1. Introduction

When the temperature varies along the interface between two immiscible fluids, the thermocapillary effect generates a tangential shear stress that drives a motion in both fluids. This effect is important in many systems such as welding (Mills et al. Reference Mills, Keene, Brooks and Shirali1998) or crystal growth from the melt (Hurle Reference Hurle1994). Crystals grown by the floating-zone technique (Pfann Reference Pfann1962) can exhibit impurity inhomogeneities caused by the onset of a time-dependent flow in the opaque melt. To understand the underlying physics, the model problem of a liquid bridge between coaxial cylindrical solid support rods has been devised. The original full-zone problem in which the cylinder-like free surface is heated symmetrically with respect to the equator (Chang & Wilcox Reference Chang and Wilcox1975) was further simplified to a half-zone problem (Schwabe et al. Reference Schwabe, Scharmann, Preisser and Oeder1978). In the half-zone problem, which is more amenable to experimentation, the liquid bridge is differentially heated via the support rods. A sketch is shown in figure 1. Basic numerical models assuming a fixed cylindrical interface were able to qualitatively predict the instability of the steady axisymmetric basic flow. For low Prandtl numbers, the first instability is inertial and leads to a steady three-dimensional flow (Levenstam & Amberg Reference Levenstam and Amberg1995; Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995), while for high Prandtl numbers, the first instability arises as a pair of azimuthally travelling hydrothermal waves (Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995), first discovered for plane layers by Smith & Davis (Reference Smith and Davis1983a). Parallel to numerical investigations, experiments have been carried out, mainly for transparent high-Prandtl-number liquids. By today, the half-zone problem, or the thermocapillary liquid bridge, has become the most important paradigm for thermocapillary convection (Kuhlmann Reference Kuhlmann1999). The thermocapillary Reynolds number ![]() ${Re}$, which is proportional to the total variation of the surface tension along the interface, is the most important parameter measuring the strength of the flow. It is thus suitable to characterise the low-Prandtl-number inertial instabilities, whereas the hydrothermal-wave instabilities at large Prandtl numbers are best characterised by the Marangoni number

${Re}$, which is proportional to the total variation of the surface tension along the interface, is the most important parameter measuring the strength of the flow. It is thus suitable to characterise the low-Prandtl-number inertial instabilities, whereas the hydrothermal-wave instabilities at large Prandtl numbers are best characterised by the Marangoni number ![]() ${Ma}={Pr}{Re}$.

${Ma}={Pr}{Re}$.

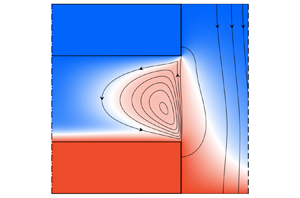

Figure 1. Schematic of a differentially heated liquid bridge (cyan) with a deformed interface ![]() $h(z)$ between the support rods (both with the same radius

$h(z)$ between the support rods (both with the same radius ![]() $r_{i}$ and length

$r_{i}$ and length ![]() $d_{rod}$) which are concentrically mounted in a tube (radius

$d_{rod}$) which are concentrically mounted in a tube (radius ![]() $r_{o}$, grey, hatched). The sketch shows the situation when the liquid is heated from above (

$r_{o}$, grey, hatched). The sketch shows the situation when the liquid is heated from above (![]() $T_{top}>T_{bottom}$, red) and an imposed gas flow (bright blue) with velocity profile

$T_{top}>T_{bottom}$, red) and an imposed gas flow (bright blue) with velocity profile ![]() $w_{g}(r)$ enters the annular region from below with a temperature

$w_{g}(r)$ enters the annular region from below with a temperature ![]() $T_{bottom}$ (blue). The polar coordinate system is centred in the liquid bridge and the gravity vector is always directed in the negative

$T_{bottom}$ (blue). The polar coordinate system is centred in the liquid bridge and the gravity vector is always directed in the negative ![]() $z$ direction.

$z$ direction.

Some features of real experiments have been very difficult to implement in numerical analyses. These are the dynamics of the free surface and the heat (and mass) transfer across it. The importance of the heat transfer for the critical Reynolds number has been pointed out by Kamotani et al. (Reference Kamotani, Wang, Hatta, Wang and Yoda2003). Its significance is also reflected by the scatter of critical Reynolds numbers for the onset of hydrothermal waves in high-Prandtl-number liquid bridges obtained in different experiments and by different investigators. The sensitivity with respect to the thermal conditions in the ambient atmosphere has been proposed to be utilised for controlling the onset of oscillations by exposing the liquid bridge to a well-defined gas flow (Yasnou, Mialdun & Shevtsova Reference Yasnou, Mialdun and Shevtsova2012). This problem has also been the subject of the Japanese–European Research and Experiments on Marangoni Instability (JEREMI) collaboration which was aimed at an experiment on the International Space Station (Shevtsova et al. Reference Shevtsova, Gaponenko, Kuhlmann, Lappa, Lukasser, Matsumoto, Mialdun, Montanero, Nishino and Ueno2014).

In early numerical investigations, the heat transfer across the interface has been treated by Newton's law of cooling (Neitzel et al. Reference Neitzel, Chang, Jankowski and Mittelmann1992; Kuhlmann & Rath Reference Kuhlmann and Rath1993). Even for an adiabatic-free surface, this model was successful in qualitatively describing the instability and its mechanism (Wanschura, Kuhlmann & Rath Reference Wanschura, Kuhlmann and Rath1997). Melnikov & Shevtsova (Reference Melnikov and Shevtsova2014) calculated the critical Marangoni number for the onset of hydrothermal waves for different variants of Newton's law. They tested models using different ambient reference temperatures: (a) the temperature of the hot wall, (b) the temperature of the cold wall and (c) an ambient temperature linearly depending on the axial coordinate. The critical Marangoni numbers as a function of the Biot number strongly depended on the heat transfer model used because neither the heat transfer coefficient for an assumed environmental reference temperature is known nor does Newton's law correctly capture the spatial dependence of the local heat transfer rate.

The sensitivity of the critical conditions on the unknown model parameters thus calls for a more accurate treatment of the problem by including the flow in the gas phase into the analysis. The present work is intended to understand how a gas flow affects the critical Reynolds number and the instability mechanism. To that end a numerical linear stability analysis of the axisymmetric steady basic two-phase flow is carried out. In addition, the influence of the dynamic deformability of the liquid–gas interface on the critical conditions is studied.

1.1. Axisymmetric two-phase flow

The typical set-up enabling a better control of the heat transfer is to mount the liquid bridge inside of a concentric shield cylinder (Preisser, Schwabe & Scharmann Reference Preisser, Schwabe and Scharmann1983). However, even if the shield cylinder is closed, sealing the gas phase, the critical Marangoni number and the modal structure depend on the wall temperature of the shield cylinder (Yano et al. Reference Yano, Nishino, Ueno, Matsumoto and Kamotani2017). For high-Prandtl-number liquids, Romanò & Kuhlmann (Reference Romanò and Kuhlmann2019) demonstrated the strong dependence of the local interfacial heat flux density on the axial coordinate. Moreover, by carrying out a large number of calculations of the steady axisymmetric thermocapillary flow in the presence of the surrounding gas, being confined to an adiabatic sealed cylindrical container, they developed fit functions for the true local interfacial heat flux valid for a wide range of Reynolds numbers and height-to-radius ratios of the liquid bridge (aspect ratio ![]() $\varGamma$). The fit function can be implemented in a single-fluid model using Newton's law with a space-dependent Biot function. This approach promises a significant reduction of the numerical effort as compared with the two-phase approach, while the thermal conditions are accurately represented.

$\varGamma$). The fit function can be implemented in a single-fluid model using Newton's law with a space-dependent Biot function. This approach promises a significant reduction of the numerical effort as compared with the two-phase approach, while the thermal conditions are accurately represented.

When the shield tube has open ends, the liquid bridge can be exposed to a defined gas flow without swirl, which has the same temperature at the inlet as the adjacent support rod. In this case, the radius ratio ![]() $\eta =r_{o}/r_{i}$ (figure 1) becomes important: for large

$\eta =r_{o}/r_{i}$ (figure 1) becomes important: for large ![]() $\eta$, viscous stresses exerted on the interface by the gas flow are small and may be negligible. In this case, the effect of the gas flow on the liquid flow is mainly thermal. If, on the other hand, the air gap

$\eta$, viscous stresses exerted on the interface by the gas flow are small and may be negligible. In this case, the effect of the gas flow on the liquid flow is mainly thermal. If, on the other hand, the air gap ![]() $\eta -1$ is small, viscous stresses become important and may even dominate.

$\eta -1$ is small, viscous stresses become important and may even dominate.

Gaponenko, Mialdun & Shevtsova (Reference Gaponenko, Mialdun and Shevtsova2012) investigated the effect of viscous stresses from the gas flow experimentally and numerically by considering the isothermal problem in which a toroidal vortex is solely driven by a gas flow through a relatively narrow annular gap with ![]() $\eta =1.\bar 6$. Depending on the strength of the gas flow, they found the axisymmetric toroidal vortex slightly displaced. Furthermore, when the dynamic viscosity of the liquid is more than 100 times that of the gas, the strength of the vortex scales linearly with the gas flow Reynolds number

$\eta =1.\bar 6$. Depending on the strength of the gas flow, they found the axisymmetric toroidal vortex slightly displaced. Furthermore, when the dynamic viscosity of the liquid is more than 100 times that of the gas, the strength of the vortex scales linearly with the gas flow Reynolds number ![]() ${Re}_{g}'$, based on the mean gas velocity and twice the width of the air gap. Similar results were reported by Gaponenko, Miadlun & Shevtsova (Reference Gaponenko, Miadlun and Shevtsova2011b). Gaponenko et al. (Reference Gaponenko, Glockner, Mialdun and Shevtsova2011a) used the same isothermal set-up, but concentrated on the effect of the gas flow on the shape of the liquid bridge. For all cases considered, the gas-flow-induced deformation of the liquid bridge was much smaller than that due to the hydrostatic pressure difference.

${Re}_{g}'$, based on the mean gas velocity and twice the width of the air gap. Similar results were reported by Gaponenko, Miadlun & Shevtsova (Reference Gaponenko, Miadlun and Shevtsova2011b). Gaponenko et al. (Reference Gaponenko, Glockner, Mialdun and Shevtsova2011a) used the same isothermal set-up, but concentrated on the effect of the gas flow on the shape of the liquid bridge. For all cases considered, the gas-flow-induced deformation of the liquid bridge was much smaller than that due to the hydrostatic pressure difference.

The same set-up, but now with differentially heated support cylinders to include the thermocapillary effect, was considered by Shevtsova, Gaponenko & Nepomnyashchy (Reference Shevtsova, Gaponenko and Nepomnyashchy2013). Using Fluent, they numerically simulated the axisymmetric flow in liquid bridges made from n-decane and 5-cSt silicone oil in air, which had a temperature identical to the upstream support rod. For a tight gap with ![]() $\eta =1.\bar 6$,

$\eta =1.\bar 6$, ![]() ${Re}_{g}' \gtrsim 100$ and a liquid bridge with an indeformable interface and twice as long as its radius, the strength and structure of the flow in the liquid are strongly affected by viscous stresses from the gas, even leading to multiple flow separations on the interface such that the surface flow is locally directed opposite to the thermocapillary stress. Furthermore, they found axisymmetric instabilities for high gas flow rates, leading to a time-dependent flow. When the air comes from the cold side, the axisymmetric waves propagate to the cold side, i.e. upstream of the gas flow. Even though the mechanical shear stress was large, the waves were interpreted as being due to a modification of the Pearson mechanism (Pearson Reference Pearson1958), because the gas is cooling the interface, potentially leading to Marangoni rolls superimposed to the basic flow which could be advected by the basic surface flow. Part of these results have been published earlier by Gaponenko & Shevtsova (Reference Gaponenko and Shevtsova2012). Gaponenko, Nepomnyashchy & Shevtsova (Reference Gaponenko, Nepomnyashchy and Shevtsova2011c) also reported similar results.

${Re}_{g}' \gtrsim 100$ and a liquid bridge with an indeformable interface and twice as long as its radius, the strength and structure of the flow in the liquid are strongly affected by viscous stresses from the gas, even leading to multiple flow separations on the interface such that the surface flow is locally directed opposite to the thermocapillary stress. Furthermore, they found axisymmetric instabilities for high gas flow rates, leading to a time-dependent flow. When the air comes from the cold side, the axisymmetric waves propagate to the cold side, i.e. upstream of the gas flow. Even though the mechanical shear stress was large, the waves were interpreted as being due to a modification of the Pearson mechanism (Pearson Reference Pearson1958), because the gas is cooling the interface, potentially leading to Marangoni rolls superimposed to the basic flow which could be advected by the basic surface flow. Part of these results have been published earlier by Gaponenko & Shevtsova (Reference Gaponenko and Shevtsova2012). Gaponenko, Nepomnyashchy & Shevtsova (Reference Gaponenko, Nepomnyashchy and Shevtsova2011c) also reported similar results.

In their numerical study using STAR-CCM+, Yano & Nishino (Reference Yano and Nishino2020) considered the axisymmetric flow in a thermocapillary liquid bridge for a moderately wide gap with ![]() ${\eta =3}$. The gas at the inlet had the same temperature as the adjacent support rod. They found viscous stresses have a negligible effect on the flow in the liquid. But the flow direction and the temperature of the shield cylinder (which was varied) had a strong influence on the interfacial heat transfer and thus on the flow, even deep inside of the liquid.

${\eta =3}$. The gas at the inlet had the same temperature as the adjacent support rod. They found viscous stresses have a negligible effect on the flow in the liquid. But the flow direction and the temperature of the shield cylinder (which was varied) had a strong influence on the interfacial heat transfer and thus on the flow, even deep inside of the liquid.

1.2. Instability of the axisymmetric two-phase flow

In one of the first experimental investigations of the effect of an axial gas flow on the onset of hydrothermal waves, Ueno, Kawazoe & Enomoto (Reference Ueno, Kawazoe and Enomoto2010) used a 2-cSt liquid bridge heated from above in air with a shield tube of ![]() $\eta =5$ and a gas temperature equal to the temperature of the support rod upstream of the airflow. They found a significant and almost linear dependence of the critical parameters on the mean gas flow rate measured by the gas flow Reynolds number

$\eta =5$ and a gas temperature equal to the temperature of the support rod upstream of the airflow. They found a significant and almost linear dependence of the critical parameters on the mean gas flow rate measured by the gas flow Reynolds number ![]() ${Re}_{g}'\in [-100,100]$. For the wide air gap used, the change of the critical onset is mainly due to thermal effects, because the gas temperature differs from that of the surface of the liquid. For the same wide air gap, Yano et al. (Reference Yano, Maruyama, Matsunaga and Nishino2016) carried out experiments with liquid bridges heated from above under a weak airflow and an air temperature as in Ueno et al. (Reference Ueno, Kawazoe and Enomoto2010). The temperature of the cylindrical shield was kept constant. Likewise, the critical Marangoni numbers depended sensitively on the gas flow rate. The critical Marangoni numbers

${Re}_{g}'\in [-100,100]$. For the wide air gap used, the change of the critical onset is mainly due to thermal effects, because the gas temperature differs from that of the surface of the liquid. For the same wide air gap, Yano et al. (Reference Yano, Maruyama, Matsunaga and Nishino2016) carried out experiments with liquid bridges heated from above under a weak airflow and an air temperature as in Ueno et al. (Reference Ueno, Kawazoe and Enomoto2010). The temperature of the cylindrical shield was kept constant. Likewise, the critical Marangoni numbers depended sensitively on the gas flow rate. The critical Marangoni numbers ![]() ${Ma}_c$ obtained could be well correlated by the normalised total heat flux through the interface, which was obtained by numerically computing the basic axisymmetric flow for the measured values of

${Ma}_c$ obtained could be well correlated by the normalised total heat flux through the interface, which was obtained by numerically computing the basic axisymmetric flow for the measured values of ![]() ${Ma}_c$. However, in terms of the total normalised heat flux through the interface, the critical Marangoni number can be extremely sensitive. This indicates, once again, that the total heat flux is not a suitable parameter to characterise the onset conditions and that the heat flux must be considered space resolved.

${Ma}_c$. However, in terms of the total normalised heat flux through the interface, the critical Marangoni number can be extremely sensitive. This indicates, once again, that the total heat flux is not a suitable parameter to characterise the onset conditions and that the heat flux must be considered space resolved.

As a first step towards a three-dimensional linear stability analysis, Ryzhkov & Shevtsova (Reference Ryzhkov and Shevtsova2012) simplified the problem by considering an indeformable infinitely long liquid bridge similar as in (Xu & Davis Reference Xu and Davis1984), but with an axial gas flow inside an annulus. An additional thermocapillary flow is driven by an imposed linear variation of the axial temperature in the whole system, while a zero axial mean flow was enforced in the liquid phase. A linear stability analysis shows that a gas flow parallel to the thermocapillary stress (co-flow) acts destabilising. A counter-flow can act stabilising or destabilising, depending on its strength. The first three-dimensional linear stability analysis for the two-phase flow in a system of finite length is reported in Shevtsova et al. (Reference Shevtsova, Gaponenko, Kuhlmann, Lappa, Lukasser, Matsumoto, Mialdun, Montanero, Nishino and Ueno2014). For a 5-cSt liquid and an air gap with ![]() $\eta =2$, it was demonstrated that the linear stability boundaries in the plane made by the thermocapillary and the gas Reynolds numbers

$\eta =2$, it was demonstrated that the linear stability boundaries in the plane made by the thermocapillary and the gas Reynolds numbers ![]() $({Re},{Re}_{g}')$ can be quite complex. For the same liquid, argon gas and

$({Re},{Re}_{g}')$ can be quite complex. For the same liquid, argon gas and ![]() $\eta =3$, Stojanovic & Kuhlmann (Reference Stojanović and Kuhlmann2020b) obtained linear stability boundaries for moderate co- and counter-flow. A representative critical hydrothermal wave which exhibits a strong spiral character was characterised and discussed by Stojanovic & Kuhlmann (Reference Stojanović and Kuhlmann2020a). The first more comprehensive linear stability analysis of the two-phase flow is due to Stojanovic, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2022). They carried out a linear stability analysis of the flow in a liquid bridge of 2-cSt silicone oil inside of a sealed adiabatic air-filled shield tube with a radius ratio

$\eta =3$, Stojanovic & Kuhlmann (Reference Stojanović and Kuhlmann2020b) obtained linear stability boundaries for moderate co- and counter-flow. A representative critical hydrothermal wave which exhibits a strong spiral character was characterised and discussed by Stojanovic & Kuhlmann (Reference Stojanović and Kuhlmann2020a). The first more comprehensive linear stability analysis of the two-phase flow is due to Stojanovic, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2022). They carried out a linear stability analysis of the flow in a liquid bridge of 2-cSt silicone oil inside of a sealed adiabatic air-filled shield tube with a radius ratio ![]() $\eta =4$.

$\eta =4$.

Targeting the supercritical behaviour, Gaponenko et al. (Reference Gaponenko, Mialdun, Nepomnyashchy and Shevtsova2021) carried out experiments on the fully developed three-dimensional flow in a liquid bridge of n-decane ![]() $({Pr}=14)$ in nitrogen using a narrow gap with

$({Pr}=14)$ in nitrogen using a narrow gap with ![]() $\eta =1.\bar 6$. Certain cases were also numerically simulated taking into account the cooling of the interface due to evaporation of the liquid. The distinguished feature of their experiments was a constant gas flow rate with a mean velocity of 0.5 m s

$\eta =1.\bar 6$. Certain cases were also numerically simulated taking into account the cooling of the interface due to evaporation of the liquid. The distinguished feature of their experiments was a constant gas flow rate with a mean velocity of 0.5 m s![]() $^{-1}$ (

$^{-1}$ (![]() ${Re}_{g}' = \text {const.}$) from the cold to the hot side of the liquid bridge, but the inlet temperature of the gas was varied. This was accomplished by the heating and cooling devices of the liquid bridge being realised by very thin plates mounted on the end faces of the support rods. Depending on the inlet gas temperature travelling and standing waves were found, as well as periodic and different quasi-periodic states. An isolated window of stability of the axisymmetric flow was detected when the gas flow was considerably hotter (

${Re}_{g}' = \text {const.}$) from the cold to the hot side of the liquid bridge, but the inlet temperature of the gas was varied. This was accomplished by the heating and cooling devices of the liquid bridge being realised by very thin plates mounted on the end faces of the support rods. Depending on the inlet gas temperature travelling and standing waves were found, as well as periodic and different quasi-periodic states. An isolated window of stability of the axisymmetric flow was detected when the gas flow was considerably hotter (![]() $28\,^\circ$C) than the mean temperature of the liquid bridge (

$28\,^\circ$C) than the mean temperature of the liquid bridge (![]() $25\,^\circ$C) which was kept constant. Hysteresis was not observed. Practically the same results have been reported earlier by Yasnou et al. (Reference Yasnou, Gaponenko, Mialdun and Shevtsova2018) who used the same set-up and the same conditions. They also measured stability boundaries as a function of the gas temperature. A similar study was undertaken by Gaponenko et al. (Reference Gaponenko, Yasnou, Mialdun, Bou-Ali, Nepomnyashchy and Shevtsova2023) using the same set-up and methods, but for the smaller mean gas velocity of 0.1 m s

$25\,^\circ$C) which was kept constant. Hysteresis was not observed. Practically the same results have been reported earlier by Yasnou et al. (Reference Yasnou, Gaponenko, Mialdun and Shevtsova2018) who used the same set-up and the same conditions. They also measured stability boundaries as a function of the gas temperature. A similar study was undertaken by Gaponenko et al. (Reference Gaponenko, Yasnou, Mialdun, Bou-Ali, Nepomnyashchy and Shevtsova2023) using the same set-up and methods, but for the smaller mean gas velocity of 0.1 m s![]() $^{-1}$.

$^{-1}$.

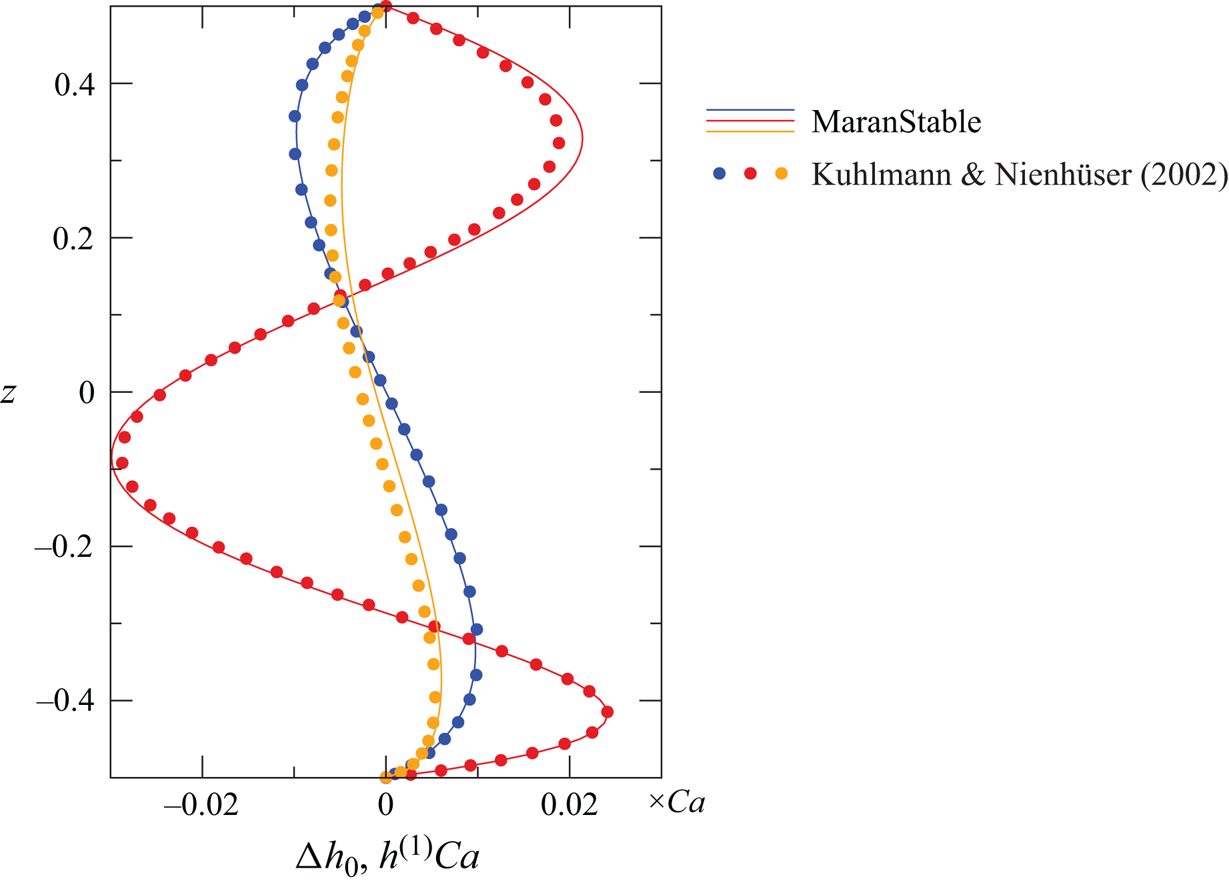

1.3. Dynamic deformations and surface waves

The interest in dynamic surface deformations of thermocapillary liquid bridges was partly stimulated by Kamotani & Ostrach (Reference Kamotani and Ostrach1998), who proposed that the onset of flow oscillations in high-Prandtl-number liquid bridges is due to the coupling between the flow and the flow-induced dynamic surface deformations via an essentially two-dimensional mechanism. Today, however, it is generally accepted that the very small dynamic surface deformations in the oscillatory supercritical flow are only passive in the absence of a gas flow (Kuhlmann & Nienhüser Reference Kuhlmann and Nienhüser2002), merely reflecting the hydrothermal wave which is created by a different mechanism (Smith & Davis Reference Smith and Davis1983a; Wanschura et al. Reference Wanschura, Kuhlmann and Rath1997), independent of dynamic deformations.

In a series of publications Ferrera et al. (Reference Ferrera, Montanero, Mialdun, Shevtsova and Cabezas2008), Montanero, Ferrera & Shevtsova (Reference Montanero, Ferrera and Shevtsova2008) and Shevtsova et al. (Reference Shevtsova, Mialdun, Ferrera, Cabezas and Montanero2008) experimentally studied dynamic surface deformations due to the thermocapillary flow for a 5-cSt liquid ![]() $({Pr}=68)$ for sub- and supercritical conditions. The magnitude of the dynamic (flow-induced) interfacial deformation due to the thermocapillary flow was found to be less than the static deformation at the threshold, and the oscillatory deformations in the supercritical flow were below micrometre size. Very small supercritical oscillatory dynamic deformations with amplitudes of the order of 0.1

$({Pr}=68)$ for sub- and supercritical conditions. The magnitude of the dynamic (flow-induced) interfacial deformation due to the thermocapillary flow was found to be less than the static deformation at the threshold, and the oscillatory deformations in the supercritical flow were below micrometre size. Very small supercritical oscillatory dynamic deformations with amplitudes of the order of 0.1 ![]() $\mathrm {\mu }$m were also measured for large liquid bridges (

$\mathrm {\mu }$m were also measured for large liquid bridges (![]() $r_{i}=5.15$ mm) of high Prandtl numbers under microgravity conditions by Yano et al. (Reference Yano, Nishino, Matsumoto, Ueno, Komiya, Kamotani and Imaishi2018b).

$r_{i}=5.15$ mm) of high Prandtl numbers under microgravity conditions by Yano et al. (Reference Yano, Nishino, Matsumoto, Ueno, Komiya, Kamotani and Imaishi2018b).

These results established that interfacial deformation induced by the liquid flow is typically small compared with the size of the liquid bridge (millimetre scale). In fact, the linear stability analysis of Carrión, Herrada & Montanero (Reference Carrión, Herrada and Montanero2020) including dynamic deformations due to the perturbation flow, but in the absence of a gas flow and using Newton's law of cooling, has shown that dynamic deformations have very little effect on the eigenvalues and eigenvectors resulting from the linear stability problem. On the other hand, Herrada et al. (Reference Herrada, López-Herrera, Vega and Montanero2011) studied dynamic deformations of an isothermal liquid bridge caused by an imposed axisymmetric coaxial gas flow in the absence of a thermocapillary flow. They found numerically that the amplitude of the surface deformations takes higher values for normal gravity conditions compared with zero gravity conditions. For the gas flow rates investigated the flow remained steady. In the presence of thermocapillarity, however, the flow may become unstable and surface wave instabilities may be triggered by the gas flow. Surface waves have been observed in low-Prandtl-number thermocapillary layers (Smith & Davis Reference Smith and Davis1983b; Bach & Schwabe Reference Bach and Schwabe2015) and in two-dimensional shallow droplets with low surface tension migrating on a flat wall under a constant temperature gradient (Hu, Zhang & Chen Reference Hu, Zhang and Chen2023). Surface waves in the plane return flow have a rather long wavelength when the surface tension is small (Davis Reference Davis1987). Based on the analysis of Smith & Davis (Reference Smith and Davis1983b) surface waves are not expected to become critical for high-Prandtl-number liquid layer and, in particular, not in axially confined liquid bridges of high Prandtl number.

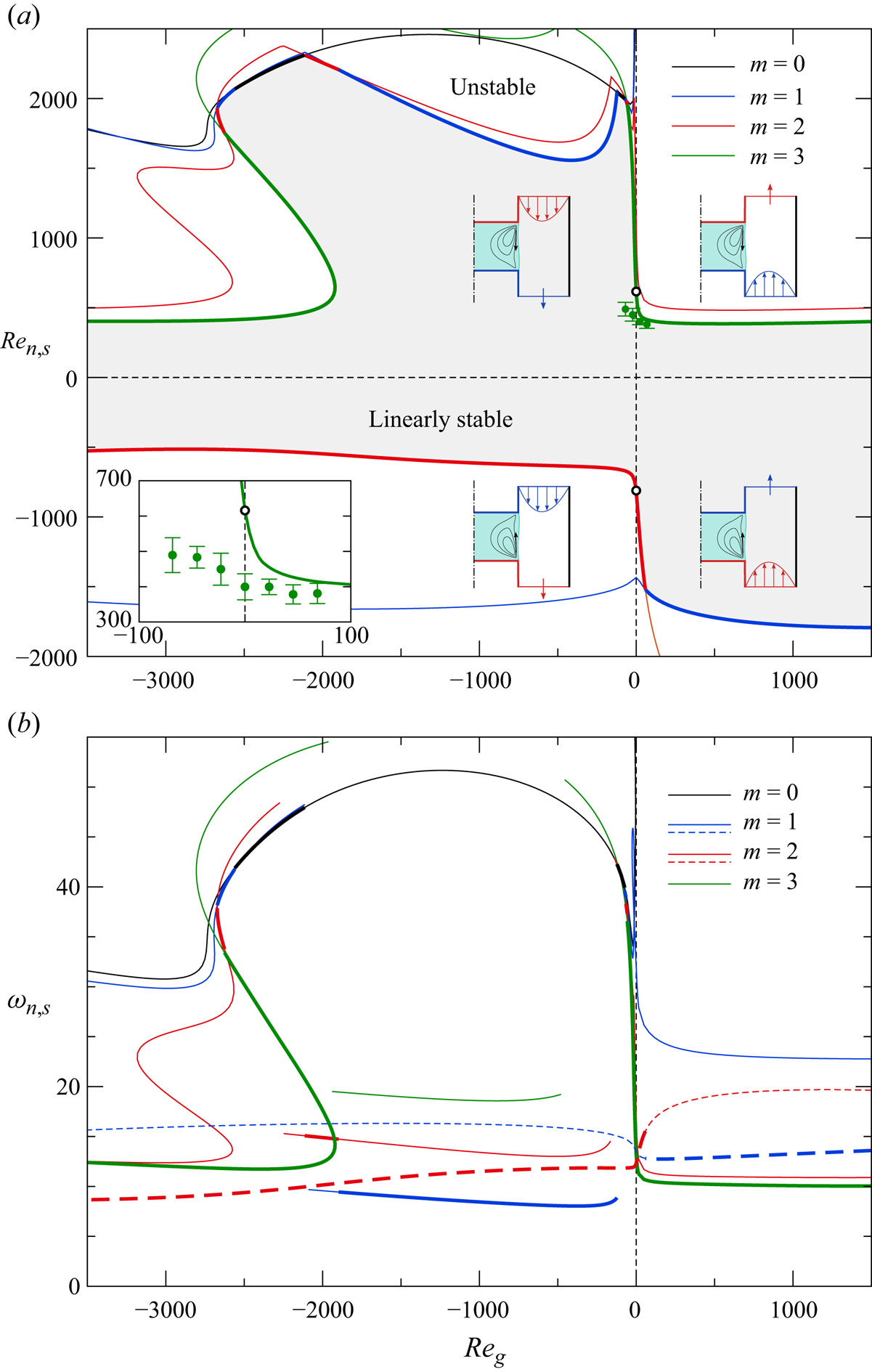

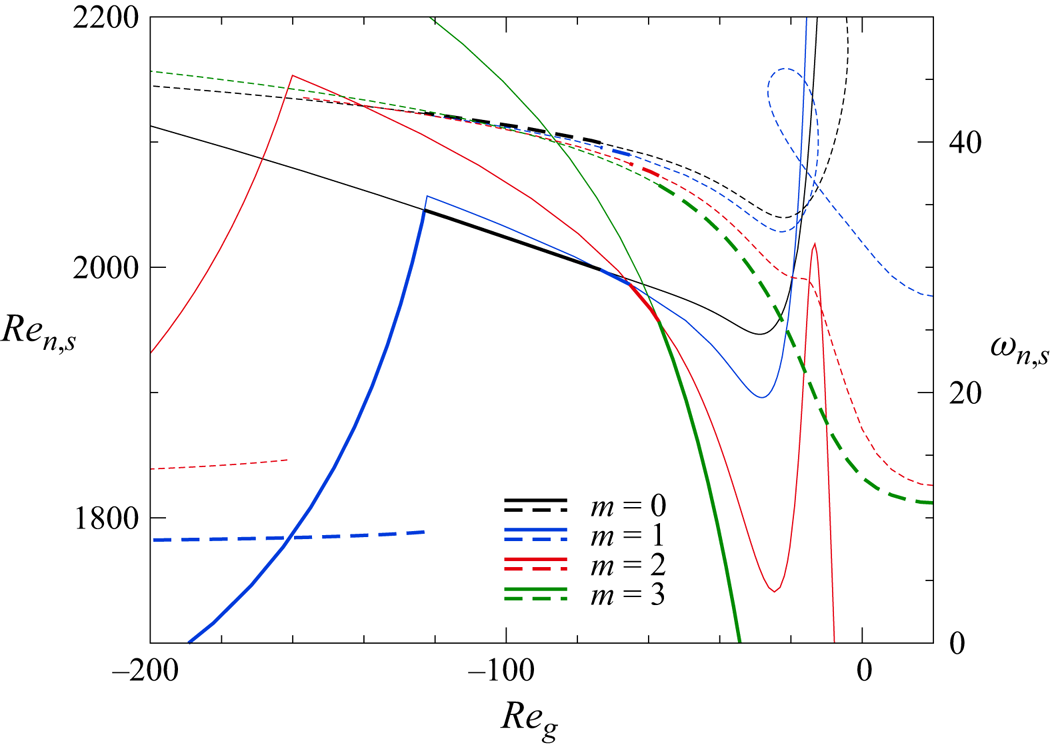

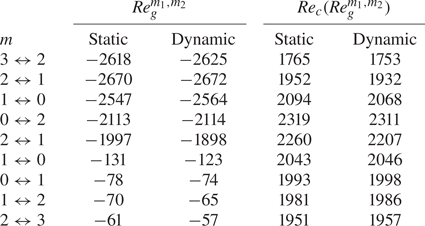

Except for the brief results of Shevtsova et al. (Reference Shevtsova, Gaponenko, Kuhlmann, Lappa, Lukasser, Matsumoto, Mialdun, Montanero, Nishino and Ueno2014) and Stojanovic & Kuhlmann (Reference Stojanović and Kuhlmann2020b) for liquids with ![]() ${Pr}=67$, a numerical linear stability analysis of the flow in thermocapillary liquid bridges under the influence of an axial gas flow has never been carried out. The present work intends to fill this gap and compute the influence of the gas flow on the stability of a set of typical parameters. In § 2, the problem is formulated. The popular combination of 2-cSt silicone oil and air is selected and the case of a wide gap with

${Pr}=67$, a numerical linear stability analysis of the flow in thermocapillary liquid bridges under the influence of an axial gas flow has never been carried out. The present work intends to fill this gap and compute the influence of the gas flow on the stability of a set of typical parameters. In § 2, the problem is formulated. The popular combination of 2-cSt silicone oil and air is selected and the case of a wide gap with ![]() $\eta =4$ is considered. Section 3 explains the numerical methods employed. Results are presented in § 4. First, the influence of the axial gas flow rate on the linear stability boundary and the critical modes is presented and analysed. Thereafter, free surface deformations due to the basic flow are discussed and their effect on the linear stability boundary is established. We close with a discussion of the results in § 5.

$\eta =4$ is considered. Section 3 explains the numerical methods employed. Results are presented in § 4. First, the influence of the axial gas flow rate on the linear stability boundary and the critical modes is presented and analysed. Thereafter, free surface deformations due to the basic flow are discussed and their effect on the linear stability boundary is established. We close with a discussion of the results in § 5.

2. Problem formulation

2.1. Set-up

We consider a liquid bridge between two coaxial cylindrical rods, both of length ![]() ${d_{rod}=1}$ mm and radius

${d_{rod}=1}$ mm and radius ![]() $r_{i}=2.5$ mm, which are separated by a distance

$r_{i}=2.5$ mm, which are separated by a distance ![]() $d=1.65$ mm, as shown in figure 1. The rods are aligned parallel to the acceleration of gravity

$d=1.65$ mm, as shown in figure 1. The rods are aligned parallel to the acceleration of gravity ![]() $\boldsymbol{g}=-g\boldsymbol{e}_z$ with

$\boldsymbol{g}=-g\boldsymbol{e}_z$ with ![]() $g=9.81$ m s

$g=9.81$ m s![]() $^{-2}$. The liquid bridge is surrounded by an ambient gas which is confined to a cylindrical tube of radius

$^{-2}$. The liquid bridge is surrounded by an ambient gas which is confined to a cylindrical tube of radius ![]() $r_{o} = 10\ \text {mm} > r_{i}$ (

$r_{o} = 10\ \text {mm} > r_{i}$ (![]() $i$ inner and

$i$ inner and ![]() $o$ outer). The geometry is characterised by the aspect ratio of the liquid bridge

$o$ outer). The geometry is characterised by the aspect ratio of the liquid bridge ![]() $\varGamma$, the rod aspect ratio

$\varGamma$, the rod aspect ratio ![]() $\varGamma _{rod}$ and the radius ratio

$\varGamma _{rod}$ and the radius ratio ![]() $\eta$ which are defined, respectively, as

$\eta$ which are defined, respectively, as

These geometry parameters are identical to those of the experimental set-up used by Romanò et al. (Reference Romanò, Kuhlmann, Ishimura and Ueno2017) and they are kept constant throughout.

The liquid bridge is made of 2-cSt silicone oil KF96L-2cs produced by Shin-Etsu Chemical (Japan), while the surrounding gas is air. Both are considered Newtonian fluids. The liquid bridge is kept in place by capillary forces due to the surface tension between the liquid and the gas and by pinning of the three-phase contact lines to the sharp circular edges of the support rods. The support rods are assumed to be perfect thermal conductors and are kept at different but constant temperatures ![]() $T_{top} = T_0 + \Delta T/2$ and

$T_{top} = T_0 + \Delta T/2$ and ![]() $T_{bottom} = T_0 - \Delta T/2$ with

$T_{bottom} = T_0 - \Delta T/2$ with ![]() $\Delta T=T_{top}-T_{bottom}$ and

$\Delta T=T_{top}-T_{bottom}$ and ![]() $T_0=(T_{top}+T_{bottom})/2$. The temperature difference

$T_0=(T_{top}+T_{bottom})/2$. The temperature difference ![]() $\Delta T$ can accept positive or negative values corresponding to heating from above or from below, respectively. Since the imposed temperature difference leads to a surface tension variation along the interface, tangential interfacial stresses are induced via the thermocapillary effect. These thermocapillary stresses drive a flow both in the liquid and in the gas phase (Kuhlmann Reference Kuhlmann1999).

$\Delta T$ can accept positive or negative values corresponding to heating from above or from below, respectively. Since the imposed temperature difference leads to a surface tension variation along the interface, tangential interfacial stresses are induced via the thermocapillary effect. These thermocapillary stresses drive a flow both in the liquid and in the gas phase (Kuhlmann Reference Kuhlmann1999).

The dependence of the surface tension

on the temperature ![]() $T$ is considered up to first order in

$T$ is considered up to first order in ![]() $T-T_0$, where

$T-T_0$, where ![]() $\sigma _0 = \sigma (T_0)$ is the surface tension at the reference temperature

$\sigma _0 = \sigma (T_0)$ is the surface tension at the reference temperature ![]() $T_0$ and

$T_0$ and ![]() $\gamma$ the negative surface tension coefficient. Apart from thermocapillary surface forces, the flow is also driven by body forces caused by the thermal expansion of the liquid and the gas. Therefore, the densities

$\gamma$ the negative surface tension coefficient. Apart from thermocapillary surface forces, the flow is also driven by body forces caused by the thermal expansion of the liquid and the gas. Therefore, the densities

of the liquid and the gas, respectively, are also considered up to first order in the temperature deviation from its algebraic mean ![]() $T_0$, where

$T_0$, where ![]() $\rho _0 = \rho (T_0)$ and

$\rho _0 = \rho (T_0)$ and ![]() $\rho _{g0}=\rho _{g}(T_0)$ are the reference densities at the mean temperature. The respective thermal expansion coefficients are

$\rho _{g0}=\rho _{g}(T_0)$ are the reference densities at the mean temperature. The respective thermal expansion coefficients are ![]() $\beta =-\rho _0^{-1}(\partial \rho / \partial T)_p$ and

$\beta =-\rho _0^{-1}(\partial \rho / \partial T)_p$ and ![]() $\beta _{g}=-\rho _{g0}^{-1}(\partial \rho _{g} / \partial T)_p$.

$\beta _{g}=-\rho _{g0}^{-1}(\partial \rho _{g} / \partial T)_p$.

A third driving force of the fluid motion is an imposed axial pressure difference between the inlet and the outlet of the gas (figure 1). The pressure difference leads to a forced flow in the annular gap between the rods and the shield tube. The direction of the mean gas flow depends on the sign of the pressure difference. Here we assume that the gas enters the annular space with a temperature equal to the rod temperature upstream of the gas flow.

For millimetric liquid bridges of the above silicone oil which can be realised under terrestrial gravity the main driving force is thermocapillarity. As long as the imposed temperature difference and the gas flow rate are small the flow in the liquid and in the gas will be axisymmetric and steady, reflecting the symmetry of the problem. Here we are interested in the stability of this steady axisymmetric flow and the dependence of its stability boundary on the forced flow in the gas phase. In order to keep this problem manageable we assume the dynamic viscosities of both fluids ![]() $\mu$ and

$\mu$ and ![]() $\mu _{g}$ as well as their thermal conductivities

$\mu _{g}$ as well as their thermal conductivities ![]() $\lambda$ and

$\lambda$ and ![]() $\lambda _{g}$ and their specific heat capacities

$\lambda _{g}$ and their specific heat capacities ![]() $c_p$ and

$c_p$ and ![]() $c_{p,{g}}$ to be constant. Moreover, the mean temperature is kept constant at

$c_{p,{g}}$ to be constant. Moreover, the mean temperature is kept constant at ![]() $T_0=25\,^\circ$C. All physical properties for both working fluids are given in table 1.

$T_0=25\,^\circ$C. All physical properties for both working fluids are given in table 1.

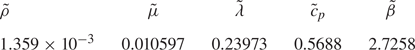

Table 1. Thermophysical properties of the working fluids 2-cSt silicone oil KF96L-2cs and air at ![]() $25\,^\circ$C.

$25\,^\circ$C.

2.2. Governing equations and boundary conditions

2.2.1. Transport equations

The flow in both the liquid and the gas phase is governed by the Navier–Stokes, continuity and energy equations. For the problem at hand it seems reasonable to simplify the governing equations and consider the Oberbeck–Boussinesq approximation (Landau & Lifschitz Reference Landau and Lifschitz1959; Mihaljan Reference Mihaljan1962) which takes into account density variations only in the buoyancy term. However, a proper treatment of flow-induced deformations of the liquid–gas interface requires higher-order corrections to the Oberbeck–Boussinesq approximation (Simanovskii & Nepomnyashchy Reference Simanovskii and Nepomnyashchy1993). Therefore, we consider the linear temperature dependence of the densities not only in the buoyancy term, but also in the entire momentum equations, the continuity equations and in the energy equations for both the liquid and the gas.

Within this approximation we consider the following equations for the velocity ![]() $\boldsymbol {u}$, pressure

$\boldsymbol {u}$, pressure ![]() $p$ and temperature field

$p$ and temperature field ![]() $T$ for the liquid phase:

$T$ for the liquid phase:

where ![]() $t$ is the time and

$t$ is the time and

is (twice) the deformation rate tensor with the identity matrix ![]() ${\boldsymbol{\mathsf{I}}} = \delta _{ij}$. In the energy equation (2.4c), the pressure contribution to the enthalpy is neglected, assuming

${\boldsymbol{\mathsf{I}}} = \delta _{ij}$. In the energy equation (2.4c), the pressure contribution to the enthalpy is neglected, assuming ![]() ${p/\rho \ll |c_p T|}$. Likewise, we neglect the pressure work and the heat due to viscous dissipation in (2.4c).

${p/\rho \ll |c_p T|}$. Likewise, we neglect the pressure work and the heat due to viscous dissipation in (2.4c).

Formally the same equations (2.4) hold for the gas phase, merely with the material parameters of the gas. To distinguish between liquid and gas we follow Stojanovic et al. (Reference Stojanović, Romanò and Kuhlmann2022) and introduce the set of coefficients

\begin{equation} \boldsymbol{\alpha} = ( \alpha_\rho,\alpha_\mu,\alpha_\lambda,\alpha_{c_p},\alpha_\beta )= \begin{cases} (1,1,1,1,1) \quad \text{for the liquid phase,}\\ (\tilde{\rho},\tilde{\mu},\tilde{\lambda},\widetilde{c_p},\tilde\beta) \quad \text{for the gas phase}, \end{cases} \end{equation}

\begin{equation} \boldsymbol{\alpha} = ( \alpha_\rho,\alpha_\mu,\alpha_\lambda,\alpha_{c_p},\alpha_\beta )= \begin{cases} (1,1,1,1,1) \quad \text{for the liquid phase,}\\ (\tilde{\rho},\tilde{\mu},\tilde{\lambda},\widetilde{c_p},\tilde\beta) \quad \text{for the gas phase}, \end{cases} \end{equation}

where ![]() $\tilde {\rho }=\rho _{g0}/\rho _0$,

$\tilde {\rho }=\rho _{g0}/\rho _0$, ![]() $\tilde {\mu }=\mu _{g}/\mu$,

$\tilde {\mu }=\mu _{g}/\mu$, ![]() $\tilde {\lambda }=\lambda _{g}/\lambda$,

$\tilde {\lambda }=\lambda _{g}/\lambda$, ![]() $\widetilde {c_p}=c_{p,{g}}/c_p$ and

$\widetilde {c_p}=c_{p,{g}}/c_p$ and ![]() $\tilde \beta =\beta _{g}/\beta$ denote the ratios of the reference densities, dynamic viscosities, thermal conductivities, specific heat capacities and the thermal expansion coefficients between the gas and the liquid. Numerical data are given in table 2.

$\tilde \beta =\beta _{g}/\beta$ denote the ratios of the reference densities, dynamic viscosities, thermal conductivities, specific heat capacities and the thermal expansion coefficients between the gas and the liquid. Numerical data are given in table 2.

Table 2. Ratios of the thermophysical parameters between air and 2-cSt silicone oil as defined in (2.6).

Scaling lengths, time, velocity, pressure and temperature by ![]() $d$,

$d$, ![]() $d^2\rho _0/\mu$,

$d^2\rho _0/\mu$, ![]() $\gamma \Delta T/\mu$,

$\gamma \Delta T/\mu$, ![]() $\gamma \Delta T/d$ and

$\gamma \Delta T/d$ and ![]() $\Delta T$, respectively, and using the same notation as for the dimensional variables, we arrive at the dimensionless version of (2.4) for both fluids:

$\Delta T$, respectively, and using the same notation as for the dimensional variables, we arrive at the dimensionless version of (2.4) for both fluids:

where we made use of the coefficients defined in (2.6). We use cylindrical coordinates ![]() $(r,\varphi,z)$ centred in the middle of the liquid bridge and a polar representation of the velocity field

$(r,\varphi,z)$ centred in the middle of the liquid bridge and a polar representation of the velocity field ![]() $\boldsymbol {u} = u\boldsymbol {e}_r + v \boldsymbol {e}_{\varphi } + w\boldsymbol {e}_z$. In (2.7), the reduced temperature and the reduced pressure are defined as

$\boldsymbol {u} = u\boldsymbol {e}_r + v \boldsymbol {e}_{\varphi } + w\boldsymbol {e}_z$. In (2.7), the reduced temperature and the reduced pressure are defined as ![]() $\vartheta =(T-T_0)/\Delta T$ and

$\vartheta =(T-T_0)/\Delta T$ and ![]() $p=(d/\gamma \Delta T)(P-\rho _0 g z)$, respectively, where

$p=(d/\gamma \Delta T)(P-\rho _0 g z)$, respectively, where ![]() $P$ indicates the dimensional pressure. Furthermore, the temperature dependence of the density is taken into account up to linear approximation with the (small) parameter

$P$ indicates the dimensional pressure. Furthermore, the temperature dependence of the density is taken into account up to linear approximation with the (small) parameter ![]() $\varepsilon =\beta \Delta T$ (and

$\varepsilon =\beta \Delta T$ (and ![]() $\varepsilon _{g}=\beta _{g}\Delta T$) measuring the magnitude of the density variation in the liquid (and in the gas).

$\varepsilon _{g}=\beta _{g}\Delta T$) measuring the magnitude of the density variation in the liquid (and in the gas).

The flow in the silicone oil under terrestrial gravity is characterised by the thermocapillary Reynolds number ![]() ${Re}$, the Prandtl number

${Re}$, the Prandtl number ![]() ${Pr}$ and the dynamic Bond number

${Pr}$ and the dynamic Bond number ![]() ${Bd}$, defined respectively as

${Bd}$, defined respectively as

Since ![]() $\Delta T$ can accept both, positive and negative values, the thermocapillary Reynolds number

$\Delta T$ can accept both, positive and negative values, the thermocapillary Reynolds number ![]() ${Re}$, the Marangoni number

${Re}$, the Marangoni number ![]() ${Ma}={Pr}{Re}$ as well as the Rayleigh number

${Ma}={Pr}{Re}$ as well as the Rayleigh number ![]() ${Ra}={Bd}{Ma}$ have a sign. As most investigations of the flow in liquid bridges consider heating from above, this configuration will be associated with

${Ra}={Bd}{Ma}$ have a sign. As most investigations of the flow in liquid bridges consider heating from above, this configuration will be associated with ![]() $({Re},{Ma},{Ra})>0$, while

$({Re},{Ma},{Ra})>0$, while ![]() $({Re},{Ma},{Ra})<0$ indicates heating from below, even though this is an unusual convention for pure buoyancy convection.

$({Re},{Ma},{Ra})<0$ indicates heating from below, even though this is an unusual convention for pure buoyancy convection.

2.2.2. Linear stability equations

The steady axisymmetric solution ![]() $\boldsymbol{u}_0 = u(r,z)\boldsymbol{e}_r + w(r,z)\boldsymbol{e}_z$ of (2.7) is called the basic flow. For sufficiently small driving forces the basic flow is stable. We are interested in the linear stability boundary of the basic flow when the thermocapillary Reynolds numbers

$\boldsymbol{u}_0 = u(r,z)\boldsymbol{e}_r + w(r,z)\boldsymbol{e}_z$ of (2.7) is called the basic flow. For sufficiently small driving forces the basic flow is stable. We are interested in the linear stability boundary of the basic flow when the thermocapillary Reynolds numbers ![]() ${Re}$ exceeds a certain threshold. For Reynolds numbers larger in magnitude than the critical Reynolds number, i.e.

${Re}$ exceeds a certain threshold. For Reynolds numbers larger in magnitude than the critical Reynolds number, i.e. ![]() ${Re}>{Re}_c>0$ for heating from above, or

${Re}>{Re}_c>0$ for heating from above, or ![]() ${Re}<{Re}_c<0$ for heating from below, the flow is time-dependent, three-dimensional or both. In order to find the critical Reynolds numbers

${Re}<{Re}_c<0$ for heating from below, the flow is time-dependent, three-dimensional or both. In order to find the critical Reynolds numbers ![]() ${Re}_c$ a linear stability analysis is carried out. To that end the general three-dimensional time-dependent solution

${Re}_c$ a linear stability analysis is carried out. To that end the general three-dimensional time-dependent solution ![]() $\boldsymbol {q}=(u,v,w,p,\vartheta )$ and

$\boldsymbol {q}=(u,v,w,p,\vartheta )$ and ![]() $\boldsymbol {q}_{g}=(u_{g},v_{g},w_{g},p_{g},\vartheta _{g})$ of (2.7) is decomposed into an axisymmetric time-independent basic flow (subscript 0) and deviations from this basic flow (indicated by a prime

$\boldsymbol {q}_{g}=(u_{g},v_{g},w_{g},p_{g},\vartheta _{g})$ of (2.7) is decomposed into an axisymmetric time-independent basic flow (subscript 0) and deviations from this basic flow (indicated by a prime ![]() $'$):

$'$):

Inserting this decomposition into (2.7) and linearising the equations with respect to the perturbation quantities yields the set of linear equations

\begin{align} &(1-\alpha_\beta \varepsilon\vartheta_0)\frac{\partial \boldsymbol{u}'}{\partial t} + {Re}(1-\alpha_\beta \varepsilon\vartheta_0)(\boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{u}'+ \boldsymbol{u}' \boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{u}_0) - \alpha_\beta \varepsilon {Re} \vartheta' \boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{u}_0 \nonumber\\ &\quad ={-}\frac{1}{\alpha_\rho}\boldsymbol{\nabla} p'+\alpha_\beta \,{Bd}\,\vartheta' \boldsymbol{e}_z +\alpha_\mu\boldsymbol{\nabla} \boldsymbol{\cdot} {\boldsymbol{\mathsf{S}}}', \end{align}

\begin{align} &(1-\alpha_\beta \varepsilon\vartheta_0)\frac{\partial \boldsymbol{u}'}{\partial t} + {Re}(1-\alpha_\beta \varepsilon\vartheta_0)(\boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{u}'+ \boldsymbol{u}' \boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{u}_0) - \alpha_\beta \varepsilon {Re} \vartheta' \boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{u}_0 \nonumber\\ &\quad ={-}\frac{1}{\alpha_\rho}\boldsymbol{\nabla} p'+\alpha_\beta \,{Bd}\,\vartheta' \boldsymbol{e}_z +\alpha_\mu\boldsymbol{\nabla} \boldsymbol{\cdot} {\boldsymbol{\mathsf{S}}}', \end{align} \begin{align} &(1-\alpha_\beta \varepsilon\vartheta_0)\frac{\partial \vartheta'}{\partial t} + {Re}(1-\alpha_\beta \varepsilon\vartheta_0)(\boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \vartheta'+ \boldsymbol{u}' \boldsymbol{\cdot} \boldsymbol{\nabla} \vartheta_0) \nonumber\\ &\quad - \alpha_\beta \varepsilon {Re} \vartheta' \boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \vartheta_0 = \frac{\alpha_\lambda}{\alpha_{c_p}{Pr}}\nabla^2 \vartheta', \end{align}

\begin{align} &(1-\alpha_\beta \varepsilon\vartheta_0)\frac{\partial \vartheta'}{\partial t} + {Re}(1-\alpha_\beta \varepsilon\vartheta_0)(\boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \vartheta'+ \boldsymbol{u}' \boldsymbol{\cdot} \boldsymbol{\nabla} \vartheta_0) \nonumber\\ &\quad - \alpha_\beta \varepsilon {Re} \vartheta' \boldsymbol{u}_0 \boldsymbol{\cdot} \boldsymbol{\nabla} \vartheta_0 = \frac{\alpha_\lambda}{\alpha_{c_p}{Pr}}\nabla^2 \vartheta', \end{align}

which describe the dynamics of the infinitesimal perturbation flow. Again (2.10) is valid for both phases, distinguished by ![]() $\boldsymbol{\alpha}$. Both phases are coupled through the boundary conditions on the interface.

$\boldsymbol{\alpha}$. Both phases are coupled through the boundary conditions on the interface.

Since the basic state is homogeneous in time ![]() $t$ and in the azimuthal coordinate

$t$ and in the azimuthal coordinate ![]() $\varphi$, the perturbations

$\varphi$, the perturbations ![]() $\boldsymbol {q}'$ and

$\boldsymbol {q}'$ and ![]() $\boldsymbol {q}'_{g}$ can be decomposed into normal modes with azimuthal wavenumber

$\boldsymbol {q}'_{g}$ can be decomposed into normal modes with azimuthal wavenumber ![]() $m\in \mathbb {N}$:

$m\in \mathbb {N}$:

where the complex conjugate (c.c.) renders the perturbations real. The complex growth rates of the normal modes with amplitudes ![]() $\hat {\boldsymbol {q}}=(\hat {u},\hat {v},\hat {w},\hat {p},\hat {\vartheta })$ and

$\hat {\boldsymbol {q}}=(\hat {u},\hat {v},\hat {w},\hat {p},\hat {\vartheta })$ and ![]() $\hat {\boldsymbol {q}}_{g} = (\hat {u}_{g}, \hat {v}_{g}, \hat {w}_{g}, \hat {p}_{g}, \hat {\vartheta }_{g})$ are denoted

$\hat {\boldsymbol {q}}_{g} = (\hat {u}_{g}, \hat {v}_{g}, \hat {w}_{g}, \hat {p}_{g}, \hat {\vartheta }_{g})$ are denoted ![]() $\psi = \psi _{j,m} \in \mathbb {C}$, where the index

$\psi = \psi _{j,m} \in \mathbb {C}$, where the index ![]() $j$ numbers the different solutions for given wavenumber

$j$ numbers the different solutions for given wavenumber ![]() $m$.

$m$.

Inserting the ansatz (2.11) into (2.10), we obtain linear differential equations in ![]() $r$ and

$r$ and ![]() $z$ for the perturbation amplitudes

$z$ for the perturbation amplitudes

\begin{align} &\psi(\hat{u}-\alpha_\beta \varepsilon u_0 \hat{\vartheta})+{Re}\left[ \left( \frac{1}{r} +\frac{\partial }{\partial r} \right) (2u_0\hat{u}) +\frac{m u_0 \hat{\hat{v}}}{r} +\frac{\partial (u_0 \hat{w}+\hat{u}w_0)}{\partial z}\right]\nonumber\\ &\quad -\alpha_\beta \varepsilon{Re}\left[ \left( \frac{1}{r}+\frac{\partial}{\partial r} \right)(\vartheta' u_0^2)+\frac{\partial (\vartheta' u_0 w_0)}{\partial z} \right] ={-}\frac{1}{\alpha_\rho} \frac{\partial \hat{p}}{\partial r}+\alpha_\mu\left[ \frac{2}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{u}}{\partial r} \right)\right.\nonumber\\ &\quad -\left.(m^2+2)\frac{\hat{u}}{r^2}+m\left(\frac{1}{r}\frac{\partial}{\partial r}-\frac{3}{r^2}\right) \hat{\hat{v}}+\left(\frac{\partial}{\partial z}+\frac{\partial}{\partial r}\right)\frac{\partial u'}{\partial z} -\frac{2}{3}\alpha_\beta \varepsilon\zeta'\right], \end{align}

\begin{align} &\psi(\hat{u}-\alpha_\beta \varepsilon u_0 \hat{\vartheta})+{Re}\left[ \left( \frac{1}{r} +\frac{\partial }{\partial r} \right) (2u_0\hat{u}) +\frac{m u_0 \hat{\hat{v}}}{r} +\frac{\partial (u_0 \hat{w}+\hat{u}w_0)}{\partial z}\right]\nonumber\\ &\quad -\alpha_\beta \varepsilon{Re}\left[ \left( \frac{1}{r}+\frac{\partial}{\partial r} \right)(\vartheta' u_0^2)+\frac{\partial (\vartheta' u_0 w_0)}{\partial z} \right] ={-}\frac{1}{\alpha_\rho} \frac{\partial \hat{p}}{\partial r}+\alpha_\mu\left[ \frac{2}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{u}}{\partial r} \right)\right.\nonumber\\ &\quad -\left.(m^2+2)\frac{\hat{u}}{r^2}+m\left(\frac{1}{r}\frac{\partial}{\partial r}-\frac{3}{r^2}\right) \hat{\hat{v}}+\left(\frac{\partial}{\partial z}+\frac{\partial}{\partial r}\right)\frac{\partial u'}{\partial z} -\frac{2}{3}\alpha_\beta \varepsilon\zeta'\right], \end{align} \begin{align} &\psi\hat{\hat{v}}+{Re}\left[\left( \frac{2}{r} +\frac{\partial }{\partial r} \right) (u_0\hat{\hat{v}}) +\frac{\partial (\hat{\hat{v}}w_0)}{\partial z}\right] =\frac{1}{\alpha_\rho}\frac{m}{r}\hat{p}+\alpha_\mu\left[{-}m\left(\frac{3}{r^2}+\frac{\partial}{\partial r}\right) \hat{u}\right.\nonumber\\ &\quad \left.+ \frac{1}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{\hat{v}}}{\partial r} \right)-(2~m^2+1)\frac{\hat{\hat{v}}}{r^2}+\frac{\partial}{\partial z}\left(\frac{\partial \hat{\hat{v}}}{\partial z}-\frac{m\hat{w}}{r}\right)-\frac{2}{3}\alpha_\beta \varepsilon\zeta'\right], \end{align}

\begin{align} &\psi\hat{\hat{v}}+{Re}\left[\left( \frac{2}{r} +\frac{\partial }{\partial r} \right) (u_0\hat{\hat{v}}) +\frac{\partial (\hat{\hat{v}}w_0)}{\partial z}\right] =\frac{1}{\alpha_\rho}\frac{m}{r}\hat{p}+\alpha_\mu\left[{-}m\left(\frac{3}{r^2}+\frac{\partial}{\partial r}\right) \hat{u}\right.\nonumber\\ &\quad \left.+ \frac{1}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{\hat{v}}}{\partial r} \right)-(2~m^2+1)\frac{\hat{\hat{v}}}{r^2}+\frac{\partial}{\partial z}\left(\frac{\partial \hat{\hat{v}}}{\partial z}-\frac{m\hat{w}}{r}\right)-\frac{2}{3}\alpha_\beta \varepsilon\zeta'\right], \end{align} \begin{align} &\psi(\hat{w}-\alpha_\beta \varepsilon w_0 \hat{\vartheta})+{Re}\left[\frac{1}{r} \frac{\partial [r(w_0 \hat{u}+\hat{w}u_0)]}{\partial r} +\frac{m w_0 \hat{\hat{v}}}{r} + 2\frac{\partial w_0\hat{w}}{\partial z}\right]\nonumber\\ &\quad-\alpha_\beta \varepsilon{Re}\left[ \left( \frac{1}{r}+\frac{\partial}{\partial r} \right)(\vartheta' u_0 w_0)+\frac{\partial (\vartheta' w_0^2)}{\partial z} \right]={-}\frac{1}{\alpha_\rho} \frac{\partial \hat{p}}{\partial z}+\alpha_\beta\,{Bd}\,\hat{\vartheta}\nonumber\\ &\quad+\alpha_\mu\left[ \frac{1}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{w}}{\partial r} \right)-m^2\frac{\hat{w}}{r^2}+\frac{\partial}{\partial z}\left( \frac{1}{r}\frac{\hat{u}}{\partial r}+\frac{1}{r}\hat{\hat{v}}+2\frac{\partial \hat{w}}{\partial z} \right)-\frac{2}{3}\alpha_\beta \varepsilon\zeta' \right], \end{align}

\begin{align} &\psi(\hat{w}-\alpha_\beta \varepsilon w_0 \hat{\vartheta})+{Re}\left[\frac{1}{r} \frac{\partial [r(w_0 \hat{u}+\hat{w}u_0)]}{\partial r} +\frac{m w_0 \hat{\hat{v}}}{r} + 2\frac{\partial w_0\hat{w}}{\partial z}\right]\nonumber\\ &\quad-\alpha_\beta \varepsilon{Re}\left[ \left( \frac{1}{r}+\frac{\partial}{\partial r} \right)(\vartheta' u_0 w_0)+\frac{\partial (\vartheta' w_0^2)}{\partial z} \right]={-}\frac{1}{\alpha_\rho} \frac{\partial \hat{p}}{\partial z}+\alpha_\beta\,{Bd}\,\hat{\vartheta}\nonumber\\ &\quad+\alpha_\mu\left[ \frac{1}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{w}}{\partial r} \right)-m^2\frac{\hat{w}}{r^2}+\frac{\partial}{\partial z}\left( \frac{1}{r}\frac{\hat{u}}{\partial r}+\frac{1}{r}\hat{\hat{v}}+2\frac{\partial \hat{w}}{\partial z} \right)-\frac{2}{3}\alpha_\beta \varepsilon\zeta' \right], \end{align} \begin{align} &\alpha_\beta \varepsilon\left[-\frac{\psi \hat{\vartheta}}{{Re}} - \frac{1}{r}\frac{\partial (r\hat{\vartheta}u_0)}{\partial r} - \frac{\partial (\hat{\vartheta}w_0)}{\partial z}\right] + \frac{1}{r} \frac{\partial [(1-\alpha_\beta \varepsilon\vartheta_0)r \hat{u}]}{\partial r}\nonumber\\ &\quad +\frac{m-\alpha_\beta \varepsilon\vartheta_0}{r}\hat{\hat{v}}+\frac{\partial[(1-\alpha_\beta \varepsilon\vartheta_0) \hat{w}]}{\partial z}=0, \end{align}

\begin{align} &\alpha_\beta \varepsilon\left[-\frac{\psi \hat{\vartheta}}{{Re}} - \frac{1}{r}\frac{\partial (r\hat{\vartheta}u_0)}{\partial r} - \frac{\partial (\hat{\vartheta}w_0)}{\partial z}\right] + \frac{1}{r} \frac{\partial [(1-\alpha_\beta \varepsilon\vartheta_0)r \hat{u}]}{\partial r}\nonumber\\ &\quad +\frac{m-\alpha_\beta \varepsilon\vartheta_0}{r}\hat{\hat{v}}+\frac{\partial[(1-\alpha_\beta \varepsilon\vartheta_0) \hat{w}]}{\partial z}=0, \end{align} \begin{align} &\psi(\hat{\vartheta}-\alpha_\beta \varepsilon\vartheta_0)+{Re}\left[\frac{1}{r} \frac{\partial [r(\vartheta_0 \hat{u}+\hat{\vartheta}u_0-\alpha_\beta \varepsilon\vartheta_0 u_0 \hat{\vartheta})]}{\partial r} +\frac{m \vartheta_0 \hat{\hat{v}}}{r} \right.\nonumber\\ &\quad \left. +\frac{\partial ( \vartheta_0\hat{w}+\hat{\vartheta}w_0-\alpha_\beta \varepsilon\vartheta_0 w_0 \hat{\vartheta})}{\partial z}\right]=\frac{\alpha_\lambda}{\alpha_{c_p}{Pr}}\left[ \frac{1}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{\vartheta}}{\partial r} \right)-m^2\frac{\hat{\vartheta}}{r^2}+\frac{\partial^2 \hat{\vartheta}}{\partial z^2}\right]. \end{align}

\begin{align} &\psi(\hat{\vartheta}-\alpha_\beta \varepsilon\vartheta_0)+{Re}\left[\frac{1}{r} \frac{\partial [r(\vartheta_0 \hat{u}+\hat{\vartheta}u_0-\alpha_\beta \varepsilon\vartheta_0 u_0 \hat{\vartheta})]}{\partial r} +\frac{m \vartheta_0 \hat{\hat{v}}}{r} \right.\nonumber\\ &\quad \left. +\frac{\partial ( \vartheta_0\hat{w}+\hat{\vartheta}w_0-\alpha_\beta \varepsilon\vartheta_0 w_0 \hat{\vartheta})}{\partial z}\right]=\frac{\alpha_\lambda}{\alpha_{c_p}{Pr}}\left[ \frac{1}{r} \frac{\partial}{\partial r} \left( r\frac{\partial \hat{\vartheta}}{\partial r} \right)-m^2\frac{\hat{\vartheta}}{r^2}+\frac{\partial^2 \hat{\vartheta}}{\partial z^2}\right]. \end{align}

In these equations, the amplitudes of the azimuthal velocities have been transformed according to ![]() $\hat {\hat {v}}=\mathrm {i} \hat {v}$ and

$\hat {\hat {v}}=\mathrm {i} \hat {v}$ and ![]() $\hat {\hat {v}}_{g}=\mathrm {i} \hat {v}_{g}$ in order to render the coefficient matrix real and, thus, save computational memory for the numerical solution (Theofilis Reference Theofilis2003). For the sake of brevity, we have abbreviated the term

$\hat {\hat {v}}_{g}=\mathrm {i} \hat {v}_{g}$ in order to render the coefficient matrix real and, thus, save computational memory for the numerical solution (Theofilis Reference Theofilis2003). For the sake of brevity, we have abbreviated the term ![]() $\boldsymbol {\nabla }\boldsymbol{\cdot}\boldsymbol {u}'$ arising in the rate-of-strain tensor for the perturbation flow by

$\boldsymbol {\nabla }\boldsymbol{\cdot}\boldsymbol {u}'$ arising in the rate-of-strain tensor for the perturbation flow by ![]() $\boldsymbol {\nabla }\boldsymbol{\cdot}\boldsymbol {u}'=\alpha _\beta \varepsilon \zeta '$. These terms represent the deviation from a solenoidal perturbation flow. As can be seen from (2.10b) they are of the orders of

$\boldsymbol {\nabla }\boldsymbol{\cdot}\boldsymbol {u}'=\alpha _\beta \varepsilon \zeta '$. These terms represent the deviation from a solenoidal perturbation flow. As can be seen from (2.10b) they are of the orders of ![]() $O(\varepsilon )$ and

$O(\varepsilon )$ and ![]() $O(\varepsilon _{g})$ for the liquid and gas phase, respectively.

$O(\varepsilon _{g})$ for the liquid and gas phase, respectively.

2.2.3. Boundary conditions

To solve the two-dimensional version of (2.7) for the basic flow and of (2.12) for the three-dimensional perturbation flow suitable boundary conditions must be defined for both flows.

Solid walls. The velocity fields must satisfy the no-slip boundary conditions

on all solid walls, namely the support rods and the cylindrical tube confining the gas radially. Since the support rods are always made from good thermal conductors (e.g. Romanò et al. Reference Romanò, Kuhlmann, Ishimura and Ueno2017; Gotoda et al. Reference Gotoda, Toyama, Ishimura, Sano, Suzuki, Kaneko and Ueno2019), constant temperatures are imposed on the rods for the basic flow, while the perturbation temperature must vanish. The shield tube, on the other hand, is typically made from a good thermal insulator to keep its thermal effect on the gas flow at a minimum. Therefore, the heat fluxes due to both the basic and the perturbation temperature field are required to vanish on the shield tube. This leads to the thermal boundary conditions

Axis of symmetry. On the axis of symmetry at ![]() $r=0$ the axisymmetric steady basic flow must satisfy

$r=0$ the axisymmetric steady basic flow must satisfy

The boundary conditions for the perturbation flow can be derived from uniqueness conditions for ![]() $\partial u/\partial \varphi$ and

$\partial u/\partial \varphi$ and ![]() $\partial \vartheta /\partial \varphi$ as

$\partial \vartheta /\partial \varphi$ as ![]() $r\to 0$ (see also Batchelor & Gill Reference Batchelor and Gill1962; Xu & Davis Reference Xu and Davis1984) and depend on the wavenumber

$r\to 0$ (see also Batchelor & Gill Reference Batchelor and Gill1962; Xu & Davis Reference Xu and Davis1984) and depend on the wavenumber ![]() $m$. They are given in table 3.

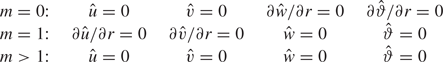

$m$. They are given in table 3.

Table 3. Boundary conditions for the perturbation flow on ![]() $r=0$.

$r=0$.

Liquid–gas interface. The flow in the liquid and in the gas phase are coupled through the interface. Since the location of the interface, described by ![]() $r=h(\varphi,z,t)$, is part of the solution, the flow and the location

$r=h(\varphi,z,t)$, is part of the solution, the flow and the location ![]() $h$ must be computed in a coupled manner. In the following we consider the axisymmetric steady basic flow and the corresponding time-independent shape function

$h$ must be computed in a coupled manner. In the following we consider the axisymmetric steady basic flow and the corresponding time-independent shape function ![]() $h_0(z)$.

$h_0(z)$.

Regardless of the shape of the interface, continuity of the temperature and of the heat flux across the interface at ![]() $r=h_0(z)$ require the thermal boundary conditions

$r=h_0(z)$ require the thermal boundary conditions

where

is the unit vector on the interface directed from the liquid into the gas. The tangent vector is defined as ![]() $\boldsymbol{t} = [(\partial _z h_0)\boldsymbol{e}_r +\boldsymbol{e}_z]/N$.

$\boldsymbol{t} = [(\partial _z h_0)\boldsymbol{e}_r +\boldsymbol{e}_z]/N$.

The velocity fields must satisfy kinematic and dynamic boundary conditions. The kinematic boundary conditions

ensure the continuity of the velocity and guarantee that a fluid element on the interface remains on the interface. The dynamic boundary condition is decomposed into a normal and a tangential stress balance by projecting the equilibrium of forces onto the normal (![]() $\boldsymbol{n}$) and tangential (

$\boldsymbol{n}$) and tangential (![]() $\boldsymbol{t}$) directions. The normal stress balance

$\boldsymbol{t}$) directions. The normal stress balance

\begin{align} &-(p_0-p_{g0}) +

\boldsymbol{n} \boldsymbol{\cdot} {\boldsymbol{\mathsf{S}}}_0

\boldsymbol{\cdot} \boldsymbol{n} + \left( \frac{1}{{Ca}}

-\vartheta_0\right)

\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n}\nonumber\\

&\quad

={-}\frac{{Bo}}{{Ca}}z-(\vartheta-\tilde{\rho}\tilde{\beta}\vartheta_{g0})\,{Bd}\,

z+\tilde{\mu}\boldsymbol{n} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{g0} \boldsymbol{\cdot} \boldsymbol{n}

\end{align}

\begin{align} &-(p_0-p_{g0}) +

\boldsymbol{n} \boldsymbol{\cdot} {\boldsymbol{\mathsf{S}}}_0

\boldsymbol{\cdot} \boldsymbol{n} + \left( \frac{1}{{Ca}}

-\vartheta_0\right)

\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n}\nonumber\\

&\quad

={-}\frac{{Bo}}{{Ca}}z-(\vartheta-\tilde{\rho}\tilde{\beta}\vartheta_{g0})\,{Bd}\,

z+\tilde{\mu}\boldsymbol{n} \boldsymbol{\cdot}

\boldsymbol{\mathsf{S}}_{g0} \boldsymbol{\cdot} \boldsymbol{n}

\end{align}

must be satisfied on ![]() $r=h_0(z)$. It is affected by the static Bond number

$r=h_0(z)$. It is affected by the static Bond number ![]() ${Bo}$ and the Capillary number

${Bo}$ and the Capillary number ![]() ${Ca}$ defined as

${Ca}$ defined as

They measure the relative importance of static and of hydrodynamic pressure differences, respectively, to the characteristic capillary pressure ![]() $\sigma _0/d$. Note that the ratio

$\sigma _0/d$. Note that the ratio ![]() $\tau ={Bd}/{Bo} = \rho _0\beta \sigma _0 / [\gamma (\rho _0-\rho _{g0})]$ is a material constant and almost a proportionality factor between

$\tau ={Bd}/{Bo} = \rho _0\beta \sigma _0 / [\gamma (\rho _0-\rho _{g0})]$ is a material constant and almost a proportionality factor between ![]() $\varepsilon$ and

$\varepsilon$ and ![]() ${Ca}$, since

${Ca}$, since ![]() $\varepsilon =(1-\tilde {\rho })\tau {Ca}$ and typically

$\varepsilon =(1-\tilde {\rho })\tau {Ca}$ and typically ![]() $\tilde {\rho }\ll 1$. In addition to (2.19) the tangential stress balance

$\tilde {\rho }\ll 1$. In addition to (2.19) the tangential stress balance

must also hold on ![]() $r=h_0(z)$. The thermocapillary stresses are represented by

$r=h_0(z)$. The thermocapillary stresses are represented by ![]() $-\boldsymbol{t}\boldsymbol{\cdot}\boldsymbol {\nabla } \vartheta _0$.

$-\boldsymbol{t}\boldsymbol{\cdot}\boldsymbol {\nabla } \vartheta _0$.

The stationary axisymmetric version of the differential equations (2.7) and the above boundary conditions for the basic state must be solved in a coupled way to yield the basic flow including the interfacial shape ![]() $h_0(z)$. The numerical solution is described in § 3. To be able to solve the problem two additional constraints for

$h_0(z)$. The numerical solution is described in § 3. To be able to solve the problem two additional constraints for ![]() $h_0$ are required, because the normal stress balance is of second order in

$h_0$ are required, because the normal stress balance is of second order in ![]() $z$. These are provided by the interface

$z$. These are provided by the interface ![]() $h_0(z=\pm 1/2 ) = 1/\varGamma$ being pinned to the sharp edges of the heated rods. In addition, for a non-volatile liquid the mass of the liquid bridge must be conserved. Since 2-cSt silicone oil is slightly volatile, accurate experiments (e.g. Yano et al. Reference Yano, Maruyama, Matsunaga and Nishino2016; Yasnou et al. Reference Yasnou, Gaponenko, Mialdun and Shevtsova2018; Gotoda et al. Reference Gotoda, Toyama, Ishimura, Sano, Suzuki, Kaneko and Ueno2019) control the volume of the liquid rather than the mass. Therefore, we impose the volume constraint

$h_0(z=\pm 1/2 ) = 1/\varGamma$ being pinned to the sharp edges of the heated rods. In addition, for a non-volatile liquid the mass of the liquid bridge must be conserved. Since 2-cSt silicone oil is slightly volatile, accurate experiments (e.g. Yano et al. Reference Yano, Maruyama, Matsunaga and Nishino2016; Yasnou et al. Reference Yasnou, Gaponenko, Mialdun and Shevtsova2018; Gotoda et al. Reference Gotoda, Toyama, Ishimura, Sano, Suzuki, Kaneko and Ueno2019) control the volume of the liquid rather than the mass. Therefore, we impose the volume constraint

\begin{equation} \varGamma^2\int_{{-}1/2}^{1/2} h_0^2(z)\,\mathrm{d} z={\mathcal{V}}, \end{equation}

\begin{equation} \varGamma^2\int_{{-}1/2}^{1/2} h_0^2(z)\,\mathrm{d} z={\mathcal{V}}, \end{equation}

where ![]() ${\mathcal {V}}=V_l/V_0$ is the liquid volume

${\mathcal {V}}=V_l/V_0$ is the liquid volume ![]() $V_l$ normalised by the volume

$V_l$ normalised by the volume ![]() $V_0={\rm \pi} r_{i}^2 d$ of an upright cylindrical liquid bridge. Throughout this investigation the liquid volume

$V_0={\rm \pi} r_{i}^2 d$ of an upright cylindrical liquid bridge. Throughout this investigation the liquid volume ![]() ${\mathcal {V}}$ is prescribed, not the mass of the liquid

${\mathcal {V}}$ is prescribed, not the mass of the liquid ![]() $M = \int _{V_l} \rho (\boldsymbol{x}) \,\mathrm{d} V$.

$M = \int _{V_l} \rho (\boldsymbol{x}) \,\mathrm{d} V$.

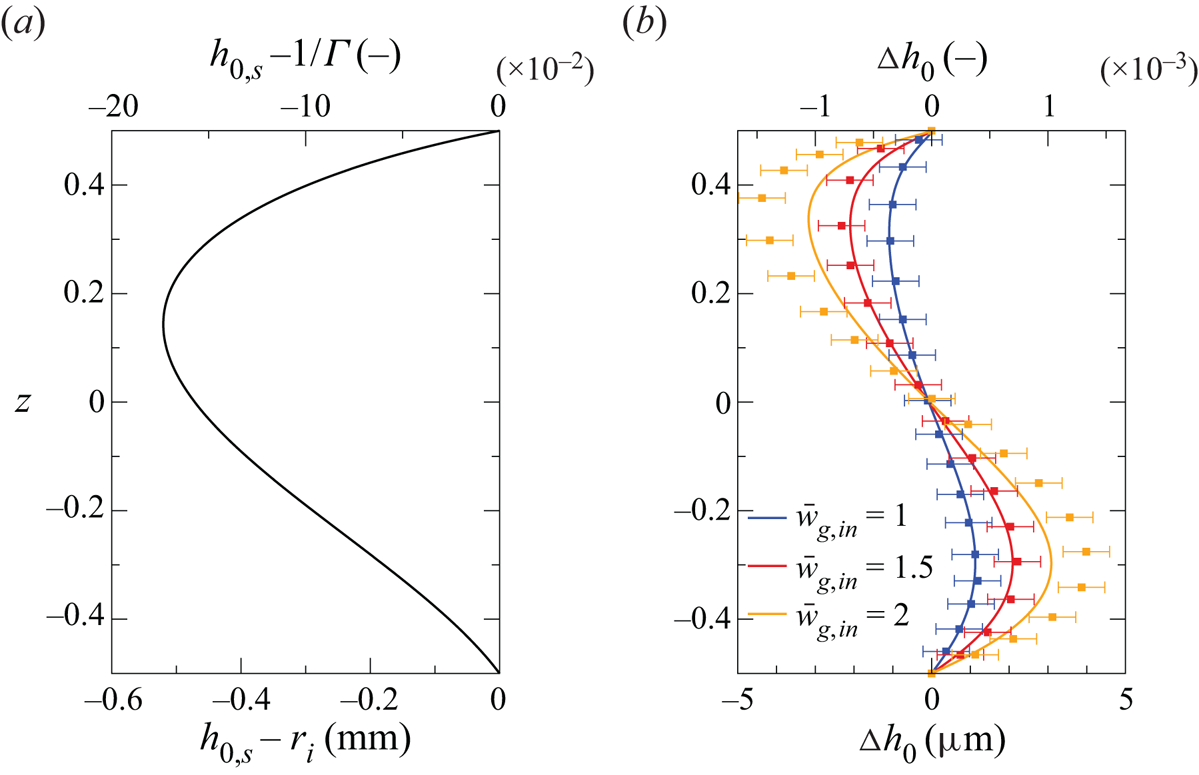

In order to identify the flow-induced contribution to the surface shape resulting from (2.19), and of its effect on the flow stability, we also consider the hydrostatic case (![]() ${\boldsymbol{u}_0=\boldsymbol{u}_{g,0}=0}$) in which (2.19) becomes the Young–Laplace equation

${\boldsymbol{u}_0=\boldsymbol{u}_{g,0}=0}$) in which (2.19) becomes the Young–Laplace equation

where ![]() $\Delta p_h$ is a constant overpressure (Kuhlmann Reference Kuhlmann1999). The resulting static surface shape is denoted

$\Delta p_h$ is a constant overpressure (Kuhlmann Reference Kuhlmann1999). The resulting static surface shape is denoted ![]() $h_{0,s}$ (subscript

$h_{0,s}$ (subscript ![]() $s$ denoting static). As long as the effect of the flow on the shape of the interface is weak,

$s$ denoting static). As long as the effect of the flow on the shape of the interface is weak, ![]() $h_{0,s}$ represents a good approximation to the true dynamic surface shape

$h_{0,s}$ represents a good approximation to the true dynamic surface shape ![]() $h_{0,d}$ (subscript

$h_{0,d}$ (subscript ![]() $d$ denoting dynamic) which results from (2.19). To assess the influence of the flow on the shape of the interface we define the dynamic surface deformation

$d$ denoting dynamic) which results from (2.19). To assess the influence of the flow on the shape of the interface we define the dynamic surface deformation ![]() $\Delta h_0 = h_{0,d} - h_{0,s}$ as the difference between both surface shapes. Similarly,

$\Delta h_0 = h_{0,d} - h_{0,s}$ as the difference between both surface shapes. Similarly, ![]() ${Re}_{c,s}$ and

${Re}_{c,s}$ and ![]() ${Re}_{c,d}$ denote the critical Reynolds numbers assuming a static or a dynamic interfacial shape, respectively, for the basic flow.

${Re}_{c,d}$ denote the critical Reynolds numbers assuming a static or a dynamic interfacial shape, respectively, for the basic flow.

Finally, interfacial coupling conditions must be provided for the perturbation flow. To reduce the computational effort, and motivated by the results of Carrión et al. (Reference Carrión, Herrada and Montanero2020), we neglect interfacial deformations due to the perturbation flow. In this approach, the interfacial conditions

where ![]() $\hat{\boldsymbol{\mathsf{S}}}=\boldsymbol {\nabla } \hat {\boldsymbol {u}} + (\boldsymbol {\nabla }\hat {\boldsymbol {u}})^{\textrm {T}} - 2/3(\boldsymbol {\nabla }\boldsymbol{\cdot}\hat {\boldsymbol {u}}){\boldsymbol{\mathsf{I}}}$, are imposed at

$\hat{\boldsymbol{\mathsf{S}}}=\boldsymbol {\nabla } \hat {\boldsymbol {u}} + (\boldsymbol {\nabla }\hat {\boldsymbol {u}})^{\textrm {T}} - 2/3(\boldsymbol {\nabla }\boldsymbol{\cdot}\hat {\boldsymbol {u}}){\boldsymbol{\mathsf{I}}}$, are imposed at ![]() $r=h_0(z)$. This approximation a priori precludes surface-wave instabilities which could possibly be triggered by the shear flow due to thermocapillary and/or mechanical stresses from the gas phase. However, such surface-wave instabilities have not yet been observed experimentally in the present flow system.

$r=h_0(z)$. This approximation a priori precludes surface-wave instabilities which could possibly be triggered by the shear flow due to thermocapillary and/or mechanical stresses from the gas phase. However, such surface-wave instabilities have not yet been observed experimentally in the present flow system.

Inlet and outlet. The gas enters the annular duct through the inlet located at ![]() $z=z_{in}$ with a dimensional mean inlet velocity

$z=z_{in}$ with a dimensional mean inlet velocity ![]() $\bar w_{g,in}$. It leaves the chamber through the outlet at

$\bar w_{g,in}$. It leaves the chamber through the outlet at ![]() $z=z_{out}$ on the opposite side. The oriented mean value

$z=z_{out}$ on the opposite side. The oriented mean value ![]() $\bar w_{g,in}$ can be either positive or negative depending on the direction of the through flow. To measure the intensity of the gas flow we define the gas flow Reynolds number

$\bar w_{g,in}$ can be either positive or negative depending on the direction of the through flow. To measure the intensity of the gas flow we define the gas flow Reynolds number

It can take positive and negative values. The Reynolds number (2.25) describes the forcing of the liquid flow due to the gas motion. As shown in Appendix A, ![]() ${Re}_{g}$ is better suited to correlate the effect of the gas motion on the liquid phase than the conventional Reynolds number

${Re}_{g}$ is better suited to correlate the effect of the gas motion on the liquid phase than the conventional Reynolds number ![]() ${Re}_{g}'$ based on the gap width

${Re}_{g}'$ based on the gap width ![]() $r_{o}-r_{i}$ and the kinematic viscosity of the gas

$r_{o}-r_{i}$ and the kinematic viscosity of the gas ![]() $\mu _{g}/\rho _{g0}$.

$\mu _{g}/\rho _{g0}$.

For ![]() ${Re}_{g} > 0$ (

${Re}_{g} > 0$ (![]() ${Re}_{g} < 0$) the forced flow is directed in positive (negative)

${Re}_{g} < 0$) the forced flow is directed in positive (negative) ![]() $z$ direction. Accordingly, the locations of the inlet and the outlet

$z$ direction. Accordingly, the locations of the inlet and the outlet

are determined by the sign of ![]() ${Re}_{g}$. To avoid entrance-length effects we assume a fully developed annular Poiseuille flow at

${Re}_{g}$. To avoid entrance-length effects we assume a fully developed annular Poiseuille flow at ![]() $z=z_{in}$:

$z=z_{in}$:

where the factor ![]() ${Re}^{-1}$ arises due to the scaling. At the outlet

${Re}^{-1}$ arises due to the scaling. At the outlet ![]() $z=z_{out}$, kinematic outflow conditions

$z=z_{out}$, kinematic outflow conditions

are imposed. Since the in- and outflow boundaries in a planned space experiment are realised by thermally conducting metallic porous media in contact with the support cylinders (S. Matsumoto, private communication), the gas enters/leaves the chamber with a homogeneous temperature

corresponding to the temperature of the rod next to the inlet/outlet. In the limit ![]() ${Re}_{g} \uparrow \downarrow 0$ (2.27) and (2.28) are replaced by rigid boundary conditions.

${Re}_{g} \uparrow \downarrow 0$ (2.27) and (2.28) are replaced by rigid boundary conditions.

Since the in- and outflow conditions are taken care of by the basic flow, the amplitudes of the perturbation flow must satisfy the homogeneous conditions

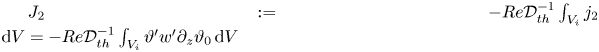

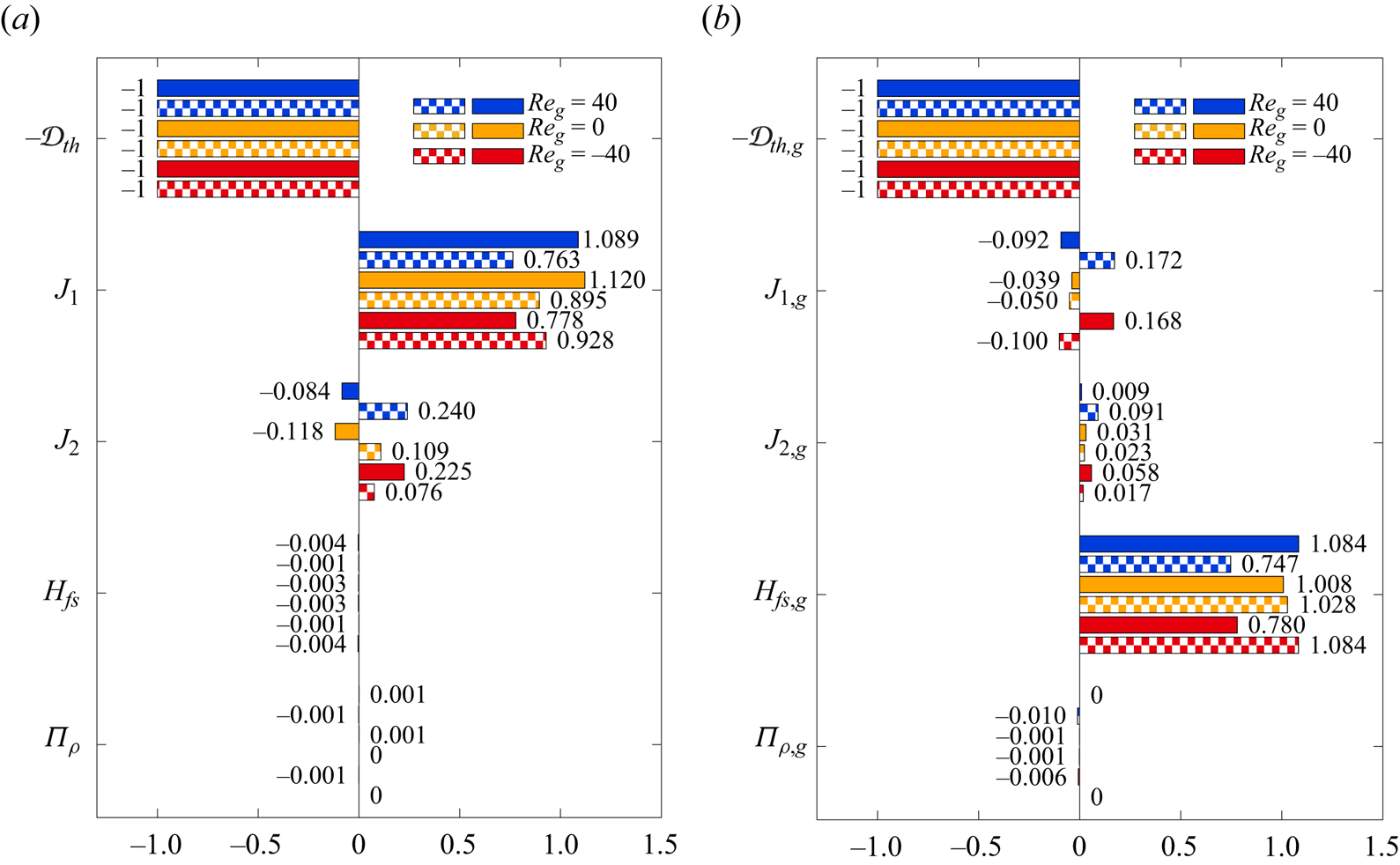

2.3. Energetics

The instability mechanism is investigated by the a posteriori energy analysis of the perturbation flow (Wanschura et al. Reference Wanschura, Shevtsova, Kuhlmann and Rath1995). The equations for the rates of change of the normalised kinetic and thermal perturbation energies in the liquid and in the gas phase

$$\begin{gather} \frac{\mathrm{d} E_{kin}}{\mathrm{d} t} = \frac{1}{{\mathcal{D}}_{kin}}\frac{\mathrm{d}}{\mathrm{d} t}\int_{V_i} \frac{{\boldsymbol{u}'}^2}{2} \,\mathrm{d} V ={-}1+ M_r + M_\varphi + M_z + \sum_{j=1}^5 I_j + B + K_{g} + \varLambda_\rho , \end{gather}$$

$$\begin{gather} \frac{\mathrm{d} E_{kin}}{\mathrm{d} t} = \frac{1}{{\mathcal{D}}_{kin}}\frac{\mathrm{d}}{\mathrm{d} t}\int_{V_i} \frac{{\boldsymbol{u}'}^2}{2} \,\mathrm{d} V ={-}1+ M_r + M_\varphi + M_z + \sum_{j=1}^5 I_j + B + K_{g} + \varLambda_\rho , \end{gather}$$ $$\begin{gather}\frac{\mathrm{d} E_{th}}{\mathrm{d} t} = \frac{1}{{\mathcal{D}}_{th}} \frac{\mathrm{d}}{\mathrm{d} t} \int_{V_i} \frac{{\vartheta'}^2}{2} \,\mathrm{d} V ={-}1 + \sum_{j=1}^2 J_j + H_{fs} + K_{th,g} + \varPi_\rho\end{gather}$$

$$\begin{gather}\frac{\mathrm{d} E_{th}}{\mathrm{d} t} = \frac{1}{{\mathcal{D}}_{th}} \frac{\mathrm{d}}{\mathrm{d} t} \int_{V_i} \frac{{\vartheta'}^2}{2} \,\mathrm{d} V ={-}1 + \sum_{j=1}^2 J_j + H_{fs} + K_{th,g} + \varPi_\rho\end{gather}$$

can be derived by multiplying (2.10a) and (2.10c) with ![]() $\boldsymbol {u}'$ and

$\boldsymbol {u}'$ and ![]() $\vartheta '$, respectively, integrating separately over the volume occupied by the liquid and by the gas, and normalising by the dissipation

$\vartheta '$, respectively, integrating separately over the volume occupied by the liquid and by the gas, and normalising by the dissipation ![]() ${\mathcal {D}}_{kin}$ and

${\mathcal {D}}_{kin}$ and ![]() ${\mathcal {D}}_{th}$, respectively. Detailed expressions and descriptions of all terms appearing in (2.31) can be found in Stojanovic et al. (Reference Stojanović, Romanò and Kuhlmann2022), who used the same notation. For a derivation of (2.31) for a full temperature dependence of all thermophysical parameters, we refer to Stojanović, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2023a). For the sake of completeness the individual terms are reproduced explicitly here. The kinetic energy budget contains the following terms which are identical with the ones known from the Oberbeck–Boussinesq approximation (Nienhüser & Kuhlmann Reference Nienhüser and Kuhlmann2002):

${\mathcal {D}}_{th}$, respectively. Detailed expressions and descriptions of all terms appearing in (2.31) can be found in Stojanovic et al. (Reference Stojanović, Romanò and Kuhlmann2022), who used the same notation. For a derivation of (2.31) for a full temperature dependence of all thermophysical parameters, we refer to Stojanović, Romanò & Kuhlmann (Reference Stojanović, Romanò and Kuhlmann2023a). For the sake of completeness the individual terms are reproduced explicitly here. The kinetic energy budget contains the following terms which are identical with the ones known from the Oberbeck–Boussinesq approximation (Nienhüser & Kuhlmann Reference Nienhüser and Kuhlmann2002):

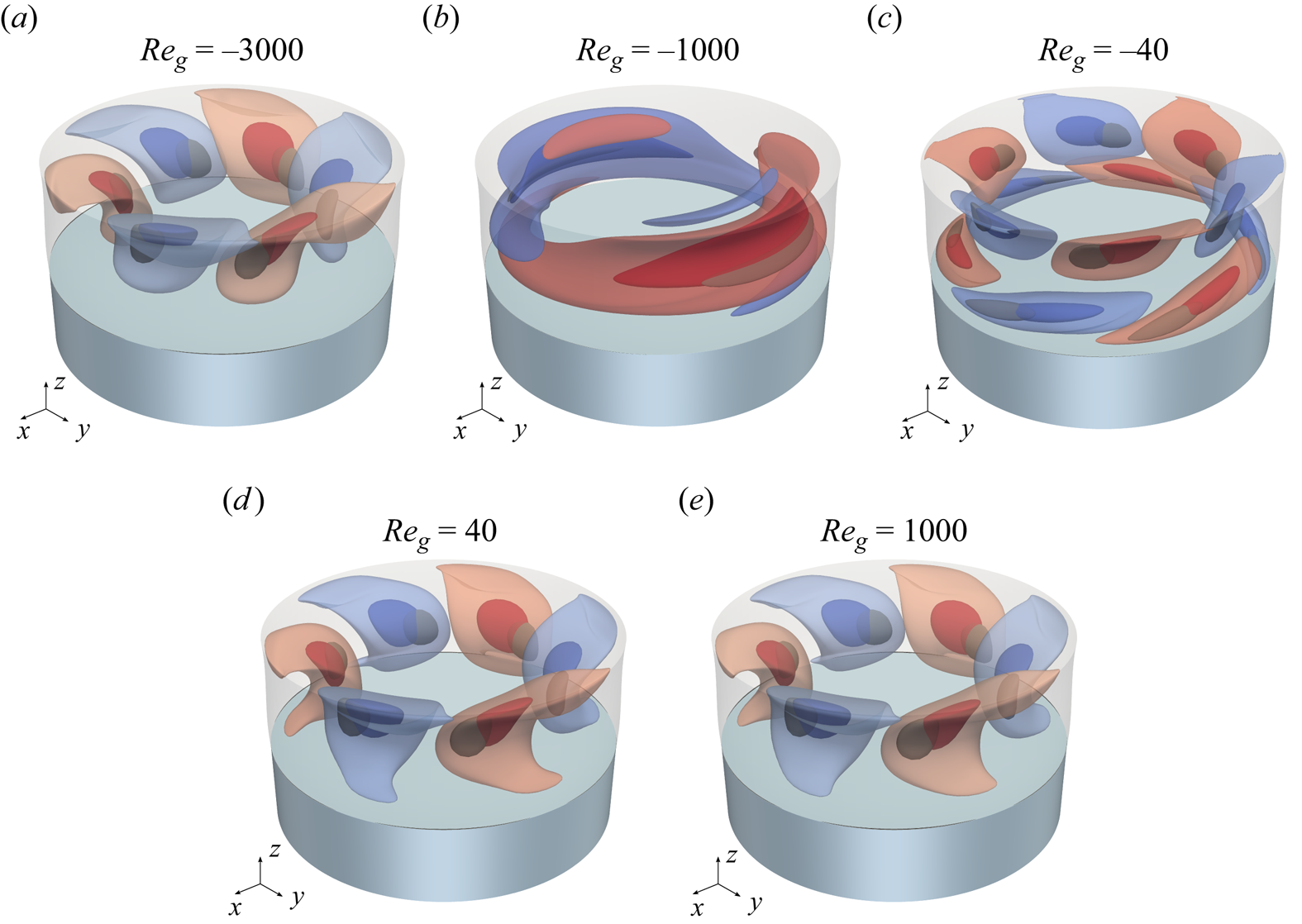

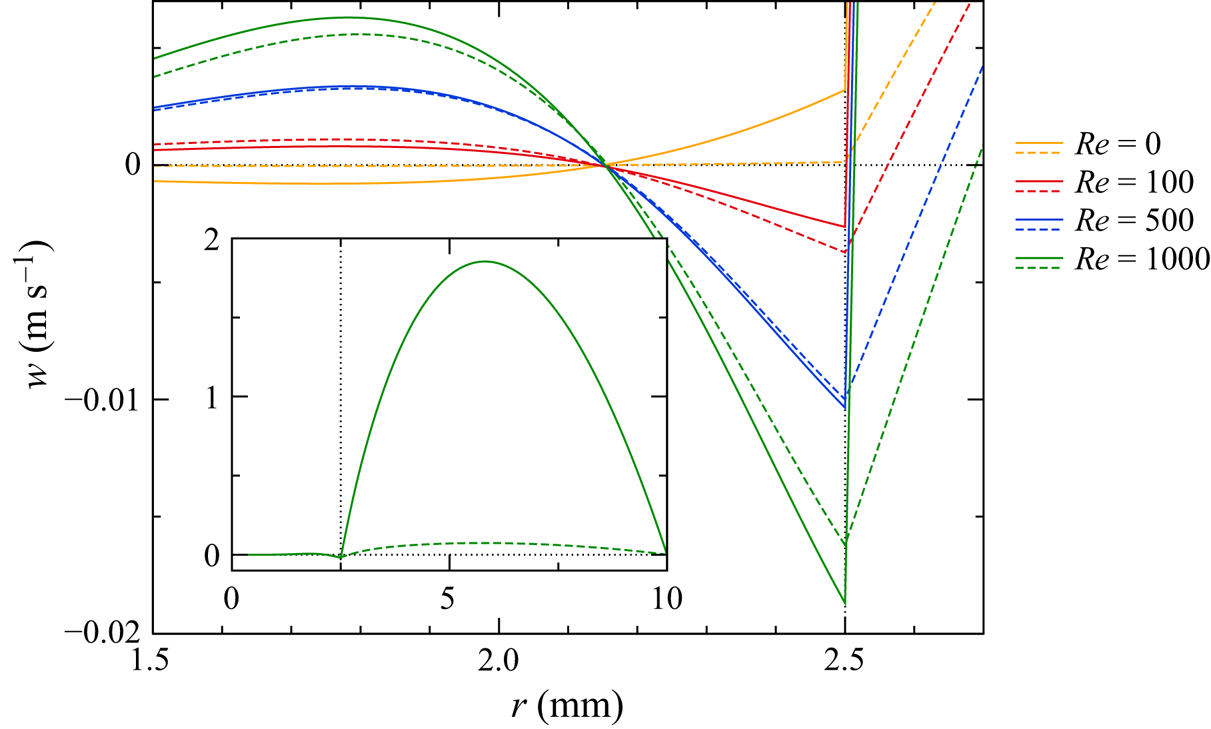

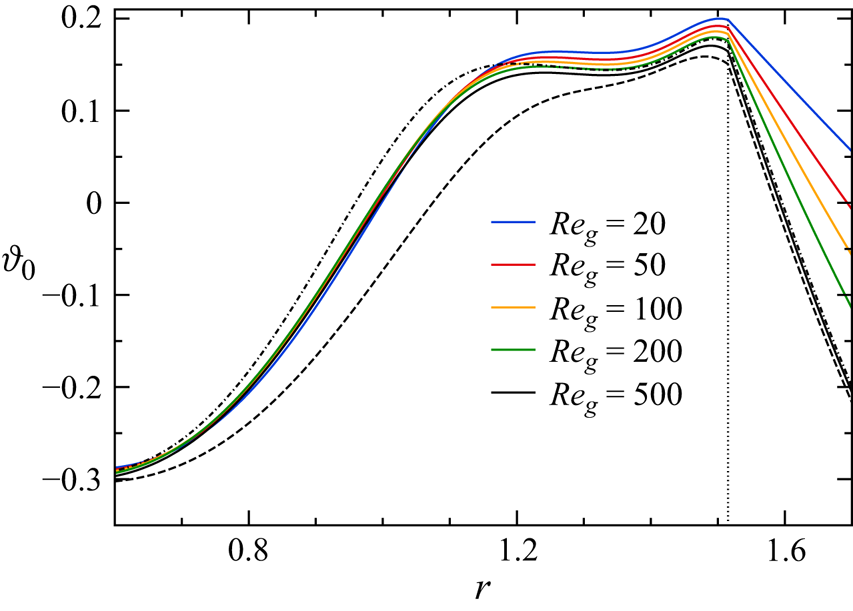

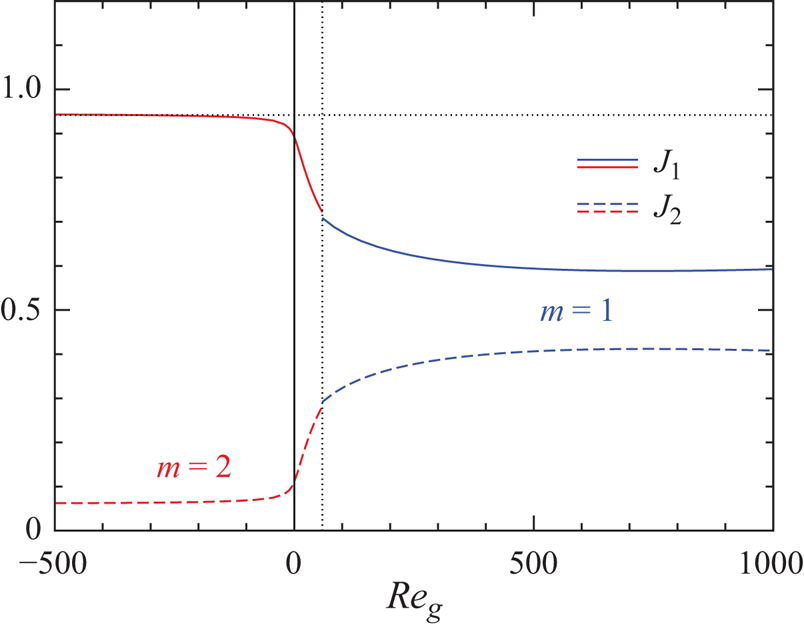

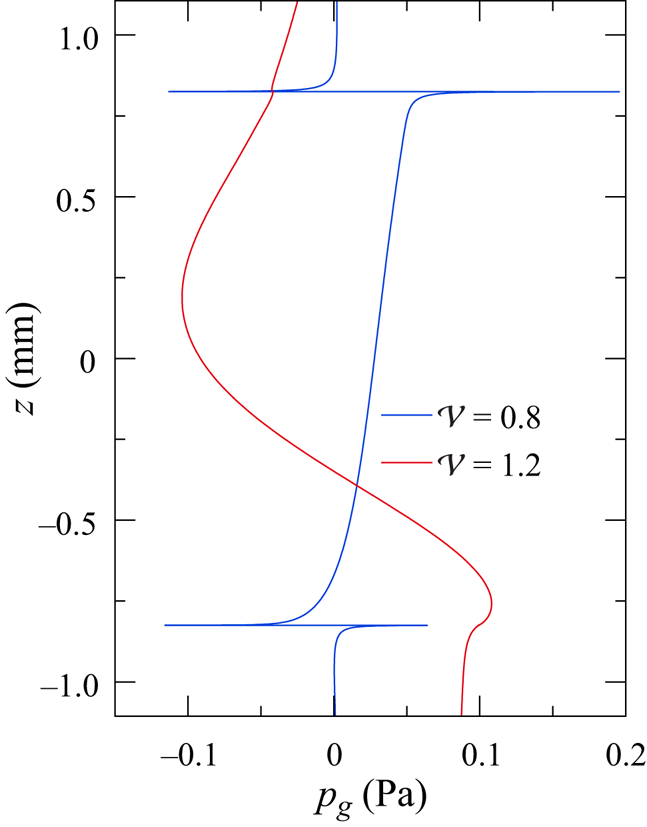

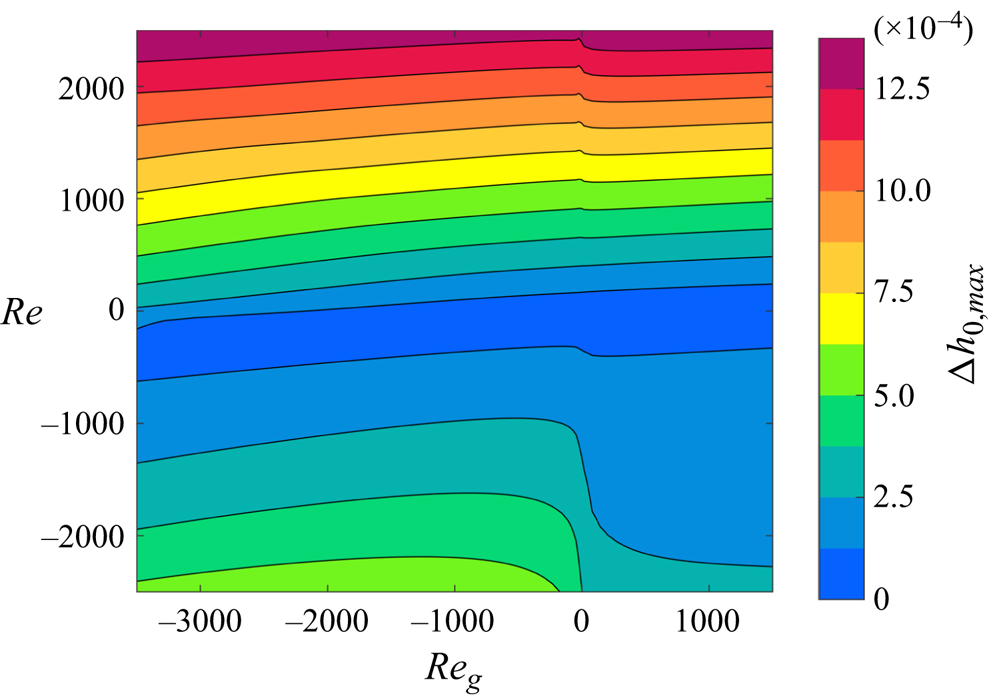

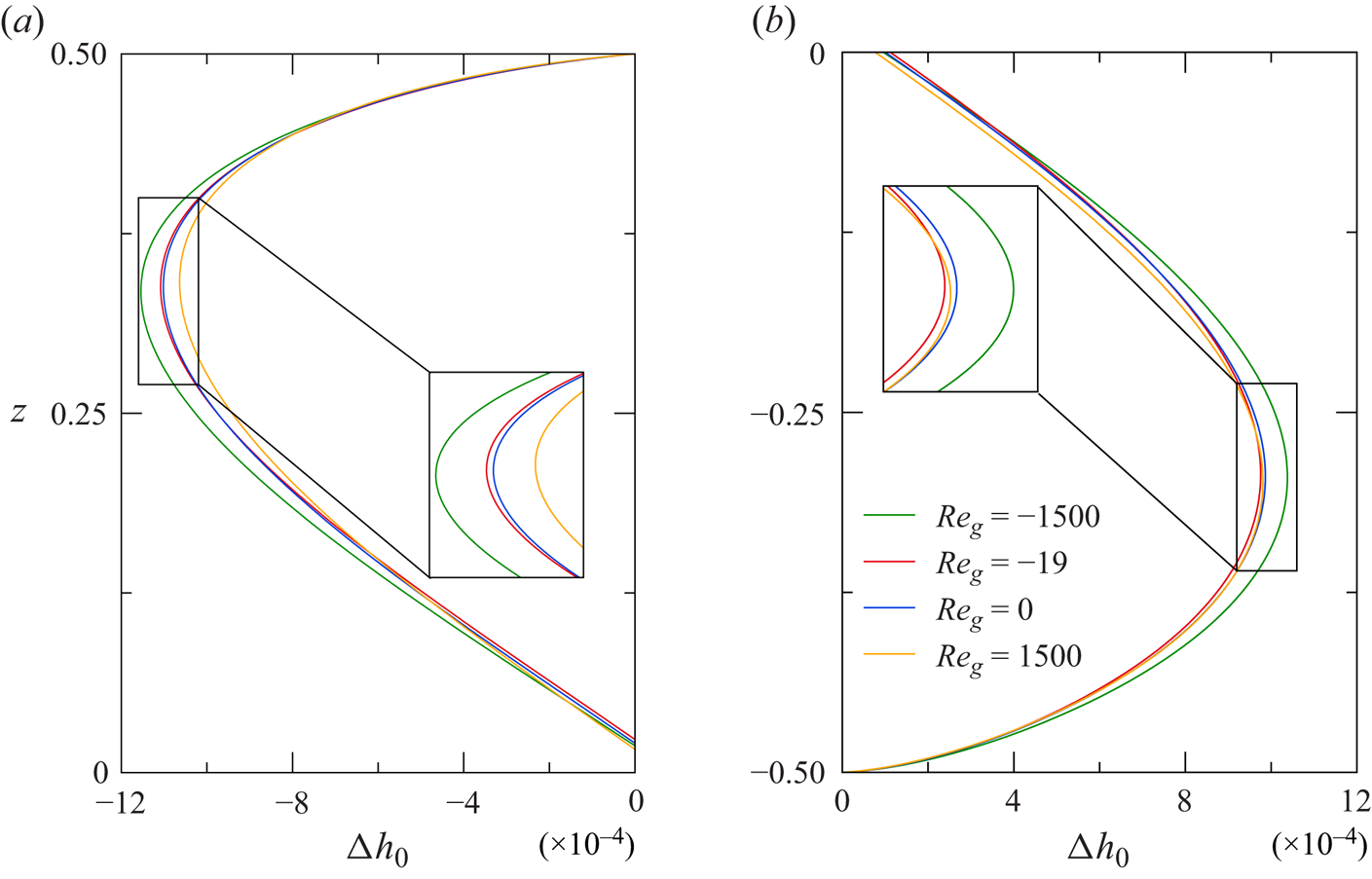

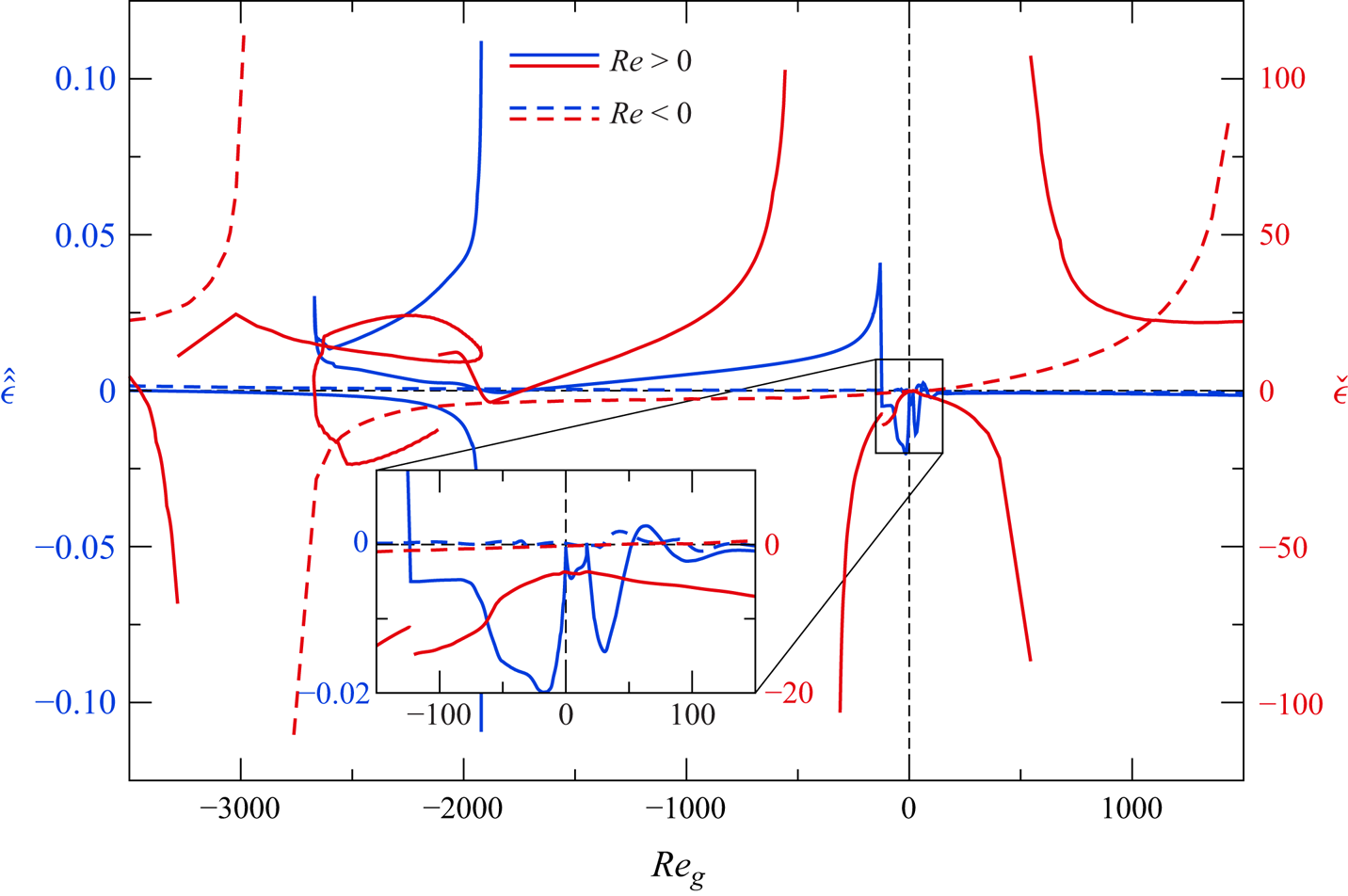

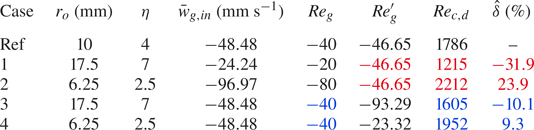

$$\begin{gather} {\mathcal{D}}_{kin} = \alpha_\mu \int_{V_i} (\boldsymbol{\nabla} \times \boldsymbol{u}')^2\, \mathrm{d} V \pm 8{\rm \pi}\alpha_\mu \int_{{-}1/2}^{1/2} ( h_0 (\partial_{zz} h_0) \hat{w}^2 - \hat{v}^2 )\,\mathrm{d} z, \end{gather}$$