Graphene oxide (GO), a compound produced by the oxidation and exfoliation of graphite, is commonly used for mass production of graphene in laboratories. GO has largely been engineered into either dispersions or gels so far, and consequently GO-derived graphene solids typically take the form of thin films or foams. Now, a group of researchers led by Jiaxing Huang of Northwestern University has greatly diversified graphene-based architectures by discovering a dough state of GO. Like flour doughs, GO doughs are soft, cohesive, and highly processable into customized three-dimensional, freestanding structures without binder additives. This study is reported in Nature Communications (doi:10.1038/s41467-019-08389-6).

The intrinsic properties of GO are promising for making doughs. “To obtain a dough state, one needs high-aspect-ratio nanomaterials so that they can entangle with each other. The entangled structure must also be able to slide to withstand plastic deformation,” Huang says. “GO works well because [its] nanosheet morphology has high aspect ratio, and earlier works have demonstrated that water in GO facilitates inter-sheet slide,” he added.

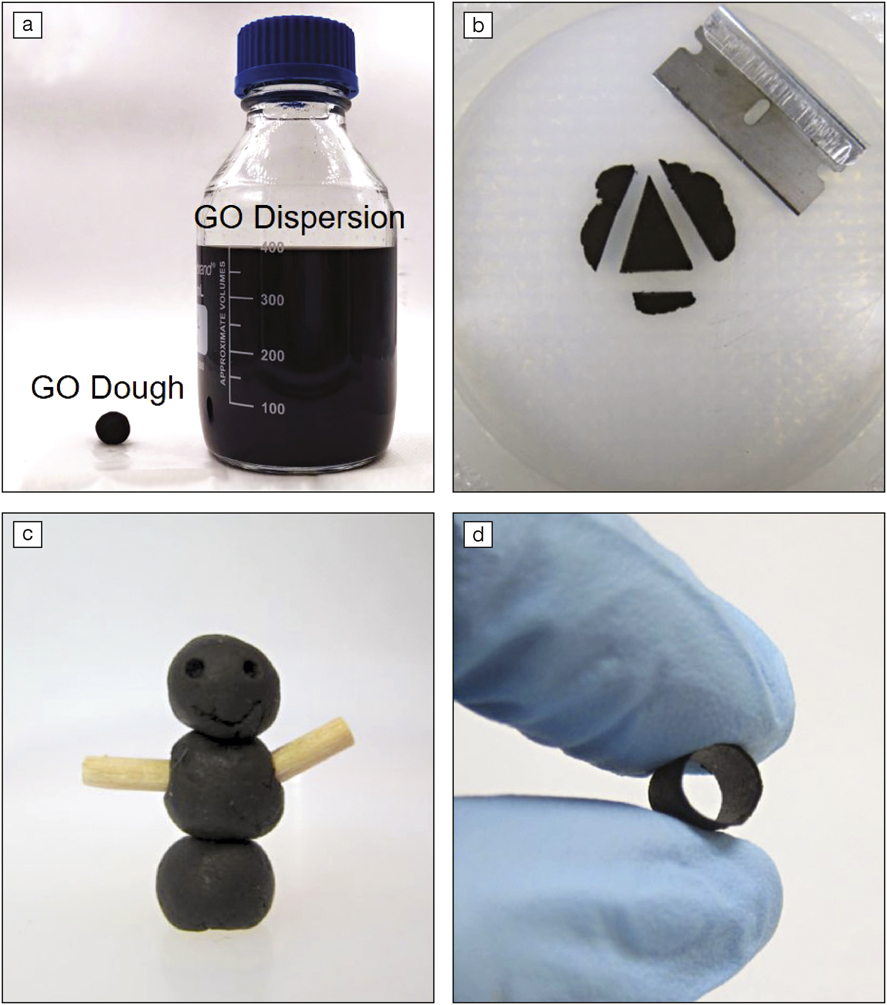

(a) A photograph of a graphene oxide (GO) dough and a GO dispersion with identical GO mass of 800 mg. GO doughs can be processed into a diverse array of self-standing, 3D shapes by (b) cutting with a blade, (c) carving with wooden sticks, and (d) rolling into a tube. Figure credits: (a) Haiyue Huang and (b–d) Nature Communications.

Obtaining GO doughs, however, is nontrivial. A dough state contains large masses of solid but only a minute amount of solvent (water), hence uniformly and thoroughly hydrating GO becomes a critical step. The researchers observed that dropping a small aliquot of water onto GO powder only resulted in local hydration of GO. “Eventually we found that moisturizing a freeze-dried GO foam with water mist from a hand-held aerosol generator, e.g., a nanospray sold as a skin care product, worked very well,” Huang says. The researchers found that the GO foams turned into doughs when the water content was between 40 and 80 wt%.

The GO doughs possess unique features that GO dispersions or gels cannot achieve. First, their volumes are much smaller than GO dispersions with identical GO masses. The compact nature eases the transportation and storage of GO products. Second, the GO doughs are readily processable into three-dimensional architectures with customized shapes by carving, pinching, and molding without structural disintegration. Third, the GO doughs can be converted to GO dispersions by diluting in water, or robust glassy GO solids by air-drying.

Marcus Worsley of Lawrence Livermore National Laboratory, who is not involved in this work, says the discovery of the GO dough form is exciting. “It will be curious to see how the properties of the GO itself, for example, lateral dimension and degree of oxidation, impact the properties of the doughs,” Worsley says. “This will be critical for the reproduction of this work in other labs.”

Collaborating with visiting professor Chun-Hu Chen from the National Sun Yat-sen University, Taiwan, the Northwestern team demonstrated that the GO doughs can function as supports for embedding electrocatalysts, as one example of unique applications of this material. In future work, the researchers will explore methods to reduce the GO doughs into various shaped graphene products. “We wish to leverage the dough state to make graphene as useable as plastics, metals, or ceramics,” Huang says.