Introduction

Wearable robots are slowly but persistently entering our everyday lives—either at work, in sports, during rehabilitation, and in other situations. Even if we do not yet use such a robot, we can certainly imagine how nice it would be to wear a device that could reduce the burden of manual work on our body, increase our abilities during sports, or allow us to perform effective rehabilitation at our homes. With continuing advancements in mechanical design, modern materials, improved power sources, miniaturization of electronics, increased rate of data processing, and better understanding of biomechanics, widespread adoption of wearable robots seems to be within reach. Nevertheless, despite all these scientific and technological advancements, many recent pioneering efforts to bring wearable robots to real-life applications were accompanied by mixed feelings of those who were supposed to benefit from them (Hensel and Keil, Reference Hensel and Keil2019; Davis et al., Reference Davis, Reid, Rempel and Treaster2020; Mortenson et al., Reference Mortenson, Pysklywec, Chau, Prescott and Townson2020).

The aim of this review article is to address the current challenges that are limiting application and wider adoption of wearable robots in various domains (e.g., industry, rehabilitation, sports, healthcare, for physically challenged individuals, harsh environments, and aeronautics) and offer an outlook on relevant solutions and approaches that could overcome these challenges. We focus on wearable robots that are typically worn over the human body—for example, stiff exoskeletons, soft actuated suits, and hybrid soft-stiff exoskeletons. However, we also mention robotic prosthetic devices wherever relevant.

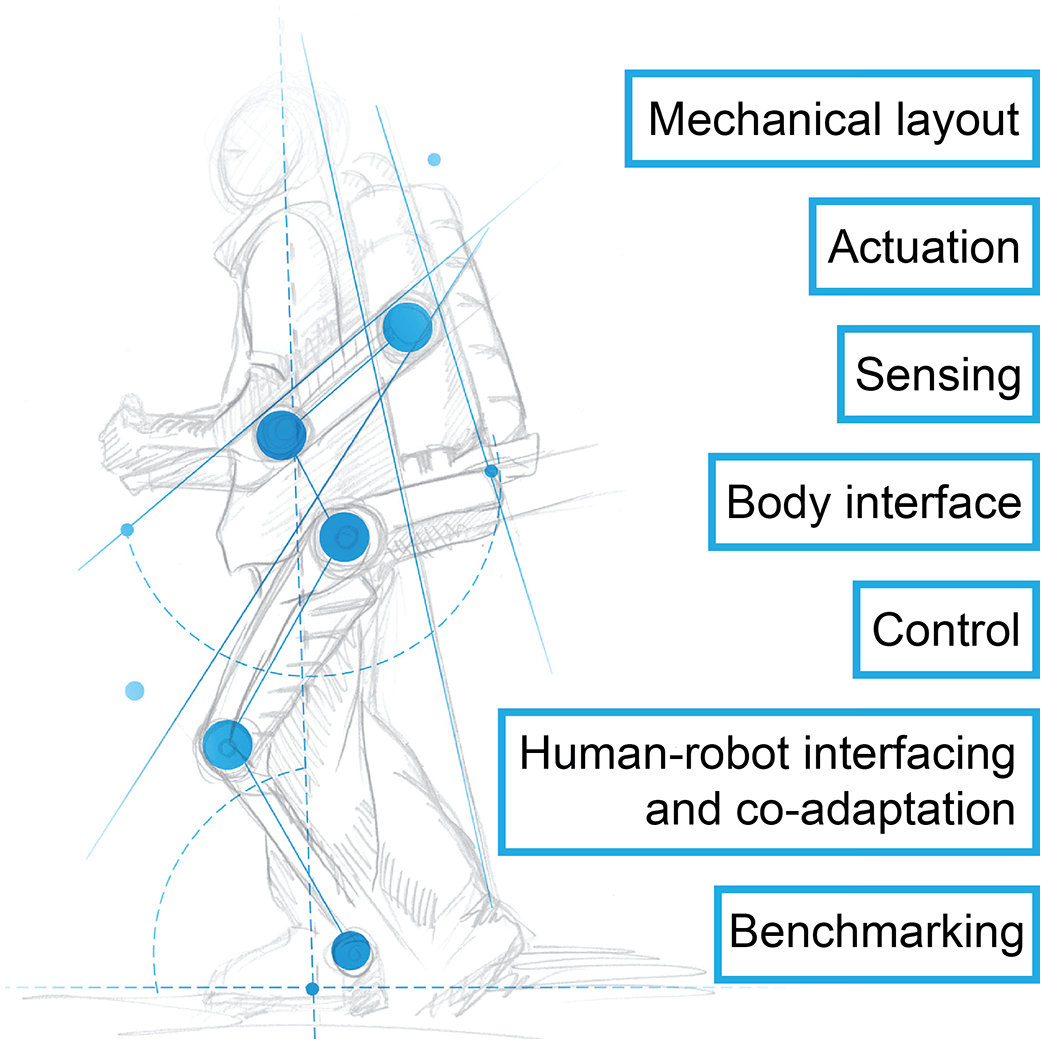

In the following seven sections, we review various aspects of wearable robots and their interaction with the human body (Figure 1). The sections start with the challenges and the rationale for why solving them is important, followed by an overview of relevant recent works related to the specific challenges. Each section then concludes with an opinion that summarizes possible solutions to advance wearable robots beyond the state of art and contribute to their wider adoption.

Figure 1. Seven aspects of wearable robots that are addressed in the following sections.

Mechanical Layout

Today’s wearable robotic devices feature a diverse variety of mechanical designs depending on the specific task they are intended to perform. Although examples of hybrid designs exist, most design approaches for wearable robots can be classified into two main categories: stiff devices, which consist of rigid, mostly metallic, structural elements, and so-called “exosuits,” which consist of flexible or even textile elements (Sanchez-Villamañan et al., Reference Sanchez-Villamañan, Gonzalez-Vargas, Torricelli, Moreno and Pons2019). The main challenge that engineers face in the development of wearable robot mechanics is to realize compact and light structures, combined with suitable kinematics so that the robot does not hinder the human’s musculoskeletal kinematics. In other words, good exoskeleton mechanical design must be able to effectively replicate or support the complex movements of the human limbs while being as unobtrusive as possible in their utilization context and in their management.

Stiff Exoskeleton Designs

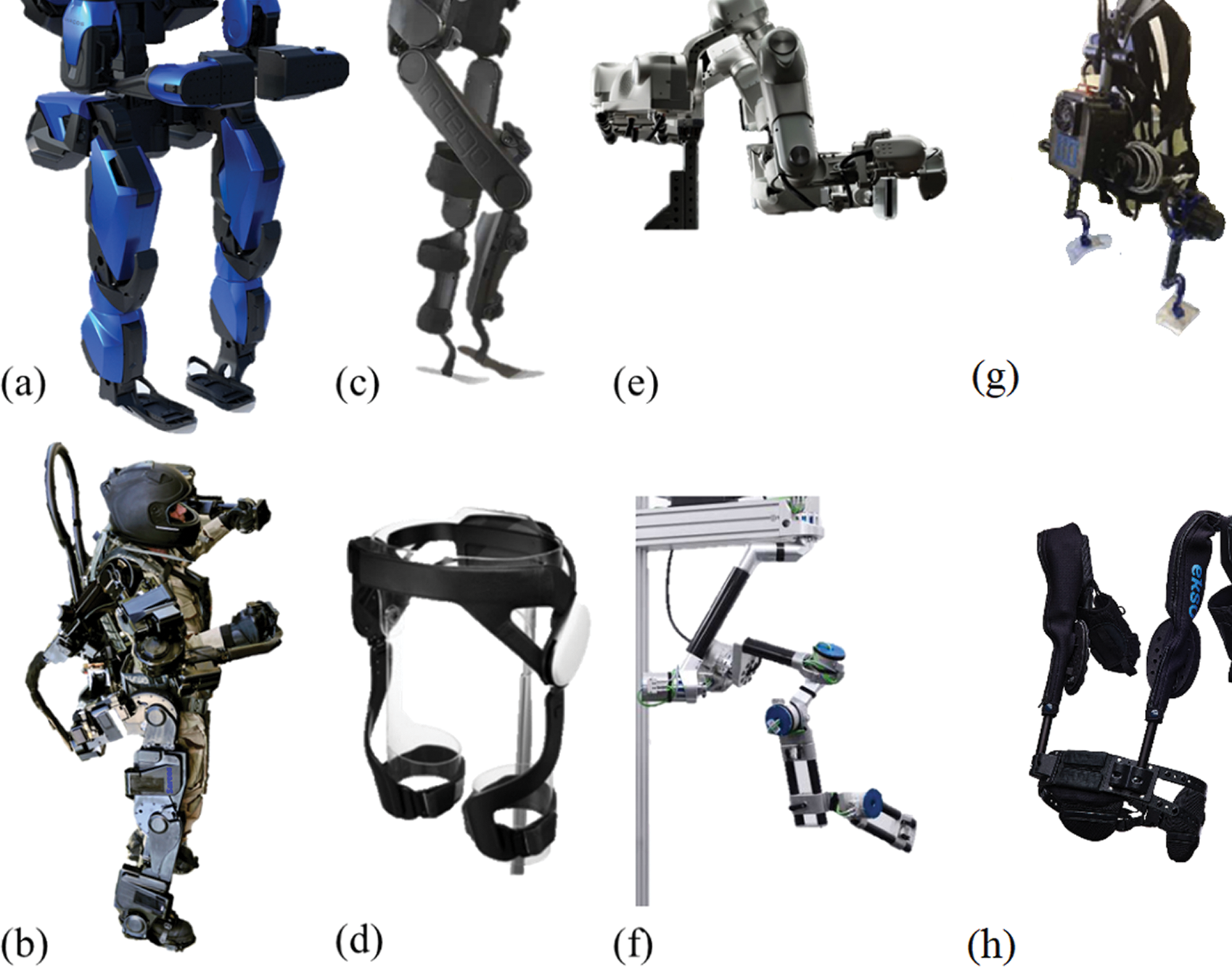

Exoskeletons with stiff structure and active joint actuation are the most widely known wearable devices and will be addressed in this section by analyzing applications for both the upper and lower limb. Depending on the amount of net active torque they can generate, they can be classified as “high-torque” or “low-torque” solutions. Specifically, “high-torque” stiff exoskeletons can generate sufficient torque to realize absolute control over the limb to which the exoskeleton is attached. This subcategory is ideal either when the wearer needs substantial support by the machine or when high levels of controllability are needed on the limb. High-torque use cases include lower limb assistance for severely impaired people, (Esquenazi et al., Reference Esquenazi, Talaty, Packel and Saulino2012; Wang et al., Reference Wang, Wang, Meijneke, van Asseldonk, Hoellinger, Cheron, Ivanenko, La Scaleia, Sylos-Labini, Molinari, Tamburella, Pisotta, Thorsteinsson, Ilzkovitz, Gancet, Nevatia, Hauffe, Zanow and van der Kooij2015; Milia et al., Reference Milia, De Salvo, Caserio, Cope, Weber, Santella, Fiorini, Baldoni, Bruschi, Bigazzi, Cencetti, Da Campo, Bigazzi and Bigazzi2016; Vouga et al., Reference Vouga, Baud, Fasola, Bouri and Bleuler2017; van der Kooij et al., Reference van der Kooij, van Asseldonk, van Oort, Sluiter, Emmens, Witteveen, Tagliamonte, Tamburella, Pisotta, Masciullo, Arquilla, Molinari, Wu, Ijspeert, Dzeladini, Thorsteinsson, Arami, Burdet, Huang, Gregoor, Meijneke, Carrozza, Micera and Pons2019; Jyräkoski et al., Reference Jyräkoski, Merilampi, Puustinen and Kärki2020; Figure 2c; www.indego.com) or power augmentation applications in which also upper limbs might be involved (Kazerooni, Reference Kazerooni2005; Marcheschi et al., Reference Marcheschi, Salsedo, Fontana and Bergamasco2011; www.sarcos.com; www.raytheon.com; Figure 2a,b). While kinematics that enables high levels of controllability of the limb is frequently used in rehabilitation applications since it allows the movement pattern to be precisely tuned to the patient’s needs (Bai and Christensen, Reference Bai and Christensen2017; Molteni et al., Reference Molteni, Gasperini, Cannaviello and Guanziroli2018), power augmentation applications typically do not demand total control of the biological joints. Indeed, within the “high-torque” class of wearable robots, some devices do not constrain the full limb of the wearer and deliberately leave freedom of movement to some biological joints. A similar approach can be found in underconstrained exoskeletons, where dedicated kinematic solutions and redundancy are exploited to maximize the wearability and usability of the device (Lo and Xie, Reference Lo and Xie2012; Tiseni et al., Reference Tiseni2019). In fact, nonfully constrained architectures may also be employed in other applications where absolute control of limb joints is not needed, such as assistive/industrial scenarios (Guizzo and Goldstein, Reference Guizzo and Goldstein2005; Bogue, Reference Bogue2018). In these applications, biological joints might not exactly match those of the robot, resolving possible joint alignment issues.

Figure 2. Stiff exoskeletons: (a) the power augmentation exoskeleton Guardian XO from Sarcos (www.sarcos.com), (b) the Raytheon XOS 2 (www.raytheon.com), (c) the lower limb rehabilitation exoskeleton Indego (www.indego.com; Farris et al., Reference Farris, Quintero and Goldfarb2011; Jyräkoski et al., Reference Jyräkoski, Merilampi, Puustinen and Kärki2020), (d) assistive lower limb exoskeleton GEMS (Lim et al., Reference Lim, Lee, Jang, Kim, Park, Seo and Shim2019), (e) the rehabilitation upper limb Harmony Exoskeleton by ReNeu Lab (www.reneu.robotics.utexas.edu/harmony-exoskeleton; Kim and Deshpande, Reference Kim and Deshpande2017), (f) rehabilitation upper limb exoskeleton ANYexo from ETH (www.sms.hest.ethz.ch/research/current-research-projects/armin-robot/ANYexo.html; Zimmermann et al., Reference Zimmermann, Forino, Riener and Hutter2019), (g) the occupation active trunk exoskeleton Robo.Mate (Huysamen et al., Reference Huysamen, Bosch, de Looze, Stadler, Graf and O’Sullivan2018), and (h) the occupational passive upper limb exoskeleton EksoVest (www.eksobionics.com/ekso-evo/; Kim et al., Reference Kim, Kim, Seok, So, Lee and Choi2018a,Reference Kim, Nussbaum, Mokhlespour Esfahani, Alemi, Alabdulkarim and Rashedib).

In all these high-torque lower/full-body exoskeletons, the mechanical structure needs to be in direct physical contact with the ground (i.e., through the feet) to support the load of the machine and the user.Footnote 1 Although significant engineering efforts have been made to lighten the structures of these devices (Farris et al., Reference Farris, Quintero and Goldfarb2011; Vouga et al., Reference Vouga, Baud, Fasola, Bouri and Bleuler2017), their mechanical structure still tends to be cumbersome due to the considerable load they need to bear as well as the high torques that have to be generated and transferred through the structure to the ground, the load, and possibly to human limbs.

On the other side of the spectrum, “low-torque” stiff exoskeletons are not capable of generating sufficient torque to realize total control over either the upper or lower limb, and thus provide only partial assistance to the user. Application domains of this class include gait assistance devices (Lim et al., Reference Lim, Lee, Jang, Kim, Park, Seo and Shim2019; Zhang et al., Reference Zhang, Xiong, Zhang, Liu, Lai, Rong and Fu2019; Figure 2d) and occupational exoskeletons, either active (Figure 2g) or passive (Figure 2h; Bogue, Reference Bogue2018; Huysamen et al., Reference Huysamen, Bosch, de Looze, Stadler, Graf and O’Sullivan2018; Theurel and Desbrosses, Reference Theurel and Desbrosses2019; www.eksobionics.com/ekso-evo/). The main function of this “low-torque” category is to assist the wearer in performing a specific motor task. As a result of the smaller force/torque exchange required by these applications, their structure is typically slimmer. These “low-torque” exoskeletons are considerably lighter than those in the “high torque” group, and to a certain extent their weight can thus be borne by the user.

Concerning the upper limb, most actuated exoskeletons for this limb are used for robot-assisted rehabilitation (Nef et al., Reference Nef, Mihelj, Kiefer, Perndl, Muller and Riener2007; Gopura et al., Reference Gopura, Bandara, Kiguchi and Mann2016; Kim and Deshpande, Reference Kim and Deshpande2017; Rehmat et al., Reference Rehmat, Zuo, Meng, Liu, Xie and Liang2018). In upper-body exoskeletons, the device can be fixed on an external platform (Caldwell et al., Reference Caldwell, Tsagarakis, Kousidou, Costa and Sarakoglou2007; Noda et al., Reference Noda, Teramae, Ugurlu and Morimoto2014), which severely limits its mobility; conversely, it can be carried entirely by the human (Balasubramanian et al., Reference Balasubramanian, Wei, Perez, Shepard, Koeneman, Koeneman and He2008), which requires sufficient fitness to support the weight.

Upper limb rehabilitation devices need to deliver torque to the wearer during physical exercise (Lo and Xie, Reference Lo and Xie2012; Mehrholz et al., Reference Mehrholz, Hädrich, Platz, Kugler, Pohl and Mehrholz2012; Wendong et al., Reference Wendong, Hanhao, Menghan, Yang, Xiaoqing, Xing and Bing2020), and typically involve designs that allow high levels of controllability of the limb (Nef et al., Reference Nef, Mihelj, Kiefer, Perndl, Muller and Riener2007; Gopura et al., Reference Gopura, Bandara, Kiguchi and Mann2016; Bai and Christensen, Reference Bai and Christensen2017). The robot is usually used in one of three modes: (a) passive mobilization, where the user relaxes their arm and the robot moves it to improve its range of motion (Brahmi et al., Reference Brahmi, Saad, Rahman and Ochoa-Luna2019); (b) assist as needed, where the robot assists voluntary movements of the patient (Reinkensmeyer et al., Reference Reinkensmeyer, Wolbrecht, Chan, Chou, Cramer and Bobrow2012); or (c) resistive or error augmentation mode, where the robot acts in opposition to the wearer’s movements (Marchal-Crespo and Reinkensmeyer, Reference Marchal-Crespo and Reinkensmeyer2009). Please refer to Section “Control” for further details. In all three modes, the torques applied to the user are relatively low compared to lower limb or power augmentation scenarios. This is also true in the case of upper limb exoskeletons for teleoperative haptic applications, which need to generate feedback torques toward the user (Mallwitz et al., Reference Mallwitz, Will, Teiwes and Kirchner2015; Buongiorno et al., Reference Buongiorno, Chiaradia, Marcheschi, Solazzi and Frisoli2019). It is worth mentioning that, although the assistive torques that need to be generated are much smaller compared to those in lower limb or power augmentation applications, the structure of these exoskeletons may need to support significant load due to the “cantilever” effect generated when the arm is extended—for example, during reaching. Therefore, despite the low required net torque, the structures of these exoskeletons may become bulky due to the need to withstand considerable gravitational load. In addition to this, upper limb exoskeleton kinematics are generally far from trivial due to the high number of degrees of freedom of the human and the complexity of the shoulder joint (Figure 2e,f; www.reneu.robotics.utexas.edu/harmony-exoskeleton; www.sms.hest.ethz.ch/research/current-research-projects/armin-robot/ANYexo.html; Kim and Deshpande, Reference Kim and Deshpande2017; Zimmermann et al., Reference Zimmermann, Forino, Riener and Hutter2019). Therefore, this exoskeleton type may need dedicated designs to allow correct replication of biological kinematics and consequently facilitate their control (Perry et al., Reference Perry, Powell and Rosen2009). In contrast to the fully actuated and typically heavy upper limb machines addressed above, there is a growing interest in exoskeletons for arm support or gravity compensation in industrial applications (Spada et al., Reference Spada, Ghibaudo, Gilotta, Gastaldi and Cavatorta2017; Kim et al., Reference Kim, Kim, Seok, So, Lee and Choi2018a,Reference Kim, Nussbaum, Mokhlespour Esfahani, Alemi, Alabdulkarim and Rashedib; Van Engelhoven et al., Reference Van Engelhoven, Poon, Kazerooni, Barr, Rempel and Harris-Adamson2018; Pacifico et al., Reference Pacifico, Scano, Guanziroli, Moise, Morelli, Chiavenna, Romo, Spada, Colombina, Molteni, Giovacchini, Vitiello and Crea2020; Goršič et al. Reference Goršic, Regmi, Johnson, Dai and Novak2020). These devices are typically passive and use elastic elements to provide the needed compensation torque.

Regardless of the application domain or body area, stiff exoskeleton designs may present wearability issues since mechanical stress is generated on the user’s skin due to the generation of shear forces at the interface point. These shear forces may occur when there is misalignment between the exoskeleton rotation axes and the corresponding human joints. This represents a nonnegligible aspect of stiff exoskeletons, where the joints’ centers of instantaneous rotation are often fixed while the human joints’ (e.g., knee or shoulder) centers of instantaneous rotation change their relative position during the motion (Veeger, Reference Veeger2000; Hollman et al., Reference Hollman, Deusinger, Van Dillen and Matava2002). As a consequence, aligning a stiff exoskeleton to a human limb might lead to undesired stresses. The amount of these stresses depends on the quality of the alignment and the capability to maintain it during motion. To deal with this, researchers are increasingly adopting original solutions that allow the exoskeleton structure to self-align to the anatomical kinematics of the wearer using additional passive degrees of freedom (Ball et al., Reference Ball, Brown and Scott2007; Toxiri et al., Reference Toxiri, Ortiz, Masood, Fernandez, Mateos and Caldwell2015; Näf et al., Reference Näf, Junius, Rossini, Rodriguez-Guerrero, Vanderborght and Lefeber2018), compliant actuation systems (Vitiello et al., Reference Vitiello, Lenzi, Roccella, De Rossi, Cattin, Giovacchini, Vecchi and Carrozza2013), or specific mechanisms (Stienen et al., Reference Stienen, Hekman, van der Helm and van der Kooij2009; Ergin and Patoglu, Reference Ergin and Patoglu2012). However, these solutions require additional space and volume and are thus not always feasible in portable devices.

Soft Exoskeleton Designs

In contrast to stiff devices, soft exoskeletons (also called exosuits) deliver mechanical power to the user using anchors that are typically made of clothing textiles and powered by cable-driven actuation (Awad et al., Reference Awad, Bae, O’Donnell, De Rossi, Hendron, Sloot, Kudzia, Allen, Holt, Ellis and Walsh2017; Schmidt et al., Reference Schmidt, Duarte, Grimmer, Sancho-Puchades, Wei, Easthope and Riener2017; Li et al., Reference Li, Yang, Yu, Chang, Zhao, Zhao, Elhajj, Xi and Liu2018; Di Natali et al., Reference Di Natali, Poliero, Sposito, Graf, Bauer, Pauli, Bottenberg, De Eyto, O’Sullivan, Hidalgo, Scherly, Stadler, Caldwell and Ortiz2019; Kim et al., Reference Kim, Kwon, Han, Park and Jo2019a,Reference Kim, Lee, Heimgartner, Arumukhom Revi, Karavas, Nathanson, Galiana, Eckert-Erdheim, Murphy, Perry, Menard, Choe, Malcolm and Walshb; Xiloyannis et al., Reference Xiloyannis, Chiaradia, Frisoli and Masia2019; Yang et al., Reference Yang, Huang, Hu, Yu, Zhang, Zhou, Carriero, Yue and Su2019; Goršič et al., Reference Goršič, Song, Dai and Novak2021; Figure 3). Furthermore, soft exoskeletons are typically ergonomic, lightweight, and often designed following bioinspired techniques to better reproduce human physiological movements (Lessard et al., Reference Lessard, Pansodtee, Robbins, Trombadore, Kurniawan and Teodorescu2018; Figure 3b). They can be employed in several domains, from medical/rehabilitation scenarios to improving the physical strength of healthy individuals (Kim et al., Reference Kim, Kwon, Han, Park and Jo2019a,Reference Kim, Lee, Heimgartner, Arumukhom Revi, Karavas, Nathanson, Galiana, Eckert-Erdheim, Murphy, Perry, Menard, Choe, Malcolm and Walshb; Figure 3c). The same work also demonstrated how a lower limb soft exosuit can reduce the metabolic cost of walking and running. Another important advantage is that, compared to stiff designs, exosuits largely maintain the natural freedom of movement of the wearer (Wehner et al., Reference Wehner, Quinlivan, Aubin, Martinez-Villalpando, Baumann, Stirling, Holt, Wood and Walsh2013; Figure 3d). However, the preservation of the freedom of movement offered by soft exosuits, as well as their comfort, depends on ergonomically appropriate design. Indeed, several recent works have focused on the design of ergonomic soft exoskeletons to minimize user discomfort (Andrikopoulos et al., Reference Andrikopoulos, Nikolakopoulos and Manesis2015; Varghese et al., Reference Varghese, Mukherjee, King, Keller and Deshpande2018; Choi et al., Reference Choi, Kang, Jung and Cho2019; Chiaradia et al., Reference Chiaradia, Tiseni, Xiloyannis, Solazzi, Masia and Frisoli2021). These studies showed how the combination of textile fibers, 3D printed plastic materials and sometimes even metal parts, should be carefully designed to offer appropriate ergonomics and avoid possible limitations of the device’s functionality.

Figure 3. Examples of soft exoskeletons: (a) the research upper limb soft exosuit from Aries Lab (Xiloyannis et al., Reference Xiloyannis, Chiaradia, Frisoli and Masia2019), (b) the CRUX soft upper limb exosuit (Lessard et al., Reference Lessard, Pansodtee, Robbins, Trombadore, Kurniawan and Teodorescu2018), (c) the research lower limb soft exosuit from the Wyss Institute (Kim et al., Reference Kim, Kwon, Han, Park and Jo2019a,Reference Kim, Lee, Heimgartner, Arumukhom Revi, Karavas, Nathanson, Galiana, Eckert-Erdheim, Murphy, Perry, Menard, Choe, Malcolm and Walshb), and (d) a lower limb pneumatic soft exoskeleton (Wehner et al., Reference Wehner, Quinlivan, Aubin, Martinez-Villalpando, Baumann, Stirling, Holt, Wood and Walsh2013).

The main disadvantage of soft exoskeletons is that the mechanical power they can deliver is still limited as compared to stiff designs (Schmidt et al., Reference Schmidt, Duarte, Grimmer, Sancho-Puchades, Wei, Easthope and Riener2017). This is mostly because the forces produced by soft exosuits inherently increase the shear stress on the human body. Indeed, although these devices may potentially offer higher comfort than stiff systems due to their compliant nature, soft exoskeletons often present problems of slipping and chafing at the anchor points due to the generation of shear forces at the interface point with the wearer (Asbeck et al., Reference Asbeck, Dyer, Larusson and Walsh2013; Yandell et al., Reference Yandell, Quinlivan, Popov, Walsh and Zelik2017). On the other hand, the effects of the mentioned shear forces on joint loading are usually negligible: the radius over which they apply forces is significantly greater than that exploited by the biological tendon, and the joint compression force decreases as a consequence of this (Lamers et al., Reference Lamers, Yang and Zelik2018). The shear force problem is instead minimized in stiff designs, where forces are applied orthogonally to the human segment (Yandell et al., Reference Yandell, Quinlivan, Popov, Walsh and Zelik2017). Another common issue of soft design approaches is the friction introduced by the employed cable-driven actuation systems (e.g., Bowden-cable transmission), which typically results in low efficiency and bad control performance of the overall system if not compensated (Jeong et al., Reference Jeong, Woo and Kong2020). Furthermore, given their soft nature, the interface points where the human limb is anchored introduce a low-stiffness series compliance that would need high actuation power and appropriate bandwidth to be overcome (Chiaradia et al., Reference Chiaradia, Xiloyannis, Solazzi, Masia and Frisoli2019). Figure 3 shows examples of upper and lower limb soft exoskeletons.

How Can Design Choices Facilitate the Adoption of Exoskeletons?

The mentioned size/weight issues typical of stiff designs have motivated a growing number of research groups to adopt methods from the field of industrial design to truly understand user needs and design exoskeletal solutions tailored to the specific application (Schmidt et al., Reference Schmidt, Duarte, Grimmer, Sancho-Puchades, Wei, Easthope and Riener2017; Laffranchi et al., Reference Laffranchi, Semprini, Manzan, Cerruti, Vassallo, De Giuseppe, Maludrottu, Succi, Chiappalone, Gruppioni and De Michieli2018). In most of these works, the main user needs that still need to be overcome are diverse: reduced donning time, lighter structures, higher autonomy of use, higher freedom of movement, increased comfort, and so forth (Gorgey, Reference Gorgey2018; Wang et al., Reference Wang, Li, Huang, Yu, Li, Chen, Carriero, Oh-Park and Su2018; Fritz et al., Reference Fritz, Patzer and Galen2019; Davis et al., Reference Davis, Reid, Rempel and Treaster2020). Researchers and companies are addressing the needs with different solutions. One approach is the utilization of high-performance materials such as carbon fiber, aluminum or aluminum–titanium alloys, which may enable the development of lighter and more flexible structures for both upper and lower limb exoskeletons, thus reducing the overall weight of the device (Frisoli et al., Reference Frisoli, Rocchi, Marcheschi, Dettori, Salsedo and Bergamasco2005; Meijneke et al., Reference Meijneke, van Dijk and van der Kooij2014; Bianchi et al., Reference Bianchi, Buonamici, Furferi and Vanni2016). A few devices propose modular architectures that allow the exoskeleton structure to be disassembled into multiple small and light modules to facilitate donning, transportation and autonomous usage by impaired subjects (Laffranchi et al., Reference Laffranchi, Semprini, Manzan, Cerruti, Vassallo, De Giuseppe, Maludrottu, Succi, Chiappalone, Gruppioni and De Michieli2018; Vassallo et al., Reference Vassallo, De Giuseppe, Piezzo, Maludrottu, Cerruti, D’Angelo, Gruppioni, Marchese, Castellano, Guanziroli, Molteni, Laffranchi and De Michieli2020; http://www.indego.com/indego/us/en/home). Finally, recent works show a growing interest in passive exoskeletons (Spada et al., Reference Spada, Ghibaudo, Gilotta, Gastaldi and Cavatorta2017; Kim et al., Reference Kim, Kim, Seok, So, Lee and Choi2018a,Reference Kim, Kim, Seok, So, Lee and Choib; Van Engelhoven et al., Reference Van Engelhoven, Poon, Kazerooni, Barr, Rempel and Harris-Adamson2018; Pacifico et al., Reference Pacifico, Scano, Guanziroli, Moise, Morelli, Chiavenna, Romo, Spada, Colombina, Molteni, Giovacchini, Vitiello and Crea2020). As these devices are typically lighter than their active counterparts, they may be able to solve the weight issue. However, as their purpose is to counteract gravity in semi-static scenarios by means of passive mechanical components, they lack the versatility of active devices.

Regarding soft exoskeletons, their application is still limited to cases where the amount of needed assistance is limited—as in “low-torque” stiff exoskeletons—due to the problems mentioned in the previous section. A limited torque generation does not necessarily represent a constraint in the application of such devices, as seen in gait assistance exoskeletons where full torque compensation is not required. Nonetheless, it can be argued that considerable efforts are still needed to design appropriate ergonomics and realize systems that can effectively increase their load capacity without generating high stress on the wearer’s biological tissues (Lotti et al., Reference Lotti, Xiloyannis, Durandau, Galofaro, Sanguineti, Masia and Sartori2020).

The search for novel solutions, both in stiff and soft exoskeletons, may be facilitated by careful analysis of users’ feedback and the inclusion of a diverse range of design disciplines besides engineering. Indeed, many innovative works are driven by approaches that dedicate considerable effort to understanding user needs and proposing solutions that are tailored to specific end-user needs. For example, user-centered design techniques have been applied to increase adoption of exoskeleton technologies in applications such as medical (Almenara et al., Reference Almenara, Cempini, Gómez, Cortese, Martín, Medina, Vitiello and Opisso2017; Laffranchi et al., Reference Laffranchi, Semprini, Manzan, Cerruti, Vassallo, De Giuseppe, Maludrottu, Succi, Chiappalone, Gruppioni and De Michieli2018; Meyer et al., Reference Meyer, Schrade, Lambercy and Gassert2019; Vassallo et al., Reference Vassallo, De Giuseppe, Piezzo, Maludrottu, Cerruti, D’Angelo, Gruppioni, Marchese, Castellano, Guanziroli, Molteni, Laffranchi and De Michieli2020), industrial (Babič et al., Reference Babič, Mombaur, Lefeber, van Dieën, Graimann, Russold, Šarabon, Houdijk, González-Vargas, Ibáñez, Contreras-Vidal, van der Kooij and Pons2017; Davis et al., Reference Davis, Reid, Rempel and Treaster2020), and assistive (Wang et al., Reference Wang, Li, Huang, Yu, Li, Chen, Carriero, Oh-Park and Su2018). Such user-centered design approaches, which may additionally incorporate industrial and ergonomics design in the development process, could serve as useful and effective tools to foster the adoption of exoskeleton technology (Hill et al., Reference Hill, Holloway, Morgado Ramirez, Smitham and Pappas2017).

A final consideration must be given to hybrid exoskeletons. The aim of these devices is to combine the light weight and comfort of soft exoskeletons with the generally higher torques generated by stiff solutions. Hybrid exoskeletons have been developed for both the upper and lower limb. For the upper limb, Rose and O’Malley (Reference Rose and O’Malley2019) proposed a hybrid hand exoskeleton that favors ergonomics, self-donning and doffing while satisfying the required range of motion and grasping force. Instead, for the lower limb, the reader might refer to the MyoSuit device, which demonstrated effective hip assistance without altering gait kinematics (Schmidt et al., Reference Schmidt, Duarte, Grimmer, Sancho-Puchades, Wei, Easthope and Riener2017; Haufe et al., Reference Haufe, Kober, Schmidt, Sancho-Puchades, Duarte, Wolf and Riener2019). Moreover, an interesting hybrid knee exoskeleton with considerable high-torque capabilities has been proposed by Su et al., and showed contained mass properties and high backdrivability (Yu et al., Reference Yu, Huang, Wang, Lynn, Sayd, Silivanov, Park, Tian and Su2019). As of today, there are no general and quantitative guidelines on how to combine stiff and soft elements in hybrid exoskeleton designs. In fact, each stiff or soft subcomponent embedded in a given hybrid design inherits the same pros and cons of stiff or soft designs seen in previous subsections. Therefore, the successful combination (and selection) of soft and stiff components for hybrid exoskeletons depends on the requirements of the specific application.

Actuation

Actuators are a major bottleneck for the development of active wearable robots. The demanding requirements imposed upon them include high torque density (torque per unit mass), backdrivability, compactness and, for untethered devices, high energy efficiency. The actuator’s torque density is especially important for actuators at distal joints due to the large metabolic cost associated with carrying mass in these locations (Royer and Martin, Reference Royer and Martin2005; Browning et al., Reference Browning, Jesse R., Rodger and Ambarish2007). Highly backdrivable actuators allow the wearer to move unimpeded when the robot is not providing assistance, for example, during the swing phase of walking or during donning and doffing. Finally, wearable robots should be as unobtrusive as possible. Actuators, which tend to protrude from the device, therefore need to be designed in small and compact form factors.

The majority of actuators for wearable robotics incorporate electric motors as prime movers (Windrich et al. Reference Windrich, Grimmer, Christ, Rinderknecht and Beckerle2016; Gopura et al., Reference Gopura, Bandara, Kiguchi and Mann2016; Veale and Xie, Reference Veale and Xie2016). The main competing technologies, hydraulic and pneumatic actuators, are typically less efficient and reliable, tend to be noisy, and require pressurized fluid supplies that are difficult to make portable in an acceptable form factor (Madden, Reference Madden2007; Veale and Xie, Reference Veale and Xie2016). Hydraulic power units driven by combustion engines do have very high power densities, which makes them interesting when high power output is required, for example, for exoskeletons intended for load carrying and human performance augmentation (National Research Council, 2004). However, the high power density of hydraulic actuators comes at the cost of high impedance (Hollerbach et al., Reference Hollerbach, Hunter and Ballantyne1992; Zinn et al., Reference Zinn, Khatib and Roth2004), which is undesirable for wearable robots. Overall, for most wearable robots that are not used for human performance augmentation, electric motors are considered to present the best trade-off between the different requirements.

Interestingly, in terms of power-to-mass ratio and energy efficiency, electric motors perform better than human muscles (Madden, Reference Madden2007). However, in wearable robots, motors need to operate dynamically at varying torques and speeds. In these conditions, their efficiency is far below the nominal value (Verstraten et al., Reference Verstraten, Flynn, Geeroms, Vanderborght and Lefeber2018). Moreover, the torque output of electric motors is low relative to the demands of wearable robots, which is why they are typically paired with high-reduction gearboxes. The dominant gearbox technologies in wearable robotics, harmonic gears and planetary gearboxes, offer high reduction ratios in compact sizes. However, their low efficiency and poor backdrivability are detrimental to the overall performance of the actuators and the wearable robot as a whole (Kazerooni, Reference Kazerooni1995; Nef and Lum, Reference Nef and Lum2009; Lv et al., Reference Lv, Zhu and Gregg2018; García et al., Reference García, Crispel, Saerens, Verstraten and Lefeber2020).

Two paths are currently followed by the research community to tackle this problem. On one hand, novel gearbox technologies with improved characteristics are being explored, as summarized by García et al. (Reference García, Crispel, Saerens, Verstraten and Lefeber2020). Recent examples include the Gear Bearing Drive (Brassitos and Jalili, Reference Brassitos and Jalili2019), and the Bilateral Drive Gear (Matsuki et al. Reference Matsuki, Nagano and Fujimoto2019). These gearboxes achieve high gear reductions at high efficiencies and in compact sizes through the use of the Wolfrom gearbox topology, combined with performance-enhancing modifications such as a carrierless design (Gear Bearing Drive) and profile shift modification (Bilateral Drive). On the other hand, quasi-direct drive has emerged as a new actuation paradigm. It combines high torque-motors with low-reduction gearboxes, resulting in energy-efficient actuators with high backdrivability (Sensinger et al., Reference Sensinger, Clark and Schorsch2011). Ideally, these gearboxes are single-stage (gear ratio below 10) since efficiency is mostly related to the number of stages. Following their success in legged robots (Seok et al., Reference Seok, Wang, Chuah, Hyun, Lee, Otten, Lang and Kim2015; Ding and Park, Reference Ding and Park2017), quasi-direct drive actuators are currently being implemented in wearable robots (Wang et al., Reference Wang, Li, Huang, Yu, Li, Chen, Carriero, Oh-Park and Su2018; Elery et al., Reference Elery, Rezazadeh, Nesler and Gregg2020; Yu et al., Reference Yu, Huang, Yang, Jiao, Yang, Chen, Yi and Su2020; Zhu et al., Reference Zhu, Nesler, Divekar, Peddinti and Gregg2021).

To further compensate for the inherent limitations of commercial motors and gearboxes, researchers have resorted to specialized actuator designs. Our musculoskeletal system is built in such a way that elastic tissues in our body (tendons, aponeuroses, elastic tissues between muscle fibers, etc.) can perform a large amount of work by passive stretch and recoil (Alexander, Reference Alexander1990). This is possible because the joint torques applied during human movements typically exhibit a linear relationship with respect to the joint angle during consistent parts of the movement (Feldman, Reference Feldman1980; Hasan, Reference Hasan1986; Frigo et al., Reference Frigo, Crenna and Jensen1996; Toxiri et al., Reference Toxiri, Ortiz, Masood, Fernandez, Mateos and Caldwell2015). Engineered actuators for wearable robots, which are designed to provide assistive torques with a similar profile, can therefore also benefit from incorporating elastic elements with well-chosen stiffness. These specialized actuators are called elastic actuators.

Springs with well-designed stiffness allow actuators to deliver peak powers well beyond the capabilities of the motor itself (Paluska and Herr, Reference Paluska and Herr2006). Elastic actuators can therefore incorporate a smaller electric motor and gearbox, resulting in an overall reduction of weight and size compared to a traditional, stiff actuator. Moreover, springs offer the possibility to mechanically store energy when the actuator performs negative work and release it when positive work is required. As such, the average power flow through the actuator is reduced, resulting in an improvement in energy efficiency of the actuator (Hollander et al., Reference Hollander, Ilg, Sugar and Herring2006; Verstraten et al., Reference Verstraten, Geeroms, Mathijssen, Convens, Vanderborght and Lefeber2017; Bolivar Nieto et al., Reference Bolivar Nieto, Rezazadeh and Gregg2019).

Elastic actuators can be subdivided into two main categories based on the placement of the spring element. By adding a (unidirectional) parallel spring to a stiff motor, one obtains a parallel elastic actuator (PEA). In this case, the parallel spring takes over a part of the load, leading to a reduction of the motor torque. The required motor speed remains unchanged since the motor is directly coupled to the output. Another option is to place the spring in between the motor and load, that is, in a series configuration. This type of actuator is called a series elastic actuator (SEA). In contrast to the PEA, a well-tuned spring lowers the speed required from the motor while the motor torque is unaffected. Although SEA and PEA provide similar levels of peak power amplification and increased energy efficiency during locomotion tasks (Verstraten et al., Reference Verstraten, Geeroms, Mathijssen, Convens, Vanderborght and Lefeber2017), the PEA has the specific ability to compensate for static torques by tuning the equilibrium angle of the spring (Beckerle et al., Reference Beckerle, Verstraten, Mathijssen, Furnemont, Vanderborght and Lefeber2016). This makes the PEA particularly suitable for upper-body exoskeletons that assist with overhead work or back-support exoskeletons for lifting tasks. Here, the parallel spring can provide the torque required to support the weight of the arms or torso as well as the load.

The performance of elastic actuators can be further enhanced by adding locking mechanisms and clutches (Plooij et al., Reference Plooij, Wolfslag and Wisse2017). Passive occupational exoskeletons often allow the user to disengage the spring providing the assistance so that it does not impede the user by generating a torque when it is not needed (Zhang and Huang, Reference Zhang and Huang2018). In a similar fashion, since little torque is required during the swing phase of gait, lower limb exoskeletons and prostheses can benefit from clutched PEAs (Haeufle et al., Reference Haeufle, Taylor, Schmitt and Geyer2012; Geeroms et al., Reference Geeroms, Flynn, Jimenez-Fabian, Vanderborght and Lefeber2017) and SEAs (Rouse et al., Reference Rouse, Mooney and Herr2014; Convens et al., Reference Convens2019) that only engage the spring during stance. In robotic ankles, a catapult-like mechanism consisting of a spring and locking mechanism could be used to deliver the explosive burst of power required during push-off in an energy-efficient way (Collins and Kuo, Reference Collins and Kuo2010; Cherelle et al., Reference Cherelle, Grosu, Matthys, Vanderborght and Lefeber2014). Clutches have also been implemented in new actuator designs with multiple springs, which can be recruited progressively to contribute to the output torque (Mathijssen et al., Reference Mathijssen, Lefeber and Vanderborght2015; Krimsky and Collins, Reference Krimsky and Collins2020).

Most springs are manufactured to exhibit a linear relationship between torque and deflection. However, in wearable robotics, the required torques are rarely perfectly linear with respect to the output angle over the entire operating range of motion. The joint stiffness profiles required for walking, for example, exhibit low stiffness at low joint flexion and high stiffness at high joint flexion (Seyfarth et al., Reference Seyfarth, Geyer, Blickhan, Lipfert, Rummel, Minekawa and Iida2006). A closer match between the spring characteristic and the required torque can be achieved by means of nonlinear transmissions. The simplest way to generate a nonlinear transmission is by providing torque to the joint through a lever (Sugar and Holgate, Reference Sugar and Holgate2013). The linear actuators driving the lever often consist of brushless DC motors combined with ball screw drives, a solution which offers relatively high reductions at high efficiencies. Other common nonlinear transmissions are cams (Realmuto et al., Reference Realmuto, Klute and Devasia2015; Gao et al., Reference Gao, Liu and Liao2018) and four-bar mechanisms (Bergelin and Voglewede, Reference Bergelin and Voglewede2012; Hyun et al., Reference Hyun, Park, Ha, Park and Jung2017).

Specialized actuator designs achieve impressive performance by relying on springs and nonlinear transmissions optimized for a specific task. The downside of this approach is significantly worse performance in off-design conditions. This issue can be mitigated by variable stiffness springs (Vanderborght et al., Reference Vanderborght, Albu-Schaeffer, Bicchi, Burdet, Caldwell, Carloni, Catalano, Eiberger, Friedl, Ganesh, Garabini, Grebenstein, Grioli, Haddadin, Hoppner, Jafari, Laffranchi, Lefeber, Petit, Stramigioli, Tsagarakis, Van Damme, Van Ham, Visser and Wolf2013; Shepherd and Rouse, Reference Shepherd and Rouse2017), variable transmissions (Mooney and Herr, Reference Mooney and Herr2013; Tran et al., Reference Tran, Gabert, Cempini and Lenzi2019), multispeed gearboxes (Sugar and Holgate, Reference Sugar and Holgate2013) or multimotor solutions (Verstraten et al., Reference Verstraten, Furnémont, López-García, Crispel, Vanderborght and Lefeber2019), which allow the relationship between the required output torque and the spring characteristic to be shaped depending on the task. However, these solutions require additional motors or mechanisms, which increase the weight of the actuator. The metabolic penalty resulting from the additional weight can be avoided by remote actuation through, for example, cable- or wire-based transmissions, as implemented in several rehabilitation exoskeletons (Veneman et al., Reference Veneman, Ekkelenkamp, Kruidhof, van der Helm and van der Kooij2006; Mao and Agrawal, Reference Mao and Agrawal2012). In portable devices, these transmissions can decrease metabolic cost by enabling a more proximal placement of the actuators, near the human’s center of mass (Asbeck et al., Reference Asbeck, De Rossi, Holt and Walsh2015).

Motor and gearbox technologies continue to improve and these improvements will promote further adoption of wearable robots in the near future. However, commercial devices for specific and simple tasks (e.g., occupational exoskeletons) may very well continue to rely on passive solutions until actuators with superior torque densities and energy efficiencies become available. The major breakthrough may arrive through the development of radically new actuator technologies such as dielectric elastomer actuators (Veale and Xie, Reference Veale and Xie2016). Until these technologies reach a mature state, we expect that advances will most likely come from specialized actuator designs as those described in this section.

Sensing

Wearable robots require advanced sensors so that they can determine the user’s actual and intended motions, determine the state of the robot itself, and use this information as a basis for robot control. Any limitations in the sensing lead to suboptimal control, which limits the overall performance of the wearable robot. These limitations can occur at one of two levels: at the lower level of individual sensors and at the higher level of multisensor fusion.

Sensor Hardware and Low-Level Processing

While wearable robot sensors suffered from significant noise-related issues in the past, extensive work has been done to address them. Challenges on the level of individual sensors now primarily involve addressing remaining gaps in knowledge related to specific sensor modalities, particularly those that are just becoming widespread in the field.

Wearable robot systems commonly include standard robot sensors integrated into the robot, such as joint encoders and strain gauges (Huang et al., Reference Huang, Cheng, Qiu and Zhang2019; Singer et al., Reference Singer, Maufroy and Schneider2020). Assuming that the robot is tightly attached to the wearer and its morphology matches the wearer, we can assume that human body kinematics can be obtained from robot body kinematics via a constant transformation (Sposito et al., Reference Sposito, Di Natali, Toxiri, Caldwell, De Momi and Ortiz2020). Commonly, pressure sensors are also built into points where the robot touches the wearer, allowing interaction forces between the wearer and robot to be measured. While these sensors have traditionally been rigid, soft sensors are becoming increasingly common in wearable robotics, potentially providing better robustness and comfort. For example, Chiaradia et al. (Reference Chiaradia, Xiloyannis, Antuvan, Frisoli and Masia2018) used soft strain sensors to monitor robot joint angles instead of traditional rigid encoders, and Kim et al. (Reference Kim, Kwon, Han, Park and Jo2019a,Reference Kim, Lee, Heimgartner, Arumukhom Revi, Karavas, Nathanson, Galiana, Eckert-Erdheim, Murphy, Perry, Menard, Choe, Malcolm and Walshb) combined deep learning with a full suit of soft strain sensors to extract full-body kinematics. Most soft strain sensors are resistive (i.e., change resistance in response to strain), though capacitive and optical sensors have also been developed for wearable robotics (Atalay et al., Reference Atalay, Sanchez, Atalay, Vogt, Haufe, Wood and Walsh2017; Jin et al., Reference Jin, Glover, Cho, Araromi, Graule, Li, Wood and Walsh2020; Kim et al., Reference Kim, Lee, Hong, Shin, Kim and Park2020). Such soft sensors will probably never entirely replace rigid sensors (since soft technologies are not needed in all applications), but are likely to be a major aspect of the next generation of wearable robotics. One limitation they currently face is that the soft sensors generally still need to be connected to “hard” electronics, though such electronic components will likely become more integrated into soft materials over the next few years as well (Sanchez et al., Reference Sanchez, Walsh and Wood2021).The weakness of sensors built into the robot is that they only obtain knowledge about wearer body parts that are attached to the wearable robot and that they require the wearer to either already move the robot (in the case of position sensors) or apply forces to the robot (in the case of force sensors) before the robot can react, reducing its assistive benefits. The latter weakness can be reduced by reducing the amount of wearer force/movement required to trigger robotic assistance, but this may cause false positives (Novak and Riener, Reference Novak and Riener2015; Tucker et al., Reference Tucker, Olivier, Pagel, Bleuler, Bouri, Lambercy, Millán, Riener, Vallery and Gassert2015). To obtain a more complete picture of the wearer, wearable robots are thus commonly augmented with two types of sensors: inertial measurement units (IMUs) and electromyography (EMG) sensors.

IMUs consist of accelerometers, gyroscopes, and (optionally) magnetometers, whose outputs can be combined to obtain IMU orientation. IMU technology is cheap and can be easily attached to wearers; thus, it is commonly placed on parts of the body not connected to the wearable robot—for example, in a leg exoskeleton, an IMU can be placed on the arm or trunk (Lazzaroni et al., Reference Lazzaroni, Tabasi, Toxiri, Caldwell, De Momi, van Dijk, de Looze, Kingma, van Dieën and Ortiz2020). Alternatively, the IMUs can be embedded in the robot itself, providing an alternative to classic robot sensors (Naseri et al., Reference Naseri, Grimmer, Seyfarth and Ahmad Sharbafi2020). As the individual components of the IMU tend to have noisy outputs, obtaining IMU orientation requires the use of techniques such as Kalman filtering (Nazarahari and Rouhani, Reference Nazarahari and Rouhani2021). IMUs that incorporate magnetometers are generally accurate in magnetically homogenous environments, as the magnetometer provides a reference estimate of magnetic north. In real-world environments with magnetic disturbances, however, IMU noise increases significantly and requires the use of advanced compensation algorithms (Slajpah et al., Reference Slajpah, Kamnik and Munih2017; Wittmann et al., Reference Wittmann, Lambercy and Gassert2019). These algorithms are present in high-grade IMU systems and can be transferred to lower-cost IMUs, but are not present in such off-the-shelf devices by default.

EMG sensors measure the electrical activity of human muscles using electrodes placed on the skin. EMG levels are proportional to muscle contraction levels, but appear prior to mechanical contraction, allowing the wearer’s intentions to be anticipated (Novak and Riener, Reference Novak and Riener2015). EMG can also be combined with measurements such as joint angles to obtain estimates of muscle dynamics and torque (Lotti et al., Reference Lotti, Xiloyannis, Durandau, Galofaro, Sanguineti, Masia and Sartori2020). Furthermore, if the wearer is too weak to move their limb themselves, EMG may still allow motion intention to be detected and the wearable robot to be moved accordingly (Yun et al., Reference Yun, Na, Esmatloo, Dancausse, Serrato, Merring, Agarwal and Deshpande2020). Additionally, EMG can be used as an effectiveness measure of the wearable robot: since wearable robots are meant to support the wearer and reduce human workload, reductions in EMG level can be considered proportional to reductions in human muscle demand (Goršič et al., Reference Goršič, Song, Dai and Novak2021; Kermavnar et al., Reference Kermavnar, de Vries, de Looze and O’Sullivan2021). However, EMG measurements also suffer from significant variability, both intersubject (due to, e.g., different fitness levels) and intrasubject (due to, e.g., fatigue and sweat); they are also prone to noise due to mechanical movement and electromagnetic interference. Methods to reduce noise have been demonstrated in the literature (Gokcesu et al., Reference Gokcesu, Ergeneci, Ertan and Gokcesu2019), but not adequately transferred to wearable robotics. Similarly, alternatives to EMG such as mechanomyography and force myography (Xiao and Menon, Reference Xiao and Menon2019) have promise as a less noisy measurement approach, but have seen limited use in wearable robotics.

Aside from these common sensor modalities, many others have been used in wearable robotics to a lesser degree but suffer from low accuracy, difficulty of incorporating into real-time control, or simply lack of evidence. For example, brain measurements (e.g., electroencephalography [EEG]) can be used to infer the wearer’s intended motions without any muscle activation, which could be used to control wearable robots for people with disabilities who cannot move on their own. Unfortunately, such brain measurements provide only limited information (e.g., left vs. right arm movement), and their utility as a stand-alone method is thus questionable except for severely paralyzed individuals (AL-Quraishi et al., Reference AL-Quraishi, Elamvazuthi, Daud, Parasuraman and Borboni2018); however, they could potentially be combined with more popular modalities such as EMG (Li et al., Reference Li, Yuan, Luo, Su, Zhao, Xu, Huang and Pi2019). As another example, heart rate, respiration and other physiological measures are commonly used as a metric of wearer workload (physical or mental) and thus robot performance (Torricelli et al., Reference Torricelli, Rodriguez-Guerrero, Veneman, Crea, Briem, Lenggenhager and Beckerle2020), and could be used to adapt the amount of robot assistance; however, while studies have suggested complex approaches to doing this (Schürmann et al., Reference Schürmann, Mohler, Peters and Beckerle2019), only limited work in this area has been done, mostly with stationary wearable robots (e.g., the Lokomat) (Koenig et al., Reference Koenig, Novak, Omlin, Pulfer, Perreault, Zimmerli, Mihelj and Riener2011a,Reference Koenig, Omlin, Bergmann, Zimmerli, Bolliger, Müller and Rienerb).

Finally, a particularly promising case of underexplored sensors should be acknowledged: all the above sensors are meant to obtain information about the wearer. However, sensors for wearable robots should also obtain information about the environment—for example, possible obstacles in the path of a person wearing a leg exoskeleton, or objects that a person wearing an arm exoskeleton may wish to manipulate. Work on such “exteroceptive” sensors has been done in multiple areas of wearable robotics. For example, in lower limb prosthetics, researchers have used depth sensors to identify obstacles in the user’s path (Liu et al., Reference Liu, Wang and Huang2016; Zhang et al., Reference Zhang, Tran and Huang2019) and segment stairs in the user’s path (Krausz et al., Reference Krausz, Lenzi and Hargrove2015); similar approaches have been used in lower limb exoskeletons (Laschowski et al., Reference Laschowski, McNally, Wong and McPhee2020) and upper limb prosthetics (Shi et al., Reference Shi, Yang, Zhao and Liu2020; Mouchoux et al., Reference Mouchoux, Carisi, Dosen, Farina, Schilling and Markovic2021). Nonetheless, further work is critically needed to incorporate environment sensing into wearable robot sensing and control.

Sensor Fusion

Sensor fusion refers to the process of combining data from multiple sensors into an estimate of the user’s motor intention or physical state; the main challenge with such fusion is that existing methods are not sufficiently robust for real-world use. Existing algorithms range from simple thresholding (e.g., activate assistance if user bends forward) to more complex approaches based on classification and regression using machine learning (Novak and Riener, Reference Novak and Riener2015; Tucker et al., Reference Tucker, Olivier, Pagel, Bleuler, Bouri, Lambercy, Millán, Riener, Vallery and Gassert2015). For example, classifiers can learn to identify desired gestures from EMG-based on a training dataset of previously recorded and manually labeled EMG data (Yun et al., Reference Yun, Na, Esmatloo, Dancausse, Serrato, Merring, Agarwal and Deshpande2020); similarly, regression algorithms can learn to estimate desired robot torque from ground reaction force (Naseri et al., Reference Naseri, Grimmer, Seyfarth and Ahmad Sharbafi2020) or EMG (Gui et al., Reference Gui, Liu and Zhang2019).

Such classification and regression have achieved high accuracies in laboratory experiments; however, the high accuracies in laboratory experiments (where conditions are largely stable and only a small set of wearer behaviors is expected) tend to not generalize to more chaotic real-world environments. For example, a wearable robot designed to support lifting tasks can, in a laboratory environment, simply classify wearer behavior as “lifting” or “not lifting,” and provide assistance only when the “lifting” class is detected (Hlucny and Novak, Reference Hlucny and Novak2020). In the real world, however, nonlifting behaviors can include a variety of actions, many of which may appear similar to lifting (e.g., squatting or stretching the arms). One possible solution is to first classify a common denominator movement, such as a pre-lift and in later stages distinguish lifting versus squatting (Jamšek et al., Reference Jamšek, Petrič and Babič2020). Alternatively, a multilevel sensor fusion algorithm is needed to first categorize the wearer’s behavior into broad classes, then more specific actions—for example, the three-level sensor fusion and control system proposed by Lazzaroni et al. (Reference Lazzaroni, Tabasi, Toxiri, Caldwell, De Momi, van Dijk, de Looze, Kingma, van Dieën and Ortiz2020) for back exoskeletons or the multilevel stumble detection system proposed by Zhang et al. (Reference Zhang, D’Andrea, Nunnery, Kay and Huang2011) for artificial legs. In such multilevel sensor fusion systems, the different levels may be based on different sensor types—for example, using information about walking terrain to switch between different EMG-based classifiers in a prosthesis (Liu et al., Reference Liu, Wang and Huang2016).

Additionally, advanced sensor fusion for wearable robots will likely need to incorporate aspects such as active and semi-supervised learning—the wearer may perform an action that the robot does not understand, and the robot must then decide whether to actively query the wearer about what they are trying to do (which may interrupt the intended action) or try to identify the action on its own (which may be inaccurate). In both cases, the robot then needs to adapt its sensor fusion rules so that it can deal with this new motion in the future. This may involve a significant but reasonable adaptation—for example, if the baseline of one of the sensors has drifted and the sensor data are thus a shifted version of previously seen data. In such cases, several authors have presented online learning strategies that can adapt robot sensor fusion rules (Spanias et al., Reference Spanias, Simon, Finucane, Perreault and Hargrove2018; Gui et al., Reference Gui, Liu and Zhang2019; Hu et al., Reference Hu, Simon and Hargrove2019; Huang et al., Reference Huang, Cheng, Qiu and Zhang2019; Zheng et al., Reference Zheng, Wang and Qiao2019). It may, however, involve a major change to the sensor fusion rules—for example, the observed action may be an entirely new type of motion, and the robot may then need to add it to its “dictionary” of possible motions. This challenge of dealing with numerous possible wearer behaviors, some of which may be unknown to the robot, represents a major challenge in wearable robotics, and improvements in this area have an immense potential.

Finally, advanced sensor fusion for wearable robots will need to consider advanced planning that does not rely on physical contact between the robot and environment. Such advanced planning can be done using, for example, the depth sensors discussed in the previous section, but remains largely underexplored (Krausz et al., Reference Krausz, Hu and Hargrove2019).

Wearable robots have made enormous strides in sensing hardware and software. Sensors can be unobtrusively integrated into the robot and/or placed on the wearer, and information from diverse sensors can be integrated into a reasonably accurate estimate of the wearer’s current and intended activity as well as physical state. While improvements can be made on the level of individual sensors (e.g., reducing IMU noise in magnetically nonhomogenous environments), we believe that the greatest gains can be made through broader adoption of less popular sensor modalities (e.g., environment sensors) and on the level of sensor fusion (e.g., multilevel sensor fusion and semisupervised learning). Such improvements will allow wearable robots to be effectively used in dynamic, unpredictable environments where they can have a major effect on human wellbeing and productivity.

Body Interface

Wearable robots cannot provide any benefits if humans do not use them. State-of-the-art wearable robots can effectively reduce workload; however, limitations related to user comfort and acceptance are a major remaining barrier to widespread use (Kermavnar et al., Reference Kermavnar, de Vries, de Looze and O’Sullivan2021), together with high cost. It was recognized in early exoskeleton research that a certain amount of discomfort was experienced by the users (Abdoli-E and Stevenson, Reference Abdoli-E and Stevenson2008; Wehner et al., Reference Wehner, Rempel and Kazerooni2009), while newer models have been reported to minimize this discomfort to a tolerable level (Sirawattanakul and Sanngoen, Reference Sirawattanakul and Sanngoen2020; Kermavnar et al., Reference Kermavnar, de Vries, de Looze and O’Sullivan2021). Some wearable robots are heavy and bulky (Stadler et al., Reference Stadler, Altenburger, Schmidhauser, Scherly, Ortiz, Toxiri, Mateos and Masood2016; Näf et al., Reference Näf, Koopman, Baltrusch, Rodriguez-Guerrero, Vanderborght and Lefeber2018; García et al., Reference García, Crispel, Saerens, Verstraten and Lefeber2020), which can interfere with the user’s freedom of movement. Even with lighter models, a certain level of discomfort and movement hindrance has been reported (Baltrusch et al., Reference Baltrusch, van Dieën, van Bennekom and Houdijk2018; Goršič et al Reference Goršic, Regmi, Johnson, Dai and Novak2020). Inevitably, the unloading of one part of the body results in an increased loading (i.e., force) on another. In spinal exoskeletons, the reduction of the load to the back is typically achieved via increased loading to the lower limbs, which can be sometimes reflected in increased leg muscle activity (Luger et al., Reference Luger, Bär, Seibt, Rieger and Steinhilber2021) and discomfort to the chest area (Hensel and Keil, Reference Hensel and Keil2019), although back exoskeletons may also reduce leg activity (Bosch et al., Reference Bosch, van Eck, Knitel and de Looze2016; Jeong et al., Reference Jeong, Woo and Kong2020). In comparison, upper limb exoskeleton interfaces can increase the loading to the spine (Weston et al., Reference Weston, Alizadeh, Knapik, Wang and Marras2018). This trade-off, as well as the effects of wearable robots on task performance, discomfort and perceived freedom of movement, must be taken into account when designing wearable robots and studying their effects. While these functional and subjective aspects of wearable robots are increasingly being addressed, research is predominantly done in laboratory environments with healthy young male participants (Kermavnar et al., Reference Kermavnar, de Vries, de Looze and O’Sullivan2021). Therefore, on-field research with different groups is needed to support the development of body interfaces, suitable for broader population. Interface design has also begun to address the issue of load transfer to other body parts. One possible way to address this is by extending the legs of the exoskeleton all the way to the ground. For instance, a recent prototype of a semi-active exoskeleton, designed in this fashion, has been reported to decrease the activity of both back and leg muscles (Wang et al., Reference Wang, Wu, Zhang, Chen, Liu, Liu, Peng and Ma2021). Novel exoskeletons such as the Guardian XO (CRI Writers, Reference Writers2018), are also being developed to support immense loads without stressing any human body parts. On the other hand, back exoskeletons with good design seem to decrease the load to the legs in addition to unloading the back (Bosch et al., Reference Bosch, van Eck, Knitel and de Looze2016; Jeong et al., Reference Jeong, Woo and Kong2020).

Exoskeleton interfaces should enable efficient transmission of mechanical power without compromising user comfort. Langlois et al. (Reference Langlois, Moltedo, Bacek, Rodriguez-Guerrero, Vanderborght and Lefeber2018) have proposed three crucial design requirements that need to be fulfilled to achieve this. First, the attachment points of the device on the human body segments should be as distant to the joint as possible to reduce interaction forces (e.g., attachment points of the hip exoskeleton on the thighs should be as close to the knees as possible). At the same time, contact areas should generally be maximized. However, caution is needed as some parts of the body may be more sensitive to pressure and increasing the surface area may not be desirable in such cases. Next, the exoskeleton should be designed in a way that prevents interface migration (e.g., sliding along the user’s body), as misalignments caused by sliding commonly reduce power transmission efficiency (Langlois et al., Reference Langlois, Moltedo, Bacek, Rodriguez-Guerrero, Vanderborght and Lefeber2018). Power transmission is also increased with larger contact point stiffness (Asbeck et al., Reference Asbeck, De Rossi, Holt and Walsh2015; Langlois et al., Reference Langlois, Rodriguez-Cianca, Serrien, De Winter, Verstraten, Rodriguez-Guerrero, Vanderborght and Lefeber2020). This can be achieved by placing the contact points over the bony prominences, such as tibial surface in case of lower limb exoskeletons (Mooney and Herr, Reference Mooney and Herr2016) or pelvis bones in case of trunk exoskeletons (Näf et al., Reference Näf, Junius, Rossini, Rodriguez-Guerrero, Vanderborght and Lefeber2018). Alternatively, the pads can be tightly attached to the user, but this can cause discomfort. Keeping in mind the importance of contact point placement, prevention of interface migration and contact stiffness, the compactness of the design should not be overlooked. For instance, the additional inertia due to the device’s weight can increase actuation demands (Langlois et al., Reference Langlois, Moltedo, Bacek, Rodriguez-Guerrero, Vanderborght and Lefeber2018).

Wearable robots for industrial environments are usually designed primarily with a focus on load reduction during strenuous physical tasks such as load lifting, overhead work and trunk bending (de Looze et al., Reference de Looze, Bosch, Krause, Stadler and O’Sullivan2016; Bao et al., Reference Bao, Pan, Fang, Wu, Yu, Cai, Yu and Wan2019). However, to allow efficient work and freedom of movement, the interface should not interfere heavily with other movements such as walking, stair climbing and sitting down or standing up. Indeed, wearable robots often decrease performance in tasks that require quickness and range of motion (Kermavnar et al., 2020). While these aspects were partially addressed in earlier research (Wehner et al., Reference Wehner, Rempel and Kazerooni2009; Bosch et al., Reference Bosch, van Eck, Knitel and de Looze2016), assessments involving subjective reports have only recently been introduced (Kozinc et al., Reference Kozinc, Baltrusch, Houdijk and Šarabon2020a). Such subjective reports allow potential drawbacks of specific wearable robots, especially those related to the interface and discomfort, to be identified. For instance, specific contact points that exert pressure on the user or limit their range of motion can be identified and considered in subsequent design (Abdoli-Eramaki et al., Reference Abdoli-Eramaki, Stevenson, Reid and Bryant2007; Baltrusch et al., Reference Baltrusch, van Dieën, van Bennekom and Houdijk2018; Baltrusch et al., Reference Baltrusch, Houdijk, van Dieën and Kruif2021; Kozinc et al., Reference Kozinc, Baltrusch, Houdijk and Šarabon2020b). Identifying the drawbacks of state-of-the-art devices should help developers optimize subsequent models. One recent example of approaches to improve the exoskeleton interface is found in the SPEXOR spinal exoskeleton. Specifically, a self-aligning mechanism was integrated into the hip joint, which prevents the sliding of the interface (Näf et al., Reference Näf, Koopman, Baltrusch, Rodriguez-Guerrero, Vanderborght and Lefeber2018; Babič et al., Reference Babič, Petrič, Mombaur, Kingma, Bornmann, González-Vargas, Baltrusch, Šarabon and Houdijk2019). With such improvements, exoskeleton interfaces could become more user-friendly. Another possible consideration for interface improvement is the option to adjust and switch off the exoskeleton’s support (Babič et al., Reference Babič, Petrič, Mombaur, Kingma, Bornmann, González-Vargas, Baltrusch, Šarabon and Houdijk2019; Wang et al., Reference Wang, Wu, Zhang, Chen, Liu, Liu, Peng and Ma2021), which allows the user to freely and efficiently perform the tasks that do not require support (e.g., walking).

As mentioned, the unloading of one part of the body inevitably results in an increased loading somewhere else. For instance, the mechanism by which spinal exoskeletons contribute to reduced workload is generation of torque around the spine and/or the hips (Bosch et al., Reference Bosch, van Eck, Knitel and de Looze2016; Stadler et al., Reference Stadler, Altenburger, Schmidhauser, Scherly, Ortiz, Toxiri, Mateos and Masood2016; de Looze et al., Reference de Looze, Krause and O’Sullivan2017, Näf et al., Reference Näf, Junius, Rossini, Rodriguez-Guerrero, Vanderborght and Lefeber2018; Babič et al., Reference Babič, Petrič, Mombaur, Kingma, Bornmann, González-Vargas, Baltrusch, Šarabon and Houdijk2019; Kermavnar et al., 2020). Even though spinal exoskeletons are designed to compensate for relatively small amounts of required spinal torque (Näf et al., Reference Näf, Koopman, Baltrusch, Rodriguez-Guerrero, Vanderborght and Lefeber2018), this unloading of the spine results in increased levels of force (and consequently pressure) on the exoskeleton attachment sites on the body (i.e., distal thighs and shoulder girdle). Similar observations have been reported for upper limb (Huysamen et al., Reference Huysamen, Bosch, de Looze, Stadler, Graf and O’Sullivan2018) and lower limb (Luger et al., Reference Luger, Seibt, Cobb, Rieger and Steinhilber2019) exoskeletons. Therefore, it is crucial to consider discomfort and pain tolerance thresholds at typical attachment sites for wearable robotic devices, and to design the devices in a way that minimize the chances of these thresholds being reached. While many studies have investigated pain thresholds with algometry (Sterling, Reference Sterling2011), their relevance to wearable robotics is limited, as the surface of force application in case of standard algometry is typically set at 1 cm2 (Graven-Nielsen and Arendt-Nielsen, Reference Graven-Nielsen and Arendt-Nielsen2010). Potentially more useful evidence is found in studies using inflatable cuffs to induce pressure at different sites, typical for attachments of wearable robots to the human body (Kermavnar et al., Reference Kermavnar, Power, de Eyto and O’Sullivan2018). There are only two studies to date that explore this issue directly. Yandell et al. (Reference Yandell, Ziemnicki, McDonald and Zelik2020) applied the pressure to the human body with fabricated exosuit interfaces for the shoulders, thigh, and shank, and thereby provided normative data for discomfort thresholds. Similarly, Kozinc et al. (Reference Kozinc, Babič and Šarabon2021) applied a pressure using exoskeleton pads and straps to the thigh, pelvic and chest/shoulder areas. Exoskeleton developers are encouraged to consider these values during the design of wearable robots. One of the most important findings of both studies is the large (up to 10-fold) interindividual variability in discomfort thresholds. Thus, further studies should critically include sufficient sample sizes to encompass this variability. Additionally, an issue that remains largely unexplored is discomfort during longer-term use of exoskeletons (i.e., over a workday), where higher discomfort or pain levels might be seen due to temporal summation (Nie et al., Reference Nie, Arendt-Nielsen, Andersen and Graven-Nielsen2005).

It is unquestionable that wearable robots have the potential to increase work performance and reduce physical loads to the body. Some exoskeletons with inferior design and poor kinematic structures and human interfaces have been shown to reduce freedom of movement and increase discomfort, which hinders widespread use. On the other hand, several models have achieved high levels of support without compromising overall user experience. Recent advances in methods to assess functional performance and discomfort, as well as the availability of normative data on discomfort tolerance, should help the developers to design better interfaces in the future.

Control

When synthesizing controllers for advanced robotic systems, it is common to create a hierarchical controller scheme where high-, mid-, and low-level control actions are locally isolated from each other, thus providing a broader understanding of the control problem in question. Wearable robots and exoskeleton systems are no exceptions to that; it is important to separately plan these controllers on different levels so that interrelations between high-level decision-making, mid-level planning and low-level actuator control can be clearly identified (Jimenez-Fabian and Verlinden, Reference Jiménez-Fabián and Verlinden2012; Tucker et al., Reference Tucker, Olivier, Pagel, Bleuler, Bouri, Lambercy, Millán, Riener, Vallery and Gassert2015). In this section, we succinctly cover low- and mid-level controllers, while high-level control is discussed in the next section.

Low-Level Control

The central problem in low-level control is to achieve high-fidelity servo tracking for actuators. This problem can be addressed via two different strategies: (a) precise position control through the use of nonbackdrivable mechanisms and high-gain controllers, and (b) force and torque control. The latter has certain advantages in terms of safe and dependable physical human–robot interaction (Vallery et al., Reference Vallery, Veneman, van Asseldonk, Ekkelenkamp, Buss and van Der Kooij2008) while the former can guarantee performance metrics if trajectory tracking is prioritized (Ohnishi et al., Reference Ohnishi, Shibata and Murakami1996).

On one hand, force-controlled systems may require hardware-level modifications in actuators, for example, deployment of custom-built springs or strain gauges (Kashiri et al., Reference Kashiri, Malzahn and Tsagarakis2017) and thus lead to hardware complexity. On the other hand, position-controlled systems generally possess high mechanical impedance at the output and are therefore deemed inappropriate for wearable robots and exoskeleton systems other than except rehabilitation procedures such as passive trajectory tracking tasks (Brahmi et al., Reference Brahmi, Saad, Rahman and Ochoa-Luna2019). Although the list of pros and cons can be further extended, force controllability is essential to establish dependable human–robot interaction control (Haddadin et al., Reference Haddadin, Albu-Schäffer and Hirzinger2009).

To implement force control at the actuator level, most systems employ SEAs in which a spring is attached between the mechanical output and motor (Pratt and Williamson, Reference Pratt and Williamson1995); see the Section “Actuation.” The direct use of spring deflection feedback leads to instability issues (Pratt et al., Reference Pratt, Willisson, Bolton and Hofman2004). To obtain fine torque tracking with guaranteed stability, one could employ cascade control strategies (Vallery et al., Reference Vallery, Ekkelenkamp, van der Kooij and Buss2007), sliding mode with disturbance observer (Sariyildiz et al., Reference Sariyildiz, Mutlu and Yu2020), or other observer-based robust control methods that are readily available for online simulation (Ozcinar and Ugurlu, Reference Ozcinar and Ugurlu2021; Ugurlu et al. Reference Ugurlu, Sariyildiz, Talha Kansizoglu, Ozcinar and Coruk2021). To this end, observer-based techniques were proven to be effective in handling perturbations due to uncertainties and unknown environmental effects (Haninger et al., Reference Haninger, Asignacion and Oh2020).

The performance of low-level force control depends on several factors: for example, actuator bandwidth, whole-body system dynamics, sensor signal quality, inner loop (current, pressure, etc.) control bandwidth, unmodeled dynamics, and sampling rate. Yet, given a completed hardware setup, one of the major contributions of a control engineer is to obtain a sufficient description of actuator dynamics. Once a sufficiently descriptive mathematical model is obtained, one can achieve fine force tracking for robot joints with pneumatic muscles (Ugurlu et al., Reference Ugurlu, Forni, Doppmann, Sariyildiz and Morimoto2019), SEAs (Vallery et al., Reference Vallery, Ekkelenkamp, van der Kooij and Buss2007, Yildirim et al., Reference Yildirim, Kansizoglu, Sendur and Ugurlu2019), hydraulic systems (Otten et al., Reference Otten, Voort, Stienen, Aarts, van Asseldonk and van der Kooij2015) and variable impedance actuators (Kaneishi et al., Reference Kaneishi, Matthew and Tomizuka2018). Through a detailed mathematical model, sensorless torque control is possible even for robot joints with nonbackdrivable mechanisms (Ugurlu et al., Reference Ugurlu, Nishimura, Hyodo, Kawanishi and Narikiyo2015). With this in mind, we argue that the implementation of force control is possible for most of systems to an extent, although it may not be a trivial task.

In summary, low-level force control at the actuator level became a standard in the wearable robotics community and there is a significant amount of literature on the topic (van der Kooij et al., Reference van der Kooij, Veneman and Ekkelenkamp2006; Veale and Xie, Reference Veale and Xie2016). The use of SEAs is arguably the most common approach owing to its relatively simple mathematical model and practical feasibility. Regardless of the actuator type, it can be argued that there is no open research question in relation to low-level control; however, engineering problems do persist. For instance, the bandwidth of mid-level control strongly depends on the low-level controller (Buerger and Hogan, Reference Buerger and Hogan2007); thus, physical low-level controllers with deterministic real-time capability and higher sampling frequencies (~5 kHz) are required. Moreover, the integration of force sensing elements always introduces certain technical challenges to be overcome (Ham et al., Reference Ham, Sugar, Vanderborght, Hollander and Lefeber2009; Kim et al., Reference Kim, Kim, Seok, So, Lee and Choi2018a,Reference Kim, Kim, Seok, So, Lee and Choib; Yildirim et al., Reference Yildirim, Sendur, Kansizoglu, Uras, Bilgin, Emre, Yapici, Arik and Ugurlu2021).

Mid-Level Control

Mid-level controllers are mostly task-specific and built on the basis of realizable actuator commands. To this end, the output of a mid-level controller is usually a link torque or position command that must be attained by the low-level controller. As nearly all wearable robotics applications involve physical interaction, impedance/admittance control is widely used (Hogan, Reference Hogan1985). In basic terms, an impedance controller outputs a certain amount of force command to render a given mechanical impedance, thus requiring force control. An admittance controller performs the same duty; instead, its transfer function is the inverse of impedance controller and it outputs a certain amount of displacement that corresponds to the aforementioned force command to render mechanical impedance. In practical applications, admittance control is preferred mostly when force-controllable actuators are not available or the torque command is not accessible; however, its tuning is more challenging and usually entails complex algorithms (Zheng et al., Reference Zheng, Wang and Qiao2019).

Regardless of the impedance/admittance formulation, both controllers enable us to manage the trade-off between position and force tracking through the rendered output impedance. Hence, wearable robots for walking assistance need to possess active impedance control to cope with ground reaction during touch-down (Veneman et al., Reference Veneman, Kruidhof, Hekman, Ekkelenkamp, Van Asseldonk and van der Kooij2007). When employed via impedance approach with highly backdrivable robots (Lv et al., Reference Lv, Zhu and Gregg2018), or via admittance approach with nonbackdrivable robots (Ugurlu et al., Reference Ugurlu, Oshima, Sariyildiz, Narikiyo and Babic2020), the locomotion control performance sufficiently increases. However, in these locomotion scenarios, human subjects are considered to be passive and the robot completely handles the walking behavior, regardless of the user-intended forces.