Published online by Cambridge University Press: 17 January 2024

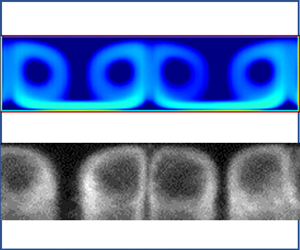

Flow between axially rotating concentric cylinders is well known to exhibit rich dynamics. Hence, Taylor instabilities have been studied, both experimentally and theoretically, for many years. Although usually studied in the abstract, such geometries arise in a range of practical situations including drilling, when a drilling fluid flow enters a well via a pipe that is the centre body and returns via the annulus between the pipe and the borehole wall. In drilling, the centre body rotates and the annular flow contains rock cuttings. Here, we report the development of an Eulerian-Eulerian solver, based on OpenFOAM, that solves for this cuttings transport problem in the presence of both gravity and Taylor vortices. To check the reliability of the solver, we conduct a set of experiments spanning a wide range of complex flow regimes. We show that the model successfully predicts, in all regimes, the observed complex redistribution of particulates. However, for suspension flows under viscously dominated conditions, high particle concentrations and in rectilinear flow, particle pressure and normal stress differences are sufficient to capture particle migration. Results show that in more complex flows exemplified by the Taylor–Couette flow studied here, more realistic predictions of non-Brownian particle migration require inclusion of forces arising through the relative velocity of the two phases including lift forces originating both from inertia and particle rotation.