Introduction

Textile finds are extremely scarce in ancient Anatolia—the region broadly corresponding to modern-day Türkiye. The soil in the region is generally too humid for the long-term preservation of fabric, though a few fragments have survived. Textile industries from the Neolithic to the end of the Bronze Age (c. 8000–1200 BC) can be reconstructed from these remains and from textile impressions on clay lumps (bullae) and a variety of tools and iconography (Andersson Strand et al. Reference Andersson Strand, Breniquet, Michel, Kulakoğu and Barjamovic2017; Maner Reference Maner, Yenişehirlioğlu and Çerçioğlu Yücel2018, Reference Maner, Pavuk, Pieniazek and Roosevelt2024; Sagona Reference Sagona2018; Yılmaz Reference Yılmaz and Yılmaz2022). In 2016 and 2018, burnt textile fragments were discovered during excavations at Beycesultan Höyük (henceforth Beycesultan), a distinctive Middle and Late Bronze Age centre, providing a window not only into the technological capabilities of the settlement, but also into its socioeconomic status and functional organisation of space. Little is known about Middle and Late Bronze Age textile manufacture and supply in Anatolia (c. 2000–1200 BC). Excavated spindle whorls, loom weights and tools help to reconstruct and understand the châine opératoire of local textile production. Cuneiform texts from the Old Assyrian Colony (c. 1972–1718 BC) and Hittite periods (c. 1650–1200 BC) also indicate the importance of wool, supply chains, textile manufacturing, trade and taxes, and underline the high value placed on wool and textiles during the Middle and Late Bronze Age in Anatolia. This article investigates the extraordinary textile fragments and tools from Beycesultan, placing them in their regional and interregional context during the Middle and Late Bronze Age.

Textile production in early societies

Textile production is one of the oldest crafts and has a significant place in ancient societies and economies. The remains of Palaeolithic and Neolithic textiles, baskets and cordage have been found in the Near East, North Africa and Europe. Early textile examples are made of plant fibres (mainly flax, Linum usitatissimum) and were produced using the same techniques as basketry, including twill and tabby weaves. The oldest known yarn was discovered in the Upper Palaeolithic layers (32 000–26 000 BP) at the Dzudzuana Cave in Georgia; the remains of dyed and undyed yarn made of wild flax might have been used for textile production (Kvavadze et al. Reference Kvavadze, Bar-Yosef, Belfer-Cohen, Boaretto, Jakeli, Matskevich and Meshveliani2009). At Çatalhöyük (seventh millennium BC; Konya, Türkiye) a tabby weave of oak bark appears to have been used to cover bodies before burial (Rast-Eicher et al. Reference Rast-Eicher, Karg and Bender Jørgenson2021). Early linen tabby weave, basketry and cordage have also been discovered at La Marmotta, Italy (eighth millennium BC; Mineo et al. Reference Mineo, Mazzucco, Rottoli, Remolins, Caruso-Ferme and Gibaja2023), while woven impressions on a clay ball from Jarmo (c. 7000 BC), are currently the earliest evidence of weaving in Iraq (Adovasio Reference Adovasio1975). By the end of the fourth millennium BC, animal husbandry and pastoralism became the primary form of livestock economy in the Near East and wool from sheep and goat began to be used for textile production, as examples from Arslantepe (Malatya, Türkiye) testify (Frangipane et al. Reference Frangipane, Andersson Strand, Laurito, Möller-Wiering, Nosch, Rast-Eicher and Lassen2009).

Ancient populations of the Ancient Near East, Egypt and the Caucasus were familiar with vat dyes and mordant dyes (Levey Reference Levey1955; Barber Reference Barber1991; Karadağ Reference Karadağ2007). The earliest evidence for dyed yarn were discovered in the Upper Palaeolithic layers of the Dzudzuana Cave (Kvavadze et al. Reference Kvavadze, Bar-Yosef, Belfer-Cohen, Boaretto, Jakeli, Matskevich and Meshveliani2009) and read thread dyed with ochre at Çatalhöyük (seventh millennium BC) (Mellaart Reference Mellaart1967; Barber Reference Barber1991). Remains of dyed textile are more frequent from the fourth millennium BC onwards and have been discovered in the Levant, Egypt, Mesopotamia, Anatolia and Europe and yellow, purple, blue, green, red and brown are among the attested colours on textile remains (Barber Reference Barber1991). Mesopotamians, Anatolians, Egyptians and Europeans were fond of bright-coloured cloths. A Cappadocian tablet from Alişar (second millennium BC; Yozgat, Türkiye) mentions “63 bright-colored (garments) for the clothing of servant boys” (Gelb Reference Gelb1935). From the Pharaoh Unas (Fifth Dynasty) onwards, red and blue fringes and pinstripes were woven into the borders of white linen to refine the garment (Riefstahl Reference Riefstahl1944) and in the cave site of Adaouste, in southern France, textile fibres dyed with red kermes dating to the Late Neolithic period have been discovered (Barber Reference Barber1991). The textiles from Beycesultan broaden our understanding of early textile production, presenting evidence for the use of technology and raw materials previously unknown in Anatolia.

Beycesultan: archaeological background

Beycesultan, a site of 35ha, is located within the borders of the Çivril District of the Denizli Province, Türkiye (Figure 1). The settlement mound is located 5km south-west of Çivril and to the north of the Çivril-Denizli highway. The excavations at Beycesultan were initiated in 1954 by Seton Lloyd for the British Archaeological Institute in Ankara and lasted six seasons until 1959 (Lloyd & Mellaart Reference Lloyd and Mellaart1962, Reference Lloyd and Mellaart1965; Lloyd Reference Lloyd1972; Mellaart & Murray Reference Mellaart and Murray1995). Lloyd identified 40 cultural layers running from the Late Chalcolithic to the end of the Bronze Age. A major discovery of these early excavations was the ‘Burnt Palace’—so named owing to its destruction by a huge fire—that dates to the first quarter of the second millennium BC (Lloyd Reference Lloyd1972). Located on the eastern cone of the site, the Burnt Palace is the most substantial palace structure yet found in western Anatolia. Its construction and layout are comparable with the contemporaneous Warsama Palace at Kültepe and the Sarıkaya administrative building at Acemhöyük in central Anatolia (Matz Reference Matz1975: 68–87).

Figure 1. Map showing the location of Beycesultan Höyük (map from https://www.harita.gov.tr/urun/denizli-fiziki-il-haritasi/422, figure by authors).

Systematic excavations were restarted by Eşref Abay in 2007. Excavations were carried out mainly on the western cone of the settlement and, between 2007 and 2018, 10 levels were determined. Level 1 dates to the Ottoman Principality Period (thirteenth–fifteenth centuries AD) and immediately overlies a two-phased Byzantine settlement (levels 2a1–a2 and 2b phases). Level 3 represents the Iron Age and was only identified in the cemetery area, 500m west of the settlement. Levels 4 and 5 date to the Late Bronze Age, while levels 6–10 belong to the Middle Bronze Age (Abay & Dedeoğlu Reference Abay and Dedeoğlu2009; Dedeoğlu & Abay Reference Dedeoğlu and Abay2014).

Discovery of textile fragments

The burnt textile fragments were discovered inside Middle and Late Bronze Age structures and are the only textile remains discovered so far at Beycesultan. The first textile fragment (Tx1) was discovered in 2016 in the north-west courtyard of room 3 from level 10 on the western cone of the settlement mound (Abay et al. Reference Abay, Dedeoğlu, Ergün, Çakar and Ünar2017) (Figure 2). Although only parts of the building have been excavated, its overall structure is rectangular and extends north-east to south-west. It is not currently clear, however, if the area called room 3 is actually a courtyard belonging to room 2 or if both rooms together form part of a larger building.

Figure 2. Site plan showing the location of Tx1 in room 3 of the Middle Bronze Age house (above) and excavation photograph showing Tx1 in situ (below) (photograph courtesy of the Beycesultan archive, figure by authors).

Rooms 2 and 3 were destroyed by fire and radiocarbon analyses date level 10 to 1915–1745 BC, thought to be contemporary with the Burnt Palace (Dedeoğlu & Abay Reference Dedeoğlu and Abay2014: 39, table 1-2). In the centre of the building is a courtyard with a square hearth and north-east of this is a 1.5m-high square platform. Along the western wall of the courtyard were found a variety of vessels, storage jars and clay basins. Due to the narrow excavated area (10 × 10m) and the limited number of architectural elements identified, it is difficult to comment further on the size, function and status of the building. The burnt textile fragment was discovered in the western part of the room, which was probably used as a workshop area. The textile had adhered to the ground and spread over an area of around 0.45m (Figure 2). A disc-shaped stone weight was discovered on top of the textile (diameter: 150mm; weight: 0.5kg), and burnt grain and remains of baskets made of branches were discovered nearby. Just to the west of the burnt textile fragment were four postholes (diameter 50mm) set at 50mm distances from each other. These postholes likely belonged to a loom.

The second textile fragment (Tx2) was discovered in 2018 in room 28 of level 5b. Room 28, a space in a large domestic house destroyed by fire (Figure 3), was dated by radiocarbon analysis to 1700–1595 BC (Dedeoğlu & Abay Reference Dedeoğlu and Abay2014: 39, Table 1-2). This house is located on the western side of the settlement mound and six rooms have been uncovered during the excavations so far. Like the other houses unearthed in layer 5b, this house has a storage room containing large storage jars. Clay chests made for storage also line the walls of room 28 and the four postholes in the section of the wall of the adjacent room may indicate that a loom had stood there. At the centre of the room stands a 2.2 × 1.5m hearth, around which several cooking pots were also found. On the southern side of the hearth, 105 shell beads, 123 ovicaprid astragali, nine spindle whorls and various stone tools have been found. Tx2 was found just to the south of the hearth in front of the southern wall, under hundreds of pottery sherds (Figure 3). Around the burnt textile were found a wooden weaving comb, the remains of a basket made of branches, four stone tools of unknown function, clay spindle whorls and loom weights, a sling pellet, perforated seashells, bone and stone beads, a polishing stone, two bronze needles, one bronze spear head and the remains of a bone object with geometric motifs possibly belonging to a weaving sword. Together, the finds from room 28 suggest that this space was probably used as a textile workshop.

Figure 3. Site plan (top) and excavation photographs (middle & bottom) showing the location of Tx2 in room 28 (photographs courtesy of the Beycesultan archive, figure by authors).

Textile tools

The textile tools discovered at Beycesultan indicate that it was a major textile producing settlement during the Bronze Age. Spinning and weaving activities can be reconstructed from the presence of spindle whorls, loom weights, needles and awls. Clay finds from levels 2–5, in particular, indicate considerable weaving activity; among the 74 clay objects recovered, 42 are spindle whorls with 25 of them found in level II (level 5b of the new excavation) (Murray Reference Murray, Mellaart and Murray1995: 118; Dedeoğlu & Abay Reference Dedeoğlu and Abay2014). At the beginning of the Middle Bronze Age, spindle whorls are truncated and biconical in shape and decorated with geometric motifs, which are sometimes filled with a decorative white paste. Murray observes that the spindle whorls of the Late Bronze Age are larger, cone shaped, decorated all over and crudely made of buff clay with white-filled incisions (Murray Reference Murray, Mellaart and Murray1995: 118). In level III (level 6 of the new excavation), the tall conical spindle whorl starts to appear and this style also prevails in level II (level 5b of the new excavation), while clay loom weights are both wedge- and crescent-shaped (Murray Reference Murray, Mellaart and Murray1995).

The excavations since 2007 have recovered the same types of spindle whorls and loom weights (Ergün Reference Ergün2013). The diameter of spindle whorls from level 5b (1700–1595 BC) varies between 22mm and 44mm; the artefacts are made of clay and bone, most are decorated with geometric motifs and their shapes are discoid, circular, conical, biconical and truncated. The spindle whorls from levels 5a1 and 5a2 (1600–1500 BC) have a diameter of 19–46mm and a truncated form; they are also decorated with geometric patterns. Loom weights from level 5b (1700–1595 BC) have various shapes: crescent, pyramidal, rectangular and triangular. The loom weights from levels 5a and 5b have crescent, pyramidal and discoid shapes. Spindle whorls from level 4a (1500–1400 BC) have diameters ranging from 25–46mm and are truncated, conical, biconical and circular in shape, while loom weights are crescent- and pyramidal-shaped.

Experimental archaeology conducted by the Tools, Textiles, Texts and Contexts (TTTC) research programme at the Centre for Textile Research at the University of Copenhagen in Denmark shows that the weight and diameter of spindle whorls determine the quality of the yarn produced (Olofson et al. Reference Olofson, Strand, Nosch, Andersson Strand and Nosch2015). Thin yarn is spun with lighter spindle whorls and thick yarn with heavier ones, as lighter spindle whorls are ineffective at spinning thick yarn and thin yarn breaks when spun with a heavier spindle whorl.

In room 28, 47 spindle whorls of different types were discovered (Table 1, Figure 4) together with five baked-clay loom weights of crescent, pyramidal and hoof shapes (Figure 4). The loom weights are an indicator that vertical warp weighted looms were used at Beycesultan. Experiments with loom weights show that the weight and thickness are two important parameters for the quality and type of the woven fabric. For example, heavier and thicker loom weights were used for coarser textile with thicker threads (Mårtensson et al. Reference Mårtensson, Nosch and Strand2009). The selection of spindle whorls and loom weights from room 28 suggests there was an established, developed and specialised textile industry producing a variety of yarn with different thicknesses and both fine and coarse fabrics.

Table 1. Types of spindle whorls in room 28 level 5b (1700–1595 BC).

Figure 4. Spindle whorls (above) and loom weights (below) from room 28. All scales are 50mm (courtesy of the Beycesultan archive).

Fibre analysis methods

Textile characterisation was performed on Tx1 and Tx2. Both were initially examined using a polarised optical microscope (OLYMPUS SZ61 (SZ2-ILST, camera C18U)) to illuminate the structure of the fibres and identify production techniques. All reference fibre samples and all chemicals for analyses were provided by the DATU-Cultural Heritage Preservation and Natural Dyes Laboratory in İstanbul, Türkiye. Indigotin dyestuff used as the reference standard was obtained from Sigma Aldrich (St Louis, Missouri, USA).

Sample preparation for HPLC-PDA analysis

The HPLC-PDA (high performance liquid chromatography with photodiode array detection) method was used to detect possible dyestuff(s) in each fabric sample. Archaeological samples were prepared according to standard procedures, as were historical samples that were not underground. Liquid samples were extracted from each textile fragment using organic solvents and 1–3mg of these samples were weighed before dyestuff analysis. The samples were hydrolysed in 400μL of a 37 per cent solution of H2O/MeOH/HCl (at a volumetric ratio of 1:1:2) and kept at 100oC for eight minutes to extract the organic dyes. Then, the samples were evaporated (at 65oC) under a gentle nitrogen flow. The dry residue was dissolved in 400μL of MeOH/H2O (2:1) and the samples were centrifuged (where necessary, further dilution and then centrifugation at 4000rpm/25oC/10 min took place). For HPLC analysis 100μL of each sample was used (Wouters Reference Wouters1985; Karadağ & Torgan Reference Karadağ and Torgan2016). As indigotin was detected in the Tx1 sample (Figure 5), dyestuff analysis was repeated with dimethyl sulfoxide. For this analysis, the sample was solubilised with 200μL dimethyl sulfoxide, then treated at 80oC for 10 minutes and analysed in HPLC (Mantzouris et al. Reference Mantzouris, Karapanagiotis and Panayiotou2014).

Figure 5. A) chromatogram of Tx1 at 255nm obtained after solubilisation with MeOH:H2O (methanol water); B) chromatogram of Tx1 at 276nm obtained after solubilisation with dimethyl sulfoxide; C) comparison of the spectrum detected in chromatogram B with the indigotin reference standard (figure by authors).

Chromatographic measurements were carried out using an Agilent 1200 series system (Agilent Technologies, Hewlett-Packard, Germany) including a G1322A Degasser, G1311A Quat pump, G1329A autosampler, G13166 Thermostatted Column Compartment and G1315D Diode Array Detector. Photodiode array detection was performed by scanning from 191–799nm with a resolution of 2nm, and the chromatographic peaks were monitored at 255, 268, 276, 350, 491, 520, 580 and 620nm—the wavelengths are those at which dye structures (anthraquinone, flavonoid, indigoid, or synthetic dyes) were detected in natural or synthetic dyes that were used to colour fibres or fabrics in history. A Nova Pak C18 analytical column (39 × 150mm, 4μm, Part No WAT 086344, Waters) was used. Analytical and guard columns were maintained at 30°C and the data station was the Agilent Chemstation. Two solvents were utilised for chromatographic separations of the hydrolysed samples—solvent A: H2O–0.1% trifluoroacetic acid and solvent B: CH3CN–0.1% trifluoroacetic acid.

SEM analysis

Scanning electron microscopy (SEM) was used to ascertain if threads were made from animal or plant fibres, such as sheep or goat wool or linen, hemp, cotton or jute fibres. Sample fibres were attached to a carbon band and coated with a gold/palladium (60/40) target to achieve a clearer image. Cross-sections of threads were also made to identify source fibres. Samples were analysed at 5keV energy using a TESCAN VEGA3 Scanning Electron Microscope (TESCAN, Brno, Czech Republic). This was equipped with backscattered electron (BSE) and secondary electron (SE) detectors and an energy-dispersive x-ray detection system. It has a thermionic emission SEM system that comes with a tungsten heated filament.

Results

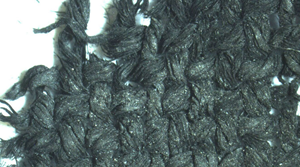

Under the optical microscope Tx1 does not show warp and weft and so is probably knitted rather than woven (Figure 6A–B). The fabric seems to be made of one or more continuous threads, similar to knitted fabrics such as nålbinding (also known as single-needle knitting). The yarn is 2.25mm thick and is Z-twisted. Comparison of longitudinal and cross-sectional SEM images of fibres from Tx1 with other reference fibres (each morphologically distinct, especially in cross-section), highlights structural similarities with hemp fibres (Figure 7). Under standard HPLC-PDA, the retention times of the Tx1 sample at a wavelength of 255nm are 26.857 and 27.235 minutes (Figure 5A). Subsequent analysis using dimethyl sulfoxide solubilisation indicates a retention time at 276nm of 28.633 minutes (Figure 5B), suggestive of the presence of indigotin. Indigoid dyes such as indigotin and indirubin show the most intense spectral absorption at 276nm wavelength (Torgan Güzel Reference Torgan Güzel2023).

Figure 6. Optical microscope images of Tx1 (A & B) and Tx2 (C; yellow scale bar = 5436.690μm) (images courtesy of the Datu Lab).

Figure 7. SEM images of Tx1: upper image) a longitudinal SEM view of the fibres in the Tx1 sample; lower image) the fibre cross-section. (images courtesy of the Datu Lab).

Optical microscopy images of Tx2 reveal a typical tabby weave (a plain weave, where the weft goes over one warp strand then under the next, and so on; Figure 6C), and the warp and weft are clear (warp density 12 ± 1 thread/cm and weft density 14 ± 1 thread/cm). The SEM image of Tx2 is not very clear (Figure 8), probably because the textile is too carbonised, though the yarn is likely to be made of plant or bark fibres such as hemp or linen. Dyestuff analysis of Tx2 did not indicate the use of any dyes (chromatographs not shown), so it is probable that the fabric was a natural colour.

Figure 8. SEM images of Tx2: upper image) a longitudinal view of the fibres in the Tx2 sample; lower image) the fibre cross-section (images courtesy of the Datu Lab).

Tabby weave

Tabby weave has been produced in Anatolia since the Neolithic period. The earliest known examples date to the seventh millennium BC and were discovered at Çayönü (Özdoğan Reference Özdoğan and Özdoğan1999: 55) and Çatalhöyük (Rast-Eicher et al. Reference Rast-Eicher, Karg and Bender Jørgenson2021). The tabby weave, and hence Tx2, was produced on a vertical loom, which has been used for thousands of years in Anatolia. Hemp is planted in the Çivril Plain today and the longue durée of this practice is indicated by Tx1. If Tx2 is also made of hemp, this would be the first example of Late Bronze Age tabby weave made from hemp in the region.

Nålbinding

Nålbinding (single-needle or knotless knitting) is a yarn-looping technique that uses a single needle to create a fabric. The needle used for nålbinding is large, flat, blunt and single eyed, and may be made of bone, wood or metal. Nålbinding is conducted from left to right and, unlike traditional knitting that uses a single continuous thread, several suitable lengths of yarn may be cut and used. The earliest example of nålbinding dates from the Neolithic and was discovered at the Nahal Hemar Cave in Israel; the fabric was probably used as headgear (Schick Reference Schick1986). The Coptic nålbinding stitch, also known as cross-knit looping, is a distinct form as “the needle loops a thread directly through stitches made in the previous row (not over the thumb) to form new stitches” (Sagona Reference Sagona2018: 9). Socks (including one red pair) dating to AD 250–420 and AD 1100–1300, discovered in Egypt and now in the Victoria and Albert Museum in London, were made using the Coptic nålbinding stitch (Grass Reference Grass1955).

At Sos Höyük in eastern Turkey and Chobareti in Georgia, textile impressions on Early Bronze Age pottery indicate cross-knit looping in single- and double-needle knitted textiles (Sagona Reference Sagona2018). A cross-knit looping sample (Figure 9A) reproduced by Claudia Sagona and impressed in play dough shows the stitch when stretched (Figure 9B) and when relaxed (Figure 9C). These are the closest examples, in terms of how they look, to interpret Tx1 from Beycesultan, specifically the relaxed cross-knit looping sample. This suggests that Tx1 was probably produced in the nålbinding or cross-knit looping technique (Figure 5).

Figure 9. Sample of single element, cross-knit looped stitch (A) and impressions made in clay when the sample is stretched (B) or relaxed (C) (after Sagona Reference Sagona2018: 11, figs. 5–7).

Indigo dyes

The history of natural dyeing is as old as the history of weaving. Natural organic dyes are obtained from a variety of sources, including plants, tree bark, insects and molluscs. These were used in the textile dyeing industry until the mid- to late nineteenth century AD. Cuneiform tablets (c. 2500–700 BC) from Mesopotamian settlements mention vat dyeing and mordant dyeing methods (Levey Reference Levey1955; Barber Reference Barber1991; Karadağ Reference Karadağ2007). Vat dyes and paints have also been used in the Aegean and eastern Mediterranean since the Early Bronze Age (Karapanagiotis et al. Reference Karapanagiotis, Mantzouris, Cooksey, Mubarak and Tsiamyrtzis2013). During the Early Minoan III and Middle Minoan II periods (c. 2200–1700 BC), eastern Crete was a major centre of purple-dye manufacturing (Betancourt et al. Reference Betancourt, Apostolakou, Brogan, Nosch and Laffineur2012). Indigo blue was one of the earliest and most popular organic dyestuffs. Archaeological excavations in the Indus Valley of the Mohenjo Daro region unearthed a small amount of indigotin dating back to 3500 BC (Marshall Reference Marshall1931: 585), suggesting that indigo may have been first used in the area of Pakistan-India. Fragments of blue yarn were identified recently in the eighth century BC Tumulus MM at Gordion, central Türkiye, which is the tomb of either King Midas or his father (Ballard et al. Reference Ballard, Newsome, Simpson and Burke2023).

Indigo sources are found all over the world, and several plants were most probably used in antiquity. Isatis tinctoria L., also known as woad (Figure 10), grows in Anatolia, the Levant and Europe, and indigo from Indigofera tinctoria was exported from Persia to Muslim Spain between the eighth and fifteenth centuries AD, and from there distributed to other European countries. Species of Indigofera produced a high-quality indigo, which was used in medieval illuminations (Melo Reference Melo, Bechtold and Mussak2009). Woad is biennial, growing as a rosette in the first year and producing a stalk up to 1.5m tall in the second year. Blue-coloured dye is obtained by fermenting the leaves of the plant (Cardon Reference Cardon2007; Karadağ Reference Karadağ2007; Hardman & Pinhey Reference Hardman and Pinhey2009).

Figure 10. Anatolian Isatis tinctoria L. (photograph by Recep Karadağ).

Blue dyed textiles and garments in cuneiform texts

Tx1 is the oldest blue fabric discovered in a Bronze Age context in Anatolia and its periphery. Cuneiform texts (c. 2500–700 BC) indicate that blue wool and garments were very valuable and popular. Woad was known by the Sumerians as š amZA.GIN.NA and dyed wool as SÍG.ZA.GÌN/uqnâtu (Levey Reference Levey1955). It was fashionable to wear a sunu (a piece of clothing that could be attached to a fine garment or was used as a headband) of dark blue wool in the mid-second millennium BC in Mesopotamia (Thavapalan Reference Thavapalan2020: 315). The Akkadian word for lapis lazuli-coloured wool is uqnû, its adjectival form uqnâtu meaning “like lapis lazuli” (Thavapalan Reference Thavapalan2020: 315). Hittite cuneiform texts mention wool and garments coloured white, blue, purple, yellow, green, red and black (Košak Reference Košak1982). The Hittite word for blue is antara and blue and purple wool is listed alongside extensive numbers of textile bundles and garments paid in tributes (Levey Reference Levey1955). Most of the lists named individuals who were bringing wool and garments probably as taxation to the capital city Hattuša. They mention the quantity of blue wool, and garments made of blue wool such as blue mašum-cloths, mantles, headbands and blue leggings (Košak Reference Košak1982: 106–46). These were garments in the wardrobe of royalty and the elite. The garment list of the Hittite Tunavi festival includes robes, undergarments and blue socks (Darga Reference Darga1984: 86–7).

Minoan frescoes at Knossos and Akrotiri show that blue textile was used to highlight certain parts of garments worn by the elite (Doumas Reference Doumas1992). Blue wool was exchanged as a gift among elites and was taken as tribute in the Late Bronze Age in the Near East, Eastern Mediterranean and Aegean (Thavapalan Reference Thavapalan2020: 316). At the tomb of Tutankhamun, dark and light blue wool was discovered, which had been dyed with indigotin (Vogelsang-Eastwood Reference Vogelsang-Eastwood, Nicholson and Shaw2000: 194–95). Blue textile and garments were therefore principally consumed and worn by elite societies in the Aegean, Anatolia, Levant and Egypt during the Middle and Late Bronze Age.

Luxury textiles

Exotic and dyed textiles have been discovered at Acemhöyük, Kaman Kalehöyük and Seyitömer Höyük in central Anatolia and at Qatna in Syria. At Acemhöyük burnt textile remains decorated with dark and light blue beads were discovered in the Sarıkaya palace together with ivory objects and seals (Özgüç Reference Özgüç1966: 21). At Kaman Kalehöyük a textile fragment made in the sumaq technique has been discovered in level IIIC room 150 (Fairbairn Reference Fairbairn2004). The textiles from Acemhöyük and Kaman Kalehöyük date to the Old Assyrian Colony Period. Fragments of woven textile and yarn have also been recovered from the Middle Bronze Age level IV C at Seyitömer Höyük. The textile was discovered in a grave and analysis indicates that it is a tabby weave made of wool and dyed with madder (Rubia tinctorum L.), which would have produced a red colour (Bilgen & Tütüncüler Bircan Reference Bilgen and Tütüncüler Bircan2017: 29). In the tomb of the Bronze Age royal palace at Qatna in Syria purple dyed fabrics in plain weave and a coloured tapestry segment woven with the kilim technique have been discovered (James et al. Reference James2009).

Conclusions

The new finds from Beycesultan present a unique glimpse into the Middle and Late Bronze Age textile industry, both at this particular site and in the region more broadly. Tx1 and Tx2 indicate that Beycesultan was producing a range of textiles, including exotic and luxury fabrics, consistent with reconstructions of economic and social structure from other material finds. Few examples of plain tabby weave have been found at Bronze Age sites in Anatolia, Mesopotamia and the Caucasus; the presence of Tx2 at Beycesultan therefore adds new evidence for the use of the warp-weighed loom during this period (Barber Reference Barber1991: 163–73) and indicates that room 28 was probably a textile workshop. Production of Tx1, and possibly also Tx2, using hemp adds a new plant fibre to the Bronze Age textile industry of the Near East.

Tx1 is the first nålbinding fabric found in Anatolia and the Near East and could indicate the transfer of technology or the trade of fabric between Anatolia and Georgia (Caucasus), where impressions of nålbinding have been found on pottery sherds (Sagona Reference Sagona2018). Identification of indigotin dyestuff indicates that Tx1 was stained with one of the indigo dyes, most likely woad as the plant grows locally in Anatolia. Associated radiocarbon dates for Tx1 place it in the period of the Old Assyrian trading colonies. These were involved in textile exchange with Assur and controlled the Anatolian market. Cuneiform texts indicate that blue fabric was worn by elite individuals and provided as tax to the capital, and remnants of such textiles have been discovered in royal tombs. The presence of Tx1 in room 3 suggests the space was part of an elite building, perhaps a palatial structure, a temple or the house of a rich trader. No cuneiform texts have thus far been discovered at Beycesultan, so its ancient name remains unknown, yet the extraordinary textile finds and workshop remains indicate that Beycesultan must have been a regional capital.

Acknowledgements

We would like to thank the Ministry of Culture and Tourism of Türkiye and the Denizli Museum for providing us the necessary permissions. Ferhat Erikan prepared the drawings and figures of the finds for which we are grateful. We are grateful to Prof. Claudia Sagona for the permission to use her cross-knit looping sample in our article. We also thank Mark Wilson and Dan Bolitho for improving the use of English in this article.

Funding statement

This research was sponsored by the Koç Üniversitesi Seed Fund Project ‘Untwist Beyce’ (SF 000.71).