanwise wavenumber (see Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) for details). The ratio

$\kappa _{y}$ the in-plane spanwise wavenumber (see Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) for details). The ratio ![]() $\bar {\lambda }_{y}/\delta$ is plotted against its streamwise counterpart

$\bar {\lambda }_{y}/\delta$ is plotted against its streamwise counterpart ![]() $\bar {\lambda }_{x}/\delta$ for each surface in figure 4, spanning the ranges

$\bar {\lambda }_{x}/\delta$ for each surface in figure 4, spanning the ranges ![]() $0.5\lesssim \bar {\lambda }_{x}/\delta \lesssim 3.0$ and

$0.5\lesssim \bar {\lambda }_{x}/\delta \lesssim 3.0$ and ![]() $0.25\lesssim \bar {\lambda }_{y}/\delta \lesssim 2.0$. For three out of the ten surfaces considered here, namely, 010_010, 022_010 and 035_010, the mean spanwise wavelength exceeds the outer length scale, i.e.

$0.25\lesssim \bar {\lambda }_{y}/\delta \lesssim 2.0$. For three out of the ten surfaces considered here, namely, 010_010, 022_010 and 035_010, the mean spanwise wavelength exceeds the outer length scale, i.e. ![]() $\bar {\lambda }_{y}/\delta >1$. As will be shown later, insufficient scale separation between

$\bar {\lambda }_{y}/\delta >1$. As will be shown later, insufficient scale separation between ![]() $\bar {\lambda }_{y}$ and

$\bar {\lambda }_{y}$ and ![]() $\delta$ can lead to atypical behaviour in both mean flow and turbulence statistics. The ratios

$\delta$ can lead to atypical behaviour in both mean flow and turbulence statistics. The ratios ![]() $\bar {\lambda }_{x}/\delta$ and

$\bar {\lambda }_{x}/\delta$ and ![]() $\bar {\lambda }_{y}/\delta$ are listed in table 2 along with other key topographical parameters.

$\bar {\lambda }_{y}/\delta$ are listed in table 2 along with other key topographical parameters.

Figure 4. Ratio of mean in-plane spanwise wavelength and outer length scale of the flow, ![]() $\bar {\lambda }_{y}/\delta$, plotted against its streamwise counterpart

$\bar {\lambda }_{y}/\delta$, plotted against its streamwise counterpart ![]() $\bar {\lambda }_{x}/\delta$ for the ten surfaces under investigation in the present study. Symbol types and colours are given in table 3.

$\bar {\lambda }_{x}/\delta$ for the ten surfaces under investigation in the present study. Symbol types and colours are given in table 3.

Table 3. Simulation parameters, including: domain sizes in the streamwise (![]() $L_{1}$) and spanwise (

$L_{1}$) and spanwise (![]() $L_{2}$) directions; mean channel height

$L_{2}$) directions; mean channel height ![]() $L_{3}$; numbers of points in the streamwise (

$L_{3}$; numbers of points in the streamwise (![]() $N_{1}$), spanwise (

$N_{1}$), spanwise (![]() $N_{2}$) and wall-normal (

$N_{2}$) and wall-normal (![]() $N_{3}$) directions; and viscous-scaled grid spacings, including streamwise (

$N_{3}$) directions; and viscous-scaled grid spacings, including streamwise (![]() $\Delta x^{+}_{1}$), spanwise (

$\Delta x^{+}_{1}$), spanwise (![]() $\Delta x^{+}_{2}$), minimum wall-normal (

$\Delta x^{+}_{2}$), minimum wall-normal (![]() $\Delta x^{+}_{3,\min }$) and maximum wall-normal (

$\Delta x^{+}_{3,\min }$) and maximum wall-normal (![]() $\Delta x^{+}_{3,\max }$) values. The line and symbol types for each case are also listed for reference.

$\Delta x^{+}_{3,\max }$) values. The line and symbol types for each case are also listed for reference.

2.2. Direct numerical simulations of rough-wall turbulent channel flow

For each surface listed in table 2, DNS of incompressible fully developed turbulent channel flow with roughness on both the upper and lower walls were performed using the iterative embedded boundary algorithm of Busse et al. (Reference Busse, Lützner and Sandham2015), which has been employed in past works related to the present study, e.g. Thakkar et al. (Reference Thakkar, Busse and Sandham2016, Reference Thakkar, Busse and Sandham2018), Jelly & Busse (Reference Jelly and Busse2018, Reference Jelly and Busse2019b), Busse & Jelly (Reference Busse and Jelly2020) and Portela et al. (Reference Portela, Busse and Sandham2021). Second-order central differences are used for the discretisation of spatial derivatives. Time advancement is achieved using a second-order accurate Adams–Bashforth scheme. An iterative variant of the Yang & Balaras (Reference Yang and Balaras2006) embedded boundary algorithm is used to resolve the rough walls. The velocity components in the streamwise (![]() $x_{1}$ or

$x_{1}$ or ![]() $x$), spanwise (

$x$), spanwise (![]() $x_{2}$ or

$x_{2}$ or ![]() $y$) and wall-normal (

$y$) and wall-normal (![]() $x_{3}$ or

$x_{3}$ or ![]() $z)$ directions are

$z)$ directions are ![]() $u_{1}$,

$u_{1}$, ![]() $u_{2}$ and

$u_{2}$ and ![]() $u_{3}$, respectively, and

$u_{3}$, respectively, and ![]() $p$ is the fluctuating hydrodynamic pressure. The flow is driven by a constant (negative) streamwise pressure gradient

$p$ is the fluctuating hydrodynamic pressure. The flow is driven by a constant (negative) streamwise pressure gradient ![]() $\varPi$, which defines the mean friction velocity as

$\varPi$, which defines the mean friction velocity as ![]() $u_{\tau }=\sqrt {(-\delta /\rho )\varPi }$. The friction Reynolds number is defined here as

$u_{\tau }=\sqrt {(-\delta /\rho )\varPi }$. The friction Reynolds number is defined here as ![]() $Re_{\tau } \equiv u_{\tau } {\delta } / \nu$, where

$Re_{\tau } \equiv u_{\tau } {\delta } / \nu$, where ![]() ${\delta }$ is the mean channel half-height, and

${\delta }$ is the mean channel half-height, and ![]() $\nu$ is the kinematic viscosity. All simulations reported here were conducted at friction Reynolds number

$\nu$ is the kinematic viscosity. All simulations reported here were conducted at friction Reynolds number ![]() $395$. For cases with

$395$. For cases with ![]() $ES_{y}>0.10$, a spanwise domain size

$ES_{y}>0.10$, a spanwise domain size ![]() $L_{2}/\delta =4.0$ was specified. For the three cases with

$L_{2}/\delta =4.0$ was specified. For the three cases with ![]() $ES_{y}=0.10$, the spanwise domain size was increased by 50 % to

$ES_{y}=0.10$, the spanwise domain size was increased by 50 % to ![]() $L_{2}/\delta =6.0$ to ensure that the topographical features decorrelate within the spanwise extent of the domain. Inner-scaled quantities are marked by superscript +, e.g. time

$L_{2}/\delta =6.0$ to ensure that the topographical features decorrelate within the spanwise extent of the domain. Inner-scaled quantities are marked by superscript +, e.g. time ![]() $t^{+}=tu^{2}_{\tau }/\nu$, space

$t^{+}=tu^{2}_{\tau }/\nu$, space ![]() $x_{i}^{+}=x_{i}u_{\tau }/\nu$, and velocity

$x_{i}^{+}=x_{i}u_{\tau }/\nu$, and velocity ![]() $u_{i}^{+}=u_{i}/u_{\tau }$. The key simulation parameters used throughout this study are consistent with the recommendations of Busse et al. (Reference Busse, Lützner and Sandham2015) and are listed in table 3.

$u_{i}^{+}=u_{i}/u_{\tau }$. The key simulation parameters used throughout this study are consistent with the recommendations of Busse et al. (Reference Busse, Lützner and Sandham2015) and are listed in table 3.

For each simulation, data were accumulated for a minimum of ![]() $Tu_{\tau }/\delta =40$ non-dimensional time units after the initial transient. In addition to collecting time-averaged data, instantaneous three-dimensional snapshots were also collected for further post-processing and analysis. Approximately 800 snapshots separated by twenty viscous-scaled time units, i.e.

$Tu_{\tau }/\delta =40$ non-dimensional time units after the initial transient. In addition to collecting time-averaged data, instantaneous three-dimensional snapshots were also collected for further post-processing and analysis. Approximately 800 snapshots separated by twenty viscous-scaled time units, i.e. ![]() $\Delta t^{+}\equiv \Delta t u_{\tau }^{2}/\nu \approx 20$, were obtained for each case listed in table 3. Reference smooth-wall data were also accumulated at matched flow conditions for comparison.

$\Delta t^{+}\equiv \Delta t u_{\tau }^{2}/\nu \approx 20$, were obtained for each case listed in table 3. Reference smooth-wall data were also accumulated at matched flow conditions for comparison.

2.3. Double-averaging methodology

Statistical quantities were computed using a time-then-space averaging procedure, more commonly known as double-averaging (Raupach & Shaw Reference Raupach and Shaw1982; Nikora et al. Reference Nikora, McEwan, McLean, Coleman, Pokrajac and Walters2007). An instantaneous field variable, say ![]() $a(\boldsymbol {x},t)$, can be double-averaged (DA) by applying first the time-averaging operator,

$a(\boldsymbol {x},t)$, can be double-averaged (DA) by applying first the time-averaging operator,

and then the spatial-averaging operator,

In (2.3), the void fraction function ![]() $\phi \equiv A_{f}(x_{3})/A$ represents the ratio of the fluid-occupied area to the total area of the wall-parallel plane,

$\phi \equiv A_{f}(x_{3})/A$ represents the ratio of the fluid-occupied area to the total area of the wall-parallel plane, ![]() $A=L_{1}L_{2}$. Instantaneous field variables are set equal to zero in solid-occupied regions, i.e.

$A=L_{1}L_{2}$. Instantaneous field variables are set equal to zero in solid-occupied regions, i.e. ![]() $a(\boldsymbol {x},t)=0$. Averaging the flow in this way ensures that only fluid-occupied points contribute towards DA statistics beneath the roughness crests. The DA quantities reported herein therefore correspond to an intrinsic average (Gray & Lee Reference Gray and Lee1977).

$a(\boldsymbol {x},t)=0$. Averaging the flow in this way ensures that only fluid-occupied points contribute towards DA statistics beneath the roughness crests. The DA quantities reported herein therefore correspond to an intrinsic average (Gray & Lee Reference Gray and Lee1977).

Considering (2.2) and (2.3), instantaneous field variables are decomposed as

\begin{equation} a(\boldsymbol{x},t) = {\underbrace{\langle \bar{a}\rangle(x_{3}) + \tilde{a}(\boldsymbol{x})}_{\bar{a}(\boldsymbol{x})}} + a^{\prime} (\boldsymbol{x},t), \end{equation}

\begin{equation} a(\boldsymbol{x},t) = {\underbrace{\langle \bar{a}\rangle(x_{3}) + \tilde{a}(\boldsymbol{x})}_{\bar{a}(\boldsymbol{x})}} + a^{\prime} (\boldsymbol{x},t), \end{equation}

where the dispersive component is defined as ![]() $\tilde {a}(\boldsymbol {x})\equiv \bar {a}(\boldsymbol {x})-\langle \bar {a}\rangle (x_{3})$, and the turbulent component is defined as

$\tilde {a}(\boldsymbol {x})\equiv \bar {a}(\boldsymbol {x})-\langle \bar {a}\rangle (x_{3})$, and the turbulent component is defined as ![]() $a^{\prime }(\boldsymbol {x},t)\equiv a(\boldsymbol {x},t) - [\langle \bar {a}\rangle (x_{3}) + \tilde {a}(\boldsymbol {x})]$. Using the triple decomposition (2.4), the local Reynolds stress tensor can be defined as

$a^{\prime }(\boldsymbol {x},t)\equiv a(\boldsymbol {x},t) - [\langle \bar {a}\rangle (x_{3}) + \tilde {a}(\boldsymbol {x})]$. Using the triple decomposition (2.4), the local Reynolds stress tensor can be defined as

The spatial average of the local Reynolds stress tensor 2.5 is defined here as

Finally, the dispersive stress tensor is defined here as

3. Results

This section contains the key results of this study and is divided into four parts. First, the impact of ![]() $ES_{y}$ upon the Hama roughness function is examined. Second, the effect of varying

$ES_{y}$ upon the Hama roughness function is examined. Second, the effect of varying ![]() $ES_{y}$ upon the fractional contribution of pressure and viscous drag to the total drag is examined. Third, the influence of

$ES_{y}$ upon the fractional contribution of pressure and viscous drag to the total drag is examined. Third, the influence of ![]() $ES_{y}$ upon first-order velocity statistics is discussed. Finally, the impact of

$ES_{y}$ upon first-order velocity statistics is discussed. Finally, the impact of ![]() $ES_{y}$ upon second-order velocity statistics and turbulence co-spectra is discussed.

$ES_{y}$ upon second-order velocity statistics and turbulence co-spectra is discussed.

3.1. Impact of spanwise effective slope upon the Hama roughness function

Surface roughness induces a downward shift in the log-law velocity profile, relative to the smooth-wall profile at matched flow conditions, commonly referred to as the Hama (Reference Hama1954) roughness function, ![]() $\Delta U^{+}$. Strictly speaking,

$\Delta U^{+}$. Strictly speaking, ![]() $\Delta U^{+}$ is an additive constant, which assumes that the inner-scale streamwise mean velocity difference between the smooth and rough walls – defined here as

$\Delta U^{+}$ is an additive constant, which assumes that the inner-scale streamwise mean velocity difference between the smooth and rough walls – defined here as ![]() $\delta U^{+}(x^{+}_{3}) \equiv \langle u^{+}_{1}\rangle _{{s}}(x^{+}_{3})-\langle u^{+}_{1}\rangle _{{r}}(x^{+}_{3})$ – is uniform in the log region. Profiles of

$\delta U^{+}(x^{+}_{3}) \equiv \langle u^{+}_{1}\rangle _{{s}}(x^{+}_{3})-\langle u^{+}_{1}\rangle _{{r}}(x^{+}_{3})$ – is uniform in the log region. Profiles of ![]() $\delta U^{+}$ normalised by the mean friction velocity are plotted against outer-scaled wall-normal position in figure 5. A histogram of the height distribution is also included (grey bars) and marks the wall-normal extent of the roughness canopy (

$\delta U^{+}$ normalised by the mean friction velocity are plotted against outer-scaled wall-normal position in figure 5. A histogram of the height distribution is also included (grey bars) and marks the wall-normal extent of the roughness canopy (![]() $h_{\min }< x_{3}< h_{max}$). Looking from left-to-right across figures 5(a–c), it is clear that

$h_{\min }< x_{3}< h_{max}$). Looking from left-to-right across figures 5(a–c), it is clear that ![]() $\delta U^{+}$ remains approximately constant from the highest crest (

$\delta U^{+}$ remains approximately constant from the highest crest (![]() $x_{3}/h_{max}=1$) to the channel half-height (

$x_{3}/h_{max}=1$) to the channel half-height (![]() $x_{3}/\delta =1$) for the majority of surfaces investigated here. Two exceptions are surface

$x_{3}/\delta =1$) for the majority of surfaces investigated here. Two exceptions are surface ![]() $022\_010$ (black dotted line in figure 5b) and surface

$022\_010$ (black dotted line in figure 5b) and surface ![]() $010\_010$ (red dotted line in figure 5a), with the latter surface showing an increase of almost 15 % when comparing the value of

$010\_010$ (red dotted line in figure 5a), with the latter surface showing an increase of almost 15 % when comparing the value of ![]() $\delta U^{+}$ at the channel half-height against that of the roughness crest. To remove any ambiguity related to variations of

$\delta U^{+}$ at the channel half-height against that of the roughness crest. To remove any ambiguity related to variations of ![]() $\delta U^{+}$ in the outer region,

$\delta U^{+}$ in the outer region, ![]() $\Delta U^{+}$ is herein defined as the mean value of the streamwise velocity difference between the highest roughness crest and the channel half-height,

$\Delta U^{+}$ is herein defined as the mean value of the streamwise velocity difference between the highest roughness crest and the channel half-height, ![]() $\Delta U^{+} \equiv 1/(\delta -h_{max})\int _{h_{max}}^{\delta }\delta U^{+}(x_{3})\,\textrm {d}x_{3}$. Other definitions of

$\Delta U^{+} \equiv 1/(\delta -h_{max})\int _{h_{max}}^{\delta }\delta U^{+}(x_{3})\,\textrm {d}x_{3}$. Other definitions of ![]() $\Delta U^{+}$ are possible: Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2015) defined

$\Delta U^{+}$ are possible: Chan et al. (Reference Chan, MacDonald, Chung, Hutchins and Ooi2015) defined ![]() $\Delta U^{+}$ as the streamwise velocity difference 50 wall units above the roughness crests in rough-wall turbulent pipe flow, whereas Busse et al. (Reference Busse, Lützner and Sandham2015) defined

$\Delta U^{+}$ as the streamwise velocity difference 50 wall units above the roughness crests in rough-wall turbulent pipe flow, whereas Busse et al. (Reference Busse, Lützner and Sandham2015) defined ![]() $\Delta U^{+}$ as the streamwise velocity difference at the centreline in rough-walled turbulent channel flow; Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015) defined

$\Delta U^{+}$ as the streamwise velocity difference at the centreline in rough-walled turbulent channel flow; Chung et al. (Reference Chung, Chan, MacDonald, Hutchins and Ooi2015) defined ![]() $\Delta U^{+}$ as the streamwise velocity difference at wall-normal height

$\Delta U^{+}$ as the streamwise velocity difference at wall-normal height ![]() $z_{c}=0.4L_{3}$ in rough-wall minimal open-channel flow.

$z_{c}=0.4L_{3}$ in rough-wall minimal open-channel flow.

Figure 5. Streamwise velocity difference ![]() $\delta U^{+}(x_{3})=\langle u_{1}^{+}\rangle _{s}-\langle u_{1}^{+}\rangle _{r}$ plotted as a function of wall-normal position for (a) Group A, (b) Group B, and (c) Group C. The histogram (grey) for each height distribution

$\delta U^{+}(x_{3})=\langle u_{1}^{+}\rangle _{s}-\langle u_{1}^{+}\rangle _{r}$ plotted as a function of wall-normal position for (a) Group A, (b) Group B, and (c) Group C. The histogram (grey) for each height distribution ![]() $P(h)$ is included for reference. All data are scaled using the mean friction velocity

$P(h)$ is included for reference. All data are scaled using the mean friction velocity ![]() $u_{\tau }$ and mean channel half-height

$u_{\tau }$ and mean channel half-height ![]() $\delta$.

$\delta$.

The Hama roughness function is plotted as a function of ![]() $ES_{y}$ in figure 6(a). Three key observations can be drawn from these data. First,

$ES_{y}$ in figure 6(a). Three key observations can be drawn from these data. First, ![]() $\Delta U^{+}$ varies by a factor of three (

$\Delta U^{+}$ varies by a factor of three (![]() $2.5<\Delta U^{+}<7.6$) for the ten roughness topographies investigated here. Second,

$2.5<\Delta U^{+}<7.6$) for the ten roughness topographies investigated here. Second, ![]() $\Delta U^{+}$ decreases monotonically as

$\Delta U^{+}$ decreases monotonically as ![]() $ES_{y}$ increases for each value of

$ES_{y}$ increases for each value of ![]() $ES_{x}$. Third,

$ES_{x}$. Third, ![]() $\Delta U^{+}$ becomes increasingly sensitive with respect to

$\Delta U^{+}$ becomes increasingly sensitive with respect to ![]() $ES_{y}$ as

$ES_{y}$ as ![]() $ES_{x}$ is reduced. To be specific, whereas increasing

$ES_{x}$ is reduced. To be specific, whereas increasing ![]() $ES_{y}$ from 0.10 to 0.35 reduces

$ES_{y}$ from 0.10 to 0.35 reduces ![]() $\Delta U^{+}$ by 12 % for surfaces with

$\Delta U^{+}$ by 12 % for surfaces with ![]() $ES_{x}\approx 0.35$ (blue symbols, Group C, figure 6a), a 35 % reduction is observed for surfaces with

$ES_{x}\approx 0.35$ (blue symbols, Group C, figure 6a), a 35 % reduction is observed for surfaces with ![]() $ES_{x}\approx 0.10$ for the same change of

$ES_{x}\approx 0.10$ for the same change of ![]() $ES_{y}$ (red symbols, Group C, figure 6a). A further 23 % reduction in the Hama roughness function is observed for surface 010_070 (red diamond, figure 6a) relative to that of surface 010_035 (red circle, figure 6a), resulting in a

$ES_{y}$ (red symbols, Group C, figure 6a). A further 23 % reduction in the Hama roughness function is observed for surface 010_070 (red diamond, figure 6a) relative to that of surface 010_035 (red circle, figure 6a), resulting in a ![]() $\Delta U^{+}$ value of just 2.4 wall units for the latter riblet-like surface. Together, these three observations demonstrate that

$\Delta U^{+}$ value of just 2.4 wall units for the latter riblet-like surface. Together, these three observations demonstrate that ![]() $ES_{y}$ is an important topographical parameter, particularly for lower-

$ES_{y}$ is an important topographical parameter, particularly for lower-![]() $ES_{x}$ surfaces.

$ES_{x}$ surfaces.

Figure 6. Hama roughness function ![]() $\Delta U^{+}$ plotted as a function of (a) spanwise effective slope,

$\Delta U^{+}$ plotted as a function of (a) spanwise effective slope, ![]() $ES_{y}$, (b) streamwise effective slope

$ES_{y}$, (b) streamwise effective slope ![]() $ES_{x}$, (c) ratio of spanwise and streamwise effective slopes

$ES_{x}$, (c) ratio of spanwise and streamwise effective slopes ![]() $ES_{y}/ES_{x}$. Data points from the past work of Busse & Jelly (Reference Busse and Jelly2020) are also included (grey circles) for comparison, along with an an exponential fit (grey line) of the form

$ES_{y}/ES_{x}$. Data points from the past work of Busse & Jelly (Reference Busse and Jelly2020) are also included (grey circles) for comparison, along with an an exponential fit (grey line) of the form ![]() $\Delta U^{+}=b_{1}+b_{2}\exp [-b_{3}(ES_{y}/ES_{x})^{2}]$, where

$\Delta U^{+}=b_{1}+b_{2}\exp [-b_{3}(ES_{y}/ES_{x})^{2}]$, where ![]() $b_{i}=\{2.35,5.33,0.207\}$. Symbol types are given in table 3.

$b_{i}=\{2.35,5.33,0.207\}$. Symbol types are given in table 3.

The Hama roughness function is plotted against ![]() $ES_{x}$ in figure 6(b). In line with the findings of Napoli et al. (Reference Napoli, Armenio and De Marchis2008) and others, increasing

$ES_{x}$ in figure 6(b). In line with the findings of Napoli et al. (Reference Napoli, Armenio and De Marchis2008) and others, increasing ![]() $ES_{x}$ from 0.10 to 0.35 causes

$ES_{x}$ from 0.10 to 0.35 causes ![]() $\Delta U^{+}$ to increase for each value of

$\Delta U^{+}$ to increase for each value of ![]() $ES_{y}$ considered here. However, it is important to note that

$ES_{y}$ considered here. However, it is important to note that ![]() $\Delta U^{+}$ may show the opposite trend for higher-

$\Delta U^{+}$ may show the opposite trend for higher-![]() $ES_{x}$ surfaces that fall within the dense regime (MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016). The Hama roughness function is plotted against the effective slope ratio

$ES_{x}$ surfaces that fall within the dense regime (MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016). The Hama roughness function is plotted against the effective slope ratio ![]() $ES_{y}/ES_{x}$ in figure 6(c), where data points from Busse & Jelly (Reference Busse and Jelly2020) have been included for comparison. Despite their differing

$ES_{y}/ES_{x}$ in figure 6(c), where data points from Busse & Jelly (Reference Busse and Jelly2020) have been included for comparison. Despite their differing ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ combinations, a reasonable collapse between the two datasets is observed, and most of the

$ES_{y}$ combinations, a reasonable collapse between the two datasets is observed, and most of the ![]() $\Delta U^{+}$ values exhibit a similar dependence upon

$\Delta U^{+}$ values exhibit a similar dependence upon ![]() $ES_{y}/ES_{x}$. To be specific, the relationship between

$ES_{y}/ES_{x}$. To be specific, the relationship between ![]() $\Delta U^{+}$ and

$\Delta U^{+}$ and ![]() $ES_{y}/ES_{x}$ can be approximated as an exponential function of the form

$ES_{y}/ES_{x}$ can be approximated as an exponential function of the form ![]() $\Delta U^{+}=b_{1}+b_{2}\exp [-b_{3}(ES_{y}/ES_{x})^{2}]$, where the coefficients

$\Delta U^{+}=b_{1}+b_{2}\exp [-b_{3}(ES_{y}/ES_{x})^{2}]$, where the coefficients ![]() $b_{i}=\{2.35,5.33,0.207\}$ were determined via nonlinear regression. A similar dependence between

$b_{i}=\{2.35,5.33,0.207\}$ were determined via nonlinear regression. A similar dependence between ![]() $\Delta U^{+}$ and the SAR parameter was reported by Busse & Jelly (Reference Busse and Jelly2020). Whilst figure 6(c) shows that

$\Delta U^{+}$ and the SAR parameter was reported by Busse & Jelly (Reference Busse and Jelly2020). Whilst figure 6(c) shows that ![]() $\Delta U^{+}$ varies significantly across the range

$\Delta U^{+}$ varies significantly across the range ![]() $0.3\lesssim ES_{y}/ES_{x}<7.0$ for a fixed value of

$0.3\lesssim ES_{y}/ES_{x}<7.0$ for a fixed value of ![]() $k^{+}$, predicting the limiting behaviour of

$k^{+}$, predicting the limiting behaviour of ![]() $\Delta U^{+}$ using the available data remains challenging. For instance, for the case where

$\Delta U^{+}$ using the available data remains challenging. For instance, for the case where ![]() $ES_{y}/ES_{x}\rightarrow \infty$ with

$ES_{y}/ES_{x}\rightarrow \infty$ with ![]() $ES_{x} = 0$ and very low

$ES_{x} = 0$ and very low ![]() $ES_{y}$,

$ES_{y}$, ![]() $\Delta U^{+}$ would likely tend to zero, since this

$\Delta U^{+}$ would likely tend to zero, since this ![]() $ES_{x}$–

$ES_{x}$–![]() $ES_{y}$ combination corresponds to an almost smooth surface. On the other hand, for

$ES_{y}$ combination corresponds to an almost smooth surface. On the other hand, for ![]() $ES_{y}/ES_{x}\rightarrow \infty$ with

$ES_{y}/ES_{x}\rightarrow \infty$ with ![]() $ES_{x} = 0$ and high

$ES_{x} = 0$ and high ![]() $ES_{y}$, it is possible that

$ES_{y}$, it is possible that ![]() $\Delta U^{+}\neq 0$, since this

$\Delta U^{+}\neq 0$, since this ![]() $ES_{x}$–

$ES_{x}$–![]() $ES_{y}$ combination corresponds to a riblet-like surface, which could either increase or decrease the levels of (viscous) drag; e.g. see Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020). Also, since the data in figure 6(c) correspond for a fixed viscous-scaled roughness height

$ES_{y}$ combination corresponds to a riblet-like surface, which could either increase or decrease the levels of (viscous) drag; e.g. see Gatti et al. (Reference Gatti, von Deyn, Forooghi and Frohnapfel2020). Also, since the data in figure 6(c) correspond for a fixed viscous-scaled roughness height ![]() $k^{+}\approx 65.8$, questions regarding how the limiting behaviour of

$k^{+}\approx 65.8$, questions regarding how the limiting behaviour of ![]() $\Delta U^{+}$ varies with roughness Reynolds number remain open.

$\Delta U^{+}$ varies with roughness Reynolds number remain open.

Nevertheless, figure 6(c) demonstrates that the Hama roughness function is sensitive with respect to surface anisotropy and gives insight into how ![]() $ES_{y}/ES_{x}$ affects

$ES_{y}/ES_{x}$ affects ![]() $\Delta U^{+}$ at a fixed roughness Reynolds number

$\Delta U^{+}$ at a fixed roughness Reynolds number ![]() $k^{+}\approx 65.8$ . Whilst

$k^{+}\approx 65.8$ . Whilst ![]() $\Delta U^{+}$ values have been obtained for a variety of anisotropic roughness in past work by Thakkar et al. (Reference Thakkar, Busse and Sandham2016) and Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), these studies not only were performed at different

$\Delta U^{+}$ values have been obtained for a variety of anisotropic roughness in past work by Thakkar et al. (Reference Thakkar, Busse and Sandham2016) and Jouybari et al. (Reference Jouybari, Yuan, Brereton and Murillo2021), these studies not only were performed at different ![]() $k^{+}$ values compared to the present study, but also did not eliminate the potential effects of other key topographical parameters upon the drag penalty, e.g. skewness, or vary

$k^{+}$ values compared to the present study, but also did not eliminate the potential effects of other key topographical parameters upon the drag penalty, e.g. skewness, or vary ![]() $ES_{y}$ or

$ES_{y}$ or ![]() $ES_{x}$ in a systematic manner (see figure 2). As a result, a meaningful comparison against these past studies and the data plotted in figure 6(c) cannot be made. On the other hand, a direct comparison can be drawn against the past data of Busse & Jelly (Reference Busse and Jelly2020) (filled grey circles, figure 6c), since that work was performed at the same

$ES_{x}$ in a systematic manner (see figure 2). As a result, a meaningful comparison against these past studies and the data plotted in figure 6(c) cannot be made. On the other hand, a direct comparison can be drawn against the past data of Busse & Jelly (Reference Busse and Jelly2020) (filled grey circles, figure 6c), since that work was performed at the same ![]() $k^{+}$ value as the present study and focused on near-Gaussian roughness with comparable

$k^{+}$ value as the present study and focused on near-Gaussian roughness with comparable ![]() $ES_{x}$ and

$ES_{x}$ and ![]() $ES_{y}$ combinations.

$ES_{y}$ combinations.

3.2. Impact of spanwise effective slope upon pressure and viscous drag

To associate physical mechanisms to changes in ![]() $\Delta U^{+}$ (figure 6), the fractional contributions of pressure and viscous drag to the total drag can be quantified. After some manipulation, the mean viscous and pressure forces per unit area acting on the surface can be written as

$\Delta U^{+}$ (figure 6), the fractional contributions of pressure and viscous drag to the total drag can be quantified. After some manipulation, the mean viscous and pressure forces per unit area acting on the surface can be written as

In (3.1) and (3.2), ![]() $\bar {p}_{0}$ is an arbitrary gauge pressure, taken here as the mean surface pressure, i.e.

$\bar {p}_{0}$ is an arbitrary gauge pressure, taken here as the mean surface pressure, i.e. ![]() $\bar {p}_{0} \equiv A^{-1}\iint \bar {p}_{s}(x_{1},x_{2})\,{\rm d} A$,

$\bar {p}_{0} \equiv A^{-1}\iint \bar {p}_{s}(x_{1},x_{2})\,{\rm d} A$, ![]() $\|\boldsymbol {\nabla } h\|$ is the magnitude of the surface normal vector, and

$\|\boldsymbol {\nabla } h\|$ is the magnitude of the surface normal vector, and ![]() ${\rm d} S$ is the incremental surface area. Further details regarding (3.1) and (3.2) are provided in Appendix B.

${\rm d} S$ is the incremental surface area. Further details regarding (3.1) and (3.2) are provided in Appendix B.

Since the present simulations were carried out under constant pressure gradient forcing, the mean hydrodynamic force balance can be expressed as ![]() $\langle F_{p}\rangle +\langle F_{\nu }\rangle =1$ (where

$\langle F_{p}\rangle +\langle F_{\nu }\rangle =1$ (where ![]() $\varPi =-1$). Hence the summed effect of pressure and viscous drag remains constant, but the relative contributions of

$\varPi =-1$). Hence the summed effect of pressure and viscous drag remains constant, but the relative contributions of ![]() $\langle F_{p}\rangle$ and

$\langle F_{p}\rangle$ and ![]() $\langle F_{\nu }\rangle$ to the total drag force,

$\langle F_{\nu }\rangle$ to the total drag force, ![]() $\langle F_{tot}\rangle \equiv \langle F_{p}\rangle +\langle F_{\nu }\rangle =1$, are free to vary. In the limit of streamwise homogeneous roughness (

$\langle F_{tot}\rangle \equiv \langle F_{p}\rangle +\langle F_{\nu }\rangle =1$, are free to vary. In the limit of streamwise homogeneous roughness (![]() $ES_{x}\rightarrow 0$), pressure drag is equal to zero, and the force balance for the current channel flow configuration reduces to

$ES_{x}\rightarrow 0$), pressure drag is equal to zero, and the force balance for the current channel flow configuration reduces to ![]() $-\varPi =\iint _{S}-\mu [({\partial \bar {u}_{1}}/{\partial x_{2}}) ({{\partial h}}/{\partial x_{2}})-{\partial \bar {u}_{1}}/{\partial x_{3}}]({1}/{\|\boldsymbol {\nabla } h\|})\,{\rm d} S$, which shows that changes in spanwise gradient of the height map, and hence changes in

$-\varPi =\iint _{S}-\mu [({\partial \bar {u}_{1}}/{\partial x_{2}}) ({{\partial h}}/{\partial x_{2}})-{\partial \bar {u}_{1}}/{\partial x_{3}}]({1}/{\|\boldsymbol {\nabla } h\|})\,{\rm d} S$, which shows that changes in spanwise gradient of the height map, and hence changes in ![]() $ES_{y}$, influence directly the levels of viscous drag. The same force balance governs the drag-increasing (or drag-reducing) properties of other streamwise homogeneous surfaces, e.g. flow-aligned riblets (Gatti et al. Reference Gatti, von Deyn, Forooghi and Frohnapfel2020). Conversely, in the limit of spanwise homogeneous roughness (

$ES_{y}$, influence directly the levels of viscous drag. The same force balance governs the drag-increasing (or drag-reducing) properties of other streamwise homogeneous surfaces, e.g. flow-aligned riblets (Gatti et al. Reference Gatti, von Deyn, Forooghi and Frohnapfel2020). Conversely, in the limit of spanwise homogeneous roughness (![]() $ES_{y}\rightarrow 0$), the force balance for the current channel flow configuration reduces to

$ES_{y}\rightarrow 0$), the force balance for the current channel flow configuration reduces to ![]() $-\varPi =\iint _{S}-\mu [2({\partial \bar {u}_{1}}/{\partial x_{1}})({{\partial h}}/{\partial x_{1}})-({\partial \bar {u}_{1}}/{\partial x_{3}} + {\partial \bar {u}_{3}}/{\partial x_{1}})]({1}/{{\|\boldsymbol {\nabla } h\|}})+[(\bar {p}_{s}-\bar {p}_{0})({{\partial h}}/{\partial x_{1}})]({1}/{{\|\boldsymbol {\nabla } h\|}})\,{\rm d} S$, and is therefore independent of

$-\varPi =\iint _{S}-\mu [2({\partial \bar {u}_{1}}/{\partial x_{1}})({{\partial h}}/{\partial x_{1}})-({\partial \bar {u}_{1}}/{\partial x_{3}} + {\partial \bar {u}_{3}}/{\partial x_{1}})]({1}/{{\|\boldsymbol {\nabla } h\|}})+[(\bar {p}_{s}-\bar {p}_{0})({{\partial h}}/{\partial x_{1}})]({1}/{{\|\boldsymbol {\nabla } h\|}})\,{\rm d} S$, and is therefore independent of ![]() $ES_{y}$ by definition. For the present surfaces, the relative importance of pressure and viscous drag sits somewhere between these two limits.

$ES_{y}$ by definition. For the present surfaces, the relative importance of pressure and viscous drag sits somewhere between these two limits.

The fractional contribution of spatially averaged pressure drag to the total drag force, ![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle$, is plotted against

$\langle F_{p}\rangle /\langle F_{tot}\rangle$, is plotted against ![]() $ES_{y}$ and

$ES_{y}$ and ![]() $ES_{x}$ in figures 7(a,b), respectively. Overall, the pressure drag data show the same trends as the corresponding

$ES_{x}$ in figures 7(a,b), respectively. Overall, the pressure drag data show the same trends as the corresponding ![]() $\Delta U^{+}$ data plotted in figure 6. In summary,

$\Delta U^{+}$ data plotted in figure 6. In summary, ![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle$ decreases as

$\langle F_{p}\rangle /\langle F_{tot}\rangle$ decreases as ![]() $ES_{y}$ increases for each value of

$ES_{y}$ increases for each value of ![]() $ES_{x}$ investigated here, and exhibits a heightened sensitivity with respect to

$ES_{x}$ investigated here, and exhibits a heightened sensitivity with respect to ![]() $ES_{y}$ as

$ES_{y}$ as ![]() $ES_{x}$ becomes smaller. Likewise, when

$ES_{x}$ becomes smaller. Likewise, when ![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle$ is plotted against

$\langle F_{p}\rangle /\langle F_{tot}\rangle$ is plotted against ![]() $ES_{y}/ES_{x}$ (figure 7c), the pressure drag contribution decreases as

$ES_{y}/ES_{x}$ (figure 7c), the pressure drag contribution decreases as ![]() $ES_{y}/ES_{x}$ increases, meaning that streamwise-elongated forms of surface roughness (

$ES_{y}/ES_{x}$ increases, meaning that streamwise-elongated forms of surface roughness (![]() $ES_{y}/ES_{x}>1$) induce less pressure drag than their spanwise-aligned counterparts (

$ES_{y}/ES_{x}>1$) induce less pressure drag than their spanwise-aligned counterparts (![]() $ES_{y}/ES_{x}<1$). Note that the fractional contribution of spatially averaged viscous drag to the total drag force would show exactly the opposite trends, since

$ES_{y}/ES_{x}<1$). Note that the fractional contribution of spatially averaged viscous drag to the total drag force would show exactly the opposite trends, since ![]() $\langle F_{\nu }\rangle \equiv 1-\langle F_{p}\rangle$ for constant pressure gradient forcing.

$\langle F_{\nu }\rangle \equiv 1-\langle F_{p}\rangle$ for constant pressure gradient forcing.

Figure 7. Fractional contribution of spatially averaged pressure drag to the total drag force, ![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle$, plotted as a function of: (a) spanwise effective slope

$\langle F_{p}\rangle /\langle F_{tot}\rangle$, plotted as a function of: (a) spanwise effective slope ![]() $ES_{y}$; (b) streamwise effective slope

$ES_{y}$; (b) streamwise effective slope ![]() $ES_{x}$; (c) ratio of spanwise and streamwise effective slopes,

$ES_{x}$; (c) ratio of spanwise and streamwise effective slopes, ![]() $ES_{y}/ES_{x}$; and (d) the Hama roughness function

$ES_{y}/ES_{x}$; and (d) the Hama roughness function ![]() $\Delta U^{+}$. Symbol types are given in table 3.

$\Delta U^{+}$. Symbol types are given in table 3.

The fractional contribution of pressure drag is plotted as a function of ![]() $\Delta U^{+}$ in figure 7(d). The data show that

$\Delta U^{+}$ in figure 7(d). The data show that ![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle$ varies by up to a factor of seven within the observed

$\langle F_{p}\rangle /\langle F_{tot}\rangle$ varies by up to a factor of seven within the observed ![]() $\Delta U^{+}$ range. Specifically, pressure drag accounts for just 10 % (

$\Delta U^{+}$ range. Specifically, pressure drag accounts for just 10 % (![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle \approx 0.1$) of the total drag on surface 010_070 (red diamond, figure 7d), compared to 74 % of the total drag (

$\langle F_{p}\rangle /\langle F_{tot}\rangle \approx 0.1$) of the total drag on surface 010_070 (red diamond, figure 7d), compared to 74 % of the total drag (![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle \approx 0.74$) on surface 035_010 (blue square, figure 7d). Whilst the dependence of

$\langle F_{p}\rangle /\langle F_{tot}\rangle \approx 0.74$) on surface 035_010 (blue square, figure 7d). Whilst the dependence of ![]() $\langle F_{p}\rangle /\langle F_{tot}\rangle$ on

$\langle F_{p}\rangle /\langle F_{tot}\rangle$ on ![]() $ES_{x}$ is well-documented (Napoli et al. Reference Napoli, Armenio and De Marchis2008; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018), the present data show that the fractional contribution of pressure drag ratio also depends on