Introduction

Four thousand years ago, two bodies were sequentially laid to rest in the barrow now known as Upton Lovell G2a. An integral component of Piggott's (Reference Piggott1938) Wessex Culture, the site remains critical to our understanding of Early Bronze Age Britain, and the assemblage of bodies, stone tools and the elaborate costume continue to place the burial centre-stage in debates about Bronze Age status, belief and metalworking. Archaeologists have focused principally on the issue of identity: who was the person wearing the elaborate costume? A shaman? A metalworker? A goldsmith? These questions bypass the second buried individual and treat the materials in the grave as solely representative of the primary inhumation. In this article, we provide a different perspective, taking an approach that is theoretically rooted in new materialism (Crellin Reference Crellin2020; Harris Reference Harris2021) in order to focus less on who someone was and more on what they did and on the surrounding materials. We combine this theoretical framework with the first microwear and scanning electron microscope (SEM-EDS) analysis of many of the site's stone tools. The results contribute new insights to Early Bronze Age crafts, especially goldworking.

Upton Lovell G2a

Located in Wiltshire, Upton Lovell G2a was a 10m circular mound, upstanding to 0.3m, which was excavated by William Cunnington in 1801. The probable primary inhumation, in a supine position, was found at the base of a 1m-deep chalk-cut grave. A second individual was found above the first in a ‘sitting posture’ (probably a crouched inhumation; Piggott Reference Piggott1962: 93). The primary burial is usually described as male, although no osteological assessment has been published (Piggott Reference Piggott1962: 96). The barrow contained a large number of grave goods, but no plans survive; whilst the written description of the excavations clearly associates certain items with the primary burial, others may have been interred with the secondary inhumation.

The primary burial's grave goods (Tables 1–2; Table S1 in the online supplementary material (OSM)) include more than 40 perforated bone points; most were found close to the individual's feet (Cunnington Reference Cunnington1806; Piggott Reference Piggott1962). Other finds by the feet include nine stone ‘rubbers’ (modified stone cobbles), a stone grooved abrader, a copper alloy awl, two broken battle axes, and four polished flint axes, three of which were complete. Further up the body, close to the legs, were three perforated boars’ tusks and four flint nodule ‘cups’. By the chest was a complete battle axe and further bone points. Other grave goods less clearly associated with either body include three jet beads, a bone bead and a jet belt ring.

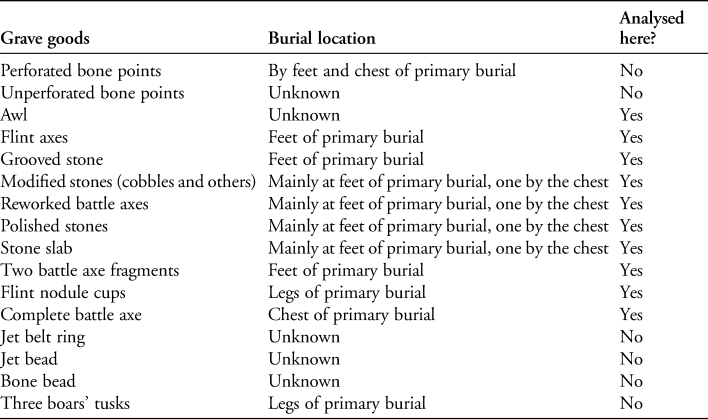

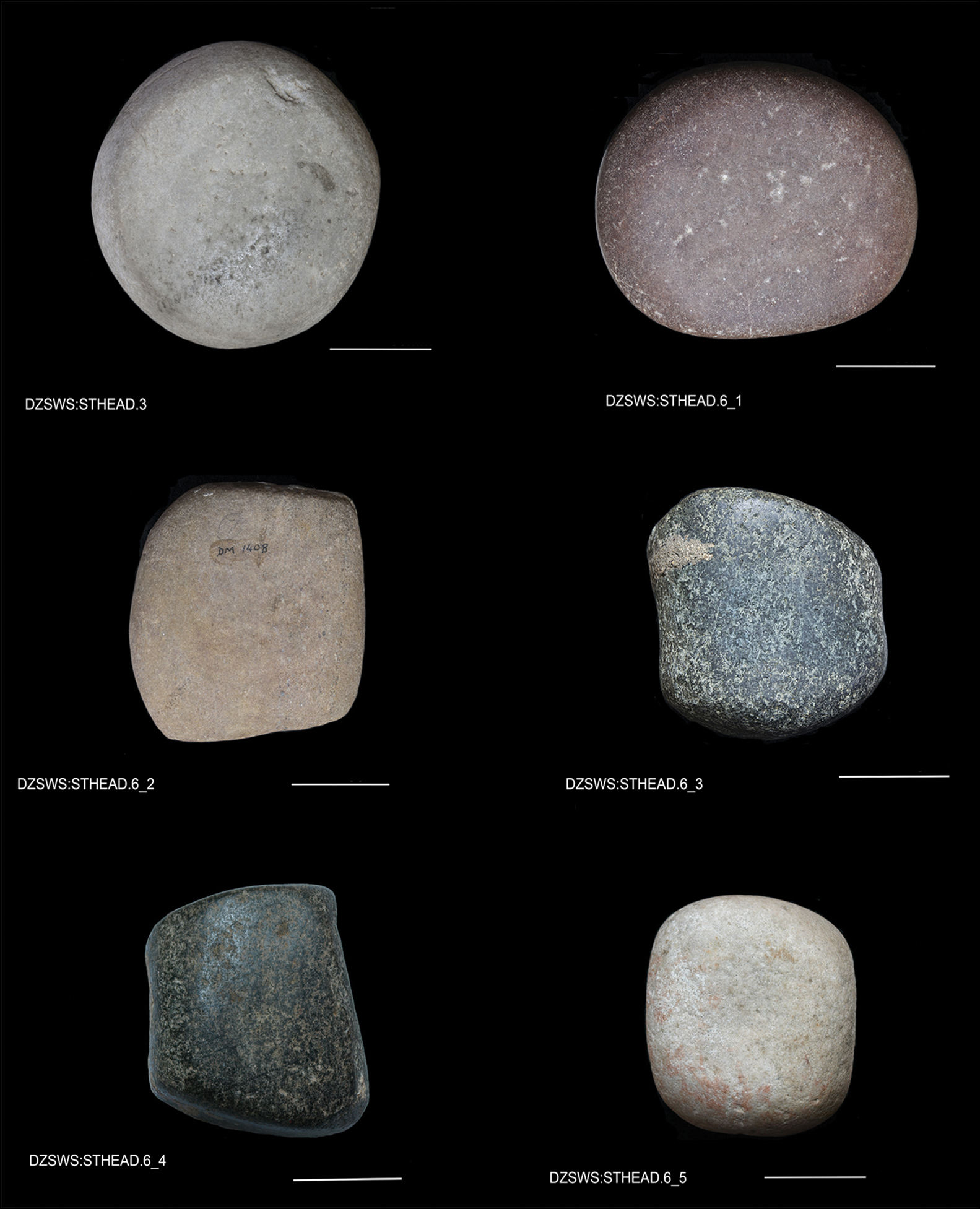

Table 1. Grave goods from Upton Lovell G2a.

Table 2. Grave goods studied as part of this article. Note that DZSWS:STHEAD.6, DZSWS:STHEAD.4A and DZSWS:STHEAD.4 (accessioned under one number) are subdivided for this research.

Shaman, metalworker, goldworker

The grave goods have attracted multiple interpretations. From the outset, the literature has emphasised the ‘primary male burial’, with little attention to the other individual (e.g. Piggott Reference Piggott1962; Boutoille Reference Boutoille and Brandherm2019; Shell Reference Shell2000). Piggott (Reference Piggott1962: 94) argued that the bone points and boars’ tusks were part of a costume and that the burial dated to c. 1500 BC. Today, the burial is considered as part of Needham's Wessex 1 group (Needham et al. Reference Needham2010), and is now thought, based on the Stage III battle axes (Roe Reference Roe1966; Roy Reference Roy2020), the type 2a/b awl (Woodward & Hunter Reference Woodward and Hunter2015: 466) and the bone points (Woodward & Hunter Reference Woodward and Hunter2015: 467), to date to between 1850–1700 BC.

Piggott (Reference Piggott1962) compared the burial to European Mesolithic examples, where such costumed individuals are interpreted as shamans. He therefore argued that the individual was both a shaman and someone of considerable prestige (Piggott Reference Piggott1962: 96). As a result, the burial is often referred to as the Upton Lovell shaman, in part to distinguish it from the nearby, richly furnished ‘golden barrow’, Upton Lovell G2e. Piggott (Reference Piggott and Crittall1973) later compared the stone grave goods to metalworking tools from continental Europe, suggesting that the individual was a metalworker. Shell (Reference Shell2000: 271), highlighting that Thurnham (Reference Thurnham1870: 425f) had identified gold traces on one of the stone tools (STHEAD.2a), employed non-destructive, semi-quantitative X-ray fluorescence to analyse the traces, demonstrating that their elemental composition was similar to examples of Early Bronze Age gold. Shell concluded that the individual may have been a shaman, a metalworker, a goldworker, or possibly all three. Recent comparative typo-morphological analyses by Boutoille (Reference Boutoille and Brandherm2019) have confirmed that some of the tools were hammers used for metalworking and one was a touchstone for assessing gold quality. To date, therefore, the grave goods have played a key role in discussion of the identity of one of the individuals buried at Upton Lovell G2a. But can we do more with these materials?

Stories in stone and metal

Seeking to consider the other stories that these objects could tell, we take a three-fold approach. First, we employ microwear analysis to study the stone and metal artefacts (see OSM1). Microwear analysis is a well-established analytical technique that studies macro- and microscopic traces on the surface of objects to understand how they were manufactured, used and handled (Keeley Reference Keeley1980; van Gijn Reference van Gijn1990, Reference Van Gijn2010; Dubreuil et al. Reference Dubreuil, Marreiros, Gibaja Bao and Ferreira Bicho2015). Woodward and Hunter (Reference Woodward and Hunter2015) have previously conducted low-magnification analysis of some objects from the burial (Table S1), focusing mainly on manufacturing traces and providing an assessment of the degree of wear. Our analysis significantly expands upon their work by conducting detailed low- and high-power microscopic analysis (up to ×200 magnification) of all the stone objects, as well as the copper alloy awl, in order to consider contact materials and kinetics. We consider how these objects were used and what kinds of gestures and motions created surface wear, taking similarities to indicate shared processes and allowing us to think about them as components of a toolkit.

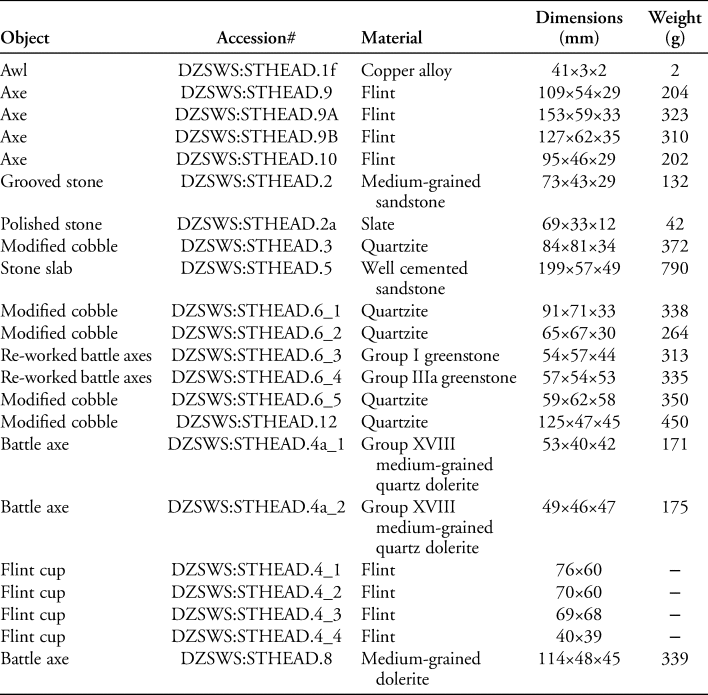

Second, this approach allows us to identify key areas on the tools’ surfaces for non-destructive compositional analysis, using SEM-EDS to detect specific elements. Comparison of the results with known gold-alloy compositions of Early Bronze Age metalwork demonstrates that the metal traces identified on the surfaces of five stone tools are consistent with an Early Bronze Age origin, alongside a sixth possible example (Table 3 & OSM2).

Table 3. Summary of the microwear and SEM evidence. Note that DZSWS:STHEAD.6, DZSWS:STHEAD.4A and DZSWS:STHEAD.4 (accessioned under one number) are subdivided for this research. NTI = no traces identified, NA = not analysed, BA = Bronze Age.

Third, we situate these approaches within a new materialist approach (Tsoraki et al. Reference Tsoraki, Barton, Crellin and Harris2020). This emphasises both the vibrancy of matter—as always in motion and contributing to the production of the world—and that materials make a fundamental contribution to history (Crellin Reference Crellin2020; Harris Reference Harris2021). This approach advances on traditional technological studies in two ways. First, whereas materials are usually approached as having fixed properties, new materialists argue that these properties emerge relationally; they change through time and in combination with other materials, people and places (cf. Barad Reference Barad2007; Bennett Reference Bennett2010). Second, ‘making’ is seen not as the simple imposition of the will of a maker on an inert material but, instead, materials play an active role in the process. Combining scientific analyses and new materialism allows us to address what things actually did, rather than seeing them as a passive reflection of, for example, identity. Hence, we build on the strengths of microwear analysis but situate the results within a perspective that emphasises the historical role of materials.

Making metal move through stone

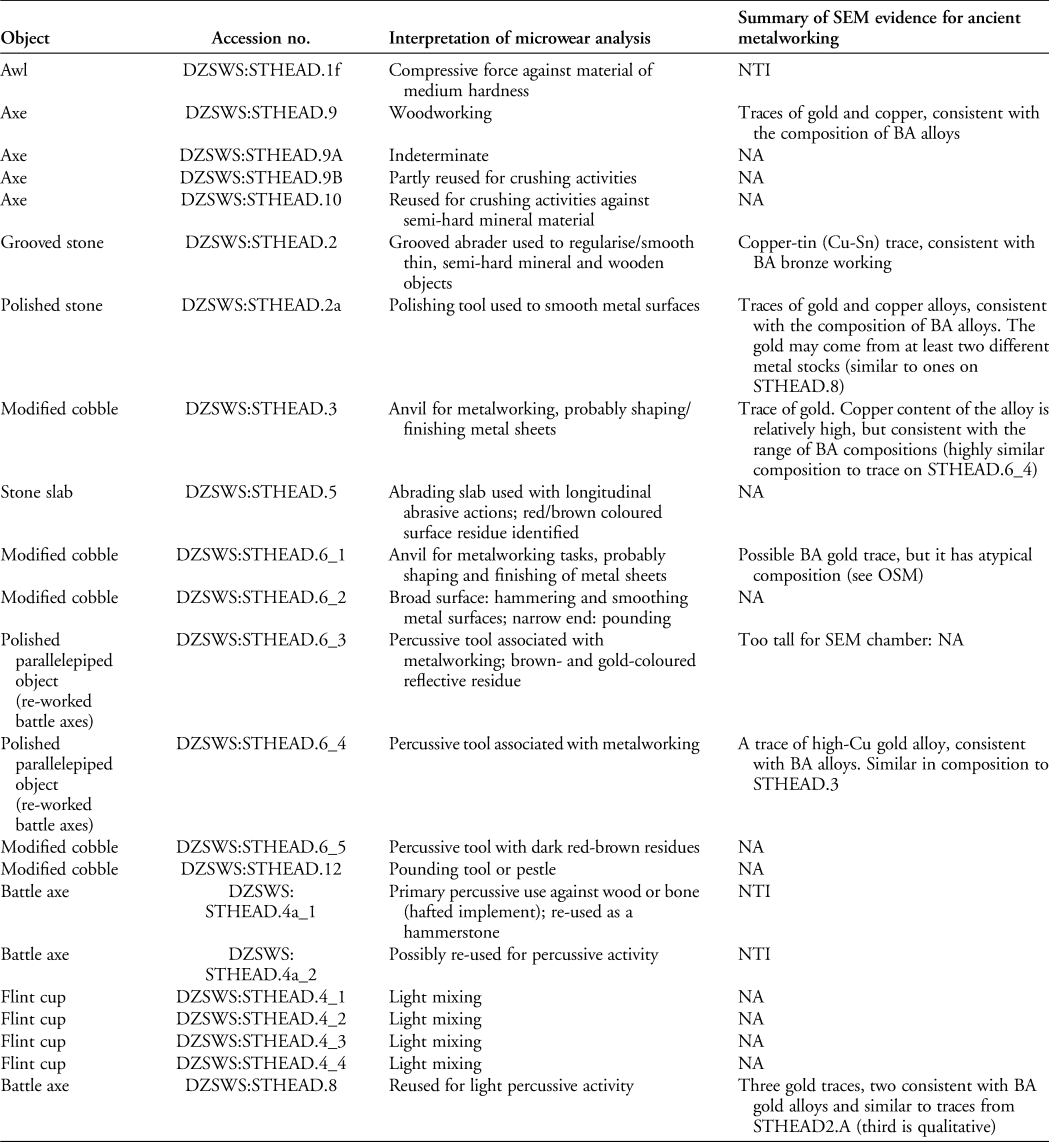

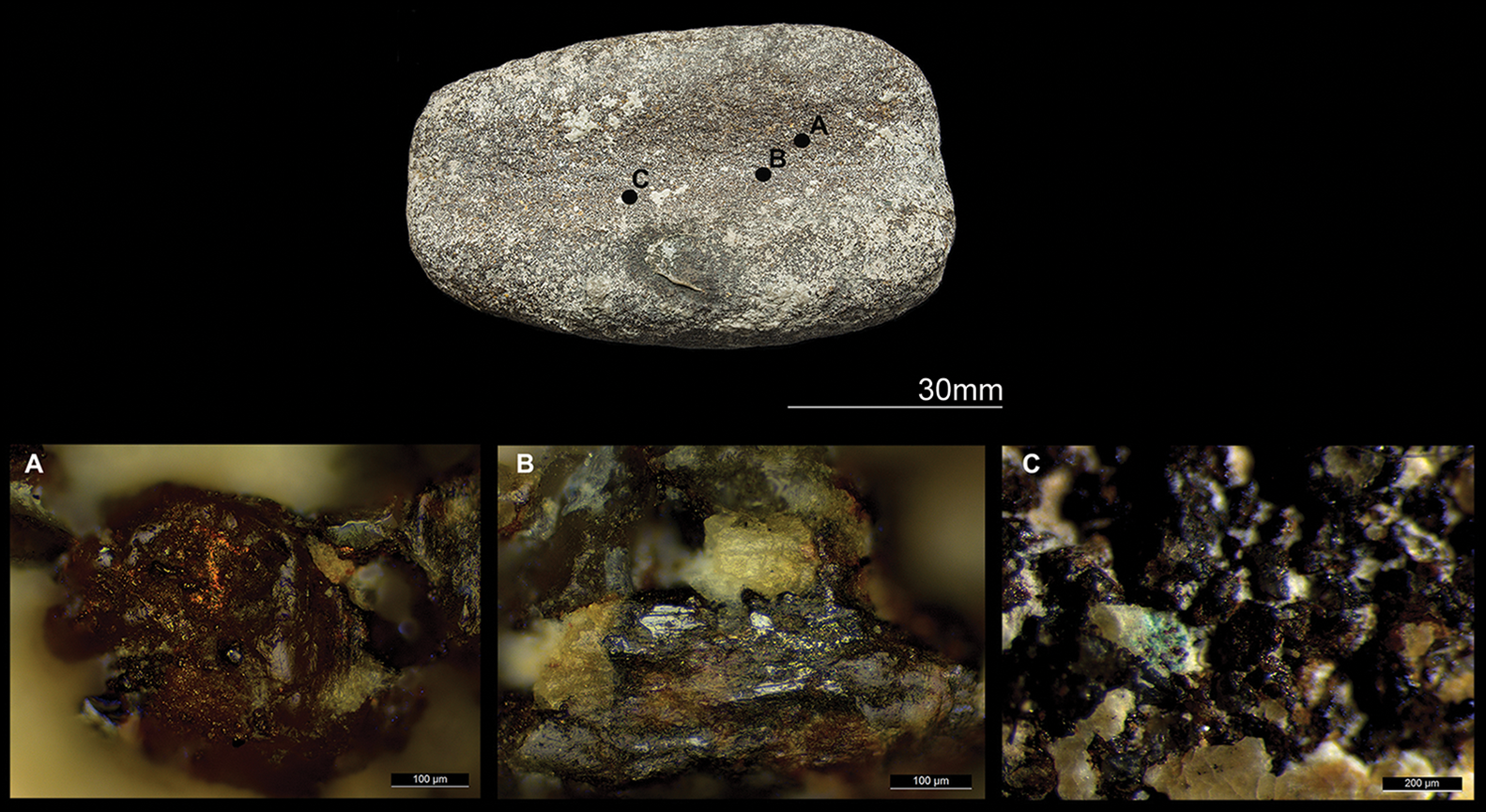

The results of the SEM-EDS analysis are presented in Table 3 (see also OSM2). From a new materialist perspective, we consider objects not as static types but as processes in motion. We therefore deliberately employ descriptive terms to define the grave goods (alongside types to allow comparison) in order to emphasise how specific objects were used. In brief, the assemblage contains modified stone cobbles of varied sizes, weights, morphologies and surface traces. These reveal critical evidence of different processes, including metalworking. Some of these stone objects were used with percussive action—either as stationary tools (anvils) or as hammers for working semi-hard mineral material of metallic origin—and display gold traces contemporaneous with their use (e.g. STHEAD.6_1; STHEAD.12) (Figure 1).

Figure 1. Hammers and anvils from Upton Lovell G2A analysed in this research; scales = 30mm (figure produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

Another group of stone tools were used for different forms of abrasive actions. The grooved abrader (STHEAD.2) was employed using a longitudinal motion to smoothen and regularise thin wooden and metal items, including bronze (Figure 2). The grave assemblage also contained a series of objects associated with the crushing and pulverising of dark red/brown mineral residues consistent with pigments, including flint axes STHEAD.9b and STHEAD.10. The four flint nodule cups all show signs of light abrasive interior wear, and three display residues; the wear traces indicate the use of these objects for light mixing—perhaps of ochres or resins. The copper-alloy awl was used with compressive force against a material of medium hardness. Taken together, these objects communicate an overlapping story of multiple materials that bring out different qualities and capacities in each other, in conjunction with the movement of humans and other material bodies.

Figure 2. Microwear traces on grooved abrader (DZSWS:STHEAD.2) (figure produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

A potential gold chaîne opératoire at Upton Lovell

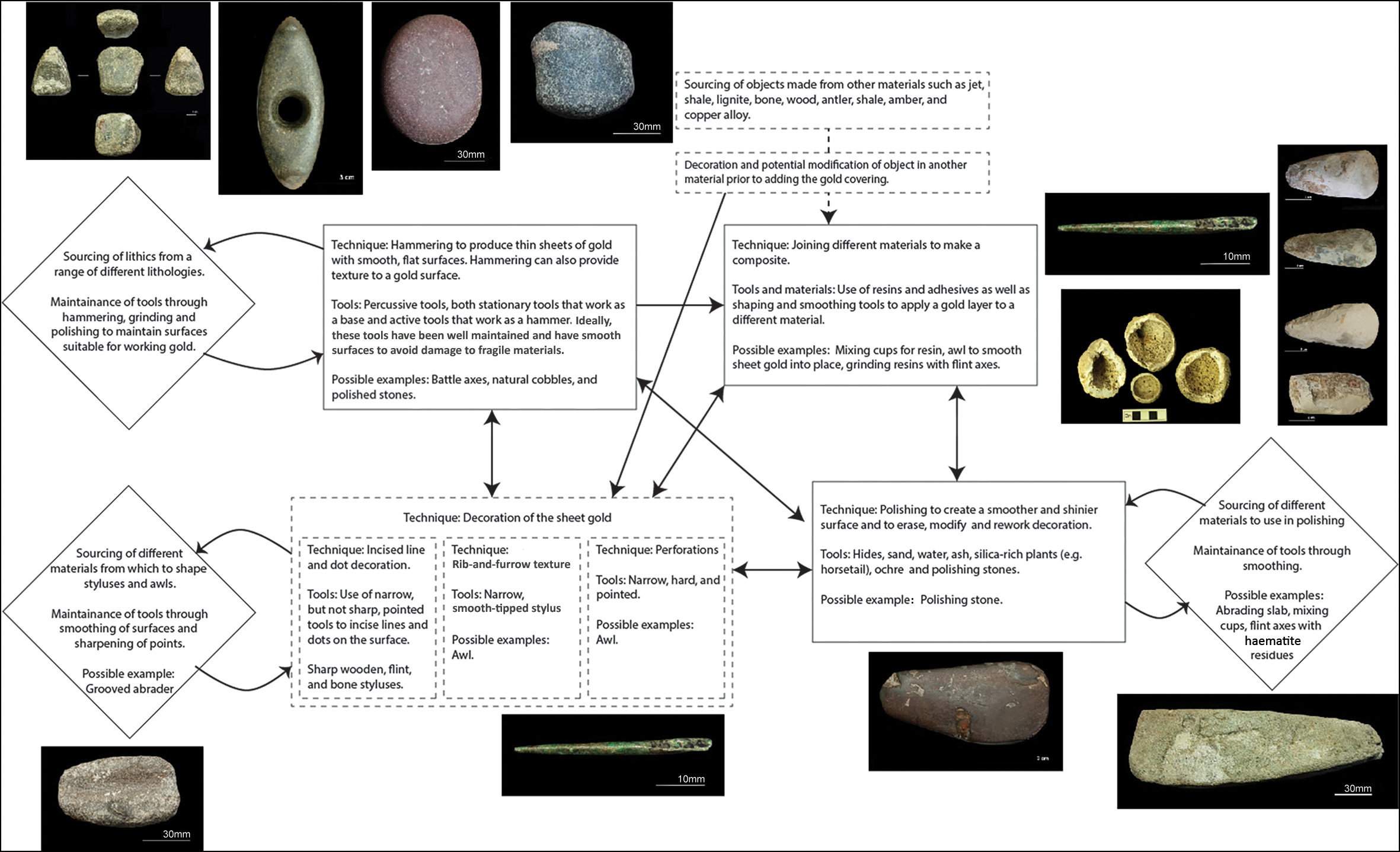

Rather than discussing the objects individually, we treat them as an assemblage and focus on what they reveal collectively about processes of making. The Upton Lovell G2a tools are best understood in relation to Needham and Sheridan's (Reference Needham, Sheridan, Meller, Pernicka and Risch2014) sheet-gold cover tradition, in which intricate incised designs are applied to sheet-gold, usually shaped around a core object made from jet, shale, amber, wood or copper (Piggott Reference Piggott1938; Taylor Reference Taylor1980; Needham & Woodward Reference Needham and Woodward2008; Needham Reference Needham, Woodward and Hunter2015; Needham et al. Reference Needham, Woodward, Hunter, Woodward and Hunter2015) (Table S2). This technology is a multi-material practice, as both the end product and the production toolkit involve multiple materials (Needham & Woodward Reference Needham and Woodward2008: 27; Needham Reference Needham, Woodward and Hunter2015: 259). Placing our use-wear analyses of the tools within the wider context of sheet-gold items (Table S2), we can begin to piece together the relational connections to consider a chaîne opératoire (Leroi-Gourhan Reference Leroi-Gourhan1964; Dobres Reference Dobres2000). We combine these strands of evidence to consider the gestures and techniques in which the tools were caught up (Figure 3).

Figure 3. A tentative chaîne opératoire for sheet-gold cover working. Diamond-shaped boxes display sourcing, production and maintenance processes. Solid rectangular boxes display production/manufacturing processes evidenced in our analyses. Dashed rectangular boxes show processes implied by the sheet-gold objects (figure produced by R. Crellin, using images produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

None of the tools in the assemblage point towards gold smelting; they instead evidence the process of working gold into a sheet, embellishing it, and applying it to other objects. The assemblage therefore suggests that the process of goldworking was multiphase and perhaps consisted of phases that were carried out by different people in different places (see Standish et al. Reference Standish, Dhuime, Hawkesworth and Pike2015: 166; cf. Delgado-Raack & Risch Reference Delgado-Raack, Risch, Lungo and Skakun2008: 247). Analysis of objects from the sheet-gold cover tradition (e.g. Taylor Reference Taylor1980: 47; Needham & Woodward Reference Needham and Woodward2008: 27) suggests that the majority had at least a two-phase history.

We have direct evidence, from percussive tools, of hammering to produce smooth, flat surfaces. Boutoille (Reference Boutoille and Brandherm2019: 204) notes that, because gold is a soft metal, hammers for working it are generally lighter and have more polished surfaces to avoid leaving traces of their use, although Taylor (Reference Taylor1980: 35) notes that various hammers could be used to texture sheet gold in different ways. Amongst the Upton Lovell grave goods are tools that were used as hammers and others that were used as stationary surfaces for hammering (Figure 1). These percussive tools demonstrate a range of different lithologies, and their surfaces were carefully prepared and maintained to allow them to function effectively. Research on metalworking tools from elsewhere in Bronze Age Europe has identified a similar range of percussive stone tools, classified into active tools for hammering and passive tools that received hammer blows (Armbruster et al. Reference Armbruster2003). Although the use of STHEAD.12 for goldworking is unclear—it could not be examined under the metallographic microscope due to its size—it was also involved in pounding materials, possibly including metal.

Early Bronze Age awls have not been subject to extensive study (Woodward & Hunter Reference Woodward and Hunter2015: 89), but have historically been associated with women, domestic contexts and leather working. Existing analyses, however, argue that they were too narrow for use in leather working and show little trace of use-damage (Thomas Reference Thomas and Thomas2005: 222; Woodward & Hunter Reference Woodward and Hunter2015: 95). Alternative suggestions for their use include tattooing and medical purposes (Thomas Reference Thomas and Thomas2005: 222; Woodward & Hunter Reference Woodward and Hunter2015: 96). Our analysis of the awl from Upton Lovell G2a, as noted above, suggests use with compressive force against a material of medium hardness. We speculate that it could have played a role in goldworking, but our wear-analysis suggests it was not used to produce the incised decoration on the surfaces of sheet gold objects (for reasoning, see OSM1). Instead, we suggest that the awl could have been used, amongst other functions, to make rib-and-furrow decoration, produce perforations (see also Corfield Reference Corfield and Trigg2012), or as part of the fitting process between the core object and the sheet-gold.

Previous research suggests that a range of pointed but often slightly blunt items, such as stylus points, were used in the production of the incised decoration and were potentially made of wood, bone or flint (Taylor Reference Taylor1980: 38; Armbruster Reference Armbruster2017: 731) (Table S2). Some of the microwear traces found on the grooved abrader STHEAD.2 could be from the production and maintenance of wooden styluses.

We know that sheet-gold was applied to other materials, and Needham and Woodward (Reference Needham and Woodward2008: 17 & 24; cf. Taylor Reference Taylor1980: 47–48) have suggested that organic resin or adhesive might have been used in this process. Whilst we do not have direct evidence of resin within the grave assemblage, the tools associated with pigment processing and the flint nodule cups could potentially have been part of this process (Table 3). The use of ochre in compound adhesives has been documented elsewhere (e.g. Kozowyk et al. Reference Kozowyk, van Gijn and Langejans2020), while hematite was found in the infilling material used in goldworking in Mycenaean Greece (Konstantinidi-Syridi et al. Reference Konstantinidi-Syvridi, Papadimitriou, Philippa-Touchais and Goumas2014). Ochre, however, may have also been used as a polishing agent (and is commonly used in the production of modern jewellery; Mattson & Jones Reference Mattson and Jones2020: 422).

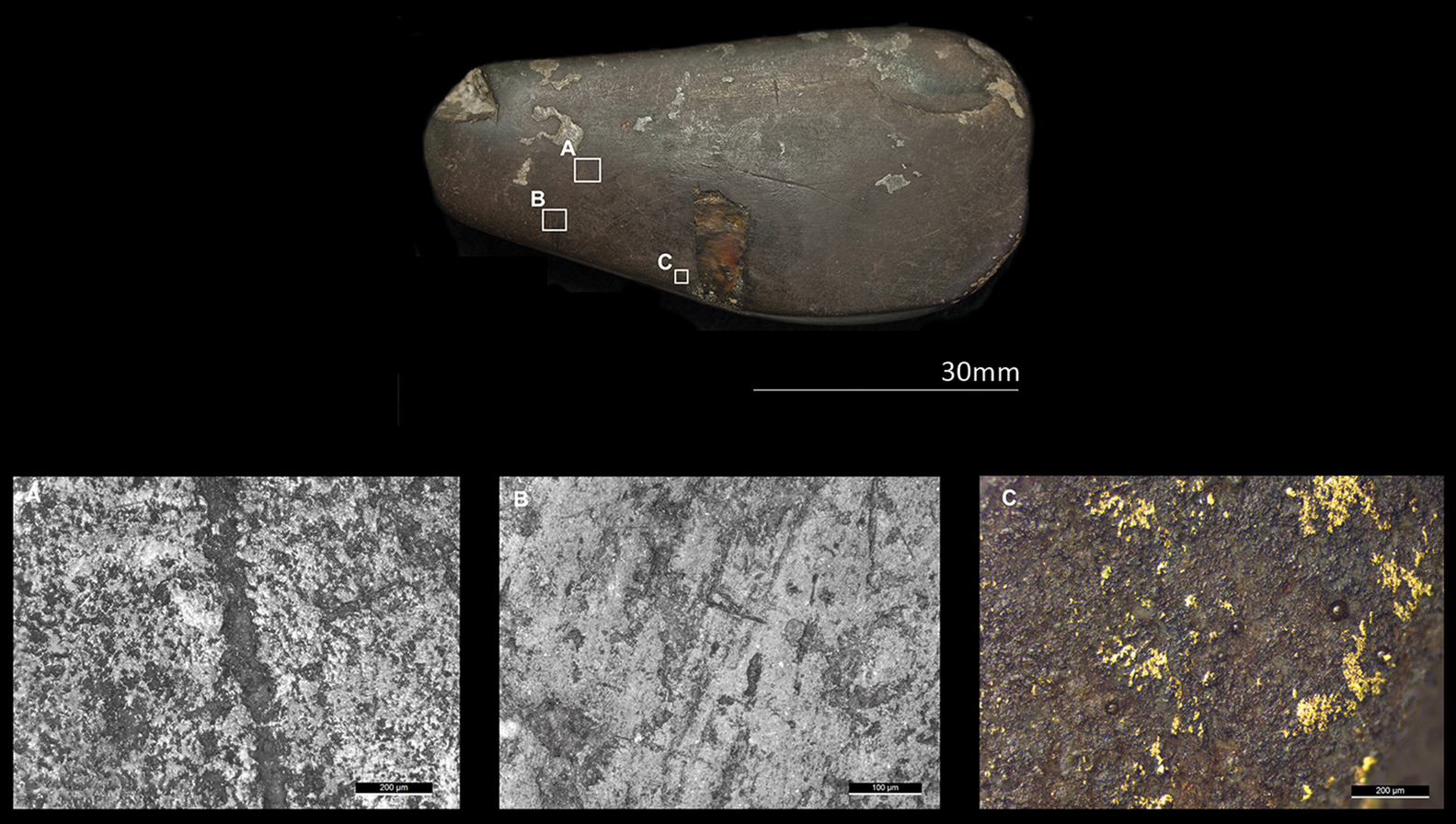

Polishing tool STHEAD.2a could also have been used to produce smoother and shinier surfaces (Figure 4). Previously identified as a touchstone (Boutoille Reference Boutoille and Brandherm2019: 206), our analysis reveals the object's use with an abrasive motion on the broad and narrow edges and ridges; while this may have resulted from its use as a touchstone, it could also suggest a function associated with polishing and finishing objects (for detail, see OSM1).

Figure 4. Microwear traces on polishing stone (DZSWS:STHEAD.2a) (figure produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

The traces of gold on the blade of flint axe STHEAD.9 are not accompanied by well-developed wear-traces; this gold could have been decorative, but it might also indicate that this axe was used for smoothing and polishing gold surfaces. Polishing gold sheet would have been an ongoing and iterative process throughout the production of these items and would also have been used to erase decorative mistakes (Taylor Reference Taylor1980: 35).

The results of our analyses point us towards a chaîne opératoire for the production of sheet-gold (Figure 3). This is not a process of mining or fiery transformation, but one of small-scale, careful working of gold, relying on a mixed-material toolkit to embellish objects made in other materials. Several authors have noted the likely use of bone, antler and horn tools in goldworking (e.g. Armbruster et al. Reference Armbruster2003: 262; Armbruster Reference Armbruster2017: 721; Simon Reference Simon, Koch, Bonifas, Wiethold and Zeeb-Lanz2017; Machling & Williamson Reference Machling, Williamson, Nimura, Chittock, Hommel and Gosden2020: 190). Might the bone points and boars’ tusks that form the ‘costume’ found in the grave (not analysed as part of this research) have functioned both as items of dress and as tools in the goldworking chaîne opératoire?

Gold as a kind of stone

Gold is a ‘star’ material in much of the Bronze Age literature: it grabs attention and is seen as valuable and prestigious (Armbruster Reference Armbruster, Fokkens and Harding2013, Reference Armbruster2017). Part of this star quality relates to its role as one of the earliest metals to be exploited. This association with status and novelty has resulted in gold being discussed differently from other materials: it is valued differently, worked differently, and those that had access to it are marked as different. In the Upton Lovell G2a assemblage, gold is an absent presence—the tools speak of goldworking, their surfaces display flecks of gold, but they are not gold itself. The toolkit in this burial was dominated by stone tools, possible parallels for which can be seen in a similar assemblage from Newgrange (O'Kelly & Shell Reference O'Kelly, Shell and Ryan1979; cf. Butler & van der Waals Reference Butler and van der Waals1966; for a wider discussion, see Clarke Reference Clarke1970). It is not a toolkit for smelting but one for working and shaping a solid, semi-hard mineral material that shared many properties with different forms of stone, worked through percussive and polishing processes. It is also a toolkit that relies heavily on being able to work stone itself, with the percussive, abrasive and polishing tools all requiring careful maintenance (Figure 3). These stone tools had shared origins as water-rolled cobbles, but were selected for their different lithologies, colours and potential functions. Their users knew how to work stone, how it behaved and how it could be used in different ways.

From this new materialist perspective, gold takes its place as one material amongst many revealed at Upton Lovell. Alongside it we find multiple stones carefully selected for their capacities to bring various qualities to the fore, both in themselves and in other materials. Through movements involving percussive action, these qualities—being smooth and flat—could be transferred from one material, or perhaps two in the case of hammer and anvil, to another. Specific gestures moved through materials, transferring an intensive force that entered the material being acted upon. Metal seems to have been one of the materials that these tools worked—in particular, gold. The smoothness of the stones was critical to the smooth metal they shaped; here was a texture that flowed from one material to another, promiscuously crossing the boundaries between objects that our typologies draw.

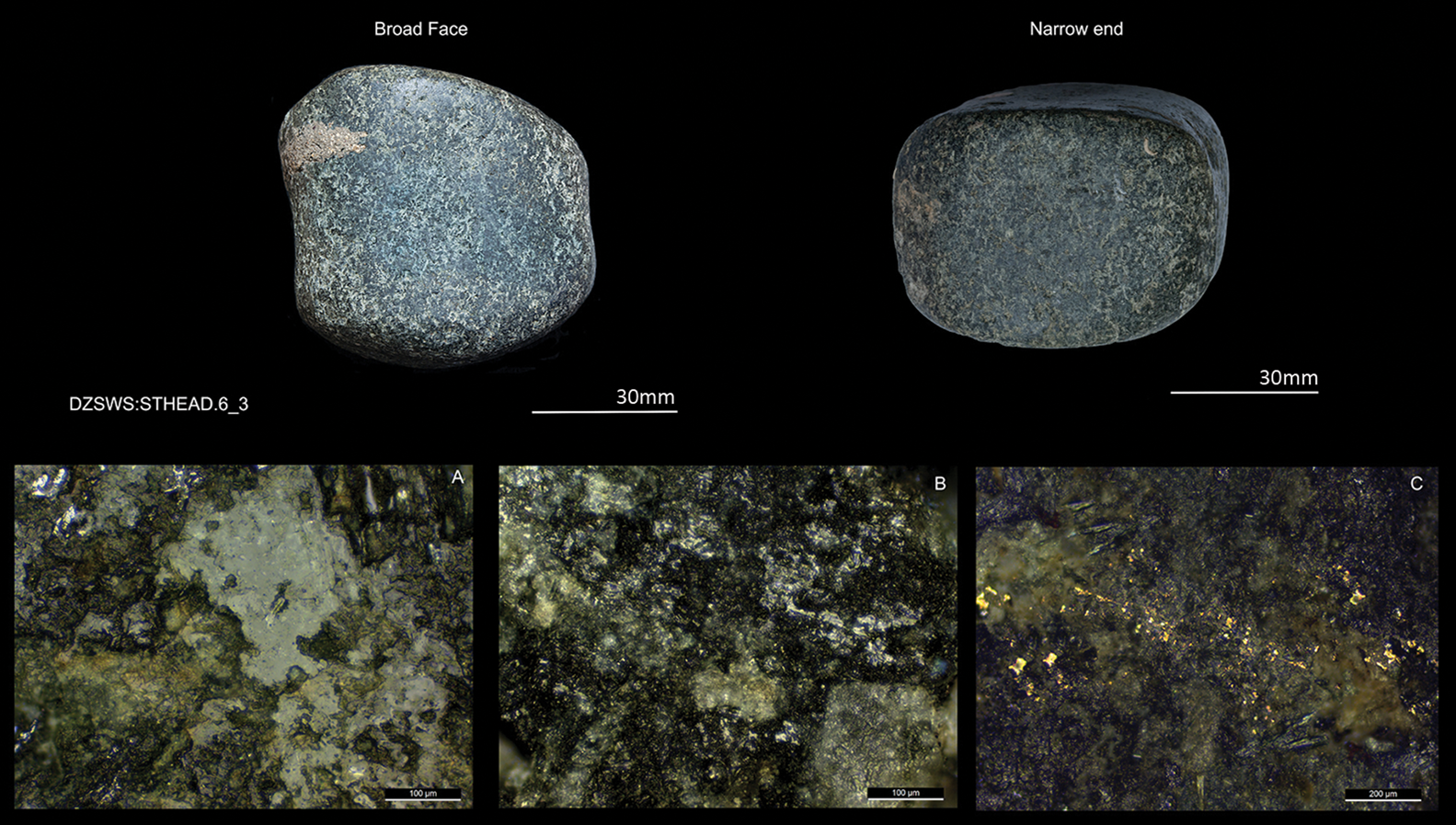

The histories of these stones are not arbitrary. This is a toolkit with both varied origins and histories. Alongside the complete battle axe, which was repurposed into a metalworking tool, several other stone tools were either definite or possible battle axes (Figures 5 & 6). Taken as a set, they display different stages of use: one had only recently become a metalworking tool (STHEAD.8); of the others, one pair is heavily worked, but they are still recognisable as battle axes (STHEAD.4A_1 & STHEAD.4A_2), while the second pair retains only hints of their previous forms (STHEAD.6_3 & STHEAD.6_4). The reuse of blunted axes as metalworking tools has been noted in other European contexts (e.g. Lynch Reference Lynch, Metz, Van Beek and Steegstra2001; Armbruster et al. Reference Armbruster2003: 257; O'Brien Reference O'Brien2004: 359; Boutoille Reference Boutoille and Brandherm2019; Hamon et al. Reference Hamon2020). Such battle axes were far from the only smooth stones that could have been selected for these purposes. In intentionally repurposing these objects, their histories rubbed off on the materials they worked.

Figure 5. Battle axes from Upton Lovell G2A at different stages of use; scales = 30mm (figure produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

Figure 6. Microwear traces on percussive tool (DZSWS:STHEAD.6_3) (figure produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

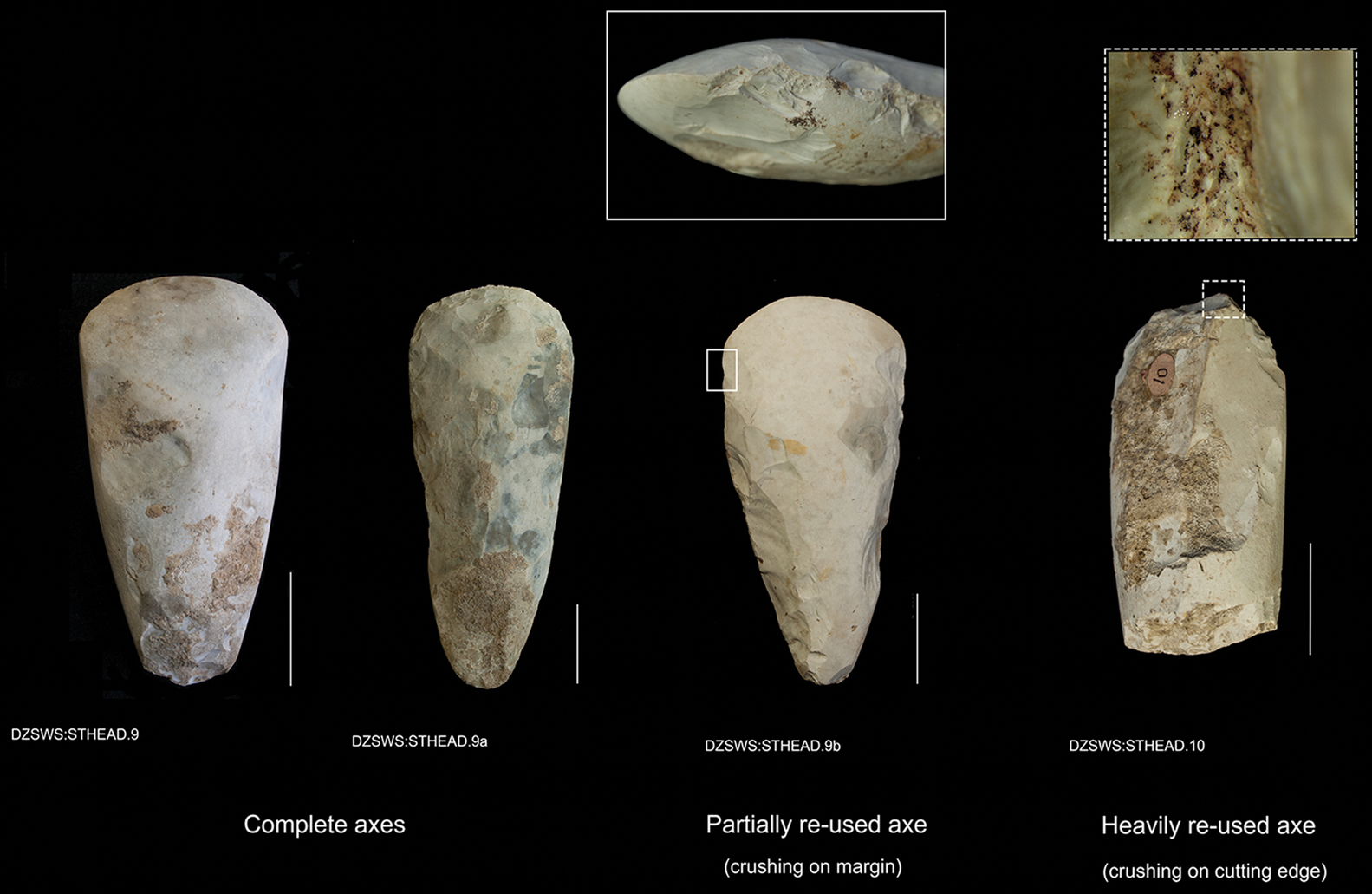

The four flint axes tell other stories; they are probably much older than the burial assemblage itself and exhibit varying levels of reuse, with careful attempts to preserve their shape, temporarily at least, as the extensively reworked STHEAD.10 shows. Indeed, we might speculate that they parallel the battle axes in illustrating different stages of use, ranging from STHEAD.9a, with its indeterminate use function, through to the heavily modified STHEAD.10 (Figure 7). At least one of these axes, STHEAD.9, has traces of gold and copper on its surface. Like the battle axes, these flint axes had stories; these stones remembered (Tsoraki et al. Reference Tsoraki, Barton, Crellin and Harris2020). The past was present in these practices, materialised in the histories of objects.

Figure 7. Flint axes from Upton Lovell G2A at different stages of use (figure produced by C. Tsoraki; photographs courtesy of Wiltshire Museum, Devizes).

Many of the cobbles are water-worn, smoothed by water's eroding power. Just as humans could polish and smooth stone, water could too. Given that gold itself was most likely extracted from waterborne deposits (Standish et al. Reference Standish, Dhuime, Hawkesworth and Pike2015), rivers may have played a key role in the emergence of these various materials, gold included.

The grave goods from Upton Lovell G2a form a striking toolkit. Each stone is shaped and marked by its past and present, its material and origin. Our analysis makes space to specify the nature of goldworking in Bronze Age Britain, and discuss how it drew on the material properties, histories and gestures that these worked stones elicited. Critically, this analysis suggests that goldworking may be different from other forms of metal production and may not, from a Bronze Age perspective, have been considered to be a metal at all, but rather something with its own relational properties that were quite different from those that entwined copper and tin. Stone materials continued to permeate technological practices associated with metalworking throughout the Bronze Age. Stone tools, including hammers, anvils, moulds, grinding tools and reworked stone axes, played an important role in the different stages of the metalworking process, from the mining and processing of ores to the shaping and finishing of objects (Butler & van der Waals Reference Butler and van der Waals1966; Clarke Reference Clarke1970; Boutoille Reference Boutoille and Brandherm2019; Fitzpatrick Reference Fitzpatrick and Brandherm2019).

Conclusions

Drawing on microwear, residue analysis and new materialist theory, we have reassessed the Upton Lovell G2a grave assemblage. The empirical techniques attend to the materials, which are reinvigorated by situating them within this emergent theoretical landscape. These approaches reveal how the grave goods disclose an intertwining set of processes. Never static, these objects changed and shifted, requiring modification, repair and reuse. They speak to a complex interweaving of bodies—human and non-human—and their varied histories. There is far more complexity here, in relations, histories, gestures and processes, than could ever be captured under the label ‘shaman’, ‘metalworker’ or ‘goldsmith’. Grave goods are more than representations of a person's identity. They are more even than critical relations in the construction of identity (cf. Brück Reference Brück2019). What these grave goods stress, when attention is paid to their stories, is quite different. They speak of material journeys, the colour of stone and the texture of gold capturing relations that flow across landscapes. Collectively, as an assemblage, these stone tools reveal a process of goldworking. But this goldworking involves as much the working of stone, in the shaping and upkeep of tools, as it does of metal. Here, we emphasise the repetitive and iterative nature of our chaîne opératoire, each action calling into being further moments of renewal of the polished stone surfaces so essential to the qualities other materials elicited. This goldworking chaîne opératoire is multi-material; it is as much a process in stone working as it is in the working of metal. From this perspective, the similarities in processing and working gold and stone mean that the former emerges as far more like the latter than our modern taxonomies would suggest.

Acknowledgements

We thank the Wiltshire Museum for their support with this research, especially Lisa Brown and David Dawson. All photographs were taken courtesy of Wiltshire Museum. We extend our thanks to Andrew Fitzpatrick for sharing a key paper and to the anonymous peer reviewers, whose comments made significant improvements.

Funding statement

This research was funded by a Leverhulme Trust Research Project Grant (RPG-2017-375).

Supplementary materials

To view supplementary material for this article, please visit https://doi.org/10.15184/aqy.2022.162.