1. Introduction

Aero-engine noise has been a critical issue for civil aviation, and a significant source for both the tonal and broadband noise originates from the fan-stage rotor–stator interaction, especially for modern high-bypass-ratio turbofan engines (Peake & Parry Reference Peake and Parry2012; Guo et al. Reference Guo, Thomas, Clark and June2019). In contrast with the conventional ways, the current novel trends to reduce fan noise may be categorized as two distinct methodologies: one is to fully make use of the interactions between sound sources and their propagation in a lined duct (Wang & Sun Reference Wang and Sun2010; Zhang et al. Reference Zhang, Wang, Du and Sun2019; Sun et al. Reference Sun, Wang, Du and Sun2022), offering a more real description to sound attenuation by including the reactions of acoustic propagation on sound sources; the other is to apply soft boundaries to stator vanes based on the application of the silent flight mechanism of owls. It is noted that the latter aspect is receiving increasing attention for both experimental and theoretical investigations. As a convenient way to introduce soft boundaries, porosity was first applied to a single aerofoil and studied both numerically (Tinetti Reference Tinetti2001; Teruna et al. Reference Teruna, Manegar, Avallone, Ragni, Casalino and Carolus2020, Reference Teruna, Avallone, Casalino and Ragni2021) and experimentally (Geyer, Sarradj & Fritzsche Reference Geyer, Sarradj and Fritzsche2010; Sarradj & Geyer Reference Sarradj and Geyer2014; Chaitanya et al. Reference Chaitanya, Joseph, Chong, Priddin and Ayton2020). Such an idea was later extended to cascade blades in order to reduce aero-engine noise (de Sousa Reference de Sousa2011; Ocker et al. Reference Ocker, Geyer, Czwielong, Krömer, Pannert, Merkel and Becker2021). In particular, a soft vane structure, which provides soft boundaries on fan stator vanes with reasonably small aerodynamic loss, is proposed by NASA (Elliott, Woodward & Podboy Reference Elliott, Woodward and Podboy2009; Jones et al. Reference Jones, Parrott, Sutliff and Hughes2009; Jones & Howerton Reference Jones and Howerton2016) to reduce rotor–stator interaction noise, and its experiments have shown promising results for potential applications in a real aero-engine. However, few studies have been made to understand the underlying mechanism of soft boundaries on cascade vanes, thus leading to little guidance for the optimum distribution of perforations in soft vane designs.

On the other hand, by the inspiration of bionics, much work has been developed to study the effects of porosity, particularly on aerofoil trailing edge noise reduction as a direct application of the mechanism for an owl's silent flight. Two-dimensional analytic models were established for a semi-infinite poroelastic plate (Jaworski & Peake Reference Jaworski and Peake2013) and for a finite aerofoil with a poroelastic extension (Ayton Reference Ayton2016), and lately with chordwise non-uniform porosity distributions (Ayton et al. Reference Ayton, Colbrook, Geyer, Chaitanya and Sarradj2021). Considerable noise reductions were observed, and a thorough review of the investigations into the silent flight of owls may be found in Jaworski & Peake (Reference Jaworski and Peake2020). Accordingly, with consideration of the cascade effect and duct geometry, the porous extension design proposed for the reduction of aerofoil broadband noise could in principle be transplanted on fan stator vanes to reduce rotor–stator interaction noise. Recently, Baddoo & Ayton (Reference Baddoo and Ayton2020) extended the two-dimensional (2-D) cascade model of Glegg (Reference Glegg1999) and Posson, Roger & Moreau (Reference Posson, Roger and Moreau2010) to first include soft boundaries corresponding to the permeable vanes. An analytic solution was obtained and solved using the Wiener–Hopf technique with consideration of multiple boundary conditions, and their discussions focused on the porosity-related complex boundary condition. However, due to the limitations of the Wiener–Hopf method, their current model could neither include non-uniform porosity distributions on vanes nor account for the three-dimensionality in an annular cascade, which have already been shown in hard-vane cases to be important for the generation of rotor–stator interaction noise (Namba Reference Namba1987). Therefore, it is of great interest to establish a fully three-dimensional (3-D) model for the acoustic scattering by annular perforated cascades and to study the effects of porosity under three-dimensionally interacting conditions. In addition, it is expected that such a model can account for non-uniform distributions of porosity, and that the soft boundary on vane surfaces is interchangeable with other locally reacting soft boundary conditions.

There are two major approaches to obtain the aeroacoustic response of a cascade: one is the singularity method, which leads to an integral equation that can be solved numerically; the other is based on the Wiener–Hopf technique, whose solution can even be expressed as explicit results. For the singularity method, with the stators modelled as zero-thickness rigid plates, solutions for 2-D cascades were first established in different ways for unsteady aerodynamic and acoustic problems (Lane & Friedman Reference Lane and Friedman1958; Kaji & Okazaki Reference Kaji and Okazaki1970; Smith Reference Smith1972). Fully 3-D lifting surface methods were then developed by Namba (Reference Namba1972, Reference Namba1977, Reference Namba1987), Lordi & Homicz (Reference Lordi and Homicz1981) and Schulten (Reference Schulten1984, Reference Schulten1997). In these 3-D semi-analytic models, vanes are replaced by surface distributed dipole sources, namely lifting surfaces. The effects of the swept and leaned vane design were studied further (Schulten Reference Schulten1997; Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017), and the vane stagger angle and camber effects could also be included (Schulten Reference Schulten1984) if they are restricted to satisfy the small-perturbation condition. These 3-D lifting surface methods were later verified by the numerical solutions of the Euler equations (Prasad & Verdon Reference Prasad and Verdon2002), whilst the semi-analytic models have clear advantages in calculation speed. For the Wiener–Hopf technique (Noble Reference Noble1958), it was applied to investigate the transmission and reflection of acoustic waves in cascades (Mani & Horvay Reference Mani and Horvay1970; Koch Reference Koch1971, Reference Koch1983) at an early stage, and now it has been developed to analyse more physical problems related to the cascade aerodynamics and aeroacoustics (Peake Reference Peake1992; Glegg Reference Glegg1999; Evers & Peake Reference Evers and Peake2002). The Wiener–Hopf technique is more suitable for 2-D analysis. However, to better understand the significant 3-D effects in annular cascades, it is necessary to adopt a fully 3-D acoustic scattering model instead of a strip theory based on 2-D solutions. The non-uniform distributions of the incident disturbance, the annular geometry of the cascade with duct wall reflections, and more importantly the 3-D interactions between different radial positions on vanes, should all be included and considered.

Additionally, a precise description of the surface impedance corresponding to the perforated vanes is also a necessity. One convenient way is to use the analytical methods based on the vortex-sound theory by introducing the concept of the Rayleigh conductivity, as summarized in Howe (Reference Howe1998). Further numerical approaches include the application of the discrete vortex methods (Jing & Sun Reference Jing and Sun2000; Dai, Jing & Sun Reference Dai, Jing and Sun2014; Hong et al. Reference Hong, Wang, Jing and Sun2020) and direct numerical simulations based on the Navier–Stokes equations (Tam et al. Reference Tam, Ju, Jones, Watson and Parrott2010). The common mechanism elucidated by these models is the sound-vortex energy conversion caused by the mean velocity through orifices under the incidence of acoustic waves, and this conversion should also affect the acoustic scattering process of perforated cascades under vortical disturbances. In this paper, however, we focus on the general effects of porosity and use designated values of the Rayleigh conductivity for the soft boundary condition on vanes for simplicity.

The present work develops a 3-D lifting surface theory for annular cascades with soft boundary vanes. Our model provides the relationship between the inlet disturbance field and the perforated vane unsteady loading, which is the dominant sound source. It is discovered that the porosity not only reduces the absolute magnitude of the responding unsteady loading on vanes, but also mitigates the interactions between different positions on vanes. In particular, it dampens the coupling among the unsteady loading at different radial positions. This can greatly change the resulting distribution of the unsteady pressure loading, and one interesting phenomenon is that with a radially constant-amplitude but phase-varying incident rotor wake, the radial phase variation of the responding unsteady loading on the perforated vanes is more similar to that of the incident wake compared to a hard-vane acoustic response. The amplitude distribution of the unsteady loading is also radially more uniform. In other words, the so-called 3-D effects in a hard-vane cascade acoustic scattering process are partly weakened by the porosity applied on the vanes. This may shed some light on the future application of porosity to utilize such characteristics to achieve better noise reduction results. Moreover, a prediction of the turbulence–cascade interaction broadband noise (as in Zhang, Wang & Sun Reference Zhang, Wang and Sun2015) using the acoustic response function established in this paper may better exploit such effects.

The rest of the paper is organized as follows. We establish our model using the singularity method in § 2, with discussions on source terms illustrating that the primary sound source is the unsteady pressure loading on the vanes. The numerical solution process of the governing integral equation is then given in § 3. In § 4, we validate our solution in two ways, by comparing with both the previous hard-vane lifting surface theory (Namba & Schulten Reference Namba and Schulten2000) and the 2-D soft-vane model based on the Wiener–Hopf method (Baddoo & Ayton Reference Baddoo and Ayton2020). Solutions with both uniform and non-uniform porosity applied on the vanes are presented in § 5, demonstrating the important 3-D effects in the annular cascade. Finally, we give our conclusions in § 6. The code used for the solutions of this research is available at https://github.com/t2206/3DporoCascade.

2. Modelling with singularity method

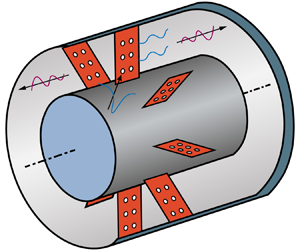

Consider an annular stator cascade of ![]() $V$ vanes inside an infinite hard-walled duct with a uniform subsonic axial mean flow of inviscid perfect gas, as shown in figure 1. A cylindrical coordinate is taken, and the axial coordinate is denoted as

$V$ vanes inside an infinite hard-walled duct with a uniform subsonic axial mean flow of inviscid perfect gas, as shown in figure 1. A cylindrical coordinate is taken, and the axial coordinate is denoted as ![]() $z$. Coordinates with superscript

$z$. Coordinates with superscript ![]() $'$ represent the coordinates of the source point, and the coordinates without

$'$ represent the coordinates of the source point, and the coordinates without ![]() $'$ are those of the observation point. The cascade is of hub radius

$'$ are those of the observation point. The cascade is of hub radius ![]() $R_h$, tip radius

$R_h$, tip radius ![]() $R_d$, and chord length

$R_d$, and chord length ![]() $b$, with a background flow of axial velocity

$b$, with a background flow of axial velocity ![]() $U$ and no swirling flow. Porosity is applied to create soft boundaries on the vanes, and the stator vanes are assumed to be identical and evenly spaced zero-thickness perforated plates with zero stagger angle and no camber. The viscosity effects near the vanes are retained with the unsteady Kutta condition applied in the form of zero pressure jump at the trailing edge and an integrable pressure singularity at the leading edge. Incident waves could be either acoustic or vortical, assuming that the disturbances are small and isentropic. In this specific paper, however, we focus on the interaction noise with incident vortical disturbances. The trailing edge self-noise is neglected here.

$U$ and no swirling flow. Porosity is applied to create soft boundaries on the vanes, and the stator vanes are assumed to be identical and evenly spaced zero-thickness perforated plates with zero stagger angle and no camber. The viscosity effects near the vanes are retained with the unsteady Kutta condition applied in the form of zero pressure jump at the trailing edge and an integrable pressure singularity at the leading edge. Incident waves could be either acoustic or vortical, assuming that the disturbances are small and isentropic. In this specific paper, however, we focus on the interaction noise with incident vortical disturbances. The trailing edge self-noise is neglected here.

Figure 1. Schematic of an annular perforated cascade.

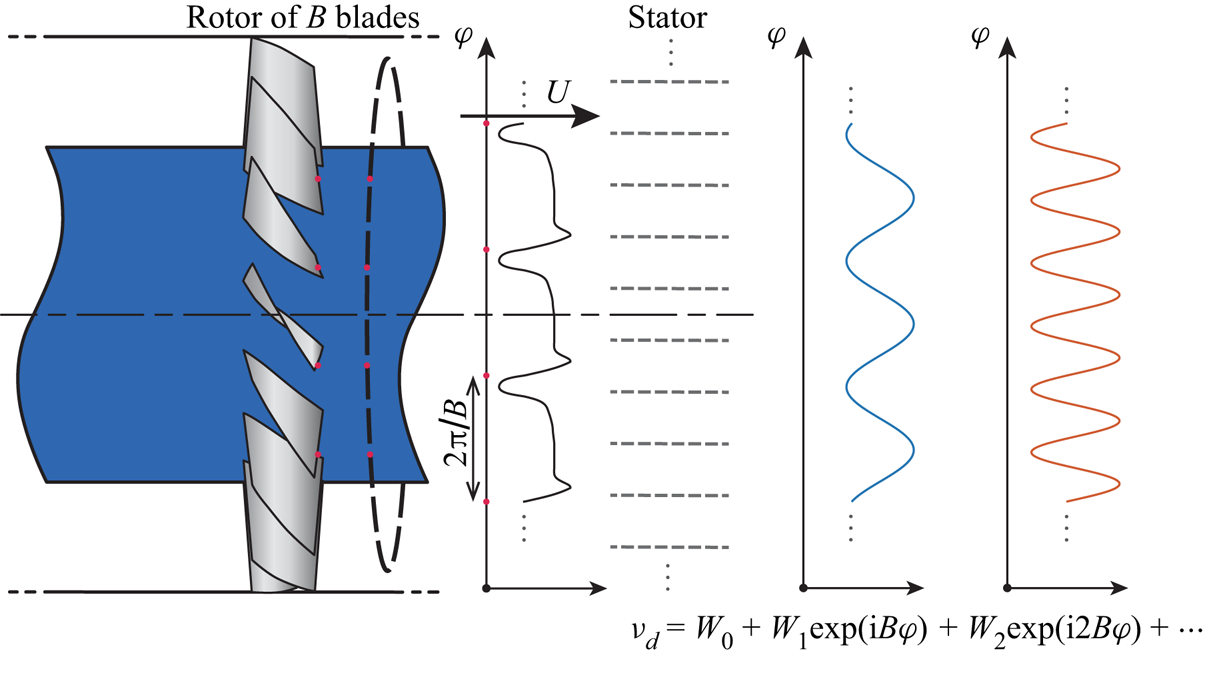

The rotor–stator interaction noise can be divided into two kinds: one is the interaction between the viscous wake of the rotor and the solid boundaries of the stator; the other is induced by the potential field of the rotor interacting with the stator. However, the potential field usually decays quickly in a turbofan-engine fan stage, therefore the rotor–stator interaction noise is dominated by the interactions caused by the viscous wake (Peake & Parry Reference Peake and Parry2012). In rotor-fixed cylindrical coordinates, the viscous wake of the rotor can be separated into a steady flow component and an unsteady component. In the steady flow field, each rotor blade will induce a velocity deficit behind it, and an evenly distributed rotor cascade of ![]() $B$ identical blades will create a velocity field with periodicity

$B$ identical blades will create a velocity field with periodicity ![]() $2{\rm \pi} /B$ in the circumferential direction, as illustrated in figure 2. Subsequently, the steady component of the rotor wake can be expanded into a Fourier's series of

$2{\rm \pi} /B$ in the circumferential direction, as illustrated in figure 2. Subsequently, the steady component of the rotor wake can be expanded into a Fourier's series of ![]() $\varphi$ in the form

$\varphi$ in the form

\begin{equation} \sum_{s=0}^{\infty}W_s(r,z) \exp({\mathrm{i}sB\varphi}), \end{equation}

\begin{equation} \sum_{s=0}^{\infty}W_s(r,z) \exp({\mathrm{i}sB\varphi}), \end{equation}

where ![]() $W_s(r,z)$ are the Fourier coefficients, and

$W_s(r,z)$ are the Fourier coefficients, and ![]() $\varphi$ is the circumferential coordinate;

$\varphi$ is the circumferential coordinate; ![]() $s$ is the order of the series. If we transform the velocity field to the stator-fixed coordinate system, then the

$s$ is the order of the series. If we transform the velocity field to the stator-fixed coordinate system, then the ![]() $s$th-order component will become

$s$th-order component will become

where ![]() $\varOmega$ is the angular rotation speed of the rotor. This corresponds to a fluctuating upwash velocity on vane surfaces at frequency

$\varOmega$ is the angular rotation speed of the rotor. This corresponds to a fluctuating upwash velocity on vane surfaces at frequency ![]() $\omega _s = sB\varOmega$, which will correspondingly induce pressure loading on vanes at the same frequency. Accordingly, the

$\omega _s = sB\varOmega$, which will correspondingly induce pressure loading on vanes at the same frequency. Accordingly, the ![]() $s=0$ part of the velocity Fourier series is responsible for the steady loading on stator vanes, while the other terms will interact with the stator cascade to create tonal noise at

$s=0$ part of the velocity Fourier series is responsible for the steady loading on stator vanes, while the other terms will interact with the stator cascade to create tonal noise at ![]() $s$ times the blade passing frequency. Hereafter, we consider the tonal interaction noise as an illustration of the noise reduction mechanism by perforations. As for the unsteady component of the rotor wake that is mostly related to the turbulences in the wake, it is responsible for the broadband rotor–stator interaction noise and might be investigated in future studies.

$s$ times the blade passing frequency. Hereafter, we consider the tonal interaction noise as an illustration of the noise reduction mechanism by perforations. As for the unsteady component of the rotor wake that is mostly related to the turbulences in the wake, it is responsible for the broadband rotor–stator interaction noise and might be investigated in future studies.

Figure 2. The steady component of the rotor wake velocity and its Fourier expansion over the circumferential direction. The Fourier components then interact with the stator cascade to produce tonal rotor–stator interaction noise.

2.1. Discussion on sound source terms

We derived our solution of the scattered field based on the generalized Lighthill's equation by Goldstein (Reference Goldstein1976, pp. 189–192), which extends Lighthill's acoustic analogy (Lighthill Reference Lighthill1952) to include the effects of solid boundaries using the generalized Green's formula (a generalization of the usual Green's formula to wave equations in a uniformly moving medium). We choose ![]() $G$ to be the Green's function for the infinite rigid wall annular duct with a uniform subsonic axial background flow, satisfying the wave equation in a medium of uniform axial velocity

$G$ to be the Green's function for the infinite rigid wall annular duct with a uniform subsonic axial background flow, satisfying the wave equation in a medium of uniform axial velocity ![]() $U$ and isentropic speed of sound denoted as

$U$ and isentropic speed of sound denoted as ![]() $c_0$, i.e.

$c_0$, i.e.

and a boundary condition of zero normal derivative at duct walls,

It is further required that ![]() $G$ satisfies the causality condition

$G$ satisfies the causality condition

In our case, the material derivative is

where ![]() $t$ is the observation time, and

$t$ is the observation time, and ![]() $\tau$ is the time of source;

$\tau$ is the time of source; ![]() $\boldsymbol {x},\boldsymbol {y}$ are respectively the spatial coordinate vectors of the observation point and the source point, and

$\boldsymbol {x},\boldsymbol {y}$ are respectively the spatial coordinate vectors of the observation point and the source point, and ![]() $z'$ is the axial coordinate in the source system.

$z'$ is the axial coordinate in the source system.

In the cylindrical coordinate system illustrated in figure 1, the Green's function for a subsonic axial flow in a hard-walled annular duct can be expressed as (Sun & Wang Reference Sun and Wang2021, pp. 92–98)

\begin{align} &G(r,\varphi,z,t\mid r',\varphi',z',\tau) =\frac{1}{4{\rm \pi}^2}\sum_{m={-}\infty}^{+\infty}\sum_{n=1}^{+\infty} \frac{\phi_m(k_{mn}r)\,\phi_m(k_{mn}r')}{2{\rm \pi}} \exp({\mathrm{i}m\varphi}) \exp({-\mathrm{i}m\varphi'}) \nonumber\\ &\quad \times \int_{-\infty}^{+\infty} \int_{-\infty}^{+\infty} \frac{\exp({\mathrm{i}\alpha(z-z')})}{\beta^2\alpha^2 + 2Mk_0\alpha-k_0^2+k_{mn}^2} \exp({-\mathrm{i}\omega(t-\tau)})\,\mathrm{d}\alpha\,\mathrm{d}\omega, \end{align}

\begin{align} &G(r,\varphi,z,t\mid r',\varphi',z',\tau) =\frac{1}{4{\rm \pi}^2}\sum_{m={-}\infty}^{+\infty}\sum_{n=1}^{+\infty} \frac{\phi_m(k_{mn}r)\,\phi_m(k_{mn}r')}{2{\rm \pi}} \exp({\mathrm{i}m\varphi}) \exp({-\mathrm{i}m\varphi'}) \nonumber\\ &\quad \times \int_{-\infty}^{+\infty} \int_{-\infty}^{+\infty} \frac{\exp({\mathrm{i}\alpha(z-z')})}{\beta^2\alpha^2 + 2Mk_0\alpha-k_0^2+k_{mn}^2} \exp({-\mathrm{i}\omega(t-\tau)})\,\mathrm{d}\alpha\,\mathrm{d}\omega, \end{align}

where ![]() $\phi _m(k_{mn}r)$ is the normalized radial eigenfunction of the hard-walled annular duct (see Sun & Wang Reference Sun and Wang2021, pp. 95–98) satisfying the orthogonality as

$\phi _m(k_{mn}r)$ is the normalized radial eigenfunction of the hard-walled annular duct (see Sun & Wang Reference Sun and Wang2021, pp. 95–98) satisfying the orthogonality as

and ![]() $k_{mn}$ is the corresponding eigenvalue of the circumferential mode

$k_{mn}$ is the corresponding eigenvalue of the circumferential mode ![]() $m$ and radial mode

$m$ and radial mode ![]() $n$ (in our notation,

$n$ (in our notation, ![]() $n=1,2,3,\ldots$). Accordingly, duct modes are denoted as

$n=1,2,3,\ldots$). Accordingly, duct modes are denoted as ![]() $(m,n)$. Here,

$(m,n)$. Here, ![]() $M=U/c_0$ is the Mach number of the background flow, and

$M=U/c_0$ is the Mach number of the background flow, and ![]() $k_0=\omega /c_0$ is the wavenumber of sound;

$k_0=\omega /c_0$ is the wavenumber of sound; ![]() $\beta$ is taken to be the Prandtl–Glauert transformation factor as

$\beta$ is taken to be the Prandtl–Glauert transformation factor as ![]() $\beta = \sqrt {1-M^2}$. By selecting this Green's function, the hard-walled duct modes will be included explicitly in the expression of the scattered pressure field, thus simplifying the following aeroacoustic analysis. The boundaries of the vanes are not included in the derivation of the Green's function, and will be considered later when establishing the integral equation using the singularity method.

$\beta = \sqrt {1-M^2}$. By selecting this Green's function, the hard-walled duct modes will be included explicitly in the expression of the scattered pressure field, thus simplifying the following aeroacoustic analysis. The boundaries of the vanes are not included in the derivation of the Green's function, and will be considered later when establishing the integral equation using the singularity method.

We then ignore the insignificant quadrupole volume source term (Goldstein Reference Goldstein1976, pp. 220–222) in the generalized Lighthill's equation to obtain the scattered pressure field in the form

\begin{equation}

p'(\boldsymbol{x},t)=\int_{{-}T}^T\int_{S(\tau)}

\frac{\partial G}{\partial y_i}\,f_i

\,\mathrm{d}S(\boldsymbol{y})\,\mathrm{d} \tau +

\int_{{-}T}^T\int_{S(\tau)}\rho_0V_n'\,\frac{\mathrm{D}_0

G}{\mathrm{D}\tau}\, \mathrm{d}

S(\boldsymbol{y})\,\mathrm{d} \tau,\quad T\rightarrow\infty

. \end{equation}

\begin{equation}

p'(\boldsymbol{x},t)=\int_{{-}T}^T\int_{S(\tau)}

\frac{\partial G}{\partial y_i}\,f_i

\,\mathrm{d}S(\boldsymbol{y})\,\mathrm{d} \tau +

\int_{{-}T}^T\int_{S(\tau)}\rho_0V_n'\,\frac{\mathrm{D}_0

G}{\mathrm{D}\tau}\, \mathrm{d}

S(\boldsymbol{y})\,\mathrm{d} \tau,\quad T\rightarrow\infty

. \end{equation}

The first integration term corresponds to the dipole sources, and the second integration term corresponds to the monopoles, as illustrated in 3(a). Here, vector ![]() $f_i$ represents the surface force acting on the fluid by the boundaries, and

$f_i$ represents the surface force acting on the fluid by the boundaries, and ![]() $V_n'$ is the normal velocity of the boundary surfaces relative to the mean flow, with

$V_n'$ is the normal velocity of the boundary surfaces relative to the mean flow, with ![]() $\rho _0$ being the density of the background flow. Also,

$\rho _0$ being the density of the background flow. Also, ![]() $\pm T$ are the upper and lower limits of the time integral, with

$\pm T$ are the upper and lower limits of the time integral, with ![]() $T$ taken to be infinity when Green's formula is used. Additionally, the surface integral

$T$ taken to be infinity when Green's formula is used. Additionally, the surface integral ![]() $\int _{S(\tau )}(\,\cdot\,)\,\mathrm {d}S(\boldsymbol {y})$ needs to be performed only on the vane surfaces, since in a hard-walled duct, both terms at the duct surfaces can be eliminated due to the inviscid flow assumption, the selection of the Green's function and the impenetrable boundary condition at duct walls (Goldstein Reference Goldstein1976, pp. 192–195).

$\int _{S(\tau )}(\,\cdot\,)\,\mathrm {d}S(\boldsymbol {y})$ needs to be performed only on the vane surfaces, since in a hard-walled duct, both terms at the duct surfaces can be eliminated due to the inviscid flow assumption, the selection of the Green's function and the impenetrable boundary condition at duct walls (Goldstein Reference Goldstein1976, pp. 192–195).

Figure 3. Illustration of (a) sources on the perforated plate and (b) the Rayleigh conductivity model.

With the ![]() $s$th-order component of the rotor wake disturbance at frequency

$s$th-order component of the rotor wake disturbance at frequency ![]() $\omega _s$ as the incident wave, the induced pressure jump across the vane can correspondingly be written as

$\omega _s$ as the incident wave, the induced pressure jump across the vane can correspondingly be written as

Here, we use the superscripts ![]() $(\pm )$ to distinguish the two surfaces of the stator vane, and we define the upper side (

$(\pm )$ to distinguish the two surfaces of the stator vane, and we define the upper side (![]() $+$) as the surface with the larger circumferential coordinate, and the lower side (

$+$) as the surface with the larger circumferential coordinate, and the lower side (![]() $-$) as the surface with the smaller circumferential coordinate. The only dominant source of the surface force

$-$) as the surface with the smaller circumferential coordinate. The only dominant source of the surface force ![]() $f_i^{(\pm )}$ is the pressure perturbation

$f_i^{(\pm )}$ is the pressure perturbation ![]() $P_s^{(\pm )}\exp ({-\mathrm {i}\omega _s \tau })$ on the upper side and the lower side of the vanes, because the shear stress is ignorable on the vane surfaces when the Reynolds numbers are high, as in practical aero-engines. The direction of the surface force

$P_s^{(\pm )}\exp ({-\mathrm {i}\omega _s \tau })$ on the upper side and the lower side of the vanes, because the shear stress is ignorable on the vane surfaces when the Reynolds numbers are high, as in practical aero-engines. The direction of the surface force ![]() $f_i^{(\pm )}$ then becomes normal to the vane surfaces. Unlike impermeable stator vanes on which

$f_i^{(\pm )}$ then becomes normal to the vane surfaces. Unlike impermeable stator vanes on which ![]() $V_n'$ is restricted to be zero, on porous vanes the unsteady loading

$V_n'$ is restricted to be zero, on porous vanes the unsteady loading ![]() ${\rm \Delta} P_s$ further produces fluctuating volume fluxes through perforations. These unsteady fluxes lead to a non-zero

${\rm \Delta} P_s$ further produces fluctuating volume fluxes through perforations. These unsteady fluxes lead to a non-zero ![]() $V_n'$ on both sides of the vane that may contribute to the monopole source term. However, under the assumption of zero-thickness vanes, the continuity across the apertures on the plate ensures that the normal velocities on the upper side (

$V_n'$ on both sides of the vane that may contribute to the monopole source term. However, under the assumption of zero-thickness vanes, the continuity across the apertures on the plate ensures that the normal velocities on the upper side (![]() $V_n'^{(+)}$) and the lower side (

$V_n'^{(+)}$) and the lower side (![]() $V_n'^{(-)}$) of the vanes are of the same absolute value but with opposite signs. Consequently, if

$V_n'^{(-)}$) of the vanes are of the same absolute value but with opposite signs. Consequently, if ![]() $h$ is the thickness of the vane, then the monopoles distributed on the two sides will form dipole-like structures with negligible dipole strength (

$h$ is the thickness of the vane, then the monopoles distributed on the two sides will form dipole-like structures with negligible dipole strength (![]() $|V_n'^{(\pm )}|\,h$) of

$|V_n'^{(\pm )}|\,h$) of ![]() ${O}(h)$, since on each side the monopole strength

${O}(h)$, since on each side the monopole strength ![]() $|V_n'^{(\pm )}|$ is finite, and the distance between the two poles goes to zero as

$|V_n'^{(\pm )}|$ is finite, and the distance between the two poles goes to zero as ![]() $h\rightarrow 0$.

$h\rightarrow 0$.

This indicates that for a thin-vane perforated cascade model with which we are concerned, the monopole source terms from the two sides of the vane are in opposite phase with the same magnitude, and will cancel each other out, with only the dipole-source-induced pressure fluctuations left in the far-field areas. Therefore, we can neglect the second term in (2.9) and deal with only the first term, i.e. the dipole source term. This is the same as in a hard-vane cascade fluid–structure interaction problem, and it greatly simplifies the expression for the scattered pressure field ![]() $p'(\boldsymbol {x},t)$. The stator vanes can correspondingly be modelled as dipole distributions using the acoustic analogy, and be replaced by lifting surfaces similar to a hard-vane situation (Namba Reference Namba1987; Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017), only with different boundary conditions on vanes. Again with the zero-thickness assumption, the integration of

$p'(\boldsymbol {x},t)$. The stator vanes can correspondingly be modelled as dipole distributions using the acoustic analogy, and be replaced by lifting surfaces similar to a hard-vane situation (Namba Reference Namba1987; Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017), only with different boundary conditions on vanes. Again with the zero-thickness assumption, the integration of ![]() $f_i$ on the two sides leaves only the pressure difference

$f_i$ on the two sides leaves only the pressure difference ![]() ${\rm \Delta} P_s$ (Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017). Consequently, the induced pressure field reduces to

${\rm \Delta} P_s$ (Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017). Consequently, the induced pressure field reduces to

\begin{equation} p'(\boldsymbol{x},t)=\int_{{-}T}^T\int_{S(\tau)} \frac{\partial G}{\partial n'}\, {\rm \Delta} P_s(\boldsymbol{y})\exp({-\mathrm{i}\omega_s \tau})\,\mathrm{d}S(\boldsymbol{y})\,\mathrm{d} \tau, \quad T\rightarrow\infty, \end{equation}

\begin{equation} p'(\boldsymbol{x},t)=\int_{{-}T}^T\int_{S(\tau)} \frac{\partial G}{\partial n'}\, {\rm \Delta} P_s(\boldsymbol{y})\exp({-\mathrm{i}\omega_s \tau})\,\mathrm{d}S(\boldsymbol{y})\,\mathrm{d} \tau, \quad T\rightarrow\infty, \end{equation}

where ![]() ${\partial }/{\partial n'}$ represents the derivative normal to the vane surfaces, and the integration domain of the surface integral

${\partial }/{\partial n'}$ represents the derivative normal to the vane surfaces, and the integration domain of the surface integral ![]() $\int _{S(\tau )}(\,\cdot \,)\,\mathrm {d}S(\boldsymbol {y})$ reduces to one plane at each vane's position instead of two planes at both the upper and lower sides. Additionally, in our model, where radially placed straight vanes are considered in a cylindrical coordinate system, the normal derivative

$\int _{S(\tau )}(\,\cdot \,)\,\mathrm {d}S(\boldsymbol {y})$ reduces to one plane at each vane's position instead of two planes at both the upper and lower sides. Additionally, in our model, where radially placed straight vanes are considered in a cylindrical coordinate system, the normal derivative ![]() ${\partial }/{\partial n'}$ is replaced by

${\partial }/{\partial n'}$ is replaced by ![]() ${\partial }/{(r'\,\partial \varphi ')}$.

${\partial }/{(r'\,\partial \varphi ')}$.

2.2. Boundary conditions

We have inherently applied a solid boundary condition on duct walls in the selection of the Green's function and a non-reflecting boundary condition on the upstream and downstream cross-sections by studying cascades in an infinite duct, as mentioned before. For the soft boundary vanes, we consider perforated plates with a rigid structure and evenly spaced circular apertures, which are modelled with the Rayleigh conductivity ![]() $K_R$. The porosity on the plates allows fluctuating volume fluxes across the apertures, resulting in a space-averaged normal velocity

$K_R$. The porosity on the plates allows fluctuating volume fluxes across the apertures, resulting in a space-averaged normal velocity ![]() $v_R=\tilde {v}_R \exp ({-\mathrm {i}\omega _s\tau })$ at the cascade vane surfaces, which is the physical velocity permitted by the soft boundary condition. The induced perturbation velocity normal to the vane surfaces is its circumferential component

$v_R=\tilde {v}_R \exp ({-\mathrm {i}\omega _s\tau })$ at the cascade vane surfaces, which is the physical velocity permitted by the soft boundary condition. The induced perturbation velocity normal to the vane surfaces is its circumferential component ![]() $v_\varphi ' = \tilde {v}'_\varphi \exp ({-\mathrm {i}\omega _s\tau })$ for the radially placed straight vanes that we studied. Let

$v_\varphi ' = \tilde {v}'_\varphi \exp ({-\mathrm {i}\omega _s\tau })$ for the radially placed straight vanes that we studied. Let ![]() $v_d=\tilde {v}_d \exp ({-\mathrm {i}\omega _s\tau })$ denote the normal disturbance velocity of the incident waves. Then on the vane surfaces, the porous plate boundary condition should be satisfied in the form

$v_d=\tilde {v}_d \exp ({-\mathrm {i}\omega _s\tau })$ denote the normal disturbance velocity of the incident waves. Then on the vane surfaces, the porous plate boundary condition should be satisfied in the form

or, after dropping the time factor, as

This boundary condition, along with the simplified generalized Lighthill's equation (2.11), is in principle sufficient to solve the problem with a given incident disturbance velocity ![]() $v_d$ if

$v_d$ if ![]() $v_R$ and

$v_R$ and ![]() $v_\varphi '$ are both related to the unknown dipole source on vanes, namely the unsteady pressure loading

$v_\varphi '$ are both related to the unknown dipole source on vanes, namely the unsteady pressure loading ![]() ${\rm \Delta} P_s$. The detailed expression of

${\rm \Delta} P_s$. The detailed expression of ![]() $v_\varphi '$ will be derived in § 2.3, and the relation of

$v_\varphi '$ will be derived in § 2.3, and the relation of ![]() ${v}_R$ to

${v}_R$ to ![]() ${\rm \Delta} P_s$ is discussed as follows. Note that (2.13) reduces to the impermeable boundary condition of a hard vane when

${\rm \Delta} P_s$ is discussed as follows. Note that (2.13) reduces to the impermeable boundary condition of a hard vane when ![]() $\tilde {v}_R=0$.

$\tilde {v}_R=0$.

For the rigid perforated vanes that we discussed, we first drop the fluctuating time factor ![]() $\exp ({-\mathrm {i}\omega _s\tau })$. Then the relation between the induced volume flux

$\exp ({-\mathrm {i}\omega _s\tau })$. Then the relation between the induced volume flux ![]() $Q$ through a single orifice from the lower (

$Q$ through a single orifice from the lower (![]() $-$) to the upper (

$-$) to the upper (![]() $+$) side, and the fluctuating pressure difference

$+$) side, and the fluctuating pressure difference ![]() ${\rm \Delta} P_s$ across the vane, may be described with the definition of the Rayleigh conductivity (Howe Reference Howe1998, § 5.3.1)

${\rm \Delta} P_s$ across the vane, may be described with the definition of the Rayleigh conductivity (Howe Reference Howe1998, § 5.3.1)

as illustrated in figure 3(b). The Rayleigh conductivity is ![]() $K_R = 2R$ for an ideal inviscid flow through circular apertures of radius

$K_R = 2R$ for an ideal inviscid flow through circular apertures of radius ![]() $R$ on a zero-thickness plate, with no tangential or bias mean flow. In more general situations such as that with a mean background flow, however,

$R$ on a zero-thickness plate, with no tangential or bias mean flow. In more general situations such as that with a mean background flow, however, ![]() $K_R$ is usually complex, and it is convenient to use its non-dimensionalized form

$K_R$ is usually complex, and it is convenient to use its non-dimensionalized form

where ![]() $\varGamma _R(\omega )$ and

$\varGamma _R(\omega )$ and ![]() $\varDelta _R(\omega )$ are real-valued functions of the frequency

$\varDelta _R(\omega )$ are real-valued functions of the frequency ![]() $\omega$, and

$\omega$, and ![]() $\varDelta _R(\omega )$ is related to the dissipation of the acoustic energy. Explicit expressions for

$\varDelta _R(\omega )$ is related to the dissipation of the acoustic energy. Explicit expressions for ![]() $K_R$ are unattainable for porous plates with tangential background flow (Howe Reference Howe1998, pp. 371–375), therefore we use designated values of conductivity to study the effects of soft-vane cascades for simplicity and to focus on the essential mechanisms of the noise reduction by porosity.

$K_R$ are unattainable for porous plates with tangential background flow (Howe Reference Howe1998, pp. 371–375), therefore we use designated values of conductivity to study the effects of soft-vane cascades for simplicity and to focus on the essential mechanisms of the noise reduction by porosity.

On the other hand, in order to extend the concept of the Rayleigh conductivity to the entire perforated vane with multiple apertures, the short-range interactions between orifices should be negligible, and this could be achieved by setting the distance ![]() $d$ between orifices much larger than the aperture radius

$d$ between orifices much larger than the aperture radius ![]() $R$. For evenly spaced perforations, this is usually ensured by restricting the fractional open area

$R$. For evenly spaced perforations, this is usually ensured by restricting the fractional open area ![]() $\alpha _H$ to be less than

$\alpha _H$ to be less than ![]() $0.04$ (Bendali et al. Reference Bendali, Fares, Piot and Tordeux2013). Another requirement to ensure a local reaction of the pressure jump is that the spacing

$0.04$ (Bendali et al. Reference Bendali, Fares, Piot and Tordeux2013). Another requirement to ensure a local reaction of the pressure jump is that the spacing ![]() $d$ should be less than half the sound wavelength

$d$ should be less than half the sound wavelength ![]() $\lambda$ (Bendali et al. Reference Bendali, Fares, Piot and Tordeux2013), which is achievable with a small-radius aperture design. Additionally, the orifice radius

$\lambda$ (Bendali et al. Reference Bendali, Fares, Piot and Tordeux2013), which is achievable with a small-radius aperture design. Additionally, the orifice radius ![]() $R$ should be small compared to the wavelength

$R$ should be small compared to the wavelength ![]() $\lambda$ such that the pressure difference

$\lambda$ such that the pressure difference ![]() ${\rm \Delta} P_s$ can be regarded as constant over the aperture. Note that in our case, where incident vortical disturbances are considered, the wavelength should be regarded as that of the scattered acoustic waves, i.e.

${\rm \Delta} P_s$ can be regarded as constant over the aperture. Note that in our case, where incident vortical disturbances are considered, the wavelength should be regarded as that of the scattered acoustic waves, i.e. ![]() $\lambda =2{\rm \pi} c_0/\omega _s$. With all the conditions satisfied, we may further average the volume fluxes

$\lambda =2{\rm \pi} c_0/\omega _s$. With all the conditions satisfied, we may further average the volume fluxes ![]() $Q$ in (2.14) using the fractional open area

$Q$ in (2.14) using the fractional open area ![]() $\alpha _H$ to smear them over the entire perforated plate surface, as was done in Hughes & Dowling (Reference Hughes and Dowling1990) and Baddoo & Ayton (Reference Baddoo and Ayton2020), and then obtain the fluctuating flow velocity normal to the vane surfaces as

$\alpha _H$ to smear them over the entire perforated plate surface, as was done in Hughes & Dowling (Reference Hughes and Dowling1990) and Baddoo & Ayton (Reference Baddoo and Ayton2020), and then obtain the fluctuating flow velocity normal to the vane surfaces as

since by continuity, ![]() ${v}_R$ should be equal to the averaged flux velocity induced by the unsteady pressure difference.

${v}_R$ should be equal to the averaged flux velocity induced by the unsteady pressure difference.

By referring to the definition of the acoustic impedance ![]() $p/v=z\rho _0 c_0$, we may further define an equivalent normalized impedance for the Rayleigh conductivity boundary condition with the fluctuation angular frequency

$p/v=z\rho _0 c_0$, we may further define an equivalent normalized impedance for the Rayleigh conductivity boundary condition with the fluctuation angular frequency ![]() $\omega _s$, expressed as

$\omega _s$, expressed as

2.3. Implementation of the lifting surface method

Hereafter, we assume that the incident disturbance has a circumferential periodicity and that its ![]() $s$th-order component wave has

$s$th-order component wave has ![]() $\sigma$ periods over one circle. (For the steady rotor wakes introduced before, we have

$\sigma$ periods over one circle. (For the steady rotor wakes introduced before, we have ![]() $\sigma =sB$.) The resulting pressure loading on a cascade of

$\sigma =sB$.) The resulting pressure loading on a cascade of ![]() $V$ identical evenly spaced vanes should consequently be in similar forms with a constant inter-blade phase angle difference

$V$ identical evenly spaced vanes should consequently be in similar forms with a constant inter-blade phase angle difference ![]() ${2{\rm \pi} \sigma }/{V}$ between the vanes. Label the vanes from

${2{\rm \pi} \sigma }/{V}$ between the vanes. Label the vanes from ![]() $1$ to

$1$ to ![]() $V$ as

$V$ as ![]() $\varphi '$ increases, and set

$\varphi '$ increases, and set ![]() ${\rm \Delta} P_s(r',z',\varphi ')\exp ({-\mathrm {i}\omega _s\tau })$ to be the unsteady loading distribution over the first vane. If the rotor is rotating in the positive direction of the circumferential coordinate, then the pressure jump on the

${\rm \Delta} P_s(r',z',\varphi ')\exp ({-\mathrm {i}\omega _s\tau })$ to be the unsteady loading distribution over the first vane. If the rotor is rotating in the positive direction of the circumferential coordinate, then the pressure jump on the ![]() $k$th stator vane would be

$k$th stator vane would be

and the corresponding circumferential coordinate on the ![]() $k$th vane is

$k$th vane is ![]() $\varphi ' + 2{\rm \pi} (k-1)/V$. Substituting the Green's function (2.7) into (2.11), and using the above periodicity of the unsteady loading on different vanes, we then have

$\varphi ' + 2{\rm \pi} (k-1)/V$. Substituting the Green's function (2.7) into (2.11), and using the above periodicity of the unsteady loading on different vanes, we then have

\begin{align} p'(\boldsymbol{x},t) &=

\frac{-\mathrm{i}}{8{\rm \pi}^3}\sum_{m={-}\infty}^{+\infty}

\sum_{n=1}^{+\infty}\phi_m(k_{mn}r)\exp({\mathrm{i}m\varphi})

\int_{S_1(\tau)}\sum_{k=1}^{V}\frac{m}{r'}

\phi_m(k_{mn}r')\exp({-\mathrm{i}m\varphi'}) \nonumber\\

&\quad

\times\exp\left({\mathrm{i}\,\frac{2{\rm \pi}}{V}\,(k-1)(\sigma-m)}\right)

\nonumber\\ &\quad \times{\rm \Delta} P_s(r',z',\varphi')

\int_{-\infty}^{+\infty} \exp({-\mathrm{i}\omega t})

\int_{-\infty}^{+\infty}

\frac{\exp({-\mathrm{i}\alpha(z-z')})}{\beta^2 +

2Mk_0\alpha - k_0^2+k_{mn}^2} \nonumber\\ &\quad

\times\int_{{-}T}^{T}

\exp({-\mathrm{i}\omega_s\tau})\exp({\mathrm{i}\omega

\tau})

\,\mathrm{d}\tau\,\mathrm{d}\alpha\,\mathrm{d}\omega\,\mathrm{d}S(\boldsymbol{y}),\quad

T\rightarrow\infty, \end{align}

\begin{align} p'(\boldsymbol{x},t) &=

\frac{-\mathrm{i}}{8{\rm \pi}^3}\sum_{m={-}\infty}^{+\infty}

\sum_{n=1}^{+\infty}\phi_m(k_{mn}r)\exp({\mathrm{i}m\varphi})

\int_{S_1(\tau)}\sum_{k=1}^{V}\frac{m}{r'}

\phi_m(k_{mn}r')\exp({-\mathrm{i}m\varphi'}) \nonumber\\

&\quad

\times\exp\left({\mathrm{i}\,\frac{2{\rm \pi}}{V}\,(k-1)(\sigma-m)}\right)

\nonumber\\ &\quad \times{\rm \Delta} P_s(r',z',\varphi')

\int_{-\infty}^{+\infty} \exp({-\mathrm{i}\omega t})

\int_{-\infty}^{+\infty}

\frac{\exp({-\mathrm{i}\alpha(z-z')})}{\beta^2 +

2Mk_0\alpha - k_0^2+k_{mn}^2} \nonumber\\ &\quad

\times\int_{{-}T}^{T}

\exp({-\mathrm{i}\omega_s\tau})\exp({\mathrm{i}\omega

\tau})

\,\mathrm{d}\tau\,\mathrm{d}\alpha\,\mathrm{d}\omega\,\mathrm{d}S(\boldsymbol{y}),\quad

T\rightarrow\infty, \end{align}

where the surface integral domain reduces to that of the first vane, ![]() $S_1(\tau )$. From the relations

$S_1(\tau )$. From the relations

\begin{equation} \left.\begin{gathered} \sum_{k=1}^{V}\exp\left[\mathrm{i}\,\frac{2{\rm \pi}}{V}\,(k-1)(\sigma-m)\right] =\left\{\begin{array}{ll} V, & m=\sigma-qV, \\ 0, & m\neq\sigma-qV, \end{array}\right. q=0,\pm1,\pm2,\ldots, \\ \lim_{T\rightarrow\infty}\int_{{-}T}^{T}\exp({-\mathrm{i}(\omega_s-\omega)\tau})\,\mathrm{d}\tau = 2{\rm \pi}\delta(\omega_s-\omega), \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \sum_{k=1}^{V}\exp\left[\mathrm{i}\,\frac{2{\rm \pi}}{V}\,(k-1)(\sigma-m)\right] =\left\{\begin{array}{ll} V, & m=\sigma-qV, \\ 0, & m\neq\sigma-qV, \end{array}\right. q=0,\pm1,\pm2,\ldots, \\ \lim_{T\rightarrow\infty}\int_{{-}T}^{T}\exp({-\mathrm{i}(\omega_s-\omega)\tau})\,\mathrm{d}\tau = 2{\rm \pi}\delta(\omega_s-\omega), \end{gathered}\right\} \end{equation}

and using the residue theorem for the infinite integration of the axial wave number ![]() $\alpha$ with the causality condition applied, the scattered sound field is related to the unsteady loading

$\alpha$ with the causality condition applied, the scattered sound field is related to the unsteady loading ![]() ${\rm \Delta} P_s$ on the first (

${\rm \Delta} P_s$ on the first (![]() $k=1$) vane by

$k=1$) vane by

\begin{align} p'(\boldsymbol{x},t) &= \frac{V\exp({-\mathrm{i}\omega_s t})}{4{\rm \pi}} \sum_{q={-}\infty}^{+\infty}\sum_{n=1}^{+\infty}\phi_m(k_{mn}r) \nonumber\\ &\quad \times\exp({\mathrm{i}m\varphi}) \int_{S_1(\tau)}\frac{m}{\kappa_{nm}r'}\, \phi_m(k_{mn}r')\exp({-\mathrm{i}m\varphi'})\,{\rm \Delta} P_s(r',z',\varphi') \nonumber\\ &\quad \times \left\{ H(z-z')\exp({\mathrm{i}\alpha_1(z-z')}) \right. \nonumber\\ &\qquad \left.{}+H(z'-z)\exp({\mathrm{i}\alpha_2(z-z')})\right\} \mathrm{d}S(\boldsymbol{y}),\quad m=\sigma-qV. \end{align}

\begin{align} p'(\boldsymbol{x},t) &= \frac{V\exp({-\mathrm{i}\omega_s t})}{4{\rm \pi}} \sum_{q={-}\infty}^{+\infty}\sum_{n=1}^{+\infty}\phi_m(k_{mn}r) \nonumber\\ &\quad \times\exp({\mathrm{i}m\varphi}) \int_{S_1(\tau)}\frac{m}{\kappa_{nm}r'}\, \phi_m(k_{mn}r')\exp({-\mathrm{i}m\varphi'})\,{\rm \Delta} P_s(r',z',\varphi') \nonumber\\ &\quad \times \left\{ H(z-z')\exp({\mathrm{i}\alpha_1(z-z')}) \right. \nonumber\\ &\qquad \left.{}+H(z'-z)\exp({\mathrm{i}\alpha_2(z-z')})\right\} \mathrm{d}S(\boldsymbol{y}),\quad m=\sigma-qV. \end{align}

Here, ![]() $\delta (\,\cdot \,)$ represents the Dirac delta function, and

$\delta (\,\cdot \,)$ represents the Dirac delta function, and ![]() $\mathrm {H}(\,\cdot \,)$ denotes the Heaviside function.

$\mathrm {H}(\,\cdot \,)$ denotes the Heaviside function.

In addition, the linearized circumferential inviscid momentum equation can be expressed as

where the circumferential perturbation velocity ![]() $v_\varphi '$ induced by the lifting surfaces also has a time dependence

$v_\varphi '$ induced by the lifting surfaces also has a time dependence ![]() $\exp ({-\mathrm {i}\omega _s t})$ such that

$\exp ({-\mathrm {i}\omega _s t})$ such that ![]() ${\partial v_\varphi '}/{\partial t} = -\mathrm {i}\omega _s v_\varphi '$. We first substitute (2.19) into (2.22), then (2.22) reduces to a first-order ordinary differential equation that can be solved to obtain the induced upwash velocity

${\partial v_\varphi '}/{\partial t} = -\mathrm {i}\omega _s v_\varphi '$. We first substitute (2.19) into (2.22), then (2.22) reduces to a first-order ordinary differential equation that can be solved to obtain the induced upwash velocity

\begin{align} v_\varphi'(\boldsymbol{x},t) &={-}\frac{V\exp({-\mathrm{i}\omega_s t})}{2{\rm \pi}\rho_0 U} \sum_{q={-}\infty}^{+\infty}\sum_{n=1}^{+\infty}\frac{m}{r}\,\phi_m(k_{mn}r) \exp({\mathrm{i}m\varphi}) \nonumber\\ &\quad \times \int_{S_1(\tau)}\frac{m}{r'}\,\phi_m(k_{mn}r') \exp({-\mathrm{i}m\varphi'})\,{\rm \Delta} P_s(r',z',\varphi') \nonumber\\ &\quad \times \left\{Q_1 \exp({\mathrm{i}\alpha_1(z-z')}) + Q_2\exp({\mathrm{i}\alpha_2(z-z')}) \right.\nonumber\\ &\qquad \left.{}+ Q_3 \exp({\mathrm{i}\alpha_3(z-z')})\right\} \mathrm{d}S(\boldsymbol{y}),\quad m=\sigma-qV, \end{align}

\begin{align} v_\varphi'(\boldsymbol{x},t) &={-}\frac{V\exp({-\mathrm{i}\omega_s t})}{2{\rm \pi}\rho_0 U} \sum_{q={-}\infty}^{+\infty}\sum_{n=1}^{+\infty}\frac{m}{r}\,\phi_m(k_{mn}r) \exp({\mathrm{i}m\varphi}) \nonumber\\ &\quad \times \int_{S_1(\tau)}\frac{m}{r'}\,\phi_m(k_{mn}r') \exp({-\mathrm{i}m\varphi'})\,{\rm \Delta} P_s(r',z',\varphi') \nonumber\\ &\quad \times \left\{Q_1 \exp({\mathrm{i}\alpha_1(z-z')}) + Q_2\exp({\mathrm{i}\alpha_2(z-z')}) \right.\nonumber\\ &\qquad \left.{}+ Q_3 \exp({\mathrm{i}\alpha_3(z-z')})\right\} \mathrm{d}S(\boldsymbol{y}),\quad m=\sigma-qV, \end{align}following procedures similar to those in the derivation of (2.21). The integration constant that occurs when solving (2.22) is taken to be zero, assuming that there is no disturbance velocity at positions far upstream (Namba Reference Namba1972). Here and above,

and

\begin{equation} \kappa_{nm} = \left\{\begin{array}{ll} \sqrt{k_0^2-\beta^2k_{mn}^2}, & \mathrm{if}\ k_0^2 > \beta^2k_{mn}^2, \\ \mathrm{i}\sqrt{\beta^2k_{mn}^2-k_0^2}, & \mathrm{if}\ k_0^2<\beta^2k_{mn}^2. \end{array}\right. \end{equation}

\begin{equation} \kappa_{nm} = \left\{\begin{array}{ll} \sqrt{k_0^2-\beta^2k_{mn}^2}, & \mathrm{if}\ k_0^2 > \beta^2k_{mn}^2, \\ \mathrm{i}\sqrt{\beta^2k_{mn}^2-k_0^2}, & \mathrm{if}\ k_0^2<\beta^2k_{mn}^2. \end{array}\right. \end{equation}

The ![]() $\exp ({\mathrm {i}\alpha _1(z-z')})$ and

$\exp ({\mathrm {i}\alpha _1(z-z')})$ and ![]() $\exp ({\mathrm {i}\alpha _2(z-z')})$ terms correspond to the upstream and downstream propagating pressure waves, and the

$\exp ({\mathrm {i}\alpha _2(z-z')})$ terms correspond to the upstream and downstream propagating pressure waves, and the ![]() $\exp ({\mathrm {i}\alpha _3(z-z')})$ term corresponds to the vortical waves convected downstream. The expressions for the scattered pressure field of the perforated cascade and its induced velocity, (2.21) and (2.23), are the same as in a hard-vane cascade lifting surface method (Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017). This is because the source characteristics of a perforated cascade and a hard-vane cascade are also the same, with only dipoles distributed on the vane surfaces, as we have proved in § 2.1.

$\exp ({\mathrm {i}\alpha _3(z-z')})$ term corresponds to the vortical waves convected downstream. The expressions for the scattered pressure field of the perforated cascade and its induced velocity, (2.21) and (2.23), are the same as in a hard-vane cascade lifting surface method (Zhang et al. Reference Zhang, Wang, Jing, Liang and Sun2017). This is because the source characteristics of a perforated cascade and a hard-vane cascade are also the same, with only dipoles distributed on the vane surfaces, as we have proved in § 2.1.

So far we have obtained the expressions for both ![]() $v_R$ and

$v_R$ and ![]() $v'_\varphi$ with an unknown unsteady loading

$v'_\varphi$ with an unknown unsteady loading ![]() ${\rm \Delta} P_s \exp ({-\mathrm {i}\omega _s t})$. However, to solve numerically for

${\rm \Delta} P_s \exp ({-\mathrm {i}\omega _s t})$. However, to solve numerically for ![]() ${\rm \Delta} P_s$, truncation of the infinite series for

${\rm \Delta} P_s$, truncation of the infinite series for ![]() $m$ and

$m$ and ![]() $n$ in (2.23) is unavoidable, and the error of truncating

$n$ in (2.23) is unavoidable, and the error of truncating ![]() $m$ is difficult to control due to the non-uniform convergence of the Fourier series (Namba Reference Namba1972). To better restrict the truncation errors and evaluate the singularities in the original equation, we apply the finite radial mode expansion method proposed by Namba (Reference Namba1972, Reference Namba1987) to approximate the original radial eigenfunctions with a limited set of

$m$ is difficult to control due to the non-uniform convergence of the Fourier series (Namba Reference Namba1972). To better restrict the truncation errors and evaluate the singularities in the original equation, we apply the finite radial mode expansion method proposed by Namba (Reference Namba1972, Reference Namba1987) to approximate the original radial eigenfunctions with a limited set of ![]() $L$ functions

$L$ functions ![]() $\psi _k^{(\infty )}(r)$:

$\psi _k^{(\infty )}(r)$:

\begin{equation} \phi_m(k_{mn}r) \approx \sum_{k=1}^{L} {BB}_{n,k}^m\,\psi_k^{(\infty)}(r). \end{equation}

\begin{equation} \phi_m(k_{mn}r) \approx \sum_{k=1}^{L} {BB}_{n,k}^m\,\psi_k^{(\infty)}(r). \end{equation}

Detailed definitions and the corresponding applications of ![]() $\psi _k^{(\infty )}(r)$ and the expansion coefficients

$\psi _k^{(\infty )}(r)$ and the expansion coefficients ![]() ${BB}_{n,k}^m$ are shown in Appendix A, and the accuracy of this approximation can be improved to any level by simply increasing

${BB}_{n,k}^m$ are shown in Appendix A, and the accuracy of this approximation can be improved to any level by simply increasing ![]() $L$ (Namba Reference Namba1972). Accordingly, after representing all the radial eigenfunctions with

$L$ (Namba Reference Namba1972). Accordingly, after representing all the radial eigenfunctions with ![]() $\psi _k^{(\infty )}(r)$ and further separating the singular parts from the regular parts of the kernel function, (2.23) can be rewritten as

$\psi _k^{(\infty )}(r)$ and further separating the singular parts from the regular parts of the kernel function, (2.23) can be rewritten as

where the final expression for the kernel function ![]() $K$ is described in (A7)–(A10). Substituting (2.28) and (2.16) into the boundary condition (2.13), we obtain one integration equation that describes the relation between the unknown

$K$ is described in (A7)–(A10). Substituting (2.28) and (2.16) into the boundary condition (2.13), we obtain one integration equation that describes the relation between the unknown ![]() ${\rm \Delta} P_s$ and the input

${\rm \Delta} P_s$ and the input ![]() $\tilde {v}_d$. With a given distribution of the normal velocity induced by the incident wave, we are able to solve the unsteady pressure loading

$\tilde {v}_d$. With a given distribution of the normal velocity induced by the incident wave, we are able to solve the unsteady pressure loading ![]() ${\rm \Delta} P_s$, and then obtain the scattered sound field

${\rm \Delta} P_s$, and then obtain the scattered sound field ![]() $p'(\boldsymbol {x},t)$ using (2.21).

$p'(\boldsymbol {x},t)$ using (2.21).

According to Morfey's definition of acoustic intensity in an irrotational uniform-entropy flow (Morfey Reference Morfey1971), the axial sound energy flux inside a background flow of axial velocity ![]() $U$ could be formulated as

$U$ could be formulated as

where ![]() $u_z$ is the axial component of the perturbation velocity, which can be solved by resorting to the momentum equation along with (2.21), and

$u_z$ is the axial component of the perturbation velocity, which can be solved by resorting to the momentum equation along with (2.21), and ![]() $\langle \,\cdot\, \rangle$ denotes the time average over one period. Integrating

$\langle \,\cdot\, \rangle$ denotes the time average over one period. Integrating ![]() $I_z$ over the annular-duct cross-section, we obtain the sound energy power propagating downstream (

$I_z$ over the annular-duct cross-section, we obtain the sound energy power propagating downstream (![]() $W_+$) and upstream (

$W_+$) and upstream (![]() $W_-$) for a cut-on mode

$W_-$) for a cut-on mode ![]() $(m,n)$ as

$(m,n)$ as

For cut-off modes, there is no axial acoustic energy flux. With the solution of the unsteady loading ![]() ${\rm \Delta} P_s$, the cut-on sound mode coefficients

${\rm \Delta} P_s$, the cut-on sound mode coefficients ![]() $P_{mn}^\pm$ can be calculated from (2.21) for observation points at axial positions downstream and upstream of the cascade. Further averaging the sound power over the cross-section, we obtain the mean acoustic intensity

$P_{mn}^\pm$ can be calculated from (2.21) for observation points at axial positions downstream and upstream of the cascade. Further averaging the sound power over the cross-section, we obtain the mean acoustic intensity ![]() $\bar {I}_{\pm }={W_\pm }/{{\rm \pi} (R_d^2-R_h^2)}$ and the corresponding sound power level (SPL) as

$\bar {I}_{\pm }={W_\pm }/{{\rm \pi} (R_d^2-R_h^2)}$ and the corresponding sound power level (SPL) as

3. Numerical solution with soft boundary conditions

With all the analytic expressions above, the integral equation (2.13) still needs to be solved numerically to obtain practical solutions. For radially placed straight vanes with zero swept or leaned angle, we may simply set the circumferential coordinate on the first vane as ![]() $\varphi '=0$, and the unsteady loading distribution will degenerate to a function of just radial and axial coordinates, denoted as

$\varphi '=0$, and the unsteady loading distribution will degenerate to a function of just radial and axial coordinates, denoted as ![]() ${\rm \Delta} P_s(r',z')$. We then expand

${\rm \Delta} P_s(r',z')$. We then expand ![]() ${\rm \Delta} P_s$ using the finite radial basis functions

${\rm \Delta} P_s$ using the finite radial basis functions ![]() $\psi _l^{(\infty )}(r)$ as

$\psi _l^{(\infty )}(r)$ as

\begin{equation} {\rm \Delta} P_s(r',z')=\sum_{j'=1}^{J} \psi_{j'}^{(\infty)}(r') \left[ A_{1j'} \cot\left(\frac{\xi'}{2}\right) + \sum_{i'=2}^{I}A_{i'j'}\sin((i'-1)\xi') \right], \end{equation}

\begin{equation} {\rm \Delta} P_s(r',z')=\sum_{j'=1}^{J} \psi_{j'}^{(\infty)}(r') \left[ A_{1j'} \cot\left(\frac{\xi'}{2}\right) + \sum_{i'=2}^{I}A_{i'j'}\sin((i'-1)\xi') \right], \end{equation}

with ![]() $I$ axial terms and

$I$ axial terms and ![]() $J$ radial terms. As is usual,

$J$ radial terms. As is usual, ![]() $J$ is taken to be the same as

$J$ is taken to be the same as ![]() $L$, and the infinite series for

$L$, and the infinite series for ![]() $n$ in the kernel function is also truncated at

$n$ in the kernel function is also truncated at ![]() $L$ terms. The Kutta condition is applied inherently here, with Glauert's transformation made to the axial coordinates for both the source position

$L$ terms. The Kutta condition is applied inherently here, with Glauert's transformation made to the axial coordinates for both the source position ![]() $z'$ and the observation location

$z'$ and the observation location ![]() $z$, as is usual in a thin aerofoil theory, i.e.

$z$, as is usual in a thin aerofoil theory, i.e.

Substituting (3.1) into (2.28), the integration with respect to the radial coordinate ![]() $r'$ could be performed analytically using the orthogonality of

$r'$ could be performed analytically using the orthogonality of ![]() $\psi _l^{(\infty )}(r)$ (Namba Reference Namba1987), with only the axial coordinate left in the surface integration to be integrated numerically.

$\psi _l^{(\infty )}(r)$ (Namba Reference Namba1987), with only the axial coordinate left in the surface integration to be integrated numerically.

Applying a collocation method to solve for the integral equation (2.13), we choose ![]() $I \times J$ evenly spaced control points on the vane at coordinates

$I \times J$ evenly spaced control points on the vane at coordinates ![]() $(\xi _i,r_j),\ i=1,\ldots,I,\ j=1,\ldots,J$, and the incident wave disturbance velocities at these positions are denoted as

$(\xi _i,r_j),\ i=1,\ldots,I,\ j=1,\ldots,J$, and the incident wave disturbance velocities at these positions are denoted as ![]() $\boldsymbol {v}_{d,ij}$. With axial evenly spaced discrete source points similar to those in Whitehead (Reference Whitehead1962), we could then perform numerical integration in the

$\boldsymbol {v}_{d,ij}$. With axial evenly spaced discrete source points similar to those in Whitehead (Reference Whitehead1962), we could then perform numerical integration in the ![]() $\xi '$ domain using the trapezoidal rule to finally obtain the discrete form of (2.28) as

$\xi '$ domain using the trapezoidal rule to finally obtain the discrete form of (2.28) as

Note that to calculate the Cauchy principal value of the integration of the singular kernel function ![]() $K$, the control points must be placed at the middle of two source points. Therefore, the axial coordinates for the control points

$K$, the control points must be placed at the middle of two source points. Therefore, the axial coordinates for the control points ![]() $\xi$ and the source points

$\xi$ and the source points ![]() $\xi '$ are selected as

$\xi '$ are selected as

where ![]() $I' = (2\eta +1) I$, and

$I' = (2\eta +1) I$, and ![]() $\eta =3$. Here,

$\eta =3$. Here, ![]() $\eta$ is an adjustable integer coefficient. With an

$\eta$ is an adjustable integer coefficient. With an ![]() $\eta$ greater than 1, the source points are denser than the control points such that the surface integration can be calculated with higher accuracy without increasing the number of control points.

$\eta$ greater than 1, the source points are denser than the control points such that the surface integration can be calculated with higher accuracy without increasing the number of control points.

We then replace ![]() ${\rm \Delta} P_s$ in (2.16) with the expansion (3.1). Due to the local reaction of the pressure fluctuations, it is simple to express the soft-wall averaged fluctuating velocity

${\rm \Delta} P_s$ in (2.16) with the expansion (3.1). Due to the local reaction of the pressure fluctuations, it is simple to express the soft-wall averaged fluctuating velocity ![]() $\tilde {v}_R$ at the discrete control points

$\tilde {v}_R$ at the discrete control points ![]() $(\xi _i,r_j)$ in a matrix form as

$(\xi _i,r_j)$ in a matrix form as

where the coefficient matrix ![]() $\boldsymbol{\mathsf{M}}_{ij,i'j'}^R$ is related to the local perforation properties

$\boldsymbol{\mathsf{M}}_{ij,i'j'}^R$ is related to the local perforation properties ![]() $\alpha _H$,

$\alpha _H$, ![]() $R$ and

$R$ and ![]() $K_R$. This additional matrix

$K_R$. This additional matrix ![]() $\boldsymbol{\mathsf{M}}_{ij,i'j'}^R$ is the key difference between the solution of a perforated cascade and a hard-vane cascade. In our case, where the soft boundary on vanes is reacting locally to the pressure fluctuations, the expansion (3.1) turns out to be very convenient for the construction of this coefficient matrix.

$\boldsymbol{\mathsf{M}}_{ij,i'j'}^R$ is the key difference between the solution of a perforated cascade and a hard-vane cascade. In our case, where the soft boundary on vanes is reacting locally to the pressure fluctuations, the expansion (3.1) turns out to be very convenient for the construction of this coefficient matrix.

Finally, we substitute (3.3) and (3.5) into (2.13) and rearrange to construct a system of linear equations with the coefficient vector ![]() $\boldsymbol {A}_{i'j'}$ as the unknown and the incident disturbance velocity vector

$\boldsymbol {A}_{i'j'}$ as the unknown and the incident disturbance velocity vector ![]() $\tilde {\boldsymbol {v}}_{d,ij}$ as the right-hand side, in the form

$\tilde {\boldsymbol {v}}_{d,ij}$ as the right-hand side, in the form

By solving this linear system, we can obtain the unsteady loading distribution on vanes for any given incident wave, and from ![]() ${\rm \Delta} P_s(r',z')$, we can further estimate the scattered sound field and its propagating acoustic energy.

${\rm \Delta} P_s(r',z')$, we can further estimate the scattered sound field and its propagating acoustic energy.

It should be noted that in the above procedures, the boundary condition of the soft-vane cascade could be replaced by different kinds of conditions with minimum effort, such as those discussed in Baddoo & Ayton (Reference Baddoo and Ayton2020), provided that the pressure fluctuation is reacting locally with the soft vanes and that an explicit form of the relation ![]() $\tilde {v}_R = f({\rm \Delta} P_s)$ is obtainable. Additionally, our method is not limited to uniform boundary conditions over the entire plate, as we can take the locally averaged value of the porosity parameter

$\tilde {v}_R = f({\rm \Delta} P_s)$ is obtainable. Additionally, our method is not limited to uniform boundary conditions over the entire plate, as we can take the locally averaged value of the porosity parameter ![]() ${\alpha _H K_R}/{({\rm \pi} R^2)}$ (also used in Ayton et al. Reference Ayton, Colbrook, Geyer, Chaitanya and Sarradj2021) at each control point. That enables us to investigate the effects of partially perforated plates or uneven distributions of porosity on vanes, as long as all vanes in the cascade are of identical porosity distribution.

${\alpha _H K_R}/{({\rm \pi} R^2)}$ (also used in Ayton et al. Reference Ayton, Colbrook, Geyer, Chaitanya and Sarradj2021) at each control point. That enables us to investigate the effects of partially perforated plates or uneven distributions of porosity on vanes, as long as all vanes in the cascade are of identical porosity distribution.

4. Validations

To validate our method, we compare our solutions with the results from two special cases: the 3-D hard-vane lifting surface model and the 2-D perforated cascade model.

4.1. Comparison with the 3-D hard-vane model

First, we set the Rayleigh conductivity ![]() $K_R$ to be zero, and our model degenerates to a hard-vane annular cascade. Comparison is made between our solutions and the results from the benchmark problem of the third computational aeroacoustics workshop (Namba & Schulten Reference Namba and Schulten2000). The duct geometry parameters are

$K_R$ to be zero, and our model degenerates to a hard-vane annular cascade. Comparison is made between our solutions and the results from the benchmark problem of the third computational aeroacoustics workshop (Namba & Schulten Reference Namba and Schulten2000). The duct geometry parameters are ![]() $R_h=0.5\,\mathrm {m}$,

$R_h=0.5\,\mathrm {m}$, ![]() $R_d=1.0\,\mathrm {m}$ and

$R_d=1.0\,\mathrm {m}$ and ![]() $b=2{\rm \pi} R_d /V$ in our dimensional model, with the rotor blade number

$b=2{\rm \pi} R_d /V$ in our dimensional model, with the rotor blade number ![]() $B=16$ and the stator vane number

$B=16$ and the stator vane number ![]() $V=24$. As shown at the beginning of § 2, this corresponds to a circumferential periodicity number

$V=24$. As shown at the beginning of § 2, this corresponds to a circumferential periodicity number ![]() $\sigma = sB$ and a disturbance frequency

$\sigma = sB$ and a disturbance frequency ![]() $\omega _s=sB\varOmega$ on the stator for the

$\omega _s=sB\varOmega$ on the stator for the ![]() $s$th-order component of the rotor wake, where

$s$th-order component of the rotor wake, where ![]() $\varOmega$ is the angular velocity of rotor rotation.

$\varOmega$ is the angular velocity of rotor rotation.

Accordingly, the incident vortical wave is defined as

where ![]() $\theta (r)$ is the radial dependence function with an arbitrary real-valued wake-periodicity or wake-obliquity parameter

$\theta (r)$ is the radial dependence function with an arbitrary real-valued wake-periodicity or wake-obliquity parameter ![]() $q$, and the wake velocity amplitude is given as a constant along the radial direction with

$q$, and the wake velocity amplitude is given as a constant along the radial direction with ![]() $w_s=0.1U$. A positive

$w_s=0.1U$. A positive ![]() $q$ represents that the wake at the stator root is ahead of that at the tip, as in typical fan designs. Results are obtained for the first-order vortical wave (

$q$ represents that the wake at the stator root is ahead of that at the tip, as in typical fan designs. Results are obtained for the first-order vortical wave (![]() $s=1$), and the spanwise non-dimensional unsteady loading distributions

$s=1$), and the spanwise non-dimensional unsteady loading distributions ![]() ${\rm \Delta} C_p={{\rm \Delta} P_s(r')}/{(0.5\rho _0 U^2)}$ at different chord positions

${\rm \Delta} C_p={{\rm \Delta} P_s(r')}/{(0.5\rho _0 U^2)}$ at different chord positions ![]() $z'/b$ are compared, as illustrated in figure 4. Radial wake periodicity parameter

$z'/b$ are compared, as illustrated in figure 4. Radial wake periodicity parameter ![]() $q$ is set to be

$q$ is set to be ![]() $q=3$, which corresponds to an average of 3 wakes intersecting each stator vane at the leading edge. The background flow Mach number is

$q=3$, which corresponds to an average of 3 wakes intersecting each stator vane at the leading edge. The background flow Mach number is ![]() $M=0.5$, the sound speed is

$M=0.5$, the sound speed is ![]() $c_0=340.0\,{\rm m}\,{\rm s}^{-1}$, the flow density is

$c_0=340.0\,{\rm m}\,{\rm s}^{-1}$, the flow density is ![]() $\rho _0 = 1.225\,{\rm kg}\,{\rm m}^{-3}$, and the rotor tip Mach number is set to be

$\rho _0 = 1.225\,{\rm kg}\,{\rm m}^{-3}$, and the rotor tip Mach number is set to be ![]() $M_t = {\varOmega R_d}/{c_0}=0.783$, which correspondingly decides the shaft speed

$M_t = {\varOmega R_d}/{c_0}=0.783$, which correspondingly decides the shaft speed ![]() $\varOmega$.

$\varOmega$.

Figure 4. Comparison of the unsteady loading at different axial positions for the ![]() $q=3$ case with the results in the benchmark problem (Namba & Schulten Reference Namba and Schulten2000). The non-dimensional loading is taken as

$q=3$ case with the results in the benchmark problem (Namba & Schulten Reference Namba and Schulten2000). The non-dimensional loading is taken as ![]() ${\rm \Delta} C_p={{\rm \Delta} P_s(r')}/{(0.5\rho _0 U^2)}$, and the leading edge position of the vane is set to be

${\rm \Delta} C_p={{\rm \Delta} P_s(r')}/{(0.5\rho _0 U^2)}$, and the leading edge position of the vane is set to be ![]() $z'=0$.

$z'=0$.

For axial positions close to the leading edge, our results agree well with both hard-vane lifting surface methods. At the positions further downstream, minor differences arise as the absolute value of the unsteady loading decreases, but overall our method matches well with the benchmark results.

We then solved for a porous 3-D annular cascade to demonstrate the convergence of our collocation method, and the results are shown in figure 5. As the number of the collocation control points ![]() $I \times J$ increases, the propagating sound power approaches a final value, and the variation between each case decreases rapidly. By increasing the number of the collocation points, our result should converge to the physical solution of the problem.

$I \times J$ increases, the propagating sound power approaches a final value, and the variation between each case decreases rapidly. By increasing the number of the collocation points, our result should converge to the physical solution of the problem.

Figure 5. Convergence of the calculated propagating sound power ![]() $W_\pm$ with increasing control points for a perforated cascade.

$W_\pm$ with increasing control points for a perforated cascade.

4.2. Comparison with the 2-D soft-vane model

Now we compare our results with the 2-D perforated cascade model of uniform porosity exploiting the Wiener–Hopf method (Baddoo & Ayton Reference Baddoo and Ayton2020). Using zero stager angle as input, we calculate 2-D results with Baddoo's code published online at https://github.com/baddoo/complex-cascade-scattering, and with the hub–tip ratio set to be 0.99, our annular cascade model approximates a quasi-2-D situation. The non-dimensional parameter ![]() $C_{II}$ of the case

$C_{II}$ of the case ![]() $II$ boundary condition in the 2-D model (Baddoo & Ayton Reference Baddoo and Ayton2020) corresponds to

$II$ boundary condition in the 2-D model (Baddoo & Ayton Reference Baddoo and Ayton2020) corresponds to ![]() $-{2\mathrm {i} U\alpha _H K_R}/{{\rm \pi} R^2 \omega _s}$ in our 3-D method. Results with different porosity parameters

$-{2\mathrm {i} U\alpha _H K_R}/{{\rm \pi} R^2 \omega _s}$ in our 3-D method. Results with different porosity parameters ![]() $C_{II}$ are compared in figures 6 and figure 7. With an inter-vane phase difference angle

$C_{II}$ are compared in figures 6 and figure 7. With an inter-vane phase difference angle ![]() $3{\rm \pi} /4$ in the 2-D model, we correspondingly choose the blade numbers to be

$3{\rm \pi} /4$ in the 2-D model, we correspondingly choose the blade numbers to be ![]() $B=18$ and

$B=18$ and ![]() $V=48$ in our 3-D solution, and solve for the first-order vortical wave incidence as in (4.1a,b) with

$V=48$ in our 3-D solution, and solve for the first-order vortical wave incidence as in (4.1a,b) with ![]() $s=1$ and

$s=1$ and ![]() $q=0$, where other input parameters are

$q=0$, where other input parameters are

\begin{equation} \left.\begin{gathered} R_h=0.99\,\mathrm{m},\quad R_d=1.0\,\mathrm{m},\quad b=0.21708\,\mathrm{m},\quad M=0.3,\\ c_0 = 340.0\,{\rm m}\,{\rm s}^{{-}1}\quad \text{and}\quad \rho_0 = 1.225\,{\rm kg}\,{\rm m}^{{-}3}. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} R_h=0.99\,\mathrm{m},\quad R_d=1.0\,\mathrm{m},\quad b=0.21708\,\mathrm{m},\quad M=0.3,\\ c_0 = 340.0\,{\rm m}\,{\rm s}^{{-}1}\quad \text{and}\quad \rho_0 = 1.225\,{\rm kg}\,{\rm m}^{{-}3}. \end{gathered}\right\} \end{equation}

The disturbance frequency is ![]() $\omega _s b /2U \in (0,30]$, and the incident vortical wave amplitude is

$\omega _s b /2U \in (0,30]$, and the incident vortical wave amplitude is ![]() $w_1=0.1U$ for both cases. Solutions from the 2-D model and our 3-D method show good agreement, with only slight differences in the magnitudes of the downstream propagating acoustic energy.

$w_1=0.1U$ for both cases. Solutions from the 2-D model and our 3-D method show good agreement, with only slight differences in the magnitudes of the downstream propagating acoustic energy.

Figure 6. Comparison of the unsteady lift coefficient ![]() $C_L={\int _{0}^{b}{\rm \Delta} P_s(z')\,\mathrm {d}z'}/{({\rm \pi} b \rho _0 U w_1 )}$ with varying porosity and frequency. Solutions of the 2-D model (Baddoo & Ayton Reference Baddoo and Ayton2020) are illustrated by the dashed lines, and results of the present 3-D model are represented by the solid lines.

$C_L={\int _{0}^{b}{\rm \Delta} P_s(z')\,\mathrm {d}z'}/{({\rm \pi} b \rho _0 U w_1 )}$ with varying porosity and frequency. Solutions of the 2-D model (Baddoo & Ayton Reference Baddoo and Ayton2020) are illustrated by the dashed lines, and results of the present 3-D model are represented by the solid lines.

Figure 7. Comparison of the non-dimensionalised sound power propagating downstream for (a) the first and (b) the second acoustic mode with varying porosity and frequency, which corresponds to figure 11 in Baddoo & Ayton (Reference Baddoo and Ayton2020). In the 3-D model, the acoustic modes correspond to annular duct modes ![]() $(18,1)$ and

$(18,1)$ and ![]() $(-30,1)$, and the acoustic power defined in (2.30) is non-dimensionalized by dividing

$(-30,1)$, and the acoustic power defined in (2.30) is non-dimensionalized by dividing ![]() $\rho _0 w_1^2U{\rm \pi} (R_d^2-R_h^2)/2$.

$\rho _0 w_1^2U{\rm \pi} (R_d^2-R_h^2)/2$.

5. Results

In the following subsections, we investigate the solutions of a pressure-free gust impinging on a porous cascade, which corresponds to a rotor–stator interaction set-up, and evaluate the resulting propagating noise. We restrict our study to the first-order incident vortical wave as defined in (4.1a,b) with ![]() $s=1$, and choose the same geometry set-ups as in § 4.1, with hub–tip ratio 0.5, blade numbers

$s=1$, and choose the same geometry set-ups as in § 4.1, with hub–tip ratio 0.5, blade numbers ![]() $B=16$,

$B=16$, ![]() $V=24$, and other input parameters

$V=24$, and other input parameters

\begin{equation} \left.\begin{gathered} M=0.5,\quad c_0=340.0\,{\rm m}\,{\rm s}^{{-}1},\quad \rho_0 = 1.225\,{\rm kg}\,{\rm m}^{{-}3},\\ M_t=0.783\quad \text{and}\quad w_1 = 0.1U. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} M=0.5,\quad c_0=340.0\,{\rm m}\,{\rm s}^{{-}1},\quad \rho_0 = 1.225\,{\rm kg}\,{\rm m}^{{-}3},\\ M_t=0.783\quad \text{and}\quad w_1 = 0.1U. \end{gathered}\right\} \end{equation}5.1. Cascade response with uniform porosity on vanes

In this subsection, we study stator vanes with uniform perforations. To illustrate the effects of porosity, we select the aperture parameters common in practice as ![]() $R=0.001\,\mathrm {m}$ and

$R=0.001\,\mathrm {m}$ and ![]() $\alpha _H = 0.02$, and set the real part of the conductivity

$\alpha _H = 0.02$, and set the real part of the conductivity ![]() $\varGamma _R$ to be zero. The imaginary part of the Rayleigh conductivity