1. Introduction

There is a high demand for novel precursors for polymer-derived silicon nitride ceramic (Si3N4-PDCs) with high mechanical, thermal, and electrical properties. Thus, several synthesis routes have been reported in the last 30 years (Balazsi, Reference Balázsi2010, Reference Balazsi2012; Colombo et al., Reference Colombo, Mera, Riedel and Sorarù2010; Mera et al., Reference Mera, Navrotsky, Sen, Kleebe and Riedel2013, Reference Mera, Gallei, Bernard and Ionescu2015; Mera & Ionescu, Reference Mera and Ionescu2013, Reference Mera and Ionescu2019; Riedel et al., Reference Riedel, Mera, Hauser and Klonczynski2006; Weinmann et al., Reference Weinmann, Ionescu, Riedel and Aldinger2013). By the incorporation of nanocarbons into the polymeric structure of the precursors, tunable and multifunctional properties for Si3N4-PDCs can be easily accessed. Polymer composites consisting of nanosized allotropes of carbon, such as fullerenes, nanotubes, and graphene, have been reported (Balazsi, Reference Balazsi2012; Wang et al., Reference Wang, Mera, Morita and Ionescu2016). Chemical functionalization of nanocarbons surface offers the possibility to develop advanced polymer composites with covalent bonding (strong interface), and excellent dispersion of nanocarbon phase within the matrix (Mohamed et al., Reference Mohamed, Chehimi and Pinson2013). Thus, classical challenge of agglomeration of nanocarbons in the polymer matrix can be solved.

2. Objective

The main objective of this study is to provide a chemical facile access to novel 0D-nanocarbon–containing Si3N4-based PDCs precursors, based on onion-like carbons (OLCs) (Bartelmess & Giordani, Reference Bartelmess and Giordani2014; Butsyk et al., Reference Butsyk, Olejnik, Romero and Plonska-Brzezinska2019; Krüger, Reference Krüger2010; Kuznetsov et al., Reference Kuznetsov, Chuvilin, Butenko, Mal’kov and Titov1994; Mcdonough & Gogotsi, Reference Mcdonough and Gogotsi2013; Mykhailiv et al., Reference Mykhailiv, Zubyk and Plonska-Brzezinska2017; Plonska-Brzezinska, Reference Plonska-Brzezinska2019; Zeiger et al., Reference Zeiger, Jäckel, Mochalin and Presser2016) -silicon diimide polymer composites. To achieve this objective, the salt-free pyridine-catalyzed transamination reaction of tetrachlorosilane (SiCl4) with hexamethyldisilazane (HMDS) was made in the presence of different contents of carboxyl-functionalized OLCs (e.g., 0.1, 0.5, 1, and 2 wt% OLCs), using a similar procedure as previously reported for graphene oxide-silicon diimide polymer composites (Wang et al., Reference Wang, Mera, Morita and Ionescu2016). The chemically functionalized OLCs were prepared through the oxidation reaction of pristine OLCs in the presence of concentrated nitric acid.

The in situ polymerization reaction is expected to provide an efficient access to well-dispersed OLC-containing silicon diimide polymer composites, with covalent interfacial bonding between the components.

3. Methods

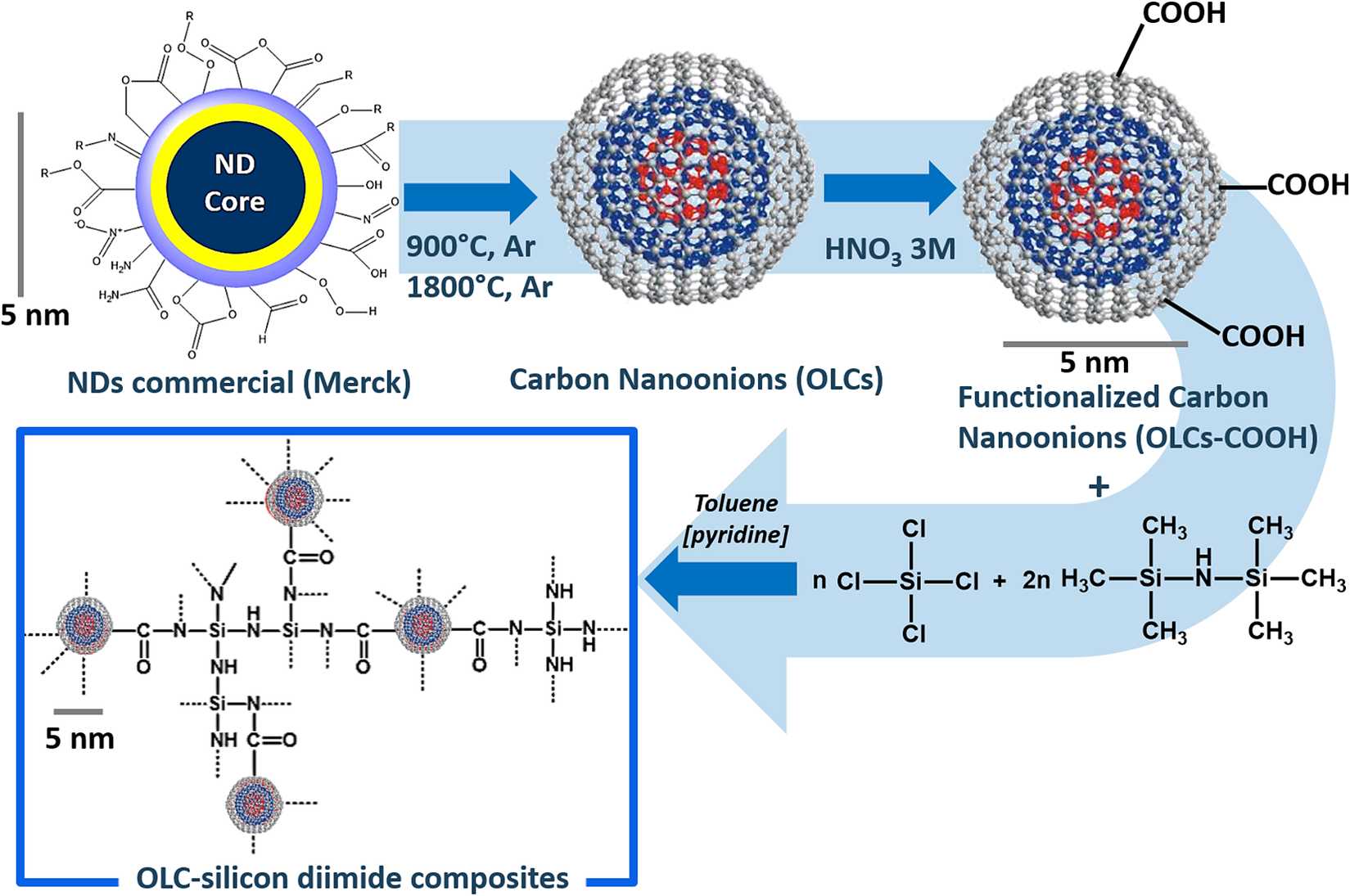

The preparation route used in this study is described in Figure 1. Further details are provided at Wang and Mera (Reference Wang and Mera2021).

Figure 1. Synthesis of onion-like carbon (OLC)-silicon diimide composites starting from commercial nanodiamonds and their graphitization and chemical functionalization by carboxyl groups, followed by polycondensation reaction with silicon tetrachloride and hexamethyldisilazane.

Pristine OLCs were obtained by the thermal graphitization of commercially available nanodiamonds (Diamond nanopowder, <10 nm particle size, Merck) at 1,800![]() $ {}^{\circ}\mathrm{C} $ in argon atmosphere. The chemical functionalization of OLCs was performed using a slightly modified oxidation process as compared with the reported (Bartelmess & Giordani, Reference Bartelmess and Giordani2014). Thus, OLCs were refluxed for 3 hr in concentrated HNO3, washed with water and then dried in vacuum, dispersed in toluene, and stirred in ultrasonic bath for 30 min (Figure 1).

$ {}^{\circ}\mathrm{C} $ in argon atmosphere. The chemical functionalization of OLCs was performed using a slightly modified oxidation process as compared with the reported (Bartelmess & Giordani, Reference Bartelmess and Giordani2014). Thus, OLCs were refluxed for 3 hr in concentrated HNO3, washed with water and then dried in vacuum, dispersed in toluene, and stirred in ultrasonic bath for 30 min (Figure 1).

The synthesis of silicon diimide was performed as reported by Wang and Mera (Reference Wang and Mera2021), using an improved synthesis protocol based on the published report by Wang et al. (Reference Wang, Mera, Morita and Ionescu2016), by reacting SiCl4 with HMDS under argon atmosphere, using Schlenk technique (Figure 1). For the synthesis of nanocomposites, HMDS and the catalyst pyridine were mixed with a dispersion of OLCs in toluene, then SiCl4 was added dropwise and the solution was stirred at 0![]() $ {}^{\circ}\mathrm{C} $ for 2 hr in ice bath.

$ {}^{\circ}\mathrm{C} $ for 2 hr in ice bath.

The insoluble and moisture-sensitive polymer composites were stored under protective atmosphere of argon (in glove box) and analyzed using different spectroscopic methods (as reported by Wang & Mera, Reference Wang and Mera2021) such as Fourier transform infrared (FTIR)-, Raman-, UV–Vis/NIR-, and photoluminescence (PL) spectroscopies.

4. Results and discussions

The covalent bonding between OLC phase and silicon diimide backbone is of critical importance for a good dispersion and avoidance of agglomeration of carbon phase as well as for a strong synergistic effect of both composing phases, resulting in an efficient interphase as well and a strong interfacial bond formation. Thus, methods such as FTIR (Figure 2a) and Raman (Figure 2b) spectroscopies provide details on the formation of amide bridges in-between OLC nanoparticles (of ˜5 nm in size as previously reported by Wang et al., Reference Wang, Mera, Morita and Ionescu2016) and the silicon atoms in the polymeric matrix (see Figure 1). UV–Vis and PL spectroscopies were applied in order to identify the electronic transitions due to defect luminescence mechanism in the composites (Farhan et al., Reference Farhan, Wang, Zhang and Li2017; Kozák et al., Reference Kozák, Sudolská, Pramanik, Cígler, Otyepka and Zbořil2016).

Figure 2. (a) Fourier transform infrared spectra (left) and (b) Raman spectra (right) of onion-like carbons (OLCs), functionalized OLCs, and OLCs-silicon diimide polymer composites with different contents of OLCs.

As observed in Figure 2b, the results support the modification of the surface of the OLCs by introducing surface functional carboxylic groups, leading to the formation of higher number of surface defects in the case of functionalized OLCs, as compared with pristine OLCs (Nguyen et al., Reference Nguyen, Nguyen, Phuong, Nguyen and Mai2011; Tripathi et al., Reference Tripathi, Bhati, Singh, Gupta, Verma, Sarkar and Sonkar2016). Silicon diimide is highly sensitive to moisture contamination. Short exposure to air results in the reaction of moisture with the Si-NH-Si units, thus forming siloxane and gaseous byproduct NH3. The reactive chlorine end-groups of silicon diimide react immediately with ammonia to form NH4Cl, as observed in Figure 2b (Vu et al., Reference Vu, Hodyss, Johnson and Choukroun2017). Besides -Cl end-groups, -Si(CH3)3 functionalities are also observed in the FTIR spectra of the composites.

According to FTIR- and UV–Vis/NIR-data, functionalized OLCs react with -HN-Si backbone, leading to the formation of expected amide (O〓C▬N<) interfacial bondings (Hetmann et al., Reference Hetmann, Wujak, Bolibok, Zięba, Wiśniewski and Roszek2018; Roguska et al., Reference Roguska, Pisarek, Andrzejczuk, Dolata, Lewandowska and Janik-Czachor2011). Thus, the presence of amide bridges underlines the covalent nature of the interface between OLCs and silicon diimide in the composites.

Rather few papers have been reported on the optical properties of silicon diimide polymers. It can be concluded from Figure 3 that the UV absorbance and the PL-quenching of OLCs-silicon diimide polymer composites depend on the content of functionalized OLCs. The reduction of PL peaks is likely due to the presence of defects in the composites (Kozák et al., Reference Kozák, Sudolská, Pramanik, Cígler, Otyepka and Zbořil2016). The Si and N dangling bonds in silicon diimide form a trap-level state and the recombination center participates in radiative transitions resulting in luminescence (Farhan et al., Reference Farhan, Wang, Zhang and Li2017). The presence of functionalized OLCs in OLCs-silicon diimide polymer composites creates new emissive deep traps, which act as luminescent trapping sites for the excitation energy, and affect the radiative e–h recombination processes by the relaxation-related spectral migration.

Figure 3. (a) UV–Vis/NIR spectra (left) and (b) PL emission spectra (right) of OLCs, functionalized onion-like carbons (OLCs) and OLCs-silicon diimide polymer composites with different contents of OLCs. All PL spectra were excited at the wavelength of 380 nm and with the excitation- and emission-slit of 10 nm. The insets show the PL emission spectra of OLCs, functionalized OLCs and the polymer composites with 1 and 2 wt% OLCs.

5. Conclusions

In conclusion, we presented a simple synthesis method for OLCs-silicon diimide composites with different contents of 0D nanocarbons, where the strong synergistic effect of the component phases is demonstrated by the PL study. Thus, chemically functionalized OLCs were successfully embedded by strong interfacial O〓C▬N< covalent bonds within the organosilicon polymer matrix. Due to their facile preparation method and promising properties, the polymer nanocomposites reported herein may be applied as suitable precursors for a novel class of “smart” 0D-nanocarbon–containing ceramic composites with custom-made structural features and multifunctional properties for various purposes, such as thermal management or environmental applications.

Authorship contributions

K.W. performed the experimental work, analyzed the data, and wrote the manuscript. G.M. mentored, designed the experiments, and edited and revised the manuscript.

Funding statement

This work was supported by the German Research Foundation DFG (Eigene Stelle, grant number IO 83/2-1).

Conflicts of interest

The authors declare no conflicts of interest.

Data availability statement

The data that support the findings of this study are available from the corresponding author, G.M., upon reasonable request.

Comments

Comments to the Author: Manuscript No. EXP-21-0016

Title: Chemical Design of Onion-like Carbon-Silicon Diimide Polymer Composites

Authors: Kaili Wanga and Gabriela Mera

The research article reported by Wanga and Mera presents a synthesis route for the synthesis of a polymer composite based on onion-like carbons (OLCs)-silicon diimide. The topic covered is interesting however the manuscript is poorly written, not structured logically, language needs improvement as most sentences are unfortunately written with poor English. This problem with the language makes it difficult to read, understand and review.

I have my suggestions listed below about this paper, and I, unfortunately, recommend it not to be published in its current form.

Abstract:

Article required to be re-written. For example in the following sentences taken from the abstract: “The preparative access to a novel class of polymer composites based on onion-like carbons (OLCs)-silicon diimide by a salt-free polycondensation reaction, it is reported. The pyridine-catalyzed polymerization reaction in the presence of various contents (0.1, 0.5, 1 and 2 wt. %) of carboxyl-functionalized OLCs in argon atmosphere, it provides composites with well-dispersed and covalently incorporated 0D nanocarbon throughout the 3D matrix of silicon diimide polymer”, it is difficult to understand what authors try to explain. The sentence in its current form does not make sense.

Introduction:

Same for another example is the first paragraph of the introduction, one can understand what authors try to tell, but the linguistic structure of the sentences is wrongly built:

“In the search for novel precursors for silicon nitride-based polymer-derived ceramic materials (Si 3 N 4 - PDCs) with high mechanical, thermal and electrical properties, several synthesis routes have been reported in the last 30 years”

In the following sentence, authors should clarify the term “strong covalent bonding”, covalent bonding between which components or molecules? what are the relationships between a stronger bond formation and a stronger interface as a result? Which interface do authors mean?

“Chemical functionalization of nanocarbons nanocarbon surfaces offers the possibility to of developing advanced polymer composites with strong covalent bonding (strong interface), and excellent dispersion of nanocarbon phase in the matrix (Ott et al., 2020; Mohamed et al., 2013).

Authors claimed as “Thus, classical challenge of agglomeration of nanocarbons in the polymer matrix can be solved.” Authors should put a stronger hypothesis in the introduction and put some more literature supporting their way should be added.

Objectives:

In the first sentence of the section “The main objective is to provide a chemical facile access to novel 0D-nanocarbon-containing Si 3 N 4-based PDCs precursors, based on onion-like carbons (OLCs) (Bartelmess and Giordani, 2014; Butsyk et al., 2019; Krüger, 2010; Kuznetsov et al., 1994; Mcdonough and Gogotsi, 2013; Mykhailiv et al., 2017; Plonska-Brzezinska, 2019; Zeiger et al., 2016) -silicon diimide polymer composites.” What do authors mean with “chemical facile access”? and “authors should either use 0D nanocarbon containing Si 3 N 4-based PDCs precursors or onion-like carbons -silicon diimide in one sentence.

In the objective section, the article hypothesis and sub-objectives/goals, reasons, should be discussed in detail, and methods of the article should be taken out from this section and put to methods section as authors re-presented them in the methods section.

Methods:

Materials and types of equipment should be listed pointing out the supplier and models. How do authors optimize the optimum reaction times and temperatures and concentrations?

Results and discussion

On page 5, authors claim that “As observed in Figure 2, the results support the modification of the surface of the OLCs by introducing surface functional carboxylic groups, leading to the formation of a higher amount of surface defects in the case of functionalized OLCs, in comparison with pristine OLCs”. How the results given in figure 2 can be interpreted as the sample has high amount of defects?

In the following sentence “According to Raman spectra in Figure 2b, the moisture contamination by the measurement in air may influence the rearrangements and further crosslinking of Si-Cl polymer end-groups and Si-NH-Si backbone leading to the formation of NH 4Cl”, it is difficult to understand what authors mean to discuss. A more explanatory discussion referring to the changes in RAMAN and FTIR spectra needed.

The authors also claimed as “The reduction of the PL peaks is likely due to defects present in the composites” Effect of decreased distance between nanoparticles due to increased concentration and covalent bonding on the PL quenching should also be taken into account.

The authors have not discussed the effect of OLC concentration on the formed composites.

Authors needed to show the particle size with DLS and TEM or SEM imaging together with the SEM images of the final composite produced.

Conclusions

As prepared materials are humidity sensitive, and thus, their further use needs attention. Do authors have any recommendations for ensuring the wider use of the as-prepared composites?