Impact Statement

Identifying the nonlinear forces generated by frictional joints is crucial for understanding and predicting the nonlinear behavior of engineering structures. However, most identification approaches cannot deal with the sharp variations and multiple motion regimes introduced by these nonlinearities in the system’s response. The method presented in this paper combines a partially-known physics-based model of the system with noisy measurements of its response in a switching Gaussian process (GP) latent force model, where multiple GPs are used to model the nonlinear force across different motion regimes and a resetting model to generate discontinuities. Regime transitions and discontinuities are inferred in a Bayesian manner, along with the nonlinear force, and can be used to implement forward models able to make reliable predictions.

1. Introduction

This paper focuses on one of the key challenges in structural dynamics: the identification of discontinuous nonlinear forces arising at the structural joints of complex mechanical systems, when an incomplete physics-based model of the system and noisy measurements of its dynamic response are available. Due to tighter tolerances and the general requirement for higher performance, it is becoming more and more essential to correctly account for the nonlinearity introduced by frictional joints in structural design and analysis. The presence of friction can produce harsh or nonsmooth phenomena such as stick–slip motions and vibro-impact, which cannot be accounted for with equivalent linear techniques even in low-amplitude vibration settings (Butlin et al., Reference Butlin, Woodhouse and Champneys2015). In particular, an approach is proposed for the identification of discontinuous and nonsmooth nonlinearities, as those introduced by dry friction in mechanical systems.

Nonlinearity in structural dynamics poses several challenges, including the need for advanced mathematical models and solution techniques, and the lack of a universal approach to the experimental testing of nonlinear structures (Wang et al., Reference Wang, Khodaparast, Shaw and Friswell2018). Nonlinear system identification plays here a fundamental role in reconciling numerical predictions with experimental investigations (Kerschen et al., Reference Kerschen, Worden, Vakakis and Golinval2006). In fact, it enables the extraction of information about the nonlinear structural behavior from experimental data and, as a consequence, the prediction of the response of these systems to different inputs. Several techniques have been developed in the recent years to deal with the detection (Worden and Tomlinson, Reference Worden and Tomlinson2001), localization (Wang et al., Reference Wang, Khodaparast, Shaw and Friswell2018), characterization (Ondra et al., Reference Ondra, Sever and Schwingshackl2017) and quantification (Carella and Ewins, Reference Carella and Ewins2011) of nonlinearities; for exhaustive reviews on this topic see (Kerschen et al., Reference Kerschen, Worden, Vakakis and Golinval2006; Ewins et al., Reference Ewins, Weekes and Delli Carri2015; Noël and Kerschen, Reference Noël and Kerschen2017). Nonetheless, most nonlinear system identification approaches cannot easily handle discontinuous and nonsmooth nonlinearities, as those introduced by dry friction in mechanical systems.

A very promising approach for dealing with smooth nonlinearities is the Gaussian process latent force model (GPLFM). The GPLFM was firstly introduced by Alvarez et al. (Reference Alvarez, Luengo and Lawrence2009) for identifying the unknown input force driving a second-order dynamical system from noisy observations of its response. The latent driving force were modelled as a zero-mean temporal Gaussian process (GP) with a stationary kernel, and the governing equation of the system (i.e., the domain knowledge) where exploited to update the GP prior to the response measurements. Although outperforming pure data-driven approaches, this formulation was computationally expensive, since GP regression scales as

![]() $ \mathcal{O}\left({T}^3\right) $

with respect to the number of data points

$ \mathcal{O}\left({T}^3\right) $

with respect to the number of data points

![]() $ T $

. To overcome this limitation, Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012) reformulated the problem as an augmented state-space model, coupling the governing equations of the system with the state-space representation of the GP latent force, whose derivation is presented in Hartikainen and Särkkä (Reference Hartikainen and Särkkä2010). In this formulation, inference could be performed sequentially by using Kalman filter (Kalman, Reference Kalman1960) and Rauch–Tung–Striebel (RTS) (Rauch et al., Reference Rauch, Tung and Striebel1965), significantly reducing the computational burden. In recent years, the use of GPLFMs in mechanical systems has been explored by several authors. In particular, the approach was applied to linear single degree-of-freedom (SDOF) (Rogers et al., Reference Rogers, Worden, Manson, Tygesen and Cross2018) and multi degree-of-freedom (MDOF) mechanical systems (Nayek et al., Reference Nayek, Chakraborty and Narasimhan2019; Rogers et al., Reference Rogers, Worden and Cross2020), as well as to nonlinear systems with a known nonlinearity (Rogers et al., Reference Rogers, Worden and Cross2020), to perform joint input-state estimation. In Rogers et al. (Reference Rogers, Worden, Manson, Tygesen and Cross2018, Reference Rogers, Worden and Cross2020), the GPLFM is also used to infer the uncertain physical parameters of the system. Further applications of the GPLFM to joint input-state identification can be found in recent experimental studies (Bilbao et al., Reference Bilbao, Lourens, Schulze and Ziegler2022; Petersen et al., Reference Petersen, Oiseth and Lourens2022; Zou et al., Reference Zou, Lourens and Cicirello2023, Reference Zou, Lourens, Iliopoulos and Cicirello2022b). Finally, in Rogers and Friis (Reference Rogers and Friis2022), the GPLFM is applied to the nonlinear identification of mechanical systems with a known driving force. In the case of a SDOF Duffing oscillator, the joint estimation of system parameters, latent states and nonlinear restoring force was performed by modelling the latter as a GP latent force. In this approach, the functional form of the nonlinear force was also reconstructed by fitting the inferred estimates with a polynomial curve, whose degree was obtained by using a Bayesian Information Criterion (Schwarz, Reference Schwarz1978). A limitation of GPLFMs is that a single GP latent force is generally not able to model sharp variations in the time series, as those generated by discontinuous nonlinearities or switching driving forces, or to handle the response of systems operating under different motion regimes. Different approaches have been developed for identifying systems driven by a sequence of latent forces. For example, Alvarez et al., Reference Alvarez, Peters, Schoelkopf and Lawrence2010 inferred the unknown switching time instants along with the GP hyperparameters. However, this approach required a prior knowledge of the number of switching points. Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012) overcame this limitation by formulating the GPLFM as a switching linear dynamical system (SLDS), where the latent driving force model transitions are governed by a discrete-time Markov model. Nonetheless, the use of switching latent force models for the identification of nonlinear systems is currently unexplored.

$ T $

. To overcome this limitation, Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012) reformulated the problem as an augmented state-space model, coupling the governing equations of the system with the state-space representation of the GP latent force, whose derivation is presented in Hartikainen and Särkkä (Reference Hartikainen and Särkkä2010). In this formulation, inference could be performed sequentially by using Kalman filter (Kalman, Reference Kalman1960) and Rauch–Tung–Striebel (RTS) (Rauch et al., Reference Rauch, Tung and Striebel1965), significantly reducing the computational burden. In recent years, the use of GPLFMs in mechanical systems has been explored by several authors. In particular, the approach was applied to linear single degree-of-freedom (SDOF) (Rogers et al., Reference Rogers, Worden, Manson, Tygesen and Cross2018) and multi degree-of-freedom (MDOF) mechanical systems (Nayek et al., Reference Nayek, Chakraborty and Narasimhan2019; Rogers et al., Reference Rogers, Worden and Cross2020), as well as to nonlinear systems with a known nonlinearity (Rogers et al., Reference Rogers, Worden and Cross2020), to perform joint input-state estimation. In Rogers et al. (Reference Rogers, Worden, Manson, Tygesen and Cross2018, Reference Rogers, Worden and Cross2020), the GPLFM is also used to infer the uncertain physical parameters of the system. Further applications of the GPLFM to joint input-state identification can be found in recent experimental studies (Bilbao et al., Reference Bilbao, Lourens, Schulze and Ziegler2022; Petersen et al., Reference Petersen, Oiseth and Lourens2022; Zou et al., Reference Zou, Lourens and Cicirello2023, Reference Zou, Lourens, Iliopoulos and Cicirello2022b). Finally, in Rogers and Friis (Reference Rogers and Friis2022), the GPLFM is applied to the nonlinear identification of mechanical systems with a known driving force. In the case of a SDOF Duffing oscillator, the joint estimation of system parameters, latent states and nonlinear restoring force was performed by modelling the latter as a GP latent force. In this approach, the functional form of the nonlinear force was also reconstructed by fitting the inferred estimates with a polynomial curve, whose degree was obtained by using a Bayesian Information Criterion (Schwarz, Reference Schwarz1978). A limitation of GPLFMs is that a single GP latent force is generally not able to model sharp variations in the time series, as those generated by discontinuous nonlinearities or switching driving forces, or to handle the response of systems operating under different motion regimes. Different approaches have been developed for identifying systems driven by a sequence of latent forces. For example, Alvarez et al., Reference Alvarez, Peters, Schoelkopf and Lawrence2010 inferred the unknown switching time instants along with the GP hyperparameters. However, this approach required a prior knowledge of the number of switching points. Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012) overcame this limitation by formulating the GPLFM as a switching linear dynamical system (SLDS), where the latent driving force model transitions are governed by a discrete-time Markov model. Nonetheless, the use of switching latent force models for the identification of nonlinear systems is currently unexplored.

In this paper, a switching (GPLFM) is proposed to identify a discontinuous nonlinear force and the latent states of an SDOF mechanical system excited by a known driving force. This method is based on the introduction of the switching GPLFM framework (Hartikainen and Särkkä, Reference Hartikainen and Särkkä2012) in the latent nonlinear restoring force model (Rogers and Friis, Reference Rogers and Friis2022), which enables: (i) the use of different GPs to model the nonlinear forces acting under different motion regimes (e.g., during sliding and sticking responses of a dry friction oscillator); (ii) the use of resetting models for generating discontinuities in the latent nonlinear force. Moreover, an approach is developed for estimating the uncertain physical parameters of the system, i.e., mass, viscous damping, and stiffness, from the identified latent states and discontinuous nonlinear force. Finally, a procedure is proposed for characterizing the functional dependency of the nonlinear friction force on the sliding velocity and determining the static friction force. This enables the evaluation of the friction force–velocity relationship and the value of the static friction force, which are robust features for the characterization of the friction law (Cabboi et al., Reference Cabboi, Marino and Cicirello2022).

The paper is organized as follows. The mathematical formulation of the switching GPLFM, along with its implementation, is introduced in Section 2. The proposed methodology is applied to the numerical case-study of an SDOF dry friction oscillator under random phase multisine excitation in Section 3. An experimental case-study is then presented in Section 4, where nonlinear system identification is performed on the stick–slip response of a single-storey frame subject to harmonic base excitation. Finally, the results are further discussed in the concluding remarks, presented in Section 5.

2. Mathematical Formulation of the Switching Gaussian Process Latent Force Model

Let us consider a nonlinear SDOF system of mass

![]() $ m $

, viscous damping coefficient

$ m $

, viscous damping coefficient

![]() $ c $

, and stiffness

$ c $

, and stiffness

![]() $ k $

, excited by the dynamic load

$ k $

, excited by the dynamic load

![]() $ u(t) $

. The governing equation of this system can be expressed as follows:

$ u(t) $

. The governing equation of this system can be expressed as follows:

where

![]() $ f\left(z,\dot{z}\right) $

is a generic unknown nonlinear function of the displacement and velocity of the mass. The identification of this nonlinear term, including its most plausible function form and parameters, is essential for the implementation of an accurate forward model of the system able to predict its response to any input forces. If a set of noisy measurements of the system’s response to a known driving force

$ f\left(z,\dot{z}\right) $

is a generic unknown nonlinear function of the displacement and velocity of the mass. The identification of this nonlinear term, including its most plausible function form and parameters, is essential for the implementation of an accurate forward model of the system able to predict its response to any input forces. If a set of noisy measurements of the system’s response to a known driving force

![]() $ u(t) $

is available, the nonlinear force can be identified by applying the GPLFM in the formulation proposed by Rogers and Friis (Reference Rogers and Friis2022). In this case, the latent force model is formulated by modeling the nonlinear function as a zero-mean GP in time with a stationary kernel

$ u(t) $

is available, the nonlinear force can be identified by applying the GPLFM in the formulation proposed by Rogers and Friis (Reference Rogers and Friis2022). In this case, the latent force model is formulated by modeling the nonlinear function as a zero-mean GP in time with a stationary kernel

![]() $ \kappa $

:

$ \kappa $

:

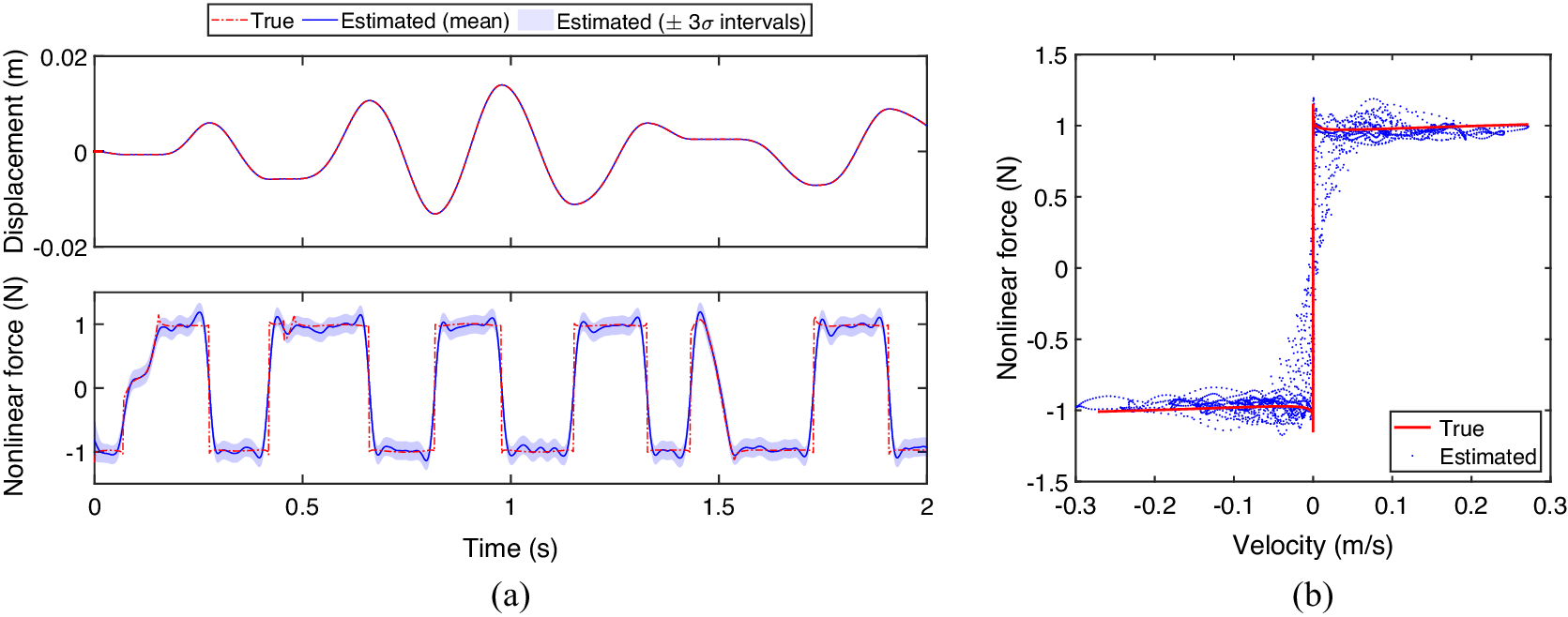

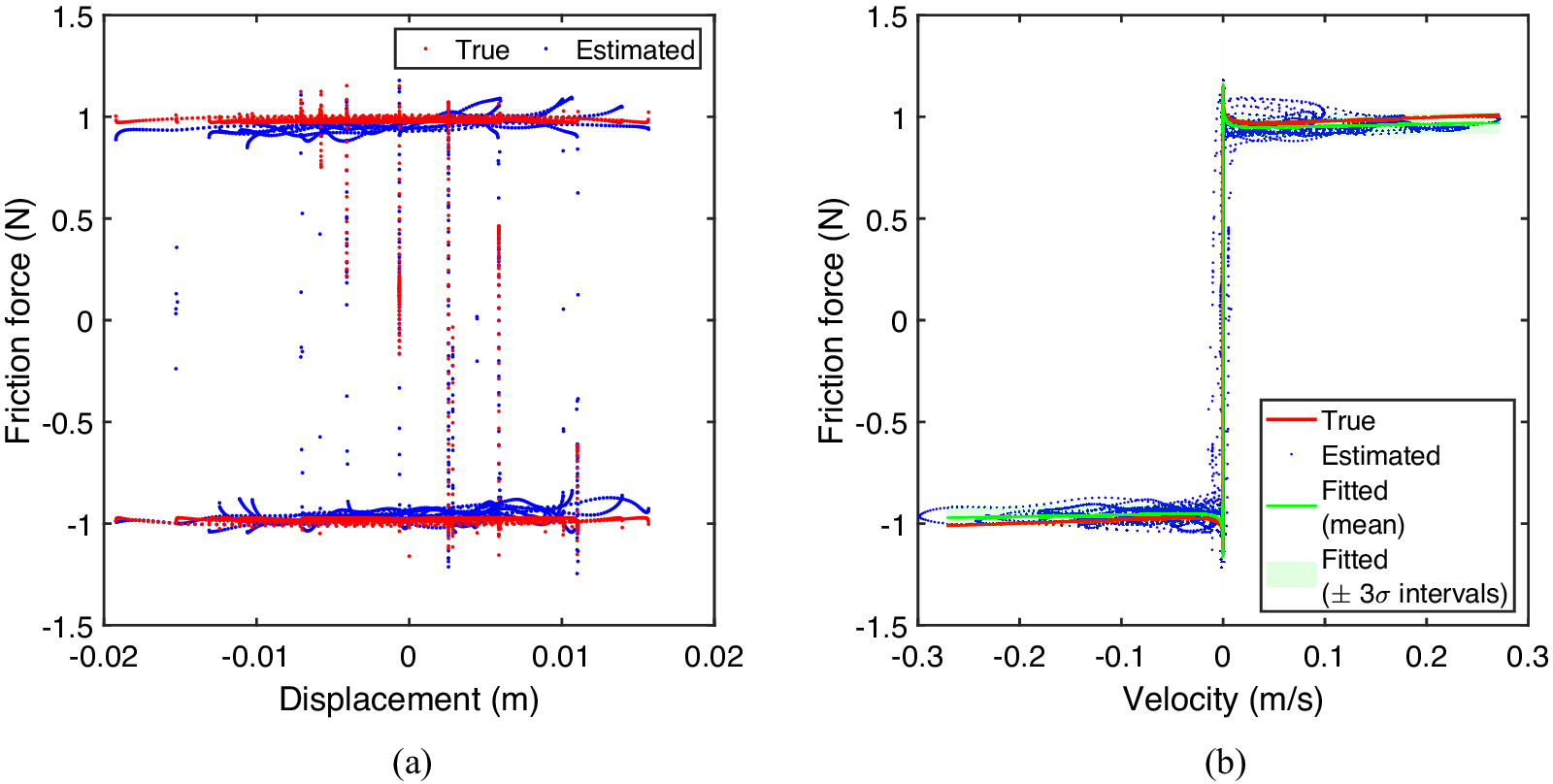

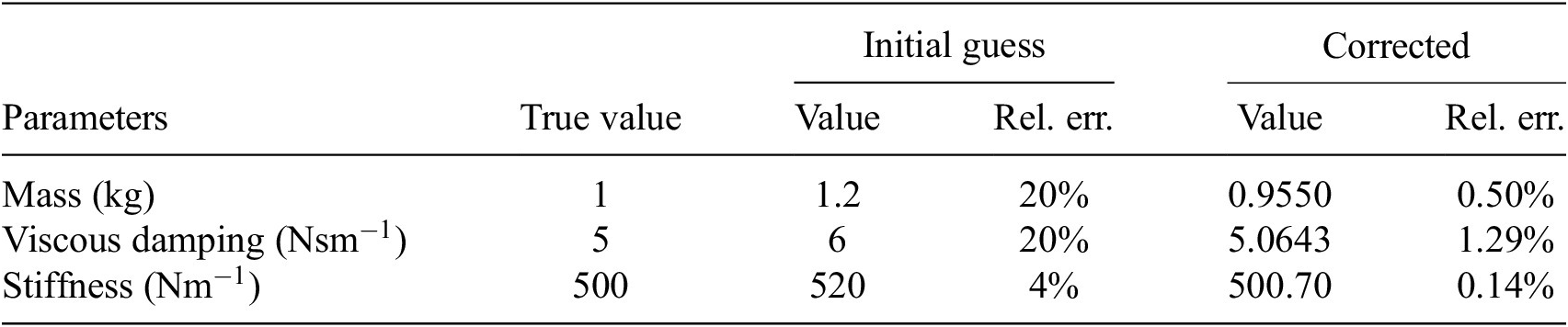

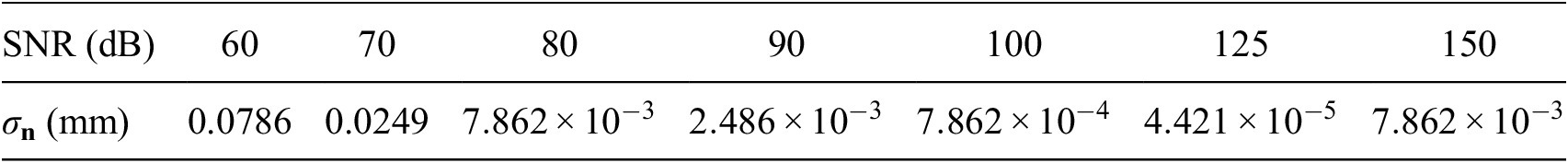

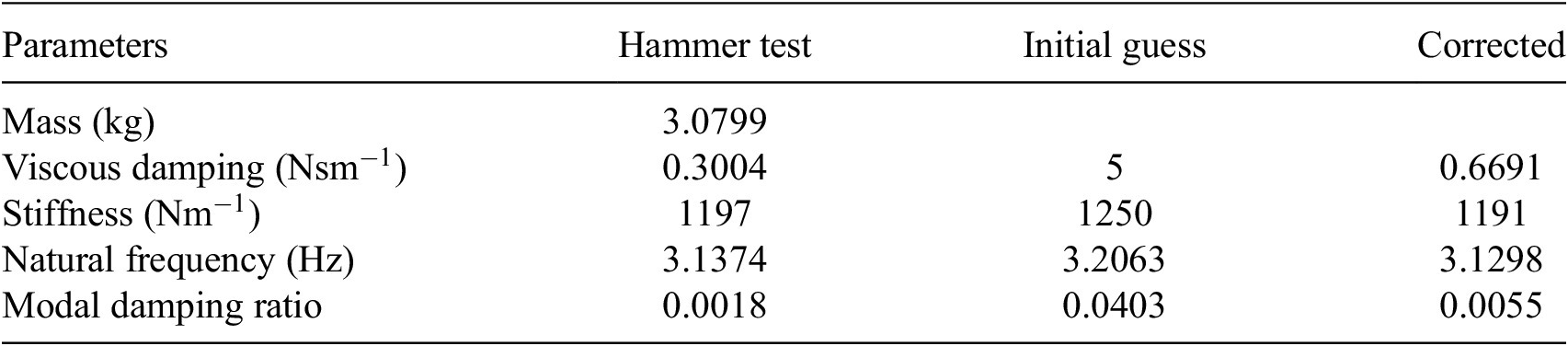

The performances of this nonlinear system identification method are strictly dependent on the ability of GPs of reconstructing the nonlinear force. A particularly challenging problem for the GPLFM is the identification of nonlinear forces whose time evolution is characterized by the presence of discontinuities or sharp variations. As an example, Figure 1 shows the performance of the GPLFM in identifying the nonlinear force in a dry friction oscillator subject to a known random phase multisine excitation, for which noisy measurements of the mass displacement are available. In this system, which is thoroughly described in Section 3, friction always opposes the sliding motion between the parts in contact, leading to the presence of a discontinuity in the nonlinear force when the sliding velocity sign changes. In Figure 1a, it can be observed that the GP tends to smooth sharp variations in the identified nonlinear force. As a result, information regarding the presence of the discontinuity will be lost during the identification process. This can also be observed from the nonlinear friction force–velocity point estimates reported in Figure 1b. Moreover, in Figure 1a, it can be observed that the friction force displays significantly different patterns during the alternation of sticking and sliding phases characterizing the stick–slip response of the system. If a single latent force is used to model the nonlinear friction force, this further affects the performance of the GPLFM.

Figure 1. Example of nonlinear restoring force identification in a dry friction oscillator (with model parameters as specified in Section 3), obtained for

![]() $ {f}_s=500 $

Hz and SNR

$ {f}_s=500 $

Hz and SNR

![]() $ =80 $

dB: displacement and nonlinear friction force time evolutions (a) and friction force vs velocity (b).

$ =80 $

dB: displacement and nonlinear friction force time evolutions (a) and friction force vs velocity (b).

2.1. Probabilistic model

A switching GPFLM is here introduced to enable the identification of complex nonlinearities characterized by discontinuities and/or generating different motion regimes in the dynamic response. This latent force model can be formulated as an SLDS in the following form:

$$ \left\{\begin{array}{l}p\left({\mathbf{x}}_t|{\mathbf{x}}_{t-1},{u}_{t-1},{s}_t\right)=\mathcal{N}\left({\mathbf{x}}_t|A\left({s}_t\right){\mathbf{x}}_{t-1}+B\left({s}_t\right){u}_{t-1},Q\left({s}_t\right)\right)\\ {}p\left({\mathbf{y}}_t|{x}_t,{u}_t,{s}_t\right)=\mathcal{N}\left({\mathbf{y}}_t|C\left({s}_t\right){\mathbf{x}}_t+D\left({s}_t\right){u}_t,R\left({s}_t\right)\right)\end{array}\right.{\displaystyle \begin{array}{l}\left(3\mathrm{a}\right)\\ {}\left(3\mathrm{b}\right)\end{array}} $$

$$ \left\{\begin{array}{l}p\left({\mathbf{x}}_t|{\mathbf{x}}_{t-1},{u}_{t-1},{s}_t\right)=\mathcal{N}\left({\mathbf{x}}_t|A\left({s}_t\right){\mathbf{x}}_{t-1}+B\left({s}_t\right){u}_{t-1},Q\left({s}_t\right)\right)\\ {}p\left({\mathbf{y}}_t|{x}_t,{u}_t,{s}_t\right)=\mathcal{N}\left({\mathbf{y}}_t|C\left({s}_t\right){\mathbf{x}}_t+D\left({s}_t\right){u}_t,R\left({s}_t\right)\right)\end{array}\right.{\displaystyle \begin{array}{l}\left(3\mathrm{a}\right)\\ {}\left(3\mathrm{b}\right)\end{array}} $$

where

![]() $ {s}_t $

is a switch variable denoting the active latent force model at the time instant

$ {s}_t $

is a switch variable denoting the active latent force model at the time instant

![]() $ t $

. For each model, the above equations correspond to the transition and observation models of the augmented linear Gaussian state-space model (LGSSM) obtained by coupling the state-space representations of the system and the latent force, as described in detail in Section 2.2.

$ t $

. For each model, the above equations correspond to the transition and observation models of the augmented linear Gaussian state-space model (LGSSM) obtained by coupling the state-space representations of the system and the latent force, as described in detail in Section 2.2.

This formulation is achieved in the same spirit of that proposed by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012) to identify dynamical systems where different latent forces can act as an input in different, and possibly overlapping, time intervals. The proposed switching latent force model mostly differs from Hartikainen and Särkkä’s model for the presence of a known input term, which enables the use of the GP latent forces for modeling the unknown nonlinear forces acting in the system. In the switching GPLFM framework, different dynamical models can be introduced to describe the evolution of the latent states and nonlinear force at different time steps, allowing the use of different governing equations to deal with different motion regimes. In the example of a dry frictional oscillator, the proposed approach allows the definition of different equations to describe the behavior of the system during sliding and sticking phases. However, to enable the presence of discontinuities in the latent nonlinear force, either at the transition between different regimes or between two sliding phases with velocities of opposite sign, it is also necessary to include a resetting model in the SLDS formulation. This model, as suggested by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012), resets the latent force components to a zero-mean Gaussian prior with a suitably chosen covariance, while leaving the output states of the system unaltered.

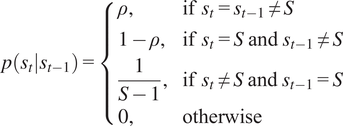

In the switching GPLFM formulation, the SLDS from Equation (3) is generally coupled with a discrete-time Markov model of form

![]() $ p\left({s}_t|{s}_{t-1}\right) $

, so that probabilistic inference can also be performed on the transitions between the different latent force models. If

$ p\left({s}_t|{s}_{t-1}\right) $

, so that probabilistic inference can also be performed on the transitions between the different latent force models. If

![]() $ S $

different models are considered, with the

$ S $

different models are considered, with the

![]() $ S $

th model operating as a resetting model, this Markov model can be written as follows:

$ S $

th model operating as a resetting model, this Markov model can be written as follows:

$$ p\left({s}_t|{s}_{t-1}\right)=\left\{\begin{array}{ll}\rho, & \mathrm{if}\hskip0.35em {s}_t={s}_{t-1}\ne S\\ {}1-\rho, & \mathrm{if}\hskip0.35em {s}_t=S\hskip0.35em \mathrm{and}\hskip0.35em {s}_{t-1}\ne S\\ {}\frac{1}{S-1},& \mathrm{if}\hskip0.35em {s}_t\ne S\hskip0.35em \mathrm{and}\hskip0.35em {s}_{t-1}=S\\ {}0,& \mathrm{otherwise}\end{array}\right. $$

$$ p\left({s}_t|{s}_{t-1}\right)=\left\{\begin{array}{ll}\rho, & \mathrm{if}\hskip0.35em {s}_t={s}_{t-1}\ne S\\ {}1-\rho, & \mathrm{if}\hskip0.35em {s}_t=S\hskip0.35em \mathrm{and}\hskip0.35em {s}_{t-1}\ne S\\ {}\frac{1}{S-1},& \mathrm{if}\hskip0.35em {s}_t\ne S\hskip0.35em \mathrm{and}\hskip0.35em {s}_{t-1}=S\\ {}0,& \mathrm{otherwise}\end{array}\right. $$

with

![]() $ 0<\rho <1 $

. Equation (4) can be interpreted as follows. If a certain (non-resetting) model is active at the time

$ 0<\rho <1 $

. Equation (4) can be interpreted as follows. If a certain (non-resetting) model is active at the time

![]() $ t-1 $

, there is a probability equal to

$ t-1 $

, there is a probability equal to

![]() $ \rho $

that such a model will remain active at the subsequent time instant

$ \rho $

that such a model will remain active at the subsequent time instant

![]() $ t $

; otherwise, a transition to the resetting model will occur. Furthermore, if the resetting model is active at the instant

$ t $

; otherwise, a transition to the resetting model will occur. Furthermore, if the resetting model is active at the instant

![]() $ t-1 $

, in the following time step there will be a transition to any of the other models, with equal probabilities. The value of

$ t-1 $

, in the following time step there will be a transition to any of the other models, with equal probabilities. The value of

![]() $ \rho $

must be chosen by the user, usually between 0.9 and 1 (see, e.g., Barber (Reference Barber2006); Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012)).

$ \rho $

must be chosen by the user, usually between 0.9 and 1 (see, e.g., Barber (Reference Barber2006); Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012)).

In summary, the switching GPLFM can take into account three different sources of uncertainty in the nonlinear system identification process:

-

• Nonlinear force model uncertainty. The lack of knowledge of the functional form of the nonlinear term in Equation (1) is addressed by modeling, for each motion regime, the unknown nonlinear force as a zero-mean temporal GP with a stationary kernel, which is then updated in a Bayesian manner by using the available response measurements and the relationship between nonlinear force and response determined by the physics-based model. The choice of the number of latent force models to be included in the SLDS, their mathematical formulation and the selection of appropriate kernel functions are here based on the available physical knowledge of the nonlinear system. For instance, in the case of a dry friction oscillator, two different latent force models can be used to model the dynamic behavior of the system in sliding and sticking motion regimes, respectively, and a further resetting model can be included in the SLDS to enable the presence of discontinuities in the identified nonlinear force; this is further detailed in Section 3.2. If no prior information is available regarding the type of nonlinearity, a standard GPLFM can used for a preliminary investigation of the nonlinear term. In fact, the identified latent force could give indications regarding the presence of multiple motion regimes and/or discontinuities, as in the example shown in Figure 1.

-

• Measurement uncertainty. As in standard GPLFMs, the measurement noise is here assumed to follow a Gaussian distribution of covariance

$ R $

; different covariance matrices can be considered across the different latent force models. While here a zero-mean Gaussian distribution is assumed, the presence of a measurement bias could also be accounted for in the procedure; further details can be found in Barber (Reference Barber2006). In the proposed approach, the measurement noise covariance is inferred along with GP hyperparameters (see Section 2.4).

$ R $

; different covariance matrices can be considered across the different latent force models. While here a zero-mean Gaussian distribution is assumed, the presence of a measurement bias could also be accounted for in the procedure; further details can be found in Barber (Reference Barber2006). In the proposed approach, the measurement noise covariance is inferred along with GP hyperparameters (see Section 2.4). -

• Regime transitions uncertainty. One of the main advantages of this approach is its ability to infer the unknown switches between the different latent force models, and therefore motion regime transitions and discontinuities. The prior knowledge about regime transitions is modeled by the Markov model introduced in Equation (4) and updated by using the response measurements, along with the latent states and forces.

The implementation of the proposed approach is schematically shown in Figure 2. In order to build the SLDS from Equation (3), it is firstly necessary to derive the state-space formulations of the system and GP latent forces, according to the procedure introduced in Section 2.2. Inference can finally be performed on the so-defined probabilistic model to retrieve the optimal GP hyperparameters and the posterior distributions for the latent states and nonlinear force, along with the sequence of motion regimes and discontinuities occurring in the time evolution. This is explained in Section 2.3.

Figure 2. Schematic representation of the switching GPLFM.

2.2. State-space formulation

Let us assume that, in Equation (1), the nonlinear term is expressed by a set of

![]() $ S-1 $

latent forces. According to the switching GPLFM formulation, one or more of these forces can be active at each time step. Each latent force can be formulated as a zero-mean temporal GP with a stationary kernel, as indicated in Equation (2). As demonstrated by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2010), these GPs can be expressed as LGSSMs. Referring for simplicity to a single latent force

$ S-1 $

latent forces. According to the switching GPLFM formulation, one or more of these forces can be active at each time step. Each latent force can be formulated as a zero-mean temporal GP with a stationary kernel, as indicated in Equation (2). As demonstrated by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2010), these GPs can be expressed as LGSSMs. Referring for simplicity to a single latent force

![]() $ f $

, this state-space representation can be expressed as follows:

$ f $

, this state-space representation can be expressed as follows:

where the vector

![]() $ \mathbf{f}=\left[f,\overset{\;}{f},\dots, {f}^{\left(\beta -1\right)}\right] $

is constructed by taking the latent force and its derivatives, and:

$ \mathbf{f}=\left[f,\overset{\;}{f},\dots, {f}^{\left(\beta -1\right)}\right] $

is constructed by taking the latent force and its derivatives, and:

$$ {A}_{c,f}=\left[\begin{array}{llll}0& 1& & \\ {}& \ddots & \ddots & \\ {}& & 0& 1\\ {}-{a}_0& \dots & -{a}_{\beta -2}& -{a}_{\beta -1}\end{array}\right],\hskip0.35em {L}_{c,f}=\left[\begin{array}{l}0\\ {}\vdots \\ {}0\\ {}1\end{array}\right] $$

$$ {A}_{c,f}=\left[\begin{array}{llll}0& 1& & \\ {}& \ddots & \ddots & \\ {}& & 0& 1\\ {}-{a}_0& \dots & -{a}_{\beta -2}& -{a}_{\beta -1}\end{array}\right],\hskip0.35em {L}_{c,f}=\left[\begin{array}{l}0\\ {}\vdots \\ {}0\\ {}1\end{array}\right] $$

Following the procedure described in Hartikainen and Särkkä (Reference Hartikainen and Särkkä2010), the coefficients

![]() $ {a}_0,\dots, {a}_{\beta -1} $

, the spectral density

$ {a}_0,\dots, {a}_{\beta -1} $

, the spectral density

![]() $ q $

of the white noise process

$ q $

of the white noise process

![]() $ w(t) $

and the dimensionality

$ w(t) $

and the dimensionality

![]() $ \beta $

of the vector

$ \beta $

of the vector

![]() $ \mathbf{f} $

can be assigned so that the latent force

$ \mathbf{f} $

can be assigned so that the latent force

![]() $ f $

corresponds to the prior of a GP with the desired covariance function. The Matérn covariance functions are particularly suitable for this implementation, since they have an analytical state-space representation. The general form of this class of functions can be written as follows:

$ f $

corresponds to the prior of a GP with the desired covariance function. The Matérn covariance functions are particularly suitable for this implementation, since they have an analytical state-space representation. The general form of this class of functions can be written as follows:

$$ \kappa \left(t,{t}^{\prime}\right)={\sigma}_f^2\;\frac{2^{1-\nu }}{\Gamma \left(\nu \right)}{\left(\frac{\sqrt{2\nu }}{l}|t-{t}^{\prime }|\right)}^{\nu }{\mathcal{K}}_{\nu}\left(\frac{\sqrt{2\nu }}{l}|t-{t}^{\prime }|\right) $$

$$ \kappa \left(t,{t}^{\prime}\right)={\sigma}_f^2\;\frac{2^{1-\nu }}{\Gamma \left(\nu \right)}{\left(\frac{\sqrt{2\nu }}{l}|t-{t}^{\prime }|\right)}^{\nu }{\mathcal{K}}_{\nu}\left(\frac{\sqrt{2\nu }}{l}|t-{t}^{\prime }|\right) $$

where

![]() $ {\mathcal{K}}_{\nu } $

and

$ {\mathcal{K}}_{\nu } $

and

![]() $ \Gamma $

are the modified Bessel and the Gamma functions respectively.

$ \Gamma $

are the modified Bessel and the Gamma functions respectively.

![]() $ {\sigma}_f $

and

$ {\sigma}_f $

and

![]() $ l $

are two hyperparameters, the first controlling the amplitude of the function, the second the lengthscale of the time variability. The smoothness parameter

$ l $

are two hyperparameters, the first controlling the amplitude of the function, the second the lengthscale of the time variability. The smoothness parameter

![]() $ \nu $

can be selected to choose the degree of smoothness of the covariance function, ranging from the exponential (

$ \nu $

can be selected to choose the degree of smoothness of the covariance function, ranging from the exponential (

![]() $ \nu =1/2 $

) to the squared exponential ()

$ \nu =1/2 $

) to the squared exponential ()

![]() $ \nu \to \mathrm{\infty} $

covariances. State-space representations have also been derived for different covariance functions, including periodic and quasi-periodic kernels (Solin and Särkkä, Reference Solin and Särkkä2014) and even some non-stationary kernels (Benavoli and Zaffalon, Reference Benavoli and Zaffalon2016). In this paper, without loss of generality, the exponential covariance function (corresponding to Matérn 1/2) will be used. In this case, Equation (5) reduces to:

$ \nu \to \mathrm{\infty} $

covariances. State-space representations have also been derived for different covariance functions, including periodic and quasi-periodic kernels (Solin and Särkkä, Reference Solin and Särkkä2014) and even some non-stationary kernels (Benavoli and Zaffalon, Reference Benavoli and Zaffalon2016). In this paper, without loss of generality, the exponential covariance function (corresponding to Matérn 1/2) will be used. In this case, Equation (5) reduces to:

where the white noise

![]() $ w $

is such that its spectral density is equal to

$ w $

is such that its spectral density is equal to

![]() $ 2{\sigma}_f^2/l $

.

$ 2{\sigma}_f^2/l $

.

The state-space representation of the GPFLM can be obtained, as suggested by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012), by coupling the state-space formulation of the zero-mean temporal GP, provided in Equation (5), with that of the dynamical system, which can be derived from Equation (1) as

$$ \dot{\mathbf{z}}(t)={A}_{c,s}\mathbf{z}(t)+{B}_{c,s}\hskip0.35em \left(u(t)-f\Big(z,\dot{z}\Big)\right)=\left[\begin{array}{ccc}0& 1& \\ {}-\frac{k}{m}& -\frac{c}{m}& \end{array}\right]\left[\begin{array}{c}z\\ {}\dot{z}\end{array}\right]+\left[\begin{array}{c}0\\ {}\frac{1}{m}\end{array}\right]\left(u(t)-f\Big(z,\dot{z}\Big)\right) $$

$$ \dot{\mathbf{z}}(t)={A}_{c,s}\mathbf{z}(t)+{B}_{c,s}\hskip0.35em \left(u(t)-f\Big(z,\dot{z}\Big)\right)=\left[\begin{array}{ccc}0& 1& \\ {}-\frac{k}{m}& -\frac{c}{m}& \end{array}\right]\left[\begin{array}{c}z\\ {}\dot{z}\end{array}\right]+\left[\begin{array}{c}0\\ {}\frac{1}{m}\end{array}\right]\left(u(t)-f\Big(z,\dot{z}\Big)\right) $$

Introducing the augmented state vector

![]() $ \mathbf{x}={\left[\begin{array}{cc}{\mathbf{z}}^{\top }& {\mathbf{f}}^{\top}\end{array}\right]}^{\top } $

, the coupling of Equations (5) and (9) results in the augmented state-space model:

$ \mathbf{x}={\left[\begin{array}{cc}{\mathbf{z}}^{\top }& {\mathbf{f}}^{\top}\end{array}\right]}^{\top } $

, the coupling of Equations (5) and (9) results in the augmented state-space model:

where:

$$ {A}_c=\left[\begin{array}{cc}{A}_{c,s}& {B}_{c,f}\\ {}\mathbf{0}& {A}_{c,f}\end{array}\right],\hskip0.35em {B}_c=\left[\begin{array}{c}{B}_{c,s}\\ {}\mathbf{0}\end{array}\right],\hskip0.35em {L}_c=\left[\begin{array}{c}\mathbf{0}\\ {}{L}_{c,f}\end{array}\right] $$

$$ {A}_c=\left[\begin{array}{cc}{A}_{c,s}& {B}_{c,f}\\ {}\mathbf{0}& {A}_{c,f}\end{array}\right],\hskip0.35em {B}_c=\left[\begin{array}{c}{B}_{c,s}\\ {}\mathbf{0}\end{array}\right],\hskip0.35em {L}_c=\left[\begin{array}{c}\mathbf{0}\\ {}{L}_{c,f}\end{array}\right] $$

In particular, the matrix

![]() $ {B}_{c,f} $

is obtained by adding

$ {B}_{c,f} $

is obtained by adding

![]() $ \beta -1 $

columns of zeros to the matrix

$ \beta -1 $

columns of zeros to the matrix

![]() $ -{B}_{c,s} $

. The above stochastic differential equation (SDE) can finally be converted to a discrete-time dynamic model in the form:

$ -{B}_{c,s} $

. The above stochastic differential equation (SDE) can finally be converted to a discrete-time dynamic model in the form:

where the transition matrix is obtained as

![]() $ A={\exp}_m\left({A}_c\Delta t\right) $

, being

$ A={\exp}_m\left({A}_c\Delta t\right) $

, being

![]() $ \Delta t $

the fixed time step, and

$ \Delta t $

the fixed time step, and

![]() $ B={A}^{-1}\left({A}_c-I\right){B}_c $

. The covariance matrix of the process noise in the discrete model can be written as

$ B={A}^{-1}\left({A}_c-I\right){B}_c $

. The covariance matrix of the process noise in the discrete model can be written as

$$ Q={\int}_0^{\Delta t}{\exp}_m\left({A}_c\left(\Delta t-\tau \right)\right){L}_c{qL}_c^{\top }{\exp}_m{\left({A}_c\left(\Delta t-\tau \right)\right)}^{\top}\mathrm{d}\tau $$

$$ Q={\int}_0^{\Delta t}{\exp}_m\left({A}_c\left(\Delta t-\tau \right)\right){L}_c{qL}_c^{\top }{\exp}_m{\left({A}_c\left(\Delta t-\tau \right)\right)}^{\top}\mathrm{d}\tau $$

where

![]() $ q $

the spectral density of the process noise in the continuous model. A more practical implementation of equation (13) is

$ q $

the spectral density of the process noise in the continuous model. A more practical implementation of equation (13) is

where

![]() $ {P}_{\infty } $

is the steady-state solution to the SDE describing the time evolution of the covariance of the state vector

$ {P}_{\infty } $

is the steady-state solution to the SDE describing the time evolution of the covariance of the state vector

![]() $ \mathbf{z} $

and can be retrieved by solving the Lyapunov equation (Särkkä and Solin, Reference Särkkä and Solin2019):

$ \mathbf{z} $

and can be retrieved by solving the Lyapunov equation (Särkkä and Solin, Reference Särkkä and Solin2019):

Finally, the transition model from Equation (12) is coupled with the observation model:

to recover a full LGSSM, In the above equation,

![]() $ \mathbf{y} $

is the observation vector,

$ \mathbf{y} $

is the observation vector,

![]() $ C $

and

$ C $

and

![]() $ D $

the observation matrices and

$ D $

the observation matrices and

![]() $ R $

the measurement noise covariance matrix. The choice of observation matrices depends on the typology of sensor used to perform the measurements: if displacements are measured the matrices will be

$ R $

the measurement noise covariance matrix. The choice of observation matrices depends on the typology of sensor used to perform the measurements: if displacements are measured the matrices will be

![]() $ C=\left[\begin{array}{ccccc}1& 0& 0& \dots & 0\end{array}\right] $

and

$ C=\left[\begin{array}{ccccc}1& 0& 0& \dots & 0\end{array}\right] $

and

![]() $ D=0 $

, while for accelerations that would be

$ D=0 $

, while for accelerations that would be

![]() $ C=\left[\begin{array}{cccccc}-k/m& -c/m& -1/m& 0& \dots & 0\end{array}\right] $

and

$ C=\left[\begin{array}{cccccc}-k/m& -c/m& -1/m& 0& \dots & 0\end{array}\right] $

and

![]() $ D=1/m $

. If only a single quantity is measured, the matrix

$ D=1/m $

. If only a single quantity is measured, the matrix

![]() $ R $

will coincide with the variance

$ R $

will coincide with the variance

![]() $ {\sigma}_n^2 $

of its measurement noise. Differently, if more typologies of sensors are used, the main diagonal of

$ {\sigma}_n^2 $

of its measurement noise. Differently, if more typologies of sensors are used, the main diagonal of

![]() $ R $

will include the variances of each measurement noise, while the off-diagonal elements will represent the measurement noise covariances and will be equal to zero if noise sources are uncorrelated. The elements of the matrix

$ R $

will include the variances of each measurement noise, while the off-diagonal elements will represent the measurement noise covariances and will be equal to zero if noise sources are uncorrelated. The elements of the matrix

![]() $ R $

can either be inferred along with the GP hyperparameters or estimated by using different techniques (see, e.g., Bilbao et al. (Reference Bilbao, Lourens, Schulze and Ziegler2022)). The first approach will used in this paper.

$ R $

can either be inferred along with the GP hyperparameters or estimated by using different techniques (see, e.g., Bilbao et al. (Reference Bilbao, Lourens, Schulze and Ziegler2022)). The first approach will used in this paper.

The LGSSM in Equations (12) and (16) has been formulated, for simplicity, by referring to the standard GPLFM case, which is retrieved from the more general formulation from Equation (3) for

![]() $ S=1 $

. The procedure for deriving the state-space model of the GPLFM is substantially the same when more latent force models are considered. In fact, in the switching GPLFM, all the matrices of the LGSSM can be derived as described above for each latent force model

$ S=1 $

. The procedure for deriving the state-space model of the GPLFM is substantially the same when more latent force models are considered. In fact, in the switching GPLFM, all the matrices of the LGSSM can be derived as described above for each latent force model

![]() $ {s}_t $

. In general, since the state-space formulations of the different latent force models are obtained independently of each other, there is no requirement for the latent forces to share the same dimensionality across the different models, implying that different kernel functions can be used in the GP priors. Moreover, not only the latent force, but also the governing equations of the system can differ for different values of

$ {s}_t $

. In general, since the state-space formulations of the different latent force models are obtained independently of each other, there is no requirement for the latent forces to share the same dimensionality across the different models, implying that different kernel functions can be used in the GP priors. Moreover, not only the latent force, but also the governing equations of the system can differ for different values of

![]() $ {s}_t $

; this will be shown in more detail in Section 3.2. Finally, the implementation of the resetting model (

$ {s}_t $

; this will be shown in more detail in Section 3.2. Finally, the implementation of the resetting model (

![]() $ {s}_t=S $

), necessary to introduce discontinuities in the latent force, is achieved by formulating the transition matrix as

$ {s}_t=S $

), necessary to introduce discontinuities in the latent force, is achieved by formulating the transition matrix as

![]() $ A(S)=\mathrm{blkdiag}\left({\exp}_m\left({A}_{c,s}\Delta t\right),\mathbf{0}\right) $

and the covariance matrix of the process noise as

$ A(S)=\mathrm{blkdiag}\left({\exp}_m\left({A}_{c,s}\Delta t\right),\mathbf{0}\right) $

and the covariance matrix of the process noise as

![]() $ Q(S)=\mathrm{blkdiag}\left({P}_{\infty }-{A}_s{P}_{\infty }{A}_s^{\top },{P}_0\right) $

, being

$ Q(S)=\mathrm{blkdiag}\left({P}_{\infty }-{A}_s{P}_{\infty }{A}_s^{\top },{P}_0\right) $

, being

![]() $ {P}_0 $

the prior covariance selected for the latent force. This formulation, proposed by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012), enables the resetting of the latent force to its prior distribution when a discontinuity occurs without introducing discontinuities in the time evolution of displacement and velocity. It is worth underlying that, if a SDOF system is considered, only a single latent force can be included in each latent force model. The case of MDOF systems, where multiple, and possibly correlated, latent forces can be considered within the same model

$ {P}_0 $

the prior covariance selected for the latent force. This formulation, proposed by Hartikainen and Särkkä (Reference Hartikainen and Särkkä2012), enables the resetting of the latent force to its prior distribution when a discontinuity occurs without introducing discontinuities in the time evolution of displacement and velocity. It is worth underlying that, if a SDOF system is considered, only a single latent force can be included in each latent force model. The case of MDOF systems, where multiple, and possibly correlated, latent forces can be considered within the same model

![]() $ {s}_t $

, would require more complex approaches, which are beyond the scope of this contribution.

$ {s}_t $

, would require more complex approaches, which are beyond the scope of this contribution.

2.3. Inference of latent states and nonlinear force

Exact inference in the SLDS formulated in Equations (3) and (4) is not computationally tractable since its complexity scales exponentially with time (Bar-Shalom et al., Reference Bar-Shalom, Li and Kirubarajan2001; Lerner, Reference Lerner2002). Therefore, the filtered and smoothed posterior distributions can only be inferred in an approximated form.

In this paper, approximated inference will be performed by implementing the approach proposed by Barber (Reference Barber2006). In this approach, the filtered and the smoothed distributions of the state of each model

![]() $ {s}_t $

, are approximated by Gaussian mixtures of

$ {s}_t $

, are approximated by Gaussian mixtures of

![]() $ I $

and

$ I $

and

![]() $ J $

components, respectively. The number of mixture components can be chosen by the user according to the computational budget and will generally be significantly smaller than

$ J $

components, respectively. The number of mixture components can be chosen by the user according to the computational budget and will generally be significantly smaller than

![]() $ {S}^t $

, which is the number of Gaussian components of the exact posterior distribution at the time instant

$ {S}^t $

, which is the number of Gaussian components of the exact posterior distribution at the time instant

![]() $ t $

.

$ t $

.

In Barber’s procedure, the filtered distributions are computed via assumed density filtering (ADF) (Alspach and Sorenson, Reference Alspach and Sorenson1972). The result of ADF at the time step

![]() $ t $

is the Gaussian mixture:

$ t $

is the Gaussian mixture:

$$ p\left({\mathbf{x}}_t|{s}_t,{\mathbf{y}}_{1:t},{u}_{1:t}\right)\cong \sum \limits_{i_t=1}^I{\mathcal{W}}_t\left({i}_t,{s}_t\right)\cdot \mathcal{N}\left({\mathbf{x}}_t|{\mu}_{t\mid t}\left({i}_t,{s}_t\right),{P}_{t\mid t}\left({i}_t,{s}_t\right)\right) $$

$$ p\left({\mathbf{x}}_t|{s}_t,{\mathbf{y}}_{1:t},{u}_{1:t}\right)\cong \sum \limits_{i_t=1}^I{\mathcal{W}}_t\left({i}_t,{s}_t\right)\cdot \mathcal{N}\left({\mathbf{x}}_t|{\mu}_{t\mid t}\left({i}_t,{s}_t\right),{P}_{t\mid t}\left({i}_t,{s}_t\right)\right) $$

for the states of each model

![]() $ {s}_t $

and an approximated expression for the corresponding model probability

$ {s}_t $

and an approximated expression for the corresponding model probability

![]() $ p\left({s}_t|{\mathbf{y}}_{1:t},{u}_{1:t}\right) $

. In the above expression, the weights

$ p\left({s}_t|{\mathbf{y}}_{1:t},{u}_{1:t}\right) $

. In the above expression, the weights

![]() $ {\mathcal{W}}_t $

are obtained as

$ {\mathcal{W}}_t $

are obtained as

![]() $ {\mathcal{W}}_t\left({i}_t,{s}_t\right)=p\left({i}_t|{s}_t,{y}_{1:t},{u}_{1:t}\right) $

. Each step of ADF requires running

$ {\mathcal{W}}_t\left({i}_t,{s}_t\right)=p\left({i}_t|{s}_t,{y}_{1:t},{u}_{1:t}\right) $

. Each step of ADF requires running

![]() $ {IS}^2 $

Kalman filters. In a similar fashion, the smoothed distributions are obtained by implementing an expectation correction (EC) algorithm, resulting in the Gaussian mixture:

$ {IS}^2 $

Kalman filters. In a similar fashion, the smoothed distributions are obtained by implementing an expectation correction (EC) algorithm, resulting in the Gaussian mixture:

$$ p\left({\mathbf{x}}_t|{s}_t,{\mathbf{y}}_{1:T},{u}_{1:T}\right)\cong \sum \limits_{j=1}^J{\tilde{\mathcal{W}}}_t\left({j}_t,{s}_t\right)\cdot \mathcal{N}\left({\mathbf{x}}_t|{\mu}_{t\mid T}\left({j}_t,{s}_t\right),{P}_{t\mid T}\left({j}_t,{s}_t\right)\right) $$

$$ p\left({\mathbf{x}}_t|{s}_t,{\mathbf{y}}_{1:T},{u}_{1:T}\right)\cong \sum \limits_{j=1}^J{\tilde{\mathcal{W}}}_t\left({j}_t,{s}_t\right)\cdot \mathcal{N}\left({\mathbf{x}}_t|{\mu}_{t\mid T}\left({j}_t,{s}_t\right),{P}_{t\mid T}\left({j}_t,{s}_t\right)\right) $$

where

![]() $ {\tilde{\mathcal{W}}}_t=p\left({j}_t|{s}_t,{y}_{1:t},{u}_{1:t}\right) $

, and an approximated expression for

$ {\tilde{\mathcal{W}}}_t=p\left({j}_t|{s}_t,{y}_{1:t},{u}_{1:t}\right) $

, and an approximated expression for

![]() $ p\left({s}_t|{\mathbf{y}}_{1:T},{u}_{1:T}\right) $

. The EC algorithm performs

$ p\left({s}_t|{\mathbf{y}}_{1:T},{u}_{1:T}\right) $

. The EC algorithm performs

![]() $ {IJS}^2 $

RTS smoothers at each time step, and is therefore more computationally expensive then ADF. Nonetheless, it is worth mentioning that the evaluation of the marginal likelihood

$ {IJS}^2 $

RTS smoothers at each time step, and is therefore more computationally expensive then ADF. Nonetheless, it is worth mentioning that the evaluation of the marginal likelihood

![]() $ p\left({\mathbf{y}}_{1:T}\right) $

, which is required for estimating the optimal hyperparameters of the latent functions, is performed within the ADF algorithm. A detailed description of ADF and EC implementation can be found in Barber (Reference Barber2006).

$ p\left({\mathbf{y}}_{1:T}\right) $

, which is required for estimating the optimal hyperparameters of the latent functions, is performed within the ADF algorithm. A detailed description of ADF and EC implementation can be found in Barber (Reference Barber2006).

2.4. Inference of GP hyperparameters

The performances of switching latent force models are not only affected by the choice of appropriate kernels for the GP latent forces, but also from the selection of the system parameters and GP hyperparameters. While an estimation procedure for uncertain system parameters will be introduced in Section 3.6, the problem of determining the optimal values for the hyperparameters in GPLFMs is addressed in what follows.

A common approach for selecting the optimal hyperparameters of the kernel function is to use maximum likelihood estimation (see, e.g., Ghahramani and Hinton (Reference Ghahramani and Hinton1996); Nayek et al. (Reference Nayek, Chakraborty and Narasimhan2019)). However, the algorithms used for determining the maximum of the likelihood function are not guaranteed to find the global maximum (Petersen et al., Reference Petersen, Oiseth and Lourens2022) and do not give information about the posterior distribution of the parameters. For this reason, different approaches have been proposed over the years. Zou et al. (Reference Zou, Lourens and Cicirello2022) and Bilbao et al. (Reference Bilbao, Lourens, Schulze and Ziegler2022) determine the optimal hyperparameters by minimizing the Hellinger distance between the empirical distribution of the measurements and the modelled Gaussian prior on the observed states; nonetheless, this approach can only be used when the response distribution is well-approximated by a Gaussian. Finally, Rogers at al. (Reference Rogers, Worden, Manson, Tygesen and Cross2018), Rogers et al. (Reference Rogers, Worden and Cross2020a), Rogers and Friis (Reference Rogers and Friis2022) recover the full posterior distribution of the parameters by using Markov Chain Monte Carlo (MCMC). In fact, while computationally more expensive, MCMC offers the advantage of a guaranteed convergence to the true posterior distribution (Gelman et al., Reference Gelman, Carlin, Rubin, Vehtari, Dunson and Stern2013).

In this paper, hyperparameters inference will be performed by using the Variational Bayes Monte Carlo (VBMC) method developed by Acerbi (Reference Acerbi2018, Reference Acerbi2020). VBMC combines variational inference and active-sampling Bayesian quadrature to perform approximate Bayesian inference, leading to a reduced computational cost compared to MCMC. Specifically, VBMC simultaneously computes an approximate posterior distribution of the model parameters and the estimated lower bound (ELBO) of the marginal likelihood. The reader is referred to the papers by Acerbi (Reference Acerbi2018, Reference Acerbi2020) for a detailed description of the VBMC method. In VBMC, the evaluation of the ELBO requires an iterative computation of the marginal likelihood of the SLDS, which is obtained as a by-product of ADF. Therefore, as schematically shown in Figure 2, each iteration requires the implementation of the LGSSM matrices by using the current values of the hyperparameters and the application of ADF. The optimal hyperparameters are finally obtained as the mean of the posterior distribution computed by VBMC and used for inferring the latent state and nonlinear force via ADF and EC.

3. Numerical Case-Study: A Dry-Friction Oscillator

Identifying the friction forces generated by contacts in mechanical systems is a critical challenge in engineering. In fact, information extracted by experimental data is essential for developing and updating friction models, as well as for making predictions about the dynamic behavior of these systems. This section presents an application of the switching GPLFM to the identification of the nonlinear friction force acting in a simulated dry friction oscillator. In particular, it is shown how the proposed methodology is not only able to identify the time evolution of the friction force, but can also be used to: (i) estimate the physical parameters of the system; (ii) reconstruct the friction force–velocity relationship; (iii) estimate the static value of the friction force. The estimated system parameters and reconstructed friction model enable the prediction of the system response to an assigned input force.

3.1. Simulated system

Let us consider the SDOF system of mass

![]() $ m=1 $

kg, viscous damping coefficient

$ m=1 $

kg, viscous damping coefficient

![]() $ c=5 $

Nsm

$ c=5 $

Nsm

![]() $ {}^{-1} $

and stiffness

$ {}^{-1} $

and stiffness

![]() $ k=500 $

Nm

$ k=500 $

Nm

![]() $ {}^{-1} $

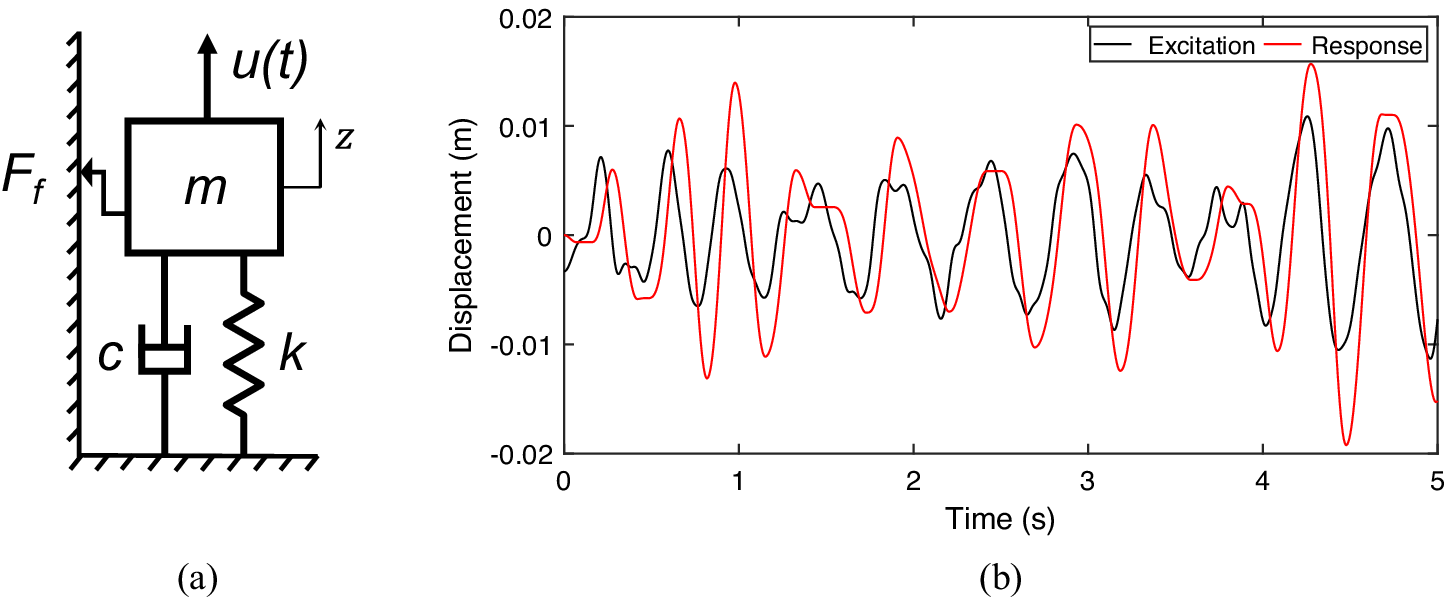

shown in Figure 3a. A friction contact occurs between the mass and a ground-fixed wall, governed by a rate-dependent friction law, and a driving force

$ {}^{-1} $

shown in Figure 3a. A friction contact occurs between the mass and a ground-fixed wall, governed by a rate-dependent friction law, and a driving force

![]() $ u(t) $

is directly applied to the mass. The governing equation of this system can be formulated as:

$ u(t) $

is directly applied to the mass. The governing equation of this system can be formulated as:

Figure 3. Mass-spring-dashpot system with a friction contact between mass and ground-fixed wall (a) and its simulated response (in red) to a random phase multisine excitation (in black, divided by the stiffness) (b).

In particular, a steady-state version of the Dieterich–Ruina’s law (Dieterich, Reference Dieterich1979; Rice and Ben-Zion, Reference Rice and Ben-Zion1996), in the formulation proposed by Cabboi et al. (Reference Cabboi, Marino and Cicirello2022):

$$ {F}_f\left(z,\dot{z}\right)=\left\{\begin{array}{cc}\left[{F}_{\ast }+a\ln \left(\frac{\mid \dot{z}\mid +\varepsilon }{V_{\ast }}\right)+b\ln \left(c+\frac{V_{\ast }}{\mid \dot{z}\mid +\varepsilon}\right)\right]\operatorname{sgn}\left(\dot{z}\right),& \mathrm{if}\;\dot{z}\ne 0\\ {}\hskip-19em u(t)- kz,\hskip5.879996em & \mathrm{otherwise}\end{array}\right. $$

$$ {F}_f\left(z,\dot{z}\right)=\left\{\begin{array}{cc}\left[{F}_{\ast }+a\ln \left(\frac{\mid \dot{z}\mid +\varepsilon }{V_{\ast }}\right)+b\ln \left(c+\frac{V_{\ast }}{\mid \dot{z}\mid +\varepsilon}\right)\right]\operatorname{sgn}\left(\dot{z}\right),& \mathrm{if}\;\dot{z}\ne 0\\ {}\hskip-19em u(t)- kz,\hskip5.879996em & \mathrm{otherwise}\end{array}\right. $$

has been used to model the friction force. The values selected for the parameters of the Dieterich–Ruina’s law are reported in Table 1. The driving force

![]() $ u(t) $

is a random phase multisine whose amplitude is generated from the JONSWAP spectrum (Hasselmann et al., Reference Hasselmann, Barnett, Bouws, Carlson, Cartwright, Enke, Ewing, Gienapp, Hasselmann, Kruseman, Meerburg, Müller, Olbers, Richter, Sell and Walden1973; Vazirizade, Reference Vazirizade2019):

$ u(t) $

is a random phase multisine whose amplitude is generated from the JONSWAP spectrum (Hasselmann et al., Reference Hasselmann, Barnett, Bouws, Carlson, Cartwright, Enke, Ewing, Gienapp, Hasselmann, Kruseman, Meerburg, Müller, Olbers, Richter, Sell and Walden1973; Vazirizade, Reference Vazirizade2019):

$$ S\left(\omega \right)=320{\left(\frac{H_s}{T_p^2}\right)}^2\cdot \frac{1}{\omega^5}\exp \left(-1.25{\left(\frac{\omega_p}{\omega}\right)}^4\right)\cdot {3.3}^{\exp \hskip0.1em \left(-\frac{1}{2{\sigma}_p^2}{\left(1-\frac{\omega }{\omega_p}\right)}^2\right)} $$

$$ S\left(\omega \right)=320{\left(\frac{H_s}{T_p^2}\right)}^2\cdot \frac{1}{\omega^5}\exp \left(-1.25{\left(\frac{\omega_p}{\omega}\right)}^4\right)\cdot {3.3}^{\exp \hskip0.1em \left(-\frac{1}{2{\sigma}_p^2}{\left(1-\frac{\omega }{\omega_p}\right)}^2\right)} $$

in the frequency range

![]() $ \omega =\left(0.02:0.02:100\right) $

Hz, using the parameters indicated in Table 2. The resulting input force is depicted in Figure 3b.

$ \omega =\left(0.02:0.02:100\right) $

Hz, using the parameters indicated in Table 2. The resulting input force is depicted in Figure 3b.

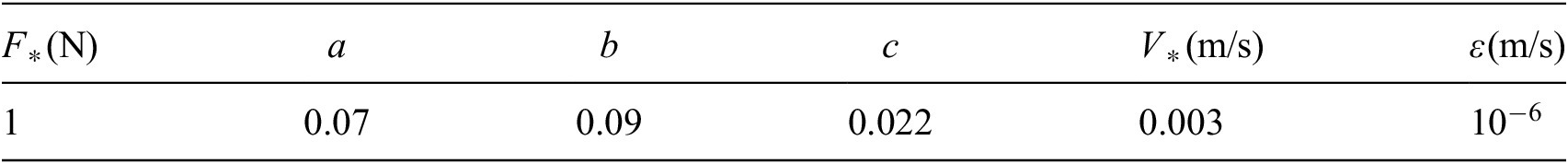

Table 1. Selected parameters for the steady-state Dieterich-Ruina’s law.

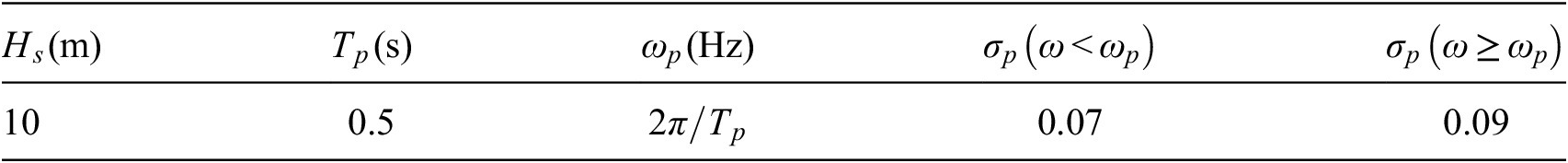

Table 2. Selected parameters for the JONSWAP spectrum.

It is assumed that noisy measurements of the mass displacement are available to be used as experimental observations in the GPLFM. To obtain these synthetic measurements, the dynamic response of the system has been simulated by using the event-driven variable-step Runge–Kutta (4,5) algorithm developed by Marino and Cicirello (Reference Marino and Cicirello2022), between the initial time instant

![]() $ t=0 $

and the specified final time

$ t=0 $

and the specified final time

![]() $ t={t}_f $

. In the simulation, the initial conditions for mass position and velocity have been set to zero. The resulting displacements, shown in Figure 3b, have then been resampled by using linear interpolation according to a fixed-step time vector, whose time step is obtained from the selected sampling frequency

$ t={t}_f $

. In the simulation, the initial conditions for mass position and velocity have been set to zero. The resulting displacements, shown in Figure 3b, have then been resampled by using linear interpolation according to a fixed-step time vector, whose time step is obtained from the selected sampling frequency

![]() $ {f}_s $

as

$ {f}_s $

as

![]() $ \Delta t=1/{f}_s $

. Finally, the resulting displacement values have been polluted with artificial white noise according to a selected signal-to-noise ratio (SNR).

$ \Delta t=1/{f}_s $

. Finally, the resulting displacement values have been polluted with artificial white noise according to a selected signal-to-noise ratio (SNR).

In the remaining of this section, the performances of the proposed switching GPLFM approach are firstly investigated and compared to the standard latent restoring force model in Section 3.2, assuming a specified set of

![]() $ {t}_f $

,

$ {t}_f $

,

![]() $ {f}_s $

and SNR values and known physical parameters of the system. A parameter estimation approach is then proposed in Section 3.3, while the performances of the switching GPLFM for varying noise levels, observation times, and sampling frequencies are investigated in Section 3.4.

$ {f}_s $

and SNR values and known physical parameters of the system. A parameter estimation approach is then proposed in Section 3.3, while the performances of the switching GPLFM for varying noise levels, observation times, and sampling frequencies are investigated in Section 3.4.

3.2. Probabilistic model for dry friction oscillators

In order to apply the proposed switching GPLFM approach to the above numerical case-study, a probabilistic model has been implemented by considering three different latent force models (

![]() $ S=3 $

).

$ S=3 $

).

-

• A first model is introduced to describe the dynamic evolution of the system during the sliding phases. The implementation of this model is carried out as described in detail in Section 2.2, with the sliding friction force modeled as a zero-mean GP with an exponential (Matérn 1/2) kernel function, In fact, while the suitability of Matérn kernels for state-space implementation has been already discussed in Section 2.2, it has been verified that similar predictions are obtained if different values of the smoothness parameter (such as 3/2 and 5/2) are considered. Hence, the exponential covariance function has been selected to reduce the dimensionality of the augmented state-space model and, consequently, the computational burden.

-

• The second model aims at describing the system behavior during the sticking phases. In this case, the response of the system is simply characterized by constant displacement and zero velocity, while the friction force is related to displacement and forcing function as described by Equation (20). This physical knowledge of the sticking behavior can be used to determine the prediction density as follows:

(22)where: $$ p\left({\mathbf{x}}_t|{\mathbf{y}}_{1:t-1},{u}_{t-1},{i}_{t-1},{s}_{t-1},{s}_t=2\right)=\mathcal{N}\left({\mathbf{x}}_t|{\mu}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right),{P}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)\right) $$

(23)and

$$ p\left({\mathbf{x}}_t|{\mathbf{y}}_{1:t-1},{u}_{t-1},{i}_{t-1},{s}_{t-1},{s}_t=2\right)=\mathcal{N}\left({\mathbf{x}}_t|{\mu}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right),{P}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)\right) $$

(23)and $$ {\mu}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)={\left[\begin{array}{c}\unicode{x1D53C}\left({z}_{t-1\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)\right),0,{u}_{t-1}-k\cdot \unicode{x1D53C}\left({z}_{t-1\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)\right)\end{array}\right]}^{\top } $$

$$ {\mu}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)={\left[\begin{array}{c}\unicode{x1D53C}\left({z}_{t-1\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)\right),0,{u}_{t-1}-k\cdot \unicode{x1D53C}\left({z}_{t-1\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)\right)\end{array}\right]}^{\top } $$

$ {P}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)={P}_{t-1\mid t-1}\left({i}_{t-1},{s}_{t-1}\right) $

. If a different kernel from Matérn 1/2 is considered, zeros can be added at the end of

$ {P}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right)={P}_{t-1\mid t-1}\left({i}_{t-1},{s}_{t-1}\right) $

. If a different kernel from Matérn 1/2 is considered, zeros can be added at the end of

$ {\mu}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right) $

to obtain the required dimensionality. It is worth underlying that the prediction density from Equation (22) can be directly filtered and smoothed in the present form, without need of defining the matrices

$ {\mu}_{t\mid t-1}\left({i}_{t-1},{s}_{t-1}\right) $

to obtain the required dimensionality. It is worth underlying that the prediction density from Equation (22) can be directly filtered and smoothed in the present form, without need of defining the matrices

$ A\left({s}_t\right) $

and

$ A\left({s}_t\right) $

and

$ B\left({s}_t\right) $

for the sticking model.

$ B\left({s}_t\right) $

for the sticking model.

-

• The third model is the resetting model, which is implemented as explained in Section 2.2, setting the prior covariance of the latent force to

$ {P}_0=0.05 $

. When activated, this model resets the latent friction force to zero, with

$ {P}_0=0.05 $

. When activated, this model resets the latent friction force to zero, with

$ {P}_0 $

as covariance), while leaving displacement and velocity unaltered. Since, as described by Equation (4), this model can only remain active for a single time step, the result is that the values assumed by the friction force immediately before and after the reset will not directly affect each other. This allows for the presence of a discontinuity in the friction force, either between a sticking and a sliding phases or between two sliding phases with different velocity sign.

$ {P}_0 $

as covariance), while leaving displacement and velocity unaltered. Since, as described by Equation (4), this model can only remain active for a single time step, the result is that the values assumed by the friction force immediately before and after the reset will not directly affect each other. This allows for the presence of a discontinuity in the friction force, either between a sticking and a sliding phases or between two sliding phases with different velocity sign.

Finally, the model transitions are governed by the Markov model introduced in Equation (4), where

![]() $ \rho $

has been set to 0.92.

$ \rho $

has been set to 0.92.

3.3. Inference of latent states and nonlinear force with known system parameters

Nonlinear force identification has firstly been performed by considering the simulated dynamic response of the system introduced above for

![]() $ {t}_f=5\hskip0.1em $

s and

$ {t}_f=5\hskip0.1em $

s and

![]() $ {f}_s=500 $

Hz. The mass displacement has been corrupted with artificial white noise by using the AWGN function of Matlab (2023), setting SNR

$ {f}_s=500 $

Hz. The mass displacement has been corrupted with artificial white noise by using the AWGN function of Matlab (2023), setting SNR

![]() $ =80 $

. The so-produced white noise has a standard deviation of

$ =80 $

. The so-produced white noise has a standard deviation of

![]() $ 7.8623\times {10}^{-3}\hskip0.1em $

mm, corresponding to a variance

$ 7.8623\times {10}^{-3}\hskip0.1em $

mm, corresponding to a variance

![]() $ {\sigma}_n^2=6.1815\times {10}^{-5}{\mathrm{mm}}^2 $

.

$ {\sigma}_n^2=6.1815\times {10}^{-5}{\mathrm{mm}}^2 $

.

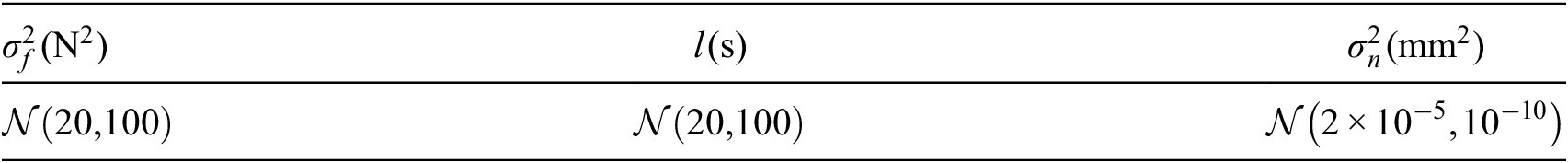

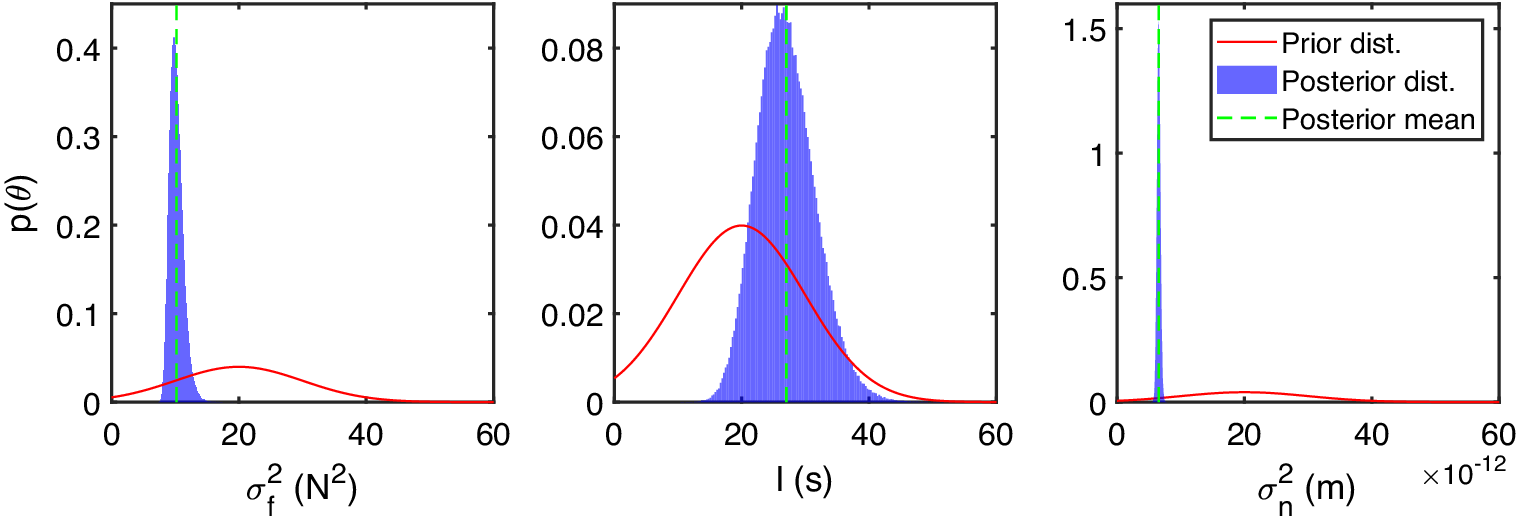

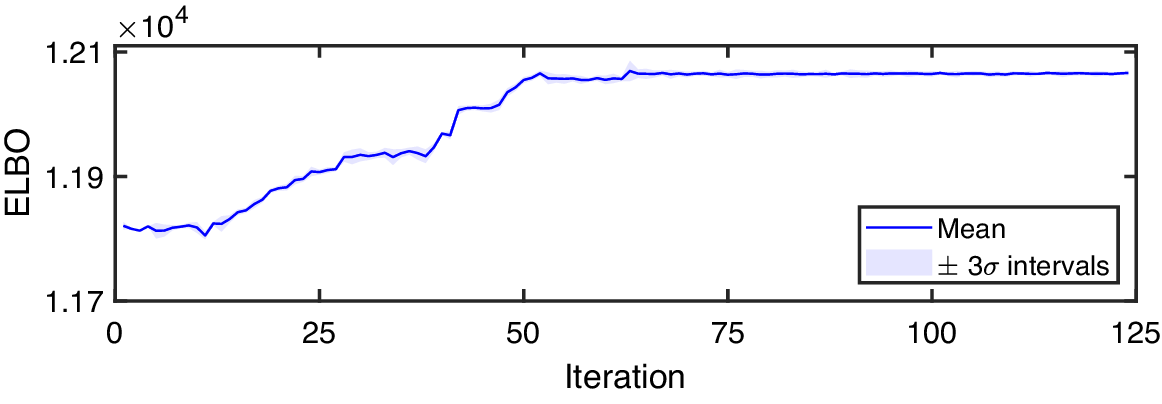

In this example, the system parameters have been assumed as known a priori and set to their true values indicated at the beginning of this section. The posterior distributions of the hyperparameters

![]() $ {\sigma}_f^2 $

,

$ {\sigma}_f^2 $

,

![]() $ l $

and

$ l $

and

![]() $ {\sigma}_n^2 $

, whose assigned priors are reported in Table 3, have been inferred by using VBMC. The prior and posterior distributions of the hyperparameters are shown in Figure 4, while the convergence of the ELBO is reported in Figure 5. As specified in Section 2.3, in the iterative evaluation of the ELBO, the log marginal likelihood is obtained as by-product of the ADF. Once the optimal GP hyperparameters have been estimated as the mean values of their posterior distributions, the latent states and nonlinear restoring force have been inferred by implementing ADF and EC. The number of Gaussian mixture components in the filtering and smoothing passes has here been set to

$ {\sigma}_n^2 $

, whose assigned priors are reported in Table 3, have been inferred by using VBMC. The prior and posterior distributions of the hyperparameters are shown in Figure 4, while the convergence of the ELBO is reported in Figure 5. As specified in Section 2.3, in the iterative evaluation of the ELBO, the log marginal likelihood is obtained as by-product of the ADF. Once the optimal GP hyperparameters have been estimated as the mean values of their posterior distributions, the latent states and nonlinear restoring force have been inferred by implementing ADF and EC. The number of Gaussian mixture components in the filtering and smoothing passes has here been set to

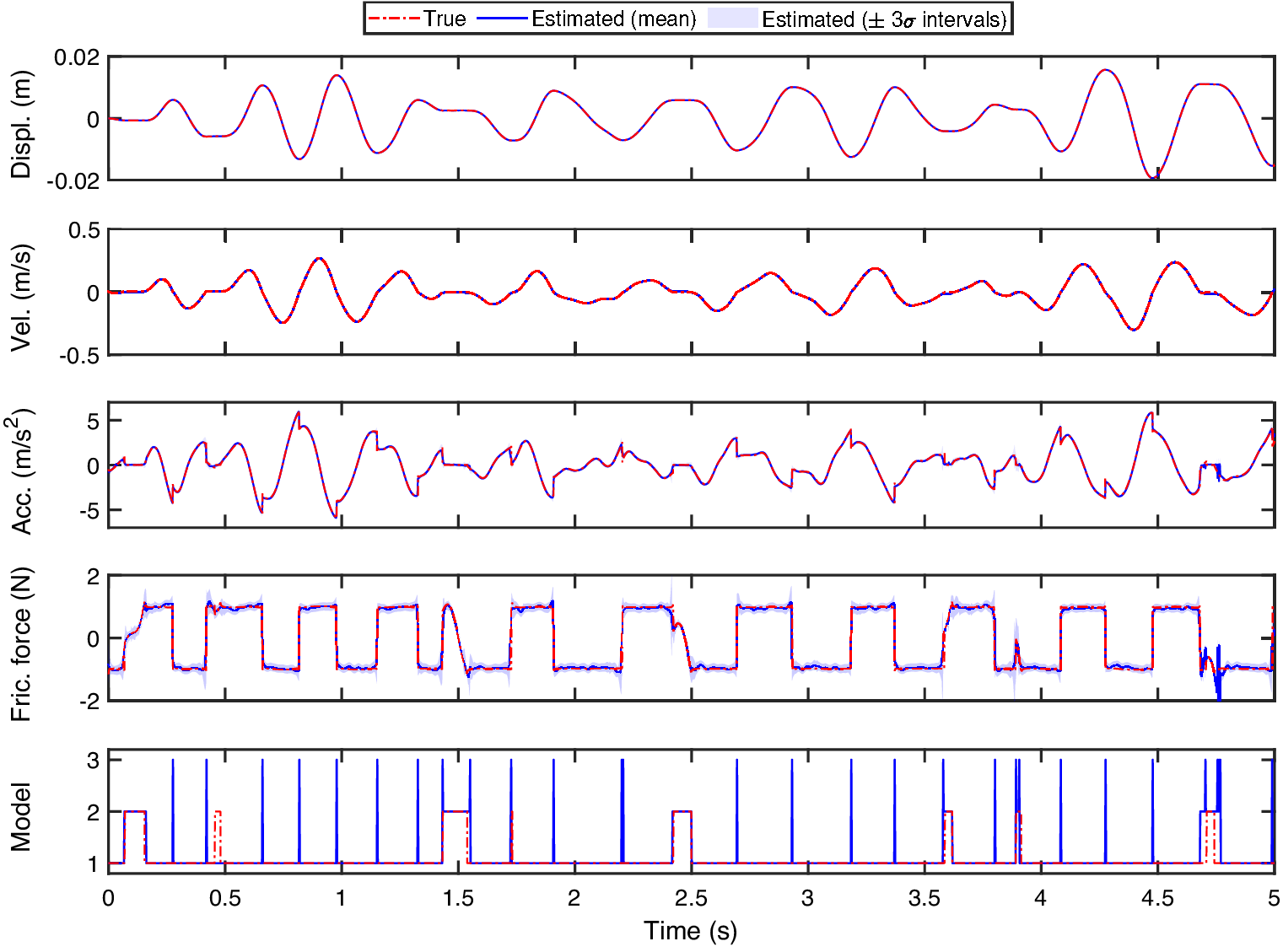

![]() $ I=J=3 $

. The estimated displacement, velocity, friction force and regime transitions are reported, along with the ground truth, in Figures 6 and 7. The agreement between the mean of the inferred distribution and the ground truth can be quantified by evaluating the normalized mean squared error (NMSE), which can be defined as

$ I=J=3 $

. The estimated displacement, velocity, friction force and regime transitions are reported, along with the ground truth, in Figures 6 and 7. The agreement between the mean of the inferred distribution and the ground truth can be quantified by evaluating the normalized mean squared error (NMSE), which can be defined as

$$ \mathrm{NMSE}\left[g\right]=\frac{1}{T{\sigma}_g^2}\sum \limits_{t=1}^T{\left({g}_t-\unicode{x1D53C}\left({\hat{g}}_t\right)\right)}^2 $$

$$ \mathrm{NMSE}\left[g\right]=\frac{1}{T{\sigma}_g^2}\sum \limits_{t=1}^T{\left({g}_t-\unicode{x1D53C}\left({\hat{g}}_t\right)\right)}^2 $$

where

![]() $ {g}_t $

and

$ {g}_t $

and

![]() $ \unicode{x1D53C}\left({\hat{g}}_t\right) $

are the ground truth and the estimated mean value of a certain quantity

$ \unicode{x1D53C}\left({\hat{g}}_t\right) $

are the ground truth and the estimated mean value of a certain quantity

![]() $ g $

at the time step

$ g $

at the time step

![]() $ t $

, respectively,

$ t $

, respectively,

![]() $ {\sigma}_g^2 $

is the variance of

$ {\sigma}_g^2 $

is the variance of

![]() $ g $

and

$ g $

and

![]() $ T $

is the number of data points. According to the above definition, a value of zero corresponds to a perfect fit between true and estimated functions, while a unitary value is obtained if

$ T $

is the number of data points. According to the above definition, a value of zero corresponds to a perfect fit between true and estimated functions, while a unitary value is obtained if

![]() $ \unicode{x1D53C}\left({\hat{g}}_t\right) $

is equal to the mean value of the ground truth at every point. The very low NMSE scores reported in Table 4 for displacement and velocity confirm their excellent agreement with the ground truth. The nonlinear force identification score is NMSE

$ \unicode{x1D53C}\left({\hat{g}}_t\right) $

is equal to the mean value of the ground truth at every point. The very low NMSE scores reported in Table 4 for displacement and velocity confirm their excellent agreement with the ground truth. The nonlinear force identification score is NMSE

![]() $ \left[{F}_f\right]=1.95\% $

, which is generally considered a very good result. Also, the acceleration, which is determined as a linear combination of states and friction force, presents a very good agreement with the ground truth (NMSE

$ \left[{F}_f\right]=1.95\% $

, which is generally considered a very good result. Also, the acceleration, which is determined as a linear combination of states and friction force, presents a very good agreement with the ground truth (NMSE

![]() $ \left[\ddot{z}\right]=0.46\% $

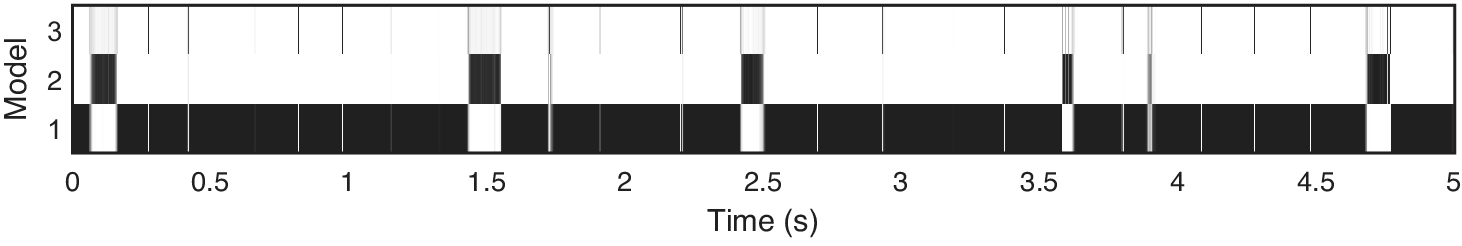

), despite the presence of discontinuities in its time evolution. Finally, in the bottom frame of Figure 6, it can be noted that most discontinuities and regime transitions are well captured by the model transitions in the switching GPLFM. Among the seven stops occurring in the observed time window, only the second has been missed; however, it can be noted that this sticking phase is particularly short and does not affect significantly the friction force value. Similarly, spikes corresponding to the resetting model activation can be observed every time that discontinuities occur between the sliding stages. It is worth remembering that the switching GPLFM frameworks allows for more latent force models to be active simultaneously and, therefore, the blue line in Figure 6 is only referred to the predominant model at each time step. A full picture of the model probabilities is instead provided in Figure 7. Here, it can be seen that the resetting model is also activated in the transitions between sliding and sticking phases, although its probability does not always overcome that of the sticking model.

$ \left[\ddot{z}\right]=0.46\% $

), despite the presence of discontinuities in its time evolution. Finally, in the bottom frame of Figure 6, it can be noted that most discontinuities and regime transitions are well captured by the model transitions in the switching GPLFM. Among the seven stops occurring in the observed time window, only the second has been missed; however, it can be noted that this sticking phase is particularly short and does not affect significantly the friction force value. Similarly, spikes corresponding to the resetting model activation can be observed every time that discontinuities occur between the sliding stages. It is worth remembering that the switching GPLFM frameworks allows for more latent force models to be active simultaneously and, therefore, the blue line in Figure 6 is only referred to the predominant model at each time step. A full picture of the model probabilities is instead provided in Figure 7. Here, it can be seen that the resetting model is also activated in the transitions between sliding and sticking phases, although its probability does not always overcome that of the sticking model.

Table 3. Prior distributions for the GP hyperparameters used in the numerical case-study.

Figure 4. Prior and posterior distributions of the GP hyperparameters inferred by VBMC in switching GPLFM

![]() $ (I=J=3) $

.

$ (I=J=3) $

.

Figure 5. Convergence of the evidence lower bound (ELBO) in VBMC inference for switching GPLFM

![]() $ (I=J=3) $

.

$ (I=J=3) $

.

Figure 6. Latent states, acceleration, nonlinear friction force, and model sequence inferred by switching GPLFM (

![]() $ I=J=3 $

) vs ground truth. Models 1, 2, and 3 stand for sliding, sticking, and resetting models, respectively.

$ I=J=3 $

) vs ground truth. Models 1, 2, and 3 stand for sliding, sticking, and resetting models, respectively.

Figure 7. Model probabilities estimated by switching GPLFM (

![]() $ I=J=3 $

). Models 1, 2, and 3 stand for sliding, sticking, and resetting models, respectively.

$ I=J=3 $

). Models 1, 2, and 3 stand for sliding, sticking, and resetting models, respectively.

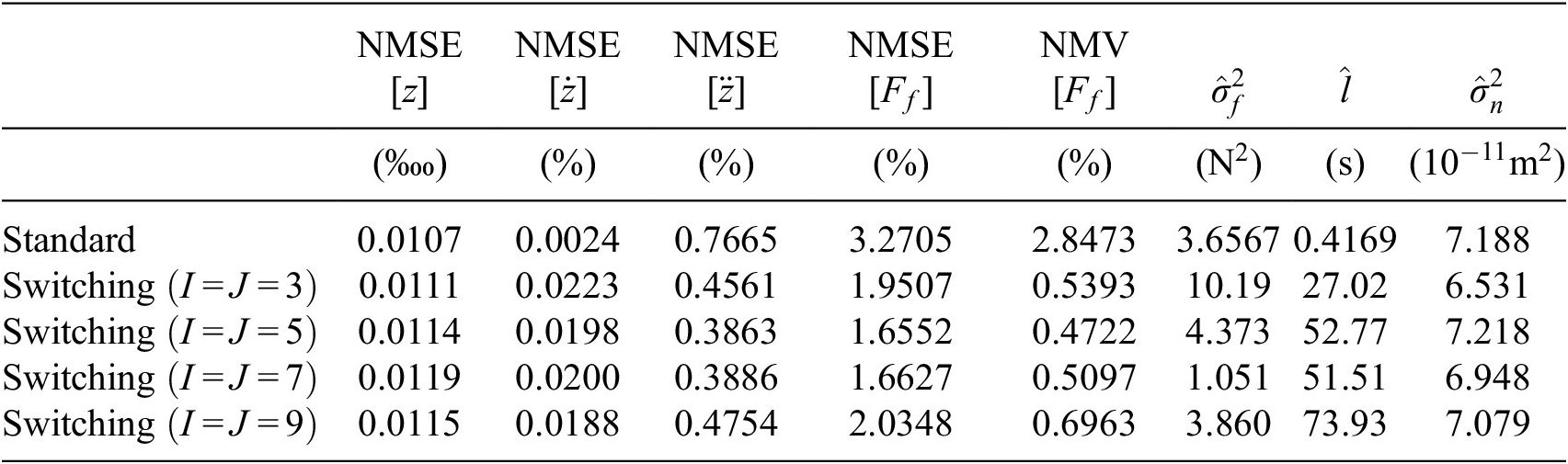

Table 4. Latent states, acceleration and nonlinear force identification error scores, and optimal hyperparameters for standard and switching GPLFMs with a varying number of Gaussian mixture components. The ground truth for the measurement noise variance is

![]() $ {\sigma}_n^2=6.182\times {10}^{-11}{m}^2 $

.

$ {\sigma}_n^2=6.182\times {10}^{-11}{m}^2 $

.

3.4. Comparison between standard and switching GPLFMs

In this subsection, the performance of the switching GPLFM in latent states and nonlinear force identification are investigated for varying number of Gaussian mixture components. For simplicity, the same number of Gaussians is used for ADF and EC

![]() $ \left(I=J\right) $

, although the EC implementation, as proposed by Barber (Reference Barber2006), also allows for a smaller number of Gaussians in the smoothed distribution (

$ \left(I=J\right) $

, although the EC implementation, as proposed by Barber (Reference Barber2006), also allows for a smaller number of Gaussians in the smoothed distribution (

![]() $ J<I $

). The standard GPLFM, which can simply be seen as a particular case of switching GPLFM for

$ J<I $

). The standard GPLFM, which can simply be seen as a particular case of switching GPLFM for

![]() $ S=1 $

,

$ S=1 $

,

![]() $ I=1 $

and

$ I=1 $

and

![]() $ J=1 $

, will be here considered as a reference case. In this case, ADF and EC will automatically reduce to Kalman filtering and RTS smoothing, respectively.

$ J=1 $

, will be here considered as a reference case. In this case, ADF and EC will automatically reduce to Kalman filtering and RTS smoothing, respectively.

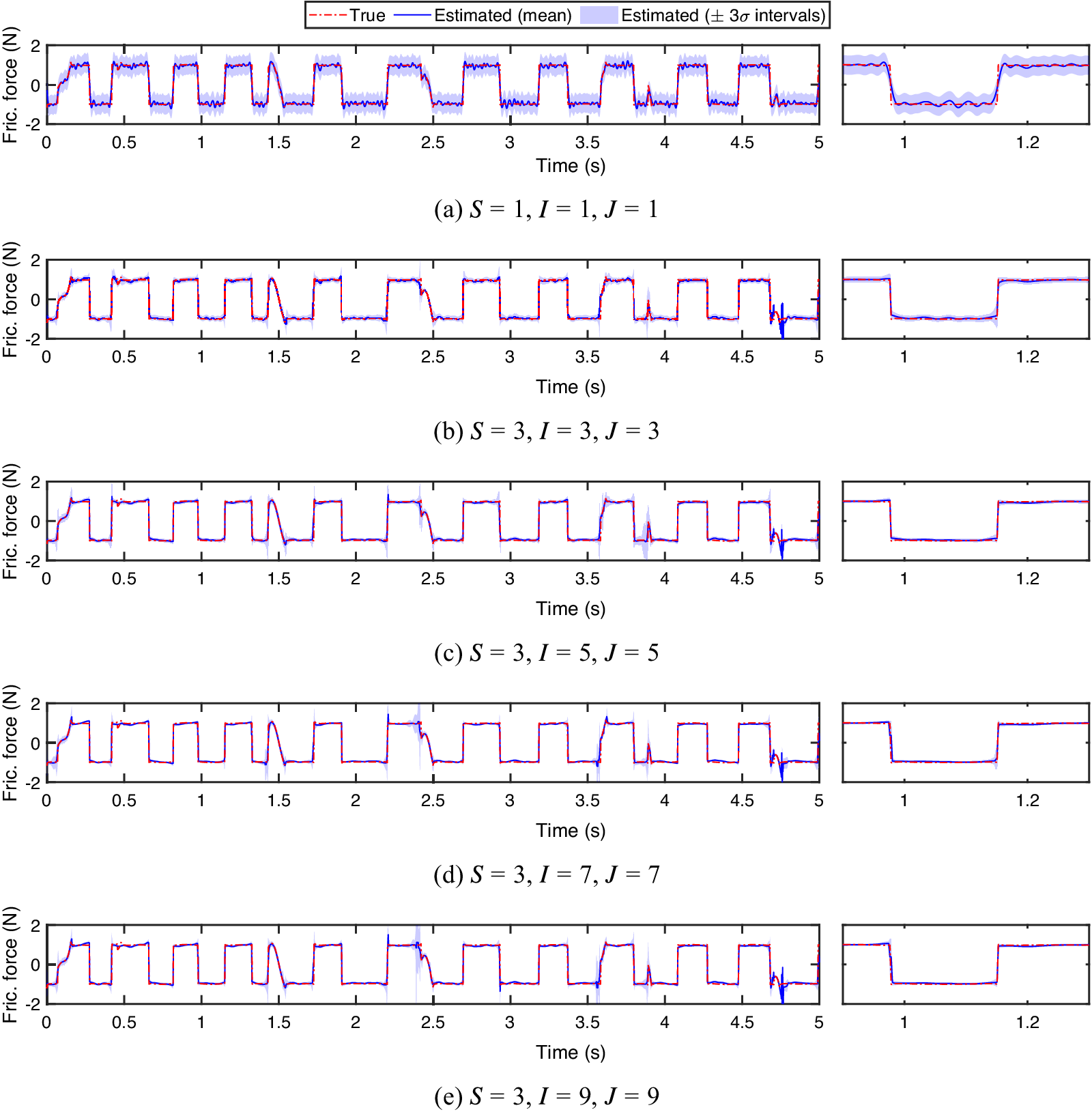

The latent states and nonlinear force identification errors obtained by using standard and switching GPLFMs (with 3, 5, 7, and 9 Gaussian components) are reported in Table 4, along with the optimal GP hyperparameters. Among the error scores, the normalized mean variance (NMV) index has been introduced as:

$$ \mathrm{NMV}\left[g\right]=\frac{1}{T{\sigma}_g^2}\sum \limits_{t=1}^T\unicode{x1D54D}\left({\hat{g}}_t\right) $$

$$ \mathrm{NMV}\left[g\right]=\frac{1}{T{\sigma}_g^2}\sum \limits_{t=1}^T\unicode{x1D54D}\left({\hat{g}}_t\right) $$

According to this definition, a zero value is obtained if the variance of the predicted function is zero at every point, while a unitary NMV corresponds to a predictive function whose variance at every time step

![]() $ t $

is equal to the overall variance of the ground truth. The identified nonlinear forces are also shown in Figure 8, where they are graphically compared to the true friction force in the time domain; a small section of the observed time window is enlarged on the right to illustrate how the different GPLFM approaches perform at discontinuities.

$ t $

is equal to the overall variance of the ground truth. The identified nonlinear forces are also shown in Figure 8, where they are graphically compared to the true friction force in the time domain; a small section of the observed time window is enlarged on the right to illustrate how the different GPLFM approaches perform at discontinuities.

Figure 8. Nonlinear friction force inferred by standard and switching GPLFMs for varying number of Gaussian components in ADF and EC (

![]() $ I=J $

) vs ground truth.

$ I=J $

) vs ground truth.

Figure 8a shows a good overall agreement between true and identified friction force obtained by using standard GPLFM. While discontinuities cannot be captured by a single latent force, the mean prediction follows quite closely the ground truth, resulting in an identification error of NMSE

![]() $ \left[{F}_f\right]=3.27\% $

. On the other hand, it can be observed that the confidence bounds around the mean prediction remain quite large (NMV

$ \left[{F}_f\right]=3.27\% $

. On the other hand, it can be observed that the confidence bounds around the mean prediction remain quite large (NMV

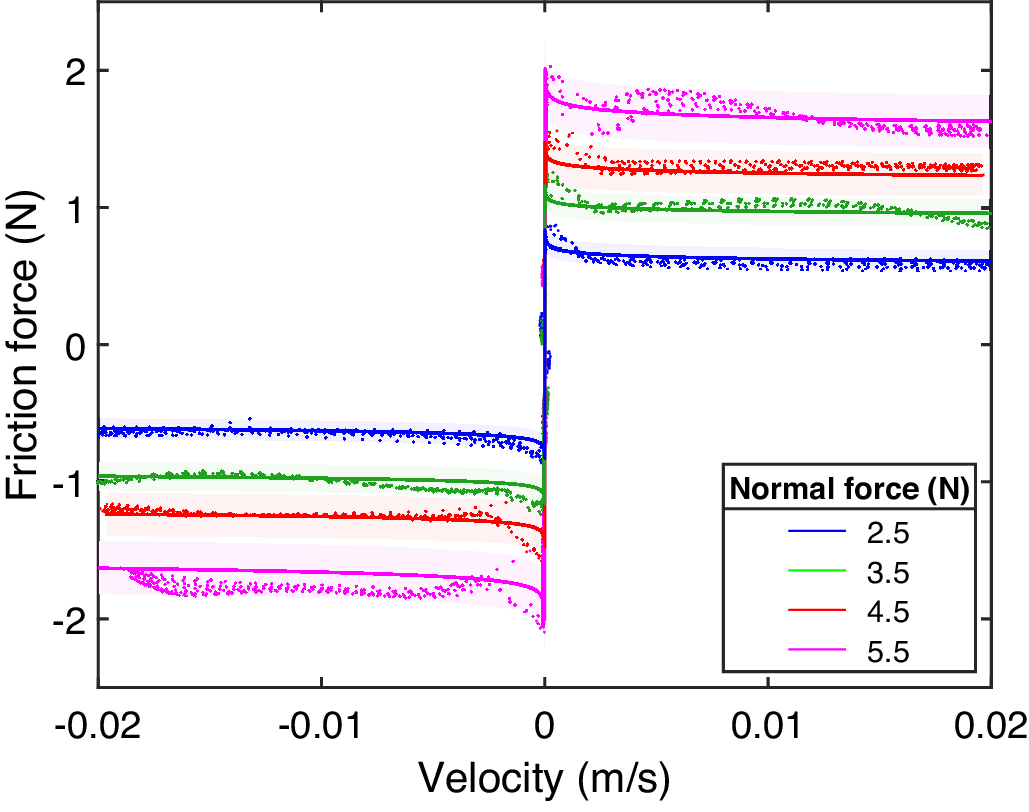

![]() $ \left[{F}_f\right]=2.85\% $