In the original publication of Coleman (Reference Coleman, Stead, Bigter, Xu, Johnson, Broker, Sukkarieh and Walsh2019), the reported tillage parameters and implement definition for the rotary hoe were based on a power take off (PTO)-driven cultivator; however, the presented energy consumption calculations were for the ground-driven implement. The name rotary hoe is used for two significantly different implements: i) a PTO-driven cultivator commonly used in the UK and Australia for aggressive soil disturbance with slow work rates, and ii) a ground-driven implement used for shallow cultivation in the US with high work rates.

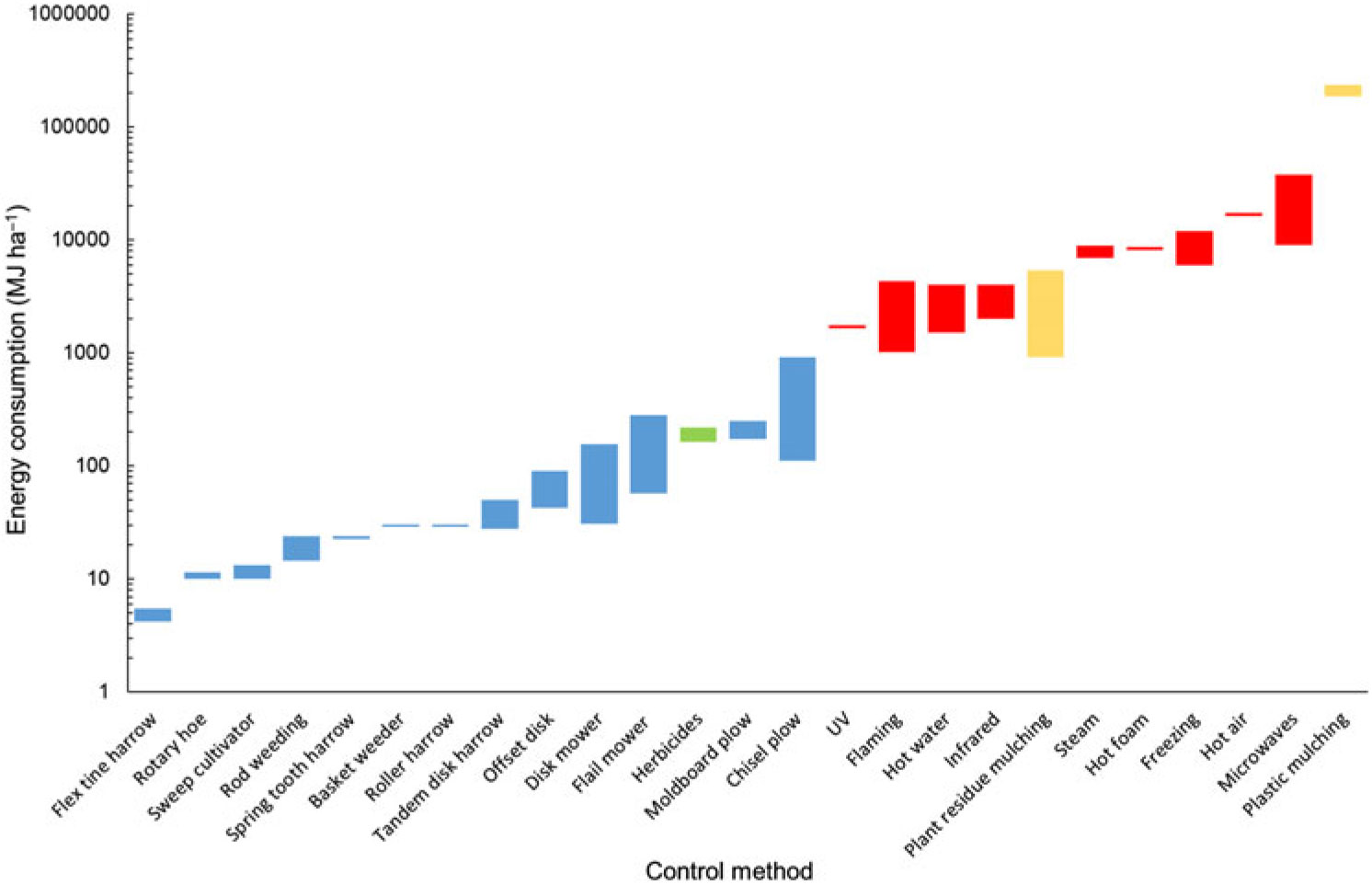

The direct energy estimate of 8 to 10 MJ ha−1 was calculated using parameters provided for the US definition of the rotary hoe in Bowman (Reference Bowman1997) and ASAE (2000), with a cultivation depth of 2 to 5 cm and a forward speed of 14 to 16 km h−1. The draft force figure provided in ASAE (2000) of 600 N m−1 relied on for energy estimates is correct; however, an additional PTO energy consumption of 2 to 4 MJ ha−1 was incorrectly included. The implement does not require any external rotational power, so the inclusion of this energy is incorrect. The correct direct energy consumption per hectare is 6 MJ ha−1. The indirect energy associated with rotary hoe tiller surface wear rates of 15 to 158 g ha−1 was based on a PTO-driven implement (Caslli et al. Reference Caslli, Hasanaj and Dimo2017). This value has been updated to match other ground-driven implements with wear rates of 30 to 96 g ha−1 (0.6 to 1.9 MJ ha−1). Energy associated with the transport of the implement (3.5 MJ ha−1) remains unchanged with similar reported equipment masses. The updated total estimated energy consumption range of 10 to 11 MJ ha−1 has been included in Figure 3, whereby the rotary hoe now sits below the sweep cultivator, based on average energy consumption. The rotary hoe entry from Table 3 has been revised to reflect the corrected direct and indirect energy consumption estimates.

The correct definition of the rotary hoe to match the energy estimation assumptions is a ground-driven implement, featuring curved steel fingers that uproot weeds by rapidly lifting the top 2 to 5 cm of soil. The curved steel fingers are mounted on a flexible, spring arm enabling fast movement over large fields, with the ground-driven wheels typically measuring 45 to 53 cm in diameter.

The authors apologize for this error.

Figure 3. Total energy requirement estimates for mechanical (blue), herbicidal (green), mulch (yellow), and thermal (red) broadcast weed control methods when used to target 2-leaf-stage seedlings at a density of 5 plants m−2. Bar length represents the range of energy consumption values estimated.

Table 3. Corrected summary of direct and indirect energy consumption for the ground-driven rotary hoe. References provided cover efficacy of control option and/or estimations for energy consumed including variables used in draft force and energy for transport calculations.

a Hatzenbichler Rotary Hoe (Hatzenbichler 2019)