Introduction

Agrotechnology including especially mineral fertilization influences changes in the level of technological parameters of potato (Solanum tuberosum L.) tubers. Not all effects induced by basic fertilization are equally stable, some of them show significant interaction with years or varieties (Sharifi et al., Reference Sharifi, Zebarth B, Hajabbasi and Kalbasi2005; Doklega, Reference Doklega2017; Sarkar et al., Reference Sarkar, Banerjee, Chakraborty, Sau, Ray, Ghosh and Deb2018). Deficiency of one of the basic nutrients always results in a decrease in yield size and quality. It is also known that for the proper development of the potato it is necessary to provide the plant with micronutrients. Of the micronutrients, boron, zinc or manganese plays a particularly important role for the potato (Kozera et al., Reference Kozera, Nowak, Majcherczak and Barczak2006). However, selenium is also a micronutrient essential for most crop species. Properly nourished with this element, plants are more resistant to stresses, physiological and fungal diseases, so its effect is the same as that of biostimulant preparations (El-Ramad et al., Reference El-Ramad, Abdalla, Taha, Taha Alshaal, El-Henawy, Faizy, Shams, Youssef, Shalaby, Bayoumi, Elhawat, Shehata, Sztrik, Prokisch, Fári, Domokos-Szabolcsy, Pilon-Smits, Selmar, Haneklaus and Schnug2016; Perfileva et al., Reference Perfileva, Graskova, Sukhov and Krutovsk2022). Previous studies have also shown that the use of selenium in potato cultivation has a beneficial effect on the number and growth of sprouts (Turakainen et al., Reference Turakainen, Hartikainen and Seppänen2004). In Poland, the average selenium content in soils is 0.27 mg Se/kg in dry matter, which is lower than the world average of 0.33 mg Se/kg (Darecki et al., Reference Darecki, Saeid and Górecki2015). Agricultural intensification is contributing to even greater selenium deficiencies in soils.

At certain developmental stages of the potato, the demand for nutrients is so high that classical, topsoil fertilization is insufficient. In such cases, foliar application of fertilizers is a good practice. The main advantage of foliar feeding is the speed of action of the ingredients and the greater degree of their usage. By this method, only part of the macronutrients (nitrogen, magnesium, sulphur) can be supplied, while the need for micronutrients can be covered 100% (Liszka-Skoczylas, Reference Liszka-Skoczylas2020).

Nitrogen and potassium (in the chloride form), which are the most yield-forming for potatoes, usually have an adverse effect on the starch content of tubers (Kumar et al., Reference Kumar, Pandey, Singh, Singh and Kumar2007; Koch et al., Reference Koch, Naumann, Pawelzik, Gransee and Thiel2020). In contrast, phosphorus (Wszelaczyńska et al., Reference Wszelaczyńska, Pobereżny, Dudek, Kuśmierek-Tomaszewska, Żarski and Pawelzik2015; Leonel et al., Reference Leonel, Do Carmo, Fernandes, Soratto, Ebúrneo, Garcia and Dos Santos2017) and potassium in the sulphate form (Kumar et al., Reference Kumar, Pandey, Singh, Singh and Kumar2007; Abdel-Salam and Shams, Reference Abdel-Salam and Shams2012; Zhang et al., Reference Zhang, Liu, Wang, Zhang, Li, Song and Zhao2018) extremely positively modify its quality. In addition to the starch content of the tubers, the yield of potato starch is mainly determined by the size of its grains (Ratuszniak and Kubas, Reference Ratuszniak and Kubas2010). Potato starch, compared to the starch of cereal plants, is characterized by a wider spectrum of grain sizes of 5–110 μm (Liszka-Skoczylas, Reference Liszka-Skoczylas2020). In addition, its quality depends on such characteristics as glutinosity, starch stability, amylose and phosphorus content, and many often overlapping or interacting factors. These factors, in addition to fertilization, include soil properties and weather conditions during the potato growing season, as well as tuber size (Wszelaczyńska et al., Reference Wszelaczyńska, Pobereżny, Dudek, Kuśmierek-Tomaszewska, Żarski and Pawelzik2015; Meise et al., Reference Meise, Seddig, Uptmoor, Ordon and Schum2019; Khlestkin et al., Reference Khlestkin, Erst, Rozanova, Efimov and Khlestkina2020).

In order for potatoes to be available for the starch industry well beyond the time of harvest, they must be stored under appropriate conditions. For starchy potato during storage, it is required to maintain constant temperature and humidity conditions (Hunjek et al., Reference Hunjek, Pranjić, Repajić and Levaj2020; Pobereżny et al., Reference Pobereżny, Wszelaczyńska, Gościnna and Spychaj-Fabisiak2020) which allow to limit quantitative (natural losses) and qualitative (starch content) losses (Peivastegan et al., Reference Peivastegan, Hadizadeh, Nykyri, Nielsen, Somervuo, Sipari, Tran and Pirhonen2019). Varieties intended for starch production need to be stored at a constant temperature of +4°C and 95% relative humidity. Failure to maintain the required storage parameters may result in deterioration of tuber quality (Czerko and Grudzińska, Reference Czerko and Grudzińska2014; Alamar et al., Reference Alamar, Tosetti, Landahl, Bermejo and Terry2017; Krochmal-Marczak et al., Reference Krochmal-Marczak, Sawicka, Krzysztofik, Danilcenko and Jariene2020). In addition, the storage time of the potato can modify the quality characteristics of starch (Wszelaczyńska et al., Reference Wszelaczyńska, Pobereżny, Dudek, Kuśmierek-Tomaszewska, Żarski and Pawelzik2015; Niu et al., Reference Niu, Li X, Tang, Zhang, Li, Cui, Mikitzel and Haroon2019; Pobereżny et al., Reference Pobereżny, Wszelaczyńska, Gościnna and Spychaj-Fabisiak2020).

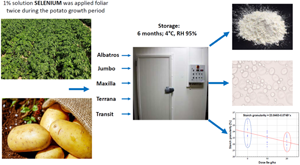

A study was undertaken to determine tuber yield, starch yield and quality traits of potato starch in relation to genetic conditions and foliar feeding of plants with selenium during cultivation. Tests were carried out directly after harvest and after 6 months of tubers storage.

Materials and methods

In 2018 and 2019, research was carried out at the Experimental Station in Mochełek (53°13′N, 17°51′E, 98.5 m a.s.l.) belonging to the Faculty of Agriculture and Biotechnology, Bydgoszcz University of Science and Technology (PBS) in Bydgoszcz, Poland. The field experiments with potato were established on lessive soil of fine-grained loamy sand, class IVa, good rye complex. Generally, a scientific experiment was set up on three factors: A – storage period (directly after harvest, after 6 months of storage), B – potato variety (‘Albatros’, ‘Jumbo’, ‘Maxilla’, ‘Terrana’, ‘Transit’), C – selenium fertilization (0, 10, 20 g Se/ha).

The soil before the experiment was characterized by a very high content of available phosphorus (P) (92.43 mg/kg), a medium content of potassium (K) (156.04 mg/kg) and a very low content of magnesium (Mg) (18.69 mg/kg) and was slightly acidic (pH 5.9 in 1 M KCl; PN-ISO 10390, 1997). The soil content of bioavailable forms of P was determined according to Egner–Riehm method (PN-R-04023, 1996b), K by Egner–Riehm method (PN-R-04022, 1996a) and Mg by Schatschabel method (PN-R-04020, 1994). The total organic carbon content was 24.31 g/kg.

The crop grown before potatoes was spring barley. Tillage operations were carried out in accordance with the requirements of optimal agrotechnology for potatoes.

Potatoes were planted between 20 and 30 April in each year. Potatoes were planted at a row spacing of 0.75 × 0.30 m. The size of the one plot for planting and harvesting was 30 m2 (3 m × 10 m). Total experiment area was 1350 m2. The number of plots was 45.

Mineral fertilizers were applied in the spring before planting, at the following rates: nitrogen – 120 kg N/ha, phosphorus – 52.3 kg P/ha, potassium – 132.8 kg K/ha. The field experiment was set up as a two-factor experiment in a randomized block design, in triplicate. The first-order factor was potato varieties [B], while the second-order factor was foliar fertilization with selenium (0, 10, 20 g Se/ha) [C].

Foliar fertilization with selenium (sodium selenite) was applied twice during the potato growth period: BBCH 40 – before flowering and BBCH 44 – after flowering (Hack et al., Reference Hack, Bleiholder, Buhr, Meier, Schnock-Fricke, Weber and Witzenberger1992). The concentration of each spray solution was 1 g Se/litre. Five starch potato varieties from seed potato producer NORIKA POLSKA S. A. were used in the study: Albatros (medium early), Jumbo (medium early), Maxilla (medium late), Terrana (very early), Transit (medium early).

Plants were harvested at full physiological potato maturity (depending on the earliness group). The very early cultivar was harvested on 25 July 2018 and 29 July 2019 (between 80 and 90 days after planting). The medium early cultivars were harvested on 10 September 2018 and 14 September 2019 (between 115 and 123 days after planting), while the medium late cultivar was harvested on 25 September 2018 and 28 September 2019 (between 130 and 138 days after planting). During harvest, the total tuber yield was determined. Additionally, starch yield was also determined based on product of total tuber yield and starch content. Samples were taken for analyses directly after harvest (10 kg) and for storage (10 kg) from each plot.

Before putting into three storage chambers (depending on the date of potatoes harvest) for 6 months tubers were weighed. Tuber samples were stored in openwork bags. Tuber trials of each variety were subjected to the curing process (preparatory period – 2 weeks). For this purpose, potato samples were placed in a storage chamber (Thermolux Chłodnictwo Klimatyzacja, Raszyn, Poland) where the air temperature was 15°C and relative air humidity was 90% for the first 14 days. During next 2 weeks the air temperature was gradually reduced to 4°C, 90% RH. Then, for the next 5 months constant conditions were maintained: 4°C and 95% RH (Czerko, Reference Czerko2011). The tubers were stored in 2 × 2 × 3.8 m polypropylene storage chamber (Thermolux Chłodnictwo Klimatyzacja) in the Institute of Agri-Foodstuff Commodity of the Bydgoszcz University of Science and Technology. The experimental chamber is fitted with an automatic temperature and humidity holding system. In addition, the chamber uses 20 mm-thick foam to stimulate environmental temperature and decrease heat loss. The storage experiment ended in mid-April.

• After 6 months of storage, the samples were evaluated for transpiration and respiration losses. Natural losses (NL) were calculated from the formula (Krzysztofik and Sułkowski, Reference Krzysztofik and Sułkowski2013) – Eqn (1):

Calculation:

NL, natural losses (%); WPS, sample weight before storage (g); WAS, sample weight after storage (g)

• After long-term storage, the starch yield was determined by taking into account the total yield of the tubers (immediately after harvest) and the natural losses and starch content of the tubers (after storage).

The scope of the analytical tests included the determination of:

• Starch content in the fresh weight (FW) of tubers by polarimetric Evers method (Zgórska, Reference Zgórska2001): 10 g of potato tissue was weighed into 100 ml volumetric flask. A total of 50 ml of 1.124% hydrochloric acid (Merck KGaA, Darmstadt, Germany) was then placed in the flask. The starch was hydrolysed in boiling water for 15 min. For the first 8 min, the flask was shaken in a horizontal orientation. After being cooled to room temperature, the suspension was purified by adding 6 ml of 4% Wolframatophosphoric acid (Roth, Germany). The flask was refilled to the mark with distilled water, and then the contents were filtered with filter paper no. 593 1/2 (Schleicher & Schuell, Germany). To determine the optical rotation of the solution containing the monosaccharide, a polarimeter (Krüuss, type P 1000, Germany) was used. The starch content of potato tubers was then calculated according to Biot's formula (Eqn (2)), assuming that the specific rotation of starch dissolved in HCl is 183.7°.

Calculation:

SC, starch content (weight k/kg); a, weight of analysed material (g); L, length of polarimeter tube (dm); α, measured rotation in degrees.

• Starch preparation by Pobereżny et al. (Reference Pobereżny, Wszelaczyńska, Gościnna and Spychaj-Fabisiak2020): A sample consisting 5 kg of potato tubers of similar size was taken for starch preparation. The potatoes were rinsed thoroughly with distilled water and cut into tiny fragments. The cubed sample was homogenized in a mixer with distilled water. The suspension was sequentially, twice, filtered through 300 and 150 μm metal strainers, passing most of the starch grains. The starch slurry was left for 2 h. Starch grains were retrieved from the extract by decanting. The remaining starch granules were sequentially washed thrice with water and then dried at 40°C (WAMED SUB-100, Warszawa, Poland) to a constant moisture content of less than 20%.

-

− Starch grain size according to Meredith (Reference Meredith1984): starch samples (0.2–1 g) were placed in a 50 ml Erlenmeyer flask. Then 20–30 ml of distilled water was added to the flask. The starch was then split into small- and large-grain fractions. The process was carried out using the method of sedimentation in water. After 5 min, the fraction of large potato starch grains was disposed and the fraction of small grains was disposed after a 90 min sedimentation period. Starch granulation (grain size distribution) was then defined with a Fritsh Analysette 22 laser analyser (Idar-Oberstein, Germany).

-

− Phosphorus content according to Noda et al. (Reference Noda, Tsuda, Mori, Takigawa, Matsuura-Endo, Saito, Hetti, Mangalika, Hanaoka, Suzuki and Yamauchi2004): To determine phosphorus content, starch samples were mineralized in a mixture of H2SO4 and H2O2. The process was carried out in an automatic Digest Automat K-438, K371 (BUCHI Labortechnik AG, Switzerland). Using a spectrophotometer (SHIMADZU UV-1800, UV Spectrophotometer System, Japan), the phosphorus content of starch was measured as inorganic phosphorus according to the ammonium-molybdenum method to further measure the phosphorus content of the starch samples. In total, 1 ml of mineralized starch sample, 2 ml of 20% Na2SO4, 2 ml of 2.78% (NH4)2MoO4 solution, 2–3 drops of 8.6% SnCl2 and 50 ml of distilled H2O were placed in a volumetric flask and kept for 30 min. Absorbance was measured at 660 nm. Chemical reagents were supplied by POCH, Gliwice, Poland.

-

− Full sticking temperature according to Standards Methods (1999): The quality of potato starch pasteurization as peak temperature was defined with the Rapid ViscoTM Analyser Super 3 (Newport Scientific Pty., Ltd., Australia). Before examination, the water content of the flour was measured. Two grams of flour were weighed in a dish and then moved to a test canister. In total, 25 g of water were then added to the canister. The canister was set up with a spatula and the equivalent moisture content of the weight of the sample and the weight of the water was adjusted.

-

Laboratory test were conducted in two replications.

The results obtained from the 2-year study were subjected to statistical calculations and significant differences were assessed using Tukey's multiple confidence intervals for a significance level of P < 0.05. The analysis of variance of the data was performed using Statistica 13.1 (StatSoft, Tulsa, OK, USA) software. Averages of results as well as standard deviation are shown in tables. The relationship between Se fertilization and potato starch quality traits was expressed by the equation regression method and shown in the figures. To obtain a synthetic picture of the overlapping relationships between the studied characteristics, a simple correlation analysis (Pearson's) was performed.

Results

Total yield, starch yield and natural tuber losses

Table 1 shows meteorological conditions during potato vegetation in the years of the study. The potato growing seasons in which the study was conducted were characterized by very unfavourable precipitation patterns. Relative to the multi-year period, these were dry years. In 2018, the average amount of precipitation was 71.5 mm lower compared to the multi-year period. In 2019, on the other hand, the amount of precipitation was 100 mm less from the beginning of April to the end of August. In 2019, June was exceptionally dry with a rainfall total of only 17.7 mm, which was the reason for the weaker vegetative growth of the potato. Plant condition was only improved by rainfall in July and August. On the other hand, the unfavourable September rainfall for potatoes in 2019 caused a delay in their maturation. The distribution of temperatures in the studied growing seasons was favourable for potato cultivation with a warm May in 2018 (the beginning of vegetation) and an extremely hot June in 2019. According to scientists from the Institute of Land Reclamation and Agrometeorology, PBS in Bydgoszcz, June 2019 was the warmest in the history of measurements in Mochełek (since 1949).

Table 1. Weather conditions in Mochełek (2018–2019)

The applied factors of the experiment significantly differentiated total tuber yield and potato starch yield (Tables 2 and 3). Of the five tested potato varieties regardless of the years and level of selenium fertilization, significantly the highest tuber yield and starch yield were: Maxilla – 44.7 and 9.03 Mg/ha and Albatros – 40.0 and 8.45 Mg/ha. On the other hand, significantly the lowest tuber yield was obtained by the cultivar Jumbo – 34.6 Mg/ha and starch yield by Terrana – 6.72 Mg/ha. The highest total and starch yields were achieved by potatoes after the application of 20 g Se/ha – an average of 39.4 and 7.94 Mg/ha, respectively. The highest natural losses after long-term storage of tubers were obtained by the Transit variety (5.0%), and the lowest losses were characterized by the Albatros variety (3.9%), with average losses for the five varieties at 4.4% (Table 2). A significant effect of foliar application of selenium during potato cultivation on the amount of natural losses was shown. The highest natural losses were obtained on the control object – 4.6% and the applied foliar selenium fertilization reduced these losses, with the most favourable dose of 20 g Se/ha – 4.3% (Table 2). After long-term storage, there was a significant reduction in starch yield – by an average of 6.5% (Table 3). Starch yield after storage significantly depended on the genetic determinants of the potato as it did immediately after harvest (Table 3). The results of our own research indicate the influence of the factors used during potato cultivation on the starch yield after storage. The highest starch yield was characterized by potatoes of varieties fertilized with 20 g Se/ha.

Table 2. Total tuber yield and natural losses of five potato cultivars depending on selenium (Se) fertilization (mean 2018–2019)

ns, non-significant; LSD, least significant difference.

a Directly after harvest.

b After 6 months storage.

Table 3. Starch yield and its content in the tubers of five potato cultivars depending on selenium (Se) fertilization and test date (mean 2018–2019)

DAH, directly after harvest; ASMS, after six months storage; CAS, change after storage; ns, non-significant; FW, fresh weight; LSD, least significant difference.

Starch content of the tubers

The starch content of the potato tubers studied significantly depended on genetic conditions (Table 3). The most starch was contained in tubers of the Albatros variety (average 211.3 g/kg) and the least in Terrana (average 182.3 g/kg). On the other hand, the applied differentiated foliar selenium fertilization significantly affected the increase of starch content in tubers regardless of genotype. In this regard, the most favourable was the dose of 20 g/ha at which tubers contained an average of 201.1 g/kg of starch. There was no significant effect of the evaluation date on the starch content of the tubers despite the fact that a reduction in its content by an average of 1.9% was obtained (Table 3). In addition, Se fertilization applied during the potato growing season reduced the loss of starch concentration (−1.7%) only at a rate of 20 g/ha.

Starch quality characteristics

The value of the proportion of large starch grains (Table 4) was significantly highest for the Maxilla variety – 24.5% (weighted average). In addition, it was shown that starch fractions with a size of >20 μm accounted for an average of 49.5% of the share of fractions with the smallest size. On the other hand, a significant positive effect of selenium biofortification at a dose of 20 g/ha was proven for starch fractions <20 μm (Table 5).

Table 4. Weighted average and change of starch granularity (%) of five potato cultivars depending on selenium (Se) fertilization and test date (mean 2018–2019)

Table 5. Starch granularity (%) of five potato cultivars depending on selenium (Se) fertilization and test date (mean 2018–2019)

DAH, directly after harvest; ASMS, after six months storage; ns, non-significant; LSD, least significant difference.

It should be noticed that the relationship of the proportion of individual fractions of starch granules changed after tuber storage. The fraction of starch grains above 60 μm decreased and those with dimensions <20 μm increased. The effect of selenium applied during potato vegetation on the size of starch granules in tubers after storage was the same as after harvest (Table 5).

The phosphoric acid content of starch is important for processing it into derived products including the production of dextrins and syrups and its high content is rather unfavourable (Hull, Reference Hull2010; Behr and Seidensticker, Reference Behr, Seidensticker, Behr and Seidensticker2020). The extreme values of total phosphorus content (Table 6), in the tested potato starch ranged from 233.2 mg P/kg for the variety Terrana unfertilized with Se to 551.2 mg P/kg ‘Maxilla’ fertilized foliarly with 20 g Se/ha. An increase in the content of phosphorus in starch after the application of selenium in the potato crop at a dose of 10 and 20 g/ha should also be noted (Table 6).

Table 6. Phosphorus content and starch full sticking temperature depending on the cultivar and selenium (Se) fertilization (mean 2018–2019)

DAH, directly after harvest; ASMS, after six months storage; CAS, change after storage; ns, non-significant; LSD, least significant difference.

In the conducted studies, there was no effect of long-term storage on the phosphorus content of starch, but there was a decreasing trend in this component by an average of 1.7% (Table 6). A much smaller decrease in phosphorus content after long-term storage of tubers was characterized by starch obtained from potatoes after fertilization with 20 g Se/ha. The influence of genetic conditions and applied selenium during potato cultivation on the phosphorus content of starch extracted from tubers after long-term storage has also been demonstrated (Table 6).

The starch extracted from tubers of the Maxilla variety had the highest average sticking temperature (69.9°C), while the Terrana variety had the lowest temperature (65.3°C). The research also showed that the sticking properties of starch were variable at different doses of applied selenium (Table 6). With increasing the dose of selenium fertilization, the sticking temperature of starch significantly increased. The highest sticking temperature was obtained when selenium was applied at a dose of 20 g Se/ha (Table 6). After long-term storage, there was only a tendency to increase the temperature of the sticking by an average of 0.9%, while after 6 months of tuber storage, the effect of genotype and selenium fertilization during potato cultivation on the starch sticking temperature was obtained (Table 6).

Discussion

There is consensus on the view that genotype determines most of the morphological characteristics of tubers. In the current study, total tuber yield and starch yield depended on the genetic determinants of the potato. In contrast, weather, soil and agrotechnical conditions can modify genetically determined traits (Camargo et al., Reference Camargo, Montoya, Córcoles and Ortega2015; Escuredo et al., Reference Escuredo, Seijo-Rodríguez, Rodríguez-Flores, Meno and Seijo2020; Wszelaczyńska et al., Reference Wszelaczyńska, Pobereżny, Kozera, Knapowski, Pawelzik and Spychaj-Fabisiak2020). The positive effect of foliar fertilization with macro- and micronutrients on total tuber yield and starch yield was observed by many researchers (Prośba-Bialczyk and Tajner-Czopek, Reference Prośba-Bialczyk and Tajner-Czopek2006; Trawczyński, Reference Trawczyński2006). Applying selenium foliarly at the highest dose resulted in maximum tuber yield and starch yield. The positive effect of foliar selenium feeding of potato is reported by Turakainen et al. (Reference Turakainen, Hartikainen and Seppänen2004) and Li et al. (Reference Li, Chen, Jiang, Hu, Xing and Du2023). Of a different opinion are Jůzl et al. (Reference Jůzl, Hlušek, Elzner and Lošak2007) and Zhang et al. (Reference Zhang, Zhao, Zhang, Zhang, Huang, Zhang and Liu2019), who, using foliar selenium fertilization, obtained the highest yields on control objects. Starch yield is predominantly determined by tuber yield, and agrotechnical factors affecting starch yield are all yield-modifying crop elements. Important agrotechnical factors determining starch yield include site selection, tillage, organic and mineral fertilization taking into account individual varietal requirements (Prośba-Białczyk, Reference Prośba-Białczyk2008; Pobereżny and Wszelaczynska, Reference Pobereżny and Wszelaczynska2011; Van Dingenen et al., Reference Van Dingenen, Hanzalova, Salem, Abel, Seibert, Giavalisco and Wahl2019). In addition, Trawczyński and Socha (Reference Trawczyński and Socha2006) report that in the cultivation of starch potato, the use of compound fertilizers with micronutrient additives is justified because it is cost-effective.

In current study, natural losses were obtained at a low level of no more than 5%. In contrast, Czerko and Jankowska (Reference Czerko and Jankowska2013) obtained natural losses of 8.5% after a long storage period. Wszelaczyńska and Poberezny (Reference Wszelaczyńska and Poberezny2011), Bhattacharjee et al. (Reference Bhattacharjee, Roy, Rahman, Haque and Rahima2014) and Alamar et al. (Reference Alamar, Tosetti, Landahl, Bermejo and Terry2017) claim that the increase in natural losses is directly proportional to the length of storage. In current research, differences in natural losses depended on the potato genotype. According to Jabłoński (Reference Jabłoński2006), varieties in which natural losses after the storage period – regardless of the influence of factors – do not exceed 12% show good storage life. In current study, selenium applied during potato cultivation reduced natural losses after long-term storage of tubers. As reported selenium affects the reduction of post-harvest losses of various horticultural crops (Puccinelli et al., Reference Puccinelli, Malorgio and Pezzarossa2017). On the other hand, according to the authors (Zarzecka et al., Reference Zarzecka, Gugała, Mystkowska and Sikorska2021) the amount of starch yield after storage is largely determined by natural losses. The current research also confirmed such a relationship (P < 0.05) (Table 7). In this study, the starch content of the tubers was obtained, which depended on the potato variety. This is confirmed by Zimnoch-Guzowska and Flis (Reference Zimnoch-Guzowska and Flis2006). According to Turakainen et al. (Reference Turakainen, Hartikainen and Seppänen2004) and Owusu-Sekyere et al. (Reference Owusu-Sekyere, Kontturi, Hajiboland, Rahmat, Aliasgharzad, Hartikainen and Seppänen2013) foliar fertilization with selenium increases the carbohydrate content of tubers. In addition, as reported by Prośba-Białczyk (Reference Prośba-Białczyk2008), foliar feeding with micronutrients, positively affects the health of plants, which has a positive effect on yield levels and starch content and yield. Meanwhile, in current research, the application of selenium at the highest dose significantly increased the starch content of the tubers. Many authors (Siddiqui et al., Reference Siddiqui, Ahmed, Phogat and Ochubiojo Emeje2021; Taufique et al., Reference Taufique, Nishizawa, Roy, Meiko, Chakraborty, Mostofa and Nara2021) have reported a reduction in the starch content of tubers after storage. This is confirmed by the results in the current work. On the other hand, the most favourable effect in this regard was the application of Se at a rate of 20 g/ha during potato cultivation. In addition, Wszelaczyńska and Poberezny (Reference Wszelaczyńska and Poberezny2011) pointed out that the reduction of starch content after storage is affected by storage time. The authors while storing potatoes observed higher losses of starch contents in tubers after 6 months compared to 3 months.

Table 7. Pearson's rank order correlation coefficients (r) for the parameters of yield tubers and starch quality (P ≤ 0.05 and 0.01)

ns, non-significant; YPT, total yield potato tubers; YS, yield starch; SC, starch content in tubers; SG, starch granularity; PTOT, phosphorus total content in starch; GT, gelatinization temperature of starch; NL, natural losses.

Starch is a natural polysaccharide that occurs in the form of grains with a large variation in shape and size (5–110 μm) and this is a varietal trait (Singh et al., Reference Singh, Singh, Kaur, Sodhi and Gill2003; Talja et al., Reference Talja, Peura, Serimaa and Jouppila2008; Wszelaczyńska et al., Reference Wszelaczyńska, Pobereżny, Dudek, Kuśmierek-Tomaszewska, Żarski and Pawelzik2015). The conducted studies showed a large variation in starch granularity depending on genetic conditions, which is in line with the results obtained by Šimková et al. (Reference Šimková, Lachman, Hamouz and Vokál2013) and Romano et al. (Reference Romano, Masi, Aversano, Carucci, Palomba and Carputo2018). Grain size determines the technological suitability of starch. Large starch grains differ in physical properties and chemical composition compared to small ones (Noda et al., Reference Noda, Takigawa, Matsuura-Endo, Kim, Hashimoto, Yamauchi and Takeda2005; Dupuis and Liu, Reference Dupuis and Liu2019). According to Kozera et al. (Reference Kozera, Nowak, Majcherczak and Barczak2006) application of micronutrient fertilization mobilizes plants for more intensive biochemical transformations, resulting in an increased proportion of large starch grains. In contrast, this study achieved an increase in the proportion of starch grains for the 0–20, 20.1–40 and 40.1–60 μm fractions. Potatoes require storage at appropriate temperatures throughout the year, but there are very few studies on changes in starch granule size during storage (Niu et al., Reference Niu, Li X, Tang, Zhang, Li, Cui, Mikitzel and Haroon2019). Long-term storage of potato tubers under constant conditions (4°C, 95% RH) generally reduced the number of granules slightly by 2.8% (Table 4). In addition, it should be noted that the size of starch grains of >60 μm has decreased. The results of current study confirm the results obtained by Sabiniano et al. (Reference Sabiniano, Ishibashi and Hironaka1995), according to which, during storage of tubers at low temperatures, granules of the largest size are decomposed into smaller ones.

The extent of the effect of natural environmental conditions and potato varietal characteristics on the phosphorus content of starch has been studied by many authors (Leonel et al., Reference Leonel, Do Carmo, Fernandes, Soratto, Ebúrneo, Garcia and Dos Santos2017; Zhang et al., Reference Zhang, Liu, Wang, Zhang, Li, Song and Zhao2018), but no consistent results were obtained. Noda et al. (Reference Noda, Tsuda, Mori, Takigawa, Matsuura-Endo, Saito, Hetti, Mangalika, Hanaoka, Suzuki and Yamauchi2004), Tsakama et al. (Reference Tsakama, Mwangwela, Manani and Mahungu2011) and Wszelaczyńska et al. (Reference Wszelaczyńska, Pobereżny, Dudek, Kuśmierek-Tomaszewska, Żarski and Pawelzik2015) determined the phosphorus content of potato starch to be higher than in current studies (Table 6), respectively: 579 and 981 mg/kg. However, it should be noted that the above-mentioned authors used different varieties and technologies in the cultivation of starch potato. On the other hand, according to the authors (Noda et al., Reference Noda, Tsuda, Mori, Takigawa, Matsuura-Endo, Saito, Hetti, Mangalika, Hanaoka, Suzuki and Yamauchi2004), the phosphorus content of starch depends not only on genetic conditions but also on the date of harvesting the potato. In potato starch, phosphorus occurs in the form of orthophosphoric acid, and is mainly found in amylopectin and is bound in the ester form. Potato starch is also known to contain more phosphorus compared to starch extracted from other plant species (Domene-López et al., Reference Domene-López, Delgado-Marín, Martin-Gullon, García-Quesada and Montalbán2019). In addition, a decrease in the phosphorus content of the starch obtained from the tubers after 6 months of storage was obtained in current study (Table 6). The effect of storage time on phosphorus content in starch was also studied by other authors (Neeraj et al., Reference Neeraj, Siddiqui, Srivastva, Bindu and Pathera2023). In the study of Neeraj et al. (Reference Neeraj, Siddiqui, Srivastva, Bindu and Pathera2023), a 33.7% increase in phosphorus content in starch was obtained after 120 days of tuber storage. The authors (Neeraj et al., Reference Neeraj, Siddiqui, Dalal, Srivastva and Pathera2021) report that the increase in phosphorus content in starch is due to an increase in dry matter content. Since phosphorus is one of the main mineral components of starch (Noda et al., Reference Noda, Takigawa, Matsuura-Endo, Kim, Hashimoto, Yamauchi and Takeda2005) then an increase in ash content indicates an increase in phosphorus content. In contrast, in current study, the decrease in phosphorus content in starch may be due to a decrease in starch content (the main component of dry matter) in the tubers after storage. This is confirmed by the significant positive correlation coefficient (P < 0.01) after storage (Table 7). In addition, as noted by Neeraj et al. (Reference Neeraj, Siddiqui, Dalal, Srivastva and Pathera2021), the phosphorus content of starch also depends on the starch extraction method used.

Due to its glutinizing properties, starch is used in the food industry as a gelling agent (Jiang et al., Reference Jiang, Gao, Li, Wang, Xia and Xiao2012). The temperature range of the glutination process, as well as its character, depends on the type and moisture content of the starch (Singh et al., Reference Singh, Singh, Kaur, Sodhi and Gill2003; Talja et al., Reference Talja, Peura, Serimaa and Jouppila2008; Tsakama et al., Reference Tsakama, Mwangwela, Manani and Mahungu2011). Our own research clearly showed that the range of starch glutination temperature significantly depended on the genetic conditions of the potato (Table 6). Similar results were obtained by Karim et al. (Reference Karim, Toon, Lee, Ong, Fazilah and Noda2007) and Pobereżny et al. (Reference Pobereżny, Wszelaczyńska, Wichrowska, Żary-Sikorska, Knapowski, Mozolewski and Pomianowski2015) in their study, which proved a significant effect of genotype on the amount of potato starch sticking temperature. A study by Karim et al. (Reference Karim, Toon, Lee, Ong, Fazilah and Noda2007) obtained a range of potato starch sticking temperatures for six varieties in the range of 66.2–68.7°C and Pobereżny et al. (Reference Pobereżny, Wszelaczyńska, Wichrowska, Żary-Sikorska, Knapowski, Mozolewski and Pomianowski2015) studying three varieties obtained 64.4–65.2°C. In contrast, in the current work, the range of starch gelation temperature was 64.2–71.2°C. In addition, it should be noted that the starch gelation temperature increased after long-term storage of tubers. The obtained increase in starch sticking temperature after tuber storage is the result of an increase in the proportion of the fraction of grains with the smallest size. This is because it is known (Nowakowska and Sucharzewska, Reference Nowakowska and Sucharzewska2002; Liszka-Skoczylas, Reference Liszka-Skoczylas2020; Xu et al., Reference Xu, Zhang, Liu, Liu, Wang, Zhang, Hu and Blecker2021) that the glutination process of smaller grains occurs at higher temperatures. In current study, such a relationship is confirmed by the positive coefficients obtained (P < 0.01 and 0.05) between the temperature of glutination and the fractions of starch grains 0–20 and 20.1–40 μm (Table 7). In addition, a significantly positive relationship between phosphorus content and the temperature of glutination was proven (P < 0.01 and 0.05). The obtained lower correlation of starch quality traits after tuber storage r = 0.654 (Table 7), compared to the evaluation immediately after harvesting, is the result of a decrease in phosphorus content in starch after long-term storage. According to Lu et al. (Reference Lu, Yada, Liu, Bizimungu, Murphy, de Koeyer, Li and Pinhero2011), an increase in phosphorus content results in less resistance of starch to heating. During starch glutination, phosphate groups become ionized and the polymer molecule assumes a negative charge. This results in a conformational change of the amylopectin molecules, which are more soluble (Lu et al., Reference Lu, Yada, Liu, Bizimungu, Murphy, de Koeyer, Li and Pinhero2011; Leonel et al., Reference Leonel, Carmo, Fernandes, Franco and Soratto2016).

In this study, a significant effect of foliar selenium fertilization on the amount of potato starch sticking temperature was also obtained. After the application of selenium, the temperature of starch sticking increased. Fertilization also affects the size of starch granules and, consequently, the sticking temperature (Eburneo et al., Reference Eburneo, Garcia, dos Santos, de Souza, Soratto, Fernandes and Leonel2018; Liszka-Skoczylas, Reference Liszka-Skoczylas2020). Different glutination temperatures at different levels of selenium fertilization may also be due to differences in starch granule size (Leszczyński, Reference Leszczyński1994). Different sticking temperatures at different selenium doses indicate that the amount of selenium affects the formation of amorphous and crystalline areas of starch. A higher sticking temperature can result in more stable amorphous regions and more ordered crystalline structures in starch. According to Zhu et al. (Reference Zhu, Zhang, Guo, Xu, Dai, Wei, Zhou and Huo2017), the application of higher doses of nitrogen fertilization results in a decrease in the sticking temperature of rice starch. On the other hand, the starch obtained from rice is characterized by smaller starch grain size compared to potato starch.

Conclusion

The highest tuber yield and starch yield were obtained by the Maxilla variety. On the other hand, the Albatros variety had the highest starch content. Increasing doses of selenium fertilization had a significantly positive effect on the increase in total starch yield, starch content and its quality parameters. At dose 20 g Se/ha, the highest grain size, sticking temperature and the highest content of total phosphorus in starch were obtained.

After long-term storage, natural losses were obtained at a low level. In addition, a reduction in starch content and quality parameters was obtained.

Acknowledgements

The authors would like to thank the Faculty of Agriculture and Biotechnology, Bydgoszcz University of Science and Technology, for their support in this research work.

Author contributions

J. P., E. W., K. R., E. T., L. D.: conceptualization, data curation, methodology, validation, formal analysis, investigation, writing – original draft, writing – review and editing, project administration.

Funding statement

This research received no specific grant from any funding agency, commercial or not-for-profit sectors.

Competing interests

None.

Ethical standards

Not applicable.