1. Introduction

Combustion noise is central to efforts to curb aircraft emissions. Noise originating in the combustor is an important contributor to overall aircraft noise, particularly during approach and landing phases. Further, combustion-generated sound can act as a source of thermoacoustic instabilities, the consequences of which may range from decreased efficiency to system failure (Lieuwen Reference Lieuwen2003). Modern lean-premixed systems designed to lower ![]() $\textrm {NO}_{x}$ emissions can be particularly susceptible to this phenomenon (Dowling & Mahmoudi Reference Dowling and Mahmoudi2015). In this sense, developing a thorough understanding of the sources of combustion noise is an important step in view of meeting increasingly strict emission targets.

$\textrm {NO}_{x}$ emissions can be particularly susceptible to this phenomenon (Dowling & Mahmoudi Reference Dowling and Mahmoudi2015). In this sense, developing a thorough understanding of the sources of combustion noise is an important step in view of meeting increasingly strict emission targets.

In the present work, we use the word noise to indicate any pressure fluctuation propagating inside or outside the system. A distinction is usually drawn between direct and indirect combustion noise (Dowling & Mahmoudi Reference Dowling and Mahmoudi2015). Direct noise results from the volumetric expansion and contraction brought about by unsteady heat release in the combustion zone. Indirect noise is generated when perturbations in the temperature, composition or vorticity generated within the combustion zone are accelerated/decelerated, creating acoustic waves. In a gas turbine, indirect noise is produced at the nozzle or turbine guide vanes, and propagates both downstream, where it contributes to overall aircraft noise (Dowling & Mahmoudi Reference Dowling and Mahmoudi2015), and upstream into the combustor, where it may lead to the onset of thermoacoustic instabilities (Polifke, Paschereit & Dobbeling Reference Polifke, Paschereit and Dobbeling2001; Goh & Morgans Reference Goh and Morgans2013; Morgans & Duran Reference Morgans and Duran2016).

Entropy noise associated with temperature fluctuations has been the topic of numerous studies since it was theorised in the 1960s (Cuadra Reference Cuadra1967). Marble & Candel (Reference Marble and Candel1977) obtained one-dimensional transfer functions for the noise generated at an isentropic compact nozzle for a low-frequency impinging entropic perturbation, in subsonic and supersonic conditions, with and without a shock in the diffuser for the supersonic case. These transfer functions were later extended to finite length nozzles for arbitrary frequencies (Goh & Morgans Reference Goh and Morgans2011; Duran & Moreau Reference Duran and Moreau2013). In the supersonic case, the entropic indirect noise generation was analysed in detail by Moase, Brear & Manzie (Reference Moase, Brear and Manzie2007) and Leyko et al. (Reference Leyko, Moreau, Nicoud and Poinsot2011), while the interaction of entropy spots with two-dimensional shock waves was studied in detail by Mahesh, Lele & Moin (Reference Mahesh, Lele and Moin1997) and Farag, Boivin & Sagaut (Reference Farag, Boivin and Sagaut2019).

In parallel to these developments, Magri, O'Brien & Ihme (Reference Magri, O'Brien and Ihme2016) and Ihme (Reference Ihme2017) developed transfer functions for the indirect noise generated at a compact nozzle due to compositional perturbations, which was generalised to non-compact nozzles in subsonic and supersonic conditions in Magri (Reference Magri2017). Further numerical investigations have shown the relative importance of the compositional mechanism relative to temperature fluctuations in a realistic rich-quench-lean combustor (Giusti, Magri & Zedda Reference Giusti, Magri and Zedda2019).

This range of theoretical and numerical studies on noise generation from temperature and composition fluctuations has spurred a number of simplified validation experiments involving the conversion of temperature and compositional disturbances into acoustic noise. In the Entropy Wave Generator (EWG) developed at Deutsches Zentrum für Luft- und Raumfahrt (DLR), entropic waves were generated in a duct using an electric heater, accelerated through a subsonic or supersonic nozzle, and the resulting pressure trace was measured further downstream of the nozzle (Bake et al. Reference Bake, Richter, Mühlbauer, Kings, Röhle, Thiele and Noll2009). In those experiments, the upstream-propagating entropy noise was not measured, even though it may play a role in thermoacoustic instabilities (Polifke et al. Reference Polifke, Paschereit and Dobbeling2001; Goh & Morgans Reference Goh and Morgans2013). Following this effort, several model experiments were developed to validate entropic indirect noise generated in convergent–divergent nozzles (Knobloch et al. Reference Knobloch, Lahiri, Enghardt, Bake and Peitsch2011; Gaetani, Persico & Spinelli Reference Gaetani, Persico and Spinelli2015; Tao et al. Reference Tao, Schuller, Huet and Richecoeur2017). Experiments conducted on the Cambridge Entropy Generator Rig focused on the upstream-propagating indirect noise (De Domenico, Rolland & Hochgreb Reference De Domenico, Rolland and Hochgreb2017). By accounting for direct noise and acoustic reflections, the indirect noise could be clearly identified and isolated in the acquired pressure traces (Rolland, De Domenico & Hochgreb Reference Rolland, De Domenico and Hochgreb2017). De Domenico, Rolland & Hochgreb (Reference De Domenico, Rolland and Hochgreb2019a) extended the compact model to non-isentropic subsonic nozzles in which entropy in the mean flow is not conserved, i.e. nozzles with pressure losses occurring in the divergent section. It was found that the non-isentropicity of a system significantly affects indirect noise generation. More recently, Rolland, De Domenico & Hochgreb (Reference Rolland, De Domenico and Hochgreb2018) used a mass injection device to validate a one-dimensional model for generation of compositional indirect noise in choked isentropic nozzles, focusing on the behaviour of upstream-propagating waves. The latter work did not consider the consequences of the non-isentropicity of the nozzles on the generation of compositional noise, nor the behaviour of downstream travelling waves. The present work tackles these two specific issues. We combine the techniques used for generation and identification of compositional noise developed by Rolland et al. (Reference Rolland, De Domenico and Hochgreb2018) with the extension of the treatment of non-isentropic nozzles in De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) to provide experimental validation of the theory for compositional noise in non-isentropic nozzles operating in subsonic-to-sonic throat conditions. The opportunity for validation under these operating conditions provides a solid foundation for the determination of the contribution of compositional and thermal indirect noise to both instabilities inside combustion chambers, as well as noise propagation downstream through nozzle guide vanes.

In the present experiments, we measure the entropic and compositional noise generated by the injection of pockets of helium, argon, carbon dioxide and methane into a mean flow of air, which is accelerated through non-isentropic nozzles. The indirect noise model proposed by De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) for entropy noise in non-isentropic nozzles is extended to include compositional noise. Measurements are obtained in subsonic-to-sonic throat conditions for low-frequency perturbations. Both the upstream- and downstream-propagating components of the indirect noise are resolved using a source identification technique based on the reverberation of sound waves in an enclosed chamber.

The paper is organised as follows. One-dimensional models for the generation of direct and indirect acoustic waves in flow ducts are presented in § 2. The effect of acoustic reflections (reverberation) of these waves is modelled in § 3 to develop a source identification method. Experiments are conducted on the Cambridge Entropy Wave Generator described in § 4, where direct, entropic and compositional noise is generated by injecting pockets of helium, argon, carbon dioxide or methane into a flow of air. The corresponding experimental pressure measurements are shown in § 5. Source and system identification is performed to clearly identify and isolate direct and indirect noise. These results are finally compared to simulations carried out with the predictions of the proposed physics-based low-order model for non-isentropic nozzle transfer functions.

2. Direct and indirect noise generation

In this work, we consider a multi-component ideal gas mixture flowing in a chamber terminated with a nozzle. We assume a quasi-one-dimensional framework: the flow variables change because of area variations and are assumed to be uniform across the duct cross-section, so the nozzle flow depends only on the axial coordinate. The gas is chemically frozen, which corresponds to a combustor situation in which the reaction process is completed upstream of the nozzle guide vanes, yet compositional fluctuations (e.g. equivalence ratio fluctuations) are generated. The flow is assumed to be advection dominated, so that viscosity, heat/species diffusivity and body forces are negligible. The multi-component gas is composed of ![]() $N$ species with mass fraction

$N$ species with mass fraction ![]() $Y_i$, molecular weight

$Y_i$, molecular weight ![]() $W_i$ and chemical potentials

$W_i$ and chemical potentials ![]() $\mu _i$. All species are expressed in terms of mixture fraction

$\mu _i$. All species are expressed in terms of mixture fraction ![]() $Z$, so that

$Z$, so that ![]() $Y_i = Y_i(Z)$, and have frozen internal energy modes, so the heat capacity only depends on the mixture composition. The conservation of mass, momentum, energy and species in their differential form read, respectively (e.g. Chiu & Summerfield Reference Chiu and Summerfield1974; Magri Reference Magri2019)

$Y_i = Y_i(Z)$, and have frozen internal energy modes, so the heat capacity only depends on the mixture composition. The conservation of mass, momentum, energy and species in their differential form read, respectively (e.g. Chiu & Summerfield Reference Chiu and Summerfield1974; Magri Reference Magri2019)

\begin{equation} \left. \begin{gathered} \dfrac{\textrm{D} \rho}{\textrm{D} t} + \rho \dfrac{\partial u }{\partial x} = \dot{S}_{m}, \\ \rho \dfrac{\textrm{D} u}{\textrm{D} t} + \dfrac{\partial p }{\partial x} = \dot{S}_{M},\\ T \dfrac{\textrm{D} s}{\textrm{D} t} + \sum_{i=1}^{N} \dfrac{\mu_i}{W_i}\dfrac{\textrm{D}Y_i}{\textrm{D}t} = \dot{S}_{s},\\ \rho \dfrac{\textrm{D}Y_i}{\textrm{D}t} = \dot{S}_i, \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \dfrac{\textrm{D} \rho}{\textrm{D} t} + \rho \dfrac{\partial u }{\partial x} = \dot{S}_{m}, \\ \rho \dfrac{\textrm{D} u}{\textrm{D} t} + \dfrac{\partial p }{\partial x} = \dot{S}_{M},\\ T \dfrac{\textrm{D} s}{\textrm{D} t} + \sum_{i=1}^{N} \dfrac{\mu_i}{W_i}\dfrac{\textrm{D}Y_i}{\textrm{D}t} = \dot{S}_{s},\\ \rho \dfrac{\textrm{D}Y_i}{\textrm{D}t} = \dot{S}_i, \end{gathered} \right\} \end{equation}

where ![]() $x$ and

$x$ and ![]() $t$ are the spatial and temporal coordinates, respectively;

$t$ are the spatial and temporal coordinates, respectively; ![]() $\rho$,

$\rho$, ![]() $p$ ,

$p$ , ![]() $T$,

$T$, ![]() $u$,

$u$, ![]() $s$,

$s$, ![]() $Y_i$,

$Y_i$, ![]() $\mu _i$ and

$\mu _i$ and ![]() $W_i$ are the local fluid density, pressure, temperature, velocity, entropy, mass fraction, chemical potential and molar fraction, respectively. The subscript

$W_i$ are the local fluid density, pressure, temperature, velocity, entropy, mass fraction, chemical potential and molar fraction, respectively. The subscript ![]() $i$ denotes the

$i$ denotes the ![]() $i$th species. The right-hand side source terms

$i$th species. The right-hand side source terms ![]() $\dot {S}_{j}$ are the local rates of change of mass, momentum, energy and species, respectively.

$\dot {S}_{j}$ are the local rates of change of mass, momentum, energy and species, respectively.

The direct and indirect noise generation processes are described by applying linear perturbations to the conservation equations (2.1) (Marble & Candel Reference Marble and Candel1977; Duran, Moreau & Poinsot Reference Duran, Moreau and Poinsot2013; Magri Reference Magri2017). The unsteady source generates direct noise, in the form of forward- and backward-propagating acoustic waves, ![]() ${\rm \pi} _d^+$ and

${\rm \pi} _d^+$ and ![]() ${\rm \pi} _d^-$, respectively (figure 1), entropic waves

${\rm \pi} _d^-$, respectively (figure 1), entropic waves ![]() $\sigma$ and compositional waves

$\sigma$ and compositional waves ![]() $\xi$. The waves manifest themselves as fluctuations in the flow variables, which can be decomposed into their mean and fluctuating components (denoted with an overbar and a prime, respectively: e.g.

$\xi$. The waves manifest themselves as fluctuations in the flow variables, which can be decomposed into their mean and fluctuating components (denoted with an overbar and a prime, respectively: e.g. ![]() $p(x,t) = \bar {p}(x) + p'(x,t)$). Furthermore, we consider linear perturbations, so that their amplitude is negligible with respect to the mean quantity (i.e.

$p(x,t) = \bar {p}(x) + p'(x,t)$). Furthermore, we consider linear perturbations, so that their amplitude is negligible with respect to the mean quantity (i.e. ![]() $p' \ll \bar {p}$). The four waves in the experiments correspond to the downstream- and upstream-propagating acoustic waves

$p' \ll \bar {p}$). The four waves in the experiments correspond to the downstream- and upstream-propagating acoustic waves ![]() ${\rm \pi} ^{\pm }$ generated by the unsteady injection of the secondary flow, the convective entropy wave

${\rm \pi} ^{\pm }$ generated by the unsteady injection of the secondary flow, the convective entropy wave ![]() $\sigma$ and the convective compositional wave

$\sigma$ and the convective compositional wave ![]() $\xi$. These waves are defined as (Magri et al. Reference Magri, O'Brien and Ihme2016):

$\xi$. These waves are defined as (Magri et al. Reference Magri, O'Brien and Ihme2016):

where ![]() $\bar {c}_p$ is the heat capacity of the flow,

$\bar {c}_p$ is the heat capacity of the flow, ![]() $\bar {\gamma }$ the specific heat capacity ratio and

$\bar {\gamma }$ the specific heat capacity ratio and ![]() $\bar {c}$ is the speed of sound. Linearising the ideal gas law gives

$\bar {c}$ is the speed of sound. Linearising the ideal gas law gives ![]() $p'/\bar {p} = \rho '/ \bar {\rho } +R'/ \bar {R} +T'/ \bar {T}$, where

$p'/\bar {p} = \rho '/ \bar {\rho } +R'/ \bar {R} +T'/ \bar {T}$, where ![]() $R$ is the gas constant of the mixture. The Gibbs equation for calorically perfect multi-component gas is

$R$ is the gas constant of the mixture. The Gibbs equation for calorically perfect multi-component gas is

\begin{equation} \sigma = \frac{ s'}{\bar{c}_p} = \frac{p'}{\bar{\gamma} \bar{p}}-\frac{\rho'}{\bar{\rho}} { + \frac{c_p'}{\bar{c}_p} -\frac{R'}{\bar{R}}} - \frac{1}{\bar{c}_p\bar{T}} \sum_{i=1}^{N} \frac{\mu_i}{W_i}\,\textrm{d}Y_i. \end{equation}

\begin{equation} \sigma = \frac{ s'}{\bar{c}_p} = \frac{p'}{\bar{\gamma} \bar{p}}-\frac{\rho'}{\bar{\rho}} { + \frac{c_p'}{\bar{c}_p} -\frac{R'}{\bar{R}}} - \frac{1}{\bar{c}_p\bar{T}} \sum_{i=1}^{N} \frac{\mu_i}{W_i}\,\textrm{d}Y_i. \end{equation}

Following Magri (Reference Magri2017), we define the chemical potential ![]() $\varPsi$ and the heat-capacity factor

$\varPsi$ and the heat-capacity factor ![]() $\aleph$ as

$\aleph$ as

\begin{gather} \varPsi = \frac{1}{\bar{c}_p\bar{T}} \sum_{i=1}^{N} \left(\frac{\mu_i}{W_i} \right) \frac{\textrm{d}Y_i}{\textrm{d}Z}, \end{gather}

\begin{gather} \varPsi = \frac{1}{\bar{c}_p\bar{T}} \sum_{i=1}^{N} \left(\frac{\mu_i}{W_i} \right) \frac{\textrm{d}Y_i}{\textrm{d}Z}, \end{gather} \begin{gather} {\aleph = \frac{R'}{\bar{R}} - \frac{c_p'}{\bar{c}_p} = \sum_{i=1}^{N} \left(\frac{1}{\bar{R}}\frac{\textrm{d} \bar{R}}{\textrm{d}Y_i} - \frac{1}{\bar{c}_p}\frac{\textrm{d} \bar{c}_p}{\textrm{d}Y_i} \right ) \frac{\textrm{d}Y_i}{\textrm{d}Z}}. \end{gather}

\begin{gather} {\aleph = \frac{R'}{\bar{R}} - \frac{c_p'}{\bar{c}_p} = \sum_{i=1}^{N} \left(\frac{1}{\bar{R}}\frac{\textrm{d} \bar{R}}{\textrm{d}Y_i} - \frac{1}{\bar{c}_p}\frac{\textrm{d} \bar{c}_p}{\textrm{d}Y_i} \right ) \frac{\textrm{d}Y_i}{\textrm{d}Z}}. \end{gather}

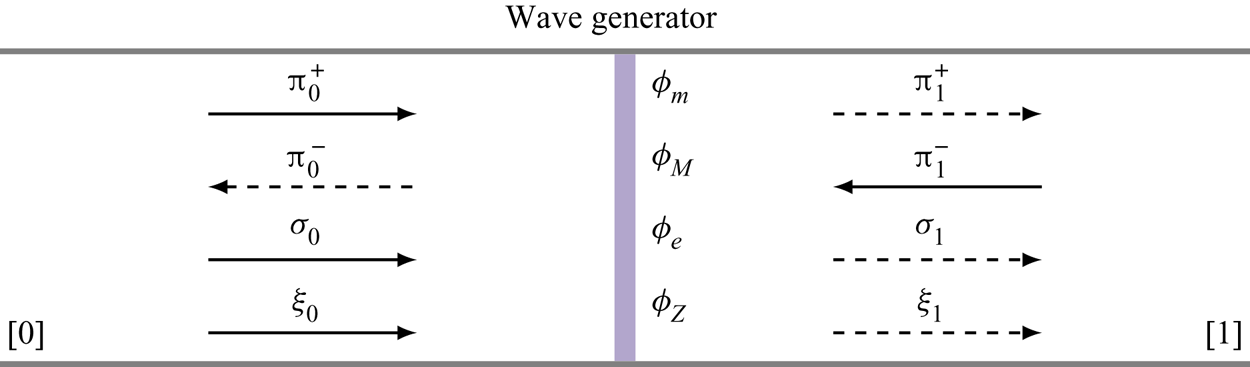

Figure 1. Direct acoustic (![]() ${\rm \pi} ^-_d$,

${\rm \pi} ^-_d$, ![]() ${\rm \pi} ^+_d$), entropic (

${\rm \pi} ^+_d$), entropic (![]() $\sigma$) and compositional (

$\sigma$) and compositional (![]() $\xi$) waves produced at a wave generator, and indirect acoustic waves (

$\xi$) waves produced at a wave generator, and indirect acoustic waves (![]() ${\rm \pi} ^-_{\sigma }$,

${\rm \pi} ^-_{\sigma }$, ![]() ${\rm \pi} ^-_{\xi }$,

${\rm \pi} ^-_{\xi }$, ![]() ${\rm \pi} ^+_{\sigma }$ and

${\rm \pi} ^+_{\sigma }$ and ![]() ${\rm \pi} ^+_{\xi }$) generated by the acceleration of entropic and compositional disturbances at a nozzle further downstream.

${\rm \pi} ^+_{\xi }$) generated by the acceleration of entropic and compositional disturbances at a nozzle further downstream.

From (2.4) and (2.5), the entropy wave ![]() $\sigma$ from (2.3) can be briefly expressed as

$\sigma$ from (2.3) can be briefly expressed as

This shows that the entropic and compositional waves are coupled, since the specific entropy is related to the local gas composition.

After being generated at the source, the entropic and compositional waves are convected with the flow downstream of the source towards the nozzle. When accelerated, they generate forward and backward entropic–acoustic waves ![]() ${\rm \pi} ^+_{\sigma }$ and

${\rm \pi} ^+_{\sigma }$ and ![]() ${\rm \pi} ^-_{\sigma }$ and compositional–acoustic waves

${\rm \pi} ^-_{\sigma }$ and compositional–acoustic waves ![]() ${\rm \pi} ^+_{\xi }$ and

${\rm \pi} ^+_{\xi }$ and ![]() ${\rm \pi} ^-_{\xi }$, as shown in figure 1. The nozzle length

${\rm \pi} ^-_{\xi }$, as shown in figure 1. The nozzle length ![]() $L_n$ is short compared to the acoustic wavelengths of the experiment

$L_n$ is short compared to the acoustic wavelengths of the experiment ![]() $\lambda$ (

$\lambda$ (![]() $L_n / \lambda < 0.01$). Therefore, the nozzle is assumed to be compact, which means that the flow variables of the approaching and discharging flow are related by algebraic jump conditions. The transversal waves can also be neglected, as the characteristic frequencies of circumferential modes,

$L_n / \lambda < 0.01$). Therefore, the nozzle is assumed to be compact, which means that the flow variables of the approaching and discharging flow are related by algebraic jump conditions. The transversal waves can also be neglected, as the characteristic frequencies of circumferential modes, ![]() $f_{circ} = ({4{\rm \pi} c}/{d}) (1-M^2)^{-1/2} \approx 10^5\ \textrm {Hz}$ (where

$f_{circ} = ({4{\rm \pi} c}/{d}) (1-M^2)^{-1/2} \approx 10^5\ \textrm {Hz}$ (where ![]() $d$ is the diameter of the duct and

$d$ is the diameter of the duct and ![]() $M$ the Mach number) are much higher than the characteristic frequencies of the injection,

$M$ the Mach number) are much higher than the characteristic frequencies of the injection, ![]() $f_{inj} \simeq 1\text{--}10 \ {\rm Hz}$ and of the longitudinal acoustic modes,

$f_{inj} \simeq 1\text{--}10 \ {\rm Hz}$ and of the longitudinal acoustic modes, ![]() $f_{long} \simeq 100\ \textrm {Hz}$.

$f_{long} \simeq 100\ \textrm {Hz}$.

2.1. Jump conditions across a wave generator

The conventional definition of direct noise in a combustion system is associated with the pressure fluctuations produced by a flame due to the unsteady heat flux. Here, by direct noise we indicate the sound generated in a non-reacting environment by a wave generator that produces unsteady perturbations in the mass, momentum and energy fluxes, as well as in the mixture fraction. This simplified formulation allows us to examine the effect of unsteady heat addition by a heating grid in a flow (working principle for the DLR and Cambridge EWG (Bake et al. Reference Bake, Richter, Mühlbauer, Kings, Röhle, Thiele and Noll2009; De Domenico et al. Reference De Domenico, Rolland and Hochgreb2017)) and the effect of fluid injection (Rolland et al. Reference Rolland, De Domenico and Hochgreb2018), which is of particular interest for the experiments in the Cambridge Entropy Wave Generator with mass addition, as well as for realistic modelling of the effects of cooling or secondary air injection in combustors.

In order to capture the effect of the wave generator on the flow variables, jump conditions are applied, whereby mass, momentum, energy and mixture fraction fluxes (![]() $\phi _m$,

$\phi _m$, ![]() $\phi _M$,

$\phi _M$, ![]() $\phi _e$ and

$\phi _e$ and ![]() $\phi _Z$, respectively) are added to the flow at a discontinuity. The generator compactness is an appropriate assumption because the length of the wave generators in the experiments is small relative to the wavelengths of interest (i.e. low frequency waves (De Domenico et al. Reference De Domenico, Rolland and Hochgreb2017)). This situation is depicted in figure 2. In addition, we assume that the magnitudes of these fluxes have small value relatively to the mean flow values (

$\phi _Z$, respectively) are added to the flow at a discontinuity. The generator compactness is an appropriate assumption because the length of the wave generators in the experiments is small relative to the wavelengths of interest (i.e. low frequency waves (De Domenico et al. Reference De Domenico, Rolland and Hochgreb2017)). This situation is depicted in figure 2. In addition, we assume that the magnitudes of these fluxes have small value relatively to the mean flow values (![]() $\bar {\phi }=0$,

$\bar {\phi }=0$, ![]() $\phi =\phi '$). The mean flow properties are assumed to be conserved across the discontinuity. Using the one-dimensional conservation equations for mass, momentum, energy and species, the flow perturbations on either side of the discontinuity can be related to the added fluxes

$\phi =\phi '$). The mean flow properties are assumed to be conserved across the discontinuity. Using the one-dimensional conservation equations for mass, momentum, energy and species, the flow perturbations on either side of the discontinuity can be related to the added fluxes ![]() $\phi _m'$,

$\phi _m'$, ![]() $\phi _M'$,

$\phi _M'$, ![]() $\phi _e'$ and

$\phi _e'$ and ![]() $\phi _Z'$

$\phi _Z'$

\begin{equation} \left. \begin{gathered} \left[\dot{m}'\right]^1_0 = \phi'_m, \\ \left[\left( p + \rho u^2 \right)' \right]^1 _0 = \phi'_M, \\ \left[\left(\rho u \left({c_p} T + \tfrac{1}{2}u^2\right)\right)' \right]^1 _0 = \phi'_e, \\ \left[Z' \right]^1 _0 = \phi'_Z. \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \left[\dot{m}'\right]^1_0 = \phi'_m, \\ \left[\left( p + \rho u^2 \right)' \right]^1 _0 = \phi'_M, \\ \left[\left(\rho u \left({c_p} T + \tfrac{1}{2}u^2\right)\right)' \right]^1 _0 = \phi'_e, \\ \left[Z' \right]^1 _0 = \phi'_Z. \end{gathered} \right\} \end{equation}

The notation ![]() $[ \bullet ]_0^1$ denotes the difference between the flow variables immediately upstream

$[ \bullet ]_0^1$ denotes the difference between the flow variables immediately upstream ![]() $[0]$ and downstream

$[0]$ and downstream ![]() $[1]$ of the discontinuity, such that

$[1]$ of the discontinuity, such that ![]() $[\bullet ]_0^1 =(\bullet )_1 -(\bullet )_0$. Normalising (2.7) results in the following perturbation equations:

$[\bullet ]_0^1 =(\bullet )_1 -(\bullet )_0$. Normalising (2.7) results in the following perturbation equations:

\begin{equation} \left. \begin{gathered} \left[\left(\dfrac{\rho'}{\bar{\rho }}\right) + \dfrac{1}{\bar{M}} \left(\dfrac{u'}{\bar{c}}\right) \right] ^1 _0 = \varphi'_m,\\ \left[\dfrac{1}{\bar{M}^2}\left(\dfrac{p'}{\bar{\gamma} \bar{p}}\right) + \left(\dfrac{\rho'}{\bar{\rho }}\right) + \dfrac{2}{\bar{M}} \left(\dfrac{u'}{\bar{c}}\right) \right]^1 _0 = \varphi'_M,\\ \left[\dfrac{\rho'}{\bar{\rho }} + \dfrac{1}{\bar{M}} \dfrac{u'}{\bar{c}} +\dfrac{1}{1+\displaystyle \frac{\bar{\gamma}-1}{2}\bar{M}^2} \left ( \bar{\gamma} \dfrac{p'}{\bar{\gamma} \bar{p}} - \dfrac{\rho'}{\bar{\rho}} +(\bar{\gamma} - 1)\bar{M} \dfrac{u'}{\bar{c}} -\aleph \xi \right) \right]^1 _0 = \varphi'_e,\\ \left[Z' \right]^1 _0 = \varphi'_Z, \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \left[\left(\dfrac{\rho'}{\bar{\rho }}\right) + \dfrac{1}{\bar{M}} \left(\dfrac{u'}{\bar{c}}\right) \right] ^1 _0 = \varphi'_m,\\ \left[\dfrac{1}{\bar{M}^2}\left(\dfrac{p'}{\bar{\gamma} \bar{p}}\right) + \left(\dfrac{\rho'}{\bar{\rho }}\right) + \dfrac{2}{\bar{M}} \left(\dfrac{u'}{\bar{c}}\right) \right]^1 _0 = \varphi'_M,\\ \left[\dfrac{\rho'}{\bar{\rho }} + \dfrac{1}{\bar{M}} \dfrac{u'}{\bar{c}} +\dfrac{1}{1+\displaystyle \frac{\bar{\gamma}-1}{2}\bar{M}^2} \left ( \bar{\gamma} \dfrac{p'}{\bar{\gamma} \bar{p}} - \dfrac{\rho'}{\bar{\rho}} +(\bar{\gamma} - 1)\bar{M} \dfrac{u'}{\bar{c}} -\aleph \xi \right) \right]^1 _0 = \varphi'_e,\\ \left[Z' \right]^1 _0 = \varphi'_Z, \end{gathered} \right\} \end{equation}

where ![]() $\bar {M}$ is the Mach number, and

$\bar {M}$ is the Mach number, and ![]() $\varphi '_m$,

$\varphi '_m$, ![]() $\varphi '_M$,

$\varphi '_M$, ![]() $\varphi '_e$ and

$\varphi '_e$ and ![]() $\varphi '_Z$ are the normalised changes in mass, momentum, energy and mixture fraction, respectively:

$\varphi '_Z$ are the normalised changes in mass, momentum, energy and mixture fraction, respectively:

where ![]() $\bar{T}_T$ is the total temperature. The injection generates acoustic, entropic and compositional waves, whose amplitude can be computed by substituting the flow variables (2.8) with their definitions (2.2), as shown in appendix A. In the scenario where there are no incoming waves (

$\bar{T}_T$ is the total temperature. The injection generates acoustic, entropic and compositional waves, whose amplitude can be computed by substituting the flow variables (2.8) with their definitions (2.2), as shown in appendix A. In the scenario where there are no incoming waves (![]() ${{\rm \pi} ^+_0={\rm \pi} ^-_1=\sigma _0=\xi _0=0}$ in figure 2), the discontinuity generates forward- and backward-propagating acoustic waves

${{\rm \pi} ^+_0={\rm \pi} ^-_1=\sigma _0=\xi _0=0}$ in figure 2), the discontinuity generates forward- and backward-propagating acoustic waves ![]() ${\rm \pi} _{d}^+={\rm \pi} _1^+$ and

${\rm \pi} _{d}^+={\rm \pi} _1^+$ and ![]() ${\rm \pi} _{d}^-={\rm \pi} _0^-$ (direct noise), as well as forward-propagating entropic and compositional waves

${\rm \pi} _{d}^-={\rm \pi} _0^-$ (direct noise), as well as forward-propagating entropic and compositional waves ![]() $\sigma =\sigma _1$ and

$\sigma =\sigma _1$ and ![]() $\xi =\xi _1$.

$\xi =\xi _1$.

Figure 2. Forward and backward acoustic (![]() ${\rm \pi} ^+$,

${\rm \pi} ^+$, ![]() ${\rm \pi} ^-$), entropic waves

${\rm \pi} ^-$), entropic waves ![]() $\sigma$ and compositional waves

$\sigma$ and compositional waves ![]() $\xi$ upstream

$\xi$ upstream ![]() $[0]$ and downstream

$[0]$ and downstream ![]() $[1]$ of a wave generator. Impinging waves (black solid line) and generated waves (black dashed line).

$[1]$ of a wave generator. Impinging waves (black solid line) and generated waves (black dashed line).

From (2.8), the entropy wave ![]() $\sigma$ and compositional wave

$\sigma$ and compositional wave ![]() $\xi$ generated at the discontinuity can be expressed as

$\xi$ generated at the discontinuity can be expressed as

Equation (2.10) shows that the production of an entropic wave is driven by three physical mechanisms. First, entropy is generated if there is a mismatch between the energy and mass perturbations (if ![]() $\varphi '_e \neq \varphi '_m$). This is physically intuitive: if energy is added with no mass to carry it, the local specific entropy increases. Second, if energy is carried with the corresponding mass, but without a matching momentum perturbation

$\varphi '_e \neq \varphi '_m$). This is physically intuitive: if energy is added with no mass to carry it, the local specific entropy increases. Second, if energy is carried with the corresponding mass, but without a matching momentum perturbation ![]() $\varphi '_M$, entropy is generated. Third, changes in the flow composition

$\varphi '_M$, entropy is generated. Third, changes in the flow composition ![]() $\varphi '_Z$ can modify the entropy: this is because the gases composing the mixture may have different entropy relatively to the main mixture. Finally, the addition of a compositional flux

$\varphi '_Z$ can modify the entropy: this is because the gases composing the mixture may have different entropy relatively to the main mixture. Finally, the addition of a compositional flux ![]() $\varphi '_Z$ leads to the generation of a compositional wave. If there is no mass, momentum and composition sources, and only energy is added to the flow, the situation simplifies to the case of an unsteady heat source

$\varphi '_Z$ leads to the generation of a compositional wave. If there is no mass, momentum and composition sources, and only energy is added to the flow, the situation simplifies to the case of an unsteady heat source ![]() $q'=\varphi '_e$ (Bake et al. Reference Bake, Richter, Mühlbauer, Kings, Röhle, Thiele and Noll2009; De Domenico et al. Reference De Domenico, Rolland and Hochgreb2017) and the model derived above then reduces to the one previously used for the EWG (Leyko, Nicoud & Poinsot Reference Leyko, Nicoud and Poinsot2009; Duran et al. Reference Duran, Moreau and Poinsot2013).

$q'=\varphi '_e$ (Bake et al. Reference Bake, Richter, Mühlbauer, Kings, Röhle, Thiele and Noll2009; De Domenico et al. Reference De Domenico, Rolland and Hochgreb2017) and the model derived above then reduces to the one previously used for the EWG (Leyko, Nicoud & Poinsot Reference Leyko, Nicoud and Poinsot2009; Duran et al. Reference Duran, Moreau and Poinsot2013).

2.2. Transfer functions for a subsonic-to-sonic compact nozzle

Indirect noise is generated when entropic or compositional convected inhomogeneities are accelerated or decelerated, as when they pass through nozzles or turbine blades. The total upstream and downstream-propagating indirect noise ![]() ${{\rm \pi} _i^-}$ and

${{\rm \pi} _i^-}$ and ![]() ${{\rm \pi} _i^+}$ waves are a combination of the entropic

${{\rm \pi} _i^+}$ waves are a combination of the entropic ![]() ${\rm \pi} _{\sigma }$ and compositional noise

${\rm \pi} _{\sigma }$ and compositional noise ![]() ${\rm \pi} _{\xi }$:

${\rm \pi} _{\xi }$: ![]() ${{{\rm \pi} _i^-}= ({{\rm \pi} _{\xi }^-}/{\xi }) {\xi } + ({{\rm \pi} _{\sigma }^-}/{\sigma }) {\sigma }}$ and

${{{\rm \pi} _i^-}= ({{\rm \pi} _{\xi }^-}/{\xi }) {\xi } + ({{\rm \pi} _{\sigma }^-}/{\sigma }) {\sigma }}$ and ![]() ${{{\rm \pi} _i^+}= ({{\rm \pi} _{\xi }^+}/{\xi }) {\xi } + ({{\rm \pi} _{\sigma }^+}/{\sigma }) {\sigma }}$. Marble & Candel (Reference Marble and Candel1977) and Magri et al. (Reference Magri, O'Brien and Ihme2016) considered the case of a subsonic isentropic nozzle and that of a supersonic nozzle with a shock in the divergent section, where the total entropy losses are localised. Viscous effects are considered to be negligible, so the flow in the nozzle is modelled as inviscid. The nozzle length is much smaller than the wavelength of the disturbances, so the nozzle is assumed to be compact. The boundary layer thickness decreases in the accelerating flow in the converging section, which means that viscous losses are small. Under these isentropic conditions, the conservation equations can be formulated as a set of jump conditions, which relate the flow variables upstream and downstream of the convergent nozzle, as follows:

${{{\rm \pi} _i^+}= ({{\rm \pi} _{\xi }^+}/{\xi }) {\xi } + ({{\rm \pi} _{\sigma }^+}/{\sigma }) {\sigma }}$. Marble & Candel (Reference Marble and Candel1977) and Magri et al. (Reference Magri, O'Brien and Ihme2016) considered the case of a subsonic isentropic nozzle and that of a supersonic nozzle with a shock in the divergent section, where the total entropy losses are localised. Viscous effects are considered to be negligible, so the flow in the nozzle is modelled as inviscid. The nozzle length is much smaller than the wavelength of the disturbances, so the nozzle is assumed to be compact. The boundary layer thickness decreases in the accelerating flow in the converging section, which means that viscous losses are small. Under these isentropic conditions, the conservation equations can be formulated as a set of jump conditions, which relate the flow variables upstream and downstream of the convergent nozzle, as follows:

\begin{equation} \left. \begin{gathered} \left[ \dot{m} \right]^2 _1 = 0, \\ \left[ T_T \right]^2 _1 = 0, \\ \left[ s \right]^2 _1 = 0, \\ \left[ Z \right]^2 _1 = 0 . \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \left[ \dot{m} \right]^2 _1 = 0, \\ \left[ T_T \right]^2 _1 = 0, \\ \left[ s \right]^2 _1 = 0, \\ \left[ Z \right]^2 _1 = 0 . \end{gathered} \right\} \end{equation}One of the main assumptions in the prior work (Marble & Candel Reference Marble and Candel1977; Magri et al. Reference Magri, O'Brien and Ihme2016; Magri Reference Magri2017) is that the flow inside the nozzle is entirely isentropic, i.e. reversible and adiabatic (apart from an eventual shock in the divergent section). In reality, pressure losses and flow recirculation may occur, especially in the diverging part of the nozzle, where the pressure gradient is adverse to the flow velocity, so that entropy is not conserved i.e. the flow is non-isentropic. These effects are included in the model of non-isentropic orifice plates (similarly to previous work by Bechert (Reference Bechert1980) and Durrieu et al. (Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001), where turbulence is generated after the throat). De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) introduced a model for describing the quasi-steady transfer functions of non-isentropic compact nozzles with subsonic-to-sonic throat conditions, a diagram of which is shown in figure 3.

Figure 3. Diagram of the flow areas at the inlet (![]() $A_1$), throat (

$A_1$), throat (![]() $A_t$), jet location (

$A_t$), jet location (![]() $A_j$) and outlet (

$A_j$) and outlet (![]() $A_2$) of a non-isentropic nozzle, with streamlines for illustration.

$A_2$) of a non-isentropic nozzle, with streamlines for illustration.

The nozzle modelled by De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) is defined by the cross-sections at the inlet ![]() $A_1$, throat

$A_1$, throat ![]() $A_t$ and outlet area

$A_t$ and outlet area ![]() $A_2$. The nozzle is modelled as compact (i.e. low-frequency perturbations) so that the shape of the nozzle between these cross-sections is immaterial. The converging part of the nozzle is modelled as isentropic regardless of the shape of the converging section (Durrieu et al. Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001; Dowling & Stow Reference Dowling and Stow2003): the assumption of isentropicity is justified for sufficiently large Reynolds numbers, and for converging flows. Viscous effects are important, particularly near the throat of the nozzle. This is taken into account by a vena contracta factor,

$A_2$. The nozzle is modelled as compact (i.e. low-frequency perturbations) so that the shape of the nozzle between these cross-sections is immaterial. The converging part of the nozzle is modelled as isentropic regardless of the shape of the converging section (Durrieu et al. Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001; Dowling & Stow Reference Dowling and Stow2003): the assumption of isentropicity is justified for sufficiently large Reynolds numbers, and for converging flows. Viscous effects are important, particularly near the throat of the nozzle. This is taken into account by a vena contracta factor, ![]() $\varGamma < 1$, such that the minimum area of the throat

$\varGamma < 1$, such that the minimum area of the throat ![]() $A_{min}$ is smaller than the geometric throat area,

$A_{min}$ is smaller than the geometric throat area, ![]() $A_t$. In the divergent section, losses and recirculation might occur due to the adverse pressure gradient. Depending on the nozzle and flow characteristics, the flow can behave somewhere between isentropic and non-isentropic. This was modelled by defining an effective jet mixing area

$A_t$. In the divergent section, losses and recirculation might occur due to the adverse pressure gradient. Depending on the nozzle and flow characteristics, the flow can behave somewhere between isentropic and non-isentropic. This was modelled by defining an effective jet mixing area ![]() $A_j$, assuming that the flow is isentropic from

$A_j$, assuming that the flow is isentropic from ![]() $A_t$ to

$A_t$ to ![]() $A_j$, and that a non-isentropic jet (Bechert Reference Bechert1980; Durrieu et al. Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001) is formed thereafter (from

$A_j$, and that a non-isentropic jet (Bechert Reference Bechert1980; Durrieu et al. Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001) is formed thereafter (from ![]() $A_j$ to

$A_j$ to ![]() $A_2$). The variable

$A_2$). The variable ![]() $A_j$ should not be identified as a specific physical area where flow detachment takes place, but it serves as a useful parameter to quantify the degree of static entropy generation and pressure losses;

$A_j$ should not be identified as a specific physical area where flow detachment takes place, but it serves as a useful parameter to quantify the degree of static entropy generation and pressure losses; ![]() $A_j$ can be used to conceptually represent the degree of non-isentropicity because it enables us to model the full range between an isentropic divergent section (

$A_j$ can be used to conceptually represent the degree of non-isentropicity because it enables us to model the full range between an isentropic divergent section (![]() $A_j=A_2$), and a fully non-isentropic divergent section (an orifice plate where

$A_j=A_2$), and a fully non-isentropic divergent section (an orifice plate where ![]() $A_j=A_{min}$). De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) define a non-isentropicity parameter

$A_j=A_{min}$). De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) define a non-isentropicity parameter ![]() $\beta =A_j/A_2$, where

$\beta =A_j/A_2$, where ![]() $\beta =1$ indicates a fully isentropic nozzle,

$\beta =1$ indicates a fully isentropic nozzle, ![]() $\beta = \varGamma A_t/A_2$ indicates a fully non-isentropic divergent section (orifice plate model) and

$\beta = \varGamma A_t/A_2$ indicates a fully non-isentropic divergent section (orifice plate model) and ![]() $\varGamma A_t/A_2 <\beta < 1$ indicates intermediate cases. This parameter is related to the nozzle pressure loss coefficient

$\varGamma A_t/A_2 <\beta < 1$ indicates intermediate cases. This parameter is related to the nozzle pressure loss coefficient ![]() $C_P \approx (1- \beta )^2$ (Lieuwen Reference Lieuwen2012). The non-isentropicity parameter

$C_P \approx (1- \beta )^2$ (Lieuwen Reference Lieuwen2012). The non-isentropicity parameter ![]() $\beta$ is not known a priori, but can be inferred from the experimental measurements of the mean flow properties upstream and downstream of the nozzle (De Domenico et al. Reference De Domenico, Rolland and Hochgreb2019a). This is done in § 5.3.

$\beta$ is not known a priori, but can be inferred from the experimental measurements of the mean flow properties upstream and downstream of the nozzle (De Domenico et al. Reference De Domenico, Rolland and Hochgreb2019a). This is done in § 5.3.

Following the previous definitions, non-isentropic nozzles can be modelled as a succession of two sections. For the isentropic region (from ![]() $A_1$ to

$A_1$ to ![]() $A_j$) the governing equations are the conservation of mass, total temperature, entropy and species as in (2.11). For the non-isentropic region (from

$A_j$) the governing equations are the conservation of mass, total temperature, entropy and species as in (2.11). For the non-isentropic region (from ![]() $A_j$ to

$A_j$ to ![]() $A_2$), the entropy is not conserved, so we use the change in momentum, which is provided by the total force on the walls (Durrieu et al. Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001)

$A_2$), the entropy is not conserved, so we use the change in momentum, which is provided by the total force on the walls (Durrieu et al. Reference Durrieu, Hofmans, Ajello, Boot, Auregan, Hirschberg and Peters2001)

resulting in the following jump conditions:

\begin{equation} \left. \begin{gathered} \left[ \dot{m} \right]^2 _j = 0, \\ \left[ T_T \right]^2 _j = 0, \\ \left[ A (p + \rho u^2 ) \right]^2_j = (1-\beta)A_2 p_j, \\ \left[ Z \right]^2 _j = 0 . \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \left[ \dot{m} \right]^2 _j = 0, \\ \left[ T_T \right]^2 _j = 0, \\ \left[ A (p + \rho u^2 ) \right]^2_j = (1-\beta)A_2 p_j, \\ \left[ Z \right]^2 _j = 0 . \end{gathered} \right\} \end{equation}After linearisation, the jump conditions for the isentropic nozzle (2.11) become

\begin{equation} \left. \begin{gathered}

\left[ \left(\dfrac{\rho'}{\bar{\rho }}\right) +

\dfrac{1}{\bar{M}} \left(\dfrac{u'}{\bar{c}}\right) \right]

^1 _0 = 0,\\ \left[

\dfrac{1}{1+\displaystyle \frac{\bar{\gamma}-1}{2}\bar{M}^2} \left (\bar{\gamma}

\dfrac{p'}{\bar{\gamma} \bar{p}} - \dfrac{\rho'}{\bar{\rho}}

+(\bar{\gamma} - 1)\bar{M} \dfrac{u'}{\bar{c}} -\aleph \xi

\right) \right ]^1 _0 = 0,\\ \left[s' \right]^1 _0 = 0,\\

\left[Z' \right]^1 _0 = 0. \end{gathered}

\right\} \end{equation}

\begin{equation} \left. \begin{gathered}

\left[ \left(\dfrac{\rho'}{\bar{\rho }}\right) +

\dfrac{1}{\bar{M}} \left(\dfrac{u'}{\bar{c}}\right) \right]

^1 _0 = 0,\\ \left[

\dfrac{1}{1+\displaystyle \frac{\bar{\gamma}-1}{2}\bar{M}^2} \left (\bar{\gamma}

\dfrac{p'}{\bar{\gamma} \bar{p}} - \dfrac{\rho'}{\bar{\rho}}

+(\bar{\gamma} - 1)\bar{M} \dfrac{u'}{\bar{c}} -\aleph \xi

\right) \right ]^1 _0 = 0,\\ \left[s' \right]^1 _0 = 0,\\

\left[Z' \right]^1 _0 = 0. \end{gathered}

\right\} \end{equation}

In the case of a non-isentropic nozzle, the entropy conservation is substituted by the linearised momentum conservation between the section ![]() $A_j$ and

$A_j$ and ![]() $A_2$ (from (2.12)), which reads

$A_2$ (from (2.12)), which reads

The isentropic and non-isentropic jumps can be linearised and solved in a matrix form as shown in appendix A. This enables us to compute a matrix of transfer functions from the inlet to the outlet of the nozzle, relating the variables across sections 1–2, ![]() $\boldsymbol {w_1} = \boldsymbol {T}_{1 \rightarrow 2} \boldsymbol {w_2}$, where

$\boldsymbol {w_1} = \boldsymbol {T}_{1 \rightarrow 2} \boldsymbol {w_2}$, where ![]() $\boldsymbol {w} = [{\rm \pi} ^{\pm },{\rm \pi} ^{\mp }, \sigma , \xi ]^T$ represents the input and output state vectors. In this way, the direct and indirect noise transfer functions of the nozzle are determined. The explicit expressions for the nozzle transfer functions contained in

$\boldsymbol {w} = [{\rm \pi} ^{\pm },{\rm \pi} ^{\mp }, \sigma , \xi ]^T$ represents the input and output state vectors. In this way, the direct and indirect noise transfer functions of the nozzle are determined. The explicit expressions for the nozzle transfer functions contained in ![]() $\boldsymbol {T}_{1 \rightarrow 2}$ can be obtained by inverting the transfer function matrices. These isentropic and non-isentropic transfer functions are compared to experimental data in § 5.3.

$\boldsymbol {T}_{1 \rightarrow 2}$ can be obtained by inverting the transfer function matrices. These isentropic and non-isentropic transfer functions are compared to experimental data in § 5.3.

3. Effect of acoustic reflections (reverberation)

The theoretical framework presented in § 2 and appendix A enables the amplitude of direct and indirect acoustic waves ![]() ${\rm \pi} _{d}^{\pm }$ and

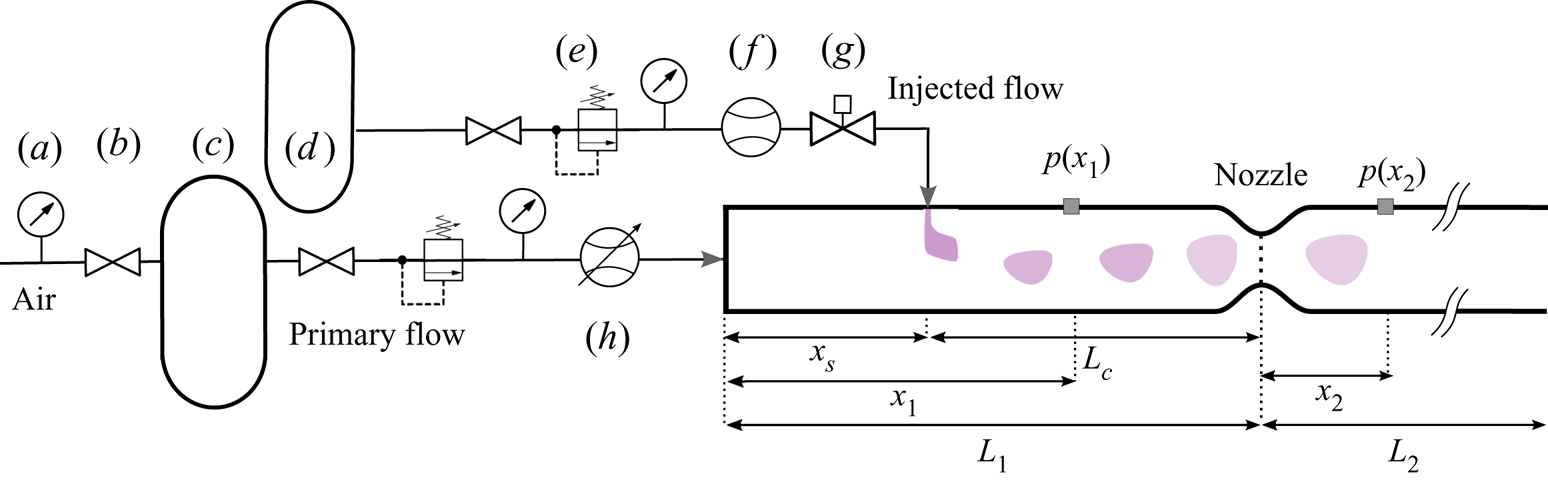

${\rm \pi} _{d}^{\pm }$ and ![]() ${\rm \pi} _{i}^{\pm }$ to be computed. Prior to direct comparisons with experiments, however, the effect of repeated acoustic reflections (reverberation) must first be determined. The method used in this work extends the time-based model described by Rolland et al. (Reference Rolland, De Domenico and Hochgreb2017) to the frequency domain. This enables source identification, whereby acoustic sources are extracted from a given pressure signal, as shown in § 3.2, considering the acoustics both upstream and downstream of the nozzle. We consider a quasi-one-dimensional system consisting of two reverberating chambers separated by a nozzle: a first chamber upstream and a second chamber downstream as shown in figure 4. The first chamber is defined by its length

${\rm \pi} _{i}^{\pm }$ to be computed. Prior to direct comparisons with experiments, however, the effect of repeated acoustic reflections (reverberation) must first be determined. The method used in this work extends the time-based model described by Rolland et al. (Reference Rolland, De Domenico and Hochgreb2017) to the frequency domain. This enables source identification, whereby acoustic sources are extracted from a given pressure signal, as shown in § 3.2, considering the acoustics both upstream and downstream of the nozzle. We consider a quasi-one-dimensional system consisting of two reverberating chambers separated by a nozzle: a first chamber upstream and a second chamber downstream as shown in figure 4. The first chamber is defined by its length ![]() $L_1$, internal inlet and outlet reflection coefficients (

$L_1$, internal inlet and outlet reflection coefficients (![]() $R_i$,

$R_i$, ![]() $R_o$), as well as the transmission coefficient across the nozzle

$R_o$), as well as the transmission coefficient across the nozzle ![]() $T_o$. We can assume that no reflections occur at the outlet of the downstream chamber of length

$T_o$. We can assume that no reflections occur at the outlet of the downstream chamber of length ![]() $L_2$ (anechoic boundary condition,

$L_2$ (anechoic boundary condition, ![]() $R_{\infty }$), as explained in § 4.1. We measure the pressure in each chamber, at locations

$R_{\infty }$), as explained in § 4.1. We measure the pressure in each chamber, at locations ![]() $x_1$ and

$x_1$ and ![]() $x_2$. By considering the repeated acoustic reflections of acoustic waves in the system, we can derive a set of acoustic transfer functions relating acoustic sources in the system to the resulting acoustic pressure. The derivation of these transfer functions is shown in appendix B.

$x_2$. By considering the repeated acoustic reflections of acoustic waves in the system, we can derive a set of acoustic transfer functions relating acoustic sources in the system to the resulting acoustic pressure. The derivation of these transfer functions is shown in appendix B.

Figure 4. Two one-dimensional chambers of lengths ![]() $L_1$ and

$L_1$ and ![]() $L_2$ separated by a nozzle. An upstream acoustic source at a location

$L_2$ separated by a nozzle. An upstream acoustic source at a location ![]() $x_{s}$ generates forward- and backward-propagating waves

$x_{s}$ generates forward- and backward-propagating waves ![]() ${\rm \pi} _{s}^+(t)$ and

${\rm \pi} _{s}^+(t)$ and ![]() ${\rm \pi} _{s}^-(t)$.

${\rm \pi} _{s}^-(t)$.

3.1. Acoustic transfer functions

The framework presented here enables the construction of a complete analytical model for the direct (![]() ${\rm \pi} _d^+, {\rm \pi}_d^-$) and indirect noise sources (

${\rm \pi} _d^+, {\rm \pi}_d^-$) and indirect noise sources (![]() ${\rm \pi} _i^+, {\rm \pi}_i^-$) (figure 1), provided that the reflection and transmission coefficients at the boundaries of each section are known (figure 4). Knowledge of the dimensions of the system, reflection coefficients, and imposed perturbations enables the acoustic pressure to be calculated directly both upstream and downstream of the nozzle as

${\rm \pi} _i^+, {\rm \pi}_i^-$) (figure 1), provided that the reflection and transmission coefficients at the boundaries of each section are known (figure 4). Knowledge of the dimensions of the system, reflection coefficients, and imposed perturbations enables the acoustic pressure to be calculated directly both upstream and downstream of the nozzle as

where ![]() $x_s$ is the location of the direct noise source (e.g. a wave generator) and

$x_s$ is the location of the direct noise source (e.g. a wave generator) and ![]() $\hat{-}$ denotes the variables in the frequency domain. The general analytical expressions for the acoustic transfer functions

$\hat{-}$ denotes the variables in the frequency domain. The general analytical expressions for the acoustic transfer functions ![]() $\mathcal {F}_1^+$,

$\mathcal {F}_1^+$, ![]() $\mathcal {F}_1^-$,

$\mathcal {F}_1^-$, ![]() $\mathcal {F}_2^+$ and

$\mathcal {F}_2^+$ and ![]() $\mathcal {F}_2^-$ are shown in appendix B. We define

$\mathcal {F}_2^-$ are shown in appendix B. We define ![]() $\tau$ as the acoustic round trip time of the waves in the duct session upstream of the nozzle, which is calculated as

$\tau$ as the acoustic round trip time of the waves in the duct session upstream of the nozzle, which is calculated as

In the low-frequency range, for an anechoic downstream termination and for sufficiently short upstream tubes (![]() $\omega \tau \ll 1$), the duct upstream of the nozzle can be represented with a single acoustic transfer function

$\omega \tau \ll 1$), the duct upstream of the nozzle can be represented with a single acoustic transfer function ![]() $\mathcal {F}$, which describes the multiple reflections of waves at the duct inlet and at the nozzle, and is not a function of the transducer or source locations, and is given by

$\mathcal {F}$, which describes the multiple reflections of waves at the duct inlet and at the nozzle, and is not a function of the transducer or source locations, and is given by

where ![]() $\alpha$ is the attenuation coefficient of the system. In this configuration, the acoustic pressures upstream and downstream of the nozzle are then given by

$\alpha$ is the attenuation coefficient of the system. In this configuration, the acoustic pressures upstream and downstream of the nozzle are then given by

\begin{equation} \left. \begin{gathered}

\dfrac{\hat{p}'}{\bar{\gamma} \bar{p}}(x_1,\omega) =

\mathcal{F} \hat{\rm \pi}_1,\\ \dfrac{\hat{p}'}{\bar{\gamma}

\bar{p}} (x_2,\omega) = \mathcal{F} \hat{\rm \pi}_2 +

\hat{\rm \pi}^+_{i}, \end{gathered} \right\}

\end{equation}

\begin{equation} \left. \begin{gathered}

\dfrac{\hat{p}'}{\bar{\gamma} \bar{p}}(x_1,\omega) =

\mathcal{F} \hat{\rm \pi}_1,\\ \dfrac{\hat{p}'}{\bar{\gamma}

\bar{p}} (x_2,\omega) = \mathcal{F} \hat{\rm \pi}_2 +

\hat{\rm \pi}^+_{i}, \end{gathered} \right\}

\end{equation}

where ![]() $\hat {{\rm \pi} }_1$ and

$\hat {{\rm \pi} }_1$ and ![]() $\hat {{\rm \pi} }_2$ are weighted sums of acoustic sources

$\hat {{\rm \pi} }_2$ are weighted sums of acoustic sources

\begin{equation} \left. \begin{gathered}

\hat{\rm \pi}_1 = (1+R_{o})(1+R_{i}) \hat{\rm \pi}_d^+

+(1+R_{i}) \hat{\rm \pi}^-_{i},\\ \hat{\rm \pi}_2 = T_{o}

(1+R_{i}) \hat{\rm \pi}_d^+ + T_{o} R_{i}

\hat{\rm \pi}^-_{i} . \end{gathered} \right\}

\end{equation}

\begin{equation} \left. \begin{gathered}

\hat{\rm \pi}_1 = (1+R_{o})(1+R_{i}) \hat{\rm \pi}_d^+

+(1+R_{i}) \hat{\rm \pi}^-_{i},\\ \hat{\rm \pi}_2 = T_{o}

(1+R_{i}) \hat{\rm \pi}_d^+ + T_{o} R_{i}

\hat{\rm \pi}^-_{i} . \end{gathered} \right\}

\end{equation}

We have used the fact that ![]() ${{\rm \pi} _d^+}/{{\rm \pi} _d^-} = (1-\bar{M}_1)/(1+\bar{M}_1)\approx 1$ because

${{\rm \pi} _d^+}/{{\rm \pi} _d^-} = (1-\bar{M}_1)/(1+\bar{M}_1)\approx 1$ because ![]() $\bar{M}_1 \ll 1$.

$\bar{M}_1 \ll 1$.

3.2. Source and system identification

Pressure measurements alone are usually not sufficient to quantify how much direct and indirect noise is generated in an experiment. Indeed, the measured acoustic signal depends on the acoustic reflections in the system, which affect direct and indirect noise waves differently. This can be overcome by carrying out source identification, whereby the amplitudes of the acoustic sources (![]() ${\rm \pi} _d^+$,

${\rm \pi} _d^+$, ![]() ${\rm \pi} _d^-$,

${\rm \pi} _d^-$, ![]() ${\rm \pi} _i^+$ and

${\rm \pi} _i^+$ and ![]() ${\rm \pi} _i^-$) are recovered from experimental pressure measurements once their multiple reflections at the boundaries of the system are taken into account. For example, in the absence of indirect noise (

${\rm \pi} _i^-$) are recovered from experimental pressure measurements once their multiple reflections at the boundaries of the system are taken into account. For example, in the absence of indirect noise (![]() ${\rm \pi} _i^+={\rm \pi} _i^-=0$), we can identify the direct noise acoustic source

${\rm \pi} _i^+={\rm \pi} _i^-=0$), we can identify the direct noise acoustic source ![]() ${\rm \pi} _d^+$ from the measured pressure

${\rm \pi} _d^+$ from the measured pressure ![]() $p'$

$p'$

Conversely if both direct and indirect noise are present in the pressure signal, we can obtain the indirect noise sources ![]() ${\rm \pi} _i^-$ and

${\rm \pi} _i^-$ and ![]() ${\rm \pi} _i^+$ as

${\rm \pi} _i^+$ as

The expressions above require knowledge of the reflection and transmission coefficients of the system. To obtain these, we can perform system identification, whereby ![]() $R_o$ and

$R_o$ and ![]() $T_o$ are inferred from pressure measurements. As shown in Rolland et al. (Reference Rolland, De Domenico and Hochgreb2017, Reference Rolland, De Domenico and Hochgreb2018), reverberated pulses decay exponentially as follows

$T_o$ are inferred from pressure measurements. As shown in Rolland et al. (Reference Rolland, De Domenico and Hochgreb2017, Reference Rolland, De Domenico and Hochgreb2018), reverberated pulses decay exponentially as follows

If ![]() $R_i$,

$R_i$, ![]() $\alpha$ and

$\alpha$ and ![]() $\tau$ are known, the expression above can be compared to the decay rate observed experimentally to obtain

$\tau$ are known, the expression above can be compared to the decay rate observed experimentally to obtain ![]() $R_o$ as demonstrated in § 5. In the absence of indirect noise (

$R_o$ as demonstrated in § 5. In the absence of indirect noise (![]() ${\rm \pi} _i^+={\rm \pi} _i^-=0$), the pressures upstream and downstream of the nozzle are related such that

${\rm \pi} _i^+={\rm \pi} _i^-=0$), the pressures upstream and downstream of the nozzle are related such that

from which the transmission coefficient ![]() $T_o$ can be obtained (if

$T_o$ can be obtained (if ![]() $R_o$ is known).

$R_o$ is known).

4. Experimental set-up

The analytical models presented in §§ 2 and 3 enable us to make predictions on the direct and indirect noise generated in a model system. In order to validate these, experiments are conducted with the Cambridge Wave Generator (CWG), in a configuration similar to the one described in De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2017) and Rolland et al. (Reference Rolland, De Domenico and Hochgreb2018). The details of these experiments are presented in this section.

4.1. The wave generator

The wave generator is shown schematically in figure 5. A primary flow of air is fed into a duct. Perturbations are generated by injecting a pulse of a secondary flow of helium, argon, carbon dioxide or methane perpendicular into the primary flow. The injection generates direct noise, as well as compositional and entropic waves, which produce indirect noise as they are accelerated through the nozzle further downstream. The main flow is supplied from the laboratory's compressed air supply, after it is filtered and fed through a 250 l air tank in order to dampen unwanted oscillations. The mass flow rate is controlled using an Alicat MCR500 mass flow controller (accuracy: ![]() ${\pm }1\,\%$). The mass flow controller is connected to the main duct via a 12 mm inner diameter, 0.7 m long flexible hose, attached via a flat flange to provide a simple acoustic boundary condition (

${\pm }1\,\%$). The mass flow controller is connected to the main duct via a 12 mm inner diameter, 0.7 m long flexible hose, attached via a flat flange to provide a simple acoustic boundary condition (![]() $R_i \approx 0.99$, see Rolland et al. Reference Rolland, De Domenico and Hochgreb2018). The duct upstream of the nozzle consists of a steel tube of 42.6 mm inner diameter and length

$R_i \approx 0.99$, see Rolland et al. Reference Rolland, De Domenico and Hochgreb2018). The duct upstream of the nozzle consists of a steel tube of 42.6 mm inner diameter and length ![]() $L_1=1.65\ \textrm {m}$. A flexible plastic duct of identical inner diameter and of length

$L_1=1.65\ \textrm {m}$. A flexible plastic duct of identical inner diameter and of length ![]() $L_2=61\ \textrm {m}$ is fitted downstream of the nozzle. The length of the downstream duct corresponds to an acoustic round-trip time of

$L_2=61\ \textrm {m}$ is fitted downstream of the nozzle. The length of the downstream duct corresponds to an acoustic round-trip time of ![]() $2L_2/\bar {c} \approx 350\ \textrm {ms}$. As a result, the outlet is effectively anechoic for

$2L_2/\bar {c} \approx 350\ \textrm {ms}$. As a result, the outlet is effectively anechoic for ![]() $t<350\ \textrm {ms}$, meaning that downstream acoustic reflections will not have any effect on the acoustic pressure in that time frame (De Domenico et al. Reference De Domenico, Rolland and Hochgreb2019a). The duct is fitted with one of two non-isentropic nozzles: a convergent nozzle (configuration C) or a convergent–divergent nozzle (configuration CD). The convergent nozzle is 24 mm long, with a linear geometric profile (

$t<350\ \textrm {ms}$, meaning that downstream acoustic reflections will not have any effect on the acoustic pressure in that time frame (De Domenico et al. Reference De Domenico, Rolland and Hochgreb2019a). The duct is fitted with one of two non-isentropic nozzles: a convergent nozzle (configuration C) or a convergent–divergent nozzle (configuration CD). The convergent nozzle is 24 mm long, with a linear geometric profile (![]() $40^{\circ }$ angle) and a throat diameter of 6.6 mm. The 61-m long tube is fitted downstream of the nozzles. Thus, the flow downstream of the converging section has an abrupt divergence, and the convergent nozzle behaves similarly to an orifice plate. The convergent–divergent nozzle consists of the aforementioned convergent nozzle with an additional divergent section. The divergent section is 230 mm long with an angle of

$40^{\circ }$ angle) and a throat diameter of 6.6 mm. The 61-m long tube is fitted downstream of the nozzles. Thus, the flow downstream of the converging section has an abrupt divergence, and the convergent nozzle behaves similarly to an orifice plate. The convergent–divergent nozzle consists of the aforementioned convergent nozzle with an additional divergent section. The divergent section is 230 mm long with an angle of ![]() $4.5^{\circ }$, with the long tube attached downstream.

$4.5^{\circ }$, with the long tube attached downstream.

Figure 5. Cambridge Wave Generator with ![]() $(a)$ pressure gauge,

$(a)$ pressure gauge, ![]() $(b)$ manual valve,

$(b)$ manual valve, ![]() $(c)$ air tank,

$(c)$ air tank, ![]() $(d)$ secondary gas tank,

$(d)$ secondary gas tank, ![]() $(e)$ pressure regulator,

$(e)$ pressure regulator, ![]() $(\,f)$ mass flow meter,

$(\,f)$ mass flow meter, ![]() $(g)$ fast response solenoid valve and

$(g)$ fast response solenoid valve and ![]() $(h)$ mass flow controller.

$(h)$ mass flow controller.

The nozzles are operated either in subsonic or sonic throat conditions in the test cases considered here (![]() $\bar {M}_T \leq 1$). It is experimentally verified that the convergent–divergent nozzle has a choking mass flow rate

$\bar {M}_T \leq 1$). It is experimentally verified that the convergent–divergent nozzle has a choking mass flow rate ![]() $\dot {m} \simeq 10.5\ \textrm {g}\,\textrm {s}^{-1}$, thus the throat reaches sonic conditions with the experimental mass flow rates. The work in De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) showed that these nozzles have a vena contracta factor of

$\dot {m} \simeq 10.5\ \textrm {g}\,\textrm {s}^{-1}$, thus the throat reaches sonic conditions with the experimental mass flow rates. The work in De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a) showed that these nozzles have a vena contracta factor of ![]() $\varGamma =0.89$ for the flow conditions considered here. The non-isentropicity parameter

$\varGamma =0.89$ for the flow conditions considered here. The non-isentropicity parameter ![]() $\beta$ for each nozzle is determined based on experimental measurements of the pressure drop across the nozzles in § 5.3, following De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a). The convergent nozzle, instead, chokes with a mass flow rate of

$\beta$ for each nozzle is determined based on experimental measurements of the pressure drop across the nozzles in § 5.3, following De Domenico et al. (Reference De Domenico, Rolland and Hochgreb2019a). The convergent nozzle, instead, chokes with a mass flow rate of ![]() $\dot {m} \simeq 13\ \textrm {g}\,\textrm {s}^{-1}$, thus the throat always operates in subsonic conditions for the experimental mass flow rates, with a measured vena contracta factor

$\dot {m} \simeq 13\ \textrm {g}\,\textrm {s}^{-1}$, thus the throat always operates in subsonic conditions for the experimental mass flow rates, with a measured vena contracta factor ![]() $\varGamma = 0.9381$. A larger vena contracta factor implies a larger effective throat area, which is reflected into a higher choking mass flow rate, as more flow is needed to reach sonic conditions. The minimum effective area experienced by the flow in the convergent-only nozzle is larger as the flow separates as soon as it leaves the throat, while, for the convergent–divergent nozzle, the effective smaller area occurs further downstream, and the flow rearranges itself with a smaller effective throat area.

$\varGamma = 0.9381$. A larger vena contracta factor implies a larger effective throat area, which is reflected into a higher choking mass flow rate, as more flow is needed to reach sonic conditions. The minimum effective area experienced by the flow in the convergent-only nozzle is larger as the flow separates as soon as it leaves the throat, while, for the convergent–divergent nozzle, the effective smaller area occurs further downstream, and the flow rearranges itself with a smaller effective throat area.

Pressure measurements are carried out using Kulite XTE-190M piezoresistive pressure transducers, which are flush mounted at locations ![]() $x_1=0.9\ \textrm {m}$ and

$x_1=0.9\ \textrm {m}$ and ![]() $x_2=1.1\ \textrm {m}$ upstream and downstream of the nozzle. Pressure transducers provide an accuracy of

$x_2=1.1\ \textrm {m}$ upstream and downstream of the nozzle. Pressure transducers provide an accuracy of ![]() $4.0\times 10^{-6}$ full scale (3.5 bar), which translates to

$4.0\times 10^{-6}$ full scale (3.5 bar), which translates to ![]() $1$ Pa for perturbations of 300 Pa. The absolute pressure is logged with a Kulite XTL-190SM transducer (accuracy

$1$ Pa for perturbations of 300 Pa. The absolute pressure is logged with a Kulite XTL-190SM transducer (accuracy ![]() $3.0\times10^{-5}$ full scale), also mounted at

$3.0\times10^{-5}$ full scale), also mounted at ![]() $x_1$. The pressure transducer signals are acquired using a National Instruments PXIe-4480 module. The signals are sampled at 10 000 Hz and phase-averaged over 100 pulses with a 0.25 Hz repetition rate. Frequencies around 50 Hz (power frequency) and above 400 Hz are filtered out, in accordance with the low frequency range of the excitation.

$x_1$. The pressure transducer signals are acquired using a National Instruments PXIe-4480 module. The signals are sampled at 10 000 Hz and phase-averaged over 100 pulses with a 0.25 Hz repetition rate. Frequencies around 50 Hz (power frequency) and above 400 Hz are filtered out, in accordance with the low frequency range of the excitation.

4.2. Pulse injection

Flow perturbations are generated by pulse injecting a secondary stream of gas into the primary air flow. Since the injected gases (helium, argon, methane or carbon dioxide) have a different entropy and composition than air, the injection generates direct noise, as well as a compositional and entropic disturbance. The injection location is varied to modify the convective length ![]() $L_c$. The convective time delay

$L_c$. The convective time delay ![]() $\tau _c=L_c/\bar {u}_1$ is the time taken for the gas disturbances to convect from the injection location to the nozzle. A fast-response micro-solenoid valve (ASCO Numatics HSM2L7H50V) is connected to the duct via a 0.1 m length of flexible tubing with a 2 mm inner diameter to inject the secondary gas, which enters the duct radially. The valve is actuated using a computer-generated pulse signal, which drives a 24 V power supply. Each pulse lasts

$\tau _c=L_c/\bar {u}_1$ is the time taken for the gas disturbances to convect from the injection location to the nozzle. A fast-response micro-solenoid valve (ASCO Numatics HSM2L7H50V) is connected to the duct via a 0.1 m length of flexible tubing with a 2 mm inner diameter to inject the secondary gas, which enters the duct radially. The valve is actuated using a computer-generated pulse signal, which drives a 24 V power supply. Each pulse lasts ![]() $\tau _p=100\ \textrm {ms}$. The injector nozzle consists of a Swagelok 1/4” fitting, through which the injected gas enters the tube. The injector can be mounted via one of several ports located along the duct, allowing for different source locations relatively to the nozzle, and thus resulting in a range of convective lengths and times. The ports are aligned with the duct centreline, so that the injected gas enters the duct in the radial direction. Simulations from Rodrigues, Busseti & Hochgreb (Reference Rodrigues, Busseti and Hochgreb2020) and experiments from De Domenico et al. (Reference De Domenico, Shah, Lowe, Fan, Ewart, Williams and Hochgreb2019b) show that the injected plume mixes sufficiently very close to the injection location, allowing for a quasi-one-dimensional approximation. Following the analysis of Broadwell & Breidenthal (Reference Broadwell and Breidenthal1984), it can be demonstrated that the full mixing penetration occurs before the spot enters the nozzle. Corresponding vorticity waves due to the momentum of the injection are shown to be negligible as the spot is convected uniformly with the mean flow. As shown in Howe (Reference Howe2010) and Dowling & Mahmoudi (Reference Dowling and Mahmoudi2015), vorticity noise is negligible for low Mach number flows. The mass flow rate of injected gas (

$\tau _p=100\ \textrm {ms}$. The injector nozzle consists of a Swagelok 1/4” fitting, through which the injected gas enters the tube. The injector can be mounted via one of several ports located along the duct, allowing for different source locations relatively to the nozzle, and thus resulting in a range of convective lengths and times. The ports are aligned with the duct centreline, so that the injected gas enters the duct in the radial direction. Simulations from Rodrigues, Busseti & Hochgreb (Reference Rodrigues, Busseti and Hochgreb2020) and experiments from De Domenico et al. (Reference De Domenico, Shah, Lowe, Fan, Ewart, Williams and Hochgreb2019b) show that the injected plume mixes sufficiently very close to the injection location, allowing for a quasi-one-dimensional approximation. Following the analysis of Broadwell & Breidenthal (Reference Broadwell and Breidenthal1984), it can be demonstrated that the full mixing penetration occurs before the spot enters the nozzle. Corresponding vorticity waves due to the momentum of the injection are shown to be negligible as the spot is convected uniformly with the mean flow. As shown in Howe (Reference Howe2010) and Dowling & Mahmoudi (Reference Dowling and Mahmoudi2015), vorticity noise is negligible for low Mach number flows. The mass flow rate of injected gas (![]() $\dot {m}_{He}$,

$\dot {m}_{He}$, ![]() $\dot {m}_{Ar}$,

$\dot {m}_{Ar}$, ![]() $\dot {m}_{CH_4}$ or

$\dot {m}_{CH_4}$ or ![]() $\dot {m}_{CO_2}$) is adjusted using a pressure regulator upstream of the micro-solenoid valve, and monitored with an Alicat M100 mass flow meter (accuracy:

$\dot {m}_{CO_2}$) is adjusted using a pressure regulator upstream of the micro-solenoid valve, and monitored with an Alicat M100 mass flow meter (accuracy: ![]() ${\pm }1\,\%$). The amount of gas is chosen to achieve a given mass fraction for each gas (

${\pm }1\,\%$). The amount of gas is chosen to achieve a given mass fraction for each gas (![]() $Y_{He}=0.02$,

$Y_{He}=0.02$, ![]() $Y_{CH_4}=0.1$,

$Y_{CH_4}=0.1$, ![]() $Y_{Ar}=Y_{CO_2}=0.2$).

$Y_{Ar}=Y_{CO_2}=0.2$).

4.3. Test cases

The experimental cases examined are chosen in order to demonstrate the influence of nozzle non-isentropicity and compositional effects on the indirect noise generated by perturbations of helium, argon, methane and carbon dioxide. Experiments are carried out with the convergent nozzle (configuration C), or the convergent–divergent nozzle (configuration CD). For each of these, we carry out tests at eleven different air mass flow rates ![]() $\dot {m}$: C1–C11 for the convergent nozzle, and CD1–CD11 for the convergent–divergent nozzle. The experimental cases are shown in tables 1 and 2.

$\dot {m}$: C1–C11 for the convergent nozzle, and CD1–CD11 for the convergent–divergent nozzle. The experimental cases are shown in tables 1 and 2.

Table 1. Experimental conditions for configuration C (convergent nozzle): upstream mean pressure ![]() $\bar {p}_1$, upstream Mach number

$\bar {p}_1$, upstream Mach number ![]() $\bar {M}_1$, throat Mach number

$\bar {M}_1$, throat Mach number ![]() $\bar {M}_t$, downstream Mach number

$\bar {M}_t$, downstream Mach number ![]() $\bar {M}_2$, primary mass flow rate

$\bar {M}_2$, primary mass flow rate ![]() $\dot {m}$ and injected mass flow rates

$\dot {m}$ and injected mass flow rates ![]() $\dot {m}_{He}$,

$\dot {m}_{He}$, ![]() $\dot {m}_{Ar}$,

$\dot {m}_{Ar}$, ![]() $\dot {m}_{CH_4}$ or

$\dot {m}_{CH_4}$ or ![]() $\dot {m}_{CO_2}$.

$\dot {m}_{CO_2}$.

Table 2. Experimental conditions for configuration CD (convergent–divergent nozzle): upstream mean pressure ![]() $\bar {p}_1$, upstream Mach number

$\bar {p}_1$, upstream Mach number ![]() $\bar {M}_1$, throat Mach number

$\bar {M}_1$, throat Mach number ![]() $\bar {M}_t$, downstream Mach number

$\bar {M}_t$, downstream Mach number ![]() $\bar {M}_2$, primary mass flow rate

$\bar {M}_2$, primary mass flow rate ![]() $\dot {m}$ and injected mass flow rates

$\dot {m}$ and injected mass flow rates ![]() $\dot {m}_{He}$,

$\dot {m}_{He}$, ![]() $\dot {m}_{Ar}$,

$\dot {m}_{Ar}$, ![]() $\dot {m}_{CH_4}$ or

$\dot {m}_{CH_4}$ or ![]() $\dot {m}_{CO_2}$.

$\dot {m}_{CO_2}$.

For each experimental condition, we perform eight tests. The secondary gases are injected into the duct with a flow rate ![]() $\dot {m}_{He}$,

$\dot {m}_{He}$, ![]() $\dot {m}_{Ar}$,

$\dot {m}_{Ar}$, ![]() $\dot {m}_{CH_4}$ or

$\dot {m}_{CH_4}$ or ![]() $\dot {m}_{CO_2}$. Tests are carried out for both a ‘long’ and ‘short’ convective length

$\dot {m}_{CO_2}$. Tests are carried out for both a ‘long’ and ‘short’ convective length ![]() $L_c$. For the ‘long’ convective length

$L_c$. For the ‘long’ convective length ![]() $L_c=0.65\ \textrm {m}$, wave dispersion effects can be identified in the plume (Rodrigues et al. Reference Rodrigues, Busseti and Hochgreb2020), as there is a relatively long convective time delay

$L_c=0.65\ \textrm {m}$, wave dispersion effects can be identified in the plume (Rodrigues et al. Reference Rodrigues, Busseti and Hochgreb2020), as there is a relatively long convective time delay ![]() $\tau _c =L_c / \bar {u}_1$ between the generation of direct and indirect noise. For the ‘short’ convective length

$\tau _c =L_c / \bar {u}_1$ between the generation of direct and indirect noise. For the ‘short’ convective length ![]() $L_c=0.05$, dispersion and dissipation is minimised and direct and indirect noise occur nearly simultaneously. The results corresponding to the ‘long’ and ‘short’ convective lengths can be compared to identify the indirect noise contribution and minimise the effect of dispersion, as shown in § 3.2. In the experiments, whereas direct noise is evaluated in the ‘long’ tube case, indirect noise is evaluated in the ‘short’ tube case, to minimise the effects of dispersion on the injected mass. In summary, 176 tests are performed in total, which are defined by the experimental condition, the injected gas and the convective length

$L_c=0.05$, dispersion and dissipation is minimised and direct and indirect noise occur nearly simultaneously. The results corresponding to the ‘long’ and ‘short’ convective lengths can be compared to identify the indirect noise contribution and minimise the effect of dispersion, as shown in § 3.2. In the experiments, whereas direct noise is evaluated in the ‘long’ tube case, indirect noise is evaluated in the ‘short’ tube case, to minimise the effects of dispersion on the injected mass. In summary, 176 tests are performed in total, which are defined by the experimental condition, the injected gas and the convective length ![]() $L_c$. For example, ‘test C1–He–long’ refers to the test carried out with a convergent nozzle (in the experimental conditions corresponding to C1 in table 1), where the injected gas is helium and the convective length is long (

$L_c$. For example, ‘test C1–He–long’ refers to the test carried out with a convergent nozzle (in the experimental conditions corresponding to C1 in table 1), where the injected gas is helium and the convective length is long (![]() $L_c=0.65\ \textrm {m}$). Each test is repeated for 100 pulses and the resulting pressure measurements are phase-averaged and filtered.

$L_c=0.65\ \textrm {m}$). Each test is repeated for 100 pulses and the resulting pressure measurements are phase-averaged and filtered.

5. Results

In this section, the analytical models derived in §§ 2.2 and 3 are compared with the experimental data acquired in the Entropy Generator Rig. While the experimental points are acquired both in subsonic and transonic conditions, the analytical transfer functions are developed only for subsonic-to-sonic nozzle flows. The non-isentropic behaviour of a supersonic divergent nozzle with losses and a shock is beyond the scope of this work.

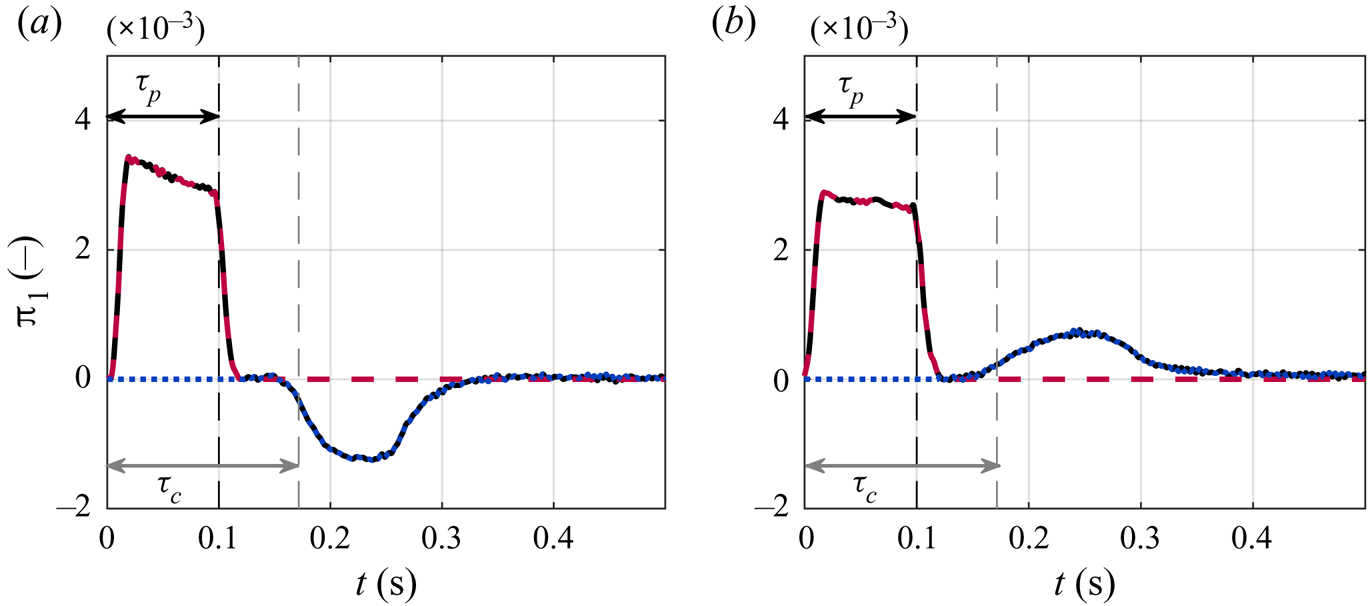

5.1. Measurements in the long tube configuration

In the ‘long’ configuration, the convective time delay ![]() $\tau _c$ is longer than the pulse duration

$\tau _c$ is longer than the pulse duration ![]() $\tau _p=100$ ms. As a result, direct and indirect noise are not generated simultaneously. Direct noise is generated during the gas injection (

$\tau _p=100$ ms. As a result, direct and indirect noise are not generated simultaneously. Direct noise is generated during the gas injection (![]() $0<t<\tau _p$) and indirect noise is generated as the gas disturbance is accelerated/decelerated through the nozzle (

$0<t<\tau _p$) and indirect noise is generated as the gas disturbance is accelerated/decelerated through the nozzle (![]() $t>\tau _c$).

$t>\tau _c$).

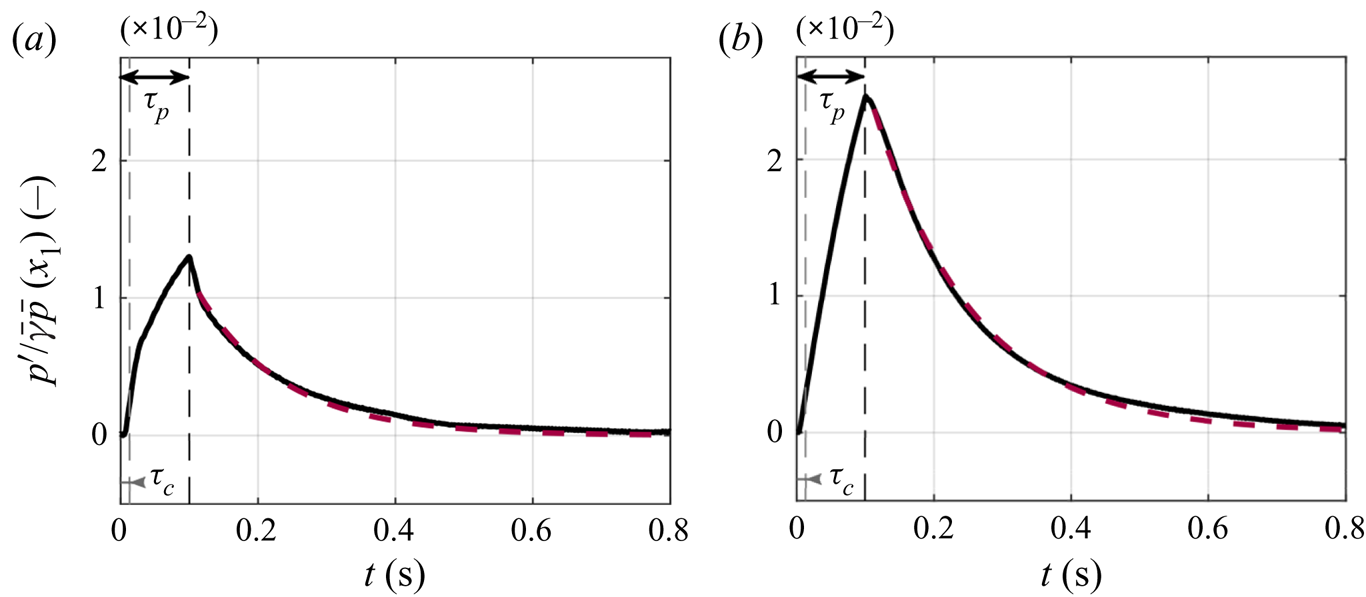

5.1.1. Upstream of the nozzle

The experimental pressure measurements upstream of the nozzle ![]() ${p'}(x_1)$ for cases C8–He–long and C8–CO2–long are shown in figures 6(a) and 6(b) respectively. In both cases, the acoustic pressure rises sharply during the valve pulse signal (

${p'}(x_1)$ for cases C8–He–long and C8–CO2–long are shown in figures 6(a) and 6(b) respectively. In both cases, the acoustic pressure rises sharply during the valve pulse signal (![]() $0<t<\tau _p$). This can be explained as follows: during the injection, acoustic waves are generated and reflected back at the inlet and the outlet of the duct with an overall round trip time (time taken for a sound wave to back and forth in the duct)

$0<t<\tau _p$). This can be explained as follows: during the injection, acoustic waves are generated and reflected back at the inlet and the outlet of the duct with an overall round trip time (time taken for a sound wave to back and forth in the duct) ![]() $\tau = 2L/\bar{c} \simeq 10\ \textrm {ms}$. This means that sound waves reflect approximately

$\tau = 2L/\bar{c} \simeq 10\ \textrm {ms}$. This means that sound waves reflect approximately ![]() $2\tau _p/\tau \approx 20$ times between the inlet and the nozzle before the end of injection time (at