Introduction

The concept of ‘specialist’ and its derivatives (‘specialized’ and ‘specialization’) indiscriminately accommodate different concerns associated with craftspeople and production. Among these let us note the level of craftsmanship, the importance and scarcity of the materials used, knowledge and skills, economical and time constraints, social roles, affiliation, gender division, and the spatial unit of analysis (e.g. Brumfiel & Earle, Reference Brumfiel and Earle1987; Costin, Reference Costin1991, Reference Costin, Feinman and Price2001; Helms, Reference Helms1993; Costin & Wright, Reference Costin and Wright1998; Hruby & Flad, Reference Hruby and Flad2007; Sofaer, Reference Sofaer, Earle and Kristiansen2010).

In Bronze Age research, the use of this terminology is even extended to designate occupational roles such as warriors, priest, and traders in an attempt to model Bronze Age trade within the framework of a political economy (Earle et al., Reference Earle, Ling, Uhnér, Stos-Gale and Melheim2015; Kristiansen & Earle, Reference Kristiansen, Earle, Kristiansen, Smejda and Turek2015; Kristiansen & Suchowska-Ducke, Reference Kristiansen and Suchowska-Ducke2015; Kristiansen, Reference Kristiansen, Kiriatzi and Knappett2017). Given the copious use and the fundamental role of specialists and their skills in this model, it would be good to know on what archaeological grounds such designation is made, and what it means to be specialized.

A recent comparative study of craft at three European Bronze Age sites—Százhalombatta-Földvár in Hungary, Thy in Denmark, and Monte Polizzo in Italy—showed considerable diversity in the production of ceramics, chipped and ground stones, worked bone, and architecture (Sofaer, Reference Sofaer, Earle and Kristiansen2010). Especially detailed studies of ceramic production at Százhalombatta-Földvár led to insights into the development and different levels of skill (Sofaer, Reference Sofaer2006; Budden, Reference Budden and Berg2008; Sofaer & Budden, Reference Sofaer, Budden, Sørensen and Rebay-Salisbury2013). Yet, when it comes to describing the social organization of production, these detailed observations are blunted because the terminology allows for little more nuance than a distinction between specialists and non-specialists (Sofaer, Reference Sofaer, Earle and Kristiansen2010: 209–12).

In this configuration, the specialist/non-specialist categorization is used to model social development through the socio-economic building block of craft specialization, and used to explain increased complexity and social inequality (Brumfiel & Earle, Reference Brumfiel and Earle1987; Earle & Kristiansen, Reference Earle and Kristiansen2010). Bronze Age metalworkers are an excellent case study through which one can question the current use of the concept of specialists, because such persons are resolutely described as skilled specialists (e.g. Childe, Reference Childe1963; Ottaway, Reference Ottaway2001; Bertemes, Reference Bertemes, Meller and Bertemes2004; Kristiansen & Larsson, Reference Kristiansen and Larsson2005; Vandkilde, Reference Vandkilde2007; Nessel, Reference Nessel, Kienlin and Zimmermann2012; Olausson, Reference Olausson, Bergerbrant and Sabatini2013). Moreover, since Childe's The Dawn of European Civilization, the metalworker has been at the forefront of Europe's distinctive development towards capitalism (Rowlands, Reference Rowlands and Bintliff1984). Currently, the focus has shifted to prestige goods, and the skilled metalworking specialist appears to serve largely political-economic concerns of an elite operating in a network of wealth exchange (Earle et al., Reference Earle, Ling, Uhnér, Stos-Gale and Melheim2015; Vandkilde, Reference Vandkilde2016). Within these, noticeably Marxist, perspectives a distinction between specialist and non-specialist suffices, even though it fails to address skill not merely as social capital but a concept worth of enquiry itself.

How much skill is needed to become a specialist? The threshold between the two textual premises of specialists versus non-specialists is far less clear-cut than the distinction suggests (i.e. essentially a Sorites paradox). It is, for instance, unclear how one ought objectively to recognize a high standard within archaeological material. Moreover, the distinction echoes and partly maintains a particular insufficiency of twentieth-century social theory: the idea that a clear separation between producers and consumers is possible (Ritzer, Reference Ritzer, Blättel-Mink and Hellmann2010). This binary logic oversimplifies complexities such as cross-craftsmanship (Brysbaert & Gorgues, Reference Brysbaert and Gorgues2017), the creation of value (Graeber, Reference Graeber2001), and the notion of ‘prosumers’ that has yet to enter the archaeological discussion (Ritzer, Reference Ritzer, Blättel-Mink and Hellmann2010).

The specialist-specialization debate

Let me first outline which aspects of the specialist-specialization debate I wish to tackle. Specialization in its simplest definition—the idea that fewer people make a class of objects than use it (Costin, Reference Costin1991: 43, Reference Costin, Feinman and Price2001: 276)—is not in question here. Not everybody would have been producing equal amounts of metal artefacts even if the knowledge was freely available, which it probably was not (Hansen, Reference Hansen, Burmeister, Hansen, Kunst and Müller-Scheessel2013, Reference Hansen, Terna and Govedarica2016). Some regions yield copious metalworking evidence, while others are virtually devoid of it. Moreover, it is clear that some metalworkers possessed superior technical skills, commonly related to specialization (Rowlands, Reference Rowlands1971: 218). The metalworkers responsible for objects like the Nebra disc or Apa-Hadjúsámson sword were undoubtedly specialists in working metal. My argument is that, while we are accurately documenting this side of the spectrum, we lose sight of the rest. The objects I would like to focus on are those that fill hundreds of pages of the Praehistorische Bronzefunde series: axes, sickles, spears, daggers, simple ornaments, and tools such as chisels and awls. They exhibit a vast variety in quality and therefore cannot all have been made by skilled specialists, or at least they were not specialists on a similar level. Evidently, the term specialist does not allow the material to speak for itself.

The problem of base criteria for recognizing a specialist in the archaeological record is well-known. The differentiation between specialist and non-specialist centres mostly around three criteria: intensity, compensation, and skill (Costin, Reference Costin, Feinman and Price2001: 275–79). The first and second premises are, however, also used to determine specialization in socio-economic terms. Full-time specialists are thought to produce for a demanding market, and are dependent on a compensation for their subsistence. This leads to an all too easily made assumption that material specialization (skill) will inevitably lead to economic specialization, or vice-versa. As a result, we often see the conflation of the concepts of specialist and craft specialization. A further and more pressing issue is that both the amount of time spent crafting (intensity) and the type and amount of compensation are hard to assess archaeologically. This leaves only the defining criteria of skill as an archaeologically recognizable variable that can be operationalized in the data. Thus, I separate material specialization, which we can examine archaeologically, from economic specialization that we have to infer.

Costin (Reference Costin, Feinman and Price2001: 283) warns us that evaluating skill is a highly subjective assessment, often incorrectly judged from the supposed quality of an object. This involves making a reference to what we think is the ideal shape of that object (Darmark, Reference Darmark2010; Kuijpers, Reference Kuijpers, Ball and Arnoldussen2015a). The topic of skill is, thus, easily claimed by cultural relativism (Bleed, Reference Bleed2008: 154). Perhaps this is one of the reasons why archaeologists tend to shy away from judgement regarding technical skill, and simply see everything as made by a skilful specialist.

While there is a cautionary message that we should take away from cultural relativism, it is not helpful if it leads to the suspension of any further questioning. The relationship between skill and quality is not straightforward. There are complexities such as context and purpose. Both may affect the tolerance of mistakes and how we evaluate skill (Kuijpers, Reference Kuijpers, Ball and Arnoldussen2015a, Reference Kuijpers, Suchowska-Ducke, Reiter and Vandkilde2015b). Depending on the purpose of the axe, some of the observed mistakes may be irrelevant. For instance, the fact that the axe from Glattfelden in Switzerland was deposited on the banks of the Rhine (Abels, Reference Abels1972: 82) might have allowed for the casting error in the blade (see Martinón-Torres & Uribe-Villegas, Reference Martinón-Torres and Uribe-Villegas2015; see below). An axe from the Sennwald-Salez hoard in north-eastern Switzerland (Bill, Reference Bill1997), made of a very particular composition, might not have served as an axe at all but rather a simulacrum (Kuijpers, Reference Kuijpers, Suchowska-Ducke, Reiter and Vandkilde2015b) or ingot (Krause, Reference Krause1988; for a thorough discussion, see Kienlin, Reference Kienlin and Wotzka2006).

I will work from the assumption that each of the eight axes below was made by one individual. Apprenticeships, and cross-craftsmanship are but two models that complicate this assumption. Moreover, there is the possibility that a single craftsperson would produce elaborate axes for special purposes and axes of poorer quality for more ordinary purposes (Olausson, Reference Olausson2008). For the moment, however, I shall leave these considerations aside. Before we can tackle such complexities, we first need to acknowledge that there are qualitative differences between objects that archaeologists have so far failed to explain. For this we need a framework, a language, and a categorization of material specialization on the basis of skill.

Economic Specialization

Despite the problems connected with defining the criteria of economic specialization (Costin, Reference Costin, Feinman and Price2001, Reference Costin2007; Kuijpers, Reference Kuijpers2008: 31), this type of specialization has been explored extensively under the heading of craft specialization. This has taken the form of discussions of part-time or full-time specialists, attached to or independent of elites, and household or workshop production (Brumfiel & Earle, Reference Brumfiel and Earle1987; Kristiansen, Reference Kristiansen, Brumfiel and Earle1987; Kristiansen & Larsson, Reference Kristiansen and Larsson2005). An implicit, yet basic, tenet of these studies is that time is understood to be economically valuable.

To master a craft one needs to be able to spend a considerable amount of time practising it (Olausson, Reference Olausson2017). It is this understanding of craftsmanship that sparked ideas about socio-economic specialization and labour divisions; you need to be exempt from other occupational duties to become skilled (Childe, Reference Childe1963: 4, 10, Reference Childe1965: 136). Though it is obviously true that much time, effort, and practice need to be invested to become skilled, this by no means equals full-time or even part-time occupation with a craft. Even within contemporary society, our time is taken up mostly by full-time jobs, but this does not in any way keep people from becoming skilled in music, sports, furniture making, knitting, jewellery, or any other field or craft. As a general rule, it is said to take about 10,000 hours of experience to become skilled at any given practice (Sennett, Reference Sennett2009: 172; Kahneman, Reference Kahneman2012: 238). Evidently, such generalization fails to address the issue properly, and it should be noted that contemporary craftspeople generally perceive their engagement with material as a lifetime of learning (Adamson, Reference Adamson2007; Wendrich, Reference Wendrich and Wendrich2012: 12). The point I wish to make is that—though likely—there is no inherent association between a high level of skill and specialization, and no need for any kind of socio-economic specialization to become skilled (cf. Olausson, Reference Olausson2017).

As a further matter, the supposed amount of time spent on specific techniques and the craft as a whole is used as a ‘measurement’ of the level of skill present and the value of the product (Costin, Reference Costin, Feinman and Price2001). This association between time and skill is a problematic attempt to infer (and quantify) skill via (modern) economic assumptions, such as the maxim that ‘time is money’. Again, this axiom is challenged even within capitalist contexts. Time seems of little consideration to craftspeople when practising their craft, and the amount of time spent crafting bears no equivalence in the difficulty of the skill used or the economic value of these skills (Crawford, Reference Crawford2009: 112–15; Sennett, Reference Sennett2009: 251). Besides, a more experienced craftsperson is likely to spend less time on a task than his inexperienced counterpart. There is, thus, an inverted relationship between gaining expertise and the value of this expertise if it were solely measured in units of time.

There is no need to completely reject the association between material specialization and socio-economic specialization. After all, time is spent. But caution is needed when assuming a direct relationship. Through uncritically applying causal correlations between skill, time, specialization, and labour division, archaeologists stretch the limits of their data. What might be strong evidence for specialization—for example, a large metalworking furnace inside a house—is oblique evidence of labour division, and not evidence for making a case about skill. There is a risk of asserting skills on the basis of a social theory rather than demonstrating them in the material (Costin, Reference Costin, Feinman and Price2001: 282, Reference Costin2007: 145).

I nevertheless accept the (economic) theorem that an object with a high level of skilfulness would, accordingly, be attributed value and could endow both its maker and its owner with a certain social status. Differences in quality visible in the material, thus, matter because they are likely to be the result of varying levels of skill, and this points to different craftspeople. There is little reason to deny prehistoric people the ability to recognize and value variation in skill, especially among those people able to work in similar crafts and thus knowledgeable about crafting skills. However, value is created in ways beyond the amount of labour and time needed to produce goods. The right actions and performance matter (Lambek, Reference Lambek2013), as do when and by whom the goods are consumed, and for what purpose (Naveh & Bird-David, Reference Naveh and Bird-David2014). Craftsmanship is much more than the mere production of commodities (Graeber, Reference Graeber2001; Cordes, Reference Cordes2005; Crawford, Reference Crawford2009; Sennett, Reference Sennett2009).

Material Specialization

In the following section, I focus strictly on technical skill, an aspect of material specialization that, in contrast to ideas about economic specialization, can be assessed through careful analyses of archaeological material, such as the Early to Middle Bronze Age axes from the North Alpine region (Figures 1 to 8) which are the subject of this article.

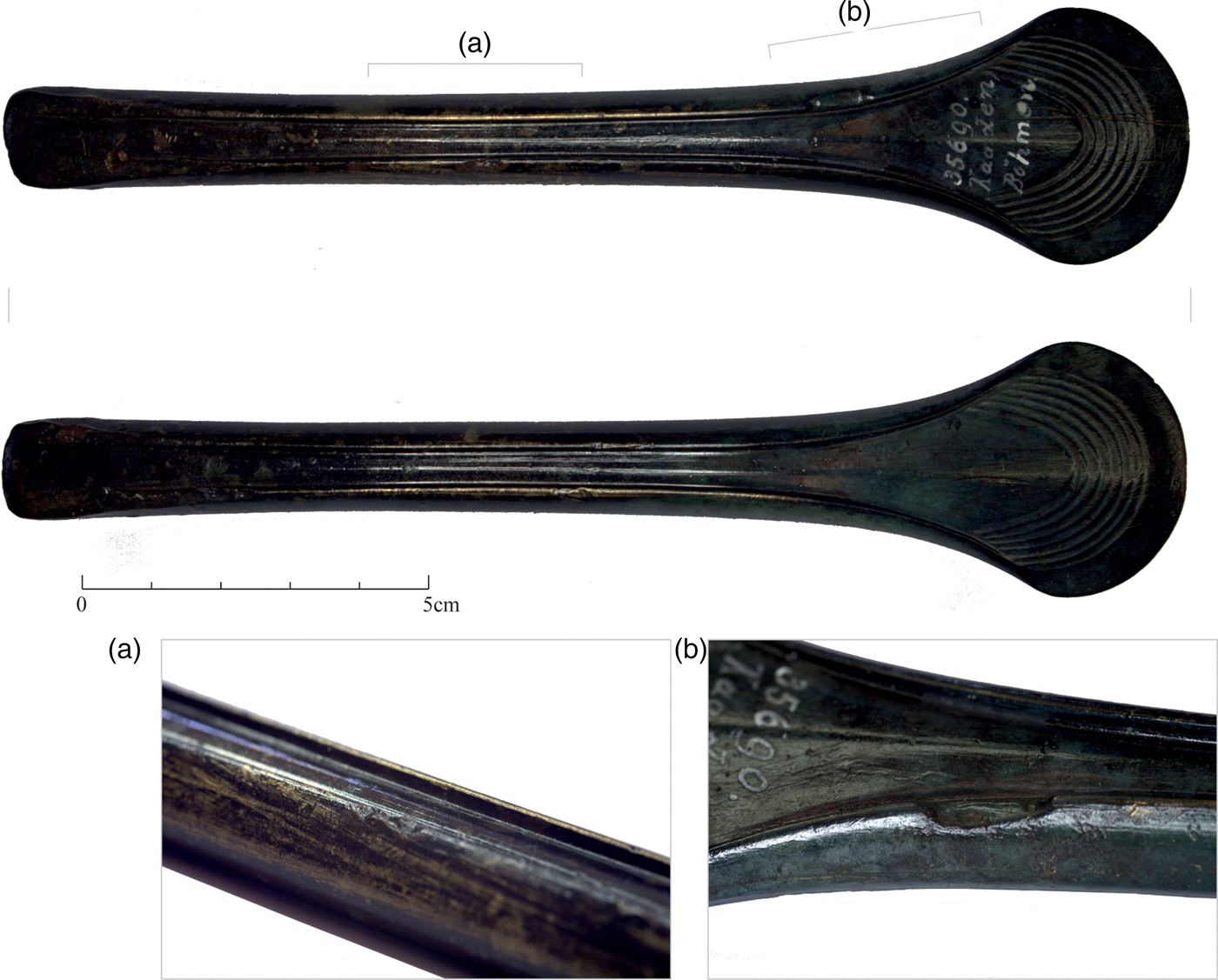

Figure 1. Axe 281, a type Lausanne from Kadaň in the Czech Republic, stray find. The axe has a sharp blade, is very well polished, decorated, and has a remarkable symmetry overall. Photographs by the author, courtesy of the Naturhistorisches Museum Wien.

First, an archaeologically workable definition of skill is needed, on the basis of which differences in the level of skill can be demonstrated. Skill is the ability to recognize and respond to the qualities of one's material. Qualities in this respect are the physical properties of the material, but more so the manner in which these properties are perceived as affordances of the material. In the case of metal, Bray re-introduced the term ‘metalleity’ to emphasize this aspect and to focus on metal as a package of attributes that are potentially available to human society (Bray, Reference Bray, Allen, Gardiner and Sheridan2012; see also Untracht, Reference Untracht1969, 5–6; Mödlinger et al., Reference Mödlinger, Kuijpers and Bergerin press). A skilled craftsperson will bring out the qualities of a material, whereas an unskilled one may not even recognize them.

The difficulty with this definition is that it does not allow for a straightforward quantitative analysis of skill. Dissimilar copper compositions of axes lead to idiosyncratic behaviour of the material; and a skilful response, thus, results in dissimilar applications of certain techniques. In other words, skill is not static, and using a similar technique can be a sign of skill when applied to one axe, but a lack of it in another. To reveal skill systematically, it is, thus, necessary to examine many individual axes in their own right and with respect to the specific qualities of the material from which they were made. As this is too large a scope for a single article, here, I make use of few exemplary axes from a study of several hundred (Kuijpers, Reference Kuijpers2017). These particular axes were chosen because they present obvious mistakes and a considerable diversity of techniques through which differences in skill are visible. They allow me, despite the small sample size, to clarify how and why I have broken down the concept of the ‘specialist’ and to propose a more nuanced interpretation of the products of craftsmanship.

The good, the bad, and the ugly

Some of the axes discussed below have been examined as part of Tobias Kienlin's (Reference Kienlin2008, Reference Kienlin2010) enquiry into the cognitive aspects of prehistoric metalworking technology. His studies provide the detailed metallographic data through which different responses to material qualities can be accurately documented. However, macroscopic examination of these axes already reveals much about skill.

In Figure 1 and 2 two axes are presented; they are of the same type (type Lausanne) but with slight differences. The most obvious of these is the additional decoration on axe 281 from Kadaň in the Czech Republic (axe numbers refer to my own database; Figure 1). Instead of addressing this difference in terms of typological variation, I am interested in what this means in terms of skill. The decoration was probably made after casting, by chiselling and subsequently grinding away the uneven dents; although we cannot exclude the possibility that the decoration had been conceptualized beforehand and was added in negative to the model (of wood or wax). If carried out to the standard observed on this axe, all traces of the production process are removed, leaving little evidence for the archaeologists. Whatever the exact technique, they represent additional steps in the chaîne opératoire. Scrutinizing the axes more closely, one can see the almost perfect symmetry of axe 281 compared to the cruder shape of axe 280 (from Gemeinlebarn in Austria). The flanges of axe 281 are sharp and well defined. The mid-rib is seamlessly aligned and of an even height. Even the mistake in one of the flanges appears to have been straightened out to some extent (Figure 1b). All in all, compared to axe 280, axe 281 seems to be the product of a more skilled metalworker. That is not to say that axe 280 (Figure 2) does not also demonstrate skill. Obviously, this craftsperson was skilful too, and able to produce a good axe. I simply wish to draw attention to the fact that there are differences between these two axes and that this observation needs to be explained. What we observe here, I argue, are different levels of skill.

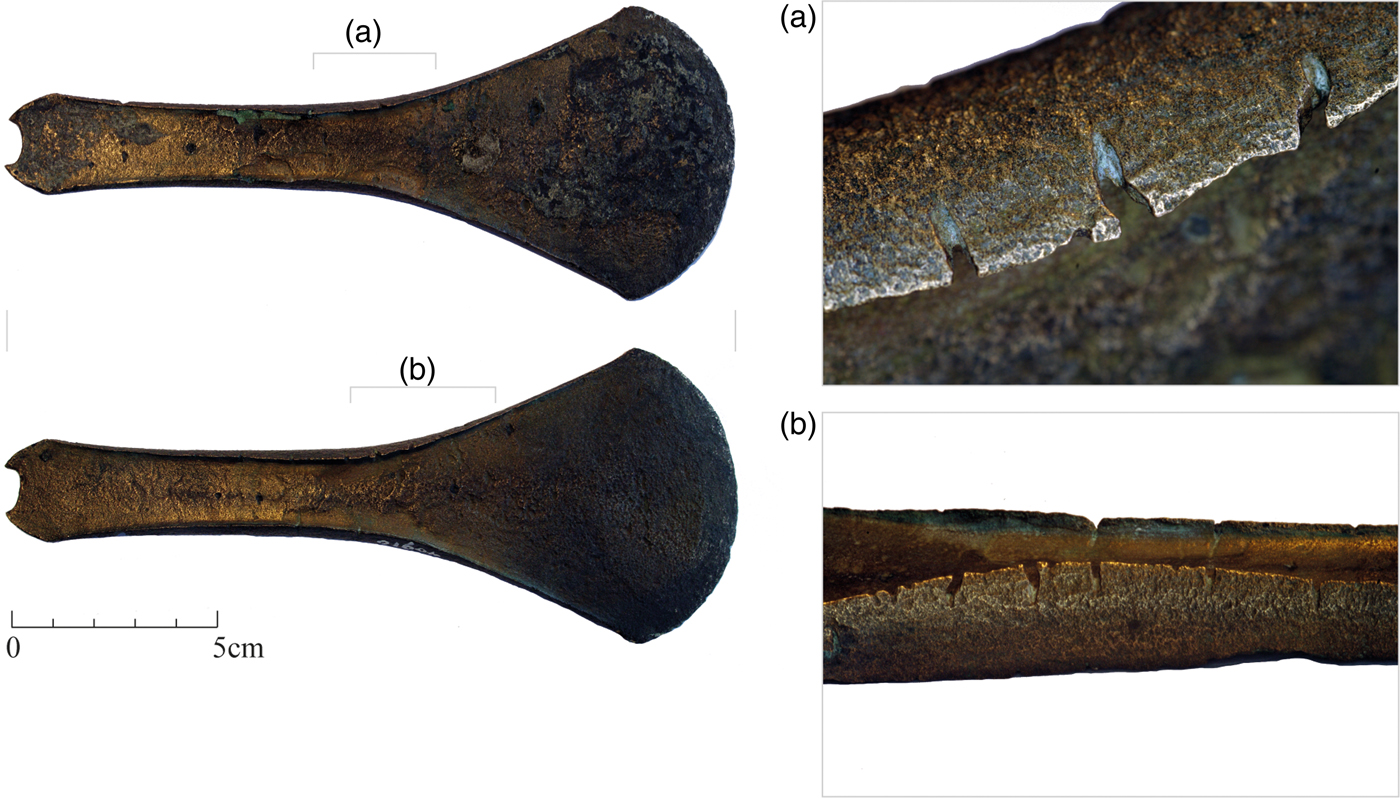

Figure 2. Axe 280, a type Lausanne, variant Gemeinlebarn, from Gemeinlebarn in Austria, found in a grave (Mayer, Reference Mayer1977: 85, no. 253). Though similar to axe 281, less care was given to the details of this axe. Photographs by the author, courtesy of the Naturhistorisches Museum Wien.

Differences in skill are also visible in the form of mistakes. Figure 3 (axe 287, from Meilen in Switzerland) shows an axe with badly fissured flanges. While these cracks would not render the axe useless, they are telling regarding the metalworker's skills. A feature of skill is purposefully constrained physical action (Adamson, Reference Adamson2007: 73). This means, for instance, the proper handling of tools, where the craftsperson does not resort to brute force but coaxes the material into shape (Risatti, Reference Risatti2007: 195). Bronze, when struck, creates a dull tone when it is in a working condition. A high-pitched tone is a (warning) sign that it has become hard and stiff and will not deform any further without cracking, but is in need of annealing (Untracht, Reference Untracht1969: 246). Recognizing such cues from the material are fundamental for its skilful working. This metalworker clearly did not do so and lacked skill in wielding a hammer, beating the flanges far too vigorously, which led to cracks. As a comparison, Figure 4 (axe 288, also from Meilen in Switzerland) shows a morphologically very similar axe. This axe has high and sharply creased flanges but without any cracks, demonstrating a distinct variation in skill.

Figure 3. Axe 287, a type Bodensee from Meilen in Switzerland, context unknown (Abels, Reference Abels1972: 79, no. 538). Note the severe cracking of the flanges due to excessive hammering. Photographs by the author, courtesy of the Landesmuseum Zürich.

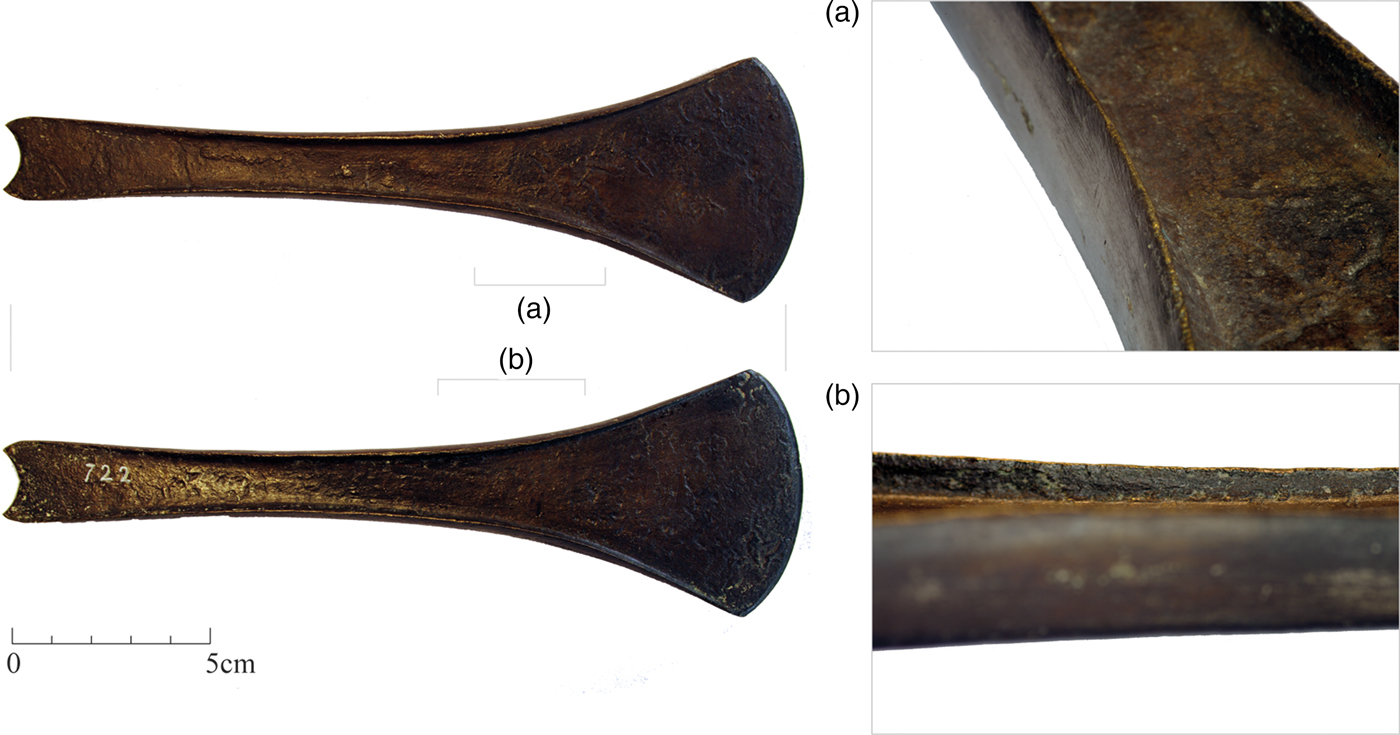

Figure 4. Axe 288, a type Meilen from Meilen in Switzerland, context unknown (Abels, Reference Abels1972: 41, no. 299). Note the high and sharp contours of the flanges. Photographs by the author, courtesy of the Landesmuseum Zürich.

Another example of a mistake is the ostentatious casting fault in axe 153 from Glattfelden in Switzerland (Figure 5). This results from air becoming trapped under the molten copper and reveals a poor casting technique. It shows that this particular axe was cast flat and probably in a mediocre, open mould. Indeed, experiments with casting in open moulds have resulted in similar casting faults, a problem that could, for instance, be solved by setting the mould at an angle and capping it with a flat stone—a solution also known to prehistoric metalworkers (Figueiredo et al., Reference Figueiredo, Pereira, Lopes, Marques, Santos and Araújo2016). There are three facets on the flanges of axe 153, indicating a basic, functional finish. The blade is asymmetrical and largely blunt. The overall shape of the axe appears crude and rough compared to its contemporaries (Abels, Reference Abels1972). Aesthetic considerations, such as symmetry and final polishing, clearly were not of primary concern for this axe.

Figure 5. Left: Chaîne opératoire of axe 153. Right: Axe 153, a type Gretchen variant D from Glattfelden in Switzerland, from the banks of the Rhine (Abels, Reference Abels1972: 82, no. 584). Overall, a very crude axe with major casting errors, roughly worked flanges, and a blunt blade. Photographs by the author, courtesy of the Landesmuseum Zürich.

Nonetheless, according to the metallographic analysis, the axe was worked further despite this casting fault. The blade has seen strong hammer-hardening, seemingly with the aim of creating a harder edge (Kienlin, Reference Kienlin2008: 432, sample no. 601501). This took the hardness of the blade far above that of most contemporary axes in the Early Bronze Age (HV [Vickers Hardness test] 260). If axe 153 was made with the intention to produce a functional tool, the quality is probably best assessed on the hardness of the blade. From this mechanical viewpoint alone, this axe should be considered well-made, despite the lack of metallurgical skill implied by the casting fault and careless finish. The resulting qualitatively good tool owes much to the inherent affordances of the material used, a tin-bronze that hardens well. Axe 153 is a good example of the difficult relationship between quality and skill, a relationship that is subject to the purpose of the object (Kuijpers, Reference Kuijpers, Ball and Arnoldussen2015a), and the constant tension between correctness and functionality (Sennet, Reference Sennett2009: 45).

A study of skill through metallographic analysis raises further complexities. Take the morphologically comparable axes 3 (from Sennwald-Salez in Switzerland) and 56 (from Sobechleby in the Czech Republic), respectively a type Salez and type Saxon (Stein, Reference Stein1979; Kienlin, Reference Kienlin2008: 45). Metallographic and compositional data show that the similarity is only skin-deep. These axes are made from two distinct copper compositions which are perceptibly different from each other. This is an important distinction, as skill is fundamentally dependent on a sensory perception of the material (Kuijpers, Reference Kuijpers2017). The most obvious difference concerns colour (Lechtman, Reference Lechtman1996; Fang & McDonnell, Reference Fang and McDonnell2011; Mödlinger et al., Reference Mödlinger, Kuijpers and Bergerin press), but the behaviour of the metal in terms of hardening, malleability, and brittleness is also different. Axe 3 was made of a copper containing a cumulative amount of arsenic, antimony, nickel, and silver of >7wt. per cent, making it surprisingly difficult to cast without porosity and to work because of the inherent brittleness caused by this composition (Lechtman, Reference Lechtman1996; Kienlin et al., Reference Kienlin, Bischoff and Opielka2006). Axe 56 was made of a copper containing between 5 and 12 per cent tin, a typical tin-bronze that has excellent casting qualities and hardens considerably when hammered (Lechtman, Reference Lechtman1996; Wang & Ottaway, Reference Wang and Ottaway2004). Prehistoric craftspeople recognized and appreciated these differences, as can be observed in a chaîne opératoire (Figures 6 and 7). The blade of axe 3 was worked carefully and received a weak hammer-hardening only (Kienlin, Reference Kienlin2008; 452, sample no. 101202), probably because of the poor casting quality and general brittleness of this material. The flanges probably also saw light hammering to shape them. A close look at one flange shows that small cracks appeared (Figure 6a); but, compared to axe 287, its maker knew exactly when to stop hammering to prevent fractures from developing.

Figure 6. Left: Chaîne opératoire of axe 3. Right: Axe 3, a type Salez from Sennwald-Salez in Switzerland, a hoard find. Note the starting cracks (a) in the flange. Photographs by the author, courtesy of the University of Vienna.

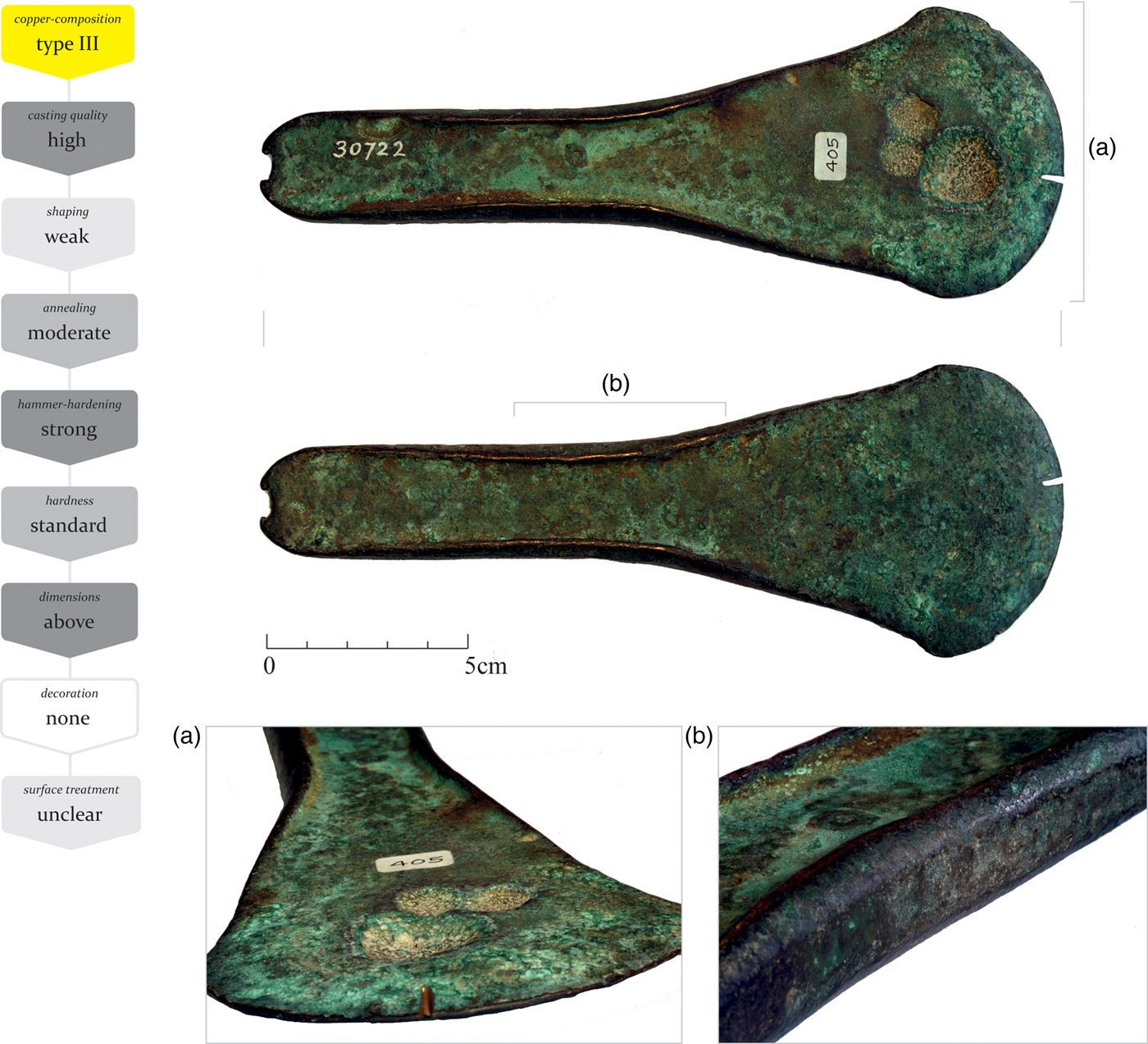

Figure 7. Left: Chaîne opératoire of axe 56. Right: Axe 56, a type Saxon from Sobechleby in the Czech Republic, a hoard find (Stein, Reference Stein1979: no. 248). A well-worked axe stressing the qualities of the material it is made from. Photographs by the author, courtesy of the Naturhistorisches Museum Wien.

Axe 56 is a high-quality cast that has been hammered to a high total reduction of 70–80 per cent (Kienlin, Reference Kienlin2008: 570, sample no. 204201) (reduction being the amount of deformation of the as-cast metal from hammering), which emphasizes the particular affordance, of this material to predictably harden well. At the same time, the metalworker appears to have been aware of the risk of reducing the metal too much in one step. This risk can be noticed because, in the 40–50 per cent range, the sulphides in tin-bronzes will start deforming, which is felt as a resistance to further deformation and heard because of the slightly higher pitch of the metal (Untracht, Reference Untracht1969: 246; Kuijpers, Reference Kuijpers2017). Axe 56 was worked exactly up to this point during the final hammer-hardening. About 30–35 per cent reduction took place in one or more rounds of shaping and annealing prior to this final hardening.

Both of these axes show the recognition of, and response to, specific affordances of the raw material, clear signs of skill.

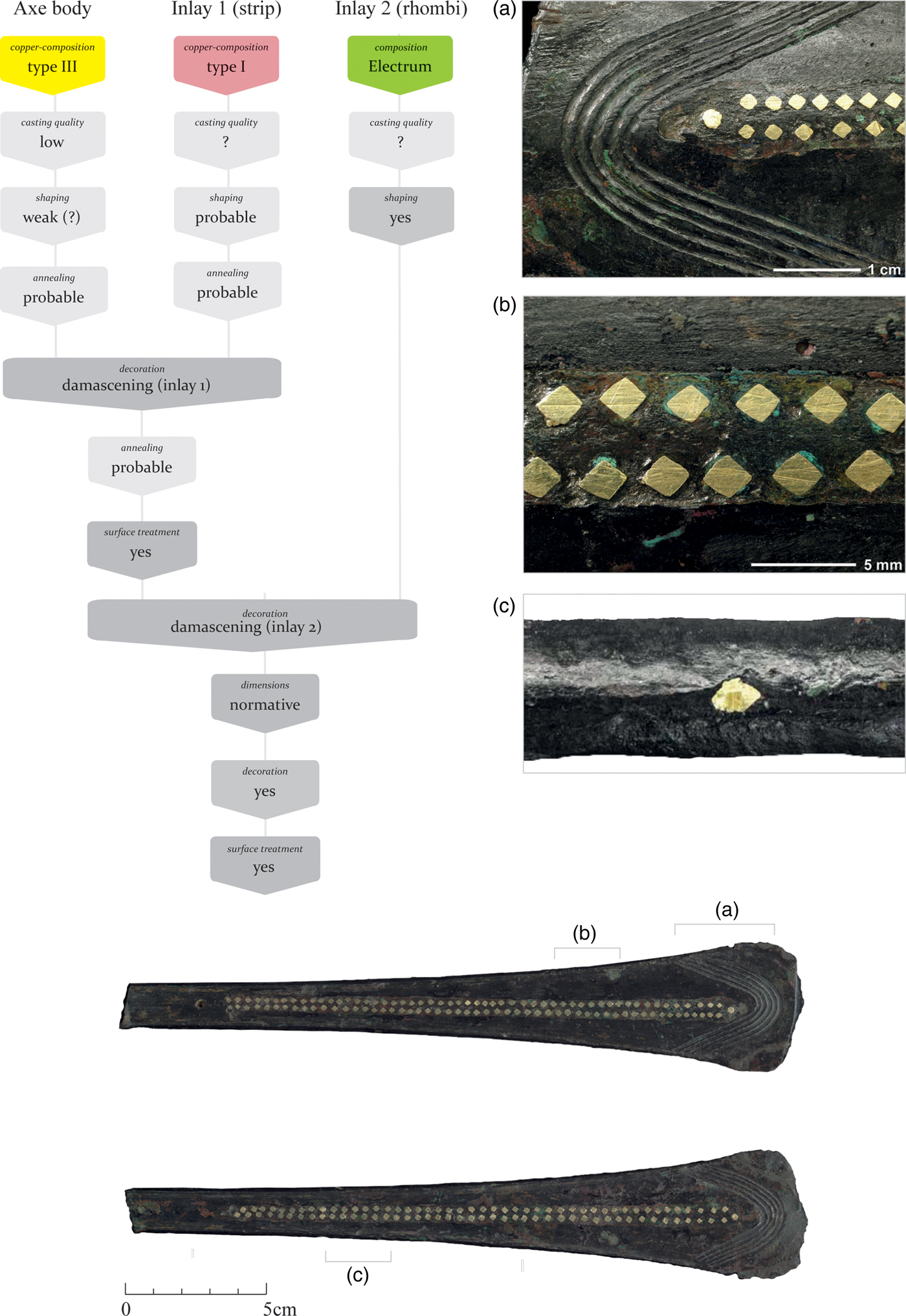

Lastly, I would like to compare all the above axes to axe 322, from Thun in Switzerland (Figure 8). This elaborate axe distinguishes itself in many ways, except for the fact that it resembles the shape of a normative axe. The copper and gold inlays create a distinct visual appearance, possibly enhanced by patination techniques (Berger, Reference Berger2012). The chaîne opératoire of this axe is elaborate, incorporating many more steps than any of the above axes. That does not mean that everything was done perfectly. For instance, the axe is very porous, which is likely to be the result of casting in a clay mould that was not baked through and that released gasses when it came into contact with the hot molten metal. The casting quality can, thus, be regarded as poor. This raises the question of whether we are dealing with multiple craftspeople working on the same product, because all the other techniques used on this axe show a high level of skill. Another option is that, given the complexity of the axe (and assuming that it was made by a single person), it is more likely that the shape of the axe was what concerned the craftsperson rather than the casting quality in terms of workability and hardness. Hence, whether or not they saw the casting as a success may have depended more on the visual properties of this axe than its mechanical properties. The inlays of different metals and polychrome effects also point towards an axe that was produced to work in the realm of the visual rather than the practical. Thus, despite variable evidence of technical skill, I follow the well-established argument that this axe was made by a highly skilled specialist (Kristiansen & Larsson, Reference Kristiansen and Larsson2005: 52–53). One can assume that this axe was a prestigious object carrying symbolic, ideological, and/or political meaning (see Helms, Reference Helms1993). However, where does that leave all the other axes?

Figure 8. Left: Chaîne opératoire of axe 322. Right and below: Axe 322, a type Rümlang variant A, also known as the Thun-Renzenbühl axe from Thun in Switzerland, from a rich male grave (Abels, Reference Abels1972: 21, no. 178; Berger et al., Reference Berger, Hunger, Bolliger-Schreyer, Grolimund, Hartmann and Hovind2013). An exceptional axe both in its chaîne opératoire and its appearance. Photographs from Berger, Reference Berger2012 and Berger et al., Reference Berger, Hunger, Bolliger-Schreyer, Grolimund, Hartmann and Hovind2013, reproduced by kind permission.

Beyond the specialist; towards skill

Following this brief examination of Early Bronze Age axes, the question is not whether there were differences in skill, but what to make of these differences. If all axes, from the exceptional Thun axe to the bulk of ordinary axes to sub-standard axes are considered to be the products of specialist metalworkers, the term becomes pointless. How can a single concept cover such divergent axes? The concept of ‘specialist’ is decidedly inaccurate in light of the variation that can easily be demonstrated. And it is not only in the category of axes that differences in skill can be noticed. More prestigious objects such as swords or neck collars, equally, show well-made and less well-made examples, and even mistakes (Mödlinger, Reference Mödlinger2011; Nørgaard, Reference Nørgaard2015; Bunnefeld, Reference Bunnefeld2016), and such variety has also been noted for Late Neolithic flint daggers, where a similar discussion of craft specialization is taking place (Apel, Reference Apel2008; Olausson, Reference Olausson2008, Reference Olausson2017).

Taking the above into consideration, and in order to present a more fine-grained analysis of the data, I propose a subdivision of the term specialist. The data shows at least four groups of specialists, or degrees of material specialization:Footnote 1

1. Amateurs: products made by these craftspeople demonstrate a basic knowledge of the craft but little refinement. The manner in which certain techniques are applied displays little appreciation of the material, and beginners’ mistakes occur. In general, poor results are to be expected, though they are acceptable (Figures 3 and 5).

2. Common craftspeople: those who have learned the craft. Their skills have become fully embodied but do not stand out. Imitation and repetition are important characteristics of this group and production can be regarded as anonymous. Production tends to be traditional and changes in the technology only occur slowly. These craftspeople produce mostly unoriginal objects and are unlikely to take (aesthetic) risks that would endanger production. The products of this group are of good quality but by no means perfect, and small mistakes occur. Their products serve a function and they simply need to be ‘good enough’ (Figures 2 and 4).

3. Master crafters: individuals who produce distinct objects that approach a high level of perfection. Their work is likely to be recognized and admired by peers. These objects are not original or unique, however. Rather, the master craftsman is a perfectionist, setting the norm for how an object should look. They are more likely to take greater risks and, therefore, to be innovative and develop new techniques. The qualities, potential, limitations, and risks of the material they work with are clearly appreciated and techniques are adjusted and applied accordingly. Their products blur the boundary between mundane and prestigious. Aesthetics seem to matter. The objects produced by this group stand out from the rest in terms of care, symmetry, surface finish, and decoration (Figures 1, 6, 7).

4. Virtuoso: exceptionally skilled craftspersons capable of creating original or even unique objects through the use of unconventional techniques. Their work explores the very limits of the material. These are the highly skilled artisans who create objects that are likely to be laden with ideological and political meaning, individuals who are admired (or feared) for their exceptional skills by the community, which may lead to a special social status (Helms, Reference Helms1993). Their objects are original even when referring to unoriginal basic principles. The exceptionally high degree of skills may make it difficult to share these skills among peers and apprentices (Figure 8).

This subdivision into four categories makes it possible to build a more detailed and colourful model, compared to the black and white specialist versus non-specialist framing discussed above. It also draws attention to a large but particularly under-theorized group of artefacts: those made by the anonymous hands of the first and second categories of craftspeople. How this group of objects has escaped our concern will be explained next.

Discussion

To clarify why this more precise handling of the data with regard to skill is important, we need to see it in light of the generally accepted model in which the Bronze Age is seen as an epoch of increasing social complexity and social stratification, particularly the assumed relationship between a powerful elite and the prestige technology of metalworking (Budd & Taylor, Reference Budd and Taylor1995; Kristiansen & Larsson, Reference Kristiansen and Larsson2005; Vandkilde, Reference Vandkilde2007). The idea of economic specialization includes the notion of attached specialists who work to produce the weapons and high-status objects of the warrior-aristocracy (Kristiansen & Larsson, Reference Kristiansen and Larsson2005: 53; Earle et al., Reference Earle, Ling, Uhnér, Stos-Gale and Melheim2015: 646) and is heavily influenced by the seminal study by Mary Helms, Craft and the Kingly Ideal (Reference Helms1993). Helms is candid about her theoretical framework, which is Brumfield and Earle's (Reference Brumfiel and Earle1987) political model of specialization and exchange of prestige goods (Helms, Reference Helms1993: 4). Her thorough anthropological study provides a convincing model for the interpretation of skilled crafting, though this paradigm is critiqued for assuming rather than explaining how certain objects signify prestige (Maurer, Reference Maurer, Tilley, Keane, Küchler, Rowlands and Spyer2006: 19–20). It is important to realize that this model is based on particular propositions, one of which is to consider only crafting that is ‘expressed as specialized skills that generally serve non-utilitarian purposes, are imbued by definition with qualities of aesthetics, and are associated with political-ideological activities and symbolism’ (Helms, Reference Helms1993: 6; original emphasis).

In my proposed categories of material specialization, the type of craftspeople Helms describes (‘artisans’) are in the third and perhaps only in the fourth category of master crafters and virtuosi. Her use of the term ‘skilled crafting’ is, therefore, a rather unfortunate choice of words in my opinion, especially given her peculiar division ‘between skilled crafting and manufacturing, between the “true” potter and the man who merely works at making pots’ (Helms, Reference Helms1993: 14–15). Helms does not deal with the ordinary craft objects produced by the largely anonymous group of common craftspeople. There is a distinct Marxist view to be discerned here in which manufacturing resembles little more than unskilled labourers producing commodities.

Extrapolating from Helms: Bronze Age artisans and elites, a story of the one per cent

Using Helm's model to interpret prehistoric bronze production has certain implications. Axiomatically, this associates the interpreted metal objects with political-ideological activities. It also means that the interpreted objects are uncritically considered to be the products of highly skilled craftspeople because Helms’ model does not take into account common craftspeople that produced utilitarian objects.

The particular conceptualization of the skilled specialist (sensu Helms’ ‘artisan’) tallies agreeably with the interests in specialization, exchange, social inequality, and the development of complex societies, a combination of topics that emerged as a new direction in archaeology in the late 1980s (Brumfiel & Earle, Reference Brumfiel and Earle1987). These became a fundamental issue in the following decade (Price & Feinman, Reference Price and Feinman1995) and eventually grew into a sweeping interpretation and commonly accepted model of Bronze Age complexity (Kristiansen & Larsson, Reference Kristiansen and Larsson2005; Earle & Kristiansen, Reference Earle and Kristiansen2010). At the same time, this line of reasoning effectively leaves the bulk of archaeological objects and their makers—the group of common craftspeople and amateurs—unaccounted for. Consequently, current interpretations of Bronze Age metalworking rely on a disproportionate and problematic bias towards exceptionally skilled metalworkers and their objects.

What about diversity?

Following the proposed distinction of craftspeople from amateur to virtuoso on the basis of skill, I argue that the current ‘political economy’ model of the Bronze Age fails to fully appreciate a large part of the archaeological record, in particular the common axes and other craft objects produced by ordinary crafters. Emphasizing wealth and prestige objects, this model is in danger of simplifying and polarizing the socio-political structure of prehistoric societies into a narrative that revolves around specialists and elites (e.g. Earle et al., Reference Earle, Ling, Uhnér, Stos-Gale and Melheim2015). Non-specialist and non-elites are underrepresented (Vandkilde, Reference Vandkilde2007: 95) because the model builds on a theoretical framework that unevenly appreciates the material culture left behind by Bronze Age people. The diversity of skill suggests the involvement of a large range of craftspeople at various levels of material specialization. Moreover, we need to acknowledge that a large group of objects, such as ordinary axes made by anonymous craftspeople, have had little attention. This category of archaeological data—craft objects that in the first place were supposed to do rather than signify something—is in need of its own theorization.

Conclusions

Currently, the specialist role of craftspeople is entertained without paying due attention to skill, to the practicalities involved in the craft, and, thus, to objects and the materials these objects were made from. Especially in tandem with an interpretation of the skilled specialist as an artisan (Helms, Reference Helms1993), a particularly favourable image of craftsmanship emerges, epitomized by a few exceptional pieces at the expense of hundreds of more or less ordinary counterparts.

The appreciation of specialists and interest in the organization of craft in the last few decades have been foremost a question considered in terms of the origins of social inequality. Archaeologists have explored economic specialization rather than material specialization, seeing skill as a time-investment and, thus, as social capital. This idea of specialization is a fundamental building block in the argumentation of (Marxist) models that advocate labour divisions, increased complexity, and social inequality. Not surprisingly, the political economy model for the Bronze Age is, therefore, teeming with specialists. Yet, we do not find specialists, social roles, or economic units in the archaeological record. We mostly recover archaeological objects, some more plentiful than others, from which we observe similarities, differences, and variations in quality.

Though it might not be possible to address skill objectively and quantitatively (but see Budden, Reference Budden and Berg2008; Darmark, Reference Darmark2010), and despite the complex relationship with quality, this does not render an enquiry into skill impossible. A comparison of similar, coeval, Early Bronze Age axes clearly reveals that they differ and these differences go beyond morphology and techniques, thus involving concerns of quality and skill.

Of course, we could interpret all the craftspeople who manufactured the axes presented here as specialists since they all mastered the craft well enough to produce such objects. However, the use of such a sweeping analytical concept collapses all craftspeople into the same category, effectively rendering superfluous a further exploration of the archaeological material. Subsuming the makers of all these axes in this broad category whittles away the differences between them. This, to me, seems antithetical to a discipline that is grounded in careful observations of material culture, some of the most valuable of which are lost if we do not consider this variation.

There is no reason to assume that such differences in skill would not also have been recognized by prehistoric people; thus, our observations may give an insight into what was perceived as quality. Henceforth, one of the main conclusions we should draw is that variability due to the presence or lack of skill is a meaningful difference for archaeologists to explore (Bleed, Reference Bleed2008).

Skill may be a challenging topic, but it is a criterion of specialization that can be delineated through careful observation of archaeological material. Following the observed variation between the axes discussed here, I propose four subcategories of material specialization: amateur, craftsperson, master, and virtuoso. These are not meant to completely replace the term ‘specialist’, but rather they allow for a more nuanced description of the social group of craftspeople when needed. Moreover, they draw specific attention to a large group of artefacts and their producers which are underrepresented in our narratives of the Bronze Age.

Lastly, through an analysis of technical skill and taking a craft perspective, archaeologists may find new ways of exploring the variability in skill and quality that is present in the archaeological record. The results may be surprising; and, in developing such a craft theory, we might find that some of the shibboleths of Marxist archaeologies need nuancing, such as a labour theory of value, and specialization as a path to complexity and social inequality.

Acknowledgements

The work presented here results from my PhD research, submitted to Cambridge University (2015) and supported by funding from the European Union's Seventh Framework Programme (FP7/2007-2013) under grant agreement no. 212402. This article was written at Leiden University as part of the project ‘Economies of Destruction’ funded by the VICI grant of the Netherlands Organisation for Scientific Research. I would like to thank Marie Louise Sørensen for her overall role as a caring supervisor and for the careful reading and commenting on earlier drafts of this article. David Fontijn is thanked for making several critical but insightful suggestions. I have benefited greatly from discussions with Catalin Popa, Tim Flohr Sørensen, Tobias Kienlin, and Nienke Broekema, exploring the thoughts that underlie this work. Catherine Frieman and three anonymous reviewers helped to tighten the argument.